The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Lockstitch Machine Operation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Lockstitch Machine Operation Interview

Q 1. What types of fabrics are best suited for lockstitch sewing?

Lockstitch machines excel at sewing a wide variety of fabrics, but some are better suited than others. The best fabrics generally depend on the weight and type of fiber.

- Lightweight fabrics: Silks, chiffons, and fine cottons sew beautifully with a lockstitch, but require a finer needle and potentially lower tension to prevent puckering.

- Medium-weight fabrics: Cottons, linens, and gabardines are ideal for lockstitch. They offer good stability, making stitch formation easier.

- Heavyweight fabrics: Denim, canvas, and upholstery fabrics can be sewn, but may require a heavier needle, stronger thread, and potentially a slower sewing speed. A walking foot can also be helpful to prevent fabric slippage.

- Knits: While tricky, knits can be sewn with a lockstitch, particularly using a ballpoint needle to prevent snagging the knit fibers. A slightly looser tension is usually beneficial.

Ultimately, the best fabric choice depends on the project and the machine’s capabilities. Experimentation is key to mastering various fabric types.

Q 2. Explain the difference between a straight stitch and a zigzag stitch on a lockstitch machine.

Both straight stitch and zigzag stitch are fundamental stitch types on a lockstitch machine, achieved by altering the needle’s movement and feed dog interaction.

- Straight Stitch: This creates a simple, linear stitch, ideal for seams and straight lines. The needle moves vertically up and down, while the feed dog moves the fabric consistently forward. Think of sewing a button onto a shirt or creating a straight seam in pants. It’s the workhorse stitch.

- Zigzag Stitch: This stitch moves the needle horizontally in addition to its vertical movement, creating a zigzag pattern. This is primarily used for decorative purposes, finishing seams to prevent fraying (overlocking), or sewing stretchy fabrics, as the zigzag has more give than a straight stitch. Imagine sewing a zig-zag seam on a stretchy sweater or edging a fabric to prevent unraveling.

The difference boils down to the needle’s lateral movement: no lateral movement for a straight stitch and controlled lateral movement for a zigzag stitch. Both stitches are created using the same interlocked thread mechanism inherent to lockstitch sewing machines.

Q 3. Describe the function of the tension control on a lockstitch machine.

The tension control on a lockstitch machine regulates the amount of pull on the upper and lower threads. Proper tension is crucial for creating a balanced, aesthetically pleasing stitch.

If the tension is too tight on the upper thread, the stitches will be pulled to the top of the fabric, creating puckering. Conversely, if the tension is too loose on the upper thread, the stitches will pull to the bottom of the fabric (and potentially loop on the underside). Similar imbalances will occur if the lower tension (controlled by the bobbin tension) is not properly adjusted.

The goal is to achieve a balanced stitch where the upper and lower threads interlock neatly, creating a uniform stitch on both sides of the fabric.

Many machines have a numbered dial for adjustment, allowing for fine-tuning based on the fabric type and thread weight. Experimentation is key to finding the optimal tension for your chosen materials. Think of it like balancing a scale: you need equal pressure from the upper and lower threads to achieve harmony.

Q 4. How do you troubleshoot a broken needle on a lockstitch machine?

A broken needle is a common occurrence. Here’s a step-by-step guide to troubleshooting:

- Safety First: Unplug the machine to prevent electrical shock before attempting any repairs.

- Remove the Broken Needle: Carefully remove the broken needle fragment using needle nose pliers or tweezers. Be cautious not to damage the needle plate or other machine parts.

- Inspect for Damage: Check the needle plate for damage from the broken needle. A bent or damaged needle plate can cause further problems. If damaged, it may need replacement.

- Insert a New Needle: Carefully insert a new needle of the correct type and size. Make sure it’s inserted correctly and fully seated.

- Test the Machine: Sew a test seam to ensure the new needle is functioning correctly. Check the tension and stitch quality.

Prevention is better than cure. Regularly inspect your needles for bending or damage and replace them promptly. A slightly bent needle, before breaking, will cause consistent stitch problems which are easy to catch early.

