Are you ready to stand out in your next interview? Understanding and preparing for Lockstitch Sewing interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Lockstitch Sewing Interview

Q 1. What types of fabrics are best suited for lockstitch sewing?

Lockstitch sewing, the workhorse of the sewing world, is remarkably versatile. However, certain fabrics are better suited than others. Generally, fabrics with a balanced weave, meaning the warp and weft threads are of similar weight and density, sew beautifully with a lockstitch.

- Ideal Fabrics: Cotton, linen, silk (depending on weight), poplin, broadcloth, gabardine, and lightweight wool all work well. These fabrics offer a good structure and hold their shape, preventing puckering or stretching during stitching.

- Challenging Fabrics: Stretchy fabrics like jersey knits or lycra can be tricky, often requiring specialized needles and stitch settings. Similarly, very delicate fabrics like chiffon or organza require finesse and potentially a smaller stitch length to avoid damage.

- Heavier Fabrics: Heavier fabrics such as denim or canvas might need a stronger needle and a longer stitch length to penetrate effectively and prevent breakage.

Choosing the right fabric is crucial for a successful project. Understanding the fabric’s weave and weight will guide your needle and thread selection, ultimately leading to a professional finish.

Q 2. Explain the difference between a straight stitch and a zigzag stitch in lockstitch sewing.

Both straight stitch and zigzag stitch are fundamental lockstitch variations, but they serve distinct purposes.

- Straight Stitch: This is the most basic lockstitch, creating a simple line of stitches. It’s ideal for seams that need strength and durability, such as in trousers or shirts. Think of it as the foundation upon which all other stitches are built. Its consistent stitch length provides a clean and reliable seam.

- Zigzag Stitch: This stitch creates a series of back-and-forth stitches, forming a zigzag pattern. It’s primarily used for decorative purposes, finishing raw edges (preventing fraying), or creating decorative seams. Its unique pattern allows greater flexibility and stretch, making it suitable for stretchy fabrics.

Imagine constructing a house: the straight stitch is like building the solid walls, providing strength and structure, while the zigzag stitch is like the decorative trim, adding visual appeal and preventing the edges from unraveling.

Q 3. How do you adjust the stitch length and width on a lockstitch sewing machine?

Adjusting stitch length and width is critical for achieving the desired result. Most lockstitch machines have dials or controls for these adjustments.

- Stitch Length: This setting determines the distance between each stitch. A shorter stitch length (e.g., 1.5-2.0 mm) provides increased strength and durability, ideal for seams that bear stress. Longer stitch lengths (e.g., 3.0-4.0 mm) are suitable for basting or top-stitching. The setting is usually controlled by a dial marked in millimeters or stitches per inch (SPI).

- Stitch Width: This setting affects the width of the zigzag stitch. A narrower zigzag is better for finishing seams, while wider settings are used for decorative purposes. The control is usually a dial or lever, and the width is often measured in millimeters.

Experimenting with different stitch lengths and widths is essential to finding the optimal setting for various fabrics and sewing projects. Always test your settings on a scrap fabric before working on your main project.

Q 4. Describe the proper needle and thread selection for various fabrics.

Proper needle and thread selection is paramount for successful lockstitch sewing. The needle must be compatible with the fabric type, and the thread must be strong enough to withstand the stress of stitching but fine enough to avoid damage.

- Lightweight Fabrics (silk, chiffon): Use a fine needle (size 60/8 or 70/10) and a thin, high-quality thread (e.g., 50 wt).

- Medium-weight Fabrics (cotton, linen): Use a medium-weight needle (size 75/11 or 80/12) and a medium-weight thread (e.g., 60 wt).

- Heavyweight Fabrics (denim, canvas): Use a heavy-duty needle (size 90/14 or 100/16) and a strong thread (e.g., 40 wt or heavier).

Matching the needle and thread to the fabric prevents needle breakage, thread breakage, skipped stitches, or damage to the fabric. Always check your needle for any bending or damage before each sewing project.

