Cracking a skill-specific interview, like one for Load and unload concrete pumping trucks, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Load and unload concrete pumping trucks Interview

Q 1. Describe the different types of concrete pumps.

Concrete pumps come in several types, each suited for different job site conditions and project scales. The most common are:

- Boom Pumps: These are the workhorses of the industry, featuring a long, articulated boom that can reach various locations and heights. Think of them as robotic arms for concrete. They’re ideal for large projects like high-rise buildings or extensive groundwork where placing concrete in hard-to-reach areas is crucial.

- Line Pumps: Simpler and more compact than boom pumps, line pumps use a long hose to convey concrete. They are best suited for smaller projects or situations where the boom pump’s size would be impractical. Imagine them as the ‘garden hose’ equivalent in the concrete world.

- Truck-Mounted Pumps: These are self-contained units integrated into the concrete truck itself. They’re efficient and convenient for smaller jobs where bringing in a separate pump might be overkill.

- Stationary Pumps: These large, powerful pumps are generally used on extremely large projects, such as dams or large infrastructure projects. They’re positioned at a central location and concrete is pumped to various points using a complex network of piping.

The choice of pump depends on factors such as the job site accessibility, the volume of concrete required, the placement locations, and budget.

Q 2. Explain the process of loading a concrete pump truck.

Loading a concrete pump involves a safe and efficient transfer of ready-mix concrete from the delivery truck to the pump’s hopper. The process typically follows these steps:

- Preparation: Ensure the pump is properly positioned, stabilized, and the area around it is clear of obstacles. This also includes verifying all safety systems are operational.

- Connecting the Delivery Truck: Position the ready-mix truck close enough for the concrete chute to reach the pump hopper. Secure the chute to both the truck and the hopper to prevent spillage.

- Initiating the Transfer: Signal the ready-mix driver to begin discharging the concrete. Monitor the flow to prevent blockages or overflow.

- Monitoring the Hopper: Keep an eye on the hopper’s fill level, ensuring it doesn’t overflow. The operator should be ready to signal the ready-mix truck driver to stop the pour, if necessary.

- Final Check: Once the transfer is complete, disconnect the chute securely and conduct a visual inspection for any leaks or spills.

It is critical to maintain constant communication between the pump operator and the ready-mix truck driver throughout this procedure.

Q 3. Detail the steps involved in unloading a concrete pump truck.

Unloading a concrete pump truck is the reverse of loading, requiring careful attention to detail and safety. Here’s the step-by-step process:

- Prepare for Unloading: Secure the pump, ensuring it’s stable and properly positioned to prevent movement during the process. The area around the pump must be free from obstacles.

- Clean the System: Flush the entire pumping system with water or a cleaning agent to prevent concrete from hardening inside the lines. This is crucial for maintaining the longevity of the pump.

- Lower Boom (if applicable): For boom pumps, carefully lower the boom to its resting position, following the manufacturer’s instructions and safety protocols.

- Shut Down the Pump: Turn off the pump’s power and hydraulics according to the established procedure. This is an essential safety step that prevents accidental operation.

- Disconnect Hoses and Chutes: Carefully disconnect all hoses and chutes, ensuring they’re secured and stored appropriately to prevent damage.

- Post-Unload Inspection: Check the entire pump for any damage, leaks, or blockages before moving or storing it.

Regular cleaning and proper shut-down procedures extend the lifespan of the equipment and prevent costly repairs.

Q 4. How do you ensure the safe operation of a concrete pump?

Safe operation of a concrete pump hinges on meticulous adherence to safety protocols and regular maintenance. This includes:

- Proper Training and Certification: Operators should be fully trained and certified to operate the specific pump model.

- Pre-Operational Checks: Always perform a thorough pre-operational inspection, checking hydraulic fluid levels, boom function, and emergency shutdown systems.

- Following Manufacturer’s Instructions: Adhere strictly to the manufacturer’s operating manual and safety guidelines.

- Wearing Appropriate PPE: Personal Protective Equipment (PPE), including safety glasses, hard hats, and gloves, is essential.

- Site Awareness: Maintain constant awareness of the surroundings to prevent accidents involving other workers or equipment.

- Regular Maintenance: Preventive maintenance is key to preventing malfunctions and ensuring the pump operates safely.

A safe operation culture starts with good planning and thorough training.

Q 5. What are the common safety hazards associated with operating a concrete pump?

Concrete pump operation presents various safety hazards, including:

- Falling Concrete: Improper placement or chute management can lead to concrete falling and causing injury.

