Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Log Grader interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Log Grader Interview

Q 1. Explain the different log grading rules and their applications.

Log grading rules vary depending on the species of tree, intended use of the lumber, and the specific grading agency’s standards. However, common themes include assessing the log’s dimensions (length and diameter), assessing the presence and severity of defects (knots, rot, checks, splits), and determining the overall quality of the wood based on its straightness, soundness, and freedom from defects.

- Visual Grading: This is the most common method, relying on visual inspection by a trained grader who assesses the log’s characteristics. Different grades are assigned based on established criteria, often resulting in grades like A, B, C, etc., with A representing the highest quality.

- Mechanical Grading: This approach uses instruments to measure log characteristics like diameter, length, and sometimes internal defects. While reducing subjectivity, it’s more expensive to implement. Data from these scans can then be used to categorize logs automatically.

- Applications: Log grading directly impacts pricing. Higher grades command higher prices because they produce greater yields of high-quality lumber, suitable for high-value applications like furniture manufacturing. Lower grades are often used for pulpwood, construction lumber, or other lower-value products.

For example, a perfectly straight, large-diameter log with minimal defects would grade higher than a smaller, crooked log with many knots. This is because the former can yield far more clear lumber, ideal for high-end uses.

Q 2. Describe the process of log scaling and measurement.

Log scaling and measurement is the process of determining the volume of a log and its grade. It’s a critical step in the forestry and lumber industry for fair pricing and efficient resource management.

The process typically involves:

- Measuring the log’s length: Using a tape measure to determine the log’s overall length. Precise measurement is essential for accurate volume calculations.

- Measuring the log’s diameter: This is typically done at both the small and large ends of the log using a diameter tape or calipers. For irregularly shaped logs, multiple measurements might be necessary.

- Determining the log’s shape: Logs are rarely perfect cylinders; they can be tapered, oval-shaped, or have irregular curves. The shape affects the calculation method used for volume.

- Calculating the log’s volume: Several formulas exist, often based on assumptions about the log’s shape (e.g., Smalian’s formula assumes a frustum of a cone). Modern technologies also employ scanning to provide highly accurate volumetric measurements.

- Grading: As mentioned earlier, the log’s volume isn’t the only factor. Visual inspection determines the grade, which greatly affects its value.

Imagine a scenario where two logs have the same volume, but one is perfectly straight and knot-free while the other is severely crooked and full of knots. The grading process accounts for this quality difference, reflecting it in the final price.

Q 3. What are the common defects found in logs and how do they affect grading?

Logs often contain defects that significantly impact their grade and value. These defects reduce the amount of usable lumber that can be obtained from the log.

- Knots: Branches embedded in the wood. Large or numerous knots reduce lumber strength and quality.

- Rot: Decayed wood due to fungal growth. Rot weakens the wood and renders it unusable in many applications.

- Checks: Radial cracks or splits in the wood. These can weaken the wood and reduce its value.

- Splits: Longitudinal cracks that extend along the grain of the wood. They can be caused by various factors like stress and drying.

- Insect damage: Holes or tunnels created by insects. This can weaken the wood and increase the risk of further decay.

- Stain: Discoloration of the wood, which can be caused by various factors, often reducing its aesthetic appeal.

The severity of a defect impacts grading. A small knot in a large log may have minimal impact, while a large rot pocket could render the log unusable. Graders use established criteria to assess the impact of each defect on the overall log grade.

Q 4. How do you determine the volume of a log using different methods?

Several methods exist for determining log volume, each with its own advantages and disadvantages. The choice depends on the accuracy needed and the resources available.

- Smalian’s Formula: This is a common formula for calculating the volume of a tapered log, assuming it’s a frustum of a cone. The formula is:

Volume = (A1 + A2) / 2 * L, where A1 and A2 are the cross-sectional areas at the smaller and larger ends, respectively, and L is the length. This requires measuring the diameters at both ends. - Huber’s Formula: This formula uses the average cross-sectional area to approximate volume:

Volume = A_avg * L, where A_avg is the average cross-sectional area, typically calculated from the mid-diameter. It’s less precise than Smalian’s formula but simpler to apply. - Newton’s Formula: This provides more accurate estimations for highly tapered logs, taking into account more detailed shape factors. But it is also more complex to calculate.

- Log Scaling Sticks: These are physical tools providing pre-calculated volumes for different log diameters and lengths. Easy to use but limited in accuracy compared to formulas.

- 3D Scanning: Modern technology allows for highly accurate measurement of the log’s shape and volume using 3D scanning. This method offers excellent precision but requires specialized equipment.

The choice of method depends on the application; a sawmill might use 3D scanning for high-value logs but Smalian’s formula for more routine processing. Understanding the limitations of each approach is essential for accuracy and efficiency.

Q 5. What are the key factors influencing log price and value?

Log price and value are influenced by several key factors, interacting in a complex way.

- Log Grade: Higher grades, signifying better quality and greater yield of usable lumber, command higher prices.

- Log Species: Certain species are more valuable due to their strength, durability, appearance, or other desirable characteristics (e.g., oak, maple, cherry).

- Log Size and Shape: Larger-diameter logs and those with straighter grain yield more usable lumber, leading to higher values. Logs with ideal shapes are also more valuable.

- Market Demand: Fluctuations in market demand for specific species or lumber grades affect prices. High demand drives up prices while low demand leads to lower prices.

- Location: The distance from the harvesting site to the mill impacts transportation costs, affecting the final price.

- Defect Levels: Logs with fewer defects fetch higher prices than those with significant damage.

- Seasonality: Prices can fluctuate due to seasonal factors, like logging restrictions during specific seasons or weather conditions that affect harvesting.

