Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Light and Color Measurement interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Light and Color Measurement Interview

Q 1. Explain the CIE 1931 color space and its limitations.

The CIE 1931 color space, also known as CIE XYZ, is a foundational color model that defines colors based on how the average human eye perceives them. It’s a three-dimensional space where each color is represented by three values: X, Y, and Z. These values represent the relative amounts of three hypothetical primary colors needed to match any given color. The Y value is particularly important as it represents luminance (brightness).

However, the CIE 1931 space has limitations. Its primary weakness lies in its non-uniform perceptual space. This means that equal distances in the XYZ space do not correspond to equal perceived differences in color. A small change in XYZ values might lead to a noticeable color shift in some areas, while a larger change might be barely perceptible in others. This non-uniformity makes it difficult to assess the visual difference between two colors accurately. Furthermore, it doesn’t accurately represent colors outside the visible spectrum, and it doesn’t fully account for individual variations in color perception.

Q 2. What are the differences between spectrophotometry and colorimetry?

Spectrophotometry and colorimetry are both used for color measurement, but they differ significantly in their approach. Spectrophotometry measures the spectral reflectance or transmittance of a sample across the entire visible spectrum (usually 380nm to 730nm). It provides a detailed spectral curve showing the amount of light reflected or transmitted at each wavelength. Think of it as a fingerprint of the object’s color. This data allows for very precise color characterization.

Colorimetry, on the other hand, calculates color values based on the spectral data obtained from spectrophotometry or other spectral measurements. It uses standard observer functions (like the CIE 1931 2° observer) to translate the spectral data into color coordinates in a specific color space (like CIE L*a*b*). It essentially summarizes the spectral information into a more manageable set of numbers that represent the color’s hue, saturation, and lightness. Colorimetry focuses on the perceived color rather than the detailed spectral characteristics.

Imagine you’re trying to describe an apple. Spectrophotometry would be like describing the precise wavelengths of light reflected from its skin, giving a comprehensive, detailed profile. Colorimetry would be like saying “It’s a red apple,” providing a summary of its overall color perception.

Q 3. Describe various types of light sources used in color measurement (e.g., D65, A, C).

Several standard light sources are used in color measurement to simulate different lighting conditions. These sources are defined by their spectral power distribution (SPD), which describes the intensity of light emitted at each wavelength.

- D65: This is the most commonly used illuminant, representing average daylight at a correlated color temperature (CCT) of 6500 K. It’s often considered the standard for many industries, as it approximates the typical daylight we experience.

- A: This illuminant represents incandescent light with a CCT of approximately 2856 K. It’s useful for evaluating colors under incandescent lighting conditions.

- C: This illuminant represents average daylight at a CCT of 6774 K. While less common than D65, it’s still used in certain applications.

- Other Illuminants: There are many other defined illuminants, including those representing fluorescent, LED, and other types of lighting. The choice of illuminant depends on the application and the intended use of the color measurement data.

Using standard illuminants ensures consistent and comparable color measurements regardless of the geographic location or the specific light source used in the measurement process. This is crucial for quality control and communication across different locations and manufacturers.

Q 4. What are metamerism and how does it impact color matching?

Metamerism is a phenomenon where two colors appear identical under one light source but different under another. This happens because the spectral power distributions of the two colors are different, but their perceived color matches due to the specific spectral sensitivity of the human eye under the given illumination. Imagine two shirts that look the same under indoor lighting (e.g., incandescent) but have a noticeably different hue when taken outside into sunlight.

Metamerism significantly impacts color matching. Two samples might pass a color match under one light source but fail under another. Therefore, specifying both the color coordinates and the illuminant is essential in color matching and quality control to avoid metameric mismatches. Industrial color matching often uses multiple illuminants to ensure a robust match across different lighting conditions. For example, in textile manufacturing, ensuring consistent color matches across different retail lighting environments is crucial for customer satisfaction.

Q 5. Explain the concept of color difference (ΔE) and its various formulas (e.g., ΔE*ab, ΔE*94, ΔE*00).

Color difference (ΔE) quantifies the perceived difference between two colors. It’s a crucial metric for color quality control, ensuring consistency and acceptability across batches or production runs. Different ΔE formulas exist, each with varying levels of complexity and perceptual accuracy.

- ΔE*ab: This is a relatively simple and widely used formula based on the CIE L*a*b* color space. It’s straightforward to calculate, but it doesn’t perfectly correlate with visual perception across the entire color gamut.

