Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Loading and unloading supplies interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Loading and unloading supplies Interview

Q 1. Describe your experience with different types of loading equipment.

My experience encompasses a wide range of loading equipment, from basic hand trucks and pallet jacks to advanced technologies like forklifts, reach trucks, and automated guided vehicles (AGVs). I’m proficient in operating various types of forklifts, including counterbalanced, reach, and order picker models, ensuring safe and efficient material handling for different load types and warehouse layouts. I’ve also worked extensively with specialized equipment such as crane systems for oversized or heavy loads and conveyor systems for streamlined throughput. For instance, in my previous role at Acme Distribution, I was responsible for training new employees on the safe operation of forklifts and ensuring regular maintenance checks were performed to prevent equipment malfunctions. My familiarity with different equipment allows me to optimize loading and unloading operations based on the specific characteristics of the goods being handled and the available resources.

- Forklifts: Counterbalanced, reach, order picker, sideloader

- Other equipment: Pallet jacks, hand trucks, conveyor systems, crane systems, AGVs

Q 2. How do you prioritize tasks when faced with multiple loading/unloading requests?

Prioritizing tasks during loading and unloading involves a strategic approach combining urgency, safety, and efficiency. I typically use a system that prioritizes requests based on factors like delivery deadlines, product fragility, and storage requirements. A crucial element is using a First In, First Out (FIFO) method for perishable goods to prevent spoilage. For example, if I have several loading requests, I’d start with those with the earliest delivery times, followed by time-sensitive or temperature-sensitive products. I also take into account the weight and size of the items, ensuring that heavier or bulkier items are loaded strategically for balance and safety. Using a well-organized loading plan, coupled with clear communication with the team, ensures smooth and timely completion of all tasks.

- Urgency: Delivery deadlines, perishable goods

- Safety: Fragile items, weight distribution

- Efficiency: Optimized loading sequences, FIFO

Q 3. Explain your experience with inventory management systems during loading/unloading.

My experience with inventory management systems during loading and unloading is extensive. I’m adept at using Warehouse Management Systems (WMS) to track inventory in real-time, ensuring accurate product identification and efficient order fulfillment. These systems allow me to scan barcodes or RFID tags to verify quantities loaded or unloaded and immediately update inventory levels. This prevents discrepancies and ensures accountability. At Beta Logistics, for instance, I used a WMS that integrated with our transportation management system (TMS), streamlining the entire process from order placement to delivery confirmation. I’m comfortable with different software interfaces and can adapt quickly to new systems, ensuring accurate and efficient inventory control throughout the entire loading/unloading process.

A typical workflow might involve: scanning items as they’re loaded onto a truck, confirming the quantity matches the order details, and then updating the system accordingly. Any discrepancies are immediately flagged and investigated.

Q 4. What safety procedures do you follow when loading/unloading heavy items?

Safety is paramount in my approach to loading and unloading heavy items. I always adhere to strict safety protocols, including wearing appropriate personal protective equipment (PPE) such as safety shoes, gloves, and high-visibility vests. Before starting any task, I inspect the equipment, the load itself, and the surrounding environment for any potential hazards. This includes ensuring that the load is properly secured and balanced to prevent tipping or shifting. I always follow the manufacturer’s guidelines for operating any loading equipment and never attempt to exceed the weight capacity of machinery. Furthermore, I meticulously adhere to site-specific safety guidelines including designated walkways and procedures for moving heavy items. I maintain awareness of my surroundings and communicate clearly with co-workers to prevent accidents. One example is my consistent use of spotters when operating forklifts in confined spaces.

- PPE: Safety shoes, gloves, high-visibility vests

- Equipment inspection: Checking for malfunctions or damage

- Load securing: Proper strapping, blocking, and bracing

- Clear communication: With co-workers to prevent collisions and accidents

Q 5. How do you ensure the accuracy of inventory counts during the loading/unloading process?

