Are you ready to stand out in your next interview? Understanding and preparing for Load Securing and Unloading interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Load Securing and Unloading Interview

Q 1. Explain the importance of proper load securing.

Proper load securing is paramount for safety and efficiency in transportation and handling. It prevents cargo shifting, damage, and accidents during transit. Imagine driving down the highway with an unsecured load – a simple bump could cause it to shift, potentially leading to a serious accident, cargo damage, and delays. Securement also protects the integrity of the goods, preventing breakage or damage which can lead to significant financial losses.

Q 2. Describe different load securing methods and when to use them.

Load securing methods vary depending on the type of cargo and the mode of transport. Common methods include:

- Strapping: Using strong webbing straps to secure the load tightly. This is highly versatile and suitable for various cargo types.

- Chaining: Applying chains for heavier loads or those requiring extra strength. Important to ensure proper tension and use of chain binders.

- Wedging: Filling gaps between cargo and vehicle walls to prevent shifting. This often involves using wooden blocks or purpose-built wedges.

- Blocking and bracing: Using structural supports to stabilize the load and prevent movement. This is particularly crucial for heavy or oddly shaped items.

- Netting: Securing smaller items or preventing them from falling off with specialized cargo nets.

The choice of method depends on factors such as the load’s weight, dimensions, fragility, and the transport conditions. For instance, fragile glassware would require gentler methods like netting and padding, while heavy steel beams would need robust chaining and blocking.

Q 3. How do you assess the weight and center of gravity of a load?

Accurately assessing weight and center of gravity is critical for safe load handling. Weight is usually determined through weighing scales or manufacturer specifications. If unsure, always err on the side of caution and use a higher weight estimate. The center of gravity (CG) is the point where the weight is evenly distributed. It’s crucial to understand the CG because a load with a high CG is more prone to tipping. We can determine the CG visually or, for complex loads, we may need to calculate it using the load’s dimensions and weight distribution. If dealing with a complex configuration of smaller items on a larger pallet, I’d create a schematic to work through the CG calculation. Improper CG assessment can lead to instability and accidents.

Q 4. What are the common hazards associated with load securing and unloading?

Hazards associated with load securing and unloading are numerous. They include:

- Crushing injuries: From loads shifting or falling.

- Struck-by injuries: From falling objects or equipment.

- Caught-in/between injuries: Getting trapped between the load and the vehicle.

- Overexertion injuries: From manually handling heavy loads.

- Slips, trips, and falls: On uneven surfaces or due to poor housekeeping.

These hazards can be mitigated through proper training, risk assessments, using appropriate equipment, and following safety protocols.

Q 5. Describe your experience with different types of lifting equipment.

My experience encompasses a wide range of lifting equipment, including:

- Forklifts: Extensive experience operating various capacities and types, including counterbalance, reach trucks, and order pickers. I’m proficient in pre-operational checks and safe operating procedures.

- Overhead cranes: Skilled in operating both overhead bridge cranes and gantry cranes, including understanding load charts, signal communication, and safe load handling techniques.

- Telehandlers: Experienced in operating telehandlers for lifting and placing loads at height while being aware of their stability limitations.

- Mobile cranes: Familiar with the setup, operation, and safety aspects of various mobile crane types, including the use of outriggers and load charts.

I’m always diligent in checking the equipment’s condition before use, ensuring it’s properly maintained and certified for safe operation.

Q 6. How do you ensure the safety of personnel during loading and unloading operations?

Ensuring personnel safety is my top priority. This involves:

- Pre-task planning: Conducting thorough risk assessments to identify and mitigate potential hazards.

- Training and communication: Ensuring all personnel are properly trained in safe loading and unloading procedures. Clear communication is crucial during lifting and moving operations, using hand signals or two-way radios as needed.

- Personal Protective Equipment (PPE): Making sure workers wear appropriate PPE, such as hard hats, safety shoes, high-visibility clothing, and gloves.

- Traffic management: Controlling access to the loading/unloading area to prevent accidents involving vehicles or pedestrians.

- Emergency procedures: Having established and communicated emergency plans, ensuring everyone knows how to respond in case of an incident.

A strong safety culture, where everyone takes personal responsibility for their safety and the safety of others, is essential.

Q 7. What are the regulations and standards you follow for load securing?

I adhere to all relevant regulations and standards, including but not limited to:

- Occupational Safety and Health Administration (OSHA) regulations (if applicable): This includes the specific standards related to material handling and crane operation.

- Department of Transportation (DOT) regulations (if applicable): These regulations cover the safe securing of loads for transportation by road, rail, sea, or air.

- Manufacturer’s guidelines: Following the manufacturer’s instructions for the use of all equipment and materials.

- Industry best practices: Staying up-to-date with industry best practices and advancements in load securing technologies.

Regular audits and training sessions are vital to ensure continuous compliance and a proactive approach to safety.

Q 8. How do you handle damaged or compromised loads?