For example, a large, straight-grained oak log with minimal defects will be far more expensive than a small, knotty pine log, reflecting its superior quality and greater yield of high-value lumber.

Q 6. Explain the different types of log sorting systems and their advantages.

Log sorting systems are crucial for efficiently managing large volumes of logs and segregating them based on size, grade, or species. The choice of system depends on factors such as volume, budget, and required accuracy.

- Manual Sorting: This involves human graders visually inspecting logs and directing them into different piles or lanes based on established criteria. Simple and adaptable but slow and labor-intensive.

- Mechanical Sorting (e.g., log scanners): Automated systems use sensors, scanners, and other technologies to measure log dimensions and characteristics, then direct them to designated areas based on pre-programmed rules. More efficient than manual sorting but requires a higher initial investment.

- Water Flumes: Logs are floated down a water channel, and their size and shape determine their path and final location. A simple system, effective for sorting based on size but less effective for grading quality.

- Automated Log Handling Systems: These sophisticated systems use robotic arms and conveyors to precisely move and sort logs based on various criteria. They offer high efficiency and precision but are the most expensive option.

For instance, a large sawmill with high-volume throughput would benefit from an automated log handling system for speed and efficiency. A smaller operation might utilize a more cost-effective manual or water flume system.

Q 7. How do you handle discrepancies in log measurements or grading?

Discrepancies in log measurements or grading can arise due to various factors – human error, equipment malfunction, or variations in grading standards. Handling these discrepancies requires a systematic approach.

- Double-checking Measurements: Independent verification of measurements using different methods or equipment can resolve simple errors.

- Reviewing Grading Criteria: Ensuring graders adhere to the established standards and criteria is essential to minimize subjectivity and bias.

- Calibration of Equipment: Regular calibration of measuring equipment, such as diameter tapes and scanners, ensures accuracy.

- Establishing Appeals Process: An appeals process allows for resolving disagreements over grading decisions, involving experienced graders or supervisors.

- Documentation: Maintaining detailed records of all measurements, grading decisions, and any discrepancies is vital for accountability and resolving issues.

- Negotiation and Compromise: In certain cases, negotiation between buyer and seller may be necessary to reach a mutually agreeable resolution.

For example, if a discrepancy arises due to a misreading of the diameter tape, re-measuring the log using another tape or a caliper could quickly clarify the issue. In more complex cases, an independent grader might be brought in to provide an unbiased assessment.

Q 8. Describe your experience using log grading software or tools.

My experience with log grading software spans several years and various platforms. I’m proficient in using both proprietary systems like those offered by major forestry companies and more general-purpose software incorporating scaling and grading functionalities. I’ve used these tools to process thousands of logs, inputting data on dimensions, defects, and species to generate accurate grading reports. For example, I’ve extensively utilized software that uses image recognition to assess log quality, minimizing human error and significantly speeding up the grading process. This software also allows for the creation of customized reports tailored to specific client needs, including detailed summaries of log volume, grade distribution, and overall value. In addition to the software, I’m experienced with various mobile applications that allow for on-site data collection and real-time updates to the central grading database.

Q 9. What are the current market trends affecting log pricing?

The log pricing market is dynamic and influenced by several key trends. Firstly, global demand, particularly from construction and manufacturing sectors in Asia and Europe, significantly impacts pricing. Increased demand leads to higher prices, while economic downturns can cause a decrease. Secondly, the availability of specific species and log sizes plays a crucial role. A shortage of high-quality logs of a particular species, like old-growth Redwood for example, can drive prices up considerably. Thirdly, sustainable harvesting practices are increasingly influencing market trends. Consumers and businesses are more conscious of environmental issues, leading to a higher premium for logs sourced from sustainably managed forests and certified through schemes like the Forest Stewardship Council (FSC). Lastly, technological advancements, such as improved logging equipment and grading software, are influencing efficiency and, consequently, pricing. These advancements can reduce costs, sometimes leading to slightly lower prices for the consumer, while simultaneously improving grading accuracy.

Q 10. How do you ensure accurate and consistent log grading?

Ensuring accurate and consistent log grading relies on a multi-faceted approach. Firstly, it begins with standardized procedures and training. All graders must be well-versed in the relevant grading rules, whether it’s a regional standard or a company-specific protocol. This usually involves extensive training and regular recalibration exercises. Secondly, consistent use of calibrated measuring tools is paramount. This includes diameter tapes, rulers, and other instruments used to assess log dimensions and defect characteristics. Regular maintenance and verification of these tools are essential to avoid measurement errors. Thirdly, utilization of advanced technologies like log scanners and grading software can significantly enhance accuracy. These tools offer objective measurements, reducing bias and human error. Finally, regular quality control checks and audits are crucial to monitor consistency across different graders and ensure adherence to established standards. Discrepancies are addressed through retraining or further calibration of equipment. Think of it like a chef using precise measurements and calibrated cooking tools to ensure consistent quality every time they prepare a dish.

Q 11. How do you identify different species of timber?

Identifying timber species involves a combination of visual examination and sometimes, more advanced techniques. Visual identification relies on characteristics like bark texture, color, grain pattern, and the scent of the wood (when freshly cut). For example, Douglas fir has a characteristic reddish-brown heartwood and distinct grain, while Ponderosa pine has a yellowish-brown color and a somewhat coarser grain. More challenging cases may require microscopic examination of wood anatomy or chemical tests to confirm species identification, especially when dealing with less common or similar-appearing species. Experienced graders often possess a keen eye and extensive practical experience, allowing them to identify a wide range of species accurately. I also use field guides and digital resources to help with identification, particularly when encountering less familiar species.