Ensuring accurate inventory counts during loading and unloading is crucial for maintaining operational efficiency and minimizing discrepancies. I use a combination of physical verification and technological aids to achieve this. This often involves double-checking quantities against packing lists and delivery notes, meticulously documenting any discrepancies, and utilizing barcode scanners and WMS integration for real-time updates. For example, after unloading a shipment, I perform a physical count of each item received and compare that against the accompanying paperwork. Any differences are immediately investigated, and a reconciliation report is created to ensure all items are accounted for and adjustments are made to the inventory database. This system minimizes errors and keeps the inventory count precise.

- Physical verification: Double-checking quantities against documents

- Technology integration: Utilizing barcode scanners and WMS

- Discrepancy reports: Documenting and investigating differences

Q 6. Describe your experience with different types of packaging and handling materials.

My experience encompasses a wide variety of packaging and handling materials, ranging from standard cardboard boxes and pallets to specialized containers for fragile or hazardous goods. I am familiar with different types of pallets, including wood, plastic, and reusable options. I understand the importance of selecting the appropriate packaging based on the product’s characteristics, weight, and fragility. For instance, I know the correct techniques for handling goods in crates or barrels, using appropriate lifting equipment and ensuring items are well-protected during transit. I’m also knowledgeable about the use of specialized materials like bubble wrap, foam inserts, and stretch wrap to prevent damage during transportation. This includes understanding the importance of proper stacking and securing to prevent collapse during transit.

- Pallets: Wood, plastic, reusable

- Protective materials: Bubble wrap, foam inserts, stretch wrap

- Specialized containers: Crates, barrels, specialized totes

Q 7. How do you handle damaged goods during the loading/unloading process?

Handling damaged goods requires a methodical approach to ensure accurate documentation and efficient resolution. Upon discovering damaged goods during loading or unloading, I immediately document the damage using photos and detailed descriptions, noting the quantity and extent of damage. This information is relayed to the relevant parties, such as the shipping company or the client. Depending on the severity and nature of the damage, we may need to initiate a claim with the shipping carrier or follow internal procedures for damaged goods returns. The damaged items are then segregated from undamaged goods to prevent further damage or contamination and handled according to our established procedures. In many cases, this might involve returning the goods for replacement or initiating a refund process. This ensures transparency and a clear record of the incident.

- Documentation: Photographs, detailed descriptions of damage

- Reporting: Notification to relevant stakeholders (shipping company, client)

- Segregation: Separating damaged goods from undamaged goods

- Resolution: Following established procedures for returns, refunds, or claims

Q 8. How do you maintain a clean and organized work area during loading/unloading?

Maintaining a clean and organized work area during loading and unloading is crucial for efficiency and safety. Think of it like this: a cluttered workspace is like a cluttered mind – it hinders productivity and increases the risk of accidents. My approach involves a multi-pronged strategy:

- Pre-shift organization: Before starting, I ensure the loading/unloading area is clear of debris, pallets are stacked neatly, and equipment is in its designated place. This prevents unnecessary tripping hazards and streamlines the process.

- Continuous cleanup: During the loading/unloading process, I regularly clear away any loose packaging, discarded materials, or spilled items. This prevents build-up and keeps the area safe and functional.

- Designated areas for waste: I utilize clearly marked areas for different types of waste, such as cardboard, plastic wrap, and other recyclable materials. This simplifies disposal and promotes recycling.

- Pallet management: Empty pallets are immediately stacked in a designated area, preventing congestion and allowing for efficient space utilization.

- Post-shift sweep: At the end of each shift, I conduct a thorough sweep of the area, removing all debris and ensuring everything is in its correct place. This leaves the space clean, organized, and ready for the next shift.

For example, during a particularly busy period unloading a truck full of fragile ceramics, maintaining a clean and organized workspace prevented accidental damage to the products. By systematically removing packaging and placing items onto the designated shelves, I avoided confusion and minimized breakage.

Q 9. Explain your experience with using RF scanners or other warehouse management systems.

I have extensive experience using RF scanners and warehouse management systems (WMS). These technologies are indispensable in ensuring accuracy and efficiency in loading and unloading operations. RF scanners, for instance, allow for real-time tracking of inventory, reducing errors in picking, packing, and shipping. I’m proficient in using various WMS software to manage inventory levels, track order fulfillment, and generate reports on productivity.