Handling damaged or compromised loads requires immediate action to ensure safety and prevent further damage. First, I conduct a thorough assessment of the extent of the damage, noting the type and location of the damage. This could involve anything from minor scuffs to significant structural compromise. I document this meticulously with photos and written notes. Then, depending on the severity, I take the appropriate steps. This could range from simple repackaging and additional securing measures for minor damage, to complete unloading and rejection of the cargo if the damage renders it unsafe for transport. For example, if a pallet has a broken board, I might use additional straps or dunnage boards to stabilize it. However, if a container is showing signs of structural weakness, it needs to be fully inspected by a qualified surveyor before continuing transport. Safety is always the top priority—if there’s any doubt about the load’s integrity, it’s removed from the transport unit.

Q 9. Explain your experience with different types of cargo.

My experience encompasses a wide range of cargo types, including general cargo, oversized and heavy-lift items, hazardous materials (Hazmat), refrigerated goods (perishables), and liquid cargo in tanks. Each requires a tailored approach to securing and handling. For instance, securing a delicate piece of machinery involves using specialized padding, bracing, and securing methods to prevent damage. Conversely, securing a stack of lumber on a flatbed necessitates attention to weight distribution, appropriate binding, and adherence to the load’s center of gravity. Experience with Hazmat involves a stricter adherence to regulations, specialized containers, and detailed documentation. Working with perishables demands maintaining the cold chain through monitoring temperature and ensuring the integrity of refrigeration units. The key is adaptable, diligent, and safe procedures appropriate for each type of cargo.

Q 10. Describe your process for inspecting cargo before loading.

My cargo inspection process is a systematic approach focused on preventing issues before loading even begins. It involves a visual inspection of the packaging, condition, and securing of individual items, and an overall check for load stability and compliance with regulations. I check for any damage, loose components, or signs of tampering. The weight and dimensions are verified against the shipping documentation. For fragile or delicate items, I carefully examine the packaging to ensure adequate protection. This is crucial because addressing problems before they lead to shifting during transit is far more efficient and cost-effective than dealing with them later. A recent example involved identifying a loose bolt on a generator during pre-load inspection. This seemingly small detail could have caused significant damage during transport had I not addressed it promptly.

Q 11. How do you manage load securing in different weather conditions?

Managing load securing in various weather conditions is vital for safe transport. I adjust my methods according to the specific weather forecast and the load’s characteristics. Strong winds require more robust securing techniques, such as using additional straps or tie-downs, ensuring adequate tension, and potentially choosing a different route. In rainy conditions, I utilize waterproof covers to protect cargo from moisture damage. For snowy or icy conditions, I need to consider the increased risk of slippage and may use anti-skid mats or chains to prevent shifting. Extreme temperatures, both hot and cold, can also affect the integrity of load securement materials, so I make sure to choose suitable materials for the conditions. Preparation and adaptability are key to maintaining load security regardless of the weather.

Q 12. What are your methods for preventing load shifting during transit?

Preventing load shifting during transit involves a multi-pronged approach. First, I ensure proper weight distribution, aiming for a balanced center of gravity. This often involves strategically placing heavier items lower and distributing weight evenly across the load. Using appropriate load securing equipment is paramount; sufficient and correctly tensioned straps, chains, or wedges are essential. I also utilize dunnage, like wood blocks or inflatable airbags, to fill any voids or gaps between cargo items to prevent movement. Choosing the right type of restraint for the specific load and securing point is vital; for example, using edge protectors to prevent damage to the cargo itself. Regular checks during transit, if possible, further reduce the risk of shifting. Imagine trying to secure a stack of books – you wouldn’t just tie a string around them! You’d use supports and make sure the whole stack is stable.

Q 13. How do you use load securing equipment effectively and safely?

Effective and safe use of load securing equipment is fundamental. I always begin by selecting the appropriate equipment for the type of load and the anticipated journey conditions. This could include chains, straps, ropes, wedges, or specialized equipment like nets or containers. Each piece of equipment has a working load limit (WLL), which I never exceed. I properly attach the equipment, ensuring it’s correctly tensioned and secured to the load and the vehicle’s securing points. Regular inspections are crucial to ensure the equipment is in good condition, free from damage or wear, and correctly tensioned throughout transit. Over-tightening can damage the load and the equipment, while under-tightening fails to provide adequate security. For example, using a ratchet strap with appropriate tension allows for securement while using a knot, though simpler, could slip and therefore isn’t ideal for every situation.

Q 14. What is your experience with load restraints and their proper application?

My experience with load restraints is extensive, covering various types and applications. Understanding the different types of restraints—chains, webbing straps, ropes, and their respective WLLs—is critical. Proper application involves using the correct type and number of restraints for the specific load and securing them to appropriate points on both the vehicle and the cargo. I always ensure that the restraints are correctly tensioned, distributing the load evenly and preventing shifting or movement. Furthermore, I understand the importance of using appropriate securing points on both the vehicle and cargo to avoid damaging either. For example, using a chain incorrectly could cause damage to the cargo, while using a rope on a heavy load could lead to insufficient securement. Correct application minimizes risks of accidents and cargo damage during transit.