Q 12. Explain the role of sustainability in log grading and harvesting.

Sustainability plays a pivotal role in modern log grading and harvesting. Sustainable practices aim to balance economic benefits with environmental protection. In log grading, this translates to promoting the use of logs from sustainably managed forests, certified by organizations like the FSC. This ensures that the timber comes from responsible sources where reforestation and biodiversity are considered. Sustainable harvesting involves selective logging practices, minimizing damage to the remaining forest and protecting sensitive ecosystems. Grading practices themselves can also promote sustainability by maximizing the utilization of logs, minimizing waste, and ensuring that logs are allocated to their most appropriate end-use based on their quality and characteristics. For instance, logs with minor defects might be used for lower-grade lumber, reducing waste while still maximizing economic value.

Q 13. Describe your experience with different log species and their grading characteristics.

My experience encompasses a wide range of log species, each with unique grading characteristics. For instance, I’m familiar with the grading of softwoods like Douglas fir, which is graded based on its size, straightness, and knot characteristics. Hardwoods like oak and maple have different grading criteria, emphasizing aspects like grain figure, color, and the presence of defects such as shakes or splits. Each species has specific grading standards, often influenced by its intended end-use. For example, logs intended for high-quality furniture may have stricter grading standards than those destined for general construction lumber. I have extensive experience with various regional and international grading rules, enabling me to adapt my grading approach to the specific species and market requirements. This requires a detailed understanding of wood properties and the specific uses for different grades of timber.

Q 14. How do you manage and resolve conflicts related to log grading?

Conflicts related to log grading are usually addressed through a transparent and collaborative process. The first step involves a thorough review of the grading assessment, comparing the grader’s notes with the actual log characteristics. If a discrepancy is identified, it is then discussed with the involved parties, such as buyers and sellers. This often involves presenting photographic evidence and detailed measurements to support the grading decision. If a resolution isn’t reached through discussion, independent arbitration might be necessary, relying on an expert in log grading to provide an objective assessment. Transparency and clear documentation throughout the entire process are crucial to prevent and resolve such conflicts efficiently and fairly. Maintaining open communication and fostering trust between parties is key to avoiding disputes in the first place.

Q 15. What are the safety protocols you follow while grading logs?

Safety is paramount in log grading. My protocol begins with a thorough pre-shift inspection of all equipment, including chainsaws, measuring tapes, and any vehicles used for transport. I always wear appropriate personal protective equipment (PPE), which includes safety boots with steel toes, high-visibility clothing, safety glasses, gloves, and hearing protection, especially when operating machinery. I maintain a safe distance from moving equipment and ensure the work area is free of debris and hazards. Before commencing any work involving machinery, I perform a comprehensive check to ensure it’s functioning correctly and meets all safety standards. Furthermore, I’m trained in first aid and emergency procedures, and I know exactly what to do in case of an accident. For instance, if a chainsaw malfunctions, I immediately shut it down, assess the situation, and report the incident to the supervisor before attempting any repairs. Regular safety training keeps me updated on best practices and new regulations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with relevant forestry regulations and standards?

I am very familiar with relevant forestry regulations and standards, including those related to sustainable forestry practices, harvesting regulations, and log grading standards specific to my region. I understand and adhere to all applicable guidelines from organizations like the [mention relevant organizations, e.g., the Forest Stewardship Council (FSC), Sustainable Forestry Initiative (SFI), etc.], ensuring that all grading activities are conducted ethically and legally. My knowledge extends to the proper documentation and reporting procedures, ensuring complete traceability and compliance with relevant laws. For example, I am adept at identifying and classifying different species of trees based on their respective regulations and understand the specific grading requirements for each. Understanding these regulations not only ensures legal compliance but also contributes to the sustainable management of forest resources.

Q 17. Describe your experience working with different clients or stakeholders.

I’ve worked with a diverse range of clients and stakeholders, including logging companies, sawmills, timber exporters, and government agencies. Working with logging companies involves understanding their harvesting methods and ensuring that the graded logs meet their specific requirements, such as volume and quality standards. With sawmills, it’s crucial to understand their production processes and tailor my grading to optimize yield and minimize waste. When working with exporters, accurate grading is essential for meeting international standards and ensuring fair pricing. My experience with government agencies has involved participating in audits and ensuring compliance with regulations. For instance, I once worked with a sawmill that needed help streamlining their log processing by optimizing the grading process to increase yield and reduce waste. Through detailed analysis of their log inventory and discussions with their management, I identified and implemented changes that resulted in a significant improvement in their operational efficiency.

Q 18. What are your methods for improving the efficiency of the log grading process?

Improving the efficiency of log grading involves a multi-pronged approach. First, using technology, such as mobile apps with automated grading tools and digital measuring systems, significantly speeds up the process and minimizes human error. Secondly, optimizing the workflow, such as implementing a better system for log sorting and organization at the yard, reduces wasted time and movement. Thirdly, improving the training of personnel and implementing standardized procedures ensures consistency and accuracy across all graders. I also believe in implementing quality control checks throughout the grading process. For example, I’ve successfully implemented a system of random sample checks to verify the accuracy of grading against established standards. This ensures that the overall grading process is consistent and accurate. Finally, continuously reviewing the entire process and seeking areas for improvement is key.

Q 19. How do you utilize data and technology in your work?

Data and technology play a vital role in modern log grading. I use digital measuring tools for precise measurements, ensuring accuracy and speed. Software applications provide assistance in data analysis, allowing me to track grading metrics, identify trends, and make informed decisions. For example, using data analytics, I can identify patterns in log quality from specific areas of the forest which can inform future harvesting strategies. I also utilize mobile apps that can automatically record grading data, significantly reducing the time spent on paperwork and improving data management. This technology also assists in real-time tracking of inventory and generating reports that meet client-specific requirements. The use of GPS technology allows for precise location tracking of logs, enhancing inventory management and traceability.

