Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Loading and unloading pallets interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Loading and unloading pallets Interview

Q 1. Describe your experience with pallet jack operation.

My experience with pallet jacks spans over eight years, encompassing various warehouse settings and product types. I’m proficient in operating both manual and electric pallet jacks, understanding their limitations and capabilities. I’ve used them extensively for tasks such as moving and stacking pallets, loading and unloading trucks, and transferring goods within a warehouse. I am comfortable navigating tight spaces and uneven surfaces with these machines and regularly perform pre-operational checks to ensure they are safe and functioning correctly.

For instance, in my previous role, we used electric pallet jacks to move heavy pallets of machinery components. My skill in precise maneuvering allowed us to avoid damage to the delicate equipment and ensure smooth workflow. In another instance, I utilized manual pallet jacks in a smaller warehouse where electric jacks weren’t feasible due to space constraints. I’m adept at adapting my technique based on the situation and the type of pallet jack available.

Q 2. What safety precautions do you take when loading/unloading pallets?

Safety is paramount in pallet loading and unloading. My safety precautions begin with a thorough pre-shift inspection of the equipment – checking for damage to the pallet jack and ensuring the load area is clear of obstructions. I always wear appropriate safety gear, including steel-toed boots and high-visibility vests. I follow proper lifting techniques to avoid strains or injuries, and I ensure all loads are stable and properly secured.

- Proper Lifting: I never lift beyond my capacity and utilize lifting aids like pallet jacks whenever possible.

- Clear Pathways: Maintaining clear pathways prevents accidents caused by tripping hazards.

- Load Securing: I use appropriate straps or other securing devices to prevent shifting loads during transit.

- Awareness of Surroundings: I am constantly aware of my surroundings, especially when operating a pallet jack in busy areas.

- Following Company Policies: I strictly adhere to all company safety policies and regulations.

For example, I once noticed a loose floorboard in a loading dock. I immediately reported it and avoided using that area until it was repaired, preventing a potential accident. Safety isn’t just about following rules, it’s about proactively identifying and mitigating risks.

Q 3. How do you ensure pallet stability during transportation?

Pallet stability during transportation is crucial. I achieve this through careful stacking and securing. The weight distribution is key; heavier items should be placed on the bottom and lighter ones on top. Pallets must be uniformly loaded, avoiding any overhang. In addition, I use appropriate strapping, shrink wrap, or other securing devices to bind the load tightly, preventing shifting during transport.

The choice of securing method depends on the type of goods being transported. For instance, fragile items might require additional padding and more robust securing methods compared to heavier, less delicate goods. Regular checks during loading and transport are important to ensure everything remains stable.

Think of it like building a tower of blocks – a stable base and even distribution are vital. A poorly balanced load is a recipe for disaster, potentially resulting in damage to goods, equipment, or even injuries.

Q 4. What are the different types of pallets you have worked with?

Throughout my career, I have worked with various pallet types, including:

- Standard Wood Pallets: The most common, made from wood, offering varying sizes and load capacities.

- Plastic Pallets: Reusable, durable, and often easier to clean than wooden pallets. These are frequently used in the food industry.

- Metal Pallets: Extremely durable and heavy-duty, ideal for very heavy loads and harsh environments.

- Gable-top Pallets: With side supports for better stability, suitable for taller or less stable items.

My familiarity with these different pallet types allows me to choose the most appropriate one for a given load and situation. Understanding the strength and structural integrity of each type is essential to prevent damage and ensure safe handling.

Q 5. Explain the proper procedure for stacking pallets.

The proper procedure for stacking pallets involves several steps to guarantee safety and stability. First, ensure a firm, level surface. Next, I start with the heaviest pallet at the bottom, then stack progressively lighter ones on top. Pallet orientation should be consistent to maintain stability. I avoid any overhanging loads and ensure that no pallet is damaged or compromised before stacking. Never stack pallets higher than the designated height limits set by the warehouse or applicable regulations.

Think of it like building a brick wall – a solid foundation and even layering are essential for preventing collapse. Improper stacking can cause serious accidents, damage to goods, and potential injuries.

Q 6. How do you identify damaged pallets?

Identifying damaged pallets is a crucial aspect of safety and efficiency. I look for:

- Broken Boards: Splintered, cracked, or broken wooden boards significantly reduce the pallet’s structural integrity.

- Loose Nails or Staples: These create hazards and can weaken the structure.

- Damaged Stringers: Broken or damaged stringers (the horizontal supports) compromise the pallet’s ability to bear weight.

- Staining or Rot: Indicates potential damage from moisture, making the pallet weaker and prone to collapse.

- Significant Wear and Tear: Overly worn or damaged pallets are unsafe and shouldn’t be used.

If a pallet shows any of these signs, I immediately tag it as damaged and remove it from use. Using a damaged pallet is a significant safety risk.

Q 7. What is your experience with different types of wrapping materials for pallets?

I have experience with several types of pallet wrapping materials, each suited for different needs:

- Shrink Wrap: A plastic film that shrinks tightly when heated, providing excellent protection from moisture and dust. It’s effective for securing goods but can be less effective for unusually shaped loads.

- Stretch Wrap: A more versatile option that stretches over the pallet to secure the load. It can easily accommodate irregularly shaped loads and offers various thicknesses based on load requirements.

- Strapping: Steel or plastic straps provide strong, secure binding, suitable for heavy or large loads.

The choice of wrapping material depends on factors such as load size, weight, fragility, and environmental conditions. For instance, in humid climates, shrink wrap might be preferred to protect against moisture, while stretch wrap is more adaptable for mixed or odd-shaped pallets.

Q 8. How do you handle discrepancies between the physical pallets and the order?

Discrepancies between the physical pallets and the order are a common occurrence in warehousing. My approach involves a methodical process to identify and resolve the issue. First, I carefully compare the physical pallet count and contents against the accompanying paperwork (e.g., packing slip, delivery note, WMS information). I meticulously check each item’s SKU (Stock Keeping Unit) and quantity against the order details.