- High-Pressure Hoses: High-pressure hoses can rupture, causing serious injury if not handled correctly.

- Moving Parts: The pump has numerous moving parts that can pose a crushing or entanglement hazard.

- Electrical Hazards: Exposure to electrical components can cause shocks or electrocution.

- Heavy Equipment: The pump itself is heavy machinery, and improper handling can lead to injury or damage.

- Environmental Hazards: Exposure to concrete dust and chemicals can be detrimental to health.

Each hazard demands strict adherence to safety regulations and best practices to mitigate the risks.

Q 6. What are your preventative maintenance procedures for a concrete pump?

Preventive maintenance is vital for the safe and efficient operation of a concrete pump. My procedures include:

- Daily Inspections: Visual inspection for leaks, damage, and wear-and-tear before each use.

- Regular Lubrication: Lubricating all moving parts according to the manufacturer’s schedule.

- Hydraulic Fluid Checks: Regularly checking and changing hydraulic fluid as needed.

- Cleaning: Thorough cleaning after each use to remove concrete residue.

- Scheduled Servicing: Following the manufacturer’s recommended maintenance schedule for major components.

- Record Keeping: Maintaining detailed records of all inspections, maintenance, and repairs.

This proactive approach minimizes downtime and extends the pump’s operational life.

Q 7. How do you troubleshoot common problems with a concrete pump?

Troubleshooting concrete pump problems requires a systematic approach. Common issues and solutions include:

- Blockages: Blockages are often caused by concrete slumping or improper cleaning. The solution usually involves flushing the lines with water or a cleaning agent under pressure.

- Low Pressure: This can stem from insufficient hydraulic fluid, worn seals, or air in the system. Checking fluid levels, inspecting seals, and bleeding air from the system usually resolves the issue.

- Leaks: Leaks indicate potential damage to hoses or seals. Inspecting the lines and replacing damaged parts are necessary.

- Boom Malfunction: Malfunction of the boom (in boom pumps) can be due to hydraulic issues or electrical faults. This usually demands a thorough check of the hydraulic system and electrical components.

- Engine Problems: Engine problems should be addressed by a qualified mechanic.

If a problem persists despite troubleshooting, it’s best to contact a qualified technician or the manufacturer for assistance.

Q 8. What are the different types of concrete and how do they affect pumping?

Different types of concrete possess varying properties that significantly impact their pumpability. The key factors are water content, aggregate size, and the type of cement used.

- Normal Concrete: This is the most common type, relatively easy to pump if the slump is correct. The aggregate size should be appropriate for the pump’s capabilities – larger aggregates can cause blockages.

- High-Performance Concrete (HPC): HPC often has a lower water-cement ratio, making it more difficult to pump. It requires more careful monitoring of slump and potentially specialized pumping techniques. We often use additives to improve flow.

- Self-Consolidating Concrete (SCC): Designed for complex forms, SCC flows readily without vibration. While generally easier to pump than normal concrete, its high viscosity can sometimes cause issues with certain pumps or long distances.

- Fiber-Reinforced Concrete (FRC): The addition of fibers can increase the concrete’s strength but might also increase its viscosity, potentially affecting pumpability. The fiber length and type need to be considered.

For example, I once worked on a project using high-performance concrete for a skyscraper. We had to use a specialized pump with a higher pressure capacity and carefully control the concrete’s mixture to avoid blockages.

Q 9. Explain the importance of proper concrete slump.

Proper concrete slump is crucial for successful pumping. Slump refers to the consistency of the concrete mix, measured by how much a cone-shaped sample collapses after being removed from a mold. A slump that is too low can cause blockages in the pump lines, resulting in costly delays and repairs. If the slump is too high, segregation (separation of aggregates and water) can occur, leading to weaker concrete and a less uniform finish.

The ideal slump range depends on the specific project and concrete mix but usually lies between 70mm to 150mm (2.75” to 5.9”). Factors like the distance to be pumped, the size of the aggregates, and the type of pump also influence the optimal slump.

I remember one instance where the slump was too low; the concrete was difficult to pump and caused the hose to clog repeatedly, delaying the entire project by several hours.

Q 10. How do you calculate the required amount of concrete for a project?

Calculating the required concrete amount involves several steps: first, accurately determining the volume of the structure to be filled. This may involve detailed architectural plans, blueprints, and on-site measurements. Then, you need to factor in any waste. Typically, a 5-10% waste factor is added to account for spillage, over-pouring, and other losses.

Let’s say you’re pouring a rectangular slab:

- Measure the length, width, and depth (thickness) of the slab in meters (or feet).