Q 5. How do you identify and troubleshoot common lockstitch sewing machine problems?

Troubleshooting lockstitch sewing problems often involves a systematic approach.

- Skipped Stitches: Check the needle for damage, ensure the thread is properly threaded, and adjust the tension. The fabric might also be too thick or too thin for the needle and thread combination.

- Broken Needle: This is usually caused by a dull needle, improper needle insertion, or sewing too fast through a thick fabric layer.

- Uneven Stitch Length or Width: Check and adjust the settings on the machine. Make sure the bobbin is correctly wound and properly inserted.

- Thread Breakage: This can be due to incorrect tension, a damaged thread, or a knotted thread. Check for any snags or kinks in the thread path.

- Tension Problems: Uneven tension leads to puckering or loose stitches. Adjust the upper and lower tension dials, working on a scrap piece of fabric to perfect the setting for the specific fabric and thread combination.

A methodical approach to troubleshooting minimizes downtime and results in a smoother, more efficient sewing process. Sometimes, a simple adjustment is all that is needed to resolve the problem.

Q 6. What are the different types of lockstitch needles and their applications?

Lockstitch needles come in various types, each suited for specific fabric types.

- Universal Needles: These are all-purpose needles suitable for a wide range of fabrics. They are a good starting point for most projects.

- Ballpoint Needles: Designed for knit fabrics, these needles have a rounded tip that prevents piercing the fabric’s loops and causing runs or ladders.

- Sharp Needles: Used for woven fabrics, these needles have a sharp point that penetrates the fibers easily.

- Stretch Needles: Similar to ballpoint needles, these are specially designed for extremely stretchy fabrics, minimizing damage to the fabric structure.

- Jeans Needles: These heavy-duty needles are made for thick fabrics like denim, with a reinforced point to reduce breakage.

Selecting the right needle ensures that the stitches are neatly formed, minimizing damage to the fabric and improving the overall quality of the finished garment.

Q 7. Explain the importance of proper tension adjustment in lockstitch sewing.

Proper tension adjustment is crucial for creating balanced, neat lockstitches. Incorrect tension leads to several problems.

- Too Much Upper Tension: The stitches will be pulled to the top of the fabric, creating puckering and possibly breakage.

- Too Much Lower Tension: The stitches will be loose and visible on the underside of the fabric, leading to a weak and uneven seam.

- Balanced Tension: The stitches should appear even on both sides of the fabric, creating a strong and neat seam. The adjustment is usually done using dials on the sewing machine for upper and lower tension.

Think of tension as a tug-of-war between the upper and lower threads. The goal is to achieve a balance where both threads interlock perfectly, creating a beautiful and durable stitch. Proper tension is the key to professional-looking results. Regular checks and fine adjustments will minimize the occurrence of sewing errors.

Q 8. How do you maintain and clean a lockstitch sewing machine?

Maintaining your lockstitch sewing machine is crucial for its longevity and performance. Think of it like regularly servicing your car – preventative care is key. Cleaning involves several steps:

- Regular Dusting: After each use, gently brush away lint and dust from the bobbin area, feed dogs, and presser foot. A soft brush or compressed air works well.

- Bobbin Case Cleaning: Periodically remove the bobbin case and clean it thoroughly with a small brush, paying close attention to any lint buildup. This prevents tension issues.

- Needle Plate Cleaning: Remove the needle plate (after unplugging the machine!) and clean out any trapped lint or debris. A small screwdriver or similar tool can help dislodge stubborn pieces.

- Oil Application: Depending on your machine’s manual, you’ll likely need to lubricate certain parts with sewing machine oil. This reduces friction and extends the machine’s life. Apply only a single drop to designated areas to avoid excess oil.

- Professional Servicing: For more in-depth cleaning and maintenance, including adjustments to timing and tension, consider taking your machine to a professional once a year or as needed.

Remember to always unplug the machine before any cleaning or maintenance activity to ensure your safety.

Q 9. Describe the process of threading a lockstitch sewing machine.

