Are you ready to stand out in your next interview? Understanding and preparing for Loading and Unloading Freight interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Loading and Unloading Freight Interview

Q 1. Describe your experience with different types of freight (e.g., palletized, loose, oversized).

My experience encompasses a wide range of freight types. I’ve handled palletized goods extensively, from delicate electronics meticulously secured on pallets to heavier construction materials stacked and shrink-wrapped for stability. Loose freight, like sacks of grain or barrels of chemicals, requires different handling and securing methods. I’ve also worked with oversized cargo, including large machinery or industrial equipment, demanding specialized loading techniques and potentially requiring permits and escorts for transport. For example, during one project involving the transport of a large transformer, we utilized a custom-built cradle and heavy-duty straps to secure it to the lowboy trailer, carefully monitoring weight distribution to prevent instability. The handling of each type necessitates adapting procedures to ensure safety and prevent damage.

Q 2. Explain your understanding of proper loading techniques to prevent damage.

Proper loading techniques are crucial for preventing damage and ensuring safe transport. It starts with assessing the cargo – its weight, dimensions, fragility, and any special handling requirements. Then, we prioritize weight distribution, ensuring the load is balanced to prevent tipping or shifting during transit. For palletized goods, this means properly stacking pallets, interleaving with appropriate dunnage (protective material) if needed. For loose cargo, we often use bracing and dividers to prevent shifting. Imagine transporting fragile glassware – proper padding and separation are vital to preventing breakage. Oversized items need careful positioning and secure fastening, often involving tie-downs and specialized equipment. We always prioritize securing the load to prevent movement; this is often achieved through various techniques such as using straps, chains, and wedges.

Q 3. How do you prioritize tasks when handling multiple shipments simultaneously?

When juggling multiple shipments, prioritization is key. I use a system that combines urgency, delivery deadlines, and cargo fragility. Time-sensitive deliveries naturally take precedence. However, fragile or perishable goods also demand immediate attention to prevent spoilage or damage. I often employ a Kanban-like system, visually tracking shipments and their progress, allowing for easy identification of bottlenecks. For instance, a rush order for medical supplies would take precedence over a less urgent shipment of building materials. This systematic approach avoids delays and ensures that all goods are handled efficiently and effectively.

Q 4. What safety measures do you follow while loading and unloading freight?

Safety is paramount in my work. Before starting, I always inspect the loading area for hazards, ensuring clear walkways and proper lighting. I adhere strictly to the regulations regarding weight limits and load distribution. Personal protective equipment (PPE), including safety shoes, gloves, and high-visibility vests, is always worn. I ensure the proper operation and maintenance of all equipment used, from forklifts to hand trucks. If working at heights, harnesses and fall protection are employed. Furthermore, team briefings ensure everyone is aware of the loading plan and potential risks. Communication is key; clear hand signals and verbal communication during loading/unloading operations are crucial to avoid accidents.

Q 5. Describe your experience using loading equipment (e.g., forklifts, pallet jacks).

I’m proficient in operating various loading equipment, including forklifts, pallet jacks, and reach trucks. I possess the necessary certifications and have consistently demonstrated safe operation practices. My experience includes handling different types of forklifts (e.g., sit-down, stand-up), adapting to the specific requirements of the cargo and the loading environment. For instance, I’ve used reach trucks in high-bay warehouses to access and retrieve goods from various levels. Regular maintenance checks and adherence to safety protocols are always followed. The efficient use of these machines significantly improves the speed and accuracy of loading and unloading operations.

Q 6. How do you ensure the accuracy of inventory during loading and unloading?

Accurate inventory is maintained through a combination of methods. We start with pre-loading verification, meticulously checking the shipment manifest against the actual goods. Throughout the loading and unloading process, I conduct visual checks and use barcode scanners to track items, ensuring that every piece is accounted for. Discrepancies are immediately reported and resolved. Post-loading checks verify that everything on the manifest has been loaded and that the load is secure. This systematic approach minimizes errors and ensures the integrity of the inventory. In cases with particularly valuable or sensitive goods, a witness or a second person may conduct a cross-check.

Q 7. What is your experience with different types of packaging and securing methods?

My experience encompasses a wide variety of packaging and securing methods. I’m familiar with various types of packaging, from simple cardboard boxes to specialized crates designed for fragile or oversized items. Securing methods depend on the cargo’s nature and the mode of transport. For example, I utilize stretch wrap for palletized goods, ensuring they remain secure and prevent shifting. For heavier items, I use straps, chains, or even specialized dunnage systems to prevent movement. Understanding the strengths and limitations of each packaging and securing method is crucial for effective damage prevention. Improper packaging or insufficient securing can lead to losses during transit. Therefore, selection is always based on the goods’ characteristics and the demands of the journey.

Q 8. How do you handle damaged or incorrect freight?

Handling damaged or incorrect freight begins with meticulous inspection. Upon receiving a shipment, I thoroughly check the packaging for any visible damage – dents, tears, or punctures. I then compare the physical goods with the accompanying documentation (bill of lading, packing list) to verify quantity and item descriptions. Discrepancies are immediately documented using a standardized damage report form. This report includes photos and detailed descriptions of the damage, the quantity affected, and the condition of the packaging.

If damage is discovered, I follow established procedures which often involve notifying the shipping company and the receiving party. Depending on the severity, the next steps may include: rejecting the entire shipment, accepting the shipment with a damage claim, or conducting a partial acceptance after separating damaged from undamaged goods. I’ve had to handle situations where pallet damage compromised the contents, requiring careful unpacking and documentation of every affected item. In other instances, incorrect items were delivered – for example, receiving red widgets instead of blue widgets. In these cases, the documented report is crucial to expediting the return and replacement process. The objective is to minimize disruption and ensure the recipient receives the correct goods in the best possible condition.