- Short shipments: If items are missing, I immediately report this to my supervisor and the relevant shipping department. I’ll document the discrepancy with photographs and detailed notes. We then initiate a process to trace the missing items, possibly contacting the supplier or checking internal inventory records.

- Over shipments: Extra items require similar diligence. I meticulously document the overage, verifying the items’ condition and ensuring they are properly stored pending investigation and resolution. This could involve coordinating with the receiving department to adjust inventory records.

- Damaged goods: Damaged goods are documented in detail (photographs, descriptions of the damage) and reported immediately. We follow established procedures for handling damaged goods, which might involve returning them to the supplier or initiating a claim for insurance purposes.

My experience shows that proactive documentation and clear communication are crucial in resolving discrepancies promptly and minimizing operational disruptions. Thoroughness is key to prevent future errors and ensure accuracy in inventory management.

Q 9. Describe your experience using a forklift (if applicable).

I hold a valid forklift license and possess extensive experience operating various forklift types, including sit-down, stand-up, and reach trucks. I’m proficient in all aspects of forklift operation, from pre-operational checks (ensuring functionality of brakes, lights, and hydraulics) to safe maneuvering in tight spaces.

Safety is always my top priority. Before every shift, I conduct a thorough pre-use inspection and adhere strictly to all safety regulations. I’m adept at navigating warehouse layouts, understanding the limitations of the forklift’s weight capacity, and operating smoothly alongside other equipment and personnel.

For instance, during peak season, I efficiently managed the movement of hundreds of pallets daily, prioritizing safety while maintaining a high throughput rate. My experience encompasses loading and unloading trucks, stacking pallets to optimized heights, and retrieving pallets from storage racks accurately and safely. I am skilled at using different forklift attachments such as clamp attachments for handling awkward loads.

Q 10. How do you prioritize tasks when handling multiple pallet loads simultaneously?

When handling multiple pallet loads simultaneously, effective prioritization is essential for optimizing efficiency and meeting deadlines. My approach focuses on several key factors:

- Urgency: I prioritize loads with the closest deadlines first. Time-sensitive orders for shipment or those needed immediately for production take precedence.

- Order size/complexity: Larger or more complex orders might require more time and resources and will be scheduled strategically to avoid bottlenecks.

- Location: I group tasks geographically to minimize travel time within the warehouse. For example, I might complete all loading tasks for one truck before moving to another area.

- Equipment availability: If I’m working with multiple forklifts or other equipment, I allocate tasks efficiently to make the best use of resources.

Visual aids like Kanban boards or digital task management systems can also aid in this process. The key is to develop a flexible yet structured approach to task management that can adapt to the dynamic demands of warehouse operations. The ultimate goal is to minimize delays, reduce errors and keep the workflow smooth.

Q 11. What is your understanding of load capacity and weight limits?

Understanding load capacity and weight limits is paramount for safety and preventing accidents. Every forklift, pallet rack, and even the warehouse floor has specific weight restrictions. I am meticulous in checking the weight capacity of each piece of equipment before use and verifying that the load I’m handling does not exceed these limits. I use weight scales to confirm the weight of pallets whenever necessary.

Exceeding weight limits can lead to serious consequences such as equipment damage, product damage, or even injuries. For example, overloading a forklift can cause it to tip over, resulting in significant damage and potential injuries. Similarly, exceeding the weight capacity of a pallet rack can cause it to collapse, creating safety hazards. I always err on the side of caution – if I am unsure about a load’s weight or the capacity of the equipment, I will seek clarification from my supervisor before proceeding.

Q 12. How do you manage a situation where a pallet is damaged or unstable?

Handling a damaged or unstable pallet requires immediate attention and a cautious approach. Safety is the top priority. I would first assess the situation, ensuring the area around the pallet is clear of personnel and other equipment.

- Damaged Pallet: For minor damage (like a few loose boards), I might carefully secure the pallet using strapping or additional supports to prevent further damage or collapse. I’d then prioritize moving it to a designated area for repair or disposal, following established procedures.

- Unstable Pallet: If the pallet is severely damaged or unstable, I would not attempt to move it myself. I’d immediately report it to my supervisor and follow the company’s established procedure for handling unstable pallets, which might involve using additional equipment or requesting assistance from maintenance or engineering.

Documentation is crucial in both cases. I would document the damage with photographs and a written description, noting any potential causes of the damage. This information aids in accident prevention and insurance claims, if necessary. The emphasis is always on safety first – preventing accidents is always preferred over rushing or attempting to solve the issue independently.

Q 13. Describe your experience with different warehouse management systems (WMS).

I have experience using several Warehouse Management Systems (WMS), including WMS A, WMS B and WMS C. (Note: Replace these with actual WMS names if you want to mention specifics). These systems manage all aspects of warehouse operations, from receiving and putaway to picking, packing, and shipping. My experience includes using these systems to track inventory, manage orders, optimize storage locations, and generate reports.

I’m familiar with using scanners to track the location and status of pallets throughout the warehouse. I’m proficient in using the system to verify order accuracy, locate inventory and receive real-time updates on orders. I understand the importance of accurate data entry to maintain the integrity of the system. The use of WMS significantly enhances efficiency, accuracy, and visibility in the entire logistics process.

Q 14. How do you maintain a clean and organized work area?

Maintaining a clean and organized work area is not just about aesthetics; it’s crucial for safety and efficiency. My approach involves several key practices:

- Regular Cleaning: I regularly sweep or use other cleaning equipment to remove debris and spills. I ensure that aisles are clear and that pallets are properly stacked to allow for safe and efficient movement.

- Organized Storage: I adhere to established storage procedures, ensuring that pallets are stored in designated locations, following proper racking guidelines. I label pallets clearly and maintain a system for easy identification and retrieval.

- Waste Disposal: I follow company policies for waste disposal, properly segregating materials for recycling and disposing of hazardous waste according to safety guidelines.

- Proactive Approach: I take a proactive approach to cleaning, addressing minor issues immediately rather than letting them accumulate. This prevents larger problems from developing and improves overall workplace safety.

A clean and organized workspace is not just aesthetically pleasing; it helps prevent accidents, improves efficiency by allowing easy movement of equipment and people, and contributes to a more positive work environment.

