Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Liquid Fertilizer Application interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Liquid Fertilizer Application Interview

Q 1. Describe your experience with different liquid fertilizer application methods.

My experience encompasses a wide range of liquid fertilizer application methods, from the simplest to the most technologically advanced. I’ve worked extensively with broadcast application, using booms on tractors to apply fertilizer evenly across large fields. This method is cost-effective for large-scale operations but can lead to uneven distribution if not carefully calibrated. I’ve also utilized band application, where fertilizer is placed precisely near the seed row, maximizing nutrient availability to the plant while minimizing losses. This technique requires specialized equipment, but it’s highly efficient. Furthermore, I’m proficient in fertigation, injecting liquid fertilizer directly into irrigation systems. This method allows for precise nutrient management, reducing environmental impact, and is particularly beneficial for crops with high nutrient demands. Finally, I have experience with injectors for chemigation, a more precise application method that allows for the controlled release of fertilizer in different irrigation zones, for example, to satisfy the nutrient requirements of a specific section within a field.

Each method presents unique advantages and disadvantages, and the best approach depends on the specific crop, soil type, field conditions, and available resources. For instance, fertigation is ideal for water-intensive crops like lettuce, while band application is favored for row crops like corn and soybeans. I’ve learned to adapt my approach based on these factors to ensure optimal results.

Q 2. Explain the importance of calibration in liquid fertilizer application.

Calibration is paramount in liquid fertilizer application because it ensures the accurate delivery of the intended nutrient dose. Inaccurate calibration can lead to either nutrient deficiency, stunting crop growth and yield, or excessive application, resulting in wasted fertilizer, environmental damage (eutrophication of water bodies), and potential harm to crops from salt buildup. Think of it like baking a cake – if you don’t measure your ingredients correctly, the result will be far from perfect.

The calibration process involves accurately measuring the application rate (e.g., gallons per acre or liters per hectare) and ensuring consistency throughout the application process. This typically involves measuring the flow rate of the fertilizer solution, the ground speed of the application equipment, and the width of the application boom. I regularly use calibration tests on various equipment to ensure accuracy and make any necessary adjustments. A common technique is to collect a known volume of the application over a set distance and time, then calculate the application rate per unit area. This ensures the dispensed fertilizer amount matches the intended rate.

Q 3. How do you ensure accurate fertilizer placement and minimize nutrient runoff?

Accurate fertilizer placement and minimizing nutrient runoff are critical for maximizing efficiency and protecting the environment. To achieve this, I employ several strategies. For starters, I carefully consider the application method, opting for methods like band application or fertigation that place nutrients directly near plant roots, minimizing losses through leaching or runoff. Furthermore, I tailor application timing to coincide with periods of high crop demand and minimize the risk of rainfall immediately after application.

Another crucial step is soil testing, which guides me in determining the precise nutrient needs of the crop and soil. This ensures I apply only the necessary amount, preventing excess nutrients from entering waterways. Employing buffer strips along water bodies acts as a natural barrier, reducing the risk of fertilizer runoff into sensitive ecosystems. Finally, I’m a strong advocate for conservation tillage methods that minimize soil disturbance and improve soil water retention, reducing the risk of nutrient loss.

Q 4. What are the common challenges in liquid fertilizer application, and how do you address them?

Common challenges in liquid fertilizer application include clogging of nozzles due to suspended solids or chemical reactions within the tank mix, uneven application due to variations in boom height or ground speed, and calibration errors leading to inaccurate nutrient delivery. Weather conditions, such as strong winds, can also affect application accuracy, increasing drift.

To address these challenges, I meticulously filter the fertilizer solution before application to prevent nozzle clogging. I also implement regular equipment maintenance and calibration checks to ensure consistent application and accuracy. When dealing with adverse weather, I often delay application until conditions improve, prioritizing accuracy and environmental protection. For example, I might use a specialized low-drift nozzle for windy conditions or split up the application across multiple days to reduce the risk of drift or runoff during a predicted rain event.

Q 5. Describe your experience with GPS-guided application systems.

My experience with GPS-guided application systems is extensive. These systems greatly enhance precision and efficiency by using GPS technology to precisely track the applicator’s location in the field. This allows for variable rate application (VRA), where fertilizer application rates are adjusted based on the specific needs of different zones within the field. This is based on soil maps or sensor data indicating variable nutrient needs. For example, GPS-guided systems would allow me to apply more fertilizer to areas with low nutrient levels and less to areas already adequately supplied, maximizing efficiency and minimizing waste.

