Unlock your full potential by mastering the most common Load Preparation interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Load Preparation Interview

Q 1. Explain the process of load planning and optimization.

Load planning and optimization is a crucial process that ensures efficient and safe transportation of goods. It involves strategically determining the best way to arrange cargo within a vehicle or container, maximizing space utilization while adhering to weight limits and safety regulations. This process encompasses several steps:

- Assessing the Cargo: This includes determining the dimensions, weight, and fragility of each item, as well as any special handling requirements.

- Choosing the Right Vehicle: Selecting the appropriate vehicle type—truck, railcar, ship, or aircraft—depends on the size, weight, and destination of the cargo.

- Developing a Loading Plan: This involves creating a visual representation of how the cargo will be arranged, considering weight distribution, center of gravity, and securing methods. Software tools often aid in this process.

- Optimizing Space Utilization: Efficient packing minimizes wasted space and reduces transportation costs. Techniques such as nesting and blocking can be employed.

- Securing the Load: This critical step involves using appropriate methods to prevent shifting or damage during transit. This might involve straps, chains, or specialized dunnage.

- Documentation: Maintaining detailed records of the loading plan, securing methods, and weight distribution is essential for compliance and traceability.

For example, imagine transporting furniture. A poorly planned load might lead to damage during transit due to shifting items. A well-optimized plan would consider placing heavier items at the bottom, using protective padding, and securing everything firmly in place.

Q 2. Describe your experience with different types of load securing methods.

My experience encompasses a wide range of load securing methods, tailored to different cargo types and transportation modes. I’m proficient in using:

- Straps: Webbing straps are versatile and effective for securing many types of cargo, offering varying tensioning capabilities. I’m skilled in choosing the appropriate strap type and ensuring proper tensioning for optimal security.

- Chains: Chains are ideal for heavy or awkwardly shaped loads. I understand the importance of using appropriate chain size and employing the correct securing techniques to prevent damage to the load and the vehicle.

- Dunnage: This includes materials like wood blocks, air bags, and inflatable bladders. They help to fill voids, prevent shifting, and protect fragile items. Proper selection and placement are key to successful load securing.

- Wire Rope: For specialized applications and heavy loads, wire rope provides exceptional strength and durability. Safe handling and proper fastening are crucial for this method.

- Load Locks and other Restraining Devices: These are particularly relevant in containerized shipping, ensuring stability and preventing cargo movement.

I always prioritize safety and comply with all relevant regulations when selecting and applying securing methods. I adapt my approach based on the specific characteristics of the load and the transportation environment.

Q 3. How do you determine the optimal weight distribution for a load?

Optimal weight distribution is critical for safe and efficient transportation. It focuses on maintaining the load’s center of gravity within the vehicle’s stability limits, minimizing stress on the vehicle and preventing tipping. Determining this involves:

- Calculating the Total Weight: Accurately weighing each item in the load and summing them up.

- Considering the Vehicle’s Weight Capacity: Ensuring the total load weight, including the vehicle’s own weight, doesn’t exceed the legal or manufacturer’s limits.

- Distributing Weight Evenly: Aiming for an even distribution across all axles to prevent overloading any single axle. Heavier items generally go lower and towards the center of gravity.

- Using Weight Distribution Charts or Software: These tools can simulate various loading arrangements and help visualize the weight distribution, making it easier to identify potential imbalances.

- Checking for Stability: Verifying that the load is stable and won’t shift during transit. This includes checking the center of gravity and ensuring sufficient securing methods.

For instance, when loading a truck with heavy machinery, you wouldn’t want to concentrate all the weight on one side. Instead, you’d strategically distribute the weight, ensuring that the load’s center of gravity remains within the truck’s safe operating limits, preventing tipping and potentially serious accidents.

Q 4. What software or tools have you used for load planning?

Throughout my career, I’ve utilized various software and tools for load planning. These include:

- 3D Load Planning Software: These programs allow for precise visualization and optimization of load arrangements, considering the dimensions and weights of individual items. Examples include (mention specific software names if applicable and comfortable disclosing them, e.g., ‘CargoSoft,’ ‘EasyCargo’).

- Weight and Balance Calculation Tools: These tools aid in precise weight distribution calculations, ensuring the load’s center of gravity is properly aligned. (mention specific tools if applicable).

- Spreadsheet Software: Spreadsheet software (such as Microsoft Excel or Google Sheets) is helpful for creating and managing loading manifests, tracking weights, and dimensions.

- Vehicle-Specific Load Management Systems: Some vehicles come equipped with onboard systems that guide the loading process and provide real-time feedback on weight distribution and stability.

The choice of software depends on the complexity of the load and the specific requirements of the transportation task. I’m proficient in using a range of such tools and adapt my approach to the specifics of each job.

Q 5. How do you handle unexpected delays or changes in load requirements?

Unexpected delays or changes in load requirements demand quick thinking and adaptability. My approach involves:

- Communication: Immediate communication with all stakeholders (clients, drivers, dispatchers) is crucial to assess the impact of the delay or change.

- Replanning: If necessary, I quickly revise the loading plan to accommodate the new requirements. This might involve adjusting the cargo arrangement, selecting a different vehicle, or changing the delivery schedule.

- Risk Assessment: I evaluate potential risks associated with the change, such as potential delays, additional costs, or safety concerns.

- Documentation: All changes are meticulously documented to maintain a clear audit trail.

- Contingency Planning: Proactive planning for potential delays and challenges helps mitigate their impact.