Q 20. Explain your understanding of log quality control.

Log quality control is a crucial aspect of the grading process. It ensures that the graded logs meet the required standards and reduces losses due to defects. This involves a rigorous process of inspecting logs for defects such as rot, cracks, insect damage, and other quality impairments. This process is guided by established grading rules and standards, resulting in consistent quality assessment across different grading procedures. The implementation of strict quality control measures ensures that only logs meeting the required specifications are accepted. This minimizes risks associated with delivering substandard logs and safeguards the reputation and financial integrity of the operations. Regularly checking the grading equipment and calibrating it as required also forms a crucial part of the quality control process. A well-defined quality control system also ensures traceability of logs, helping in identifying the source of any defects or problems encountered further downstream.

Q 21. How do you handle stressful situations during log grading operations?

Stressful situations in log grading can arise from time pressure, demanding clients, or unexpected challenges such as inclement weather. My approach involves prioritizing tasks, focusing on one challenge at a time, and maintaining clear communication with my team and clients. I use time management techniques like prioritizing tasks based on urgency and importance, ensuring that the most critical aspects are handled first. Deep breaths and short breaks help to manage stress effectively. Maintaining open communication with my team ensures that everyone is aware of potential challenges and works collaboratively to resolve them. If a particularly challenging situation arises, I do not hesitate to seek guidance from more experienced colleagues or supervisors. For instance, when faced with a large backlog of logs and a tight deadline, I prioritize the most urgent orders and delegate tasks effectively to my team while maintaining clear communication to manage expectations. This proactive approach minimizes pressure and fosters a collaborative environment.

Q 22. How do you stay up-to-date with the latest advancements in log grading?

Staying current in log grading requires a multi-faceted approach. I actively participate in professional organizations like the American Society of Civil Engineers (ASCE) and attend relevant conferences and workshops focusing on forestry, timber engineering, and sustainable resource management. These events often feature presentations on the latest grading technologies and standards, such as advancements in automated grading systems using AI and machine learning. I also subscribe to industry publications like Forest Products Journal and regularly review research papers published in peer-reviewed journals to stay abreast of new research on wood properties and grading methodologies. Finally, I maintain a network of colleagues and experts in the field, engaging in regular discussions and knowledge sharing to ensure I remain at the forefront of this evolving discipline.

Q 23. Describe your problem-solving skills in relation to log grading issues.

My problem-solving approach to log grading issues is systematic and data-driven. I begin by thoroughly analyzing the problem, gathering all relevant information including log dimensions, species, defects, and the intended end-use of the lumber. I then apply my knowledge of established grading rules and standards (e.g., those from the American Lumber Standard Committee) to assess the situation. If the issue involves a complex defect or an unusual log characteristic, I might utilize advanced imaging techniques or consult relevant literature and expert opinions. For example, when faced with a log exhibiting unusual fungal decay, I would conduct a thorough visual inspection, potentially supplement it with a moisture meter reading, and compare my findings with established defect guidelines to determine the appropriate grade. Throughout the process, I prioritize accurate data collection and meticulous documentation to ensure transparency and repeatability. This structured approach helps in reaching efficient and accurate solutions even in ambiguous scenarios.

Q 24. What are your strengths and weaknesses as a Log Grader?

My strengths lie in my detailed understanding of various log grading standards and my ability to accurately assess log quality under diverse conditions. My experience with various grading tools, both manual and automated, contributes to my efficiency and accuracy. I also possess excellent communication skills enabling effective interaction with loggers, sawmill operators, and other stakeholders. One area I aim to improve is my proficiency in using the latest advanced log scanning and grading software. While I’m familiar with the basics, I recognize the value of deepening my expertise in this rapidly advancing technological field. I am actively seeking opportunities to enhance my skills in this area through training and hands-on experience.

Q 25. What are your salary expectations?

My salary expectations are commensurate with my experience and skills, and aligned with the market rate for experienced log graders in this region. I am open to discussing a competitive compensation package that reflects my value and contribution to your organization.

Q 26. Why are you interested in this position?

I am highly interested in this position because of your company’s reputation for sustainable forestry practices and its commitment to quality. The opportunity to contribute to such a responsible and forward-thinking organization is very appealing. Furthermore, the prospect of working with your advanced log-handling and processing equipment is exciting, and I believe my skills and experience would be a valuable asset to your team.

Q 27. Where do you see yourself in five years?

In five years, I see myself as a highly valued and respected member of your team, proficient in all aspects of log grading and potentially taking on a leadership role. I envision expanding my expertise in areas such as automated grading systems and contributing to the development of new and improved grading procedures. My goal is to continuously improve my skills and contribute to the company’s success through efficient and accurate log grading, ensuring the highest quality lumber products.

Q 28. Do you have any questions for me?

I have a few questions for you. Firstly, can you describe the specific grading standards and software used in this role? Secondly, what are the company’s plans for incorporating new technologies into the log grading process in the near future? Finally, what are the typical career progression opportunities within your organization for someone in this position?

Key Topics to Learn for Log Grader Interview

- Log Grading Standards: Understanding various grading rules and regulations (e.g., species-specific grading, defect identification, and size classifications). Be prepared to discuss the rationale behind these standards.

- Log Measurement and Volume Calculation: Mastering different methods for accurately measuring log dimensions (diameter, length) and calculating volume using various formulas. Practice applying these calculations to different log shapes and sizes.