Furthermore, GPS guidance prevents overlapping or missed areas, leading to a more uniform and efficient application. The data generated by these systems helps to track application patterns, create field maps and analyze the efficacy of fertilizer usage and adjust strategies over time. This data-driven approach is crucial for optimizing fertilizer management and achieving sustainable agricultural practices.

Q 6. How do you determine the appropriate fertilizer rate for a given crop and soil type?

Determining the appropriate fertilizer rate involves a multifaceted approach. First, I conduct a thorough soil test to analyze the existing nutrient levels. Then, I consider the specific nutrient requirements of the chosen crop, referencing university extension publications, research trials, and industry best practices to determine the optimal amounts of nitrogen, phosphorus, and potassium (NPK) and other micronutrients necessary for optimal growth. Crop growth stage also needs to be considered, as the needs of the crop changes as it grows.

Next, I factor in environmental conditions, including soil type, climate, and rainfall. Sandy soils, for example, have higher leaching potential, requiring adjustments to the fertilizer rate to prevent nutrient loss. I may use a fertilizer calculator or specialized software to integrate these factors and calculate the precise fertilizer rate. This process often involves taking into consideration the crop’s yield goals, historical data from the field, and economic considerations. The goal is to strike a balance between maximizing yield and minimizing environmental impact and fertilizer expenses.

Q 7. What safety precautions do you follow when handling and applying liquid fertilizers?

Safety is my utmost priority when handling and applying liquid fertilizers. Before starting any application, I always meticulously review the Safety Data Sheet (SDS) for the specific fertilizer product, understanding its potential hazards and necessary precautions. I wear appropriate personal protective equipment (PPE), including gloves, eye protection, and protective clothing, to prevent skin and eye contact with the fertilizer.

I ensure the application equipment is properly maintained and calibrated to prevent leaks or spills. I also carefully follow all local and national regulations concerning fertilizer storage, handling, and application. Furthermore, I’m trained in emergency response procedures, knowing how to handle spills or accidental exposures. I consistently emphasize safe work practices and provide regular safety training to my team. A culture of safety is paramount, and I lead by example, always prioritizing safety over speed or convenience.

Q 8. Explain your understanding of fertilizer nutrient ratios and their impact on crop growth.

Fertilizer nutrient ratios represent the proportions of nitrogen (N), phosphorus (P), and potassium (K), the primary macronutrients essential for plant growth. They are typically expressed as an N-P-K ratio, for example, 10-10-10. This indicates a 10% nitrogen, 10% phosphorus, and 10% potassium composition by weight. The specific ratio required varies greatly depending on the crop, soil type, and growth stage.

Understanding these ratios is critical because different crops have different nutrient demands. A legume, for instance, might need a higher nitrogen ratio (like 20-10-10) than a root crop like potato which may benefit from a higher phosphorus ratio (e.g., 10-20-10), to support root development. Incorrect ratios can lead to nutrient deficiencies, limiting growth, yields, and even causing plant stress. For example, insufficient nitrogen may lead to stunted growth and pale leaves, while a lack of phosphorus can impede root development and flowering.

In my work, I carefully analyze crop needs and soil conditions to recommend optimal N-P-K ratios. I use this knowledge to create customized fertilizer blends or to make informed decisions when choosing commercial fertilizers based on their N-P-K ratios to meet specific requirements. This ensures efficient nutrient utilization and maximized crop yields.

Q 9. How do you interpret soil test results to determine fertilizer needs?

Soil testing is fundamental to determining fertilizer needs. A comprehensive soil test provides vital information about the levels of essential nutrients, pH, and organic matter content. I interpret these results to identify nutrient deficiencies or excesses. For example, if the test shows low phosphorus levels, we can adjust the fertilizer application to include a higher phosphorus content.

My approach involves a detailed review of the soil test report. I consider the target crop’s nutrient requirements at various growth stages, factoring in the soil’s inherent fertility. Then, I use established nutrient recommendations from state agricultural extension services or peer-reviewed research. For example, if the soil test shows a potassium deficiency and the crop in question has high potassium demands (like corn), a fertilizer with an elevated potassium ratio would be essential.

Beyond simply correcting deficiencies, I also consider potential imbalances. Excess of one nutrient can hinder the uptake of others. It’s a holistic process requiring an understanding of plant physiology, soil chemistry, and nutrient interaction. The goal is to optimize nutrient availability for healthy plant growth and environmentally sound fertilizer management.

Q 10. Describe your experience with different types of application equipment (e.g., boom sprayers, injectors).

I have extensive experience with various liquid fertilizer application equipment. This includes boom sprayers, which are excellent for covering large areas uniformly and injectors, which allow for precise placement within irrigation systems.