Q 15. Describe your experience with different types of unloading equipment.

My experience encompasses a wide range of unloading equipment, from simple hand tools like pallet jacks and straps to sophisticated automated systems. I’m proficient with various types of forklifts (e.g., counterbalance, reach truck, order picker), cranes (both mobile and overhead), and conveyor belt systems. I’ve also worked with specialized equipment like vacuum lifters for delicate cargo and side loaders for efficient container unloading. Each piece of equipment demands a different skill set and safety protocol, and I’ve always prioritized understanding the specific operating procedures and limitations before use. For example, when unloading fragile ceramics, using a vacuum lifter minimizes risk of damage compared to a forklift. Similarly, using a reach truck in a narrow warehouse maximizes space efficiency compared to a larger counterbalance forklift.

- Forklifts: Extensive experience operating various types, ensuring safe load handling and maneuvering in diverse environments.

- Cranes: Proficient in rigging techniques and load securing for safe crane operations, adhering to weight limits and stability calculations.

- Conveyor systems: Skilled in monitoring and troubleshooting conveyor belt operations to ensure smooth and efficient unloading.

- Specialized equipment: Experienced with vacuum lifters, side loaders, and other specialized equipment tailored to specific cargo types.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prioritize safety while maintaining efficiency during unloading?

Prioritizing safety while maintaining efficiency is paramount. It’s not a trade-off; they are intrinsically linked. My approach involves a systematic process starting with a thorough pre-unloading inspection. This includes checking the load’s stability, the condition of the unloading equipment, and the surrounding work area. Then, I establish clear communication channels with the team, ensuring everyone understands their roles and responsibilities. We utilize safety equipment like high-visibility vests, safety shoes, and appropriate PPE for the specific unloading task. Regularly reviewing the safety guidelines and addressing any potential hazards prevents accidents and streamlines the workflow. For example, if unloading involves working at heights, fall protection measures like harnesses are crucial. Similarly, clear signaling during forklift operation is essential to avoid collisions and injuries. Implementing a checklist and regular safety briefings are invaluable.

Q 17. How do you ensure the integrity of the cargo during unloading?

Ensuring cargo integrity requires a multifaceted approach. It starts with understanding the specific requirements of the goods being unloaded—their fragility, weight distribution, and susceptibility to environmental factors (temperature, humidity). Proper handling techniques are crucial; this includes using appropriate equipment and techniques to avoid jarring movements or impacts. We carefully plan the unloading sequence to minimize stress on the cargo and consider using protective materials like padding or dunnage where necessary. For instance, fragile items might require custom crates and careful placement during unloading. Regularly inspecting the cargo during unloading identifies potential problems early on. Documentation of any damage is vital, providing a record for claims and improving future handling procedures. Using technology like temperature monitoring devices for sensitive goods further contributes to integrity.

Q 18. What is your experience with inventory management related to loading and unloading?

My experience with inventory management in loading and unloading involves using both manual and computerized systems. I’m familiar with using scanners to track items, updating inventory databases in real-time, and reconciling physical counts with system records. Accurate tracking minimizes discrepancies, prevents losses, and ensures efficient stock management. In addition to tracking individual items, we monitor overall quantities to avoid overcrowding or insufficient storage space. Experience with different inventory management software such as WMS (Warehouse Management Systems) has enhanced my ability to handle large volumes of data and generate reports effectively. I am also skilled in addressing discrepancies that may arise and performing thorough investigations to find the root cause and prevent future issues. For example, I have used WMS systems to optimize our warehouse layouts and improve pick-and-pack efficiency.

Q 19. Explain your understanding of proper documentation for load securing.

Proper documentation for load securing is crucial for legal compliance, insurance purposes, and traceability. Documentation includes the type of securing equipment used (e.g., straps, chains, wedges), their condition, and the method of securing the load. This often involves detailed diagrams showing the placement of securing points and tension measurements. Important information such as the weight of the load, its center of gravity, and any special handling instructions should be meticulously recorded. The driver’s signature and date of loading/unloading is typically also included. Electronic documentation using handheld devices and software is becoming increasingly common, allowing instant access and easier tracking of load information. For example, a Bill of Lading is a key document showing the details of the goods being transported, while cargo securing documentation offers specifics about how the goods were secured and by whom.

Q 20. How do you handle unexpected delays or challenges during loading or unloading?

Handling unexpected delays or challenges requires adaptability and problem-solving skills. My approach focuses on identifying the root cause of the delay (e.g., equipment malfunction, weather conditions, logistical issues). Once the cause is identified, we create a contingency plan to address it. This might involve finding alternative equipment, adjusting the unloading sequence, or seeking assistance from colleagues or supervisors. Open communication is crucial during such situations, keeping all stakeholders informed of progress and any potential impacts. For instance, if there’s an equipment malfunction, we may need to contact maintenance while temporarily using alternative methods to proceed with the unloading, ensuring minimal disruption. Proper risk assessment and having a backup plan in place are crucial components of handling unexpected circumstances.

