The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Loading and Unloading Cargo Ships and Vessels interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Loading and Unloading Cargo Ships and Vessels Interview

Q 1. Describe the different types of cargo handling equipment used in ports.

Ports utilize a diverse range of cargo handling equipment, each designed for specific tasks and cargo types. Think of it like a specialized toolbox for moving goods.

- Container Cranes: These massive structures lift and move containers between ships and the dock. Imagine them as giant robotic arms, incredibly precise and powerful.

- Ship-to-Shore (STS) Cranes: Similar to container cranes but specifically designed for the larger scale of container vessels. They’re the workhorses of container terminals.

- Reach Stackers: These are mobile machines that lift and stack containers in yards. They’re essential for organizing and storing containers efficiently, like a giant forklift for shipping containers.

- Forklifts: Smaller and more versatile than reach stackers, forklifts are used for moving individual pallets and smaller cargo units within the port and warehouse.

- Gantry Cranes: These cranes run on rails and are used for lifting heavy and oversized cargo that doesn’t fit in standard containers. Think of transporting exceptionally large machinery or unusual shapes.

- Conveyors: Belt systems that move packages and smaller cargo automatically, speeding up the process and reducing manual labor.

The choice of equipment depends on factors like the type of cargo, vessel size, and port infrastructure. A smaller port might rely heavily on forklifts, while a major container terminal will have numerous STS cranes and automated systems.

Q 2. Explain the process of securing cargo during transport.

Securing cargo is critical to prevent damage and accidents during transit. It’s like building a strong, protective cage around your goods. The methods used depend on the type of cargo and the mode of transport.

- Containerized Cargo: Containers are themselves a form of secure packaging. However, contents within the container need to be secured to prevent shifting during transit. This often involves using lashing straps, dunnage (protective materials), and bracing to keep goods from moving around. Imagine filling empty space with airbags or foam to prevent jostling.

- Breakbulk Cargo: This refers to goods that aren’t in containers. Securing involves careful stacking, using strong ropes, chains, and blocks to prevent the cargo from shifting or collapsing. Think of how you would stack heavy boxes in a moving truck, making sure everything is stable.

- Hazardous Cargo: Requires specialized securement techniques and often additional packaging and labeling to ensure safety and prevent spills or leaks. This involves strict adherence to international regulations and employing methods to neutralize any potential hazards.

Proper documentation of securing methods is crucial, both for insurance purposes and to ensure safe handling throughout the journey. A detailed manifest outlining the method and materials used is essential.

Q 3. What are the safety regulations related to cargo handling?

Safety is paramount in cargo handling. Regulations are designed to protect workers, the environment, and the cargo itself. These regulations are often stringent and cover various aspects.

- Personal Protective Equipment (PPE): Workers must wear appropriate PPE, such as hard hats, safety glasses, gloves, and safety boots, to protect against falls, impacts, and hazardous materials.

- Safe Lifting Practices: Strict procedures govern the use of lifting equipment to prevent accidents. This includes regular inspections and maintenance of equipment, proper training of operators, and adherence to weight limits.

- Hazardous Materials Handling: Specific regulations dictate how hazardous materials are handled, stored, and transported. This includes proper labeling, ventilation, and emergency response plans.

- Workplace Safety: Ports must maintain safe working environments, including proper lighting, clear walkways, and adequate training for all personnel. This also covers emergency procedures and communication protocols.

- International Maritime Organization (IMO) Regulations: These international standards guide the safe transportation of goods by sea, covering many aspects of cargo handling, storage, and security.

Non-compliance can result in severe penalties, including fines and operational suspensions. Safety audits and regular training are key to maintaining a safe working environment.

Q 4. How do you ensure the efficient loading and unloading of containers?

Efficient container loading and unloading relies on optimized processes and technology. Think of it like a well-oiled machine where every component works in harmony.

- Yard Management Systems (YMS): These software systems optimize the flow of containers within the terminal, minimizing travel time and maximizing space utilization. They’re like a traffic controller for containers, directing them to their designated locations.

- Automated Crane Systems: Automated STS cranes and other handling equipment significantly speed up the process and reduce reliance on manual labor. This improves efficiency and reduces the risk of human error.

- Optimized Vessel Stowage Planning: Careful planning of container placement on the vessel ensures efficient loading and unloading sequences. This minimizes the time spent searching for containers and improves the overall turnaround time.

- Pre-planning and Communication: Clear communication between the ship, terminal operators, and cargo owners ensures that all parties are aware of the loading and unloading plan. This reduces delays and misunderstandings.

The goal is to minimize the time the vessel spends in port. Every minute counts, impacting cost and schedule.

Q 5. What are the challenges of handling hazardous cargo?

Handling hazardous cargo presents unique challenges, requiring specialized expertise and stringent safety protocols. It’s like dealing with delicate and potentially dangerous materials that need extra care and attention.

- Safety Concerns: The primary challenge is the potential for accidents involving fire, explosions, or exposure to toxic substances. Strict safety measures are crucial, including special handling equipment and trained personnel.

- Regulatory Compliance: Stringent regulations and documentation requirements govern the transport and handling of hazardous materials. These regulations often change and require constant monitoring to ensure compliance.

- Specialized Equipment and Facilities: Specialized equipment and designated areas are often required for safe handling and storage. This can increase the cost of operations.

- Security Risks: Hazardous cargo can be a target for theft or malicious acts, demanding enhanced security measures.

Effective risk assessment and mitigation are crucial for managing the challenges associated with hazardous cargo. This involves pre-shipment inspections, ongoing monitoring, and well-defined emergency response plans.

Q 6. Explain the importance of proper documentation in cargo handling.

Proper documentation is the backbone of efficient and compliant cargo handling. It’s like a detailed roadmap that guides every step of the process.

- Bills of Lading: These documents serve as contracts between the shipper, carrier, and consignee, outlining the terms of carriage and responsibilities.

- Packing Lists: These lists detail the contents of each package, facilitating accurate inventory management and customs clearance.

- Cargo Manifests: These documents list all cargo on board a vessel, crucial for efficient loading, unloading, and tracking.

- Hazardous Material Declarations: These forms declare the presence and nature of hazardous materials, allowing for safe handling and compliance with regulations.

- Customs Documents: Necessary for importing and exporting goods, these forms comply with import/export laws and procedures.

Accurate and complete documentation streamlines the entire process, prevents delays, facilitates customs clearance, and reduces the risk of disputes. It’s the key to a smooth and transparent operation.