Boom sprayers are versatile and commonly used for field crops. They offer control over application rate and nozzle selection. Proper calibration is key to ensure accurate application, preventing over-fertilization or under-fertilization. I’m proficient in calibrating boom sprayers to ensure even distribution and proper application rates based on factors like spray pressure, nozzle type and speed of travel.

Injectors, on the other hand, provide a more targeted approach, blending liquid fertilizer directly into the irrigation water. They are especially useful for orchards, vineyards, and high-value crops. My experience encompasses troubleshooting injector systems and ensuring the correct fertilizer concentration for optimal efficiency and plant health. I am familiar with maintenance of both systems, including nozzle cleaning and pressure checks to maintain optimal function.

Q 11. How do you troubleshoot common equipment malfunctions during application?

Troubleshooting equipment malfunctions requires a systematic approach. I begin by identifying the problem and narrowing down potential causes. For instance, if a boom sprayer isn’t delivering a consistent spray, the issue might be clogged nozzles, insufficient pressure, or a faulty pump. I methodically check each component.

My troubleshooting strategy includes:

- Visual Inspection: Checking for leaks, damaged hoses, or worn parts.

- Pressure Checks: Verifying adequate pressure within the system.

- Nozzle Cleaning: Regularly cleaning nozzles to ensure consistent spray pattern.

- Calibration Checks: Regular checks to ensure accurate application rates.

- Pump Inspection: Assessing pump operation and potential wear and tear.

If the issue persists after these initial steps, I might need to consult the equipment manual or contact a qualified technician. Proper maintenance and preventative measures are key to minimizing malfunctions and maximizing equipment lifespan.

Q 12. What is your experience with variable rate technology (VRT) in fertilizer application?

Variable Rate Technology (VRT) represents a significant advancement in fertilizer application. VRT uses GPS technology and soil maps to apply fertilizer at varying rates across a field, optimizing nutrient use and minimizing environmental impact. This is crucial because nutrient needs aren’t uniform across fields; there are often areas of higher or lower fertility.

My experience with VRT includes data interpretation from soil sampling, prescription map generation and integration into application equipment. I’ve managed projects where soil samples were analyzed, generating prescription maps showing variable fertilizer rates. These maps are then uploaded to VRT-capable equipment which adjusts application rates in real-time according to the prescription.

Using VRT has led to substantial improvements in fertilizer efficiency and reduced nutrient runoff, contributing to both economic and environmental benefits. I’ve seen firsthand how VRT minimizes fertilizer waste by applying only the necessary amount in each specific area, reducing input costs and optimizing yields.

Q 13. How do you maintain accurate records of fertilizer application?

Accurate record-keeping is essential for compliance and effective farm management. I maintain detailed records of all fertilizer applications, including date, field location, fertilizer type, N-P-K ratio, application rate, equipment used, and weather conditions. This is crucial for tracking fertilizer investments, analyzing yield data, and meeting regulatory requirements.

My record-keeping system combines digital and paper-based methods. I use farm management software to track fertilizer applications electronically, generating reports on fertilizer costs and application rates for individual fields or entire farms. This data allows for trend analysis and informed decision-making in future seasons. I also keep physical copies of invoices and delivery receipts, ensuring a comprehensive audit trail.

This meticulous approach guarantees accuracy and traceability for audits and for evaluating the effectiveness of fertilizer programs, improving strategies over time and demonstrating responsible environmental stewardship.

Q 14. Explain your understanding of environmental regulations related to fertilizer application.

Understanding and adhering to environmental regulations is paramount in liquid fertilizer application. These regulations aim to minimize water pollution from nutrient runoff and protect sensitive ecosystems. Regulations vary by location, but commonly address issues such as application timing, buffer zones around water bodies, and the use of best management practices (BMPs).

My understanding encompasses the following crucial areas:

- Nutrient Management Plans: Developing tailored plans based on soil tests, crop requirements, and local regulations.

- Buffer Zones: Maintaining appropriate distances between application areas and water bodies to prevent nutrient runoff.

- Application Timing: Avoiding applications during periods of heavy rainfall or when runoff is likely.

- Best Management Practices (BMPs): Implementing strategies like conservation tillage and cover cropping to reduce soil erosion and nutrient loss.

- Reporting and record-keeping requirements: Maintaining detailed application records for compliance purposes.

I actively stay updated on current regulations and adapt my practices to ensure compliance and protect the environment. This commitment to responsible fertilizer management is an integral part of my professional approach.

Q 15. How do you manage potential nutrient deficiencies in crops?