Q 15. What is your experience with inventory control procedures related to pallets?

My experience with inventory control procedures related to pallets is extensive. It goes beyond simply counting pallets; it encompasses the entire lifecycle, from receiving to shipping. I’m proficient in using various inventory management systems (IMS) to track pallet location, quantity, and contents. This includes utilizing barcode or RFID scanning to ensure accurate data entry. A crucial aspect is regularly reconciling physical counts with the IMS data to identify and rectify discrepancies. For instance, I’ve implemented a cycle-counting system in previous roles, where specific pallet areas are audited regularly to minimize the impact of potential errors. This proactive approach allowed us to identify and resolve issues before they escalated into major inventory discrepancies.

I also have experience with implementing FIFO (First-In, First-Out) and FEFO (First-Expired, First-Out) methods to manage perishable goods, ensuring efficient stock rotation and minimizing waste.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the accuracy of pallet counts?

Ensuring the accuracy of pallet counts is paramount. My approach involves a multi-layered system. Firstly, I always begin with a pre-count estimate based on shipping manifests or delivery expectations. Then, I conduct a physical count, often employing a buddy system for double-checking. This involves two people independently counting the pallets and comparing their results. Discrepancies are immediately investigated. Secondly, I use RF scanning devices to record the count digitally, eliminating manual data entry errors and providing real-time inventory updates. Regularly comparing the physical count with the system’s record helps identify any inconsistencies. For example, if the system shows 50 pallets but we only physically find 48, we’d investigate potential reasons like misplacement or damaged pallets.

Finally, I perform random spot checks throughout the day to catch any errors early. This proactive approach ensures the accuracy of pallet counts at all times.

Q 17. How familiar are you with OSHA regulations regarding pallet handling?

I am very familiar with OSHA regulations (Occupational Safety and Health Administration) concerning pallet handling. I understand the importance of following safety procedures to prevent workplace accidents. This includes proper training on forklift operation, safe stacking practices, load stability, and the use of appropriate personal protective equipment (PPE), such as safety shoes, gloves, and high-visibility vests. I am well-versed in OSHA’s guidelines on load capacity for forklifts, safe pallet racking procedures to prevent collapses, and the necessity of maintaining a clean and organized work environment to eliminate tripping hazards. I’ve personally conducted safety training sessions for my teams and actively enforced these standards in my previous roles.

Furthermore, I know the importance of regularly inspecting equipment and reporting any maintenance needs promptly. Safety is not just a regulation; it’s a priority.

Q 18. How do you prevent injuries while loading/unloading pallets?

Preventing injuries while loading and unloading pallets is a top priority. It starts with proper training on safe lifting techniques to avoid strains and sprains. This includes using mechanical aids like pallet jacks or forklifts whenever possible. Before any lifting, I always visually assess the load’s weight and stability. Overly heavy pallets require additional personnel or the use of equipment. We maintain a clear and unobstructed work area, free of debris and clutter, to avoid tripping hazards. Furthermore, implementing a buddy system, especially when handling unusually heavy or awkward pallets, offers an extra layer of safety.

Regular equipment maintenance and inspection are crucial for preventing malfunctions. Finally, I ensure all team members consistently wear appropriate PPE, such as safety shoes and gloves.

Q 19. Explain your process for securing pallets during transport.

Securing pallets during transport is critical to preventing damage and ensuring safety. The method depends on the mode of transport. For truck shipments, I ensure pallets are properly stacked, avoiding overhanging loads and ensuring the weight is evenly distributed to maintain stability. Appropriate load-securing devices are used—including straps, chains, or netting—to prevent shifting during transit. These devices must be correctly tensioned and fastened to prevent slippage. For example, if we’re transporting fragile goods, extra care is needed in stacking and securing with appropriate padding to avoid damage.

Detailed documentation of the secured load is vital, including the type of securing devices used, tension levels, and the number of pallets. This information is necessary for both insurance purposes and to comply with transportation regulations.

Q 20. Describe your experience with RF scanning devices in the context of pallet management.

My experience with RF scanning devices in pallet management is extensive. I’ve used these devices to track pallets throughout their entire journey within a warehouse, from receiving to shipping. This technology allows for real-time inventory updates, eliminating manual data entry and significantly improving accuracy. For instance, when receiving a shipment, I use the scanner to record the pallet ID, quantity, and other relevant information directly into the inventory management system. This instantly updates the system, providing an accurate and up-to-the-minute account of our stock.

RF scanning also facilitates efficient order picking and shipment processing. The system can guide pickers to specific pallet locations, reducing errors and improving efficiency. Furthermore, it helps identify potential discrepancies in stock levels quickly.

Q 21. What is your approach to problem-solving when faced with unexpected challenges in pallet handling?

My approach to problem-solving in pallet handling involves a structured, methodical process. First, I identify the problem clearly. Is there a damaged pallet? A delay in receiving shipments? Equipment malfunction? Once identified, I gather all relevant information, involving other team members if necessary, to get a complete picture of the situation. Then, I brainstorm potential solutions, considering the safety implications of each. Prioritizing safety is paramount. After evaluating the potential solutions, I implement the most feasible and safest one, documenting the steps taken. Finally, I follow up to assess the effectiveness of the solution and make any necessary adjustments. For instance, if a pallet jack malfunctions, I’d arrange for immediate repair or replacement while temporarily using alternative equipment to avoid disrupting operations.

This structured approach ensures efficient problem-solving while always placing safety first.

Q 22. How do you adapt to changing work demands regarding pallet loading/unloading?

Adapting to changing work demands in pallet loading/unloading is crucial for efficiency and safety. It involves flexibility and a proactive approach. For instance, if a sudden rush order arrives requiring a different pallet configuration, I immediately assess the situation. This includes checking the available space, the type of goods, and any specific handling requirements. I then adjust my workflow accordingly, prioritizing urgent tasks and communicating any potential delays to supervisors. I’m comfortable working with varied pallet sizes and weights and can quickly transition between tasks, ensuring timely completion even under pressure. For example, I once had to switch from loading heavy machinery onto oversized pallets to unloading delicate electronics onto smaller ones within a single shift. I prioritized the electronics to prevent damage and then efficiently handled the machinery later. My experience with diverse situations has made me adaptable to any challenge.