- ΔE*94: This formula improves on ΔE*ab by introducing weighting factors to better account for perceptual variations across different color regions. It offers better perceptual uniformity than ΔE*ab.

- ΔE*00: This is a more complex formula that aims for even better perceptual uniformity and accounts for the influence of chroma and lightness on color difference perception. It is considered the most perceptually uniform formula but more computationally demanding.

The choice of ΔE formula depends on the application’s specific needs and tolerance levels. For many applications, ΔE*94 offers a good balance between accuracy and computational simplicity. A smaller ΔE value indicates a smaller perceived color difference, while a larger value indicates a more noticeable difference. Acceptable ΔE thresholds vary depending on the industry and application; for example, tighter tolerances are often required for high-end products.

Q 6. How do you calibrate a spectrophotometer?

Calibrating a spectrophotometer is essential to ensure accurate and reliable color measurements. The calibration procedure involves adjusting the instrument to compensate for any inherent variations or drift in its sensors and electronics. The steps generally include:

- Warm-up: Allow the spectrophotometer to warm up for a specified time as recommended by the manufacturer. This allows the instrument’s components to stabilize and reach optimal operating conditions.

- Dark Current Calibration: This involves measuring the instrument’s signal in the absence of any light. This measurement helps to correct for any background noise.

- White Calibration (or Reference Calibration): A highly reflective white standard (e.g., a Spectralon tile) is measured to establish the reference point for 100% reflectance. This ensures accurate scaling of the spectral data.

- (Optional) Wavelength Calibration: Depending on the instrument and its needs, a wavelength calibration may be necessary to ensure that wavelengths are correctly registered within the spectrophotometer’s measurement range.

Calibration should be performed regularly according to the manufacturer’s instructions to ensure the instrument’s accuracy and maintain consistent measurement results over time. Regular maintenance and calibration are crucial for reliable color measurement.

Q 7. What are the common sources of error in color measurement?

Several factors can introduce errors in color measurement. Careful attention to detail is crucial for obtaining accurate results.

- Instrument Errors: These include variations in instrument calibration, sensor degradation, and electronic noise. Regular calibration and maintenance can mitigate these.

- Sample Preparation: Improper sample preparation, including surface variations, glossiness, texture, or even the presence of dust, significantly impacts measurements. Proper sample preparation is paramount.

- Operator Errors: Incorrect instrument handling, improper placement of the sample, or variations in measurement technique can lead to errors. Standardized procedures and operator training are critical.

- Ambient Conditions: Temperature and humidity fluctuations can affect the instrument’s performance and the sample’s properties. Controlled environmental conditions are important for reliable measurements.

- Illuminant Variations: Using inappropriate illuminants, or variations in illuminant settings between measurements, can lead to inconsistent results. Careful selection and consistent use of specified illuminants are necessary.

Addressing these potential error sources through careful planning, standardized procedures, regular calibration, and proper instrument maintenance ensures the accuracy and reliability of color measurement data. For instance, in the paint industry, slight variations in color due to errors during the measurement process can lead to significant production issues and financial losses.

Q 8. Describe different types of spectrophotometers (e.g., 0/45°, d/8°).

Spectrophotometers are instruments used to measure the spectral reflectance or transmittance of a material, providing a detailed analysis of how it interacts with light at different wavelengths. Different geometries are used to simulate real-world viewing conditions.

- 0/45° geometry: This is a common geometry used to measure the reflectance of a surface. The light source is positioned at 0° (normal to the surface), and the reflected light is measured at a 45° angle. This helps minimize the specular (mirror-like) reflection and emphasizes diffuse reflection, giving a more accurate representation of the perceived color under typical viewing conditions. This is ideal for assessing the color of matte or slightly textured materials like paints or fabrics.

- d/8° geometry: This geometry incorporates both diffuse and specular components. The ‘d’ signifies diffuse illumination (light is spread evenly across the sample), and the ‘8°’ signifies the angle at which the reflected light is measured. The inclusion of specular reflectance is important for materials with a glossy finish, like plastics or coated paper, providing a more accurate representation of the visual appearance. A d/8° measurement often gives a better match to human visual perception for these types of materials.

- Other geometries: Various other geometries exist, tailored to specific needs like the sphere geometry used for measuring total reflectance, including both specular and diffuse components, suitable for powders or highly diffusing materials.

The choice of geometry depends on the sample type and the intended application.

Q 9. How do you determine the spectral power distribution of a light source?