Managing nutrient deficiencies starts with accurate diagnosis. We use a combination of methods: visual observation of crop symptoms (chlorosis, necrosis, stunted growth), soil testing to determine nutrient levels, and tissue analysis to assess nutrient uptake by the plant. For example, yellowing leaves (chlorosis) can indicate nitrogen deficiency, while purple discoloration might point to phosphorus deficiency. Once the deficiency is identified, a tailored liquid fertilizer blend is formulated to address the specific needs. This often involves increasing the concentration of the deficient nutrient(s) in the next application. A soil test before planting is crucial to proactively address potential issues, allowing for a preventative fertilization plan rather than reactive measures.

For example, if soil tests reveal low potassium levels, we might incorporate a potassium-rich liquid fertilizer into the application schedule, adjusting the concentration based on the severity of the deficiency and the crop’s growth stage.

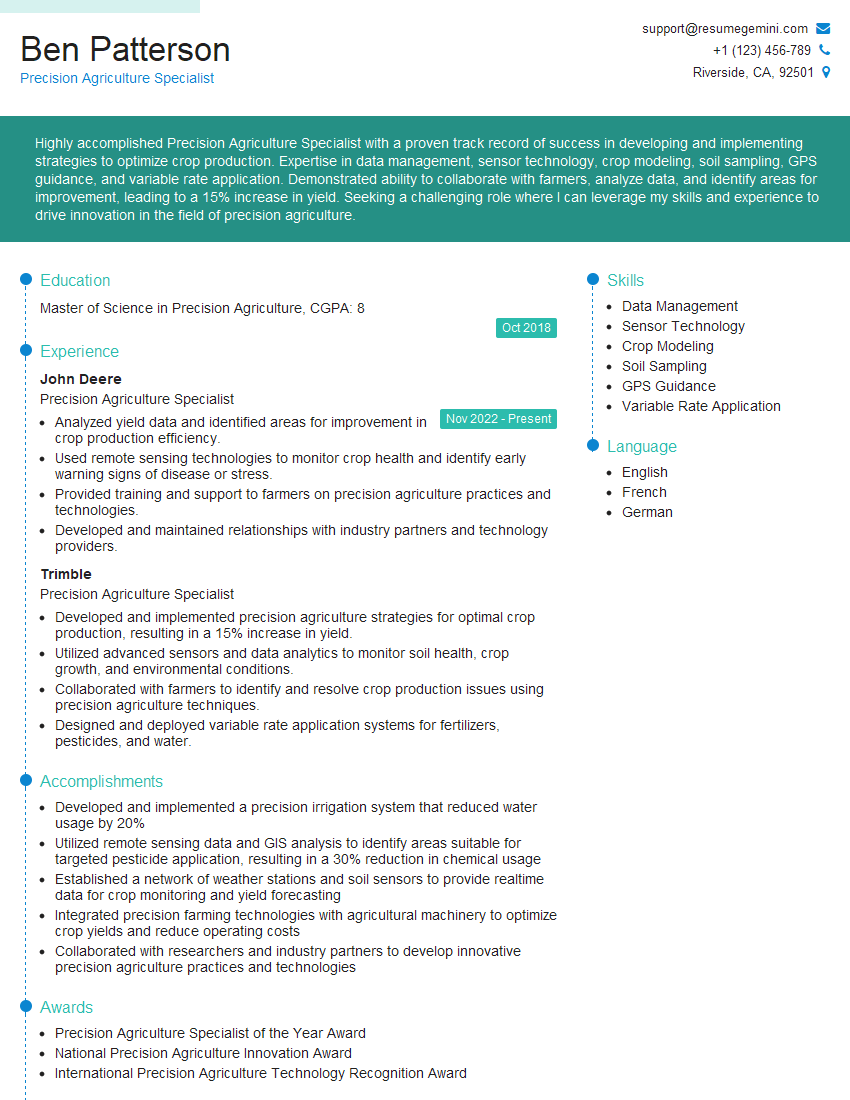

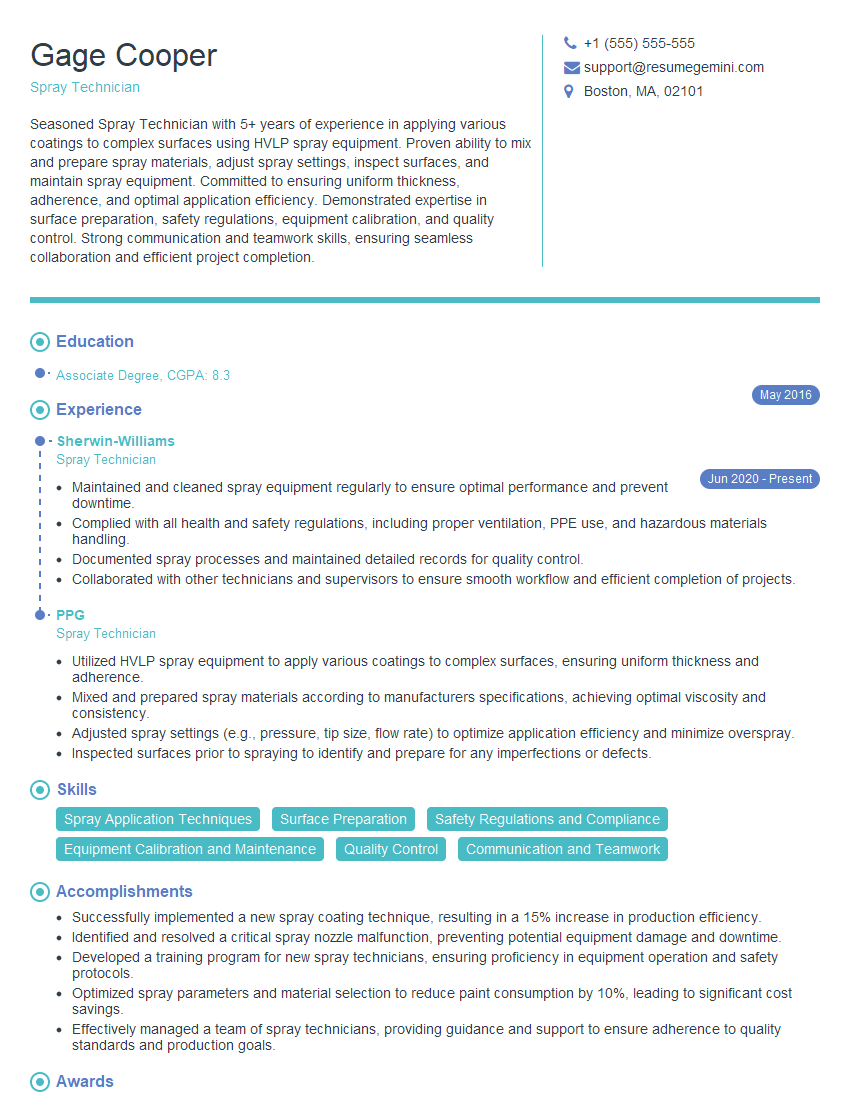

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you monitor the effectiveness of fertilizer application?

Monitoring effectiveness involves several steps. Firstly, regular visual inspections of the crop are conducted to observe growth patterns and overall health. We compare this against established growth stages and expected yields for that particular crop. Secondly, we utilize tissue analysis to quantitatively measure nutrient uptake. This provides a precise picture of nutrient levels within the plant itself, showing how effectively the fertilizer is being absorbed and utilized. Finally, we compare yield data from fertilized areas with control areas (if available) or previous years’ yields to gauge the impact of fertilizer application on productivity. This allows us to assess the return on investment and fine-tune our strategies for future applications.

For instance, if tissue analysis reveals low magnesium levels despite magnesium application, we might investigate factors like soil pH or water availability, which may impede nutrient uptake. This iterative process of observation, analysis, and adjustment is key to optimizing fertilizer effectiveness.