Q 9. Describe your experience with warehouse management systems (WMS).

My experience with Warehouse Management Systems (WMS) is extensive. I’ve worked with several systems, including [mention specific WMS software if comfortable, otherwise omit], and I’m proficient in using them to manage inventory, track shipments, and optimize warehouse operations. A WMS is more than just software; it’s a tool that significantly streamlines the loading and unloading processes. For instance, I use WMS to generate accurate picking lists, ensuring that the correct items are retrieved efficiently from designated storage locations. This directly impacts loading times and reduces the risk of errors. Further, WMS allows me to track the real-time location of goods within the warehouse, which is crucial for managing incoming and outgoing shipments and resolving any discrepancies quickly. I’m comfortable with features like barcode scanning, radio frequency identification (RFID) technology integration, and generating reports for inventory management and operational analysis. A well-utilized WMS is vital for minimizing errors, maximizing space utilization, and ensuring efficient flow of goods.

Q 10. Explain your understanding of shipping documentation and procedures.

Shipping documentation is the backbone of the freight industry. I’m intimately familiar with various documents, including bills of lading, packing lists, commercial invoices, certificates of origin, and customs documentation. The bill of lading acts as a contract between the shipper, carrier, and consignee. The packing list details the contents of each package with descriptions, quantities, and weights. These documents are critical for accurate tracking and inventory management throughout the entire shipping process.

My understanding extends to the procedures involved in handling these documents. I meticulously verify the accuracy of information on each document to ensure it matches the physical goods being loaded or unloaded. Discrepancies are immediately reported to avoid delays and potential problems. For international shipments, I am especially careful with customs declarations and related documentation, understanding the necessity of accurate information to avoid delays or customs penalties. I’ve been personally involved in resolving discrepancies in shipping documents and successfully guided shipments through international customs by ensuring the documentation was both accurate and complete.

Q 11. How do you maintain a clean and organized work area?

Maintaining a clean and organized work area is non-negotiable in the freight industry. It’s a safety issue and an efficiency booster. My approach involves several key strategies:

- 5S Methodology: I apply the 5S methodology – Sort, Set in Order, Shine, Standardize, and Sustain – to systematically organize the workspace. This involves regularly removing unnecessary items, placing frequently used tools within easy reach, and regularly cleaning the area to eliminate debris and potential hazards.

- Designated Areas: I ensure that all materials and equipment have designated storage locations. This helps prevent clutter and ensures that items are easily accessible when needed.

- Regular Cleaning: At the end of each shift, I meticulously sweep, remove debris, and tidy the work area. This reduces the risk of accidents caused by slippery surfaces or tripping hazards.

- Communication: I regularly communicate with colleagues to maintain a shared understanding of organization and cleanliness standards.

A well-organized workspace isn’t just visually appealing; it improves efficiency by minimizing the time spent searching for tools and materials. It also creates a safer environment, significantly reducing the risk of accidents.

Q 12. Describe your experience with different types of transportation vehicles.

My experience encompasses various types of transportation vehicles commonly used in freight handling. This includes:

- Semi-trailer trucks: I’m proficient in loading and unloading goods onto and from various types of semi-trailers, including dry vans, refrigerated trailers (reefers), and flatbeds. I understand the importance of proper weight distribution and securing cargo to prevent damage during transit.

- Box trucks: I have experience with loading and unloading goods from box trucks of various sizes, adept at maneuvering items within the confined space efficiently and safely.

- Railcars: I’ve worked with loading and unloading freight from railcars, understanding the specific safety protocols required for this type of operation.

- Intermodal containers: I have hands-on experience loading and unloading goods into and out of various sizes of shipping containers, both for domestic and international shipments. Understanding how to secure the goods inside the containers and verifying their condition is a key focus.

My experience extends to knowing the limitations and capabilities of each vehicle type, ensuring that the right vehicle is used for the right shipment, to maximize efficiency and safety.

Q 13. How do you comply with safety regulations during loading and unloading?

Safety is paramount during loading and unloading operations. I meticulously adhere to all relevant safety regulations and company policies. This includes:

- Proper Lifting Techniques: I always use proper lifting techniques to prevent injuries. This includes bending at the knees, keeping the back straight, and using appropriate lifting equipment when necessary.

- Personal Protective Equipment (PPE): I consistently wear appropriate PPE, such as safety shoes, gloves, and high-visibility vests, to protect myself from potential hazards.

- Safe Equipment Operation: I’m trained in the safe operation of various pieces of equipment, such as forklifts, pallet jacks, and hand trucks, and I always follow the manufacturer’s instructions and safety protocols.

- Load Securing: I carefully secure all loads to prevent them from shifting during transit. This includes using appropriate straps, chains, and other securing devices.

- Hazard Awareness: I’m vigilant about identifying and avoiding potential hazards, such as uneven surfaces, obstacles, and heavy traffic.

Regular safety training and refresher courses ensure my knowledge remains current and my practices are aligned with the best safety practices within the industry. I always report any unsafe conditions to my supervisor immediately.

Q 14. How do you identify and address potential hazards in the loading/unloading process?

Identifying and addressing potential hazards is a proactive approach to safety. My hazard identification process involves a systematic approach:

- Pre-shift Inspection: Before starting any loading or unloading activity, I conduct a thorough inspection of the work area to identify any potential hazards such as damaged flooring, uneven surfaces, debris, or poorly stacked pallets.

- Equipment Checks: I inspect all equipment to ensure it is in good working order and properly maintained, before commencing operations.

- Load Assessment: I assess the load to identify any potential instability issues. This includes evaluating the weight, size, and distribution of the goods.

- Environmental Factors: I consider environmental factors such as weather conditions (rain, snow, ice) which may increase the risk of slips, trips, or falls.

- Traffic Management: I ensure that adequate measures are in place to control traffic flow in the loading/unloading area to prevent accidents involving vehicles or pedestrians.