In my previous role, we used a WMS that integrated with our RF scanners. The system guided me through the picking process, displaying the required items and quantities on the scanner’s screen. Upon scanning each item, the WMS automatically updated the inventory and generated a packing list. This minimized errors and significantly sped up the entire process. This eliminated the need for manual data entry, reducing the chances of human error associated with manually inputting information.

Furthermore, my familiarity with WMS allows me to identify and troubleshoot issues quickly. For example, I once encountered a discrepancy between the system’s inventory count and the physical inventory. By systematically investigating the discrepancy using the WMS tools, I was able to identify the error and rectify it swiftly, preventing any further disruptions.

Q 10. How do you manage your time effectively during peak loading/unloading periods?

Effective time management during peak periods is crucial. It’s all about prioritizing tasks, optimizing workflows, and working smart, not just hard. My approach usually involves:

- Prioritization: I focus on tasks with the tightest deadlines or highest priority first. This ensures that the most critical items are handled efficiently.

- Workflow Optimization: I constantly look for ways to streamline the process. This may involve adjusting the loading/unloading sequence, optimizing the use of equipment, or delegating tasks effectively (when applicable).

- Communication: Maintaining clear communication with colleagues and supervisors is key. This helps anticipate potential bottlenecks and find solutions proactively.

- Breaks and hydration: Surprisingly, taking short, strategic breaks to stay hydrated and refreshed helps maintain productivity. A tired mind makes mistakes.

- Continuous improvement: After each peak period, I review my performance, identifying areas where I can improve my time management skills.

For instance, during a recent holiday rush, by strategically assigning tasks and proactively communicating potential delays, I was able to manage the increased workload effectively and maintain on-time delivery.

Q 11. What is your experience with working in a fast-paced environment?

I thrive in fast-paced environments. The energy and challenge are what I enjoy. My experience working in high-volume distribution centers has honed my ability to react quickly, adapt to changing situations, and stay focused under pressure. I am comfortable making quick decisions and prioritizing tasks based on urgency. It’s like a well-orchestrated symphony – each movement needs to be precise and efficient.

For example, during a major product launch, we faced a massive surge in orders. The pressure was intense, but through clear communication, efficient prioritization, and coordinated teamwork, we successfully fulfilled all orders on time and without compromising quality. I view these challenges as opportunities to demonstrate my resourcefulness and resilience.

Q 12. How do you handle unexpected delays or problems during loading/unloading?

Unexpected delays or problems are inevitable in loading/unloading. My approach is to remain calm, assess the situation, and take decisive action. The key is proactive problem-solving.

- Assessment: First, I carefully assess the nature and extent of the problem. Is it a damaged pallet? A missing item? A mechanical failure?

- Communication: I immediately inform my supervisor and relevant team members about the delay and the problem’s nature. Clear communication prevents confusion and ensures a coordinated response.

- Problem-solving: I then work to find the best solution, prioritizing safety and efficiency. This might involve finding a workaround, requesting assistance, or contacting the appropriate personnel.

- Documentation: I meticulously document the issue, the resolution steps taken, and any necessary follow-up actions. This ensures accountability and aids in preventing similar issues in the future.

For example, during a recent storm, a power outage caused a significant delay in the loading process. I immediately informed my supervisor, implemented contingency plans (switching to manual processes), and worked with the team to minimize the disruption, ensuring minimal impact on the delivery schedule.

Q 13. Describe your experience with various loading techniques (e.g., stacking, palletizing).

I’m proficient in various loading techniques, including stacking, palletizing, and other specialized methods depending on the cargo’s nature.

- Stacking: I understand the principles of weight distribution and stability when stacking items. I ensure that heavier items are placed on the bottom and that the stack remains balanced to prevent collapse. Different items require different stacking strategies – fragile items need extra care and padding.

- Palletizing: I’m experienced in building stable and secure pallets, correctly using stretch wrap and other securing materials. The goal is to maximize space while minimizing the risk of damage during transportation. I’m familiar with different pallet types and sizes, adapting to the specific requirements of the shipment.