Q 7. How do you manage delays in cargo operations?

Delays in cargo operations are inevitable, but effective management can minimize their impact. It’s like navigating a traffic jam – you need a plan to get through it.

- Proactive Monitoring: Regularly track the progress of cargo and identify potential delays early on. This allows for timely intervention and mitigation strategies.

- Communication and Coordination: Maintain open communication with all stakeholders involved, including shippers, carriers, port authorities, and customs officials. This enables quick problem-solving and collaborative efforts.

- Contingency Planning: Develop and implement contingency plans to address potential disruptions, such as inclement weather, equipment failures, or port congestion. This includes alternative routes, backup equipment, or flexible scheduling.

- Problem-Solving and Decision-Making: A swift and efficient decision-making process is crucial when delays occur. This requires assigning responsibility, analyzing the root cause, and implementing solutions efficiently.

Effective communication, proactive planning, and a flexible approach are key to minimizing the impact of delays and ensuring cargo reaches its destination on time.

Q 8. What are the key performance indicators (KPIs) for cargo handling?

Key Performance Indicators (KPIs) for cargo handling are crucial for measuring efficiency, safety, and overall effectiveness of port operations. They allow us to track progress, identify bottlenecks, and make data-driven improvements. These KPIs are typically categorized into several areas:

- Throughput: This measures the volume of cargo handled per unit of time (e.g., tons per hour, containers per hour). A high throughput indicates efficient operations. For example, tracking the number of containers unloaded per hour from a vessel allows for comparison against targets and identification of areas for improvement in crane utilization or labor deployment.

- Turnaround Time: This measures the time it takes to completely load or unload a vessel. Reducing turnaround time is critical for maximizing port capacity and minimizing vessel downtime. A reduction from 24 hours to 18 hours translates to a significant increase in port efficiency.

- Cargo Damage Rate: This tracks the percentage of damaged cargo during handling. A low rate demonstrates careful handling procedures and minimizes losses. Implementing stricter safety protocols and improved training can help reduce this rate.

- Safety Incidents: The number of accidents or near misses during cargo handling operations is a vital indicator. A low rate reflects a safe working environment. Regular safety audits, employee training, and adherence to safety regulations contribute to this KPI.

- Cost per Unit Handled: This KPI looks at the overall cost of handling cargo relative to the volume handled. Lower costs indicate operational efficiency. Optimizing equipment utilization and labor scheduling can directly influence this.

- Inventory Accuracy: This measures the accuracy of inventory records compared to the physical stock. High accuracy ensures smooth operations and reduces discrepancies. Regular stock checks and the implementation of robust inventory management systems contribute to this.

By consistently monitoring and analyzing these KPIs, we can identify areas needing improvement and optimize our cargo handling processes.

Q 9. Describe your experience with different types of cargo (e.g., bulk, breakbulk, containers).

My experience encompasses a wide range of cargo types, each presenting unique challenges and requiring specialized handling techniques.

- Bulk Cargo: I’ve worked extensively with bulk cargo, such as grains, ores, and coal. This involves coordinating the use of specialized equipment like conveyor belts, ship loaders, and grabs to efficiently transfer large quantities of homogenous material. For example, during the unloading of iron ore, we need to ensure a smooth flow to avoid blockages and optimize the usage of the unloading system.

- Breakbulk Cargo: Breakbulk cargo, consisting of individual pieces or palletized units, necessitates careful planning and handling. This involves using cranes, forklifts, and other equipment to load and unload diverse items, requiring a strong understanding of weight distribution and securing methods. I recall a project involving the handling of oversized steel components, requiring meticulous planning for safe loading and unloading to prevent damage.

- Containerized Cargo: I have significant experience with containerized cargo, the most common type today. This includes managing the efficient flow of containers, ensuring accurate stacking, and coordinating their movement using cranes, straddle carriers, and terminal tractors. A recent project involved optimizing the flow of containers during peak season to minimize congestion and meet tight deadlines.

My experience spans various port environments and includes managing both import and export operations for diverse commodity types, ensuring compliance with safety regulations and international standards.

Q 10. How do you handle damaged or lost cargo?

Handling damaged or lost cargo requires a systematic and thorough approach, emphasizing documentation, investigation, and communication.

- Immediate Documentation: Upon discovery, we thoroughly document the damage or loss, including photographs, descriptions, and the cargo’s condition before and after the incident. This documentation is essential for insurance claims and investigations.

- Investigation: A thorough investigation is conducted to determine the cause of the damage or loss. This might involve reviewing handling procedures, equipment logs, and interviewing personnel involved. This helps to prevent future incidents.

- Notification: We immediately notify the relevant parties, including the shipper, consignee, and insurance company. Transparency is vital in maintaining good relationships.

- Claims Processing: We assist in filing insurance claims, providing all necessary documentation to support the claim. This includes photos, reports, and other evidence.

- Resolution: We strive for fair resolution, whether it’s arranging repairs, replacement, or issuing compensation. The goal is always customer satisfaction.

Throughout this process, maintaining meticulous records is paramount. For instance, a detailed report on a damaged container, including the container number, the nature of the damage, and witnesses’ statements, is critical for a successful insurance claim.

Q 11. Explain your experience with inventory management in a port environment.

Effective inventory management in a port environment is crucial for efficient operations and preventing delays. This involves tracking cargo from the moment it arrives until it leaves the port.

My experience includes implementing and managing inventory systems, using both manual and automated methods. This involved:

- Real-time Tracking: Implementing systems that track cargo location and status in real-time, using barcode scanners, RFID tags, or specialized software. This ensures transparency and minimizes the risk of misplacement.

- Data Analysis: Analyzing inventory data to identify trends, predict demand, and optimize storage space. This allows for proactive decision-making and efficient resource allocation.

- Integration: Integrating the inventory system with other port systems, such as customs and transportation management systems. This streamlines the overall process and prevents data discrepancies.

- Regular Audits: Conducting regular physical stock checks to verify accuracy and address discrepancies promptly. This guarantees the integrity of the inventory data.

For example, during peak season, real-time tracking helps us quickly locate specific containers, ensuring prompt delivery to clients and preventing delays in the supply chain.

Q 12. How do you coordinate with other teams (e.g., customs, trucking)?

