Cracking a skill-specific interview, like one for Line Striping, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Line Striping Interview

Q 1. What types of pavement markings are you familiar with?

As a line striping expert, I’m familiar with a wide range of pavement markings, each serving a specific purpose. These markings are crucial for guiding traffic, improving safety, and managing traffic flow. They can be broadly categorized into:

- Solid Lines: Indicate restrictions, such as no passing zones or lane dividers. Think of the solid yellow line down the center of a two-lane highway – it clearly shows where passing is prohibited.

- Dashed Lines: Allow for lane changes or passing when safe to do so. A dashed white line between lanes often signals that changing lanes is permitted if it’s safe to do so.

- Broken Lines: A combination of solid and dashed lines, often used to delineate various traffic situations.

- Arrows: Indicate the direction of traffic flow, often used at intersections or merge points. For instance, arrows painted on the approach to a roundabout clearly direct drivers into the correct lane.

- Crosswalks: Clearly marked pedestrian crossings, vital for pedestrian safety. The classic white stripes help pedestrians and drivers understand where it’s safe to cross and stop.

- Symbols and Lettering: Used to convey additional information, such as speed limits, parking restrictions, or warning symbols.

- Stop Bars: Clearly demarcated areas where vehicles should stop before a crosswalk or intersection. They often are marked with a solid white line.

Understanding the different types and their meanings is fundamental to ensuring the safety and efficiency of our roads.

Q 2. Describe the process of applying thermoplastic pavement markings.

Applying thermoplastic pavement markings is a precise process demanding both skill and the right equipment. It’s a hot-applied method, offering superior durability compared to other paint-based markings. Here’s a step-by-step overview:

- Preparation: The pavement surface needs to be clean, dry, and free of debris. Any existing markings need to be removed. This is usually done by grinding or blasting.

- Application: Thermoplastic material is heated in a specialized extrusion machine until it becomes a molten liquid. This liquid is then applied to the pavement through a precise line-striping machine, creating lines of the desired width and thickness.

- Setting: The hot thermoplastic quickly cools and sets, forming a durable marking that bonds well with the asphalt. This rapid setting minimizes disruption to traffic.

- Quality Control: After application, a final check is done to ensure the lines are straight, uniform, and meet the specified dimensions. Any imperfections are rectified immediately.

Imagine it like baking a cake; you need the right ingredients (thermoplastic), the correct temperature (precise heating), and careful handling (smooth application) to get the perfect result. The difference is that this ‘cake’ is incredibly durable and helps keep traffic flowing smoothly.

Q 3. Explain the importance of proper traffic control during line striping operations.

Proper traffic control is paramount during line striping operations. Worker safety and minimizing disruption to traffic flow are the top priorities. Neglecting traffic control can lead to accidents and significant delays. Effective traffic control involves:

- Advanced Warning: Signage, such as temporary road closures or lane reductions, should be placed well in advance to alert drivers.

- Flaggers: Trained flaggers guide traffic safely around the work zone, ensuring the protection of both the workers and drivers.

- Traffic Cones and Barricades: These help delineate the work area, preventing vehicles from entering the zone unexpectedly.

- Proper Signage: Clear, concise signage that is easily understood communicates the situation effectively.

- Pilot Cars: In some cases, especially for longer stretches of work, pilot cars might be used to lead traffic through the work zone safely.

For example, a poorly managed traffic control setup during a road striping project could lead to a vehicle driving through the freshly laid thermoplastic, damaging the new markings and potentially causing an accident.

Q 4. What safety measures are crucial when operating line striping equipment?

Safety is the absolute number one priority. Operating line striping equipment demands vigilance and adherence to safety protocols. Crucial safety measures include:

- Personal Protective Equipment (PPE): This includes safety glasses, gloves, high-visibility clothing, and steel-toe boots to protect against potential hazards.

- Machine Safety Checks: Before operating any equipment, a thorough inspection is vital to ensure everything is functioning correctly and safely. This includes checking fluid levels, tire pressure, and overall machine condition.

- Awareness of Surroundings: Maintaining constant awareness of traffic and pedestrian movements is essential. Distractions should be avoided at all costs.

- Proper Training: All operators should receive comprehensive training on the safe operation and maintenance of the equipment.

- Emergency Procedures: Operators must be familiar with emergency procedures and know how to react to unforeseen circumstances.