- Specialized techniques: Depending on the goods, I may utilize specialized techniques such as blocking and bracing to protect sensitive items or using specific equipment for oversized or oddly-shaped loads.

In one instance, I had to load a shipment of delicate glassware. By carefully using appropriate padding materials and employing a specific stacking method, I ensured that the glassware arrived at its destination undamaged. My understanding of different loading techniques proved invaluable in preventing breakage and ensuring safe delivery.

Q 14. How do you ensure the safety of yourself and others during loading/unloading operations?

Safety is my paramount concern. I strictly adhere to all safety protocols and regulations during loading/unloading operations. This involves:

- Personal Protective Equipment (PPE): I consistently use appropriate PPE, including safety shoes, gloves, high-visibility vests, and safety glasses, depending on the task and potential hazards.

- Safe Lifting Techniques: I always utilize proper lifting techniques to avoid back injuries. When lifting heavy objects, I ensure I have assistance and use lifting aids where necessary.

- Equipment Safety: I inspect all loading equipment – forklifts, pallet jacks, etc. – before use to ensure they are in good working condition. I report any defects immediately.

- Awareness of Surroundings: I maintain a constant awareness of my surroundings, watching out for potential hazards such as moving vehicles, uneven surfaces, and other workers.

- Following Procedures: I always follow established safety procedures and regulations, participating in safety training sessions and adhering to company policies.

A significant aspect of safety involves communication. If I notice a potentially unsafe condition, I immediately report it to my supervisor. Preventing accidents before they happen is a critical part of my job. I believe that a safe workplace is a productive workplace.

Q 15. What is your understanding of load capacity and weight limitations?

Load capacity and weight limitations are crucial for safety and efficiency in loading and unloading operations. Load capacity refers to the maximum weight a vehicle or structure can safely carry, while weight limitations specify restrictions based on factors like axle weight, bridge formulas, and individual item weight. Exceeding these limits can lead to structural damage, accidents, and legal repercussions.

For instance, a truck might have a gross vehicle weight rating (GVWR) of 80,000 lbs. This means the combined weight of the truck, its cargo, and the driver cannot exceed this limit. Similarly, individual pallets might have weight restrictions printed on them. Understanding these limitations requires careful planning and accurate weight measurement, often using scales and load planning software.

In practice, this involves checking the vehicle’s specifications, weighing the cargo, and ensuring that the distribution of weight is balanced to prevent overloading any specific axle. For example, heavier items should be placed lower and towards the center of gravity.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you use technology (e.g., scanners, software) to support loading/unloading operations?

Technology plays a vital role in modern loading and unloading. Barcode and RFID scanners help track individual items, ensuring accuracy and preventing misplacement. Warehouse Management Systems (WMS) software integrates with scanners and provides real-time updates on inventory levels, order status, and location of goods. This enables efficient picking, packing, and loading.

For example, when a driver arrives for a shipment, the system can automatically generate a loading manifest, and the scanner confirms that each item loaded matches the manifest. Furthermore, transport management systems (TMS) streamline communication and tracking during transit. Route optimization software can also improve efficiency by determining the most efficient loading sequence based on weight distribution and delivery routes.

In some advanced facilities, automated guided vehicles (AGVs) and robots are employed for efficient and safe movement of goods within the warehouse, significantly reducing manual handling and risk.

Q 17. How do you identify and address potential hazards related to loading/unloading?

Identifying and addressing hazards is paramount in loading/unloading. Common hazards include falling objects, crushed limbs, struck-by accidents involving vehicles, and slips, trips, and falls. A thorough risk assessment is the first step, identifying potential hazards specific to the operation, load type, and environment.

Measures to mitigate these risks include proper training for personnel, use of Personal Protective Equipment (PPE) such as safety shoes, high-visibility vests, and hard hats, implementing safe lifting techniques, using appropriate equipment (e.g., forklifts, pallet jacks with load stabilizers), and ensuring clear communication and designated walkways free of obstructions. Regular maintenance of equipment and a clean, well-lit work environment are also crucial.