Q 5. What are the common causes of skipped stitches on a lockstitch machine?

Skipped stitches are frustrating, but usually stem from easily fixable causes.

- Incorrect Needle/Thread Combination: Using the wrong size needle for the thread or fabric type can lead to skipped stitches. Make sure they are compatible.

- Bent or Damaged Needle: A bent or dull needle will not penetrate the fabric consistently, resulting in skipped stitches. Replace the needle immediately.

- Incorrect Tension: Improper thread tension, either too tight or too loose, can cause skipped stitches. Adjust the tension dial to achieve a balance.

- Poor Thread Quality: Using low-quality, weak, or damaged thread can also lead to skipped stitches. Use high-quality thread appropriate for the fabric and machine.

- Dirty Machine: Lint and debris can build up in the machine’s workings, causing skipped stitches. Regular cleaning is vital.

- Bobbin Problems: A poorly wound bobbin, incorrect bobbin placement, or a damaged bobbin case can also cause skipped stitches.

Troubleshooting involves systematically checking each potential cause, one by one, until the issue is resolved. It’s a process of elimination, guided by your knowledge of the machine.

Q 6. How do you adjust the stitch length on a lockstitch machine?

The stitch length on a lockstitch machine controls the distance between each stitch. It’s usually adjusted using a dial or lever on the machine.

A shorter stitch length is typically used for seams that need to be strong and durable, such as in clothing construction. A longer stitch length is suitable for basting or gathering. You’ll see this adjustment dial clearly labeled on your machine.

The dial is often marked with numbers or lines that correlate to stitch length, usually measured in stitches per inch (SPI). A lower number indicates a longer stitch, while a higher number represents a shorter stitch. Always refer to your machine’s manual for specific instructions and recommended settings.

Q 7. Explain the importance of proper needle selection for different fabrics.

Proper needle selection is paramount for achieving high-quality stitches and preventing damage to both the fabric and the machine.

Different fabrics have varying thicknesses and fiber structures, and the right needle will ensure proper penetration without damaging the fabric or breaking the needle. For example:

- Fine fabrics (silk, chiffon): Require fine needles (size 60/8 or smaller) to avoid piercing holes.

- Medium-weight fabrics (cotton, linen): Usually use needles of size 70/10 or 80/12.

- Heavyweight fabrics (denim, canvas): Need heavier needles (size 90/14 or larger) to penetrate the dense material.

- Knit fabrics: Require ballpoint needles to glide between the knit loops without piercing them and causing runs.

Choosing the wrong needle can lead to skipped stitches, broken needles, or damaged fabric. Always consult your machine’s manual or a fabric-specific guide for the appropriate needle size and type.

Q 8. How do you maintain and clean a lockstitch machine?

Maintaining a lockstitch machine is crucial for its longevity and efficient operation. Think of it like regularly servicing your car – preventative maintenance is key. My cleaning and maintenance routine involves several steps:

Daily Cleaning: After each use, I remove lint and thread scraps from the bobbin area, hook assembly, and feed dogs using a small brush and compressed air. This prevents build-up that can lead to jams and poor stitch quality. Think of it as tidying your workspace – a clean machine equals clean stitches.

Weekly Cleaning: I’ll perform a more thorough cleaning, including removing and cleaning the bobbin case, needle plate, and presser foot. I use a lint-free cloth and sewing machine oil specifically designed for this purpose. This is like a mini-tune-up, ensuring all parts are lubricated and functioning smoothly.

Monthly Maintenance: This involves a more comprehensive check, including checking the timing of the machine, tension adjustments, and examining the needle for damage. I might also replace the needle as a preventative measure, even if it doesn’t appear damaged. This is like your car’s annual service – identifying potential problems before they escalate.

Annual Servicing: For high-usage machines, I recommend a professional service at least once a year. This involves a detailed inspection and any necessary adjustments or repairs by a qualified technician. This is similar to a major service for your car, ensuring everything is in perfect working order.

Q 9. What safety precautions should be followed when operating a lockstitch machine?