I always say, ‘Safety first, stripes second!’ It’s not just a slogan – it’s a commitment to ensuring everyone’s well-being.

Q 5. How do you ensure accurate line striping measurements and application?

Achieving accurate line striping requires precision and attention to detail. We use several methods to guarantee accuracy:

- Accurate Measurement: Precise measurements are taken before application using measuring wheels or laser measuring tools to determine the exact lengths and positions of lines.

- Line Striping Machines: Modern machines have features like GPS guidance and automatic controls, which help maintain straight lines and consistent widths.

- Templates and Guides: For more intricate designs or specialized markings, templates and guides are employed to ensure uniformity.

- Regular Calibration: Equipment is regularly calibrated to ensure that measurements and application are consistently accurate. This helps eliminate any errors resulting from machine wear or discrepancies.

- Quality Control Checks: Regular inspections and checks are performed during and after the application to identify and correct any inconsistencies or deviations from the plan.

Imagine trying to paint a straight line without a ruler – it’s nearly impossible to get perfect results! The same principle applies to line striping; accurate tools and methods are essential for producing high-quality results.

Q 6. What are the different types of line striping equipment you’ve used?

Throughout my career, I’ve had the opportunity to work with various line striping equipment, ranging from smaller, hand-guided machines to large, sophisticated models. These include:

- Hand-guided Stripers: These smaller machines are suitable for smaller jobs or intricate designs, offering good maneuverability.

- Self-Propelled Stripers: These machines are ideal for larger areas, providing increased efficiency and speed, and minimizing operator fatigue.

- Airless Sprayers: Used for applying larger areas of pavement markings, particularly with traffic paint.

- Thermoplastic Extrusion Machines: These machines are used to melt and apply thermoplastic marking materials, as discussed earlier.

- Line Layout Equipment: This includes string lines, measuring wheels, and laser-guided systems for precise line marking planning.

The choice of equipment depends heavily on the scale and complexity of the project, and of course always adhering to all safety standards.

Q 7. How do you handle different weather conditions during line striping?

Weather significantly impacts line striping operations. Different weather conditions require different approaches and, in some cases, complete suspension of work. Here’s how we handle different scenarios:

- Rain: Line striping cannot be done in the rain. The pavement needs to be completely dry for proper adhesion of the markings. We wait for suitable weather.

- Extreme Heat: In extreme heat, the thermoplastic material can set too quickly, impacting the quality of the markings. The material may also become too viscous to apply smoothly. We adjust our application techniques to accommodate this, or work during cooler parts of the day.

- Cold Temperatures: Cold temperatures can make the thermoplastic material difficult to work with. We need to ensure the material is adequately heated, and possibly adjust our equipment parameters.

- Wind: High winds can affect the application process, making it difficult to create clean and consistent lines. We monitor wind speed to determine the workability of the conditions.

- Freezing Temperatures: Work should be entirely suspended if freezing temperatures are anticipated or experienced.

Weather is a constant factor we have to monitor, adapt to, and plan for. Safety and quality can be significantly impaired by unfavorable weather conditions.

Q 8. What are the common challenges in line striping, and how do you overcome them?

Line striping, while seemingly straightforward, presents several challenges. One major hurdle is weather conditions. Rain, extreme heat, or even high humidity can significantly impact paint adhesion and drying time, leading to uneven lines or premature wear. Another challenge is surface preparation; uneven surfaces, cracks, or debris can affect the quality and longevity of the striping. Finally, traffic management during the striping process is crucial to ensure both worker safety and minimal disruption to traffic flow.

To overcome these, we utilize various techniques. For weather, we employ careful scheduling, using weather forecasts to plan our work. We may need to postpone projects if conditions are unsuitable. For surface preparation, we meticulously clean and repair the surface before applying paint. This involves pressure washing, crack filling, and removing any debris. Effective traffic management involves utilizing cones, barricades, and flag persons to guide traffic safely around the work area. Sometimes, night work is necessary to minimize disruption.

Q 9. Explain the importance of proper surface preparation before line striping.

Proper surface preparation is paramount to the success of any line striping project. Think of it like painting a house – you wouldn’t paint directly onto a dirty, cracked wall, would you? Similarly, applying paint to a poorly prepared surface will lead to poor adhesion, premature fading, and ultimately, a need for costly repairs.

The preparation process typically involves several steps: Cleaning the surface to remove dirt, oil, and debris using a pressure washer; Repairing any cracks or damage using appropriate fillers; Priming the surface, if necessary, to enhance paint adhesion; and finally, Profiling (if needed) to improve the bond between the pavement and the paint.