Determining the spectral power distribution (SPD) of a light source involves measuring the amount of radiant power emitted at each wavelength across the visible spectrum (approximately 380nm to 780nm). This is done using a spectroradiometer, a specialized instrument that’s similar to a spectrophotometer but designed for light sources instead of materials. The instrument captures the emitted light, separates it into its constituent wavelengths using a diffraction grating or prism, and measures the intensity of each wavelength. The resulting data is presented as a graph or a table showing the power (often in watts per nanometer) for each wavelength.

In practice, the spectroradiometer is carefully calibrated and positioned to collect the light accurately. The measurement must be taken in a controlled environment to eliminate extraneous light sources and ensure consistent results. The obtained data then provides a detailed description of the light’s color temperature, color rendering capabilities and other characteristics.

Q 10. Explain the concept of color rendering index (CRI).

The Color Rendering Index (CRI) is a quantitative measure of how accurately a light source renders the colors of objects compared to a reference source (usually incandescent light). CRI values range from 0 to 100, with higher values indicating better color rendering. A CRI of 100 means the colors under the test light source appear exactly the same as under the reference source. A lower CRI implies that colors appear distorted or less vibrant.

CRI is calculated by comparing the color rendering of eight test color samples under the light source being evaluated with their appearance under the reference source. The differences in color appearance are quantified, and a single CRI value is derived. It’s crucial to note that CRI doesn’t tell the whole story of color rendition; some light sources might have a high CRI but still produce slightly unnatural color shifts.

For example, a light source with a CRI of 90 or higher is generally considered good for color-critical applications like museums or art galleries, where accurate color rendition is crucial. Lower CRI values might be acceptable for less demanding applications.

Q 11. What are the key factors to consider when selecting a spectrophotometer for a specific application?

Selecting the right spectrophotometer depends on several key factors:

- Application type: Are you measuring the color of textiles, plastics, paints, or something else? Different materials require different measurement geometries (0/45°, d/8°, sphere).

- Measurement accuracy and precision: The required level of accuracy depends on the application. Precise color matching in industrial manufacturing demands higher precision than general quality control.

- Sample size and shape: Consider the size and shape of your samples. Some spectrophotometers are designed for large samples, while others are better suited for small or irregularly shaped ones.

- Spectral range: The instrument’s spectral range should cover the wavelengths relevant to your application (typically the visible spectrum, but potentially UV or near-infrared as well).

- Budget: Spectrophotometers can range in price from a few thousand to tens of thousands of dollars. A balance must be found between cost and required performance.

- Software and data analysis capabilities: The instrument’s software should be user-friendly and provide the necessary data analysis tools, such as color difference calculations or tolerance checking.

Choosing the right spectrophotometer is like selecting the right tool for a specific job. A thorough understanding of the application requirements is essential for making an informed decision.

Q 12. How do you interpret spectral data?

Spectral data from a spectrophotometer typically shows the reflectance or transmittance of a material across a range of wavelengths. Interpreting this data involves understanding what these values represent and how they relate to color perception.

A graph of spectral data shows the reflectance or transmittance (as a percentage) on the vertical axis and the wavelength (in nanometers) on the horizontal axis. High reflectance at certain wavelengths indicates that the material reflects those colors strongly, while low reflectance indicates absorption. For instance, a material with high reflectance in the red wavelengths (around 650nm) will appear reddish.

The spectral data can be used to calculate color coordinates (e.g., CIE L*a*b*), color difference values (e.g., ΔE), and other colorimetric parameters that help to quantify and compare colors.

In short, interpreting spectral data requires expertise in colorimetry and an understanding of the relationship between spectral reflectance or transmittance and perceived color.

Q 13. Explain the difference between absolute and relative color measurement.

The difference between absolute and relative color measurement lies in the reference point used for the measurement.

- Absolute color measurement: This measures the color of a sample relative to a known standard, typically a perfect white diffuser (reflectance of 100% at all wavelengths). The instrument is calibrated using this white standard, ensuring that all measurements are referred to the same reference. It’s essential for situations where precise colorimetric values are required.

- Relative color measurement: This type of measurement compares the color of a sample to another sample, which serves as the reference. The color differences are reported without assigning absolute color values. This approach is common in quality control where the aim is to assess consistency or deviations from a particular batch or target sample, for instance comparing the new production batch to a previous one.

The choice between absolute and relative measurement depends on the application needs. Absolute measurement is needed for precise color specification, while relative measurement is sufficient for assessing color consistency.

Q 14. What is color tolerance and how is it specified?

Color tolerance specifies the acceptable range of variation for a given color. It defines the boundaries within which a color is considered acceptable, even if it slightly deviates from the target color. This is critical for manufacturing consistency, as it’s impossible to achieve perfect color matches every time.