Coordination with various teams is essential for seamless cargo handling. Effective communication and collaboration are key. My approach includes:

- Customs: Proactive communication with customs officials to ensure smooth clearance processes. This includes submitting all necessary documentation in advance and addressing any queries promptly. For example, prior to a shipment’s arrival, we provide all the required paperwork and manifest information to the customs agency for pre-clearance.

- Trucking Companies: Coordinating with trucking companies to ensure timely pickup and delivery of cargo. This includes scheduling pickups, providing accurate delivery information, and managing any potential delays. For instance, we work closely with the trucking companies to ensure that the appropriate type of truck is available based on the type and weight of the cargo.

- Shipping Lines: Maintaining clear communication with shipping lines to manage vessel schedules and ensure cargo is ready for loading and unloading on time. This could include discussing potential delays and making adjustments as needed.

- Internal Teams: Close collaboration with internal teams such as operations, safety, and maintenance, ensuring that everyone is informed and aligned on the overall plan. Daily briefings are crucial for efficient coordination.

Using shared platforms and communication tools improves visibility and ensures that everyone is on the same page throughout the entire process, resulting in smooth and efficient operations.

Q 13. Describe your experience with various types of cranes and lifting equipment.

My experience with cranes and lifting equipment is extensive, covering various types and applications.

- Ship-to-Shore Cranes (STS): These massive cranes are essential for loading and unloading containers from vessels. I’m proficient in their operation and safety procedures, including load weight verification, and swing radius management.

- Rubber-Tyred Gantry Cranes (RTGs): These mobile cranes are used for stacking containers in the yard. Understanding their maneuverability and limitations is crucial for efficient yard operations.

- Reach Stackers: These versatile machines are used for lifting and transporting containers within the yard. I’m familiar with their capabilities and safe operating procedures.

- Forklifts: Essential for handling breakbulk cargo and various other materials within the port. Safe operating practices and load capacity understanding are critical.

- Mobile Harbor Cranes: These cranes offer flexibility and are used for loading and unloading various types of cargo, including breakbulk and project cargo. Their versatility allows for handling goods that might not be suitable for containerized transport.

Beyond operation, I also have experience in crane maintenance scheduling and safety inspections, ensuring equipment reliability and adherence to safety standards. Regular maintenance prevents costly breakdowns and minimizes safety risks.

Q 14. What are the different methods for loading and unloading bulk cargo?

Various methods exist for loading and unloading bulk cargo, each tailored to the specific type of cargo and port infrastructure.

- Grabs: These mechanical claws are used to scoop up bulk materials and transfer them to conveyors or trucks. This method is common for unloading materials such as grains and ores.

- Conveyor Belts: These systems efficiently transfer large volumes of bulk material from the vessel’s hold to storage areas. They are often integrated with ship loaders and unloaders for seamless transfer.

- Bucket Elevators: These vertical conveyors are used to lift bulk materials to higher levels for storage or transfer. They’re particularly useful in handling materials that require vertical movement.

- Pneumatic Systems: These systems use air pressure to transport bulk materials through pipes. This method is suitable for handling fine powders or materials that are easily damaged. This method is less common due to the significant infrastructure required.

- Suction Systems: These systems use vacuum pumps to draw bulk material from the vessel’s hold. Suitable for handling fine powders and granules, ensuring minimal product damage.

The choice of method depends on factors like the cargo’s properties, the vessel’s design, and the available infrastructure. For example, a port handling coal would likely use a combination of grabs and conveyor belts, while a port handling grain might prioritize conveyor systems for efficiency.

Q 15. How do you ensure the safety of personnel during cargo handling operations?

Ensuring personnel safety during cargo handling is paramount. It’s not just about following regulations; it’s about fostering a safety-first culture. We achieve this through a multi-layered approach.

- Pre-operational Safety Briefings: Before any operation begins, a thorough briefing covers all potential hazards, specific equipment usage, emergency procedures, and the day’s tasks. This includes reviewing the vessel’s safety plan and any specific risks associated with the cargo itself (e.g., hazardous materials).

- Personal Protective Equipment (PPE): Mandatory PPE, including safety helmets, high-visibility vests, safety footwear, gloves, and hearing protection, is provided and strictly enforced. Regular inspections ensure equipment is in good working order.

- Proper Training and Certification: All personnel involved, from stevedores to crane operators, must be properly trained and certified in their respective roles. Regular refresher courses are essential to maintain competency and address evolving safety standards.

- Safe Working Practices: Implementing and consistently monitoring adherence to strict safe working practices is crucial. This includes maintaining a clear communication system, designated walkways, proper lifting techniques, and regular equipment maintenance checks to minimize the risk of accidents. For example, ensuring there’s sufficient spacing between equipment and personnel and implementing traffic management systems to prevent collisions.

- Emergency Response Plan: A well-defined and regularly practiced emergency response plan is critical. This includes procedures for dealing with fires, medical emergencies, spills, and equipment malfunctions. Regular drills and simulations keep everyone prepared and knowledgeable.

For instance, during a recent operation involving oversized cargo, we implemented a detailed traffic management system using hand signals and designated marshals to ensure the smooth and safe movement of the cargo and personnel.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the environmental considerations related to cargo handling?

Environmental concerns are increasingly important in cargo handling. We aim to minimize our impact through several strategies.

- Air Quality: Controlling emissions from equipment is vital. This includes using low-emission equipment, regular maintenance to reduce exhaust fumes, and employing effective dust suppression techniques. For example, water sprays can help minimize dust during the loading and unloading of bulk materials.

- Water Pollution: Preventing spills and leaks is crucial. This involves robust containment measures, appropriate handling of hazardous materials, and immediate response plans for accidental spills. We also utilize oil spill containment booms and absorbent materials during operations near water bodies.

- Waste Management: Proper waste disposal is essential. This involves segregating different types of waste (hazardous and non-hazardous) and ensuring their responsible disposal in accordance with relevant regulations. We work with certified waste management companies to ensure environmentally compliant disposal.

- Noise Pollution: Minimizing noise pollution is addressed by employing quieter equipment where possible, using noise-reducing barriers and scheduling noisy operations during less sensitive times of the day or night.

- Compliance with Regulations: We meticulously adhere to all international and local environmental regulations and actively seek opportunities to surpass minimum standards to improve our environmental performance. This involves obtaining and maintaining the necessary permits and licenses.

For example, during a recent project, we employed specialized equipment designed to reduce particulate matter emissions during the handling of bulk minerals, significantly lowering our environmental footprint.

Q 17. How do you prevent cargo theft and pilferage?