For example, if a crucial component for a shipment is delayed, I would immediately communicate this to the client and explore alternative solutions, such as prioritizing other less time-sensitive items or utilizing expedited shipping for the missing component. The focus remains on minimizing disruption and ensuring timely delivery while maintaining safety and compliance.

Q 6. Explain your understanding of different transportation modes and their impact on load preparation.

Different transportation modes have distinct implications for load preparation. Understanding these nuances is key to efficient and safe transport.

- Road Transport (Trucks): Requires careful consideration of weight limits, axle loads, and maneuvering space. Securement needs to withstand the rigors of road travel.

- Rail Transport: Involves larger load volumes and requires attention to shock absorption and stability during transit. Securement against impact and vibration is crucial.

- Sea Transport (Ships): Exposure to extreme weather conditions necessitates robust securing methods and protection against moisture and saltwater damage. Understanding stowage plans and container stacking guidelines is key.

- Air Transport (Aircraft): Weight and balance are paramount, along with strict adherence to aviation regulations. Load distribution needs to be exceptionally precise and secure to prevent damage during flight.

For example, a load destined for sea transport would require different securing techniques compared to a load for air transport. Marine containers offer a level of protection, but internal securing is still crucial, especially for fragile goods. Air cargo necessitates even more rigorous securing to prevent shifting during potentially turbulent conditions.

Q 7. Describe your experience with hazardous materials handling and load preparation.

Handling hazardous materials requires specialized knowledge and meticulous attention to detail. My experience includes:

- Understanding Regulations: Profound knowledge of regulations (such as those set by the Department of Transportation (DOT) in the US or equivalent agencies in other countries) governing the transportation of hazardous materials is crucial.

- Proper Packaging and Labeling: Ensuring that hazardous materials are packaged according to regulations and clearly labeled with hazard symbols and identification numbers.

- Segregation of Incompatible Materials: Avoiding the co-loading of incompatible hazardous materials to prevent dangerous reactions.

- Emergency Response Planning: Being prepared for potential incidents and having a clear plan in place for handling emergencies.

- Specialized Equipment: Using specialized equipment and containers designed for safe transportation of hazardous materials.

For instance, transporting flammable liquids necessitates the use of approved containers and placards, and adherence to strict loading procedures. Failure to comply with these regulations can result in serious safety consequences, highlighting the importance of proper training and adherence to strict protocols.

Q 8. How do you ensure compliance with relevant regulations and safety standards during load preparation?

Ensuring compliance during load preparation is paramount for safety and legal reasons. It involves a multi-step process starting with a thorough understanding of all applicable regulations, which vary by location, cargo type, and transportation mode. This includes adhering to weight limits, dimension restrictions, and hazardous materials handling regulations (like those outlined by DOT in the US or ADR in Europe).

Practically, this means:

- Regularly reviewing and updating knowledge of relevant regulations: Staying informed about changes is crucial. I utilize online resources, industry publications, and training courses to maintain compliance.

- Pre-loading inspections: A meticulous inspection of the cargo and the vehicle before loading ensures that everything meets regulations and is secure for transport.

- Proper documentation: Maintaining accurate and complete paperwork, including manifests, bills of lading, and safety certificates, is essential for demonstrating compliance. Any issues or deviations from the plan must be meticulously documented.

- Using certified equipment and personnel: Employing appropriately licensed drivers and using properly maintained equipment is non-negotiable. For example, using a correctly calibrated weighbridge is critical for ensuring that the total weight doesn’t exceed limits.

- Emergency preparedness: Having a plan in place for potential incidents, such as spills or accidents, is vital and requires appropriate training and equipment.

For example, when loading hazardous materials, I ensure the appropriate placards and markings are clearly displayed and that the cargo is secured according to the specific requirements for that material, which may involve using specialized containers or securing methods.

Q 9. How do you calculate the total weight and dimensions of a load?

Calculating the total weight and dimensions is fundamental to safe and efficient load preparation. It’s not just about adding up numbers; it’s about understanding the distribution of weight and how that impacts stability.

The process typically involves:

- Individual item weighing and dimensioning: Each item in the load needs to be accurately measured for weight and dimensions (length, width, and height). We use scales and measuring tools for this. Specialized software can help automate this process for complex loads.

- Weight and dimension consolidation: Once individual measurements are taken, they are added up to get the total weight and dimensions of the load. This requires careful consideration of the packaging and any additional securing materials.

- Center of gravity calculation (for complex loads): For large or irregularly shaped items, calculating the center of gravity is crucial for stability. This prevents tipping during transport. Specialized software can help with this calculation.

- Accounting for variations and tolerances: It’s important to account for potential weight variations and add a safety margin to the calculated values to ensure the load doesn’t exceed the vehicle’s capacity.

Imagine loading a truck with furniture. We wouldn’t simply throw everything in; we’d carefully position heavier items lower and towards the center, lighter items higher, ensuring the weight is evenly distributed to prevent tipping. The total weight, dimensions, and center of gravity calculations are essential for proper securing and safe transportation.

Q 10. What are the key considerations when preparing a load for long-distance transportation?

Preparing a load for long-distance transportation requires additional considerations due to the increased risks associated with prolonged transit time and potential environmental factors.

Key considerations include:

- Enhanced securing: The load needs to be exceptionally well-secured to withstand vibrations and potential shocks over longer distances. We use appropriate straps, bracing, and other securing materials to prevent shifting or damage.