Q 23. What is your understanding of the importance of efficient pallet handling?

Efficient pallet handling is paramount for several reasons. Firstly, it directly impacts productivity. Optimizing pallet stacking and securing reduces wasted time and resources, leading to faster turnaround times in warehouses and distribution centers. Think of it like a well-organized toolbox – every tool has its place, making it easy to find and use. Secondly, efficiency minimizes the risk of damage to goods and equipment. Properly secured pallets prevent shifting during transport, protecting products from damage and reducing the costs associated with returns or replacements. Finally, efficient handling improves workplace safety. By following proper procedures and using appropriate equipment, we mitigate the risk of workplace injuries caused by strain, falls, or collisions. For example, a poorly stacked pallet can lead to an accident, causing potential injury and significant financial repercussions. My experience has shown that meticulous planning and execution contribute to a safe and efficient operation.

Q 24. What types of physical demands are associated with this job, and how do you meet those demands?

This job demands significant physical strength and stamina. It involves repetitive lifting, bending, twisting, and pushing/pulling heavy objects. I’ve built up my physical endurance over the years through consistent exercise and maintaining a healthy lifestyle. This includes regular strength training to build muscle mass and cardiovascular exercise to improve stamina. I also emphasize proper lifting techniques – always bending at the knees, keeping my back straight, and using proper equipment like pallet jacks or forklifts to minimize strain. I understand the importance of recognizing my physical limits and asking for assistance when necessary, to prevent injury. Prioritizing safety is key. For example, I always utilize available equipment like lift trucks and conveyors, and I communicate any concerns about excessively heavy or awkwardly shaped items to my supervisors.

Q 25. What is your experience with various pallet sizes and configurations?

I have extensive experience with a wide variety of pallet sizes and configurations. I’m familiar with standard pallets (48×40 inches), half-pallets, and even custom-sized pallets. Understanding the dimensions is crucial for optimizing space and stability. I also have experience with different pallet materials like wood, plastic, and metal, each requiring slightly different handling techniques. For example, plastic pallets are often lighter but can be more prone to damage under heavy weight. I always adapt my techniques to suit the specific pallet type and the goods being loaded, ensuring secure and safe placement. My knowledge extends to understanding different pallet configurations such as block stacking, cross-docking, and the importance of maintaining appropriate weight distribution to prevent imbalance and collapse.

Q 26. How do you handle different types of cargo loaded onto pallets?

Handling diverse cargo requires a keen understanding of material handling best practices. I’m adept at handling fragile goods, requiring careful placement and padding. I use appropriate packaging materials to prevent damage and ensure the safe transport of delicate items. For heavier items, I utilize proper lifting techniques and equipment to prevent injuries. Hazardous materials require special attention – I’m trained in handling hazardous materials according to relevant safety regulations, using appropriate PPE and following established protocols for loading and unloading to prevent any accidents. I pay particular attention to the weight distribution of the cargo on the pallet, ensuring stability and preventing potential tipping. For example, I might distribute heavier items evenly across the pallet, then place lighter items in the gaps, creating a more balanced load.

Q 27. Describe your experience with the various tools and equipment used in pallet handling.

My experience with pallet handling equipment is comprehensive. I’m proficient in operating forklifts, pallet jacks, conveyors, and hand trucks. I’m also familiar with using stretch wrap, shrink wrap, and straps to secure pallets and their contents. I understand the importance of regular maintenance and safety checks on all equipment before use. I’m certified in operating forklifts and pallet jacks and understand the importance of adhering to safety guidelines when using this equipment. I’m also comfortable using scanning equipment to track pallets and their contents throughout the supply chain. For example, if a forklift needs maintenance, I won’t operate it until a qualified technician has checked it over. Safety is my highest priority.

Q 28. What are your salary expectations for this position?

My salary expectations are commensurate with my experience and skills, and in line with the industry standard for this position. I am open to discussing a competitive salary range based on the specifics of this role and the overall compensation package. I value a fair and competitive wage reflective of my commitment and contribution to the company’s success.

Key Topics to Learn for Loading and Unloading Pallets Interview

- Safe Pallet Handling Techniques: Understanding proper lifting, carrying, and stacking procedures to prevent injuries and damage.

- Equipment Operation: Familiarity with forklifts, pallet jacks, and other machinery used in loading and unloading; highlighting experience with safety protocols and operational procedures.

- Inventory Management & Organization: Demonstrating knowledge of efficient pallet placement, organization strategies within warehouse environments, and inventory tracking systems.

- Load Stability and Security: Understanding how to secure loads to prevent shifting or damage during transport; this includes knowing different types of load securing methods.

- Warehouse Layout and Workflow: Demonstrating awareness of efficient warehouse flow, including receiving, staging, storage, and shipping processes; and how to optimize individual contributions to overall efficiency.

- Compliance and Regulations: Understanding relevant safety regulations (OSHA, etc.) and company-specific policies related to pallet handling and warehouse operations.

- Problem-solving and Troubleshooting: Ability to identify and address issues such as damaged pallets, incorrect labeling, or equipment malfunctions; showcasing problem-solving skills and initiative.

- Teamwork and Communication: Highlighting experience collaborating with team members, following instructions, and communicating effectively with supervisors and colleagues.