Safety is paramount when operating any sewing machine, especially a high-speed lockstitch machine. My safety precautions include:

Always unplug the machine before cleaning or performing maintenance. This prevents accidental shocks or injuries. Think of it like turning off the power to your house before working on the electrical system – safety first.

Keep fingers away from moving parts, especially the needle. This is an obvious but crucial point. Never reach into the machine while it’s running, and always use the appropriate safety guards where provided.

Use proper lighting to avoid eye strain. Poor lighting can lead to accidents and fatigue.

Maintain a clean and organized workspace. Cluttered workspaces increase the risk of accidents. A clear workspace improves focus and reduces the chances of tripping or knocking the machine over.

Wear appropriate clothing – avoid loose clothing or jewelry that could get caught in the machine. Tuck in loose hair, and be mindful of your surroundings.

Follow the manufacturer’s instructions. This includes safety guidelines and warnings.

Q 10. Describe your experience with high-speed lockstitch machines.

I have extensive experience with high-speed lockstitch machines, particularly those used in industrial settings. My experience spans various brands and models, from basic to highly sophisticated computerized machines. I’m comfortable working with machines capable of exceeding 5000 stitches per minute. Working with these machines requires a precise and efficient technique, emphasizing speed and consistent stitch quality. A key difference from standard machines lies in the increased precision and maintenance demands required to keep them functioning smoothly at such high speeds. For example, I’ve worked extensively with Juki, Singer, and Dürkopp Adler high-speed models, mastering their unique adjustments and maintenance needs.

During my time at [Previous Company Name], I was responsible for optimizing the production line by identifying and resolving bottlenecks associated with high-speed lockstitch machines. This included diagnosing and fixing mechanical issues, performing preventative maintenance, and training other operators on best practices.

Q 11. How do you identify and correct thread jams?

Thread jams are a common issue with lockstitch machines, but a systematic approach can quickly resolve them. My troubleshooting involves:

Inspect the thread path: Carefully check the entire thread path, from the spool to the needle, to identify any obvious obstructions or kinks in the thread. This often reveals the problem immediately.

Check the tension: Incorrect thread tension can cause jams. Ensure the upper and lower tensions are correctly adjusted according to the fabric and thread being used.

Examine the needle: A bent or damaged needle can lead to jams. Replace the needle if it’s damaged or worn. A slightly bent needle is often difficult to spot but will cause problems.

Clean the bobbin case: Lint and thread debris can accumulate in the bobbin case, causing jams. Remove and clean the bobbin case thoroughly.

Check the hook assembly: The hook assembly is a complex part, and issues there can cause severe jams. A more thorough inspection might be needed or even professional help.

Retrace the steps: If the issue is still unresolved, carefully repeat the threading process, checking each step for errors. Sometimes, a minor misstep can lead to a jam.

Q 12. What is your experience with different types of lockstitch machine needles?

My experience encompasses a wide range of lockstitch machine needles, each suited for different fabrics and stitch types. I’m familiar with various needle systems, including 130/705 H (system 134), 15×1 (system 134), and others, and understand the nuances of their applications. For example:

System 134 needles are widely used for their versatility and are suitable for a range of fabrics.

Ballpoint needles are best for knit fabrics to avoid snagging.

Sharp needles are ideal for woven fabrics.

Stretch needles are specifically designed for stretchy materials.

Choosing the right needle is critical for optimal stitch quality and minimizing needle breakage. The wrong needle can lead to skipped stitches, broken threads, and even damage to the machine.

Q 13. How do you ensure consistent stitch quality?

Consistent stitch quality is achieved through a combination of factors. My approach focuses on:

Proper Threading: Accurate threading is the foundation. I meticulously follow the threading sequence, ensuring the thread is properly seated in each guide and tensioner.

Correct Tension Adjustment: Appropriate tension balances the upper and lower threads, preventing puckering or loose stitches. I fine-tune this setting based on the fabric type and thread weight.

Needle Selection: Choosing the correct needle for the fabric type is essential. I use a system to match needles based on fabric properties.

Regular Maintenance: Consistent cleaning and lubrication of the machine prevent problems that affect stitch quality.