- Weather protection: Protection from rain, snow, or extreme temperatures is essential. This could involve using tarpaulins, weatherproof packaging, or climate-controlled containers.

- Route planning and potential hazards: Identifying potential hazards along the route (like low bridges or rough terrain) is vital for selecting the best transportation option and ensuring the load’s safety.

- Extended monitoring: Regular monitoring throughout the journey might be necessary, especially for sensitive or time-sensitive cargo. Technology like GPS tracking can be used to monitor the location and condition of the load.

- Documentation for extended trips: Comprehensive documentation is crucial for longer trips, including detailed load plans, maintenance records for the vehicle, driver logs, and any communication logs.

For instance, transporting delicate artwork across the country requires specialized packaging and climate control throughout transit. Each step must be documented to meet insurance requirements and show due diligence.

Q 11. How do you manage documentation related to load preparation and transportation?

Documentation management is crucial for accountability, traceability, and compliance. I use a combination of digital and physical methods to manage this effectively.

The process involves:

- Load preparation checklists: These detail all the steps taken during load preparation, including inspections, weight and dimension measurements, securing methods, and any special instructions.

- Bills of lading and shipping manifests: These documents provide details of the shipment, including the origin, destination, cargo details, and parties involved.

- Waybills and delivery receipts: These track the movement of the goods and confirm their delivery.

- Hazardous materials documentation: If hazardous materials are involved, specific documentation and permits are required.

- Digital record-keeping: Using digital systems for tracking and managing documents improves efficiency and simplifies access to information. We use specialized transportation management systems (TMS).

- Archiving: Maintaining accurate records is vital, so we have a robust archiving system, both physical and digital, to comply with regulatory requirements and for future reference.

Each step is meticulously documented to maintain a clear audit trail. This is essential for insurance claims, regulatory audits, and resolving any potential disputes.

Q 12. How do you prioritize different loads based on urgency and delivery deadlines?

Prioritizing loads based on urgency and deadlines requires a structured approach. I typically use a system that considers several factors.

The process includes:

- Categorization by urgency: Loads are categorized as high, medium, or low urgency based on delivery deadlines and customer requirements.

- Deadline assessment: Deadlines are carefully analyzed, considering potential delays and transit times.

- Resource allocation: Resources (vehicles, personnel) are allocated based on priority to ensure timely delivery of urgent loads.

- Communication and coordination: Effective communication with customers and transportation providers is key to managing expectations and ensuring smooth operations.

- Real-time tracking and adjustments: Using real-time tracking and monitoring allows for prompt adjustments to the schedule if unexpected delays occur.

Imagine having a rush order for medical supplies alongside a regular shipment of consumer goods. The medical supplies would take priority due to their time-sensitive nature, requiring immediate allocation of resources and potentially expedited shipping.

Q 13. What is your experience with load balancing and its impact on fuel efficiency?

Load balancing is the art of distributing weight evenly within a vehicle to optimize fuel efficiency, stability, and tire wear. Uneven weight distribution can lead to increased fuel consumption, instability, and premature tire wear.

My experience demonstrates that proper load balancing directly impacts fuel efficiency. I’ve seen a reduction in fuel consumption by up to 15% in certain cases by optimizing weight distribution. This is achieved through:

- Careful placement of heavy items: Heavier items are placed lower and closer to the center of gravity, distributing weight evenly.

- Using load-securing techniques: Properly securing the load prevents shifting during transit, maintaining balance.

- Utilizing load-measuring tools: Weigh bridges and other tools help to accurately measure weight distribution and ensure balance.

- Using load-balancing software (in some cases): Sophisticated software can assist in planning optimal weight distribution for complex loads.

For example, when transporting heavy machinery, I’d carefully plan the positioning of components to minimize sway and maximize fuel efficiency. By ensuring a balanced load, we also reduce wear and tear on the vehicle and tires, extending their lifespan and reducing maintenance costs.

Q 14. Describe your experience with different types of cargo and their specific loading requirements.

I have extensive experience handling diverse cargo types, each with unique loading requirements. This includes:

- General cargo: This encompasses a wide range of items, from boxes and pallets to furniture and appliances. The key here is careful stacking and securing to prevent damage during transit.

- Hazardous materials (Hazmat): This requires specialized knowledge and adherence to strict regulations. Proper containment, labeling, and documentation are crucial. I am trained in handling various classes of hazardous materials and possess the necessary certifications.

- Oversized and heavy cargo: These require specialized equipment and permits for transportation. Careful planning and execution are necessary to ensure safe and legal transport. This includes obtaining necessary permits and coordinating with escort vehicles where needed.

- Refrigerated cargo: Maintaining the correct temperature is crucial for perishable goods. This requires using refrigerated trucks and monitoring temperature throughout transit.

- Liquid cargo: Specialized containers and secure handling techniques are vital to prevent spills and damage. This often involves understanding and utilizing various types of tanks and pumps.

Handling each cargo type requires a different approach, from specialized packaging and equipment to specific safety protocols and documentation. For instance, loading live animals requires specialized expertise and the utmost care to ensure their welfare and safety during transportation.

Q 15. How do you prevent damage to goods during load preparation and transit?

Preventing damage during load preparation and transit is paramount. It involves a multi-faceted approach focusing on proper securing, packaging, and handling of goods. Think of it like building a sturdy house – each element is crucial to the overall strength and protection.

Proper Packaging: Using appropriate packaging materials like corrugated boxes, bubble wrap, or specialized containers based on the fragility and nature of the goods. For instance, fragile electronics require more cushioning than sturdy furniture.