Failing to properly prepare the surface can result in lines that peel, chip, or fade quickly, necessitating costly rework and potentially causing safety hazards due to reduced visibility.

Q 10. Describe your experience with different types of paint and their application methods.

My experience encompasses a range of paints, each with its own characteristics and application methods. Water-based acrylic paints are commonly used for their quick drying time, low odor, and environmental friendliness. They are easy to apply but might require more coats for optimal opacity. Solvent-based paints, though more durable and weather-resistant, have a strong odor and longer drying times. They usually offer better longevity in high traffic areas.

Application methods vary depending on the paint type and project size. For smaller projects, a hand-held striping machine might suffice. However, for larger jobs, we use specialized airless sprayers for quicker and more efficient coverage, ensuring a uniform line width. We also use line stripers with pre-measured rollers for controlled and precise application of paint, especially for complex designs. Finally, traffic paint markers offer an excellent option for quick temporary markings or touch-ups.

Q 11. How do you maintain and repair line striping equipment?

Regular maintenance is key to extending the lifespan and ensuring the optimal performance of line striping equipment. This involves daily checks of the machine’s components, including the hoses, pumps, and spray guns, for any leaks, clogs or damage. We perform regular cleaning, especially after each use, to prevent paint buildup.

More extensive maintenance, like filter replacements and lubrication, is carried out according to the manufacturer’s recommendations. We also keep a well-stocked inventory of spare parts to minimize downtime in case of repairs. Safety checks, such as ensuring proper grounding, are crucial before every use. For example, I recently had to replace a worn-out spray tip, which significantly improved the quality of the line. Preventive maintenance ensures our equipment is always ready for the job and produces the best results.

Q 12. What are the regulatory requirements for line striping in your area?

Regulatory requirements for line striping vary by location, but generally involve adherence to local and state transportation codes. These codes often specify the required paint type, line widths, colors, and placement based on the type of roadway (e.g., highway, residential street). We need to ensure our work complies with these guidelines. For instance, highway striping often has more stringent standards related to reflectivity and durability than parking lot striping.

We obtain all necessary permits and approvals before commencing any project and maintain meticulous records to document our work and ensure compliance. Regular inspections and audits by the relevant authorities are common, and we are prepared to provide detailed documentation.

Q 13. How do you manage a line striping crew?

Managing a line striping crew effectively involves clear communication, proper training, and a strong emphasis on safety. Before any project, I conduct a thorough briefing with the team, covering the project plans, safety procedures, and expected timelines. We utilize established communication channels, such as two-way radios, to maintain constant contact on-site, improving efficiency and responsiveness.

Team training is essential. This includes safety training, familiarization with the equipment, and proper application techniques. I promote a culture of teamwork and collaboration, ensuring every member understands their role and responsibilities. Regular performance evaluations and feedback sessions are vital to maintain high standards and address any performance gaps. Safety is paramount; regular safety meetings, and on-site safety inspections are crucial aspects of my management style.

Q 14. How do you read and interpret line striping plans and specifications?

Reading and interpreting line striping plans and specifications requires careful attention to detail. These plans typically include detailed drawings showing the layout of lines, their widths, colors, and the specific materials to be used. Understanding symbols and abbreviations is essential, as these plans often use a standardized notation system.

I meticulously review all aspects of the plans, checking for any discrepancies or inconsistencies before starting the project. I cross-reference dimensions, ensure correct paint types are specified, and verify any specific instructions regarding placement, such as curve radii and transitions. Any ambiguities are clarified with the client or engineer before commencing the work to avoid errors and ensure the project meets all requirements. Precision and careful adherence to the specifications are key to a successful outcome.

Q 15. Describe your experience with different types of pavement surfaces.

My experience encompasses a wide range of pavement surfaces, each requiring a tailored approach to line striping. I’ve worked extensively with asphalt, concrete, and even specialized surfaces like porous pavements and textured overlays. Asphalt, for instance, needs a primer to ensure proper paint adhesion, while concrete requires a different preparation method to achieve optimal results. Porous pavement necessitates using specific paints designed for permeability. Understanding the specific properties of each surface – its porosity, texture, and existing coatings – is crucial for selecting the right paint and ensuring a durable, high-visibility marking.