Stitch Length Adjustment: I adjust the stitch length to suit the fabric and the desired aesthetic.

Consistent Speed: While speed is important in high volume, maintaining a consistent speed reduces inconsistencies.

Q 14. How do you handle different types of sewing machine malfunctions?

Handling sewing machine malfunctions requires a systematic approach. My troubleshooting process involves:

Identify the Problem: Start by precisely defining the issue. Is the machine making unusual noises? Are stitches skipping? Is the needle breaking frequently? This is crucial to pinpoint the cause.

Check the Obvious: Before diving into complex repairs, check simple things such as power supply, thread, needle, and bobbin case for issues.

Consult the Manual: The manual provides troubleshooting guidance and diagrams, and it’s essential to consult this resource.

Isolate the Problem: Determine if the issue is mechanical, electrical, or related to tension. For example, a motor hum indicates an electrical issue, while inconsistent stitching points to tension or needle problems.

Attempt Basic Repairs: Try simple fixes like adjusting tension, replacing the needle, or cleaning the bobbin case. If you’re unsure, don’t attempt complex repairs.

Seek Professional Help: If the problem persists, it’s best to seek the assistance of a qualified technician. They have the expertise and tools for complex repairs.

Q 15. Explain the process of threading a lockstitch machine.

Threading a lockstitch machine might seem daunting, but it’s a methodical process. Think of it like building a tiny, precise highway for the thread to travel on. First, you raise the presser foot and the needle to its highest position. Then, you’ll begin by threading the upper thread, following the designated path, typically indicated by arrows on the machine. This usually involves passing the thread through the tension discs (which control the upper thread tension), then through the take-up lever, and finally into the needle. Next, you’ll thread the bobbin. Each machine has its own unique bobbin-winding system and bobbin case, but it generally involves winding thread onto the bobbin, carefully inserting it into the bobbin case, and then placing the bobbin case into the bobbin area of the machine. Once both the upper and lower threads are in place, you gently pull both threads to the rear of the machine, holding them, and then begin sewing. A simple test stitch should show you if the machine is threaded correctly – you should see a neat lockstitch forming. If not, carefully retrace your steps, checking each point of the threading path.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your preferred methods for maintaining consistent stitch tension?

Maintaining consistent stitch tension is crucial for professional-quality sewing. Think of it like balancing a scale: you need equal ‘pull’ from both the upper and lower threads to create a perfectly formed stitch. My preferred methods involve fine-tuning the machine’s tension dials. Each machine will have an upper tension dial, usually a numbered dial, and a method of adjusting the bobbin tension (often by adjusting the bobbin case spring). I start with the manufacturer’s recommended setting as a baseline and then make small adjustments, testing with scraps of the fabric I intend to use. If the stitches are loose on the top, I increase the upper tension slightly. If the stitches are loose on the bottom, I tighten the bobbin tension. If the stitches look bunched on the top and the bobbin thread is showing on the top surface, I decrease the upper tension. It’s iterative: sew a test seam, inspect, adjust, repeat until the stitch is even and secure on both sides of the fabric. The type of fabric also influences tension, with heavier fabrics needing slightly higher tension than lighter fabrics. For example, a heavy denim might require a higher upper tension setting compared to a fine silk.

Q 17. How do you handle fabric puckering during sewing?

Fabric puckering is a common issue, often caused by an imbalance in tension, improper needle selection, or feeding issues. It’s like trying to force two different sized pieces together – it won’t work smoothly. My first step is to check my stitch tension, ensuring it’s evenly balanced as discussed previously. Next, I carefully examine the needle, ensuring it’s sharp and appropriate for the fabric type. Using a dull needle can cause the stitches to skip and pull the fabric. If the needle is fine, I move on to examine the feed dogs. Are they appropriately adjusted to handle the fabric thickness? Sometimes, fabric too thick for the presser foot might cause uneven feed and puckering. I also consider using a walking foot if the issue persists. A walking foot helps move the top and bottom layers evenly, preventing puckering by helping to evenly feed all layers of the fabric.

Q 18. How do you troubleshoot problems related to fabric feed?