Secure Loading: This includes using appropriate load securing devices such as straps, dunnage (fill material to prevent shifting), and blocking to prevent shifting or falling during transit. Imagine a stack of books; without proper support, they’ll topple over.

Weight Distribution: Evenly distributing weight across the load to avoid overloading any single area. This prevents stress on the vehicle and potential damage to goods. Think of it like balancing a scale – uneven weight causes instability.

Environmental Protection: Using weatherproof coverings (tarps) to protect goods from rain, snow, or extreme temperatures. Protecting goods from the elements is crucial for preventing damage and spoilage.

Handling Procedures: Implementing and enforcing proper handling procedures throughout the process, including using appropriate equipment (forklifts, pallet jacks) and training personnel on safe handling practices. Avoiding careless drops or throws is vital.

By systematically addressing these aspects, we significantly minimize the risk of damage and ensure the safe arrival of goods at their destination.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle discrepancies or errors in load manifests or shipping documents?

Discrepancies in load manifests or shipping documents can cause significant delays and disruptions. My approach involves a systematic process to identify, rectify, and prevent future occurrences.

Immediate Verification: Upon receiving the manifest, I meticulously compare it against the actual loaded goods. This involves physically checking each item against the document, noting quantity and condition.

Discrepancy Reporting: Any discrepancies, like missing items or incorrect quantities, are immediately reported to the relevant parties (warehouse, shipping department, client). Clear, documented communication is crucial.

Root Cause Analysis: We then conduct a root cause analysis to identify why the discrepancy happened. This could range from data entry errors to picking errors in the warehouse. Understanding the root cause helps in implementing preventive measures.

Corrective Actions: Based on the root cause analysis, corrective actions are implemented, such as improved inventory management systems, additional checks during picking and packing, or better training for staff.

Documentation: All discrepancies, investigations, and corrective actions are meticulously documented to maintain a record and demonstrate accountability.

For example, if a pallet of goods is missing from a shipment, I would immediately initiate an investigation involving the warehouse team to trace its location and determine if it was incorrectly loaded or misrouted.

Q 17. Explain your understanding of load factor and its importance in transportation.

Load factor refers to the percentage of available space utilized in a transportation vehicle. It’s a critical metric in transportation because it directly impacts profitability and efficiency. A higher load factor translates to lower transportation costs per unit.

Importance:

Cost Optimization: Higher load factors mean fewer trips are needed to transport the same volume of goods, reducing fuel costs, driver expenses, and overall transportation expenses.

Improved Profitability: By maximizing space utilization, companies can increase their revenue per shipment and improve their profit margins.

Environmental Impact: Fewer trips lead to lower fuel consumption and reduced carbon emissions, making it environmentally friendly.

Example: A truck with a capacity of 20 pallets that is loaded with 18 pallets has a load factor of 90%. If we can increase the load factor to 95% (19 pallets), we’ll see tangible savings on the next shipment.

Q 18. How do you utilize technology to improve load preparation efficiency?

Technology plays a crucial role in improving load preparation efficiency. We utilize various systems to streamline processes, enhance accuracy, and optimize resource allocation.

Transportation Management Systems (TMS): TMS software helps in route optimization, load planning, and real-time tracking of shipments. It automates many manual processes, reducing human error.

Warehouse Management Systems (WMS): WMS provides real-time visibility into inventory levels, enabling accurate picking and packing. It helps prevent errors in selecting items for loading.

Barcode and RFID Scanning: Using barcode or RFID technology for identifying and tracking items ensures accurate loading and minimizes discrepancies. This helps prevent misloaded items or missing items.

Load Planning Software: Specialized software helps optimize load placement, minimizing empty space and ensuring stability during transport. This software can suggest optimal pallet placement for balance and weight distribution.

Data Analytics: Analyzing data from different systems provides insights into trends, allowing for proactive improvements in load preparation processes. For example, we can identify frequently misloaded items and take preventive measures.

By leveraging these technologies, we not only increase efficiency but also reduce errors, improve accuracy, and achieve significant cost savings.

Q 19. What metrics do you use to assess the success of your load preparation efforts?

Assessing the success of load preparation involves tracking several key metrics.

On-Time Shipments: The percentage of shipments that leave on schedule. This indicates efficiency in the entire process.

Load Factor: As discussed earlier, a higher load factor indicates better space utilization and cost savings.

Damage Rate: The percentage of shipments arriving with damaged goods. A low damage rate reflects effective load securing and handling practices.

Order Accuracy: The percentage of orders that are picked and loaded correctly. This metric helps identify areas for improvement in the warehouse processes.

Transportation Costs: Tracking transportation costs per unit helps monitor efficiency and identify areas for cost reduction.

Customer Satisfaction: Gathering feedback from customers regarding their experience with deliveries helps assess overall process effectiveness.

By regularly monitoring these metrics and analyzing trends, we can identify areas for improvement and continuously optimize our load preparation efforts.

Q 20. Describe your experience with load consolidation and its benefits.

Load consolidation involves combining smaller shipments from multiple shippers into a single larger shipment to leverage economies of scale and improve efficiency. Think of it as a shared taxi service—instead of many individual vehicles, a single larger one carries multiple passengers (shipments) to their destinations, saving costs and time.

Benefits:

Reduced Transportation Costs: Consolidation lowers the cost per unit by utilizing more efficient transportation modes, such as full truckload shipments.

Improved Efficiency: Fewer shipments mean less handling, fewer paperwork, and smoother logistical processes.