- Asphalt: Requires priming to ensure adhesion. Different asphalt types (e.g., open-graded, dense-graded) influence paint selection.

- Concrete: Often needs cleaning and potentially etching to enhance paint grip. Surface temperature and moisture content are critical considerations.

- Porous Pavements: Demand specialized, permeable paints to allow water drainage, maintaining the pavement’s functionality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the longevity and visibility of pavement markings?

Longevity and visibility of pavement markings are paramount for safety and efficiency. Several factors contribute to this. First, selecting high-quality, durable paint or thermoplastic is key. Thermoplastic, for example, offers superior longevity compared to paint, especially in high-traffic areas. Proper surface preparation – cleaning, priming, and etching when needed – is equally important for optimal adhesion. Finally, applying the markings to the correct specifications, including proper thickness and consistent application, significantly impacts their lifespan and visibility. Regular maintenance, such as repainting faded lines, is also critical. I always recommend a preventative maintenance schedule tailored to the specific traffic volume and environmental conditions of each project.

For enhanced visibility, I consider factors like retroreflectivity (the ability to reflect light at night), especially using materials with high retroreflective beads. Proper line width and design, following standards like MUTCD (Manual on Uniform Traffic Control Devices), further optimize visibility. For example, using wider lines in areas with poor visibility or higher speeds makes them more easily noticeable.

Q 17. What is your experience with using GPS or other technology for line striping?

GPS technology has revolutionized line striping. I routinely utilize GPS-guided striping machines for large-scale projects. This ensures accurate placement of lines, minimizing deviations and improving efficiency. The GPS system guides the machine along pre-programmed paths, reducing manual labor and human error. I’ve also utilized other technologies such as laser-guided systems for increased precision, particularly for complex geometries or intricate markings. Integrating this technology into my workflow has led to significant improvements in speed, accuracy, and overall project quality. On smaller projects, I might use a total station or even carefully measured layouts for accurate line placement.

Q 18. Describe your experience with different types of striping materials (e.g., paint, thermoplastic).

My experience covers a broad spectrum of striping materials. I’m proficient with both water-based paints and solvent-based paints, each offering distinct advantages and disadvantages. Water-based paints are environmentally friendlier but generally have shorter lifespans than solvent-based ones. I also have extensive experience with thermoplastic, which offers superior durability and longevity, especially in high-traffic areas and harsh climates. The choice of material depends on the specific project requirements, including budget, traffic volume, and environmental conditions. For example, thermoplastic is ideal for highways and busy intersections, while water-based paints might suffice for less-demanding areas like parking lots. I’m also familiar with epoxy paints, known for their resistance to chemicals and abrasion. The decision-making process involves careful consideration of various factors like budget, longevity needs, and environmental impacts.

Q 19. How do you handle unexpected issues or delays during a project?

Unexpected issues are an inevitable part of any project. My approach involves proactive planning, including contingency plans for potential problems. For example, I always factor in potential weather delays. If unexpected issues do arise – like discovering underground utilities during excavation or encountering unforeseen pavement conditions – I immediately assess the situation, communicate with the client, and develop a solution collaboratively. This often involves adjusting the schedule, exploring alternative approaches, or potentially bringing in specialized equipment or personnel. Transparency and open communication with the client are vital to managing unexpected challenges effectively. I’ve found that flexible problem-solving, drawing on my experience with diverse scenarios, allows for efficient resolution and minimizes disruption.

Q 20. What is your experience with quality control procedures for line striping?

Quality control is fundamental to my approach. It begins with meticulous planning and preparation, ensuring accurate measurements and adherence to specifications. During the striping process, regular inspections are crucial. I check line width, paint consistency, and alignment regularly. After completion, a final comprehensive inspection verifies that all lines are accurately placed, uniformly applied, and meet the required standards. This inspection includes checking for gaps, inconsistencies, and other imperfections. Documentation – including photos and records of materials used – forms a vital part of the quality control process. This ensures accountability and allows for efficient troubleshooting if any issues arise later. I follow relevant industry standards and specifications, and I maintain detailed project records for future reference. This rigorous process assures the quality and longevity of the pavement markings.

Q 21. How do you calculate the amount of paint needed for a specific project?