Threading a lockstitch machine might seem daunting, but it’s a straightforward process once you understand the steps. It’s like following a recipe – each step is crucial for the final result. Let’s outline the process, assuming a standard top-loading machine:

- Raise the Presser Foot: This allows for easy threading.

- Raise the Needle to its Highest Point: This gives you optimal access to the threading path.

- Thread the Upper Tension Discs: Carefully guide the thread through the tension discs, usually located on top of the machine. Ensure the thread is seated properly to avoid tension problems.

- Follow the Thread Path: Most machines have clear markings indicating the thread path. Follow these guides, moving the thread through the take-up lever, and then down to the needle.

- Thread the Needle: This requires a delicate touch. Insert the thread from front to back, ensuring it’s securely seated.

- Wind the Bobbin: Place the empty bobbin on its spindle, thread it, and wind it with the machine’s bobbin winder. A properly wound bobbin is crucial for smooth sewing.

- Insert the Bobbin: Carefully place the wound bobbin into the bobbin case. Many machines have a simple latch mechanism to secure the bobbin case.

- Test the Threading: Slowly rotate the handwheel to check for smooth thread flow. You should see the needle move up and down, and the bobbin thread should come up to meet the upper thread to form a stitch.

Always consult your machine’s manual for specific instructions, as the threading process can vary slightly between models.

Q 10. What safety precautions should be taken while operating a lockstitch sewing machine?

Safety should always be your top priority when operating any sewing machine. Think of it like working in a workshop – safety precautions are non-negotiable. Here are key safety precautions:

- Unplug the Machine: Always unplug the machine before cleaning, oiling, or making any adjustments. This prevents electrical shock.

- Keep Fingers Clear: Never put your fingers near the needle while the machine is running. Guide fabric carefully, avoiding any accidental contact.

- Proper Foot Pedal Use: Use the foot pedal gently and gradually, avoiding sudden movements that could cause accidents.

- Sharp Objects: Keep sharp objects away from the machine to avoid accidents.

- Machine Maintenance: Regular maintenance, as discussed earlier, helps prevent malfunctions and reduces the risk of accidents.

- Proper Workspace: Maintain a clear and well-lit workspace to prevent accidents and ensure easy access to your materials.

- Suitable Clothing: Avoid loose clothing or jewelry that could get caught in the machine.

Remember, a safe workspace leads to a productive and enjoyable sewing experience. Safety is not just a suggestion; it’s a necessity.

Q 11. How do you handle fabric that is prone to fraying during lockstitch sewing?

Dealing with fabrics that fray easily, like silk or chiffon, requires extra care during lockstitch sewing. It’s like working with a delicate painting – careful handling is key. Here are some strategies:

- Pre-treat the Fabric: Use pinking shears to cut the fabric edges, preventing excessive fraying. Alternatively, you can apply a seam sealant or use a serger to finish the edges before sewing.

- Use a Smaller Stitch Length: This reduces the stress on the fabric and helps prevent unraveling during sewing.

- Use a Walking Foot: A walking foot helps feed the fabric evenly through the machine, minimizing pulling and stretching, which are the main causes of fraying for delicate fabrics. It’s like having an extra pair of hands to assist in the feeding process.

- Use Stabilizing Techniques: Consider using lightweight interfacing or tissue paper under the fabric to provide extra stability. You can easily tear this away after sewing.

- Slow and Steady Sewing: A slower speed gives you more control, allowing you to avoid pulling or stretching the fabric as you sew.

Choosing the right needle for the fabric type is also essential. A sharp needle, suited to the fabric’s weight, prevents skipped stitches and snags that contribute to fraying. Always test your technique on a scrap piece of fabric first.

Q 12. How do you sew curves and corners accurately using lockstitch?

Sewing curves and corners accurately with a lockstitch requires a bit of practice, but mastering the technique will improve your sewing dramatically. It’s like learning calligraphy – precision is key. Here’s how:

- Ease into Curves: When sewing a curve, guide the fabric smoothly and avoid abrupt turns. Slow and steady is especially important here.