Increased Space Utilization: Maximizes space utilization in transportation vehicles, minimizing empty space and transportation costs.

Improved Environmental Impact: Fewer trucks on the road mean reduced fuel consumption and carbon emissions.

For example, a company shipping small orders to various retail stores might consolidate these orders into one larger shipment going to a regional distribution center. This lowers the overall transportation cost while maintaining timely deliveries to the stores.

Q 21. How do you collaborate with other departments, such as warehousing and transportation, during load preparation?

Effective collaboration with warehousing and transportation departments is vital for successful load preparation. We use a variety of methods to ensure seamless communication and coordination.

Regular Meetings: We hold regular meetings with warehouse and transportation managers to discuss upcoming shipments, address potential issues, and share relevant information.

Shared Systems: Using integrated systems (WMS, TMS) allows real-time visibility into inventory levels, shipment status, and transportation schedules.

Clear Communication Channels: We maintain open communication channels using email, instant messaging, and project management tools for prompt updates and issue resolution.

Joint Planning: We collaborate on load planning, ensuring the warehouse team selects and packs items efficiently and that the transportation team has all the necessary information for effective routing and delivery.

Feedback Loops: We establish feedback loops to identify potential problems early and take corrective actions. This involves continuous improvement and adaptation based on shared experiences.

This collaborative approach ensures that every aspect of the process is aligned, from receiving orders in the warehouse to delivering them to the customers. A streamlined, collaborative approach helps prevent delays and minimize errors.

Q 22. What are some common challenges in load preparation and how do you overcome them?

Load preparation, while seemingly straightforward, presents several challenges. Inconsistent order volumes, for example, can make accurate forecasting difficult, leading to either wasted resources or insufficient capacity. Another common issue is inaccurate product data – incorrect dimensions or weights can throw off load planning, resulting in inefficient space utilization or even safety hazards. Finally, last-minute order changes or unexpected delays in receiving goods can disrupt the carefully planned schedule and cause significant setbacks.

To overcome these, I employ a multi-pronged approach. For inconsistent order volumes, I utilize forecasting techniques like exponential smoothing or ARIMA modeling, supplemented by regular communication with sales and production teams to gain insights into future demand. For inaccurate data, I implement rigorous data validation processes, integrating data from multiple sources and conducting regular audits. This ensures data consistency and accuracy. For unexpected disruptions, I maintain a buffer in my scheduling, incorporating contingency plans and flexibility into the process, allowing for adjustments without major disruptions. Communication is key – proactively informing all stakeholders of changes and potential delays prevents misunderstandings and maintains transparency.

Q 23. How do you adapt your load preparation strategies to different customer requirements?

Adapting load preparation strategies to diverse customer requirements is crucial for success. Some customers prioritize speed, while others focus on cost-effectiveness or specialized handling requirements. For example, a customer shipping perishable goods will demand temperature-controlled transportation and rapid delivery, demanding a completely different approach than a customer shipping bulk materials that can tolerate longer transit times.

My approach involves detailed discussions with each customer to understand their specific needs, constraints, and priorities. This includes understanding their product characteristics, delivery timelines, budget limitations, and any special handling instructions. I then tailor the load preparation strategy accordingly. This might involve using different types of packaging, selecting appropriate transportation modes, optimizing routes for speed or cost, and even implementing specialized loading techniques to accommodate fragile or oversized items. A robust communication system throughout the process ensures all parties are informed and that the final load meets the customer’s expectations.

Q 24. Describe your experience with inventory management and its impact on load preparation.

Inventory management is intrinsically linked to efficient load preparation. Accurate inventory tracking allows for precise load planning, preventing overstocking or shortages. Without real-time inventory visibility, it’s easy to underestimate or overestimate the required quantity of goods, leading to delays or wasted resources. For example, if the inventory system shows insufficient stock of a particular item, we can proactively communicate the delay to the customer and adjust the load plan accordingly.

My experience involves utilizing various inventory management systems, from simple spreadsheets to sophisticated ERP software. I’m proficient in using these systems to track inventory levels, monitor stock movement, and identify potential shortages. Furthermore, I employ forecasting techniques to predict future demand and optimize inventory levels, minimizing storage costs and ensuring timely availability of goods for load preparation. I actively participate in inventory reviews and reconciliation processes to maintain data integrity and ensure the system accurately reflects reality. This holistic approach minimizes errors and ensures smooth and efficient load preparation.

Q 25. How do you handle emergency situations that impact load preparation?

Emergency situations, such as equipment malfunctions, unexpected weather events, or sudden order cancellations, can significantly impact load preparation. My response is guided by a structured, prioritized approach. First, I assess the situation’s impact and determine the extent of the disruption. Then, I prioritize tasks based on urgency and criticality. For example, if a key piece of equipment fails, I immediately arrange for repairs or replacement while simultaneously exploring alternative solutions to mitigate delays. If weather threatens to cause delays, I will liaise with transportation providers to explore alternate routes or hold the shipment until conditions improve.

Effective communication is paramount in such situations. I immediately notify all affected stakeholders, including customers, transportation providers, and internal teams. Transparency builds trust and helps to manage expectations. We develop contingency plans to address potential disruptions, adapting the load preparation process to minimize the impact of the emergency. A flexible and resilient planning process is vital to effectively manage unforeseen circumstances.

Q 26. Explain your understanding of supply chain risk management and its relevance to load preparation.