- Calculate the volume: Volume = Length x Width x Depth (in cubic meters or cubic feet).

- Apply the waste factor: Total volume = Volume x (1 + Waste Factor). For instance, if the calculated volume is 10 cubic meters and the waste factor is 5%, Total volume = 10 x (1 + 0.05) = 10.5 cubic meters.

Finally, convert cubic meters (or cubic feet) to cubic yards, the standard unit for ordering ready-mix concrete. Different concrete plants may have different conversion factors, so it is imperative to confirm this with the supplier.

Q 11. Describe your experience with different pumping techniques.

Throughout my career, I’ve gained extensive experience with various concrete pumping techniques, including:

- Line Pumping: This is the most common method, involving a series of flexible hoses connected to the pump truck. It’s versatile but requires careful management to avoid kinks and blockages. The distance and elevation are critical factors affecting the success of this method.

- Boom Pumping: Using a large, articulated boom, this method offers greater reach and maneuverability, ideal for difficult-to-access areas like high-rise buildings or congested workspaces. This method requires specialized training, as misoperation can result in serious damage to the boom or surrounding structures.

- Truck-Mounted Pumps: These pumps are directly attached to the mixer truck, eliminating the need for separate pumps and lines but often have a shorter pumping range.

I’ve successfully used all three techniques on numerous projects, adapting the method to suit the specific challenges and requirements of each site. For instance, on a recent high-rise project, the boom pump’s flexibility was essential to reach the upper floors efficiently.

Q 12. How do you handle equipment malfunctions during a pumping operation?

Equipment malfunctions can halt a project quickly, so immediate and effective action is critical. My approach involves these steps:

- Safety First: Immediately shut down the pump and clear the area of personnel.

- Assess the Problem: Identify the exact nature of the malfunction – is it a hydraulic leak, a blockage in the line, a motor failure, etc.? This assessment often involves visual inspection and listening to identify unusual sounds.

- Troubleshooting: Attempt basic troubleshooting based on experience and training. This could involve clearing blockages (with proper procedures and safety precautions), checking fluid levels, or checking electrical connections.

- Communication: Contact the appropriate service personnel (pump truck supplier/mechanic) to report the issue and arrange for repairs.

- Documentation: Thoroughly document the malfunction, the troubleshooting steps taken, and the resolution in the project records.

I once encountered a sudden hydraulic leak during a critical pour. Quick action – shutting down the pump, alerting the crew, and contacting the supplier for immediate repair – minimized downtime and avoided significant project delays.

Q 13. What safety measures do you take when working at heights?

Safety at heights is paramount. My approach encompasses a multi-layered strategy:

- Proper Harness and Fall Protection: Always use a full-body harness, connected to a secure anchor point, following manufacturer’s guidelines. The anchor point is vital, and its security must be thoroughly verified. Regular inspection of the harness and other safety equipment is non-negotiable.

- Safe Access and Egress: Ensure that safe access and egress points are available and utilized – this might involve scaffolding, ladders, or designated stairwells. These should be inspected regularly and be in accordance with all safety regulations.

- Awareness and Communication: Maintain constant awareness of surroundings and communicate with colleagues. Ensure everyone understands the safety procedures and potential hazards.

- Appropriate Training and Certification: I have the necessary training and certifications for working at heights and regularly undertake refresher courses to remain updated on best practices.

On one occasion, a colleague nearly slipped while working at a significant height. My quick response, using our pre-established safety protocols, avoided a serious accident. This reinforced the importance of rigorous adherence to safety measures.

Q 14. How do you communicate effectively with other construction workers?

Effective communication is the cornerstone of a safe and productive work environment. My approach involves:

- Clear and Concise Language: I use clear, concise language, avoiding jargon where possible. I ensure everyone understands the instructions.

- Active Listening: I actively listen to others’ concerns and feedback, providing a collaborative environment.

- Non-Verbal Communication: I use hand signals, body language, and visual aids to ensure that all team members understand directions, even in noisy environments.

- Regular Communication: I maintain open and regular communication with the site foreman, other pump operators, and the construction crew to keep everyone informed of progress, potential issues, and safety concerns.

- Pre-Job Briefings: A thorough pre-job briefing that sets expectations and addresses any safety concerns is always essential.

Effective communication is critical for a successful project. For example, a clear communication channel prevented a costly accident where a worker would have unknowingly walked into a boom’s swing radius during an operation.

Q 15. Explain your experience with different types of concrete placement.