Color tolerance is specified using color difference formulas, such as ΔE (Delta E), which quantifies the difference between two colors in a perceptually uniform color space like CIE L*a*b*. A common tolerance might be ΔE ≤ 2, which would mean that any color falling within a ΔE of 2 units from the target color would be considered acceptable. The tolerance value itself depends on the application’s sensitivity to color variation; tighter tolerances are necessary for applications where even minor color differences are visible or undesirable.

Color tolerance is often represented graphically using tolerance ellipses or other visual aids that illustrate the permissible color range in a color space. These ellipses are defined by the chosen color difference formula and the specified tolerance value (e.g., ΔE).

Q 15. How do you manage color consistency across different production batches?

Maintaining color consistency across production batches is crucial for ensuring product quality and brand reputation. This involves a multi-faceted approach focusing on controlled processes and precise measurement. Think of it like baking a cake – you need the same ingredients, in the same quantities, and baked at the same temperature each time to get the same result.

Standardization of Raw Materials: Using consistent batches of raw materials with certified color characteristics is paramount. This often involves rigorous supplier quality control and specifying acceptable color tolerances.

Calibration of Equipment: Regular calibration of spectrophotometers and other color measurement devices is essential. These instruments, which measure the spectral reflectance or transmittance of materials, need to be checked against standards to ensure accuracy. Think of it like calibrating a kitchen scale – you need to ensure it’s measuring correctly.

Color Management Software: Employing color management software helps translate color information across different devices and stages of production. This software creates color profiles for each component in the process, from the initial design to the final product, enabling consistent color reproduction.

Process Control: Establishing and adhering to strict process control procedures, including controlled environmental conditions (temperature, humidity), ensures consistent results. Inconsistent conditions can subtly alter color.

Regular Color Measurements: Implementing regular color measurements throughout the production process allows for early detection of deviations from the target color. This proactive approach enables corrective actions before significant issues arise. Regular checks are essential.