Preventing cargo theft and pilferage requires a comprehensive security approach.

- Access Control: Restricting access to the cargo area is paramount. This involves secure fencing, controlled entry points with access cards or security personnel, and constant monitoring of the terminal area using CCTV cameras.

- Cargo Monitoring: Utilizing real-time tracking systems, such as GPS trackers embedded in containers, allows us to monitor cargo location and movement throughout the entire handling process. This provides an early warning system for any unauthorized access attempts.

- Security Personnel: Employing trained security personnel provides a visible deterrent and allows for proactive monitoring of the cargo area, identifying and responding to suspicious activities promptly.

- Container Sealing and Inspection: Properly sealed containers with tamper-evident seals provide an extra layer of security. Regular inspections of containers before and after handling help detect any signs of tampering or unauthorized entry.

- Background Checks and Training: Thorough background checks and comprehensive security training for all personnel involved in cargo handling minimize the risk of internal theft.

In one instance, we successfully apprehended thieves attempting to breach a container using advanced surveillance systems which automatically alerted security personnel. The use of this technology highlights the importance of proactive security measures.

Q 18. Explain your experience with using cargo handling software or systems.

I have extensive experience using various cargo handling software and systems, including Terminal Operating Systems (TOS) and specialized logistics platforms.

- TOS Experience: I’m proficient in using TOS software to manage vessel scheduling, berth allocation, gate management, yard operations, and cargo tracking. This includes tasks such as generating reports, monitoring real-time performance indicators, and optimizing workflows.

- Logistics Platforms: I’ve worked with various cloud-based logistics platforms for managing documentation, communication, and tracking cargo throughout the entire supply chain. These systems often integrate with TOS and other relevant systems, providing a holistic view of the operation.

- Data Analysis and Reporting: I am comfortable analyzing data generated by these systems to identify bottlenecks, improve efficiency, and optimize resource allocation. Generating insightful reports is crucial for informed decision-making.

- System Integration: I understand the importance of seamless system integration and have experience integrating different cargo handling software and systems to improve communication and data flow across different departments and stakeholders.

For example, I once used a TOS to optimize vessel scheduling, resulting in a 15% reduction in port turnaround time, which significantly improved efficiency and reduced costs.

Q 19. How do you handle unexpected situations or emergencies during cargo operations?

Handling unexpected situations and emergencies requires a calm, decisive approach and a well-rehearsed plan. My experience has taught me the importance of preparedness and rapid response.

- Assessment and Prioritization: The first step is a rapid assessment of the situation to identify the severity of the problem and prioritize actions based on the level of risk involved. This includes evaluating the potential impact on personnel, cargo, and the environment.

- Emergency Response Procedures: Following established emergency response procedures is crucial. This involves activating emergency services, implementing established safety protocols, and clearly communicating the situation to relevant stakeholders.

- Communication and Coordination: Clear and effective communication is vital, particularly during emergencies. This involves utilizing all available communication channels to keep everyone informed, coordinate efforts, and ensure a unified response.

- Problem-Solving and Decision-Making: Quick and effective decision-making under pressure is essential. Based on the assessment of the situation, we initiate necessary actions to resolve the problem, minimizing potential damages and ensuring personnel safety.

- Post-Incident Review: Following any significant incident, a thorough post-incident review is conducted to identify the root causes, lessons learned, and areas for improvement. This allows for adjustments in procedures to enhance preparedness and prevent similar occurrences in the future.

In one case, we successfully managed a sudden equipment malfunction during a crucial operation by swiftly activating our emergency response plan, preventing any major delays or accidents.

Q 20. What are your skills in problem-solving and decision-making in high-pressure situations?

Problem-solving and decision-making in high-pressure situations are critical skills in cargo handling. My approach is methodical and data-driven.

- Data Analysis: I systematically gather and analyze relevant data to understand the problem’s context and identify potential solutions. This could involve reviewing historical data, operational reports, or conducting on-site assessments.

- Risk Assessment: I evaluate the potential risks and consequences associated with different courses of action. This ensures we make informed decisions that minimize potential negative impacts.

- Resource Allocation: I efficiently allocate available resources to implement the chosen solution. This involves coordinating personnel, equipment, and other resources to achieve the desired outcome.

- Communication and Collaboration: I foster open communication and collaboration with team members and other stakeholders. This ensures everyone is on the same page and that solutions are implemented effectively.

- Adaptability: I am adaptable and comfortable adjusting strategies based on new information or unexpected developments. Flexibility is essential in high-pressure situations where the situation may rapidly evolve.

For example, when faced with a sudden surge in cargo volume during peak season, I successfully reorganized workflows and re-allocated resources, preventing significant delays and maintaining operational efficiency.

Q 21. How do you maintain accurate records and documentation of cargo handling activities?

Maintaining accurate records and documentation is crucial for compliance, operational efficiency, and accountability.

- Digital Documentation: We utilize digital documentation systems to maintain accurate and readily accessible records of all cargo handling activities. This includes using electronic cargo manifests, loading plans, and equipment logs.

- Data Entry and Verification: Data entry processes are carefully managed to ensure accuracy. This includes implementing double-checking procedures and regular data audits to detect and correct any errors.

- Barcode and RFID Technology: Utilizing barcode and RFID technology allows for precise tracking and verification of cargo throughout the handling process. This minimizes errors and enhances accuracy in documentation.

- Record Retention: We adhere to strict record-retention policies, ensuring that all relevant documents are securely stored and easily retrievable. This complies with regulatory requirements and aids in efficient auditing.

- Reporting and Analysis: The collected data is used to generate reports that provide insights into operational performance, which helps to identify areas for improvement and optimize resource allocation.

For example, our detailed digital records allowed us to quickly resolve a discrepancy in cargo documentation during a recent audit, highlighting the importance of meticulous record-keeping.

Q 22. Describe your experience with different types of ships and their unique loading/unloading requirements.

My experience spans various vessel types, each demanding unique handling approaches. Think of it like assembling a complex puzzle – each piece (cargo type and vessel design) requires specific tools and techniques. For instance, loading a container ship (like a massive LEGO set) involves precise stacking and securing of standardized containers using specialized cranes. This contrasts sharply with bulk carriers (imagine a giant sandpit), where unloading grain or ore necessitates high-capacity conveyors and careful management of dust and spillage. Then you have tankers (think of giant liquid containers) which require careful procedures to prevent spills and explosions, needing specialized pumps and hoses. Finally, Ro-Ro (roll-on/roll-off) ships (picture a massive parking garage for vehicles) demand careful maneuvering of vehicles and equipment with the help of ramps and specialized machinery. Each vessel’s structural design, cargo type, and intended destination influences the loading and unloading strategy, emphasizing safety and efficiency.