Supply chain risk management (SCRM) is crucial for efficient load preparation. It involves identifying, assessing, and mitigating potential disruptions that could impact the entire supply chain, from raw material sourcing to final delivery. Risks can range from supplier failures and natural disasters to political instability and economic downturns.

In load preparation, SCRM translates to incorporating backup plans and diversification strategies. This includes sourcing materials from multiple suppliers to reduce dependency on a single source, utilizing alternative transportation routes, and maintaining sufficient safety stock to buffer against disruptions. Regular risk assessments, including scenario planning, help identify potential vulnerabilities and develop proactive mitigation strategies. Monitoring geopolitical and economic factors, coupled with robust communication networks, ensures timely responses to evolving risks. A proactive SCRM strategy enhances the resilience of the load preparation process, minimizing the impact of unforeseen events and ensuring on-time delivery.

Q 27. How do you ensure on-time delivery and meet customer expectations?

Ensuring on-time delivery and meeting customer expectations requires a meticulous and proactive approach. This starts with accurate forecasting and planning, utilizing historical data and considering potential risks. I leverage technology, such as route optimization software, to select the most efficient routes and transportation modes. Real-time tracking of shipments allows for proactive identification and resolution of potential delays.

Clear communication with all stakeholders – customers, transportation providers, and internal teams – is vital. Regular updates on shipment status and proactive notifications about any potential delays or issues build trust and manage expectations. A robust feedback mechanism helps to continuously improve the process and address any recurring issues. By combining careful planning with proactive communication and efficient technology, we can ensure consistently reliable on-time deliveries that meet and exceed customer expectations.

Q 28. Describe your proficiency in using specific load planning software (e.g., specific software names).

I possess extensive experience with various load planning software packages. My proficiency includes using SAP TM (Transportation Management) for route optimization, shipment planning, and freight cost analysis. I also have hands-on experience with Oracle Transportation Management (OTM), focusing on its features for warehouse management and load consolidation. In addition, I’m familiar with several other solutions, including smaller, niche software for specific applications. For example, I’ve used [Specific Niche Software Name - Example: Route4Me] for last-mile delivery optimization.

My skills extend beyond merely using the software; I understand the underlying logic and can effectively configure these systems to meet specific business needs. I’m able to design custom reports, integrate the software with other enterprise systems, and troubleshoot any technical issues that may arise. I view these software solutions not merely as tools, but as strategic assets in optimizing the entire load preparation process, improving efficiency, and reducing costs.

Key Topics to Learn for Load Preparation Interview

- Understanding Load Profiles: Learn to analyze and interpret different load profiles (e.g., constant, ramp-up, step) and their implications for system performance.

- Data Generation Techniques: Master methods for generating realistic and representative load data for testing, including synthetic data generation and real-world data transformation.

- Load Testing Tools & Frameworks: Familiarize yourself with popular load testing tools (e.g., JMeter, LoadRunner) and their functionalities. Understand scripting and result analysis.

- Performance Metrics & Analysis: Know how to identify key performance indicators (KPIs) like response time, throughput, and error rate. Practice interpreting performance test results and identifying bottlenecks.

- Infrastructure Considerations: Understand the relationship between load preparation and the underlying infrastructure. This includes network configuration, server capacity, and database performance.

- Test Environment Setup: Learn best practices for setting up realistic and representative test environments that accurately mimic production conditions.

- Load Test Planning & Design: Understand the process of planning and designing effective load tests, including defining test objectives, scope, and metrics.

- Problem-Solving & Troubleshooting: Develop your ability to identify and resolve issues encountered during load testing, such as performance bottlenecks and unexpected failures.