Q 17. Describe your experience with different types of liquid fertilizers (e.g., UAN, DAP).

I have extensive experience with various liquid fertilizers. Urea Ammonium Nitrate (UAN) solutions are widely used for nitrogen supplementation, offering a convenient and readily available source. I’ve worked with different UAN concentrations, adjusting application rates based on crop needs and soil conditions. Diammonium Phosphate (DAP) is another crucial component, providing both phosphorus and nitrogen. DAP solutions are effective for early-season growth where strong root development and early fruiting are critical. I have also worked with blends containing micronutrients like zinc, iron, and manganese, tailored to specific crop requirements and soil deficiencies. The choice of fertilizer depends heavily on the crop’s needs, the soil’s characteristics, and the specific growth stage. The most effective approach often involves a tailored blend designed to meet the crop’s unique requirements.

For example, in corn production, I might opt for a higher nitrogen UAN solution during the vegetative stage to promote rapid growth, then shift towards a blend incorporating phosphorus and potassium as the plant approaches maturity.

Q 18. How do you handle unexpected weather conditions during fertilizer application?

Unexpected weather conditions, such as heavy rain or strong winds, can significantly impact fertilizer application. My approach is to closely monitor weather forecasts and postpone application if conditions are unfavorable. Heavy rain can wash away the fertilizer before it can be absorbed by the soil, leading to nutrient loss and reduced effectiveness. Strong winds can cause drift, resulting in uneven application and potential damage to surrounding vegetation. In cases of imminent rain, applying fertilizer with a larger droplet size can help improve retention in the soil. If heavy rain is expected soon after application, the risk of nutrient runoff becomes very high, potentially contaminating water sources, so delaying is the best course of action. Ultimately, flexibility and responsiveness to changing weather are vital to optimizing application timing and mitigating potential problems.