For instance, before unloading a truck, I would ensure the area is clear, the truck is properly secured, and that personnel are positioned safely away from moving parts. Heavy items would be handled with appropriate machinery and using proper lifting techniques. Spotters should always be used when maneuvering vehicles in confined spaces.

Q 18. Describe your experience working with different types of transportation vehicles.

My experience encompasses a wide range of transportation vehicles, including semi-trailers (dry vans, refrigerated units, flatbeds), box trucks, and smaller delivery vans. Each vehicle type presents unique loading and unloading challenges. For example, securing cargo on a flatbed requires specialized techniques and tie-down equipment to prevent shifting during transit. Refrigerated units necessitate monitoring temperature and handling perishable goods with care. The loading process differs significantly between these vehicles; semi-trailers often utilize forklifts and loading docks, while smaller vans may require manual loading and unloading.

Understanding the specific features and limitations of each vehicle type is vital. This includes knowing how to safely operate loading ramps, secure cargo using appropriate techniques, and understand weight distribution considerations for balanced handling and safe driving.

Q 19. How do you communicate effectively with drivers and other team members?

Effective communication is the cornerstone of safe and efficient loading/unloading. I use clear and concise language, avoiding jargon, and confirming understanding through active listening. Pre-loading briefings with drivers are essential to confirm delivery details, check for any specific handling requirements (fragile goods, hazardous materials), and ensure everyone understands the plan.

During the loading process, clear hand signals and verbal communication with spotters and forklift operators are crucial for safety. I use two-way radios or other communication devices for seamless coordination with team members. Post-loading, I verify the count and condition of the goods with the driver, documenting any discrepancies or damages.

I always maintain a professional and respectful demeanor, ensuring that everyone feels heard and understood. Clear, timely communication helps to resolve conflicts efficiently and contributes to a positive and productive work environment.

Q 20. What measures do you take to prevent theft or damage of goods during loading/unloading?

Preventing theft and damage involves multiple layers of security. This begins with secure storage of goods before and after loading. Proper inventory management, including regular counts and reconciliation, is critical. During loading, I would visually inspect goods for any pre-existing damage and document any discrepancies. Secure sealing of trailers and containers is also important, using tamper-evident seals. Surveillance cameras and security personnel can deter theft and provide evidence in case of incidents.

Proper packaging is also vital. Fragile items need adequate protection to prevent damage during handling. Clearly labeling packages with appropriate handling instructions helps ensure careful treatment throughout the process.

For high-value goods, additional security measures such as GPS tracking or specialized security containers might be necessary. Regular audits of security procedures and staff training on theft prevention are essential to maintain a robust security system.

Q 21. Describe your experience with different types of materials (e.g., fragile, hazardous).

I have extensive experience handling diverse materials, from fragile electronics and glassware to hazardous chemicals and food products. Each material type requires specific handling techniques and safety precautions.

Fragile goods demand extra care, using appropriate cushioning materials and ensuring careful stacking and placement. Hazardous materials require adherence to stringent regulations, including proper labeling, handling procedures, and safety equipment like respirators and gloves. Specific permits and documentation might also be required for the transport of hazardous materials. Perishable goods require temperature-controlled environments and careful monitoring to maintain quality.

The key is to always consult relevant Safety Data Sheets (SDS) for hazardous materials and follow best practices for handling different materials. This ensures the safety of personnel and the preservation of goods throughout the entire process.

Q 22. How do you adapt to changes in loading/unloading schedules or requirements?

Adaptability is key in loading and unloading. Unexpected delays, last-minute changes to delivery schedules, or even sudden shifts in the type of goods being handled are common occurrences. My approach involves several steps. First, I meticulously review the updated schedule or requirements to fully understand the changes. This includes checking for any impact on my planned workflow, potential resource conflicts (like equipment or personnel), and any new safety protocols. Then, I prioritize tasks based on urgency and dependencies, making sure to communicate any potential delays or resource needs to my supervisor immediately. I leverage my experience to identify efficient alternatives, such as adjusting loading patterns or re-sequencing tasks to accommodate the changes while maintaining safety standards. For example, if a high-priority delivery requires immediate attention, I’ll re-allocate resources to ensure timely completion without compromising the safety of other ongoing tasks. Finally, I maintain open communication throughout the process to ensure everyone is aware of the changes and their impact.