Next Steps

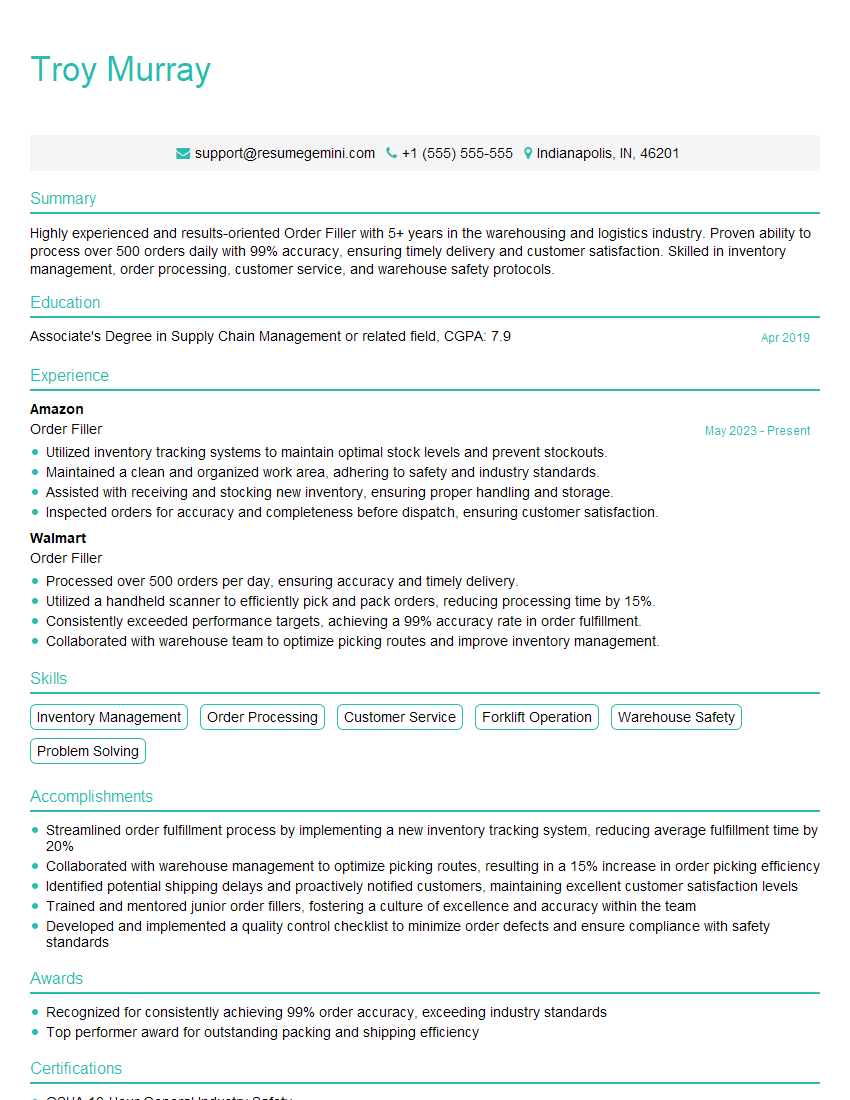

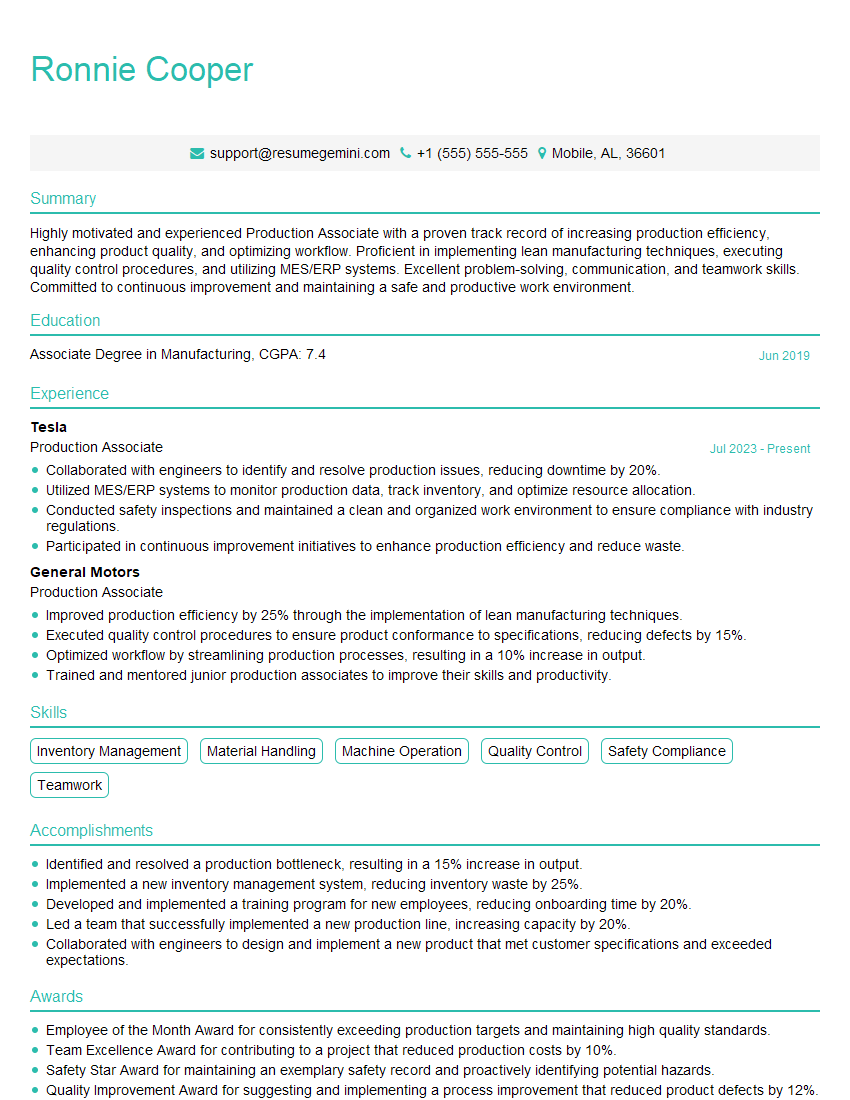

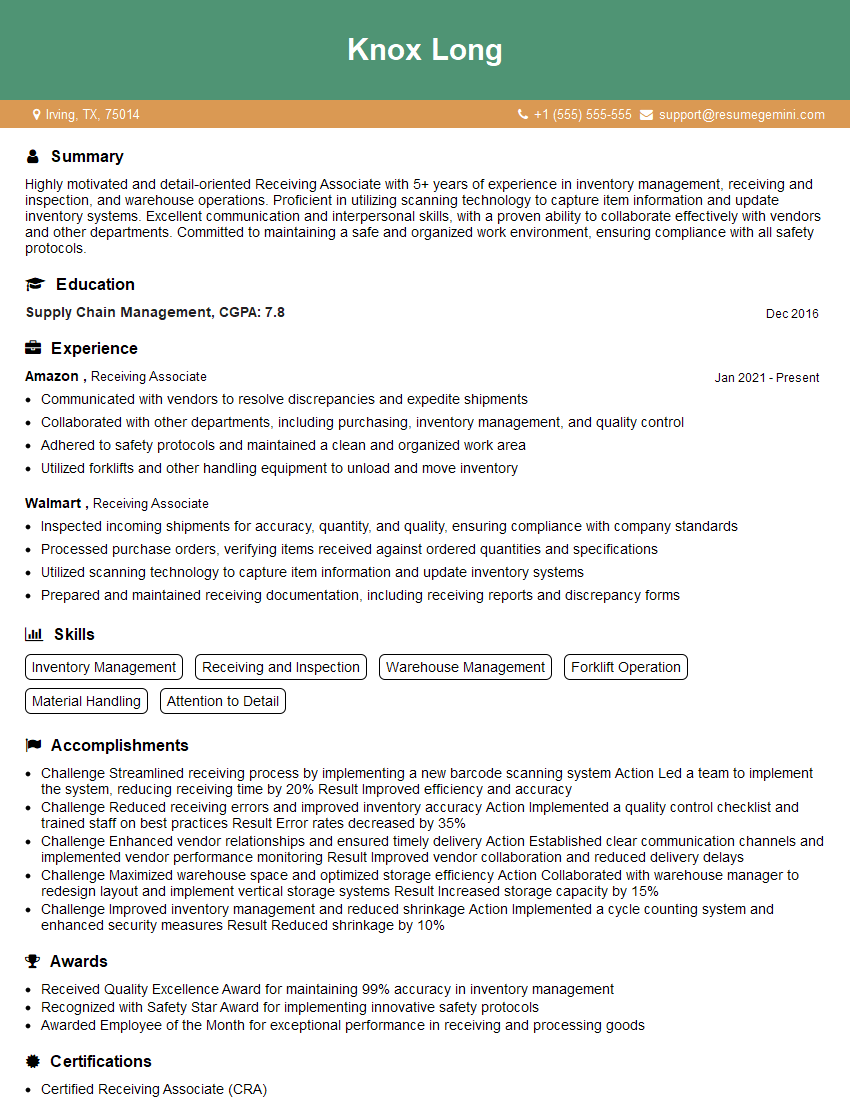

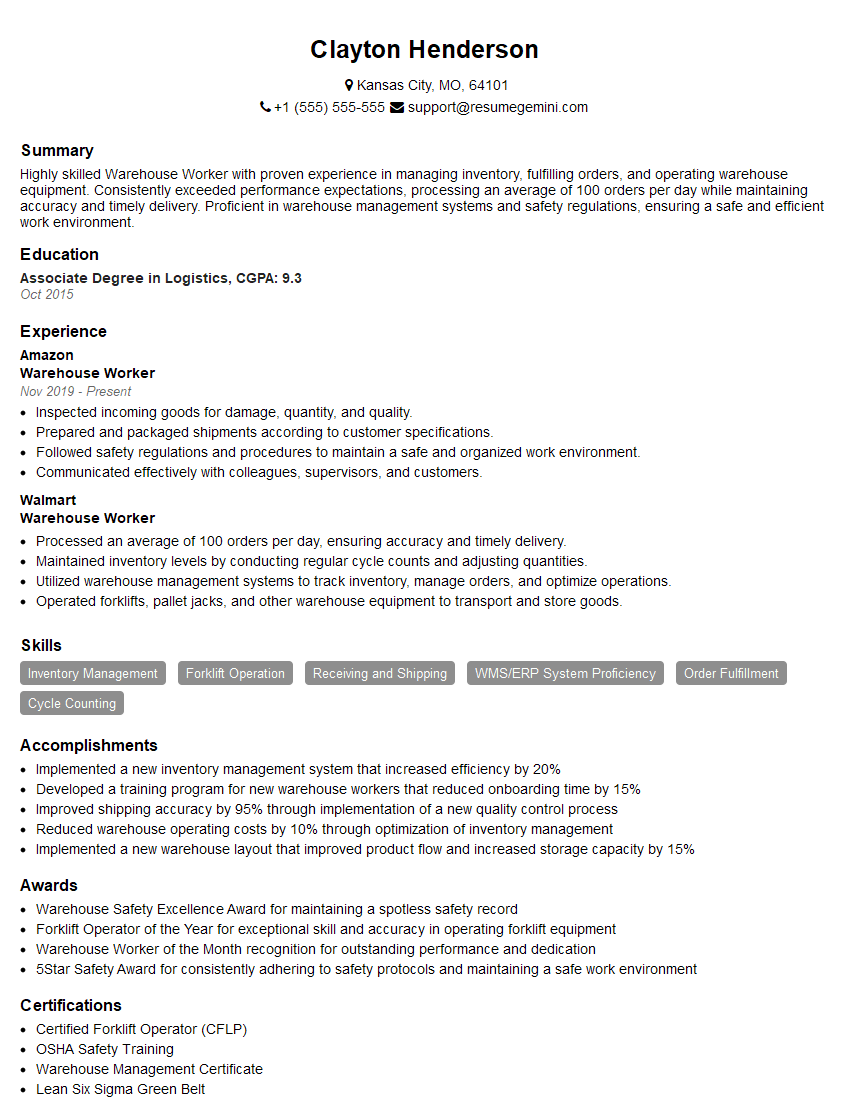

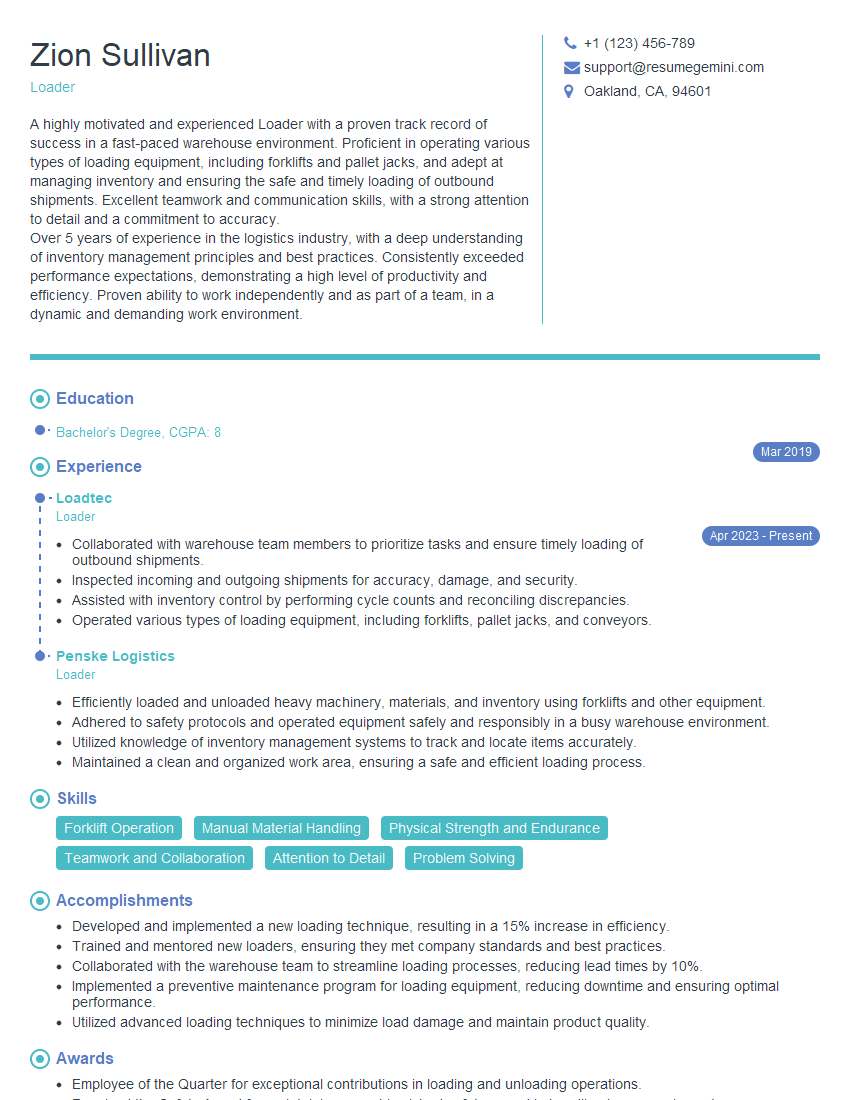