My experience encompasses a wide range of concrete placement techniques, from traditional boom pump operations to specialized methods like line pumping and placing concrete in congested urban areas. I’ve worked on projects involving everything from high-rise building foundations to intricate residential pours and large-scale infrastructure projects. For instance, on a recent high-rise project, we utilized a boom pump to precisely place concrete up to 40 stories high, requiring careful coordination and precise maneuvering to avoid obstructions and ensure the concrete reached its destination without segregation. Conversely, on a smaller residential project, a line pump proved more efficient due to limited access.

- Boom Pumps: Excellent for large projects and vertical placement. Requires careful planning for reach and obstacle avoidance.

- Line Pumps: Ideal for confined spaces and smaller projects where maneuverability is key.

- Truck-mounted Pumps: Versatile solution, often used for smaller to medium-sized projects.

I am proficient in adapting my techniques to the specific demands of each project, prioritizing safety and efficiency in all operations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the quality of the concrete being pumped?

Ensuring quality concrete throughout the pumping process is paramount. This starts even before the pumping begins. I meticulously check the concrete mix design for compliance with project specifications and ensure the concrete is mixed properly at the batch plant. Then, during the pumping process, I carefully monitor several key factors:

- Slump Test: Regularly checking the slump of the concrete to ensure it’s within the specified range. A slump that’s too low indicates a dry mix that’s difficult to pump, while a slump that’s too high can lead to segregation.

- Visual Inspection: Constantly observing the concrete as it’s being pumped for signs of segregation (separation of aggregates and cement paste) or bleeding (water separating from the concrete). I look for any abnormalities like significant variations in colour or texture.

- Pump Pressure Monitoring: Keeping a close eye on the pump pressure. Sudden increases or decreases can indicate a problem with the pump or the concrete itself. This is something I always review and discuss with the pump operator

- Communication: Maintaining constant communication with the batch plant and the placing crew to address any issues immediately.

By proactively monitoring these factors, I can quickly identify and rectify any problems, ensuring that the concrete placed meets the highest quality standards.

Q 17. How do you deal with unexpected delays or changes in the work schedule?

Unexpected delays are a common occurrence in construction. My approach to handling them involves proactive planning, clear communication, and a flexible attitude. If a delay occurs due to material delivery, I immediately inform the project manager and the placing crew. We then explore alternative solutions like adjusting the pumping schedule or finding alternative materials if necessary. In case of equipment malfunction, we prioritize prompt repair and communicate any revised timelines.

- Problem Assessment: Quickly identify the cause of the delay.

- Communication: Keep all stakeholders informed.

- Alternative Solutions: Explore ways to mitigate the impact of the delay.

- Documentation: Maintain detailed records of the delay and any remedial actions.

For example, once we experienced a sudden power outage during a critical pour. By quickly switching to a backup generator and communicating effectively, we minimized downtime and completed the pour without compromising the structural integrity of the project.

Q 18. What is your experience with different types of ground conditions?

Experience with varied ground conditions is crucial for safe and efficient concrete pumping. I’ve worked on projects with everything from stable, compacted soil to challenging terrains including soft ground, rocky areas, and even underwater placements. The key is proper planning and selecting the appropriate pumping methods. For soft ground, we might need to use ground mats or temporary access roads to distribute the weight of the truck. On rocky sites, we might need specialized equipment or different placement strategies. Underwater placement requires specialized pumps and techniques. Safety procedures are adapted to each unique situation.

- Site Assessment: Thoroughly evaluating the ground conditions before commencing work.

- Equipment Selection: Choosing appropriate pumping equipment and support structures.

- Safety Measures: Implementing necessary safety protocols for each ground condition.

- Contingency Planning: Developing strategies to address potential challenges.

One project involved pumping concrete across a swampy area. We successfully utilized temporary ground supports and adjusted the pumping pressure to counteract the soft ground conditions and successfully delivered the concrete to the specified location.

Q 19. How do you maintain cleanliness and organization at the job site?

Maintaining a clean and organized job site is critical for safety and efficiency. My approach emphasizes proactive measures rather than reactive cleanup. This includes implementing a comprehensive waste management plan, designating specific areas for material storage, and regularly clearing debris from the work area. I also ensure that all equipment is properly maintained and stored after use. The team I lead always makes an effort to leave the site cleaner than we found it.

- Waste Management: Establishing a clear system for waste disposal and recycling.

- Designated Areas: Clearly defining storage areas for materials and equipment.

- Regular Cleanup: Implementing a regular schedule for cleaning the work area.

- Equipment Maintenance: Ensuring that all equipment is properly maintained and stored.