- Pivot at the Corners: For sharp corners, stop the machine with the needle down at the corner point. Pivot the fabric, and then lower the presser foot before continuing. This creates a clean, mitered corner.

- Use Clips to Guide Fabric: Using clips to hold and manipulate the fabric helps to maintain the shape of the curve and avoids distortion during the sewing process.

- Practice on Scraps: Before tackling your project, practice your curves and corners on scrap fabric to hone your skills. This will also help you refine your technique and ensure accuracy.

- Appropriate Stitch Length: Use a slightly shorter stitch length in curves and corners to avoid stretching and to make the stitches more secure.

Remember, consistent pressure on the foot pedal and gentle guidance of the fabric are essential for accurate lockstitch sewing of curves and corners.

Q 13. What is the purpose of a walking foot on a lockstitch sewing machine?

A walking foot is a specialized presser foot attachment for lockstitch sewing machines designed for feeding fabrics evenly through the machine. Imagine it as a pair of tiny feet that grip both the top and bottom layers, preventing slippage or shifting of layers. This is particularly useful for:

- Difficult Fabrics: It excels with thick, multiple-layered materials (like denim or canvas), preventing the top layer from feeding faster than the bottom layer, which commonly causes puckering or feeding issues.

- Matching Patterns: The walking foot helps to accurately align patterns in fabrics, crucial for quilting and other projects that require precise pattern matching.

- Preventing Slipping: It’s invaluable when working with slippery fabrics (like satin or silk) that tend to slip under the conventional presser foot.

- Feeding Evenly: This foot ensures the consistent feeding of all layers of the fabric, leading to neat, even stitching.

While not necessary for all projects, a walking foot is a great investment for anyone who frequently works with challenging fabrics or intricate projects where precise feeding is essential.

Q 14. Describe your experience with different types of lockstitch sewing machines (e.g., single needle, double needle).

My experience encompasses a wide range of lockstitch machines, from basic single-needle models to more advanced double-needle and industrial machines. Each type has its own strengths and weaknesses.

- Single-Needle Machines: These are the most common type, suitable for a wide variety of sewing tasks. They’re versatile, easy to maintain, and are a great starting point for many sewers. I’ve extensively used these for garment construction, alterations, and general sewing projects.

- Double-Needle Machines: These machines have two needles, creating two parallel rows of stitching. This is ideal for finishing seams, creating decorative stitching, and making professional-looking hems with double stitching. I’ve found these particularly useful for creating clean-finished edges on knits and other stretchy fabrics.

- Industrial Lockstitch Machines: These are heavier-duty machines designed for high-volume production. They’re incredibly robust and efficient, but require more specialized knowledge to operate and maintain. I’ve used industrial machines in production settings where speed and durability are paramount.

My experience working with these different types allows me to select the appropriate machine for any given task, taking into consideration the fabric type, project complexity, and desired outcome. Understanding the nuances of each machine type is crucial for efficiency and high-quality results.

Q 15. Explain the importance of proper presser foot pressure in lockstitch sewing.

Proper presser foot pressure is paramount in lockstitch sewing because it directly impacts the quality and consistency of your stitches. Think of the presser foot as the hand that gently guides the fabric under the needle. Too much pressure can cause puckering, breakage of delicate fabrics, or even damage to the needle. Too little pressure, and the fabric will feed unevenly, leading to skipped stitches or inconsistent stitch length. The ideal pressure ensures the fabric is held firmly but not strained.

Finding the right pressure often involves experimentation. Many modern machines have an adjustable pressure dial. Start with the machine’s recommended setting for your fabric type, then adjust slightly, testing on a scrap piece of the same fabric before proceeding with your project. For example, a lightweight silk might need minimal pressure, while heavy canvas would require significantly more.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure consistent stitch quality throughout a sewing project?