Q 19. What is your experience with data analysis and reporting in relation to fertilizer application?

Data analysis and reporting are crucial to optimizing fertilizer application. I utilize data from soil tests, tissue analyses, yield monitoring systems, and weather data to create comprehensive reports. This data helps track fertilizer effectiveness, identify trends, and make informed decisions about future applications. I’m proficient in using spreadsheet software and statistical analysis to evaluate the impact of different fertilizer strategies. For instance, I’ve built models correlating nitrogen application rates with yield data to predict optimal fertilization strategies for future seasons. This analytical approach allows for continuous improvement and adaptation of our fertilizer management practices, resulting in greater efficiency and cost-effectiveness.

For example, if yield data indicates a lower than expected yield in a specific field despite adequate fertilizer application, I might re-examine soil characteristics, irrigation practices, or pest control measures to identify other limiting factors.

Q 20. How do you ensure the compatibility of different liquid fertilizers in a blend?

Ensuring compatibility is paramount when blending liquid fertilizers. Incompatibility can lead to precipitation (formation of solids), reduced nutrient availability, or even damage to application equipment. I use compatibility charts and conduct small-scale compatibility tests before large-scale blending. The order of mixing can also be critical. Generally, we follow the manufacturer’s recommendations and established best practices for specific fertilizers. Mixing should be gradual, with constant stirring, to ensure a homogeneous solution. It’s also crucial to understand the chemical properties of each fertilizer to avoid potentially reactive combinations. A thorough understanding of fertilizer chemistry is essential for safe and effective blending.

For example, mixing certain phosphorus-containing fertilizers with calcium-containing fertilizers can lead to precipitation. Always start by consulting the fertilizer manufacturer’s recommendations for mixing procedures.

Q 21. Describe your understanding of the impact of soil pH on fertilizer effectiveness.

Soil pH significantly influences the availability of nutrients to plants. Different nutrients have optimal pH ranges for uptake. For example, phosphorus availability is reduced in highly acidic or alkaline soils. Similarly, the availability of micronutrients like iron and manganese is affected by pH. I routinely measure soil pH before determining a fertilizer program. Soil pH management techniques, such as liming (to raise pH) or adding sulfur (to lower pH), might be incorporated to ensure that nutrients are readily available for plants. By maintaining the soil pH within the optimal range for the target crop and specific nutrients, we can maximize fertilizer effectiveness and improve crop yield and overall health. Ignoring soil pH can lead to significant nutrient deficiencies, even with proper fertilizer application.

For example, if the soil pH is too high, the application of iron might be largely ineffective, regardless of the amount of iron fertilizer used, unless the soil pH is first adjusted.

Q 22. How do you calculate the amount of fertilizer needed for a specific field area?

Calculating fertilizer needs begins with a soil test to determine nutrient deficiencies. This test provides the required amount of each nutrient (e.g., nitrogen, phosphorus, potassium) per unit area, typically expressed in pounds per acre (lbs/acre) or kilograms per hectare (kg/ha). We then need to know the field’s area. Let’s say the soil test indicates a need for 100 lbs/acre of nitrogen, and the field is 10 acres.

The calculation is straightforward: 100 lbs/acre * 10 acres = 1000 lbs of nitrogen needed. However, liquid fertilizers are often expressed in different units, such as gallons per acre or percentage of nutrient content. For example, if our chosen nitrogen fertilizer is a 28-0-0 solution (28% nitrogen), we need to convert the pounds of nitrogen needed to gallons. We’d use the fertilizer’s concentration to make this conversion. Assuming a density of approximately 11 pounds per gallon for 28-0-0, we would perform the following calculation:

1000 lbs Nitrogen / (0.28 lbs Nitrogen/lb fertilizer * 11 lbs fertilizer/gallon) ≈ 321 gallons

Therefore, approximately 321 gallons of 28-0-0 liquid nitrogen fertilizer would be required for the 10-acre field. This calculation always involves knowing the nutrient content of the specific fertilizer product and accurately measuring the field’s area using GPS or other surveying methods for precision. Ignoring these steps can lead to under or over fertilization, both of which negatively impact crop yields and environmental sustainability.

Q 23. What are the best practices for storing and handling liquid fertilizers?

Safe storage and handling of liquid fertilizers are paramount to prevent environmental contamination and worker safety. The key aspects include:

- Proper Tank Selection: Use tanks made of materials compatible with the fertilizer’s chemical composition, usually fiberglass, stainless steel, or polyethylene. Avoid tanks showing signs of corrosion or leaks.