A clean and organized site not only enhances safety but also boosts morale and productivity among the team. It also creates a positive impression on clients and other stakeholders.

Q 20. What are the legal requirements for operating a concrete pump?

Operating a concrete pump involves adhering to various legal requirements. These vary by jurisdiction but generally include:

- Licensing and Certification: Possessing the necessary licenses and certifications to operate the specific type of concrete pump used.

- Safety Regulations: Strict adherence to all relevant Occupational Safety and Health Administration (OSHA) or equivalent regulations, including those related to personal protective equipment (PPE), fall protection, and confined space entry.

- Vehicle Regulations: Complying with all traffic laws and regulations while transporting the concrete pump. This includes proper licensing and maintenance of the vehicle.

- Environmental Regulations: Following environmental regulations regarding concrete waste disposal and runoff management.

Ignoring these regulations can lead to serious consequences, including fines, suspension of operations, and even legal action. I always prioritize safety and regulatory compliance in all my operations.

Q 21. Describe your experience with different concrete delivery methods.

My experience with concrete delivery methods includes a variety of approaches, each selected based on the project’s scale and logistical factors. I’ve worked with ready-mix trucks delivering directly to the pump, as well as more complex systems involving conveyors and specialized delivery vehicles for challenging terrain. Each system comes with its own set of benefits and challenges, and selecting the optimal approach requires an understanding of project-specific constraints such as site access, the volume of concrete required, and the available infrastructure.

- Ready-mix Trucks: The most common method, simple and versatile.

- Conveyors: Useful for large projects where concrete needs to be transported over long distances.

- Specialized Delivery Vehicles: Essential for projects in challenging terrains.

For example, on a project with limited site access, I successfully coordinated the use of smaller ready-mix trucks to ensure the continuous supply of concrete to the pump. This involved close collaboration with the ready-mix company to create a precise delivery schedule, mitigating potential delays.

Q 22. How do you ensure the proper placement of concrete?

Proper concrete placement hinges on understanding the pour plan and coordinating seamlessly with the construction team. It’s not just about getting the concrete *to* the right place; it’s about getting it there efficiently, consistently, and without segregation.

- Pre-Pour Planning: Before a single drop of concrete leaves the pump, I carefully review the blueprints, noting the placement points, required slump (consistency of the concrete), and any special considerations like intricate formwork or congested areas. I discuss the pour plan with the foreman and other team members to anticipate potential challenges and establish clear communication channels.

- Strategic Boom Placement: I strategically position the boom to minimize the need for excessive maneuvering, preventing segregation (separation of the concrete’s components) caused by excessive pumping distances or harsh angles. Think of it like a well-aimed basketball shot – you need the right trajectory for a clean and accurate placement.

- Consistent Flow Rate: I control the flow rate carefully, adjusting it according to the concrete’s slump and the size of the placement area. Too fast, and you risk segregation and air pockets; too slow, and the concrete might start to set before it’s fully placed.

- Continuous Monitoring: I constantly monitor the concrete’s placement, ensuring it’s being evenly distributed and that the required consolidation techniques (vibrating or rodding) are being employed to eliminate air pockets and ensure a strong, homogenous structure. Regular communication with the team ensures any issues are quickly identified and addressed.

For example, on a recent high-rise project, I had to carefully place concrete around intricate steel reinforcement in a confined area. Precise boom control and a slow, steady flow rate were crucial to avoid damaging the reinforcement or causing segregation.

Q 23. What are the signs of a malfunctioning concrete pump?

Recognizing a malfunctioning concrete pump is crucial for preventing costly delays and potential safety hazards. Early detection is key.

- Reduced Pumping Pressure/Output: A significant drop in pumping pressure or output is a major red flag, possibly indicating issues with the pump’s hydraulic system or a blockage in the pipeline.

- Unusual Noises: Grinding, squealing, or knocking sounds from the pump’s components can signal wear and tear, impending failure, or a lack of lubrication.

- Excessive Vibration: Unusual vibrations in the pump truck, especially when idle, can point to imbalances or mechanical problems within the pump’s components.

- Leaks: Fluid leaks (hydraulic oil or concrete) are obvious signs of damage or failure in seals, pipes, or other critical components. These require immediate attention.

- Overheating: If the pump is overheating frequently, it may indicate a problem with the cooling system, an overloaded motor, or a blockage causing increased friction.

For instance, during one project, I noticed a consistent decrease in pumping pressure and a high-pitched squeal. After shutting down the pump and checking, we found that a critical seal was failing and needed immediate replacement, preventing a major delay.

Q 24. Describe your experience with cleaning and maintaining a concrete pump.