Consistent stitch quality relies on a multi-pronged approach: using the correct needle and thread for your fabric, maintaining consistent speed, ensuring proper tension, and of course, using the correct presser foot pressure (as discussed above). Regularly cleaning and maintaining your sewing machine is also crucial. Lint and dust buildup can impact the machine’s performance, leading to uneven stitches. Imagine a well-oiled machine versus a rusty one – the difference in performance is significant.

Before starting a large project, I always test my stitch settings on a scrap of the intended fabric. This allows me to fine-tune the tension and stitch length to achieve a perfectly consistent stitch quality throughout the project. This simple step prevents wasted time and material later on.

Q 17. Describe your experience with different sewing techniques using lockstitch.

My experience with lockstitch encompasses a broad range of techniques, from basic straight seams to more complex applications like topstitching, bound buttonholes, and even decorative stitching using various stitch patterns. I’ve worked extensively with different seam finishes, such as serging, pinking, and French seams, to enhance durability and appearance. For example, I’ve used lockstitch for creating tailored garments, where precise stitch placement and consistent tension are vital for a professional finish.

I’ve also experimented with appliqué techniques, using lockstitch to secure decorative fabrics to a base fabric. The challenge here lies in maintaining an even stitch length and preventing puckering while working with varying fabric thicknesses. This requires careful control of the presser foot pressure and feed dog speed.

Q 18. How do you identify and repair common sewing machine malfunctions?

Troubleshooting sewing machine malfunctions requires a systematic approach. I begin by identifying the problem: is the machine not stitching at all? Are the stitches inconsistent? Is the thread breaking frequently? Common problems often involve improper threading, needle issues, tension problems, or lubrication issues.

My troubleshooting steps typically involve:

- Checking the bobbin case and winding for proper tension and thread placement.

- Inspecting and replacing the needle if it’s bent or damaged.

- Adjusting the upper and lower thread tension.

- Cleaning and oiling the machine according to the manufacturer’s instructions.

- Checking the timing of the machine’s hook and needle.

If the problem persists after these steps, I consult the machine’s manual or seek professional assistance.

Q 19. What is your experience with industrial lockstitch sewing machines?

I have extensive experience with industrial lockstitch sewing machines, having used them in both high-volume production settings and smaller custom work environments. Industrial machines are significantly more powerful and durable than domestic machines, capable of handling heavier fabrics and higher sewing speeds. They often feature specialized attachments and feed mechanisms for specific applications.

Working with industrial machines demands a different skill set. The higher speed and power require precision and a thorough understanding of the machine’s mechanics. Safety is also paramount due to the increased speed and power of these machines. I’m proficient in maintaining and troubleshooting industrial lockstitch machines, ensuring optimal performance and minimizing downtime.

Q 20. What are some common fabric types and thread choices for lockstitch projects?

The choice of fabric and thread is crucial for achieving optimal results in lockstitch sewing. Fabric choices range widely, from lightweight silks and linens to heavy-duty denim and canvas. Thread selection must complement the fabric weight and type. For instance, fine cotton thread is appropriate for delicate fabrics, while heavier-duty polyester thread is better suited for thicker materials.

Some common fabric-thread pairings include:

- Lightweight fabrics (silk, chiffon): Fine cotton or silk thread.

- Medium-weight fabrics (cotton, linen): All-purpose cotton or polyester thread.

- Heavyweight fabrics (denim, canvas): Heavy-duty polyester or nylon thread.

It’s also important to consider the thread’s color and sheen to match the fabric and project requirements.

Q 21. How would you adjust your sewing technique for different fabric weights?

Adjusting sewing technique for different fabric weights involves modifying several key settings and actions. Heavier fabrics generally require a longer stitch length to prevent breakage and puckering. The feed dogs should also be adjusted to maintain an even feed rate, preventing the fabric from bunching or skipping. Increased presser foot pressure is often needed to manage heavier fabrics, as mentioned before.

Conversely, lighter fabrics might require a shorter stitch length for better durability and a reduction in presser foot pressure to prevent damage. Slowing down the sewing speed can provide better control, especially when dealing with delicate or slippery fabrics. Using a walking foot can greatly improve the even feed of multiple layers of fabrics, a helpful addition when sewing with bulky or slippery material.