- Container Ships: Focus on efficient stacking plans, ensuring weight distribution and stability. I’ve worked on optimizing routes for automated crane operations, reducing turnaround times.

- Bulk Carriers: Emphasis is on high-throughput unloading systems. My expertise lies in predicting and mitigating potential problems like hold flooding and efficient waste disposal.

- Tankers: Rigorous safety protocols are paramount. I have experience managing the cleaning process, ensuring compliance with environmental regulations.

- Ro-Ro Ships: Coordination is key to facilitate the smooth flow of vehicles. Experience includes managing traffic flow and securing vehicles effectively to prevent damage.

Q 23. How do you ensure compliance with international maritime regulations?

Compliance with international maritime regulations is non-negotiable, it’s about safety and responsibility. Think of it as following a strict recipe for a complex dish – each step is crucial for a successful outcome. We adhere to the International Maritime Organization (IMO) conventions, SOLAS (Safety of Life at Sea), MARPOL (Marine Pollution) and the ISPS Code (International Ship and Port Facility Security Code). This involves meticulous documentation, regular inspections, and the implementation of robust safety management systems (SMS). For example, ensuring that all cargo is properly stowed, secured and documented with regards to its hazardous nature and proper documentation is a crucial part of this process. Any deviation could lead to significant penalties, environmental damage, or even loss of life.

We use specialized software to manage cargo manifests and ensure that the correct documentation and certificates are presented before the commencement of operations. We regularly conduct audits and training sessions to remind the crew about these regulations. Non-compliance isn’t an option; it’s about safeguarding lives, the environment, and the company’s reputation.

Q 24. What is your experience with risk assessment and mitigation in cargo handling?

Risk assessment and mitigation are fundamental to safe cargo handling; it’s like playing chess, anticipating potential threats and planning countermeasures. We employ a systematic approach, identifying potential hazards (unstable cargo, weather conditions, equipment failure) and evaluating their likelihood and consequences. This involves considering the human factor – fatigue, training levels, and communication effectiveness. For example, during a storm, we’d assess the risks of continued loading/unloading, possibly halting operations to prevent accidents. Mitigation strategies would involve securing loose cargo, diverting operations, or utilizing specialized equipment to handle high winds.

We use a combination of qualitative and quantitative methods, developing detailed risk matrices and emergency response plans. Each operation has a pre-defined risk assessment and mitigation plan that is reviewed and adjusted as needed, before, during, and after each operation. Regular safety meetings and drills help reinforce best practices and improve our response to unexpected incidents. This proactive approach saves time, prevents accidents, and ensures the safety of personnel and cargo.

Q 25. How do you manage the workforce during peak periods or high cargo volume?

Managing the workforce during peak periods requires strategic planning and efficient resource allocation – think of it as orchestrating a symphony; each instrument (worker) must play its part in harmony. We use a combination of strategies including:

- Pre-planning: Analyzing historical data to predict peak demand and staffing requirements.

- Overtime management: Offering fair compensation and minimizing excessive overtime to avoid fatigue.

- Temporary staffing: Utilizing temporary workers to supplement the core team during high-volume periods.

- Improved communication: Employing clear and concise communication channels to streamline instructions and enhance coordination.

- Technology integration: Using software to track cargo flow, assign tasks efficiently, and manage worker schedules.

Careful workforce scheduling considering break times, fatigue, and shift patterns is crucial to ensure safety and prevent errors. We also maintain open communication channels, providing regular updates and addressing concerns promptly.

Q 26. Describe your experience with training and mentoring new employees in cargo handling.

Training and mentoring are essential for maintaining a skilled and safe workforce. I believe in a hands-on approach, combining classroom learning with practical on-the-job training. For new employees, we begin with comprehensive safety inductions, covering risk assessment, emergency procedures, and equipment operation. This is followed by a structured apprenticeship program, where experienced workers mentor new hires, guiding them through various cargo handling procedures. We regularly review and update our training materials to reflect new technologies and industry best practices.

I encourage continuous learning, offering opportunities for upskilling and professional development. This includes attending workshops, participating in simulations, and receiving feedback on their performance. Mentoring is not just about passing on technical skills but also nurturing a strong safety culture. It’s about building a team that is knowledgeable, motivated, and committed to high standards.

Q 27. What are your salary expectations for this position?

My salary expectations are in line with the industry standard for a professional with my experience and qualifications. I am open to discussing a compensation package that reflects the responsibilities and challenges of this position and aligns with the company’s salary structure. I am more interested in a package that includes opportunities for professional development and advancement.

Q 28. What are your career goals?

My career goals involve achieving a senior management role within the maritime logistics industry. I aim to leverage my expertise to optimize cargo handling processes, enhance safety protocols, and contribute to a more sustainable and efficient maritime sector. I am particularly interested in exploring opportunities related to technological advancements in cargo handling and automation. My long-term objective is to lead a team, mentoring and developing future generations of maritime professionals.

Key Topics to Learn for Loading and Unloading Cargo Ships and Vessels Interview

- Cargo Handling Techniques: Understanding various methods like container cranes, forklifts, and conveyor belts, their limitations, and safety protocols.

- Cargo Securing and Lashing: Practical application of securing different types of cargo to prevent damage during transit, including knowledge of relevant regulations and best practices.

- Types of Cargo and their Handling Requirements: Differentiating between bulk cargo, breakbulk cargo, and containers, and understanding their specific handling needs and potential hazards.

- Inventory Management and Documentation: Accurate tracking of cargo throughout the loading and unloading process, including familiarity with bills of lading, cargo manifests, and other shipping documents.

- Safety Regulations and Procedures: Deep understanding of international maritime safety standards (e.g., SOLAS), port regulations, and emergency response procedures.

- Port Operations and Logistics: Knowledge of the overall flow of cargo through a port, including scheduling, coordination with other parties, and potential bottlenecks.

- Problem-Solving in Cargo Handling: Ability to troubleshoot issues that may arise during loading and unloading, such as damaged cargo, equipment malfunctions, or weather-related delays.

- Technology in Cargo Handling: Familiarity with modern technologies used in cargo handling, such as automated systems, GPS tracking, and communication networks.