Fabric feed problems are often related to the feed dogs, the presser foot, or the machine’s overall maintenance. Think of the feed dogs as the machine’s ‘teeth’, gripping and moving the fabric. If the feed is inconsistent, I first check if the feed dogs are clean and free of debris. Often lint and thread build-up can interfere. A simple cleaning often resolves this. Next, I inspect the presser foot to ensure it’s correctly positioned and firmly pressing down on the fabric. An improperly adjusted presser foot pressure can prevent the feed dogs from working efficiently. Finally, I check for any mechanical issues like bent or broken parts in the feed mechanism itself; this may require professional attention.

Q 19. Describe your experience with different types of presser feet.

I’ve extensive experience with various presser feet, each designed for a specific purpose. The standard general-purpose foot is my workhorse, used for most straight stitching. However, I routinely use specialized feet like the zipper foot for installing zippers, requiring precision placement, a buttonhole foot for creating consistent, professional-looking buttonholes, the walking foot, as discussed, for even feeding of multiple layers, a rolled-hem foot for creating neat rolled hems, and a blind-hem foot for creating nearly invisible hems. Selecting the right presser foot is like choosing the right tool for a job; using the wrong one will always lead to imperfect results.

Q 20. How do you determine the correct speed for sewing different fabrics?

Sewing speed depends entirely on the fabric and the desired stitch quality. Think of it like driving – you wouldn’t drive at highway speeds on a bumpy, unpaved road. Delicate fabrics like silk or chiffon require slow speeds to avoid damage and ensure a clean stitch. Heavyweight fabrics like denim or canvas can generally tolerate higher speeds but will still benefit from a slower pace for accurate stitching in intricate areas. A moderate pace is suitable for medium-weight fabrics. I generally start slow, assessing the fabric’s response to the needle and adjusting the speed accordingly, always prioritizing quality over speed. The machine’s capabilities also need to be considered: some machines may not handle high speeds well.

Q 21. How do you work in a fast-paced, high-production environment?

In fast-paced environments, efficiency and accuracy are paramount. I thrive in these situations. My approach involves a combination of preparation, methodical work, and consistent quality checks. Preparation is key – ensuring my machine is well-maintained, correctly threaded, and fitted with the appropriate needle and presser foot for the job. A methodical approach means focusing on the task, maintaining a steady pace, and avoiding rushed actions that lead to mistakes. Regular checks of the stitch quality and seam construction help to catch any issues early on. This helps ensure the work meets quality standards even under pressure. I’m confident in my ability to manage time effectively, maintain high standards and collaborate efficiently within a team.

Q 22. What is your experience working with patterns and specifications?

My experience with patterns and specifications is extensive. I’m proficient in interpreting both technical drawings and industry-standard grading systems. This involves understanding seam allowances, marking placement, and the nuances of different fabric types. For example, working with a pattern for a tailored jacket requires a deep understanding of how the pattern pieces interact to create the final garment. I’ve handled complex patterns requiring multiple fabric layers and intricate stitching techniques, ensuring precise execution of each element. I also have experience in adapting patterns to accommodate variations in fabric weight and drape.

I am adept at using digital pattern-making software, which allows for quick and efficient modifications to existing patterns, and the generation of patterns from scratch. My attention to detail ensures the final product precisely matches the given specifications, resulting in consistent quality across various projects.

Q 23. How do you ensure quality control in your work?

Quality control is paramount in lockstitch machine operation. My approach is multi-faceted. Firstly, I meticulously inspect the fabric before commencing the operation for any defects like holes, stains, or inconsistencies in the weave. This prevents the creation of faulty end products. Secondly, I regularly check stitch quality throughout the sewing process—ensuring consistent tension, stitch length, and even feeding of the fabric. I utilize various tools like seam gauges and magnifying glasses to check for inconsistencies.

Thirdly, I maintain a detailed record of my work, noting any challenges encountered, corrections made, or adjustments to settings. This helps in identifying trends and addressing potential issues proactively. Finally, a thorough final inspection of the finished garment involves checking for seam integrity, proper alignment of pattern pieces, and adherence to specifications. It’s like building a house – you check every brick to ensure the final structure is sound.