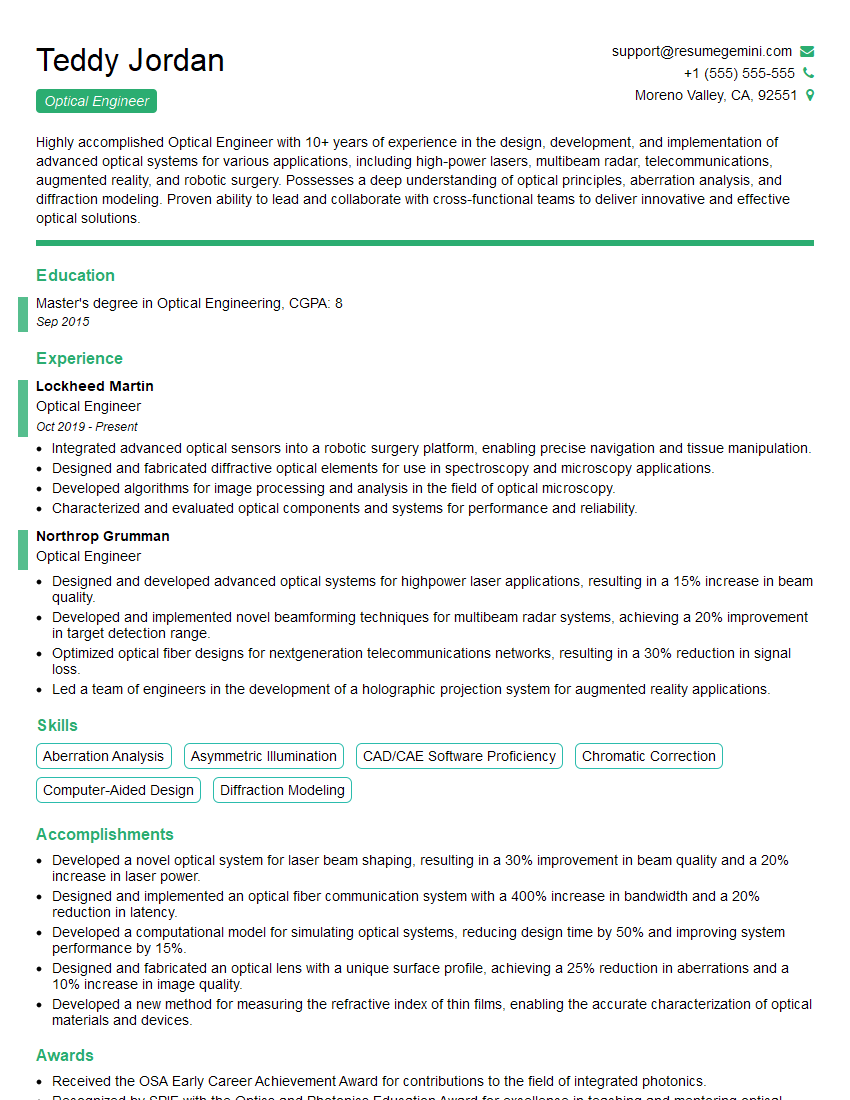

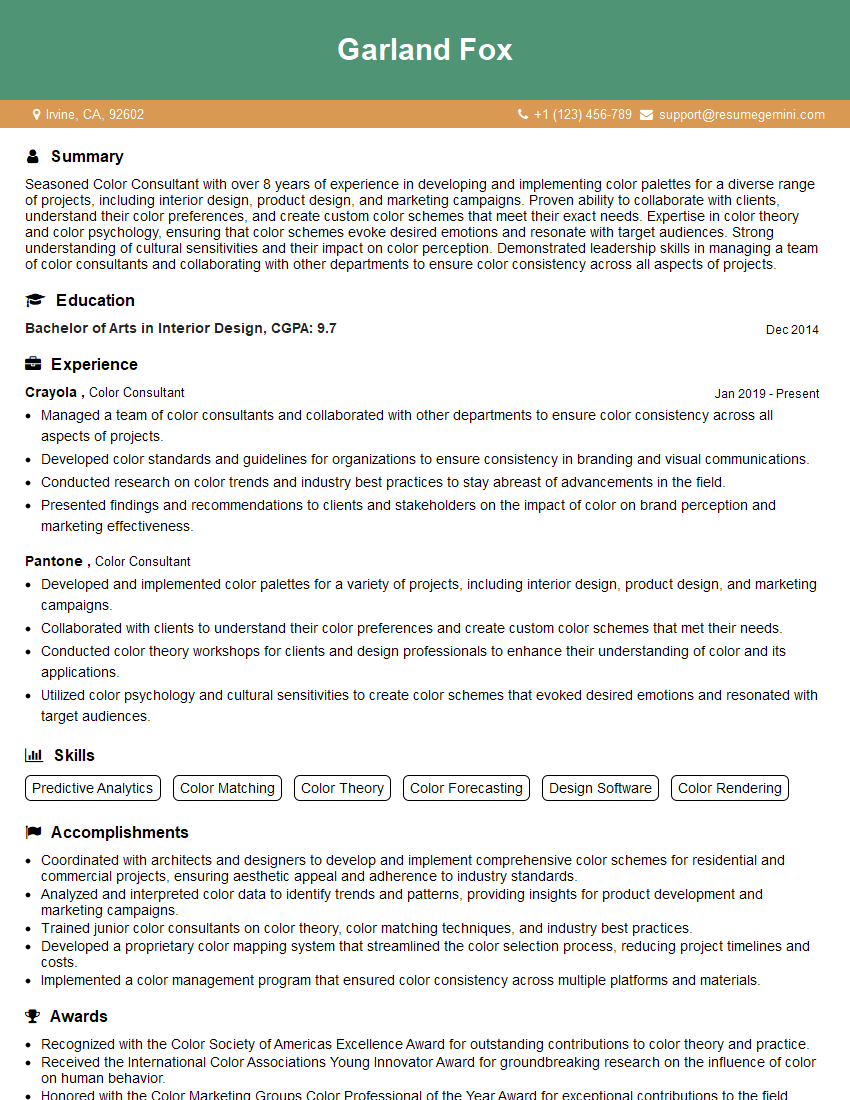

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the applications of color measurement in the textile industry?

Color measurement plays a vital role in the textile industry, from the initial design stage to the final product. Accurate color measurement ensures consistency across different production batches and minimizes costly discrepancies.

Dyeing and Finishing: Color measurement ensures consistent dye recipes and finishing processes, resulting in uniform color across fabric rolls. Inconsistent dyeing can lead to significant waste and customer dissatisfaction.

Quality Control: Color measurement helps maintain quality standards by comparing the actual color of the fabric with the target color, ensuring that each batch meets specifications. Deviations indicate potential problems in the production line.

Color Matching: Color measurement helps match the color of new fabrics to existing ones, facilitating consistent colors across product lines. It’s about precise replication of colors.

Inventory Management: Color measurement allows for accurate inventory management by identifying and classifying different colors, making tracking easier and reducing waste from incorrect color identification.