Once a hazard is identified, I take immediate action to mitigate the risk. This might involve reporting the hazard to my supervisor, temporarily halting operations, or implementing immediate corrective actions like cleaning up spills or using proper safety equipment. My goal is to create a hazard-free work environment.

Q 15. How do you communicate effectively with drivers and other warehouse personnel?

Effective communication is the cornerstone of a smoothly functioning loading and unloading operation. I prioritize clear, concise, and respectful communication with drivers and warehouse personnel. This involves active listening, ensuring I understand their needs and concerns, and using appropriate language and tone. For example, when a driver arrives with a late delivery, I avoid accusatory language and instead focus on collaboratively finding a solution, such as prioritizing their unloading to minimize further delays. With warehouse staff, I use a combination of verbal instructions, visual aids like loading manifests, and written checklists to ensure tasks are understood and completed accurately. Regular team briefings keep everyone informed of priorities and potential challenges. Open communication fosters a collaborative environment and prevents misunderstandings, reducing the likelihood of errors and delays.

- Active Listening: Truly hearing what the other person is saying and asking clarifying questions.

- Clear Instructions: Providing simple, unambiguous instructions, avoiding jargon.

- Visual Aids: Using diagrams or maps to clarify locations or processes.

- Regular Feedback: Providing constructive feedback and acknowledging good work.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with handling hazardous materials.

Handling hazardous materials requires meticulous attention to detail and strict adherence to safety regulations. In my previous role, I was trained and certified in the handling and transportation of various hazardous materials, including Class 1 explosives and Class 3 flammable liquids. My experience encompasses the entire process, from receiving and inspecting shipments for damage or leaks to safely unloading, storing, and loading them according to proper protocols. This includes using appropriate personal protective equipment (PPE), such as respirators, gloves, and safety glasses. We used specialized equipment, such as spill containment kits and forklifts equipped for hazardous materials handling. I’m proficient in completing all required documentation, including Safety Data Sheets (SDS) review and shipping manifests, meticulously tracking and managing the movement of these materials. For instance, I once prevented a potential accident by noticing a damaged container of flammable liquid and immediately isolating it, reporting the issue to the supervisor, and initiating the necessary containment procedures. Safety is paramount; proper handling procedures are not just a guideline, but the absolute cornerstone of safe operations.

Q 17. How do you manage time effectively to meet deadlines?

Time management is crucial in freight handling. I utilize several strategies to ensure deadlines are met. First, I prioritize tasks based on urgency and importance, using techniques like the Eisenhower Matrix (urgent/important). This allows me to focus on the most critical tasks first. Next, I create detailed schedules and checklists, breaking down large tasks into smaller, manageable steps. I also incorporate buffer time into my schedule to account for unexpected delays or issues. Proactive communication with drivers and warehouse staff keeps everyone informed of timelines and potential roadblocks, facilitating collaborative problem-solving. For example, if I anticipate a backlog, I’ll communicate with drivers to coordinate arrivals, ensuring a smooth workflow. Regular monitoring of progress allows for timely adjustments if needed. Technology plays a vital role; I’m proficient in using warehouse management systems (WMS) to track inventory and shipments, providing real-time visibility into the process and streamlining operations.

Q 18. What is your experience with inventory management techniques?

My experience encompasses various inventory management techniques, including FIFO (First-In, First-Out), LIFO (Last-In, First-Out), and FEFO (First-Expired, First-Out). The choice of method depends on the nature of the goods. For perishable goods, FEFO is essential. For non-perishable items, FIFO ensures that older stock is moved out first, minimizing storage costs and waste. I’m skilled in using barcode scanners, RFID technology, and WMS software to accurately track inventory levels, monitor stock rotation, and identify discrepancies. Accurate inventory control reduces waste, prevents stockouts, and improves operational efficiency. For example, by implementing FIFO for non-perishable items, we reduced our storage costs by 15% and minimized the risk of obsolescence. I also regularly conduct cycle counts to verify inventory accuracy, and I’m adept at investigating and resolving any discrepancies found during these counts.

Q 19. How do you adapt to changing work priorities?

Adaptability is essential in this fast-paced environment. I approach changing priorities by staying organized and maintaining clear communication. I prioritize tasks based on the new information, using effective time management to re-allocate resources efficiently. Flexibility is key; I’m comfortable shifting between tasks and responsibilities as needed to support the team’s overall objectives. For instance, if an urgent shipment requiring immediate handling arrives, I prioritize it while still maintaining overall workflow efficiency. This involves adjusting the schedule, coordinating with team members, and possibly communicating with clients about potential delays or adjustments to the original plan. I see change not as a disruption, but as an opportunity to demonstrate problem-solving skills and enhance operational efficiency.

Q 20. How do you handle stressful situations during peak periods?

Peak periods bring increased pressure, but I handle stress effectively by maintaining a calm and organized approach. I prioritize tasks based on urgency, focusing on one task at a time to avoid feeling overwhelmed. Clear communication with my team prevents confusion and allows for collaborative problem-solving. I also take short breaks to regroup and maintain focus. Prior planning and preparedness are vital; anticipating peak demands and having contingency plans in place minimizes stress during these critical times. For instance, I ensure that extra personnel are available during peak seasons and that all equipment is in optimal working order. This proactive approach helps mitigate potential bottlenecks and keeps the operation running smoothly, even under pressure.

Q 21. Explain your knowledge of weight limitations and load capacity.

Understanding weight limitations and load capacity is paramount for safety and legal compliance. I am familiar with weight restrictions for vehicles, loading docks, and storage areas. I utilize scales and load-bearing indicators to ensure that loads are within safe limits. This includes considering weight distribution to prevent overloading or imbalance. I am knowledgeable about various types of vehicles and their load capacities. For example, I know the difference in weight limits between a standard box truck and a flatbed trailer. I also understand the importance of securing loads properly to prevent shifting during transit, adhering to regulations like those set by the Department of Transportation. Failure to comply with weight limits can lead to accidents, damage to equipment, and significant financial penalties, and I always prioritize safe and legal operations.