Q 24. What is your experience with different types of sewing machine oils and lubricants?

My experience encompasses a range of sewing machine oils and lubricants, each suited for specific machine components and operating conditions. I understand the importance of using the correct lubricant to prevent friction, corrosion, and premature wear. For example, I use a high-quality, lightweight oil for the hook mechanism and shuttle, ensuring smooth operation and preventing build-up. A heavier grease is employed for moving parts that require more robust lubrication, such as the needle bar drive.

I’m familiar with different types of oils, including those designed for high-speed machines, and those formulated for specific machine brands or models. Regular lubrication is a key part of preventive maintenance and contributes significantly to the longevity and efficiency of the sewing machines. I always refer to the machine’s maintenance manual for specific lubrication recommendations.

Q 25. How do you identify and resolve problems with bobbin winding?

Bobbin winding problems are common but usually easily solved. The most frequent issues are uneven winding, resulting in a loose or tight bobbin, or a completely tangled bobbin. I troubleshoot these by first checking the bobbin case for any obstructions or damage. Sometimes, a small piece of lint can cause major problems.

Next, I verify the tension settings on the bobbin winder. Incorrect tension leads to uneven winding. I’ll adjust the tension dial until the winding is smooth and consistent, making sure the thread feeds easily without being pulled too tightly or too loosely. If the bobbin continues to wind poorly, I’ll check the bobbin itself for defects, and finally inspect the bobbin winder mechanism for any mechanical faults. Following this systematic approach ensures a quick resolution to the problem.

Q 26. What is your experience with automated or computerized lockstitch machines?

I have significant experience operating computerized lockstitch machines, including those with advanced features like automatic stitch length adjustment, pattern sequencing, and digital control panels. These machines offer greater precision and efficiency compared to their manual counterparts. For instance, in mass production environments, computerized machines are essential for maintaining consistency across numerous garments. The programmable settings allow for quick changes between different stitch types and lengths, increasing overall productivity.

I’m comfortable programming stitch patterns, adjusting speed and tension settings digitally, and troubleshooting any software or hardware-related issues. My knowledge extends to the maintenance and calibration of these sophisticated machines, ensuring optimal performance and longevity. My experience with computerized machines allows me to seamlessly integrate technology into the sewing process, leading to enhanced quality and increased output.

Q 27. How do you prioritize tasks and manage time effectively?

Prioritizing tasks and managing my time effectively involves a combination of planning and execution. Before commencing work, I thoroughly review the project specifications and deadlines, breaking down larger tasks into smaller, more manageable sub-tasks. This creates a clear roadmap, preventing me from feeling overwhelmed. I utilize a prioritized task list, focusing on time-sensitive projects first.

I also allocate specific time blocks for different tasks, ensuring focused execution. For example, I might dedicate the morning to high-precision sewing tasks and the afternoon to less intricate work. Regular breaks are essential to maintain focus and prevent fatigue, which could compromise quality. This systematic approach ensures that I meet deadlines and consistently deliver high-quality work.

Q 28. Describe your experience with troubleshooting and repairing sewing machines.

Troubleshooting and repairing sewing machines is a skill I’ve developed over years of experience. My approach is methodical. When a machine malfunctions, I start with a visual inspection, checking for obvious problems such as broken needles, damaged threads, or loose parts. I then systematically check the machine’s major components including the motor, timing mechanism, needle bar, hook, and feed dogs.

I’m familiar with diagnosing common issues like skipped stitches, inconsistent stitch length, or broken needles. My problem-solving skills enable me to identify the root cause of the malfunction, and then use appropriate tools and techniques for repair. This might involve cleaning, lubricating, adjusting tensions, or replacing worn-out parts. I always consult manuals and diagrams when needed, and I’m adept at using specialized tools for adjustments and repairs. My goal is to minimize downtime and ensure the machines are operational efficiently.