Customer Satisfaction: Ultimately, consistent color across batches results in higher customer satisfaction, as customers expect the products they buy to match their expectations and previous purchases.

Q 17. What are the applications of color measurement in the paint and coatings industry?

In the paint and coatings industry, color measurement is fundamental for achieving consistent color reproduction, ensuring quality, and meeting customer expectations. It’s similar to a painter carefully mixing colors to match a specific shade.

Formulation: Color measurement is crucial during the formulation stage to precisely determine the right proportions of pigments and binders to achieve the desired color. Slight errors can lead to noticeable differences.

Quality Control: Color measurement ensures consistent color across different production batches, reducing waste and maintaining quality standards. Maintaining quality ensures consistent results for customers.

Color Matching: Color measurement allows for accurate color matching, enabling manufacturers to reproduce specific colors from different samples or previous batches. This is important for maintaining brand consistency.

Metamerism Control: Metamerism, a situation where colors look the same under one light source but different under another, is a concern in the paint industry. Color measurement helps identify and manage metameric matches, ensuring consistent color appearance across different lighting conditions.

Regulatory Compliance: Color measurement plays a role in meeting industry regulations and standards for color accuracy and consistency. Regulations often set strict tolerances for color differences.

Q 18. How do you handle color measurement challenges in different materials (e.g., metallic, transparent)?

Measuring color in different materials presents unique challenges due to their optical properties. Metallic surfaces reflect light differently than matte surfaces, and transparent materials transmit light, requiring different measurement techniques.

Metallic Surfaces: Metallic surfaces exhibit specular reflections (mirror-like reflections), which can significantly affect color measurement. Specialized measurement geometries, such as using a sphere spectrophotometer, are needed to account for these reflections and obtain accurate color data.

Transparent Materials: Transparent materials transmit light, requiring the use of specialized spectrophotometers designed to measure transmittance rather than reflectance. Careful consideration of the thickness of the material is also important.

Glossy Surfaces: High-gloss surfaces also cause specular reflections, and require adjustments to the measurement process, often involving techniques to minimize or exclude specular reflections.

Textured Surfaces: Textured surfaces can introduce variations in color appearance due to uneven surface scattering. Techniques to average these variations are needed for reliable measurements.

Fluorescence: Some materials fluoresce, emitting light at different wavelengths than those of the incident light source. Using specialized spectrophotometers with UV-Vis capabilities is important for handling materials with fluorescence.

Q 19. Describe your experience with color management software (e.g., X-Rite i1Profiler, Datacolor SpyderX).

I have extensive experience with color management software, including X-Rite i1Profiler and Datacolor SpyderX. These software packages are essential tools for characterizing displays, printers, and other color devices.

Profiling: I’ve used these packages to create ICC profiles for various devices, ensuring accurate color reproduction across different hardware and software platforms. A profile acts like a translator, ensuring devices understand each other’s color languages.

Color Transformation: I’m proficient in using these tools to transform color data between different color spaces (e.g., sRGB, Adobe RGB) to maintain color consistency across different workflows. It’s about making sure the same color appears the same across various platforms.

Quality Control: I use the software’s color analysis features to assess color accuracy and consistency, identifying and addressing discrepancies before they become major issues in production. This is a crucial aspect of quality control.

Troubleshooting: I’ve utilized the software’s diagnostic tools to troubleshoot color-related problems, identifying the source of errors and implementing solutions. Finding the root of a problem is essential for fixing color inconsistencies.

Q 20. Explain your familiarity with color standards and color atlases.

I am well-versed in various color standards and atlases, which are essential references for consistent color communication and quality control. They serve as a common language for color.

Pantone Matching System (PMS): I’m familiar with the Pantone system, a widely used color matching system for printing and design, using its color books to ensure accurate color reproduction across various applications.

RAL Color System: I’m also familiar with the RAL system, widely used in Europe for paint and coatings, providing a standardized color palette for consistent color identification.

Munsell Color System: My knowledge extends to the Munsell system, a color space that describes colors based on hue, value (lightness), and chroma (saturation), which is a key theoretical base in many color measurement techniques.

Color Atlases: I have experience using various color atlases as physical references for color matching and quality control, offering a visual comparison to measured data.

CIE Standards: I understand and apply the CIE (Commission Internationale de l’Éclairage) standards for colorimetry, providing a scientific basis for color measurement and communication.

Q 21. How do you assess the color quality of printed materials?