- Environmental Considerations: Understanding the environmental impact of cargo handling and the importance of sustainable practices.

Next Steps

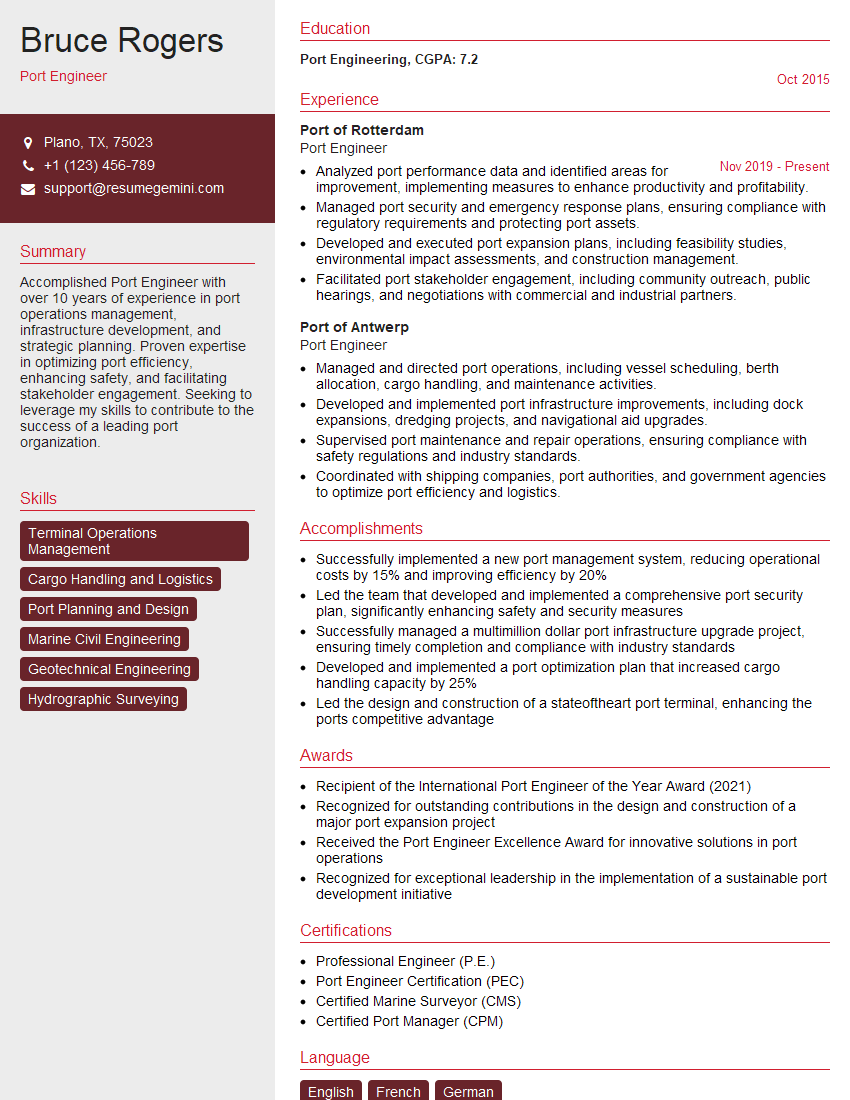

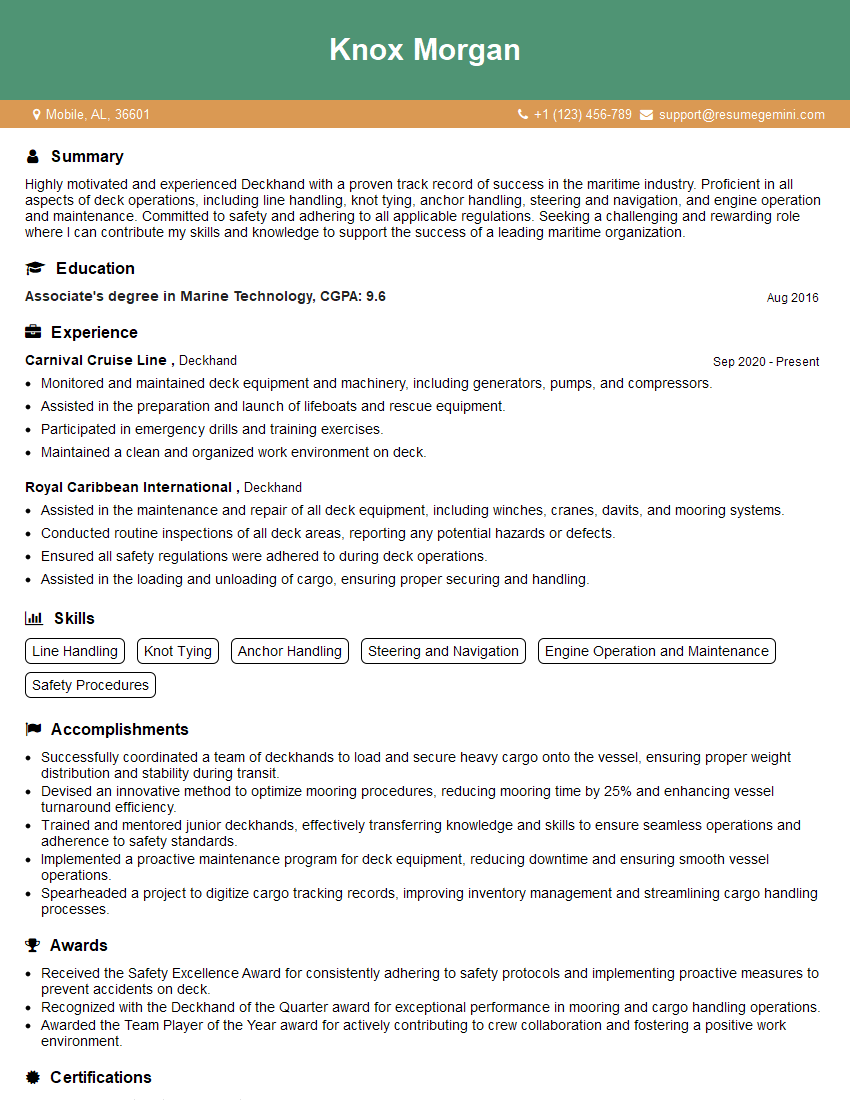

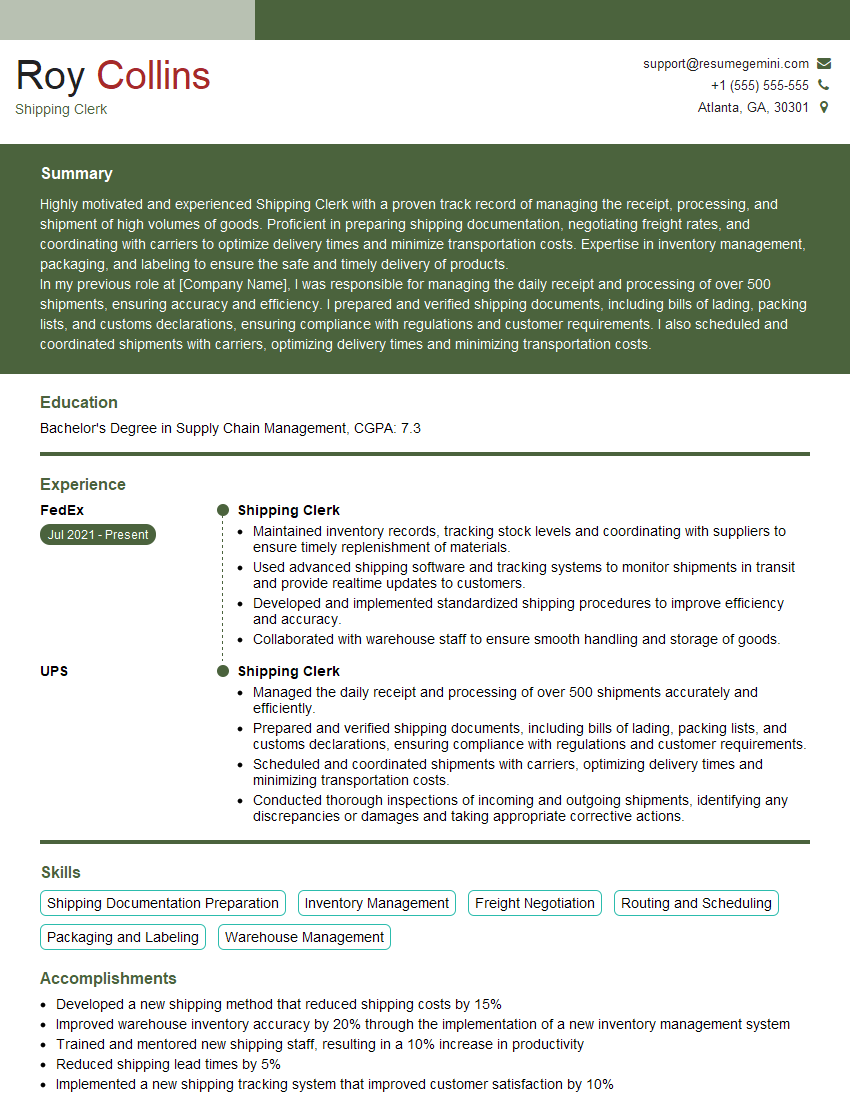

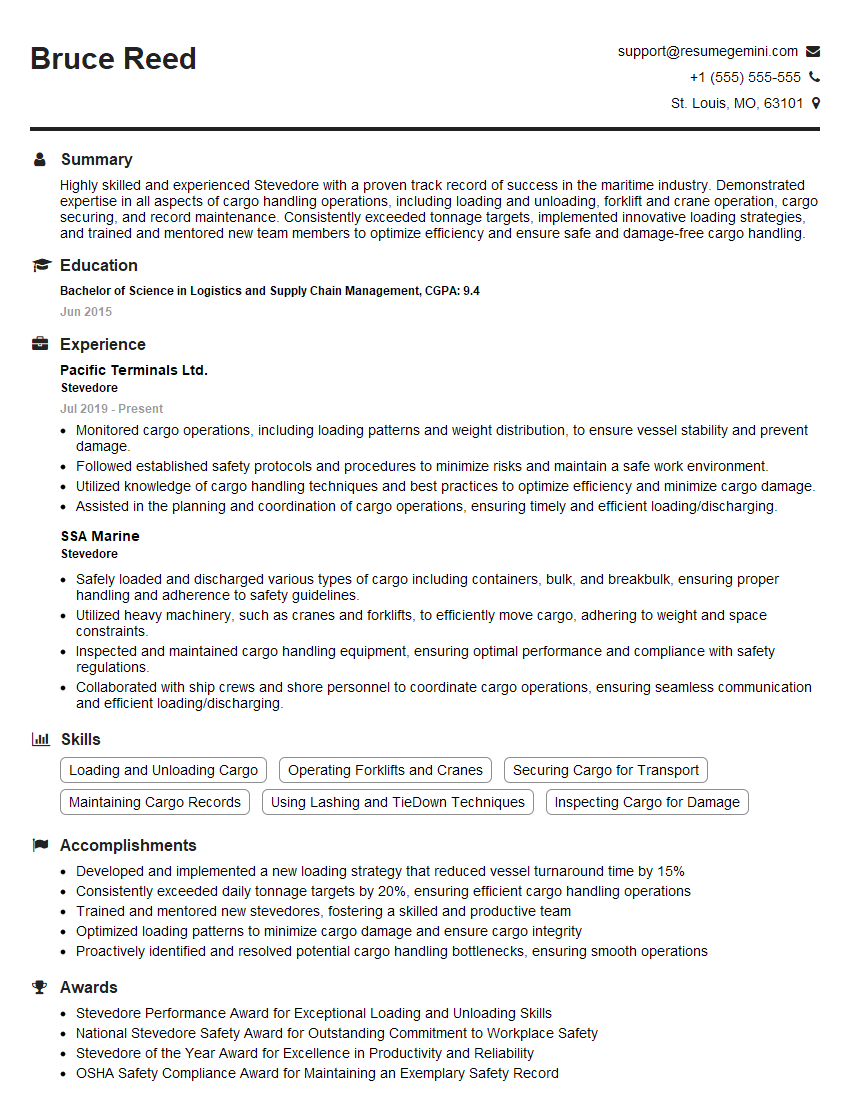

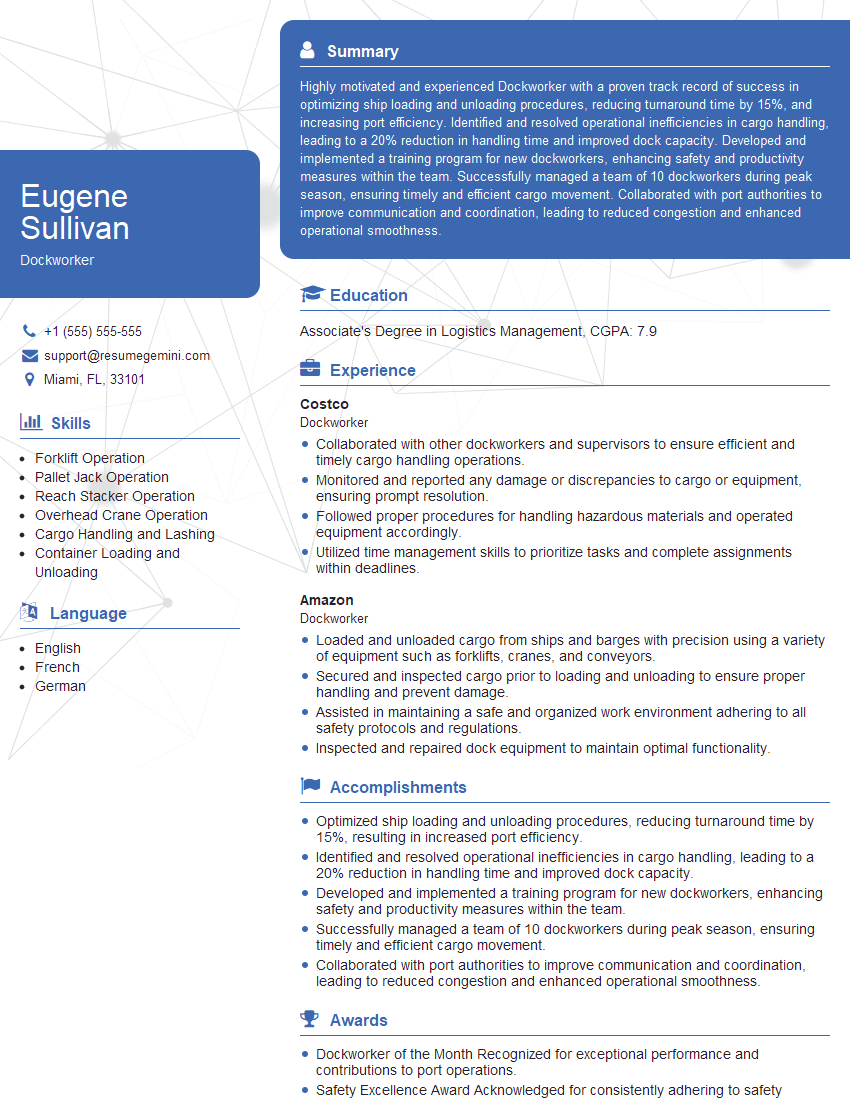

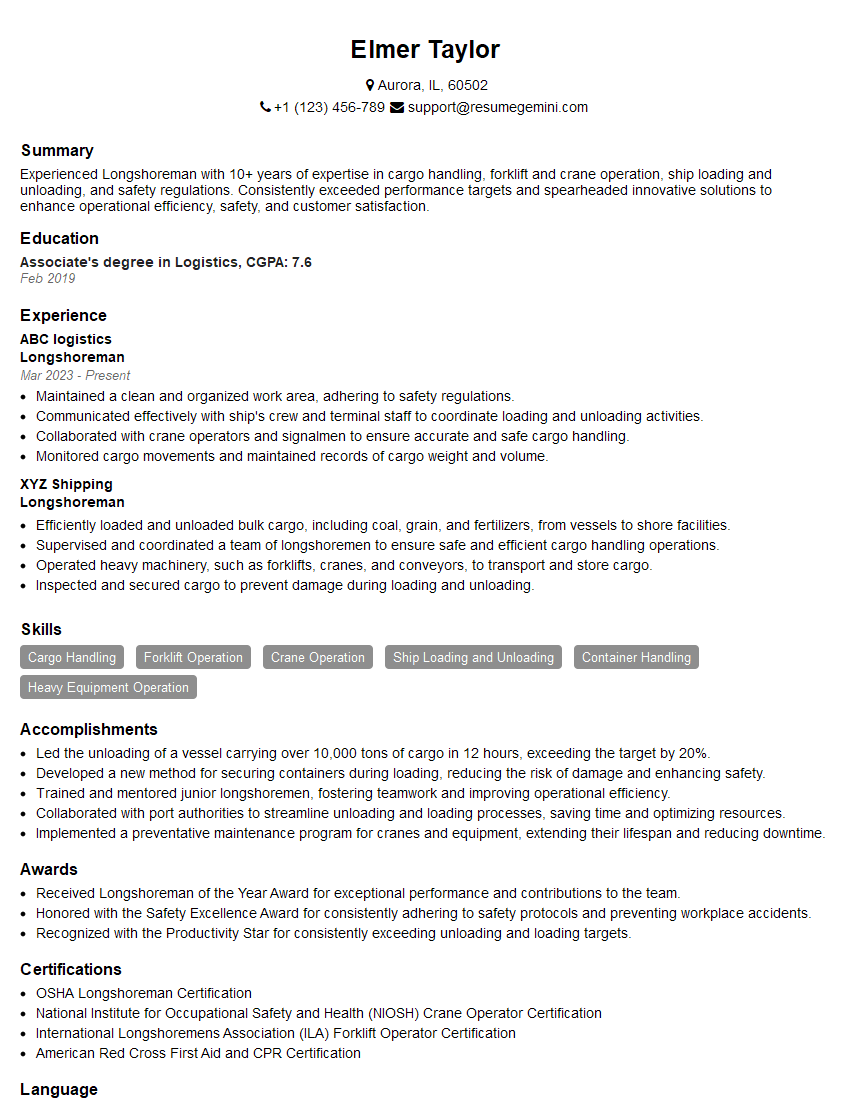

Mastering the skills involved in loading and unloading cargo ships and vessels opens doors to exciting career opportunities within the maritime industry, offering potential for growth and advancement. To maximize your job prospects, it’s crucial to present your qualifications effectively. Building an ATS-friendly resume is key to getting your application noticed by potential employers. We strongly recommend using ResumeGemini to create a professional and impactful resume that showcases your skills and experience. ResumeGemini provides examples of resumes tailored to Loading and Unloading Cargo Ships and Vessels to help you get started. Invest in your future – build a winning resume with ResumeGemini today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good