Q 23. What are your strengths in terms of physical fitness and stamina for loading/unloading?

Physical fitness and stamina are paramount in this profession. Years of experience have built up my strength and endurance significantly. I regularly engage in exercises that target key muscle groups used in lifting, pushing, and pulling heavy objects. This includes weight training focusing on legs, back, and core, as well as cardiovascular exercises to build stamina and endurance. I believe in maintaining a healthy diet to fuel my body and support my physical demands. My work history demonstrates my consistent ability to handle demanding physical tasks throughout long shifts, maintaining efficiency and safety throughout. I actively monitor my physical condition and take appropriate breaks to avoid fatigue, which reduces risk of injury.

Q 24. How do you prioritize efficiency and speed without compromising safety?

Efficiency and speed are important, but safety always comes first. I prioritize safety by strictly adhering to all safety regulations and company policies, including proper lifting techniques, use of personal protective equipment (PPE), and securing loads properly. I start by assessing the situation, planning the loading/unloading sequence methodically, and making sure the work area is clear of obstacles. I utilize proper lifting techniques to minimize strain and risk of injury – bending my knees, keeping my back straight, and lifting with my legs. Teamwork also enhances efficiency; I coordinate with colleagues to maximize efficiency, assigning tasks logically based on individual strengths and ensuring everyone adheres to safety protocols. For instance, one person could focus on securing loads while another handles the loading/unloading process itself, ensuring a smooth and safe operation. We also practice regular safety checks and communication, allowing us to quickly address any potential hazards.

Q 25. Describe a time you had to solve a problem related to loading/unloading. What was your solution?

During a particularly busy period, we encountered a significant problem with a shipment of fragile ceramics. The original pallet wasn’t adequately secured, and several boxes were damaged during transport. To solve this, I immediately stopped the unloading process and assessed the situation. I realized the problem stemmed from improper packaging and insufficient pallet wrapping. My solution involved communicating with the supervisor, requesting additional stronger packaging materials, and collaborating with the team to meticulously repackage the remaining undamaged ceramics, ensuring adequate padding and secure wrapping. We also implemented a revised loading procedure, prioritizing fragile items and utilizing extra bracing to prevent further damage. Following these measures, the remaining shipment was successfully unloaded without further incident. This experience highlighted the importance of proactive problem-solving and effective communication in ensuring safe and efficient operations.

Q 26. What is your experience with loading/unloading temperature-sensitive goods?

I possess extensive experience handling temperature-sensitive goods, including pharmaceuticals, perishable foods, and other items requiring specific temperature control. My experience covers various aspects of this, from using and monitoring specialized equipment like refrigerated trucks and containers, ensuring the integrity of the cold chain throughout the entire loading and unloading process. I understand the importance of adhering to strict temperature guidelines, using appropriate thermal protection during transportation and handling, and properly documenting temperature readings throughout. I’m familiar with using temperature monitoring devices and reporting any deviations from required temperature ranges. For example, when unloading frozen goods, I make sure the unloading is swift to minimize temperature fluctuations, and I always check the temperature of the goods using a thermometer before and after unloading. This attention to detail ensures the goods arrive at their destination in optimal condition.

Q 27. How do you ensure compliance with all relevant safety regulations and company policies?

Safety is my utmost priority. I ensure compliance with all relevant regulations and company policies by actively participating in safety training programs, regularly reviewing safety procedures, and immediately reporting any safety concerns. I meticulously follow all established procedures for handling materials safely and wear appropriate personal protective equipment (PPE), including gloves, safety shoes, and high-visibility vests. I am also proficient in using safety equipment, such as forklifts and pallet jacks, according to proper training and regulations. I consistently encourage my colleagues to maintain a safe working environment and am always vigilant about spotting and mitigating potential hazards. My track record demonstrates a consistent commitment to a safe workplace, which has led to minimal incidents during my career.

Q 28. What are your salary expectations for this role?