Assessing the color quality of printed materials involves a combination of visual inspection and instrumental measurement to ensure accuracy and consistency. This is crucial for meeting customer expectations and maintaining brand identity.

Visual Inspection: Visual inspection under controlled lighting conditions is the first step. This helps to identify gross color variations that might be missed by instrumentation alone.

Spectrophotometric Measurement: Instrumental measurement using a spectrophotometer is crucial for objective color assessment. This provides numerical data on color differences (ΔE) between the printed material and the target color.

Color Difference Formulas: Different color difference formulas (e.g., ΔE*ab, ΔE*00) are used to quantify color differences, each having its own strengths and weaknesses depending on the application.

Colorimetric Software: Colorimetric software analyzes the spectrophotometer data, calculating color differences and providing reports on color accuracy and consistency. Software allows for easy comparison of colors.

Lighting Conditions: Assessment needs to consider different lighting conditions as metamerism can cause colors to appear differently under various light sources. It is best to measure under standard illuminants, like D50.

Q 22. What is the impact of ambient light on color measurement?

Ambient light significantly impacts color measurement because it introduces an uncontrolled light source that can alter the perceived color of the object being measured. Imagine trying to judge the true color of a fabric swatch under a dim, yellow incandescent light versus bright, daylight-balanced fluorescent lighting – the color will appear drastically different! This is because the ambient light adds its spectral components to the light reflected by the object, leading to inaccurate readings.

To minimize this, color measurements are ideally performed under controlled lighting conditions, often using a calibrated light source such as a D65 illuminant (simulating average daylight) within a light booth or integrating sphere. These environments minimize the influence of external light and ensure consistent illumination for accurate measurements.

For example, in the textile industry, consistent color is crucial. Without controlled lighting, a fabric batch might appear slightly different depending on the factory lighting, leading to rejected products. Controlled ambient light ensures that the colorimeter or spectrophotometer provides a consistent measurement regardless of the surrounding environment.

Q 23. How do you ensure the accuracy and repeatability of color measurements?

Ensuring accuracy and repeatability in color measurement requires a multi-faceted approach. It starts with using properly calibrated instruments. Spectrophotometers and colorimeters need regular calibration checks using standardized color tiles or reference materials. This calibration verifies the instrument’s accuracy against known standards.

Beyond instrument calibration, meticulous sample preparation is crucial. This involves ensuring the sample surface is clean, free from dust or scratches, and presented consistently to the instrument. The angle of measurement and the size of the measurement area should be consistent across all measurements. Standardizing sample preparation significantly reduces measurement variability.

Finally, controlled environmental factors such as temperature and humidity play a significant role. Some materials are sensitive to changes in these parameters, affecting their color appearance. Maintaining consistent environmental conditions ensures repeatable measurements. Think of a piece of dark chocolate; its color can appear slightly different depending on the temperature – a warm environment can make it look less glossy and slightly duller than in a cool environment. Controlling these factors ensures consistent readings over time.

Q 24. Explain different types of color spaces (e.g., XYZ, LAB, RGB, CMYK).

Different color spaces represent color information in different ways, each with its own strengths and weaknesses.

- RGB (Red, Green, Blue): This is an additive color space used in displays like computer monitors and televisions. It mixes red, green, and blue light to create different colors. Values range from 0 to 255 for each component.

- CMYK (Cyan, Magenta, Yellow, Key/Black): This is a subtractive color space used in printing. It works by subtracting colors from white light using cyan, magenta, yellow, and black inks. It’s less precise than other color spaces.

- XYZ: This is a device-independent color space that serves as a foundation for other spaces. It’s based on the CIE standard observer, representing the average human color perception. It’s often used for spectral data analysis but lacks intuitive representation.

- LAB: This is a device-independent color space designed to mimic human color perception more closely than XYZ. ‘L’ represents lightness, ‘a’ represents the red-green axis, and ‘b’ represents the yellow-blue axis. It’s widely used for color difference calculations and quality control.

For example, an RGB value of (255, 0, 0) represents pure red, while the same color might be represented differently in CMYK depending on the printing process. LAB provides a more uniform perception of color differences, making it easier to compare colors across different devices and processes.

Q 25. What is the relationship between color temperature and correlated color temperature (CCT)?

Color temperature refers to the temperature of a black body radiator that emits light of a comparable color to the light source. It’s expressed in Kelvin (K). A higher Kelvin value indicates cooler light (bluish), while a lower value indicates warmer light (reddish).