Q 21. Describe your experience with using a forklift or other heavy machinery.

I have extensive experience operating forklifts and other heavy machinery, always adhering to strict safety regulations. My certifications and training cover various types of forklifts, including counterbalance, reach trucks, and order pickers. I understand the importance of pre-operational checks, including inspecting the machine’s condition, checking fluid levels, and verifying that all safety systems are functioning correctly. I’m well-versed in maneuvering heavy machinery in various warehouse environments, navigating obstacles safely and efficiently. I am also proficient in using other equipment such as pallet jacks and hand trucks. My experience extends to adhering to weight limits, understanding load centers and proper lifting techniques to prevent tipping or damage. Before each use, a pre-operation inspection is standard procedure to mitigate safety risks.

Q 22. How do you address load securing issues that arise during transit?

Addressing load securing issues during transit requires a systematic approach. First, safety is paramount; if the load is compromised, we must prioritize stopping the vehicle in a safe location, away from traffic and other hazards. Then, a thorough assessment is needed. This involves identifying the exact nature of the problem – is it shifting cargo, broken straps, or damage to the vehicle itself? Once the cause is determined, we implement corrective actions, which might involve:

- Re-securing the load: This may require tightening existing straps, adding additional securing devices (like chains or wedges), or re-arranging the cargo for better weight distribution.

- Temporary repairs: In cases of minor damage to the securing equipment, temporary repairs might suffice, but these must be followed up with proper repairs as soon as possible.

- Documentation: Meticulous documentation of the issue, corrective actions, and the condition of the load is critical for insurance purposes and preventing future incidents. We’d include photos and detailed descriptions of the damage and repairs.

- Communication: Immediate communication to the relevant parties, including dispatch, the driver, and potentially the customer, is crucial, informing them of the situation and the plan to address it.

For example, if I noticed a load of pallets shifting during transit due to insufficient blocking and bracing, I’d pull over safely, assess the situation, and likely add more blocking material between the pallets and the walls of the trailer, and re-secure with additional straps. Then, I’d contact dispatch to update them on the situation and the actions taken, including documentation with pictures.

Q 23. How do you communicate effectively with drivers and other team members regarding load securing?

Effective communication is the cornerstone of safe load securing. I prioritize clear, concise, and unambiguous communication, tailored to the audience. With drivers, I ensure they understand the weight limits, proper securing techniques for specific cargo types, and the importance of regular checks during transit. We use pre-trip checklists and a shared communication platform (email, or app) to confirm load integrity. With the loading/unloading team, communication is equally crucial, using clear hand signals and verbal cues to coordinate movements, ensuring safety during loading and unloading operations.

For instance, I might use a simple, standardized checklist for drivers, illustrated with pictures for clarity, clearly explaining the correct placement of straps and wedges for various types of goods. With the warehouse team, I’d frequently conduct briefings emphasizing careful handling of fragile goods and maintaining a safe working distance from moving machinery or vehicles.

Q 24. What are your strategies for preventing accidents during loading and unloading?

Preventing accidents during loading and unloading involves a multi-pronged approach encompassing pre-emptive measures, procedural adherence, and fostering a safety-conscious culture. My strategies include:

- Proper training: Ensuring all personnel are thoroughly trained in safe loading and unloading techniques, including hazard identification and risk mitigation.

- Clear procedures: Establishing and strictly adhering to documented procedures which detail steps involved in loading and unloading specific cargo types and utilizing proper equipment.

- Equipment maintenance: Regular inspection and maintenance of all equipment, such as forklifts, pallet jacks, and securing devices, to ensure they are in optimal working condition. Faulty equipment is a major risk factor.

- Safe work environment: Maintaining a clean, organized, and well-lit work area, free from clutter and hazards. This minimizes the chances of slips, trips, and falls.

- Hazard identification and risk assessment: Conducting regular risk assessments to identify potential hazards and implement appropriate control measures. This proactive approach allows addressing potential issues before they can cause accidents.

- Personal Protective Equipment (PPE): Mandatory use of appropriate PPE including safety shoes, gloves, and high-visibility vests.

For example, before starting a loading operation involving a forklift, I’d always ensure the area is clear, the forklift is inspected, and the operator has undergone safety training and knows the exact location of all load securing points.

Q 25. Describe a time you had to solve a load securing problem.

During a shipment of delicate glass sculptures, we encountered a problem during transit. The load, while secured with straps, started shifting due to unexpected road conditions. Upon inspection, I discovered that the securing straps were insufficiently taut and the added weight of the sculptures had exceeded the initial calculations. The glass was at risk of breakage.