Q 22. Describe your experience with different types of seams (e.g., flatlock, French seam).

My experience encompasses a wide range of seam types, crucial for achieving diverse aesthetic and functional outcomes in garment construction. Lockstitch sewing is the foundation, but I’m proficient in many others. For instance, a flatlock seam, created using a serger or coverstitch machine, offers a clean, stretchy finish ideal for activewear or swimwear. It’s essentially a decorative and functional seam in one, offering excellent durability and flexibility. In contrast, a French seam, a more intricate technique using two separate seam allowances enclosed within each other, provides a beautifully finished, and very neat, inside and outside of the garment and is great for sheer fabrics where raveling is a concern. I’ve also worked extensively with other seam types including: basic single seams, double seams for extra strength, welt seams for pockets, and felled seams for a durable and professional finish, which are each suited to different fabrics and projects. The choice depends entirely on the garment’s intended use, fabric type, and desired aesthetic.

For example, I recently constructed a tailored blazer requiring precise French seams on the inner lining for a luxurious, high-quality finish, and then used a simple, strong lockstitch on the outer fabric for its durability. Understanding these nuances is critical for producing high-quality garments.

Q 23. How do you assess the quality of a finished seam in lockstitch sewing?

Assessing seam quality in lockstitch sewing involves a multi-faceted approach. I look for several key indicators:

- Stitch Consistency: Even stitch length and consistent tension are crucial. Inconsistent stitching points to potential problems with the sewing machine or improper thread tension settings. I’ll visually inspect and feel it to ensure its evenness and security.

- Seam Strength: A properly constructed seam should withstand considerable stress without breaking. I’ll gently tug on the seam to test its resilience. Any sign of weakness or fraying indicates a need for reinforcement.

- Neatness and Finish: The seam allowance should be neatly trimmed and pressed, reflecting professionalism and attention to detail. Overly bulky seams or uneven trimming suggest carelessness.

- Alignment: The seam should run straight and true, matching the pattern pieces accurately. Misalignment creates a visibly sloppy garment.

By systematically evaluating these factors, I can ensure the highest possible quality and durability of the finished garment. Any flaws found lead me to investigate and rectify the cause, whether it’s a machine issue or a technique that needs refining.

Q 24. How do you handle different seam allowances based on the project specifications?

Seam allowances vary based on several factors: fabric type, project style, design specifications, and even the sewing machine’s capabilities. Pattern instructions specify these allowances precisely, usually expressed as a measurement in inches or centimeters. For example, a 5/8 inch seam allowance is very common, while tailoring projects often call for smaller allowances, like 1/4 inch. I always check the pattern carefully before cutting fabric.

My approach involves:

- Precise Measurement: I always use a ruler to measure the exact seam allowance consistently.

- Fabric Type Consideration: Heavier fabrics might need a wider seam allowance for strength, while lighter, more delicate fabrics require a smaller one to avoid bulk.

- Adaptive Techniques: Sometimes, patterns call for specific seam finishes. A narrow seam allowance may be needed when finishing with a serger to prevent bulk, whereas a wider allowance is better when using a flat fell or double stitch.

- Following Specifications to the Letter: The instructions are paramount – altering seam allowances without understanding the rationale might compromise the garment’s fit and integrity.

By diligently following these steps, I ensure that the seam allowance contributes to the overall success of the project. Inconsistent seam allowances are an easy way to spoil the look and fit of an otherwise well-constructed piece.

Q 25. What is your experience with pattern reading and interpretation?

Pattern reading and interpretation are fundamental skills for lockstitch sewing. My proficiency allows me to confidently translate a 2D pattern into a 3D garment. This involves understanding various symbols, markings, and instructions found within the pattern. I can interpret grading charts to adjust sizing and understand notations regarding seam allowances, notches, and darts.