Calculating paint quantities requires accurate measurements and consideration of several factors. First, I precisely measure the total length of lines to be striped. Then, I determine the required line width. The paint manufacturer’s specifications provide the coverage rate per gallon (or liter) for a specific line width and type of paint. This coverage rate might vary depending on the surface type. For example, a porous surface might absorb more paint than a smooth, sealed surface. I add an additional percentage (typically 10-15%) to account for overspray, spillage, and potential imperfections. The formula is straightforward: Total length * line width * coverage rate per unit area + contingency percentage = total paint required. For complex projects with multiple line widths or types of paint, a detailed breakdown for each section is necessary. This methodical approach ensures that sufficient paint is available, preventing delays and waste.

Q 22. Describe your experience with different types of line marking patterns.

Line marking patterns are incredibly diverse, each serving a specific purpose in managing traffic flow and safety. My experience encompasses a wide range, from simple solid lines and dashed lines used for lane delineation on highways, to more complex patterns like crosswalks, arrows, symbols (stop signs, speed limits), and parking space markings. I’m proficient in applying these patterns using various techniques and equipment, adapting to different surface types (asphalt, concrete) and environmental conditions.

- Solid Lines: These denote lane boundaries, often used on highways and roads to prevent lane changes. The thickness varies depending on the application – thicker lines for major highways.

- Dashed Lines: Indicate permitted passing areas, allowing drivers to safely overtake other vehicles. The length and spacing of the dashes are crucial for conveying the legal speed and safety level allowed.

- Crosswalks: A fundamental pedestrian safety element, these use a combination of lines and often additional markings like raised pavement markers.

- Arrows: These clearly direct traffic flow at intersections or in complex road layouts. Accurate placement and clear visibility are paramount.

- Parking Bay Markings: These usually involve a combination of lines to define individual parking spaces, as well as access lanes.

I’ve worked on projects ranging from small parking lots to large multi-lane highways, requiring a detailed understanding of relevant regulations and best practices for each pattern’s application.

Q 23. What are the common causes of line striping defects, and how to prevent them?

Line striping defects can significantly impact safety and require immediate attention. Common causes include:

- Inadequate Surface Preparation: Oil, dirt, or loose debris on the surface will prevent proper adhesion of the paint, leading to peeling or premature failure.

- Incorrect Paint Application: This might be due to improper nozzle adjustments, inconsistent speed, or insufficient paint coverage, resulting in uneven lines, gaps, or faded areas.

- Poor Weather Conditions: Extreme heat, cold, rain, or high humidity can negatively affect paint adhesion and drying time.

- Substandard Materials: Using inferior quality paint or beads (for reflectivity) can lead to rapid degradation and a shorter lifespan for the markings.

- Equipment Malfunction: Issues with the striping machine, such as nozzle clogging or inconsistent paint flow, can create defects.

Prevention involves meticulous preparation. This includes thoroughly cleaning and preparing the surface, using appropriate primers where necessary, selecting high-quality paints and beads suitable for the environment, and regularly maintaining the equipment. Careful monitoring of weather conditions is essential to ensure ideal application parameters. Proper training of personnel on equipment operation and paint application techniques is also crucial.

Q 24. What are your methods for ensuring accurate line width and spacing?

Ensuring accurate line width and spacing is paramount for safety and clarity. My methods involve a multi-pronged approach:

- Precise Equipment Calibration: I meticulously calibrate the line striping machine before each project, verifying paint flow rate, nozzle size, and wheel spacing to match the desired line width and spacing. We use precision measuring tools to double-check.

- GPS and/or Automated Guidance Systems: On larger projects, we leverage GPS guidance systems or automated steering capabilities to maintain consistent line placement and spacing, enhancing accuracy and efficiency.

- Regular Monitoring and Adjustments: Throughout the striping process, I continually monitor the line width and spacing, making adjustments as needed to compensate for variations in surface conditions or equipment performance. This often involves visual checks and spot measurements using measuring tapes and/or laser measuring devices.

- Quality Control Checks: Upon completion, a thorough quality control check is performed to ensure that the striping meets the specified requirements and safety standards. This includes visual inspections, measurements, and photographic documentation.

We treat accuracy as a core value, understanding the potential safety implications of even minor discrepancies. A methodical approach, combined with state-of-the-art technology, guarantees the highest standards.

Q 25. How do you deal with environmental regulations during line striping?

Environmental regulations are always top of mind. My approach involves:

- Using Environmentally Friendly Paints: We prioritize using low-VOC (Volatile Organic Compound) paints to minimize air pollution and comply with local and national regulations. I’m familiar with the specific requirements for different paint types and their environmental impact.