Q 22. How familiar are you with load securing techniques and regulations?

Load securing is paramount to safe and efficient freight transport. My familiarity extends to both the practical application of various securing techniques and a deep understanding of the regulations governing them. I’m well-versed in regulations like those from the Department of Transportation (DOT) and other international standards.

This includes understanding different types of cargo and choosing appropriate securing methods. For example, loose cargo might require the use of dunnage (protective material like airbags or wood blocks) and proper strapping, while palletized goods may necessitate secure wrapping and anti-slip mats. I understand the importance of weight distribution to prevent shifting during transit.

- Understanding Different Securing Methods: I’m proficient in using straps, chains, nets, and other securing devices, always ensuring they are correctly tensioned and properly fastened.

- Regulations & Compliance: I’m meticulous about adhering to all relevant regulations, ensuring documentation is complete and accurate for auditing purposes. This includes understanding weight limits, securing requirements based on the type of vehicle, and proper labeling.

- Risk Assessment: Before securing any load, I conduct a thorough risk assessment considering factors like the type of cargo, the distance it will be transported, and the weather conditions.

Q 23. How do you ensure proper documentation of freight movements?

Proper documentation is crucial for tracking freight and managing liability. My approach involves a multi-step process starting from the initial order. This ensures traceability and accountability throughout the entire process.

- Bill of Lading (BOL): Accurate and complete BOLs are essential, verifying shipment details, including sender and receiver information, cargo description, weight, and quantity. I always double-check this critical document.

- Shipping Manifest: I carefully create and maintain a shipping manifest, listing all items in a shipment, their quantities, and weights. This acts as an internal tracking tool and helps in quicker reconciliation of discrepancies.

- Proof of Delivery (POD): Obtaining and securely filing PODs is a priority. Electronic POD systems are preferred as they provide a clear audit trail.

- Damage Reports: In case of damage, comprehensive damage reports with photographic evidence are created and documented for insurance claims and inventory management.

I use digital tools to manage and store this documentation, ensuring easy access and efficient retrieval when needed. This approach also assists in compliance auditing.

Q 24. What experience do you have with different types of loading docks and equipment?

My experience encompasses a variety of loading dock configurations and equipment. I’ve worked with level docks, dock shelters, and various types of loading ramps, and I’m familiar with their operational characteristics and safety procedures.

- Dock Levelers: I’m adept at safely operating dock levelers, ensuring they are correctly positioned and secured before loading or unloading begins. This prevents accidents and damage to both equipment and goods.

- Forklifts and Pallet Jacks: I’m certified to operate forklifts and pallet jacks, adhering strictly to safety protocols. I understand their limitations and the safe operating procedures within a warehouse or loading dock environment.

- Conveyors and Other Automated Systems: I have experience working with conveyor systems and other automated loading/unloading equipment, understanding their functions and the need for careful monitoring for optimal efficiency and safety.

I adapt quickly to different setups and am always focused on maximizing efficiency and safety, regardless of the equipment being used.

Q 25. Describe a time you resolved a loading/unloading problem.

During a particularly busy holiday season, a shipment of perishable goods arrived with improper temperature controls, causing a significant portion of the cargo to spoil. This threatened major losses for the client. My initial response involved calmly assessing the situation, contacting the client immediately, and initiating a damage assessment. We quickly isolated the affected goods, taking photographs as evidence.

Simultaneously, I contacted our transport partner to initiate an investigation into the temperature control failure. In collaboration with the client, we decided to prioritize the remaining viable goods for immediate delivery, implementing emergency rerouting to minimize further spoilage. The lost goods were documented, and a claim was promptly initiated with the carrier.

The situation highlighted the need for robust contingency plans. We implemented better real-time temperature monitoring systems after the incident, to prevent future occurrences and enhance operational efficiency.

Q 26. How would you handle a situation where a shipment is missing or damaged?

Handling missing or damaged shipments requires a systematic approach focusing on investigation, documentation, and communication.

- Immediate Assessment: Upon detection, I immediately assess the extent of the damage or the specifics of the missing items, taking detailed notes and photographs.

- Investigation: I thoroughly investigate potential causes, reviewing loading and unloading procedures, transport documentation, and potentially security footage. This is crucial for determining responsibility and initiating claims if necessary.

- Documentation: I create detailed reports of the damage or missing items, including photographic evidence, weights, and any other relevant information. This documentation is vital for insurance claims and reconciliation with the client.

- Communication: Timely and transparent communication with the client, transportation company, and any other relevant parties is essential. I promptly inform them of the issue, and the steps I’m taking to resolve it.

- Claim Management: If necessary, I meticulously prepare and submit insurance claims, providing all necessary documentation to expedite the process.

My goal is to resolve the issue efficiently, minimizing disruption to the client and recovering any potential losses.

Q 27. What are your salary expectations for this position?

My salary expectations are in line with the market rate for this position, considering my experience and skills. I’m open to discussing a competitive compensation package that reflects my value to the company.

Q 28. What are your long-term career goals?

My long-term career goals involve progressing to a supervisory or managerial role within logistics and supply chain management. I’m eager to further develop my expertise in optimizing freight handling processes and contributing to overall operational efficiency. My commitment to safety and continuous improvement makes me confident in my ability to take on increased responsibilities.

Key Topics to Learn for Loading and Unloading Freight Interview

- Safety Regulations and Procedures: Understanding and adhering to OSHA regulations, proper lifting techniques, and hazard identification to ensure a safe work environment. Practical application includes demonstrating knowledge of load securing methods and equipment operation.