Cleaning and maintaining a concrete pump is paramount for its longevity and reliable performance. It’s a multi-step process that I rigorously follow after each pour.

- Immediate Cleaning: As soon as the pour is complete, I begin the cleaning process by flushing the pipeline with clean water to remove any residual concrete. This prevents the concrete from hardening inside the system.

- Thorough Cleaning: Once the pipeline is clear, a specialized cleaning agent is used to remove any remaining hardened concrete deposits. This often involves disassembling certain sections for thorough cleaning, using appropriate brushes and tools.

- Lubrication: I lubricate all moving parts, including the hydraulic system, according to the manufacturer’s specifications. This ensures smooth operation and prevents excessive wear and tear.

- Inspection: I perform a thorough inspection of the pump and its components, checking for any signs of wear, damage, or leaks. I document findings and address minor issues before they escalate into major problems.

- Regular Maintenance Schedule:Beyond the post-pour cleaning, I adhere to a regular maintenance schedule, encompassing tasks like oil changes, filter replacements, and system checks to preempt potential issues.

For instance, I’ve developed a checklist to ensure that every component is inspected and cleaned properly. This systematic approach avoids overlooking critical steps and ensures the pump is in optimal condition for the next project.

Q 25. How do you handle different types of weather conditions?

Weather significantly impacts concrete pumping operations. Proper planning and adaptation are crucial for successful completion of the project.

- Extreme Heat: High temperatures accelerate concrete setting time, necessitating faster pumping speeds and potentially requiring the use of retarders (additives to slow down setting) in the mix design. We also need to ensure adequate hydration of the pump and personnel.

- Cold Weather: Cold temperatures can slow down the setting time of concrete, but more critically, they can cause water in the concrete to freeze, compromising its strength and workability. I would use heated water and admixtures (chemicals that affect the setting and properties of the concrete) to help prevent freezing and ensure the concrete remains pumpable. I would cover the placed concrete with insulation to protect it from frost damage.

- Rain and Wind: Rain can wash away concrete, while strong winds can make boom control difficult and increase the risk of accidents. I would use protective measures like tarps to protect the concrete from rain. I would also assess the wind conditions to determine if it’s safe to operate the boom.

For example, during a winter pour, I used heated water in the mix and insulated the freshly placed concrete to prevent it from freezing. Detailed planning, proactive adjustments, and close monitoring are essential in unpredictable weather.

Q 26. Describe your experience with different types of concrete mix designs.

Experience with various concrete mix designs is crucial to achieving successful pours. I’ve worked with numerous mixes, each tailored to the specific application.

- Slump: I’m adept at adjusting the pumping technique according to the slump of the concrete. High-slump concrete (more fluid) requires careful control to prevent segregation, while low-slump concrete (stiffer) demands higher pressure and potentially additional vibration.

- Mix Components: I understand how different aggregates (sand, gravel, etc.), cement types, and admixtures affect the concrete’s properties, including its workability, strength, and setting time.

- Special Mixes: I’ve worked with specialized concrete mixes for specific applications, such as high-performance concrete for high-rise buildings or self-consolidating concrete (SCC) for complex formwork.

For example, I once worked on a project with self-consolidating concrete which requires a different pumping technique than traditional mixes to prevent segregation. My familiarity with SCC allowed for smooth and efficient placement.

Q 27. What is your experience with troubleshooting hydraulic systems on a concrete pump?

Troubleshooting hydraulic systems on a concrete pump requires a systematic approach and a strong understanding of hydraulic principles.

- Identifying the Problem: This starts with accurately identifying the problem, whether it’s a leak, loss of pressure, erratic movement, or unusual noises. This may involve visual inspections, pressure tests, and listening for unusual sounds.

- Checking Fluid Levels: Low hydraulic fluid levels indicate leaks or insufficient maintenance, which must be addressed immediately.

- Inspecting Hoses and Connections: A visual inspection can uncover leaks, cracks, or loose connections in the hoses and fittings.

- Testing Valves and Pumps: Malfunctioning valves or pumps can disrupt the hydraulic system’s flow and pressure. Testing involves checking for proper operation and identifying any faulty components.

- Understanding Hydraulic Schematics: Thorough understanding of the pump’s hydraulic schematics is crucial for tracing the flow of hydraulic fluid and locating the source of the problem.

For example, once I identified a leak in a hydraulic hose by observing a consistent oil drip. Replacing the hose and bleeding the air from the system restored the proper function. Proactive maintenance and a systematic approach greatly reduce downtime.