My solution was a two-part approach: first, we secured the load more firmly by using additional ratchet straps and strategically placed wooden blocks to prevent shifting. This provided immediate stabilization. Then, we contacted the customer to communicate the problem and the solutions we implemented, highlighting that the shipment might be slightly delayed. We also documented everything in detail, including pictures of the repositioned load. The sculptures arrived safely, and we learned a valuable lesson about the importance of accurate weight assessment and using more robust securing strategies for such fragile goods.

Q 26. How do you stay updated on best practices and regulations for load securing?

Staying updated on best practices and regulations is crucial in this field. I actively participate in industry conferences and workshops, regularly review updated guidelines from organizations such as the [Mention relevant organizations, e.g., OSHA, Department of Transportation], and subscribe to relevant industry publications and online resources. I also actively engage with other professionals in the field to share knowledge and best practices. Continuous learning is essential for staying ahead of the curve and ensuring that I’m always applying the most effective and compliant methods.

Q 27. What is your experience with different types of packaging and how it impacts load securing?

My experience with various packaging types profoundly influences load securing strategies. Different packaging materials have varying degrees of strength and protection, impacting how a load is secured. For example:

- Pallet-wrapped goods: These require securing the entire pallet unit, focusing on preventing the pallet from tipping or shifting.

- Loose goods in boxes: Requires more attention to weight distribution to prevent crushing or damage to individual boxes. Internal bracing and dunnage may be necessary.

- Bulk goods: These need special consideration, often requiring specialized techniques and equipment to maintain structural integrity during transit.

- Fragile goods: Demand utmost care and specialized packing materials and securing techniques to prevent breakage. This may include custom crates or specialized cushioning.

Understanding the packaging and its inherent strengths and weaknesses is critical in determining the appropriate securing method. A sturdy crate holding fragile items needs different securing than a pallet of sturdy boxes. This knowledge significantly impacts the choice of securing devices and techniques ensuring optimal protection during transit.

Q 28. How would you train a new employee on safe load securing and unloading procedures?

Training a new employee on safe load securing and unloading procedures is a phased approach. It begins with classroom instruction covering theoretical aspects like load weight calculations, regulations, types of securing devices, hazard identification, and risk assessment. This is followed by hands-on training in a controlled environment, where the new employee practices loading, securing, and unloading under supervision. This practical session includes using different types of cargo and securing devices. Emphasis is placed on proper technique, safety protocols, and use of personal protective equipment (PPE).

The training also incorporates scenario-based exercises, simulating real-world situations like load shifting or equipment malfunction. This allows the employee to apply their knowledge and develop problem-solving skills. Finally, ongoing mentorship and observation on the job provide opportunities for continuous learning and improvement. We use a structured training program with checklists and assessments to ensure competency and adherence to safety standards. Successful completion of the program is a prerequisite for independent work.

Key Topics to Learn for Load Securing and Unloading Interviews

- Understanding Load Types and Characteristics: Identifying different cargo types (e.g., palletized goods, loose materials, oversized items), their weight distribution, and potential hazards.

- Safe Lifting and Handling Techniques: Proper use of lifting equipment (forklifts, cranes, hand trucks), understanding weight limits, and adhering to safety regulations to prevent injuries.

- Securing Methods and Equipment: Knowledge of various load securing techniques (e.g., strapping, chains, netting), understanding appropriate equipment for different cargo, and the importance of proper tensioning.

- Regulations and Compliance: Familiarity with relevant safety regulations (OSHA, etc.), understanding load securement standards, and documentation requirements.

- Risk Assessment and Prevention: Identifying potential hazards associated with loading and unloading, developing risk mitigation strategies, and implementing safety protocols.

- Practical Application: Scenario-based problem solving – visualizing how to secure different types of loads efficiently and safely in various conditions (e.g., varying weather, different vehicle types).

- Emergency Procedures: Understanding procedures for handling accidents, damaged loads, or equipment malfunctions, including reporting and communication protocols.

- Warehouse and Yard Management: Understanding efficient loading/unloading procedures to optimize space utilization and workflow in warehouse and yard environments.

- Communication and Teamwork: The importance of clear communication with team members, supervisors, and clients to ensure safe and efficient operations.