- Freight Handling Techniques: Mastering efficient loading and unloading procedures for various types of freight (pallets, boxes, containers, etc.), including understanding weight distribution and balance. Practical application includes describing experience with different types of loading equipment (forklifts, hand trucks, etc.) and optimizing space utilization within vehicles.

- Inventory Management and Documentation: Accurately recording freight details, tracking inventory, and verifying load manifests. Practical application includes demonstrating experience with inventory management software or systems, and detailing experience with accurate record-keeping and reporting.

- Logistics and Transportation Knowledge: Understanding the overall supply chain, transportation modes (truck, rail, ship), and the importance of on-time delivery. Practical application includes describing experience with route planning, scheduling, or dispatching.

- Problem-Solving and Adaptability: Addressing unexpected challenges such as damaged goods, delays, or equipment malfunctions. Practical application includes describing a past situation where you had to solve a problem related to freight handling and explain the steps you took.

- Teamwork and Communication: Working effectively with colleagues, supervisors, and clients to ensure smooth operations. Practical application includes showcasing your ability to communicate clearly and efficiently in a team environment.

Next Steps

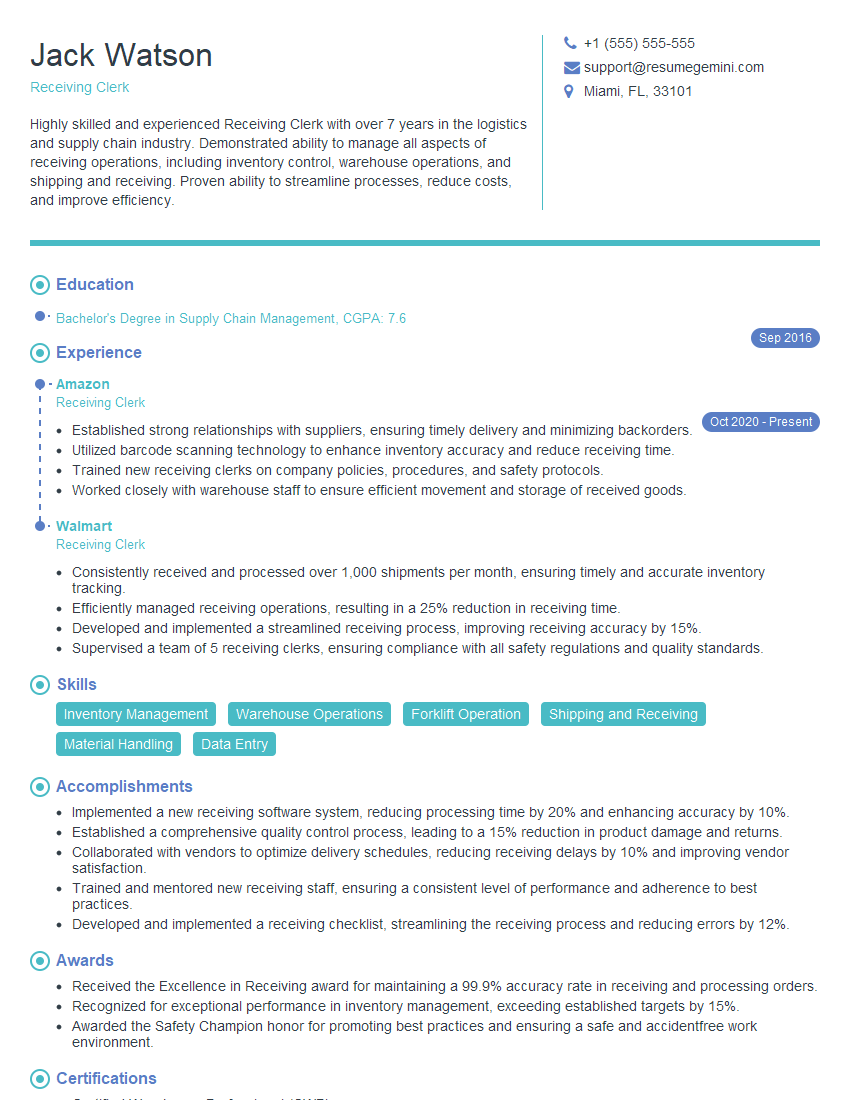

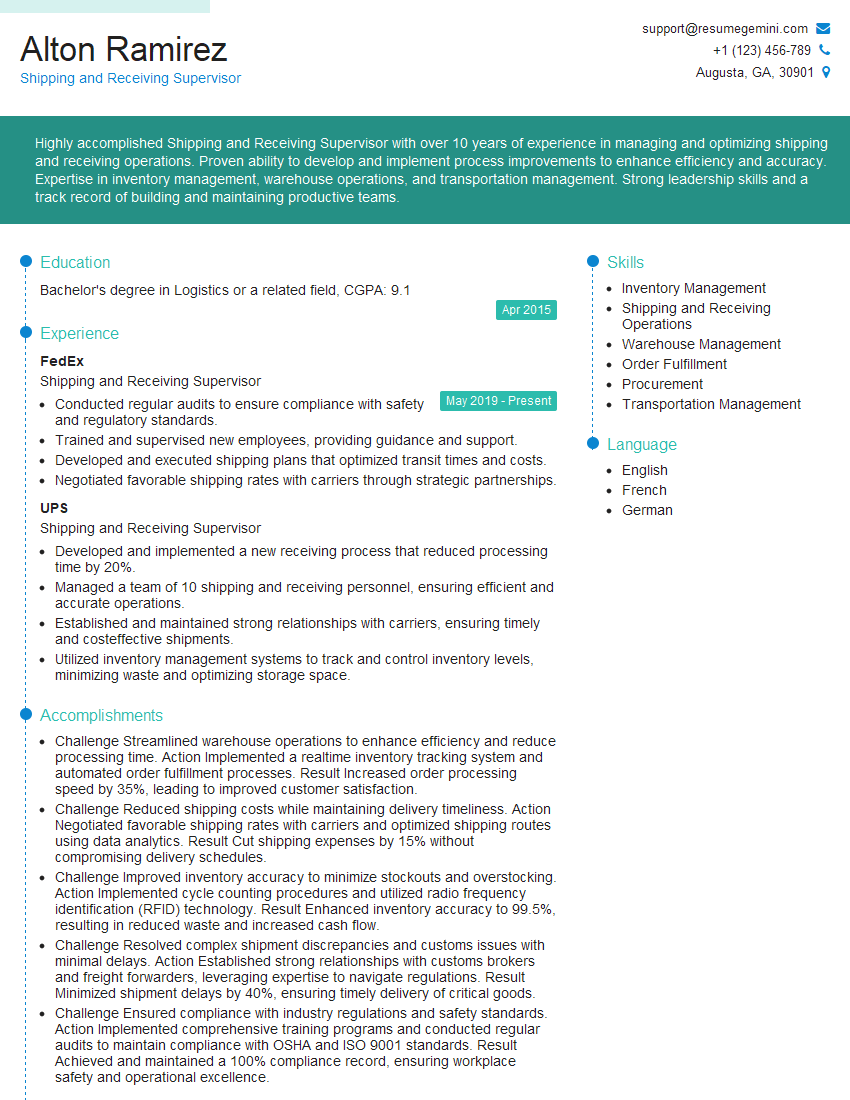

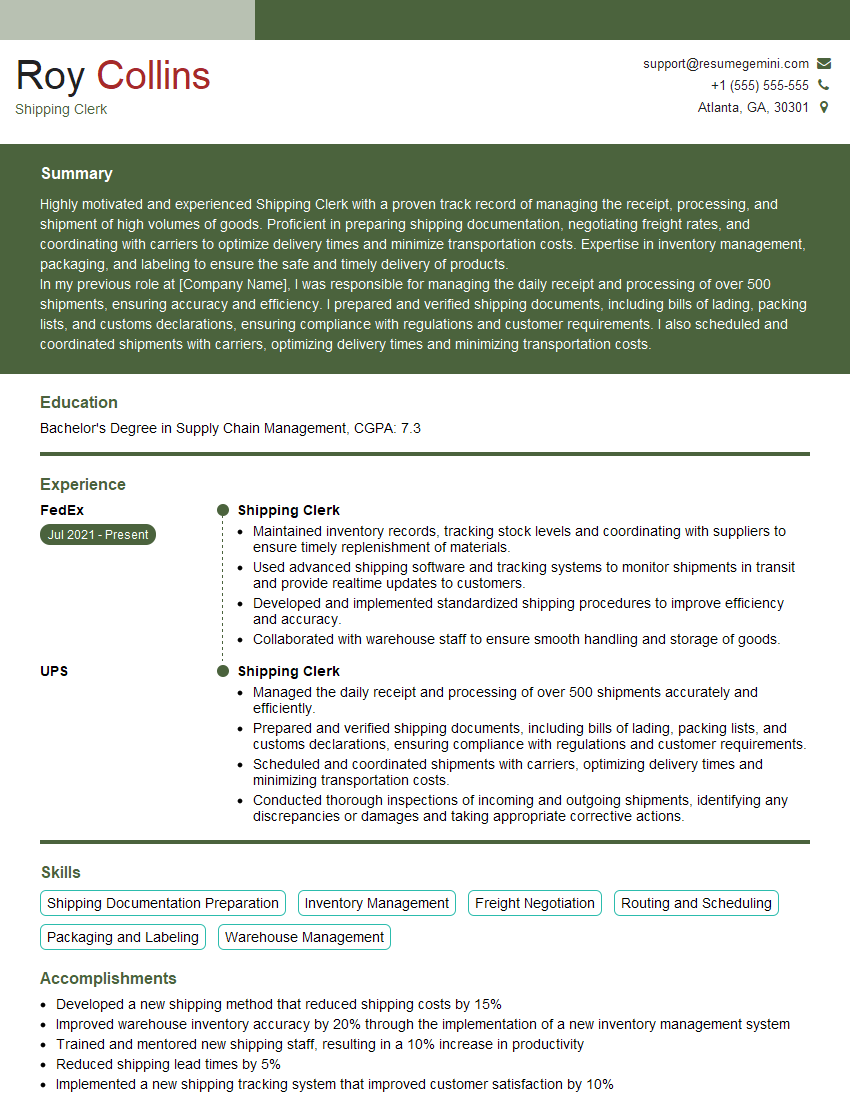

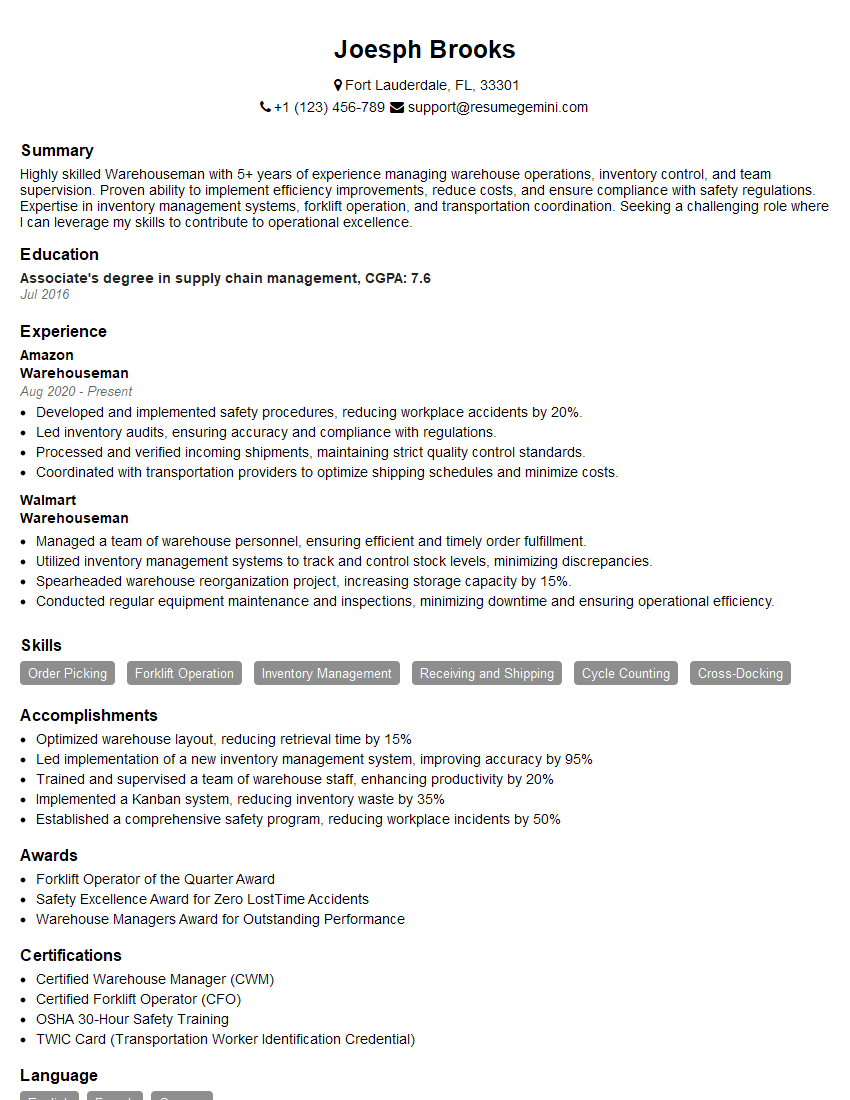

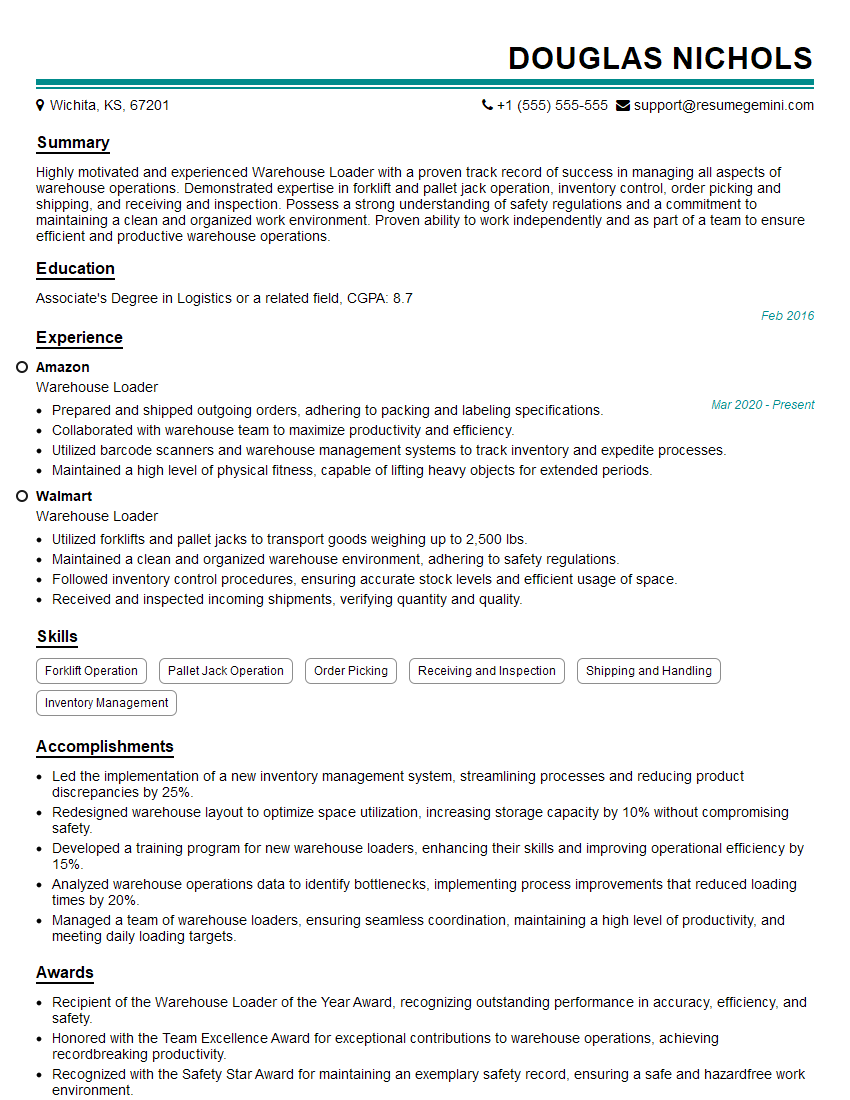

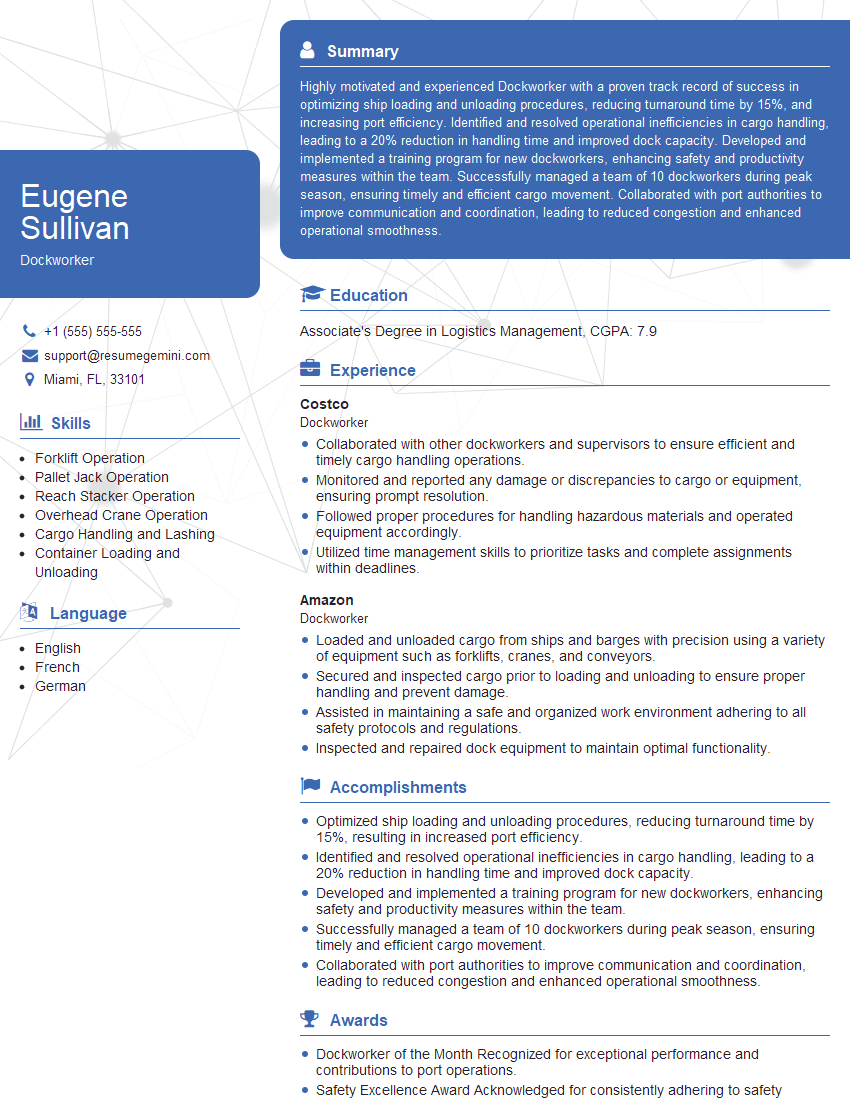

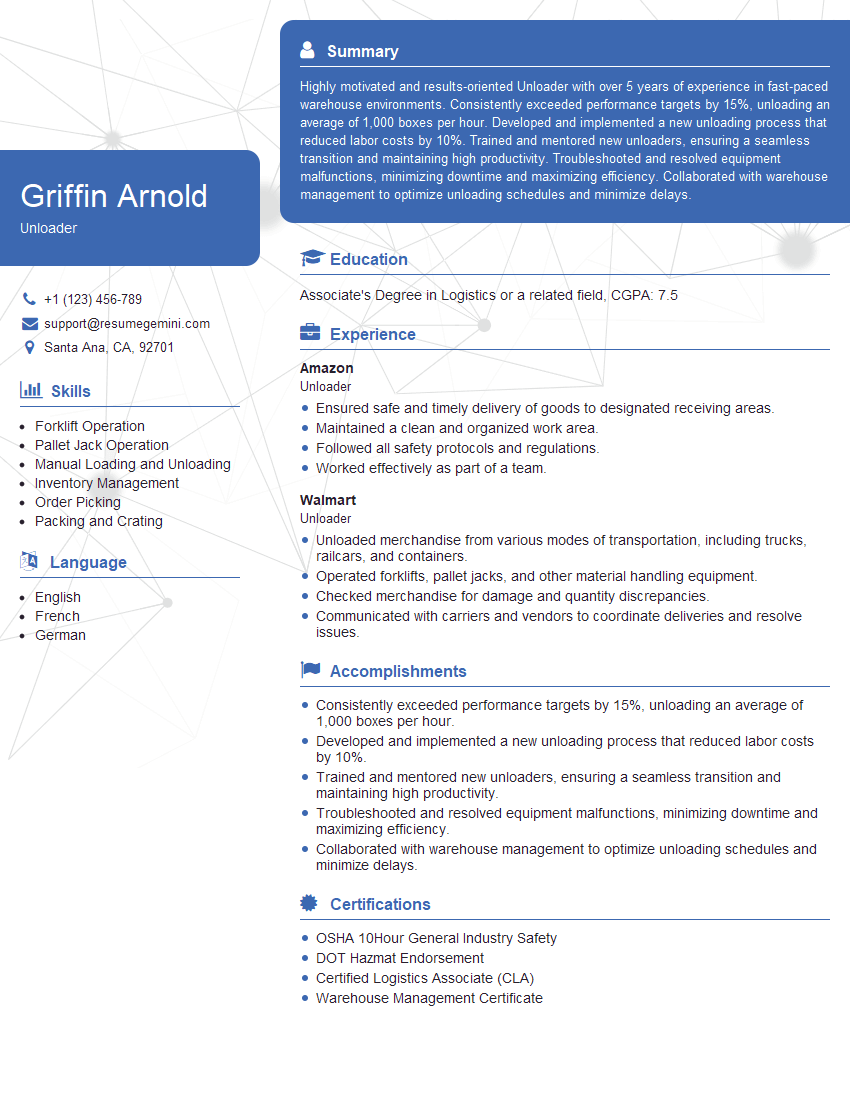

Mastering loading and unloading freight skills opens doors to diverse career paths within logistics, warehousing, and transportation, offering opportunities for advancement and increased earning potential. An ATS-friendly resume is crucial for getting your application noticed by potential employers. ResumeGemini can help you craft a compelling resume that highlights your skills and experience effectively, maximizing your chances of landing your dream job. Examples of resumes tailored to Loading and Unloading Freight are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good