Q 28. How do you ensure compliance with all relevant safety regulations?

Safety is paramount in concrete pumping operations. Compliance with relevant regulations is non-negotiable. My approach incorporates several key measures:

- Pre-Pour Site Assessment: I perform a thorough site assessment before commencing any work, identifying potential hazards such as overhead power lines, unstable ground, or congested areas.

- Personal Protective Equipment (PPE): Ensuring every member of the crew wears appropriate PPE, including safety helmets, high-visibility vests, safety glasses, and gloves, is mandatory.

- Proper Signage and Barriers: I use appropriate signage and barriers to cordon off the work area, keeping unauthorized personnel away from the active pump and the concrete placement area.

- Emergency Procedures: All crew members are trained on the emergency procedures, including the location of emergency exits, fire extinguishers, and first-aid kits.

- Regular Equipment Inspections: Regular inspection and maintenance of the concrete pump and associated equipment, including the boom and outriggers, ensure their safe and effective operation.

- Adherence to Local Regulations: I am fully aware of and strictly adhere to all relevant local and national safety regulations and codes of practice concerning concrete pumping.

For instance, on a recent project near a busy road, we implemented a comprehensive traffic management plan, including flaggers and signage, ensuring worker and public safety.

Key Topics to Learn for Load and Unload Concrete Pumping Truck Interviews

- Understanding Truck Components: Familiarize yourself with the various parts of a concrete pumping truck, including the pump, boom, chassis, and hydraulic systems. Knowing their function and potential points of failure is crucial.

- Safe Loading Procedures: Learn the correct procedures for loading concrete into the truck, including the importance of checking the consistency of the concrete mix and ensuring a stable and even distribution within the hopper.

- Efficient Unloading Techniques: Master different unloading techniques, considering factors like placement accuracy, pump pressure, and boom articulation. Understand how to adjust these parameters for various job site conditions.

- Maintenance and Troubleshooting: Learn basic preventative maintenance tasks and common troubleshooting steps. Being able to identify potential problems and address them efficiently is highly valued.

- Safety Regulations and Procedures: Understand and adhere to all relevant safety regulations and procedures related to operating and maintaining concrete pumping trucks. This includes personal protective equipment (PPE) and site safety protocols.

- Communication and Teamwork: Discuss the importance of clear communication with the pumping crew and other workers on the job site. Effective teamwork is essential for efficient and safe operations.

- Job Site Specifics: Consider how different job site environments (e.g., confined spaces, challenging terrain) affect loading and unloading procedures and safety precautions.