My salary expectations are commensurate with my experience, skills, and the demands of this role. I am open to discussing a competitive compensation package based on industry standards and the specifics of this position. I’m confident my expertise and commitment make me a valuable asset, and I am eager to learn more about the compensation and benefits offered.

Key Topics to Learn for Loading and Unloading Supplies Interview

- Safety Regulations and Procedures: Understanding and adhering to OSHA regulations, proper lifting techniques, and hazard identification to ensure a safe work environment. Practical application includes demonstrating knowledge of specific safety equipment and procedures.

- Inventory Management and Tracking: Efficiently managing inventory levels, verifying counts against delivery manifests, and identifying discrepancies. Practical application involves describing methods for accurate stock tracking and reporting inconsistencies.

- Equipment Operation and Maintenance: Familiarization with various loading and unloading equipment (forklifts, pallet jacks, conveyors). Practical application includes demonstrating understanding of basic maintenance checks and safe operation procedures. Troubleshooting common equipment issues is also crucial.

- Load Planning and Optimization: Efficiently organizing and securing loads to maximize space and prevent damage during transit. Practical application involves describing strategies for optimizing load placement to minimize shifting and damage.

- Communication and Teamwork: Effective communication with colleagues, supervisors, and drivers. Practical application includes describing scenarios where teamwork and clear communication were essential for efficient loading and unloading.

- Time Management and Efficiency: Meeting deadlines and working efficiently under pressure. Practical application involves outlining strategies for prioritizing tasks and managing time constraints in a busy warehouse environment.