- Designated Storage Area: Store tanks on a level, well-drained surface away from waterways, wells, and other sensitive areas. Contain spills using berms or containment structures.

- Secondary Containment: Have a secondary containment system in place (a larger containment area surrounding the tank) to capture spills or leaks.

- Labeling and Identification: Clearly label tanks with the fertilizer type, concentration, and date received. Use appropriate hazard symbols according to regulations.

- Emergency Response Plan: Have a detailed emergency response plan readily available for dealing with spills or leaks, including contact information for emergency services and clean-up procedures.

- Personal Protective Equipment (PPE): Always wear appropriate PPE such as gloves, eye protection, and respirators when handling liquid fertilizers. Follow the manufacturer’s safety guidelines provided on the Safety Data Sheet (SDS).

Ignoring these practices can lead to soil and water contamination, harming both the environment and human health. For example, improper storage leading to a leak can contaminate groundwater sources.

Q 24. Explain your understanding of the potential environmental impact of fertilizer runoff.

Fertilizer runoff is a significant environmental concern. Excess nutrients (nitrogen and phosphorus) from fertilizers applied to fields can leach into waterways through surface runoff or groundwater infiltration. This can cause several problems:

- Eutrophication: Excess nutrients in water bodies fuel excessive algae growth (algal blooms). These blooms deplete oxygen, leading to fish kills and harming other aquatic life.

- Water Quality Degradation: High nutrient levels can make water unsuitable for drinking and other purposes. Nitrates, for example, pose human health risks.

- Dead Zones: In extreme cases, large areas of water bodies become devoid of oxygen (hypoxic), creating ‘dead zones’ that cannot support life. The Gulf of Mexico’s dead zone is a well-known example.

- Greenhouse Gas Emissions: Nitrogen runoff can contribute to greenhouse gas emissions, particularly nitrous oxide, a potent greenhouse gas.

Minimizing runoff requires careful consideration of application timing, methods (e.g., minimizing tillage), and rates, as well as the use of buffer strips and other conservation practices.

Q 25. How do you address issues with fertilizer burn or damage to crops?

Fertilizer burn or crop damage can occur due to excessive application rates, improper application timing, or unfavorable weather conditions. The symptoms typically include leaf scorch, yellowing, wilting, and stunted growth.

Addressing these issues involves:

- Immediate Actions: Irrigate the affected area to dilute the fertilizer concentration and help wash it away from plant tissues. Avoid further fertilizer applications until the damage is assessed.

- Assessment: Determine the severity of the damage. In mild cases, plants may recover, while severe cases may require replanting.

- Adjustments: For future applications, reduce the fertilizer rate or adjust application timing to prevent similar incidents. Split applications (applying fertilizer in smaller doses over time) can reduce the risk of fertilizer burn.

- Soil Testing: Conduct a soil test to ensure the correct nutrient levels are applied in subsequent applications. This helps tailor fertilizer application to the actual plant needs.

- Consider Crop Tolerance: Some crops have higher tolerances to fertilizer salts than others. Choose fertilizer types and application methods that minimize the risk of damage to the specific crop being grown.

One example I encountered was applying fertilizer during a period of drought. The fertilizer salts accumulated at the plant roots, resulting in considerable burn. Adjusting application timing to coincide with anticipated rain and splitting the application helped prevent such issues in subsequent seasons.

Q 26. What is your experience with integrated pest management (IPM) strategies related to fertilization?

Integrated Pest Management (IPM) integrates various strategies to control pests, with fertilization playing a crucial role. Proper fertilization ensures plants are healthy and vigorous, making them less susceptible to pest infestations. A strong plant is naturally more resilient to pest and disease pressure. Conversely, nutrient deficiencies can weaken plants, making them more vulnerable.

My approach involves:

- Soil Testing: Understanding the soil’s nutrient profile allows for balanced fertilization, minimizing deficiencies that may make plants weak and attract pests.

- Nutrient Timing: Supplying nutrients at critical growth stages enhances plant vigor and pest resistance.

- Careful Selection of Fertilizers: Choosing fertilizers that contribute to soil health, supporting beneficial soil microbes, further reduces the likelihood of pest problems.

- Monitoring: Regularly monitoring crop health for any signs of stress or pest infestations allows for timely intervention, including adjusting fertilization strategies if necessary.

- Biological Control: IPM also incorporates biological control methods such as using beneficial insects or microbial agents that combat pests. Balanced fertilization supports a healthy environment conducive to these beneficial organisms.

For example, a potassium deficiency can weaken plants, making them more susceptible to fungal diseases. Proper potassium fertilization strengthens plant cell walls, enhancing resistance to these diseases, lessening the need for chemical interventions.