Next Steps

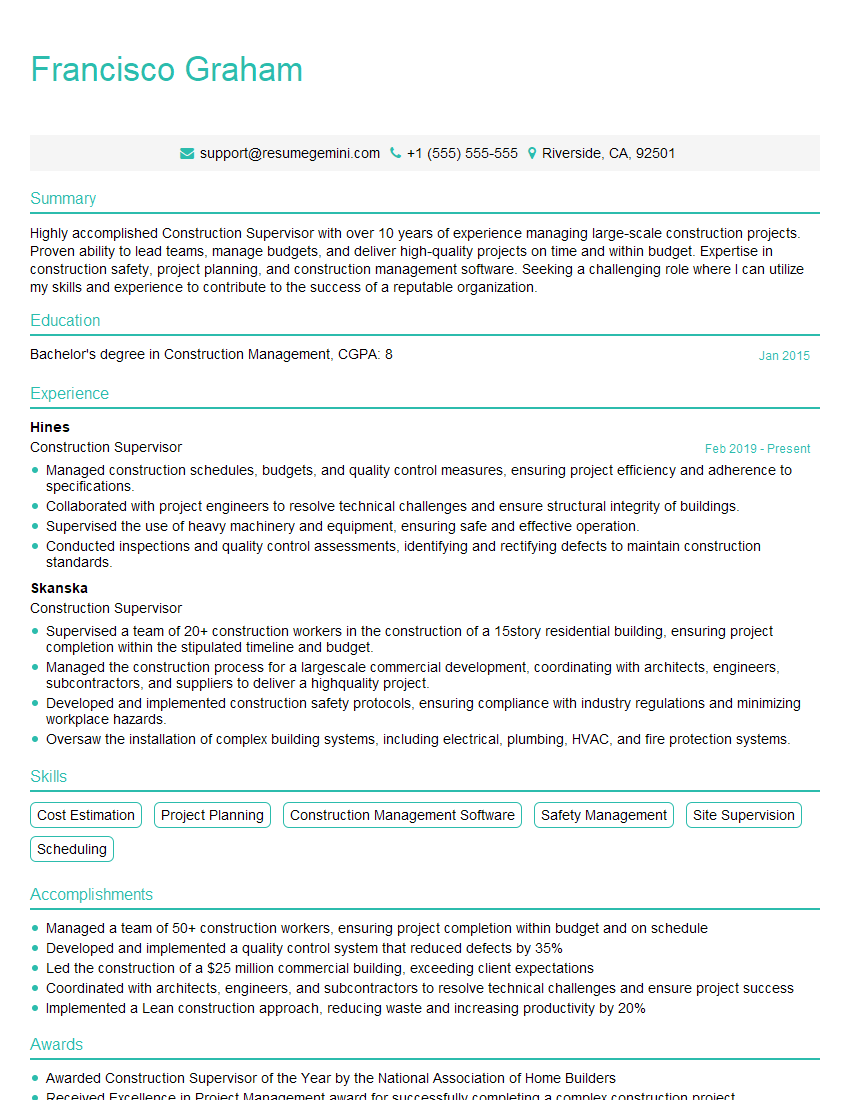

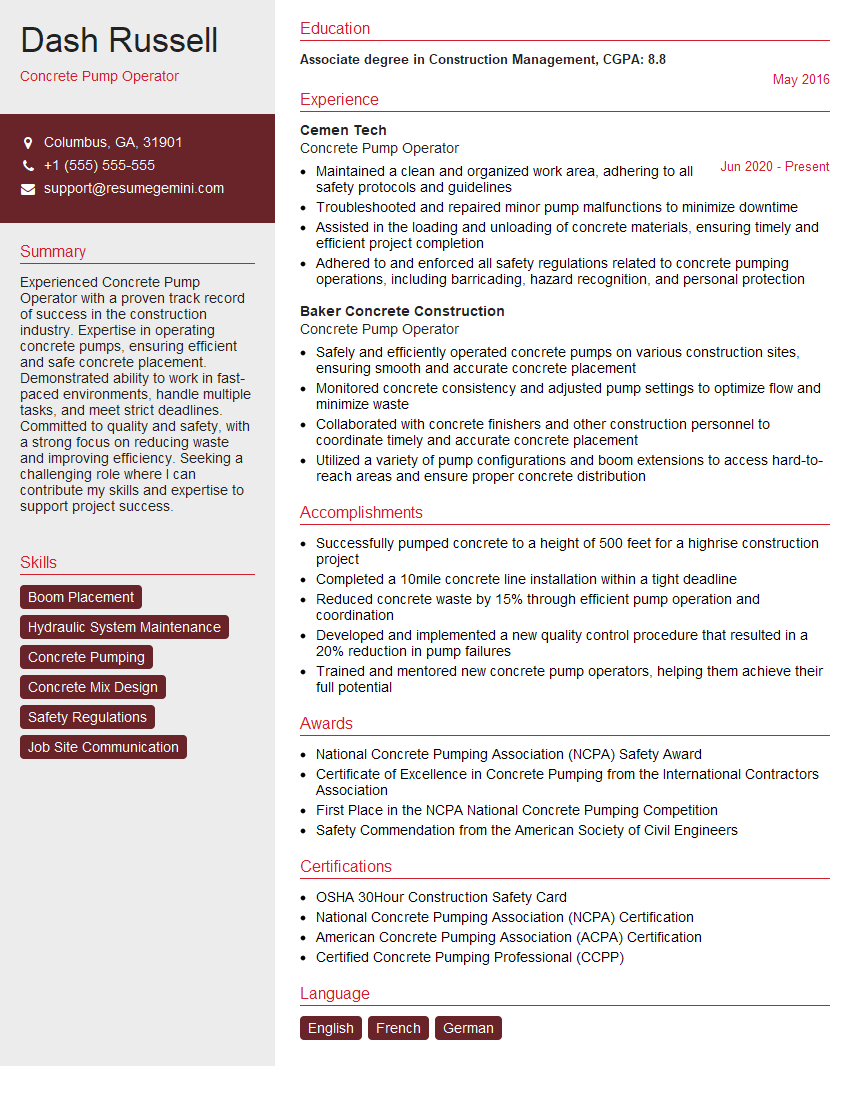

Mastering the skills required to load and unload concrete pumping trucks opens doors to a rewarding career with excellent growth potential in the construction industry. This specialized skillset is highly sought after, leading to competitive salaries and opportunities for advancement. To maximize your job prospects, creating a strong, ATS-friendly resume is critical. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to Load and Unload Concrete Pumping Truck positions are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good