Next Steps

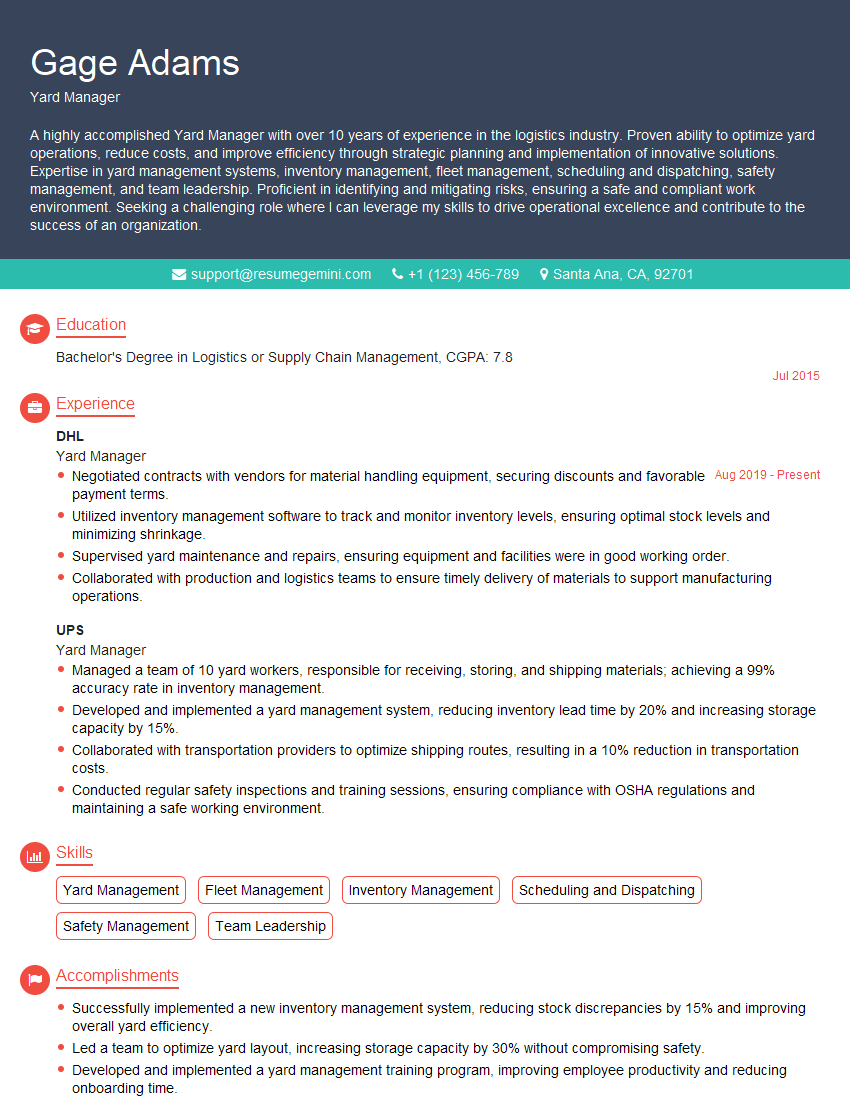

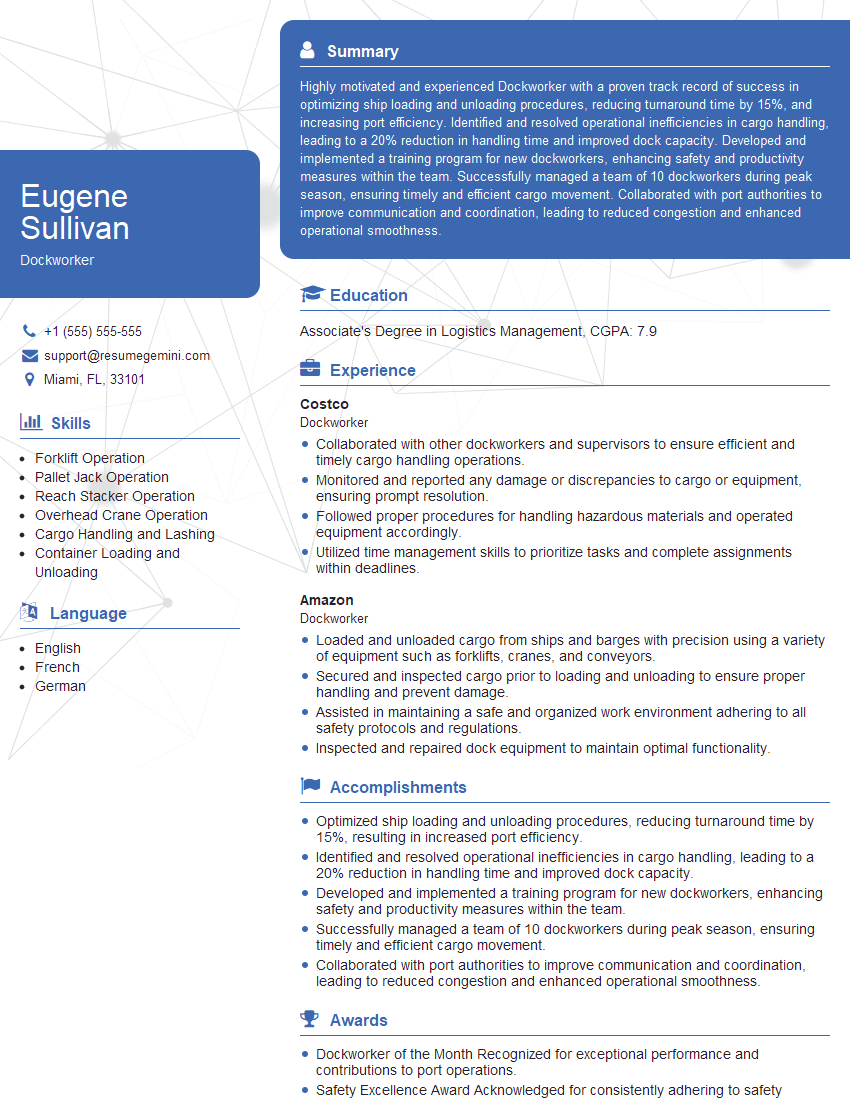

Mastering loading and unloading supplies skills is vital for career advancement in logistics, warehousing, and supply chain management. These skills are highly sought after and demonstrate your ability to contribute effectively to a team and maintain a safe and efficient operation. To significantly enhance your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume that highlights your skills and experience. We provide examples of resumes tailored to loading and unloading supplies positions to guide you in crafting a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good