I approach pattern reading systematically, starting with a thorough review of all instructions and diagrams before cutting the fabric. This prevents mistakes and ensures I have a clear understanding of the steps involved. I regularly work with both commercial and self-drafted patterns and am comfortable adapting them to meet specific needs or design specifications. I’m also skilled at identifying potential fitting issues based on pattern construction and can make adjustments to ensure a well-fitting garment. A case in point: I once had to adapt a commercial pattern for a client with a high bust, requiring careful adjustments of the bodice pattern pieces before cutting.

Q 26. What are some common sewing machine maintenance procedures?

Regular maintenance is crucial for the longevity and optimal performance of a sewing machine. My routine includes:

- Cleaning: Regularly removing lint and dust from the bobbin case, feed dogs, and other components with a brush and compressed air is vital. This prevents build-up that could affect the machine’s operation.

- Lubrication: Applying appropriate sewing machine oil to moving parts according to the manufacturer’s instructions is essential for reducing friction and wear. This step is important for a smooth-running machine.

- Needle Changes: Using sharp, appropriately sized needles for the fabric type is paramount. A dull needle can damage fabric and lead to broken threads. I change needles frequently, often after completing one project.

- Tension Adjustment: I regularly check and adjust the upper and lower thread tension to ensure balanced stitching. Incorrect tension results in uneven stitching, and sometimes broken threads or skipped stitches.

- Timing Belt Check: Periodic checks ensure the timing belt is correctly aligned, to ensure the machine stitches perfectly and smoothly.

These simple steps prevent costly repairs and ensure that my sewing machine operates at peak efficiency, resulting in high-quality stitches and consistent results. Neglecting maintenance can lead to machine breakdowns, wasting valuable time and potentially causing costly repairs.

Q 27. How would you adapt to changes in sewing specifications or project deadlines?

Adaptability is essential in a dynamic sewing environment. When faced with changes in specifications or deadlines, I approach the situation systematically. Firstly, I carefully review the changes and identify their impact on the existing plan. Then, I prioritize tasks based on urgency and importance, communicating with relevant parties to clarify expectations and potential bottlenecks.

For example, if a deadline is shortened, I might reassess the workflow and allocate more resources or work overtime, possibly seeking additional support from the team if necessary. Changes to sewing specifications may require a re-evaluation of materials and techniques to maintain quality and accuracy. Throughout the process, I maintain open communication with supervisors to keep them apprised of progress and any challenges encountered. My experience helps me to assess situations quickly, adjust the plan effectively, and maintain productivity.

Q 28. Describe your experience working in a team environment within a sewing production setting.

I’ve worked extensively in team-based sewing production settings, valuing collaboration and effective communication. In such environments, teamwork is paramount for meeting production goals and maintaining quality. My contributions include actively participating in team discussions to find solutions to problems, helping colleagues, and sharing expertise. I’m comfortable working as part of a larger assembly line or a smaller team focused on a specific garment, adapting my approach to fit the project and team dynamics.

A recent example involved a complex project with a tight deadline, where our team had to work closely together to coordinate tasks and ensure efficient workflow. Each member had a specific role and expertise (cutting, stitching, finishing), requiring careful scheduling and clear communication to stay on track. By supporting and assisting colleagues, we successfully completed the project on time and to the highest standard.

Key Topics to Learn for Lockstitch Sewing Interview

- Machine Operation & Maintenance: Understanding the mechanics of a lockstitch sewing machine, including threading, tension adjustment, needle selection, and basic troubleshooting.

- Stitch Types & Applications: Knowing the different types of lockstitch (e.g., straight stitch, zigzag stitch) and their appropriate applications in various fabrics and garment construction.

- Fabric Selection & Properties: Understanding how different fabric types (e.g., woven, knit) impact stitch selection, needle size, and sewing techniques.

- Seam Construction & Finishing: Mastering techniques for creating strong, durable seams, including seam allowances, different seam finishes (e.g., serging, overlocking), and understanding their impact on garment quality.

- Pattern Interpretation & Cutting: Ability to interpret sewing patterns, accurately cut fabric pieces, and understand marking techniques.