Q 27. Describe your experience with different types of nozzles and their effects on application uniformity.

Nozzle selection significantly impacts application uniformity. Different nozzles produce various spray patterns, droplet sizes, and flow rates. The choice depends on factors like fertilizer type, application equipment, wind conditions, and target crop.

- Flat Fan Nozzles: Produce a wide, flat spray pattern, ideal for covering broad areas uniformly. They are commonly used with boom sprayers.

- Cone Nozzles: Create a cone-shaped spray pattern, useful for spot treatments or targeted applications.

- Air Induction Nozzles: Incorporate air to create larger droplets, reducing drift in windy conditions. This is crucial for liquid fertilizers.

- Pressure Compensating Nozzles: Maintain a consistent spray pattern even with variations in pressure, improving application accuracy on uneven terrain.

Smaller droplet sizes generally provide better coverage, but increased drift is a potential drawback. Larger droplets, however, might lead to less uniform coverage, especially with uneven terrain. Choosing the right nozzle requires careful consideration of these factors. For example, on windy days, larger droplet sizes are preferable to minimize drift and ensure the fertilizer reaches its intended target. Incorrect nozzle selection leads to non-uniform fertilizer distribution and hence uneven crop growth.

Q 28. How do you ensure the accuracy of your fertilizer application maps and prescriptions?

Accurate fertilizer application maps and prescriptions are essential for efficient and environmentally sound nutrient management. The accuracy depends on several factors:

- High-Precision GPS: Utilizing high-accuracy GPS equipment for field mapping is crucial for precise delineation of field boundaries and variable application zones.

- Soil Sampling and Analysis: Thorough soil sampling, employing a grid sampling strategy for example, followed by laboratory analysis ensures data representing the variability in nutrient needs within a field.

- Calibration of Equipment: Regularly calibrating application equipment (e.g., sprayers) is vital for ensuring the correct amount of fertilizer is applied at the prescribed rate. This may include flow rate calibration and nozzle verification.

- Data Management Software: Using GIS-based software allows for creating and managing detailed application maps, integrating soil test data, yield maps, and other relevant information.

- Verification and Validation: After application, ground truthing (checking fertilizer distribution on the ground) should be performed to validate the accuracy of the application. This might involve collecting samples from different areas of the field and analyzing nutrient levels.

In my experience, errors in application maps can stem from inaccurate GPS data or errors in data entry. Regular calibration and quality control checks are essential to minimize these errors. For instance, a slight error in GPS coordinates can cause a significant discrepancy in fertilizer application in larger fields, potentially leading to over- or under-fertilization in specific areas.

Key Topics to Learn for Liquid Fertilizer Application Interview

- Fertilizer Types and Properties: Understanding different liquid fertilizer formulations (e.g., NPK ratios, micronutrients), their chemical properties, and storage requirements.

- Application Equipment and Techniques: Familiarity with various application methods (e.g., boom sprayers, injectors, fertigation), their advantages and disadvantages, and proper calibration procedures. Includes understanding nozzle selection and pressure regulation.

- Soil Science and Nutrient Management: Knowledge of soil types, nutrient uptake by plants, and factors influencing fertilizer effectiveness (e.g., soil pH, organic matter content). This includes understanding soil testing and interpreting results.

- Calibration and Rate Control: Mastering the precise calculation of fertilizer application rates based on soil tests, crop needs, and equipment specifications. This includes understanding and troubleshooting potential calibration issues.

- Environmental Considerations: Awareness of environmental regulations and best practices for minimizing fertilizer runoff, leaching, and other potential negative impacts on water quality and ecosystems.

- Safety Procedures and Regulations: Understanding and adhering to safety protocols for handling and applying liquid fertilizers, including personal protective equipment (PPE) and emergency response procedures.

- Troubleshooting and Maintenance: Ability to diagnose and resolve common problems with application equipment, including pump malfunctions, nozzle clogging, and pressure inconsistencies.

- Data Analysis and Record Keeping: Understanding the importance of accurate record-keeping for tracking fertilizer applications, yields, and other relevant data for future optimization.

Next Steps

Mastering liquid fertilizer application opens doors to rewarding careers in agriculture, offering opportunities for specialization and advancement. A strong understanding of these techniques showcases your practical skills and commitment to efficient and sustainable agricultural practices. To maximize your job prospects, create an ATS-friendly resume that highlights your relevant experience and skills. ResumeGemini is a trusted resource for building professional resumes, and we provide examples of resumes tailored to Liquid Fertilizer Application to help you get started. Investing time in crafting a compelling resume significantly increases your chances of landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good