Key Topics to Learn for Lockstitch Machine Operation Interview

- Machine Setup and Maintenance: Understanding the different components of a lockstitch machine, their functions, and proper setup procedures. This includes threading the machine correctly, adjusting tension, and performing routine maintenance tasks like oiling and cleaning.

- Stitch Types and Adjustments: Familiarity with various stitch types achievable on a lockstitch machine and how to adjust settings (stitch length, width) to achieve desired results for different fabrics and applications. Practical experience adjusting settings to compensate for different fabric weights and types is crucial.

- Fabric Handling and Feeding Techniques: Mastering efficient fabric handling techniques to prevent puckering, stretching, or other common sewing errors. Understanding how fabric type impacts feeding and the adjustments needed for optimal results. This also includes understanding different feed dog mechanisms.

- Troubleshooting Common Issues: Identifying and resolving common problems like skipped stitches, broken needles, thread breakage, and uneven stitching. Demonstrating problem-solving skills and a methodical approach to troubleshooting is key.

- Safety Procedures and Regulations: Knowledge of relevant safety protocols associated with operating lockstitch machinery, including proper handling of needles, maintenance practices, and emergency procedures. Understanding and adhering to workplace safety regulations.

- Production Efficiency and Speed: Understanding techniques to optimize production speed while maintaining consistent stitch quality. This includes knowledge of efficient workflow and minimizing downtime.

- Different Lockstitch Machine Types: Familiarity with various types of lockstitch machines (e.g., industrial vs. domestic) and their specific characteristics and applications. Understanding the differences in functionality and maintenance.