Next Steps

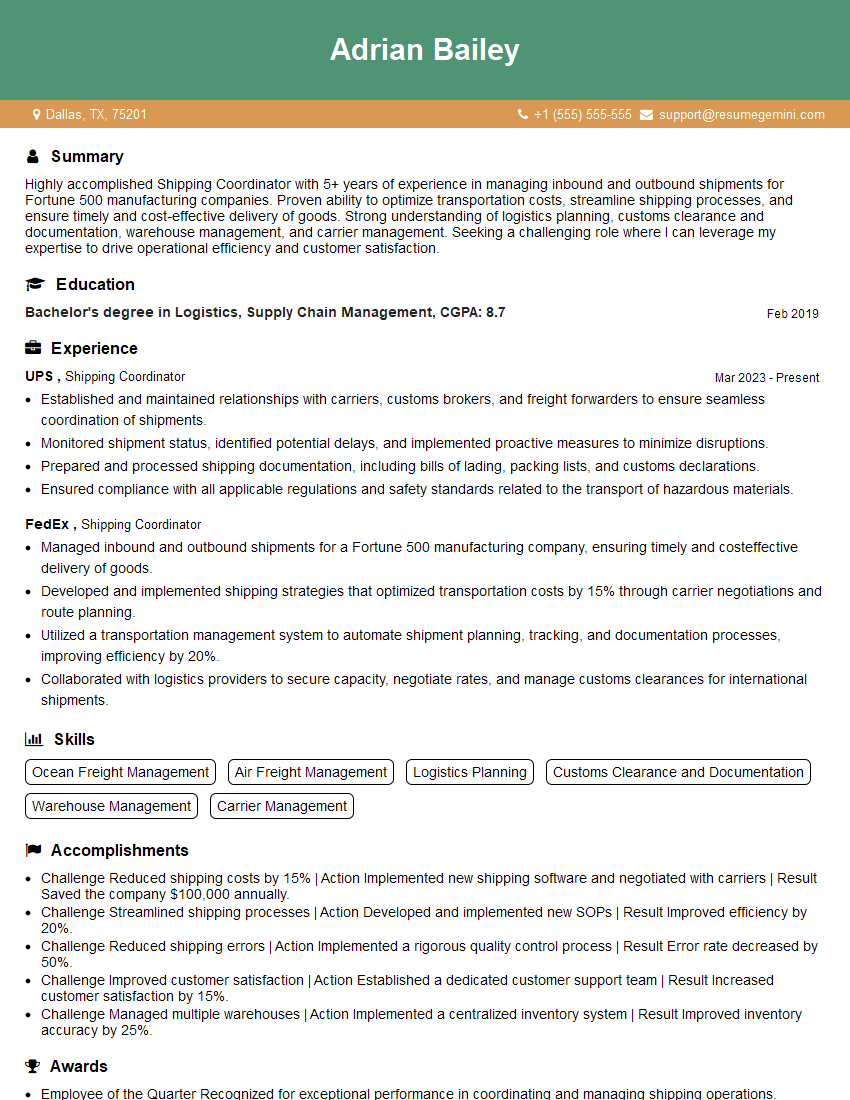

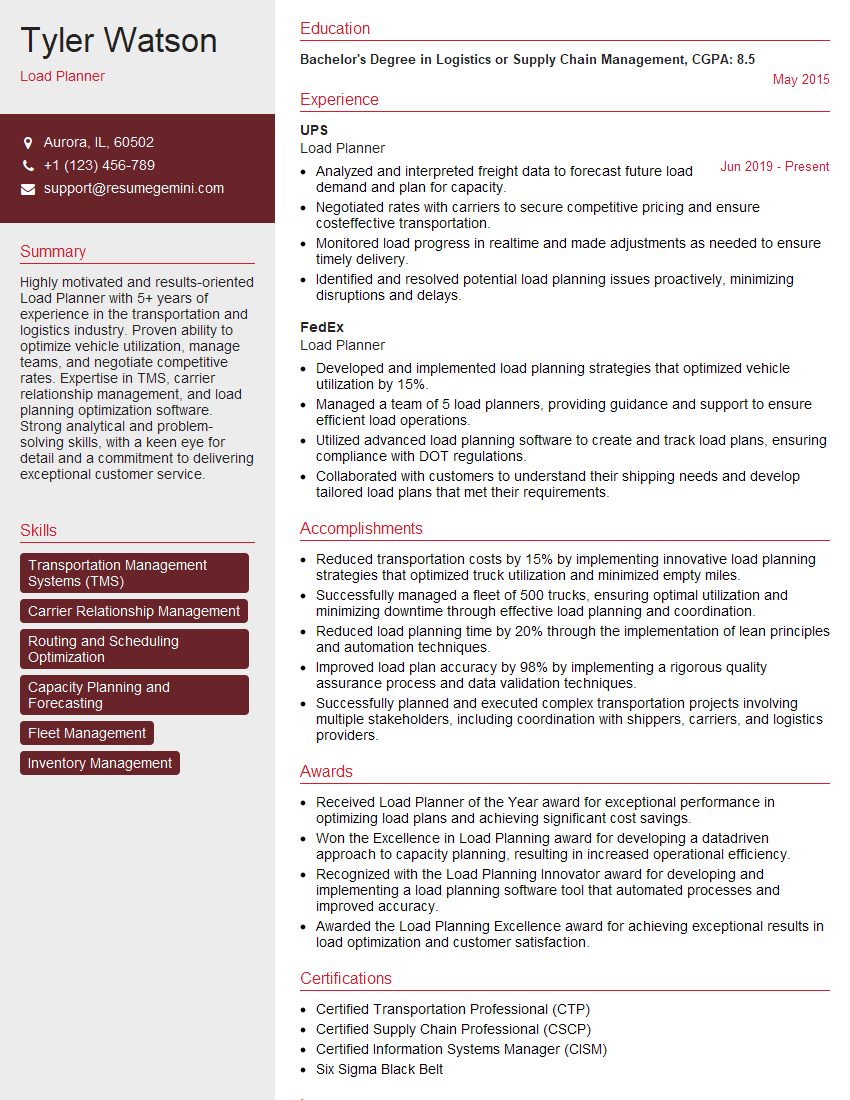

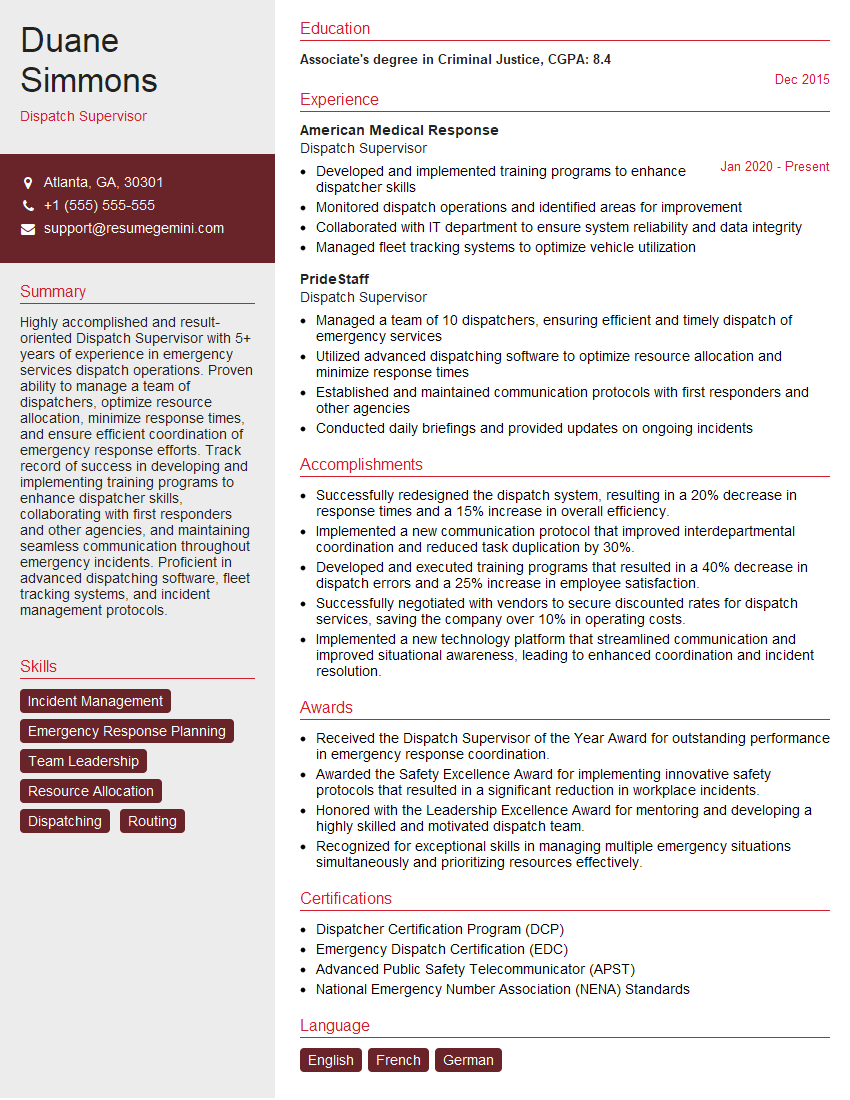

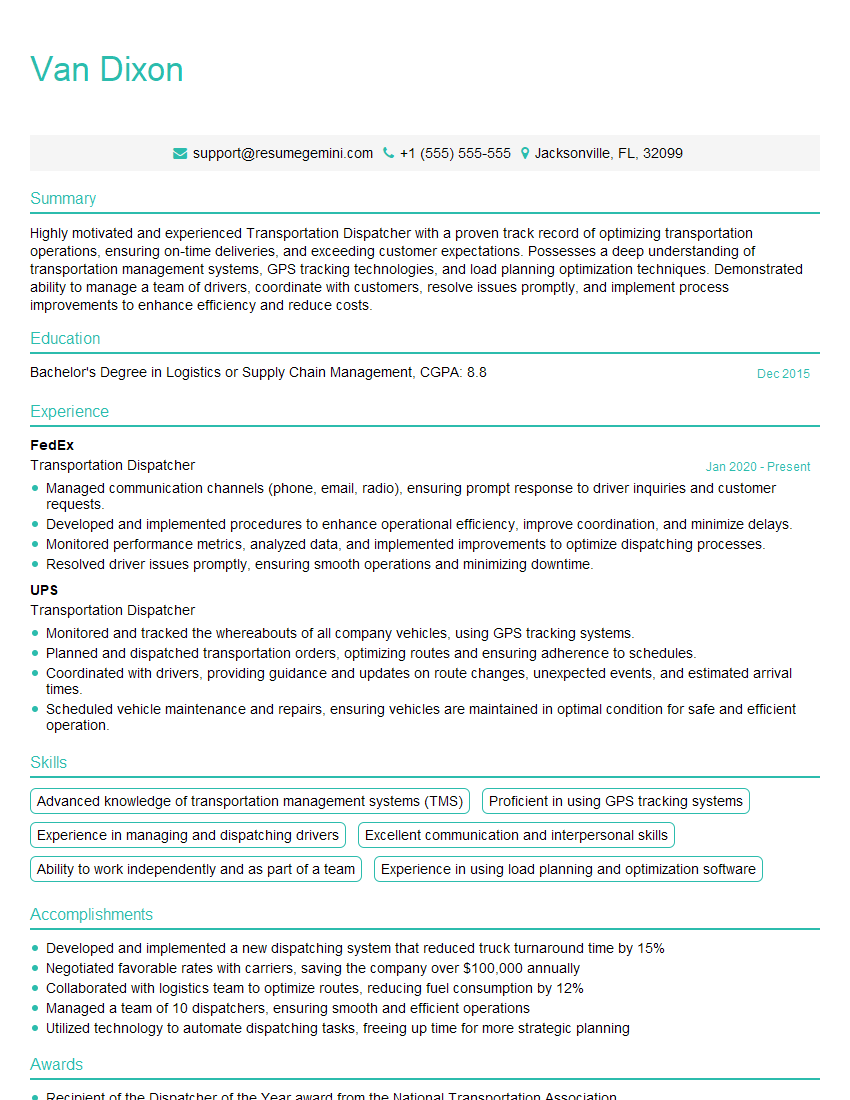

Mastering load preparation is crucial for a successful career in performance engineering and ensures you can contribute significantly to building robust and scalable systems. A well-crafted resume is your first step towards landing your dream job. Make sure your resume is ATS-friendly to maximize its visibility to recruiters. ResumeGemini is a trusted resource to help you create a professional and impactful resume that highlights your skills and experience in Load Preparation. Examples of resumes tailored to Load Preparation are provided to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good