- Proper Waste Disposal: All leftover paint, solvents, and cleaning materials are disposed of responsibly in accordance with local environmental guidelines. We always have a plan for waste management before we start any project.

- Spill Prevention and Response: We implement robust measures to prevent accidental spills during transportation and application, and have detailed response plans in case of incidents. This includes using absorbent materials and following established clean-up procedures.

- Stormwater Management: We take steps to minimize runoff into storm drains, such as using appropriate containment measures and following best practices for paint application in areas prone to runoff.

Environmental responsibility isn’t just a legal requirement; it’s an ethical one. We strive to minimize our environmental footprint in every project, ensuring sustainable practices are at the core of our operations.

Q 26. What is your experience with working in confined spaces or near traffic?

I possess significant experience working in confined spaces and near traffic. Safety protocols are meticulously followed in both instances.

- Confined Spaces: When working in parking garages or other confined areas, I ensure adequate ventilation, utilize appropriate personal protective equipment (PPE), including respirators, and adhere strictly to confined space entry procedures. We always have a spotter and communication systems in place.

- Near Traffic: Working near traffic necessitates a highly structured and organized approach. We use traffic control devices such as cones, warning signs, and flaggers to create safe work zones and clearly delineate the boundaries between traffic and the work area. All team members receive extensive training on traffic safety awareness and procedures, and we frequently assess potential hazards and adjust our procedures accordingly.

Safety is non-negotiable. We continuously assess and mitigate risks in all work environments, prioritizing the well-being of our team and the public.

Q 27. How do you ensure the safety of both your crew and the public?

Safety is paramount. My approach is built on a foundation of proactive measures, continuous monitoring, and thorough training.

- Pre-Job Safety Briefing: Before each project, we conduct a comprehensive safety briefing, reviewing the specific hazards associated with the site, the equipment being used, and the necessary safety precautions. Each team member is required to acknowledge their understanding and agreement with these procedures.

- Personal Protective Equipment (PPE): Appropriate PPE, including safety vests, gloves, eye protection, and hearing protection, is provided and mandatory for all team members. The type and level of PPE is selected based on the specific hazards of the project.

- Traffic Control and Work Zone Safety: When working near traffic, we implement comprehensive traffic control measures, and our team is trained on flagging and maintaining safe work zones.

- Regular Safety Audits: Regular safety audits and inspections are carried out to identify and correct any potential hazards. This includes checking the condition of equipment and ensuring compliance with safety regulations.

- Emergency Procedures: We have well-defined emergency procedures in place, including communication protocols and response plans for various potential incidents.

Safety isn’t just a checklist; it’s a culture we cultivate within our team, and this dedication translates to a significantly lower risk of accidents and injuries.

Q 28. What is your experience with project scheduling and budgeting for line striping projects?

Project scheduling and budgeting are crucial for successful line striping projects. My experience encompasses the entire process, from initial planning to final completion.

- Detailed Project Planning: I begin by conducting a thorough site survey to accurately assess the scope of work, identify potential challenges, and develop a detailed project plan. This includes determining the type and quantity of materials needed, the required labor hours, and the necessary equipment.

- Accurate Cost Estimation: Based on the project plan, I prepare a comprehensive budget that accurately reflects all anticipated costs, including materials, labor, equipment rental, transportation, and any other relevant expenses.

- Realistic Scheduling: I develop a realistic project schedule that takes into account weather conditions, traffic patterns, and other potential delays. This often involves using project management software and considering potential buffer time to account for unexpected situations.

- Progress Monitoring and Reporting: Throughout the project, I closely monitor progress and provide regular reports to stakeholders, highlighting achievements, challenges, and any required adjustments to the schedule or budget. This ensures transparency and proactive management of potential issues.

My approach to project management is data-driven and focused on efficiency. I’ve successfully delivered numerous projects on time and within budget, reflecting my proficiency in this aspect of line striping.

Key Topics to Learn for Line Striping Interview

- Safety Regulations and Procedures: Understanding and applying relevant OSHA and local safety regulations, including proper use of PPE and traffic control techniques.

- Line Marking Materials and Equipment: Familiarity with different types of paint, thermoplastic, and other marking materials; knowledge of application equipment like stripers, sprayers, and hand tools; understanding of material storage and handling.

- Roadway Geometry and Design: Understanding basic road design principles, including lane widths, curve radii, and sight distances; ability to interpret plans and specifications.