Next Steps

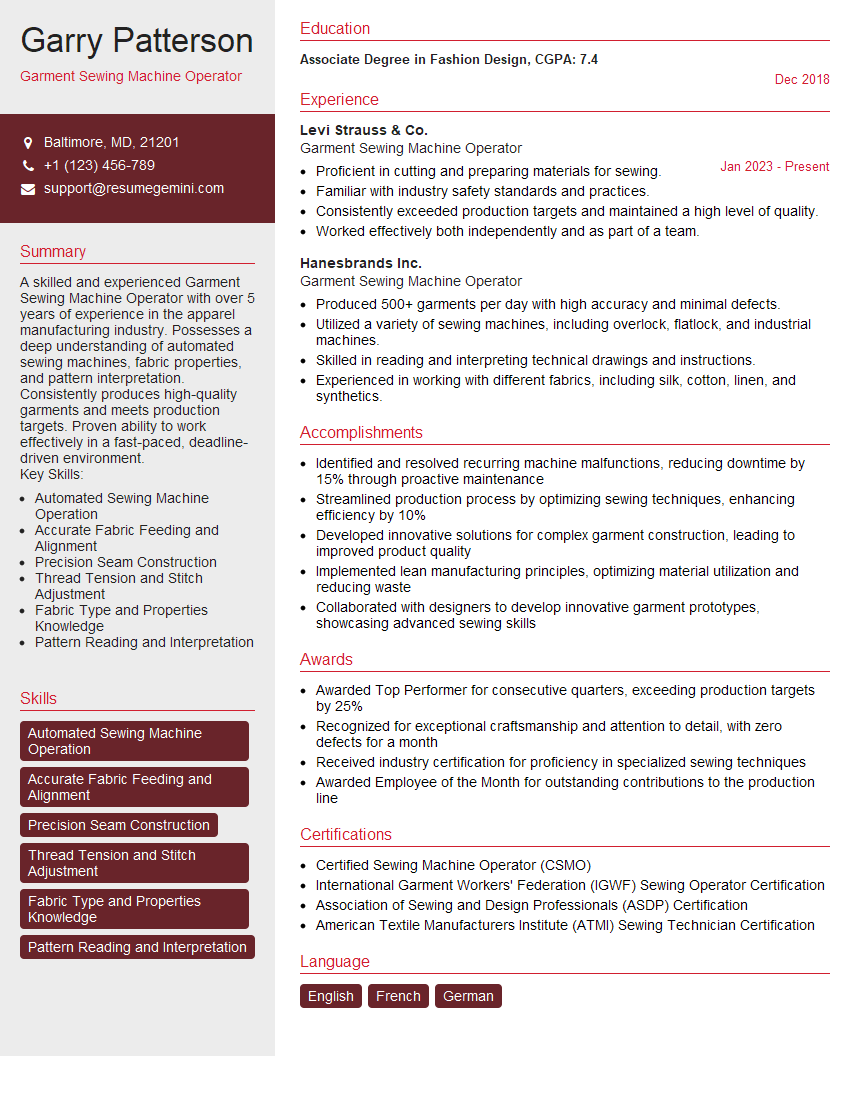

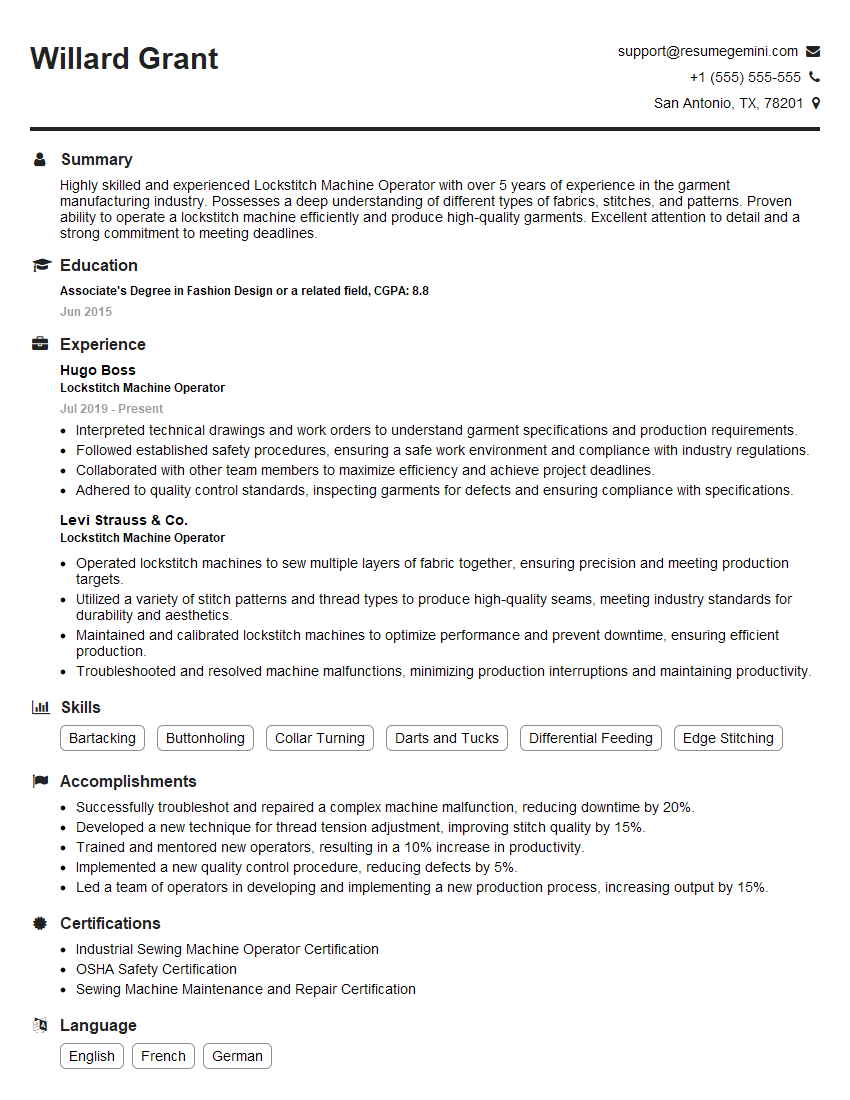

Mastering lockstitch machine operation is vital for a successful and rewarding career in the garment manufacturing or related industries. It opens doors to diverse roles and opportunities for advancement. To maximize your job prospects, focus on building a strong, ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource to help you create a professional and impactful resume. They provide examples of resumes tailored specifically to Lockstitch Machine Operation, allowing you to create a document that highlights your abilities and catches the attention of potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good