- Quality Control & Inspection: Identifying common sewing defects and implementing quality control measures to ensure consistent stitch quality and garment accuracy.

- Safety Procedures & Ergonomics: Understanding and adhering to safety protocols while operating sewing machinery and maintaining proper posture and ergonomics to prevent injury.

- Problem-solving & Troubleshooting: Diagnosing and resolving common sewing machine issues, such as skipped stitches, broken needles, or tension problems.

- Industry Best Practices: Familiarity with industry standards, quality control measures, and efficient production techniques.

Next Steps

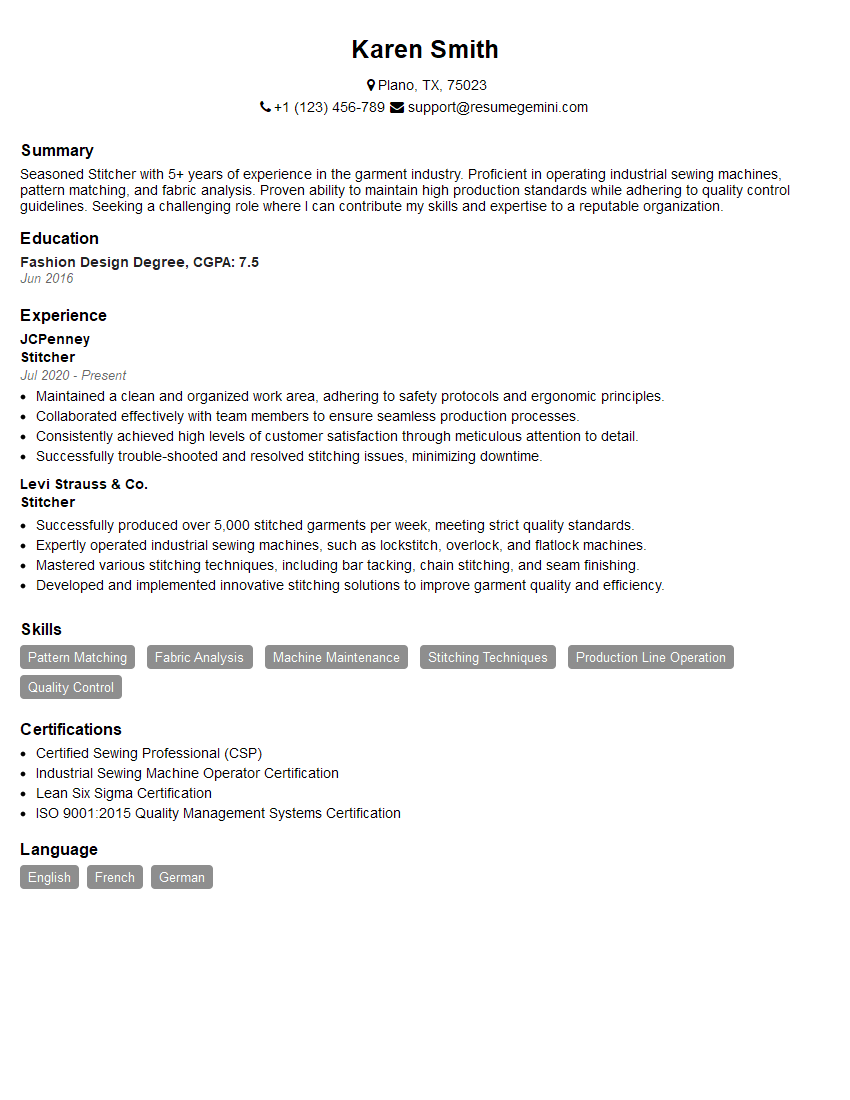

Mastering lockstitch sewing opens doors to a wide range of exciting career opportunities in the fashion, textile, and manufacturing industries. To maximize your chances of landing your dream job, a strong and well-crafted resume is essential. An ATS-friendly resume ensures your application gets noticed by recruiters. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored to Lockstitch Sewing to guide you through the process, helping you present yourself as the ideal candidate.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good