- Striping Techniques and Methods: Mastering various striping techniques like hand-striping, machine striping, and the application of different marking types (e.g., solid lines, dashed lines, arrows).

- Quality Control and Inspection: Knowing how to inspect completed work for accuracy, uniformity, and adherence to specifications; understanding quality control measures and addressing discrepancies.

- Problem-Solving and Troubleshooting: Ability to identify and resolve common issues encountered during striping operations, such as material defects, equipment malfunctions, or adverse weather conditions; demonstrating effective problem-solving skills.

- Project Management and Time Management: Understanding project timelines, resource allocation, and the ability to efficiently manage time and resources to complete projects on schedule and within budget.

- Communication and Teamwork: Effective communication with supervisors, team members, and clients; demonstrating strong teamwork skills and the ability to work collaboratively in a field environment.

Next Steps

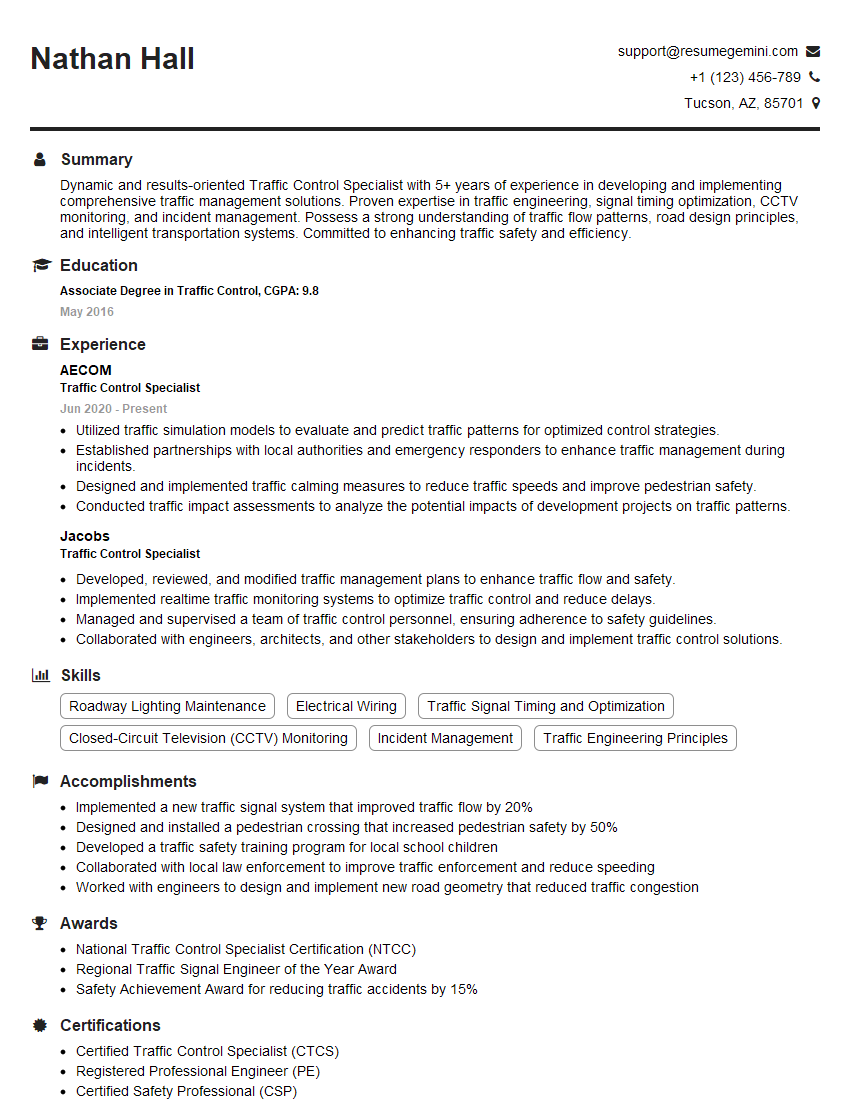

Mastering the art of line striping opens doors to a rewarding career with opportunities for advancement and specialization. A strong understanding of the technical aspects, combined with proven work ethic and safety consciousness, will set you apart. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is essential for getting your application noticed by potential employers. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the Line Striping industry. Examples of resumes specifically designed for Line Striping professionals are available to help guide you. Invest time in crafting a compelling resume – it’s your first impression and a key step towards landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good