Correlated Color Temperature (CCT) is used to characterize the color of light sources that don’t perfectly match the black-body radiator curve. It’s the temperature of the black body whose color most closely resembles the light source. The CCT is an approximation, but it provides a useful way to compare the color appearance of different light sources.

For instance, a tungsten filament light bulb might have a color temperature of around 2700K (warm white), whereas daylight might have a CCT around 6500K (cool white). The difference reflects their distinct color characteristics.

Q 26. Describe your experience with different measurement geometries and their applications.

Measurement geometries significantly impact the accuracy and type of color measurement obtained. They define the angle at which light is incident on and reflected from the sample. Common geometries include:

- 45/0°: Light is incident at a 45-degree angle and measurement is taken at 0 degrees (perpendicular to the surface). This is often used for samples with significant texture, as it reduces the influence of surface gloss.

- d/8° (diffuse/8°): Light is diffused onto the sample and measurement is taken at an 8-degree angle. This geometry minimizes the influence of surface gloss, making it suitable for many types of materials.

- specular included/excluded: This option refers to whether the specular component (reflection from the surface) is included or excluded from the measurement. Glossy surfaces require careful consideration of specular components for accurate color assessment.

In practice, the choice of geometry depends on the application. For example, the automotive industry often uses specular included measurements to assess the final appearance of a car’s paint, while textiles often utilize 45/0° or d/8° measurements to reduce the impact of surface texture on color assessment.

Q 27. How would you troubleshoot a problem with inconsistent color measurements?

Troubleshooting inconsistent color measurements is a systematic process. I would follow these steps:

- Verify Instrument Calibration: The first and most crucial step is to check the spectrophotometer or colorimeter’s calibration using standard reference materials. If the instrument is out of calibration, this will directly lead to inaccurate and inconsistent readings.

- Examine Sample Preparation: Assess whether the samples were prepared consistently. Differences in sample presentation (orientation, cleanliness, surface condition) can lead to variations in measurements. Are there any issues with the sample itself, such as inconsistencies within the material?

- Control Environmental Factors: Ensure consistent temperature, humidity, and ambient light during measurements. Fluctuations in these factors can influence color readings, especially for sensitive materials.

- Review Measurement Parameters: Check the measurement geometry, aperture size, and other instrument settings. Inconsistencies in these parameters can contribute to variations in the results.

- Repeat Measurements: Conduct multiple measurements on the same sample to assess the repeatability of the readings. A high standard deviation indicates significant variability that needs further investigation.

- Instrument Maintenance: If the problem persists, investigate potential instrument malfunctions. Regular maintenance and cleaning of the spectrophotometer or colorimeter are critical.

By methodically checking each aspect, the root cause of the inconsistency can be identified and corrected. It’s akin to troubleshooting a car engine problem; you check each system systematically until the fault is found.

Key Topics to Learn for Light and Color Measurement Interview

- Radiometry and Photometry: Understand the fundamental differences and relationships between radiometric and photometric quantities (e.g., radiant flux vs. luminous flux, irradiance vs. illuminance). Explore their practical applications in various lighting scenarios.

- Colorimetry and Color Spaces: Master the concepts of color matching, tristimulus values, and different color spaces (e.g., CIE XYZ, RGB, LAB). Practice converting between color spaces and understand the limitations of each.

- Spectrophotometry: Learn about the principles of spectrophotometry and its role in characterizing light sources and materials. Understand how spectral data is used to determine color and other optical properties.

- Light Sources and Measurement Instruments: Familiarize yourself with common light sources (e.g., LEDs, incandescent lamps, fluorescent lamps) and their spectral characteristics. Understand the functionality and limitations of various light measurement instruments (e.g., spectrophotometers, colorimeters, integrating spheres).

- Color Appearance and Metamerism: Grasp the concepts of color appearance and how factors like viewing conditions and observer adaptation affect perceived color. Understand the phenomenon of metamerism and its implications for color matching.

- Applications in Industry: Explore the practical applications of light and color measurement in various industries, such as display technology, automotive lighting, textiles, and food processing. Be prepared to discuss specific examples and challenges.

- Data Analysis and Interpretation: Develop your skills in analyzing spectral and colorimetric data. Practice interpreting results and drawing meaningful conclusions from measurements.

- Troubleshooting and Calibration: Understand common issues encountered in light and color measurement and how to troubleshoot them. Know the importance of instrument calibration and its impact on measurement accuracy.

Next Steps

Mastering Light and Color Measurement opens doors to exciting career opportunities in diverse fields, offering excellent prospects for growth and innovation. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored specifically to the Light and Color Measurement field to guide you in crafting a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good