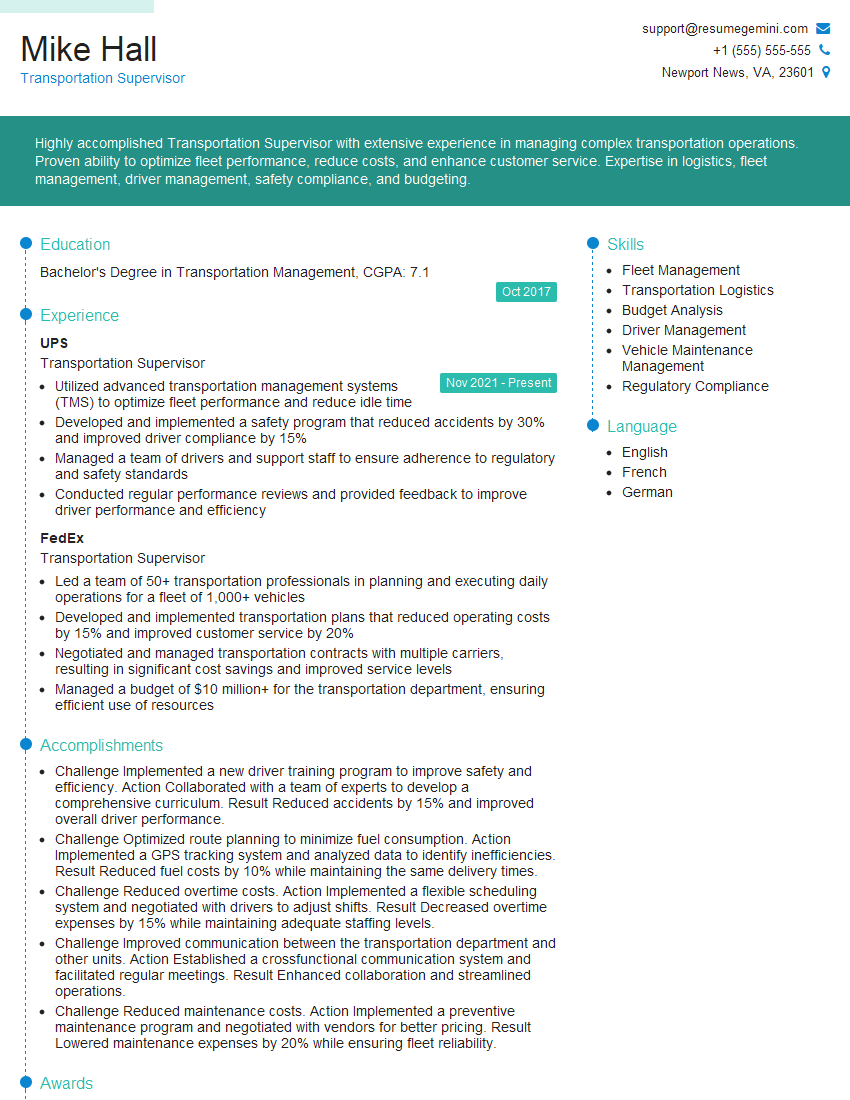

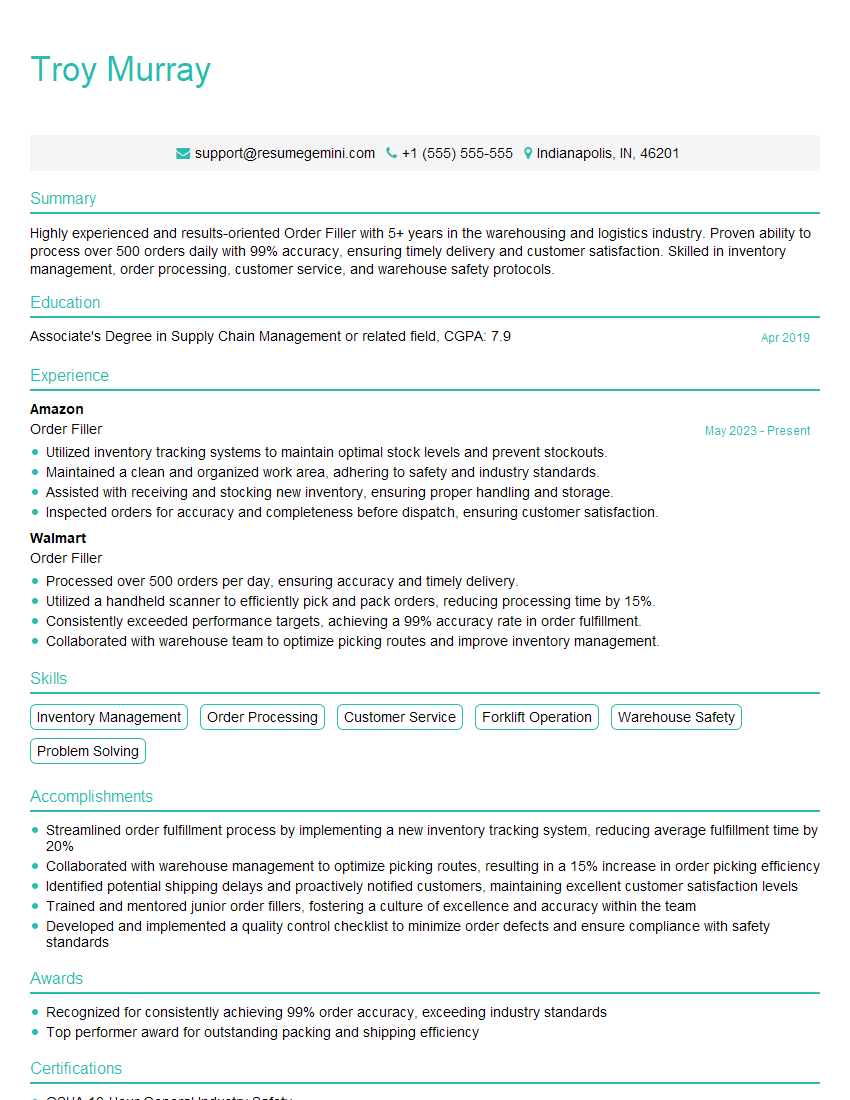

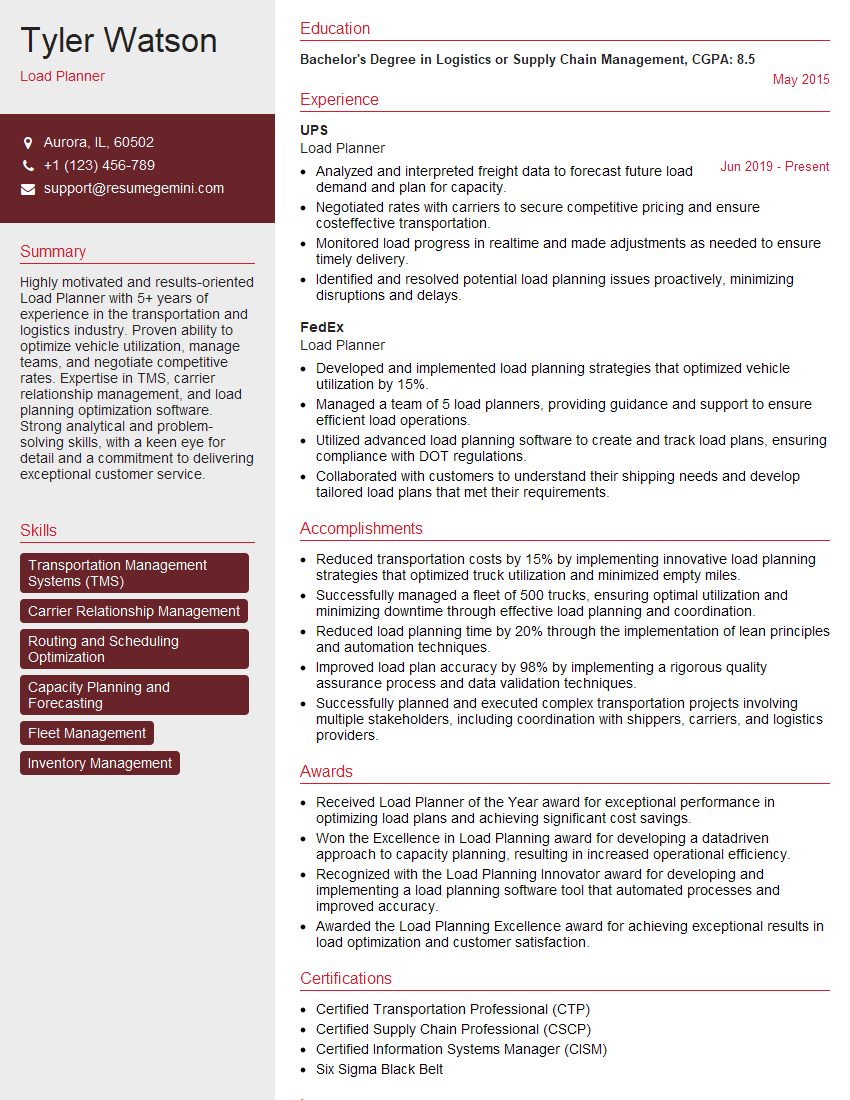

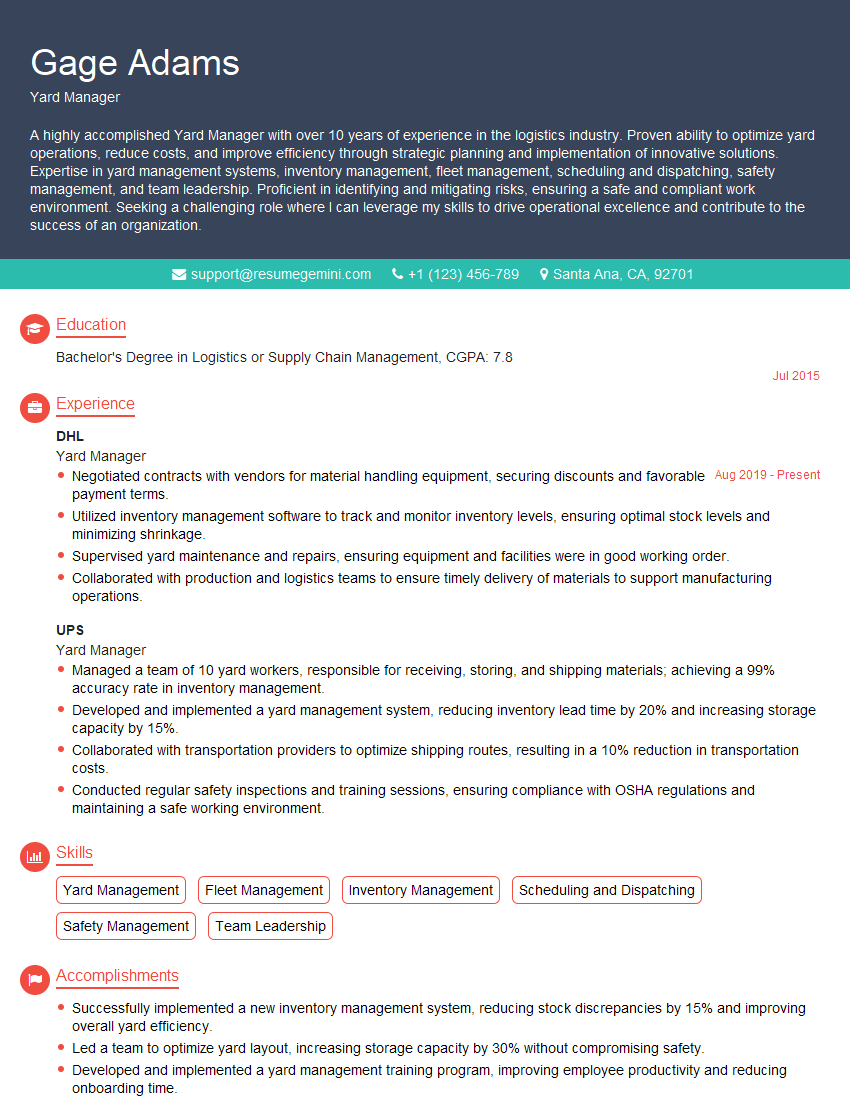

Next Steps

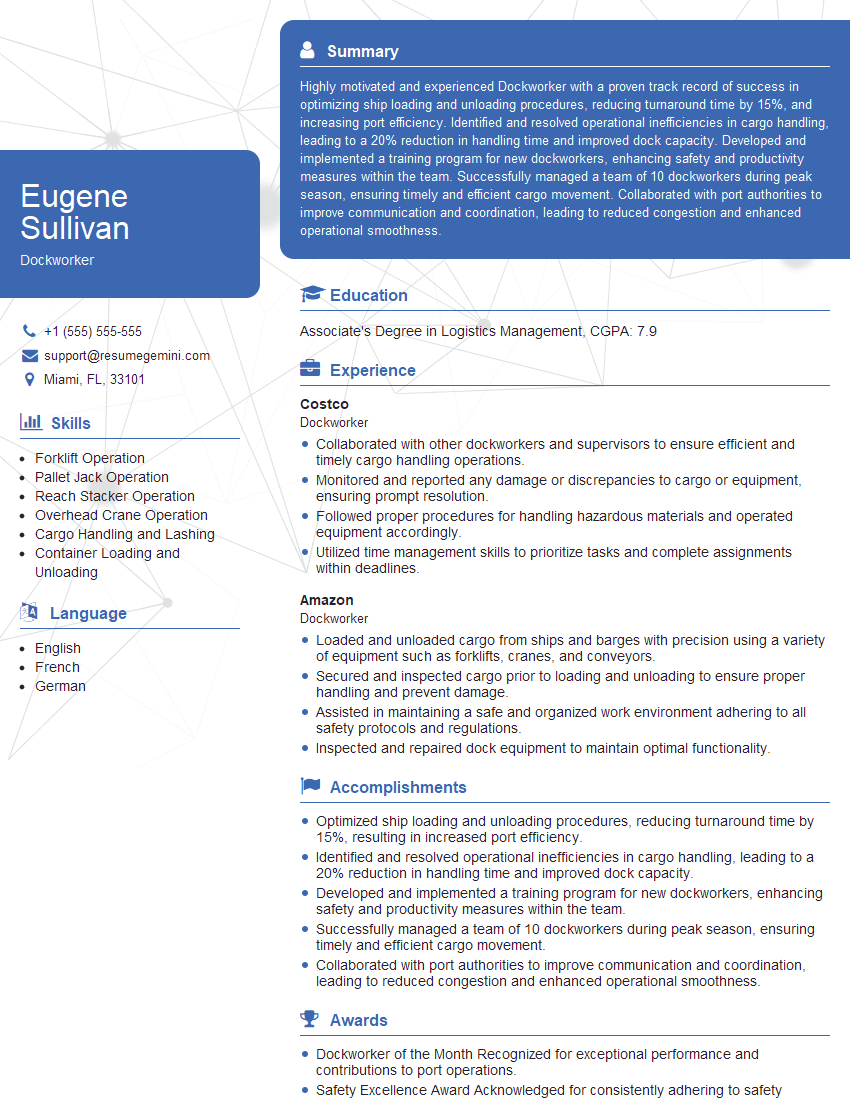

Mastering Load Securing and Unloading is crucial for career advancement in logistics and transportation. A strong understanding of safety and efficiency significantly increases your value to potential employers. To stand out, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume that gets noticed. Examples of resumes tailored to Load Securing and Unloading professionals are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good