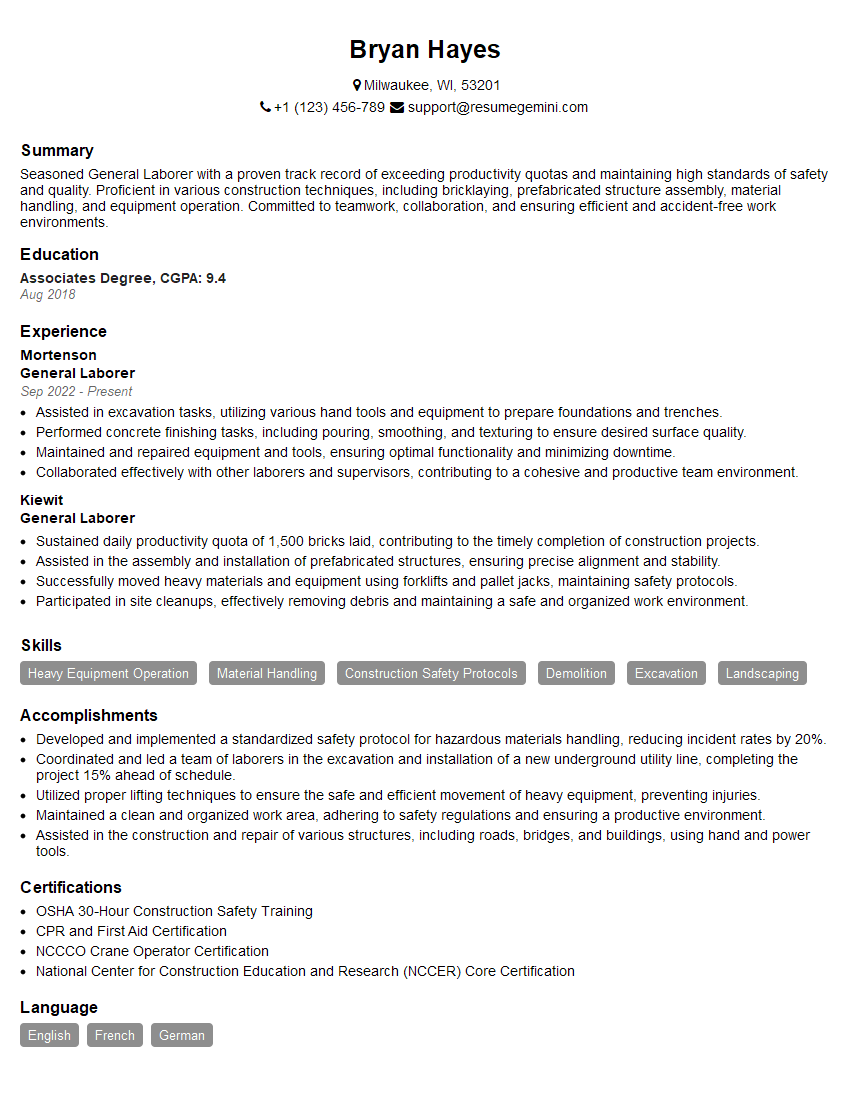

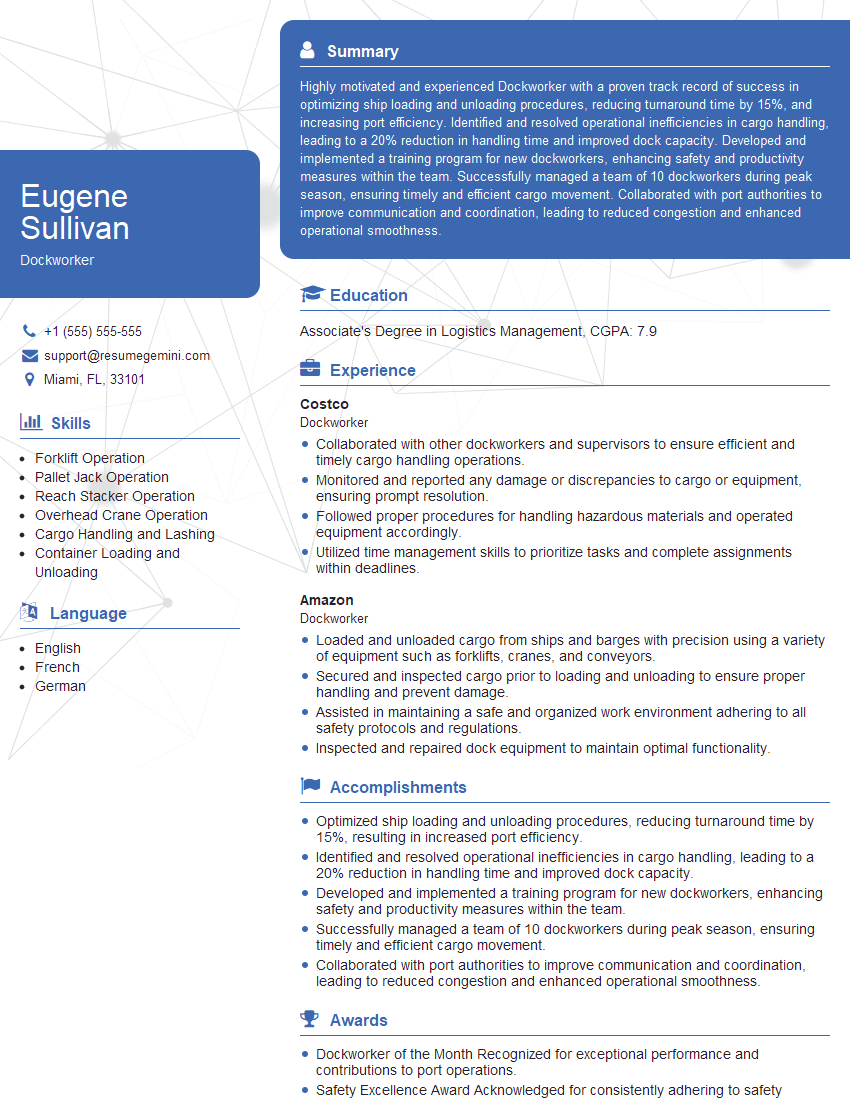

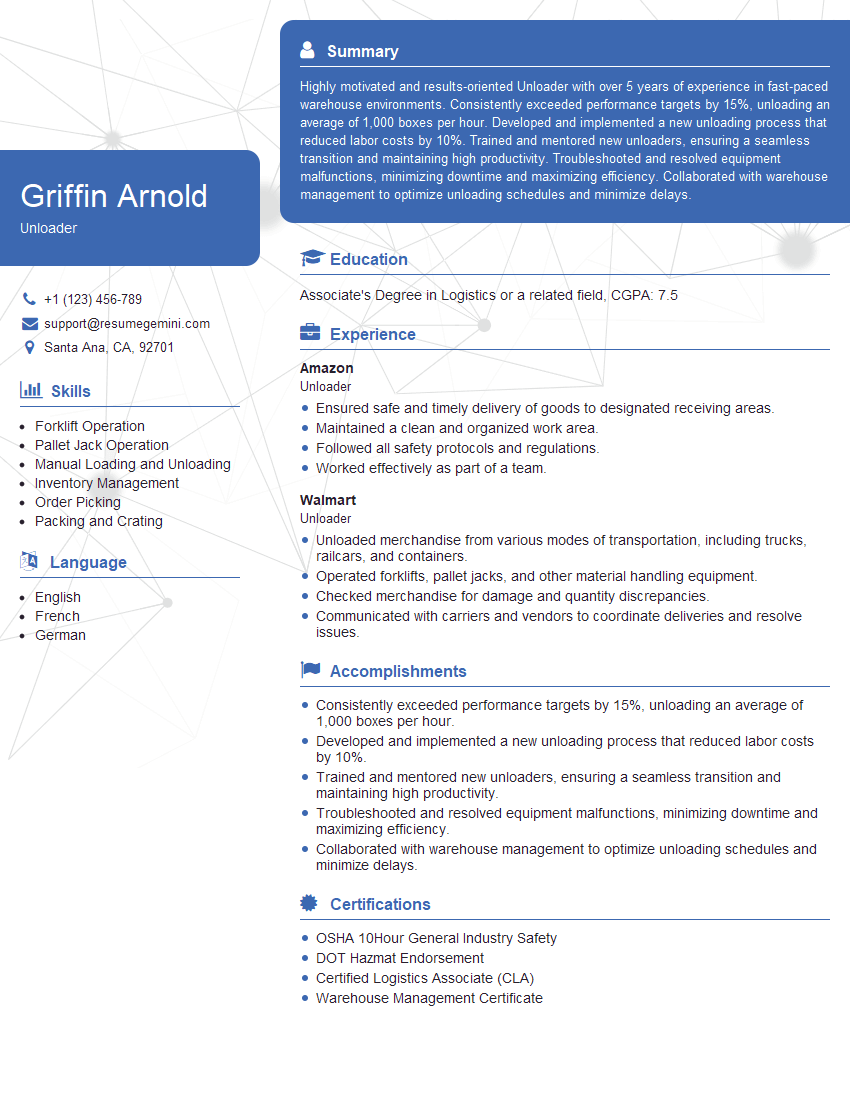

Mastering the skills of loading and unloading pallets opens doors to diverse career opportunities within logistics, warehousing, and distribution. A strong understanding of these processes is highly valued by employers, making you a competitive candidate for advancement. To further enhance your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your skills and experience. We offer examples of resumes tailored to loading and unloading pallets to help you create a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good