- Defect Identification and Assessment: Develop a strong understanding of common log defects (e.g., knots, rot, checks, splits) and their impact on grade and value. Practice identifying and assessing the severity of these defects.

- Log Sorting and Classification: Familiarize yourself with the practical application of log grading in a sawmill or processing environment. Understand the process of sorting logs based on grade and size for optimal yield and efficiency.

- Software and Technology Used in Log Grading: Research the common software and technologies used in modern log grading (e.g., optical scanners, grading software). Demonstrate familiarity with their capabilities and limitations.

- Quality Control and Assurance in Log Grading: Understand the importance of quality control and assurance in maintaining consistent grading standards and minimizing errors. Be prepared to discuss quality control measures and processes.

- Health and Safety Practices in Log Yards and Mills: Be familiar with the safety regulations and procedures related to working with logs and in sawmill environments.

Next Steps

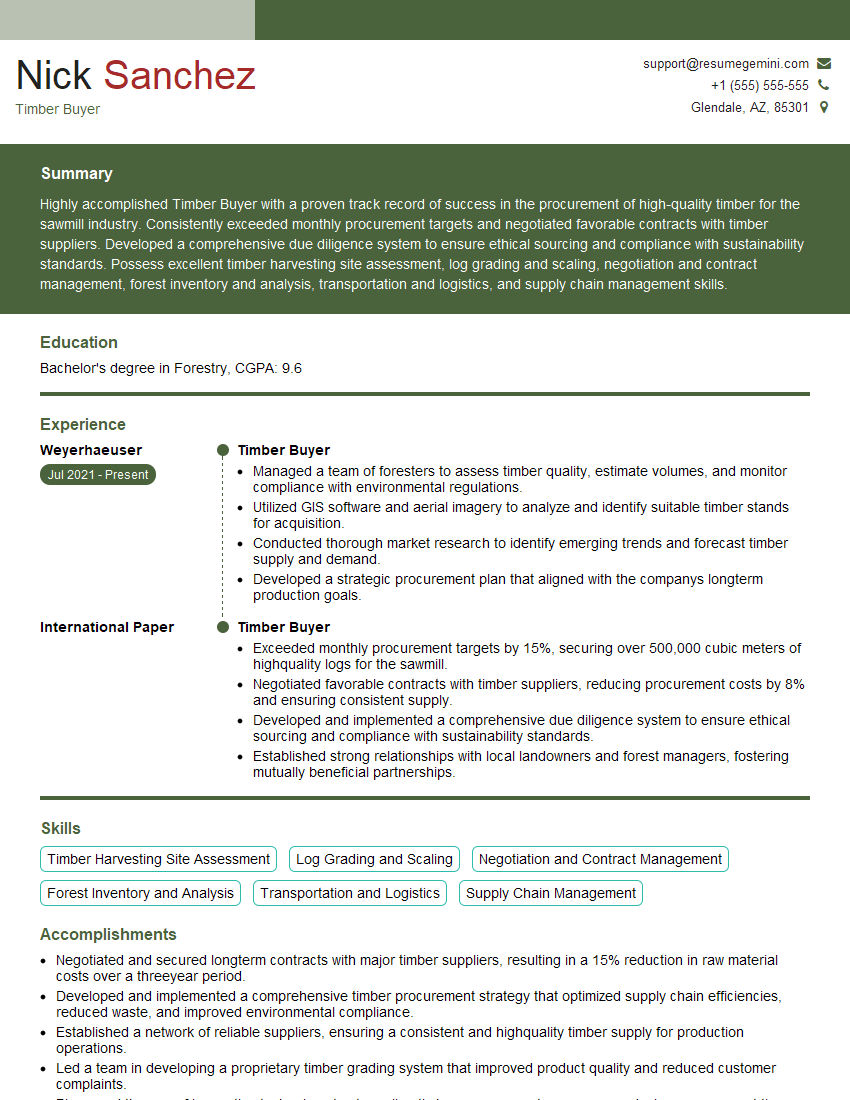

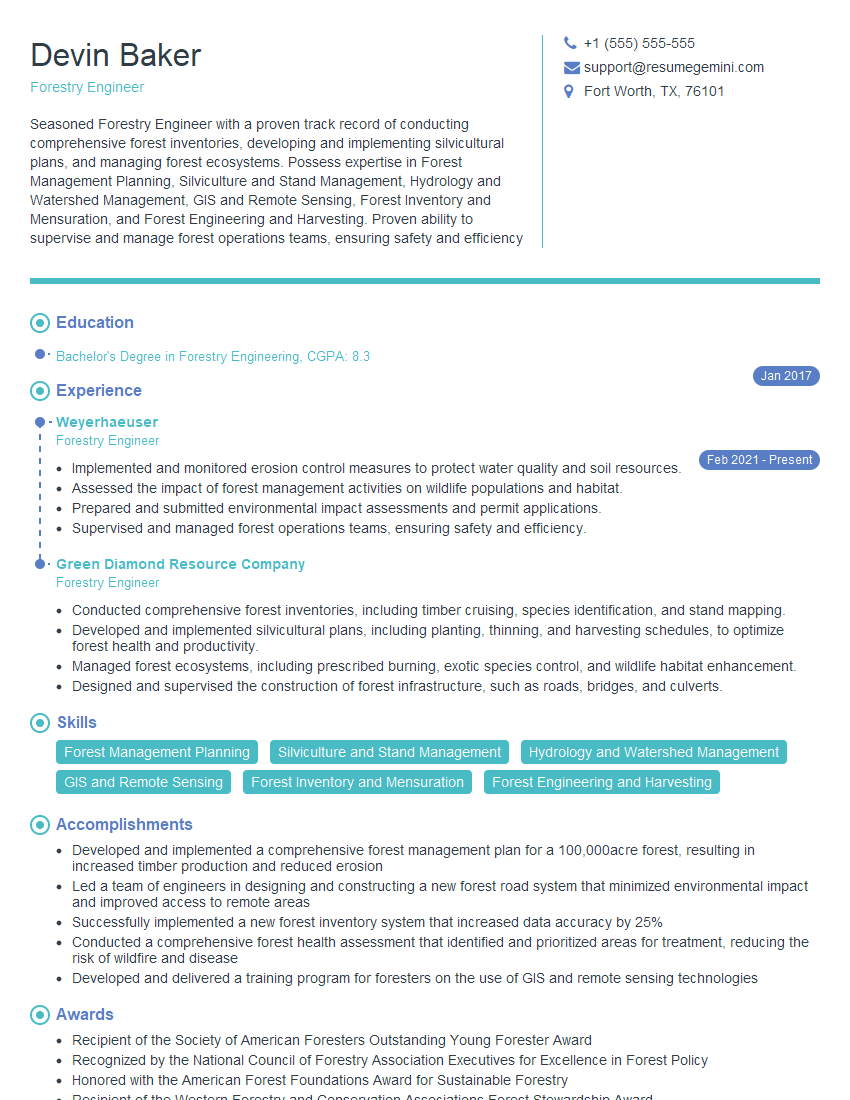

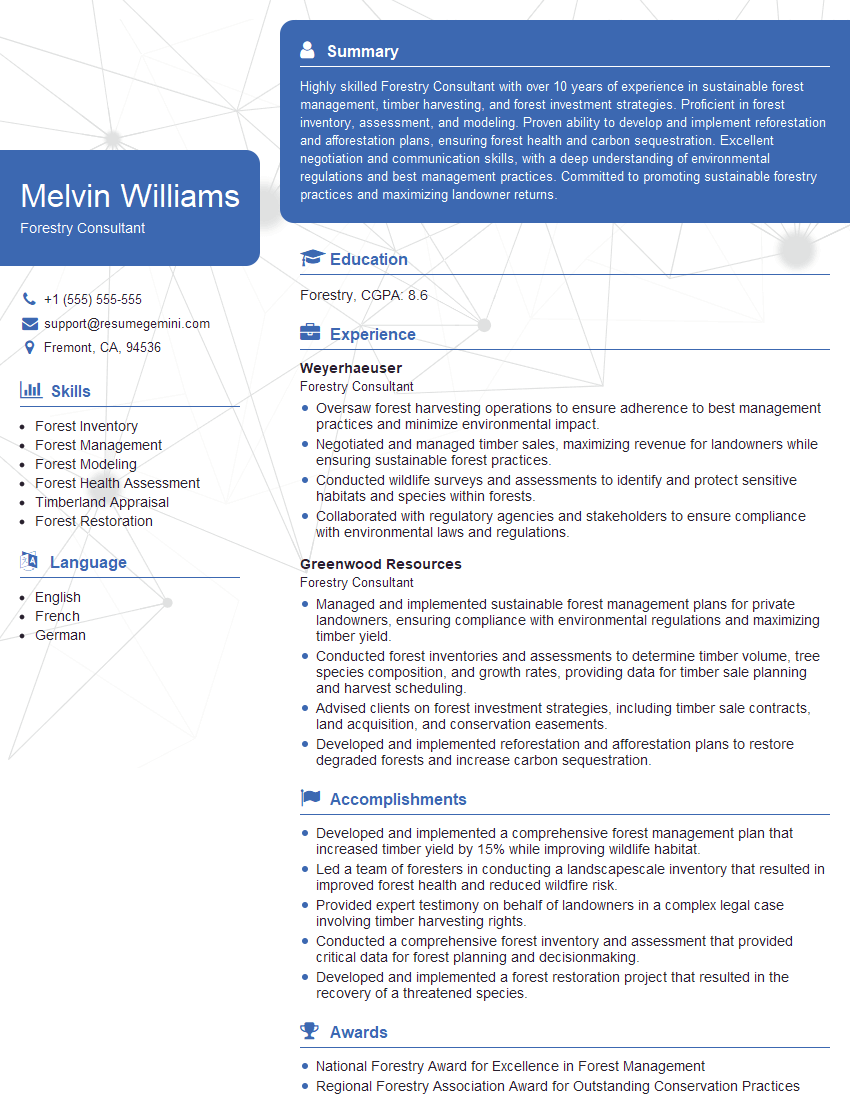

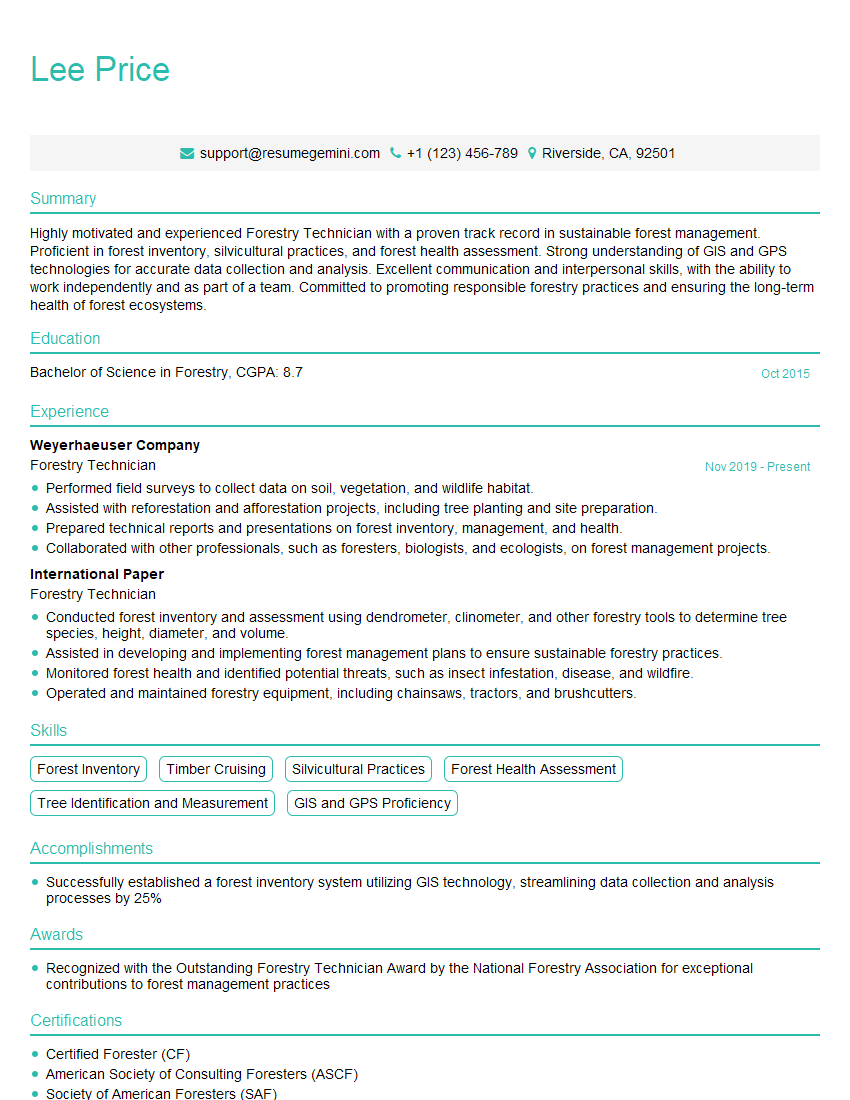

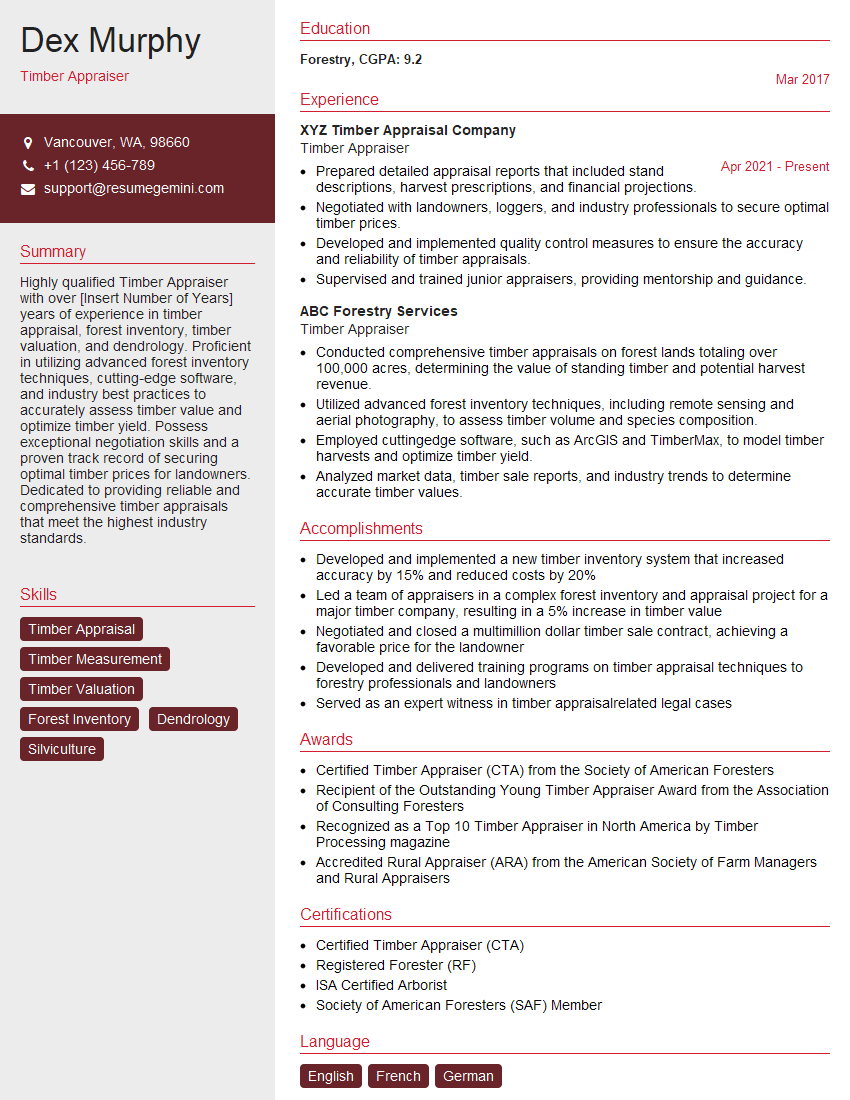

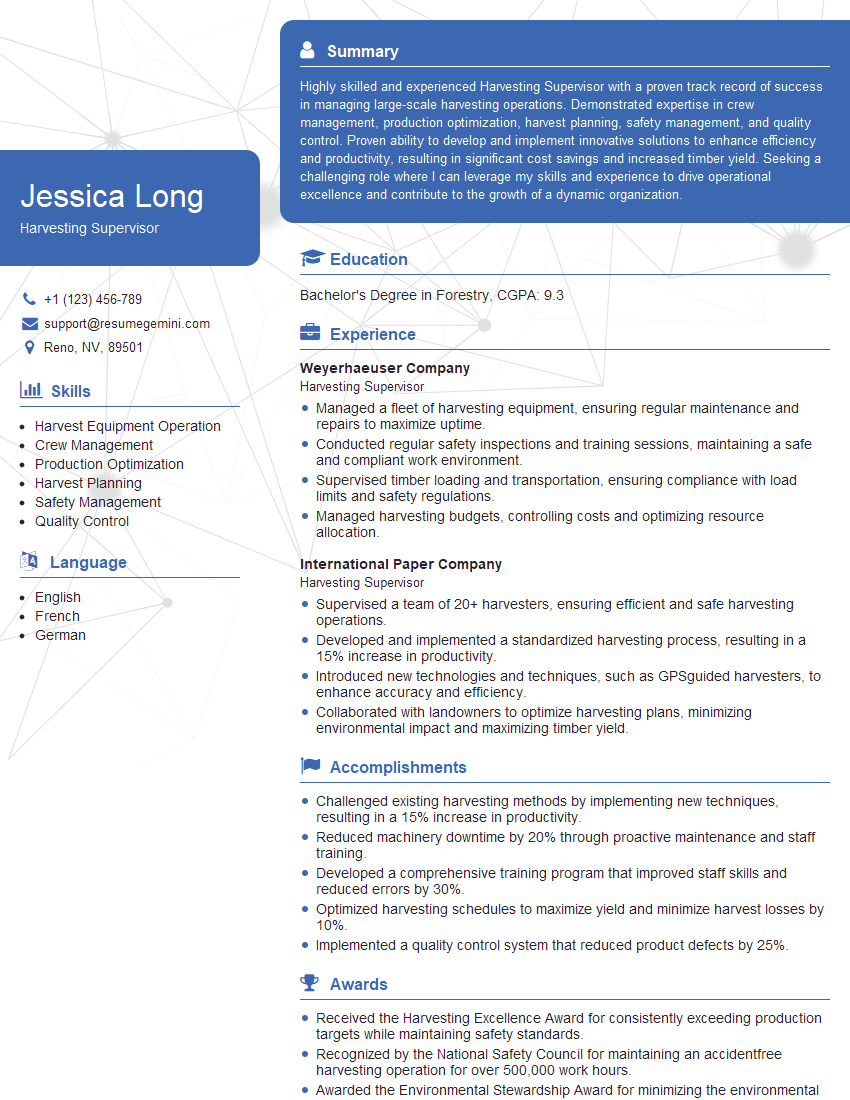

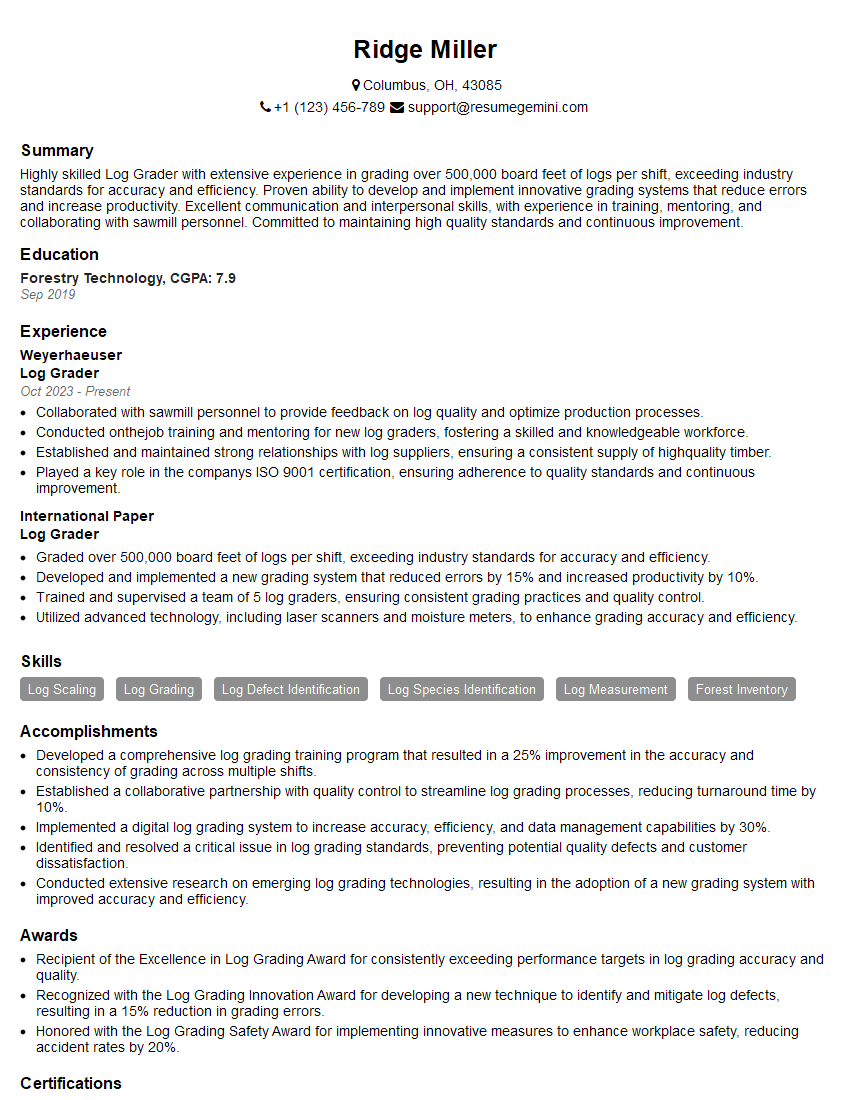

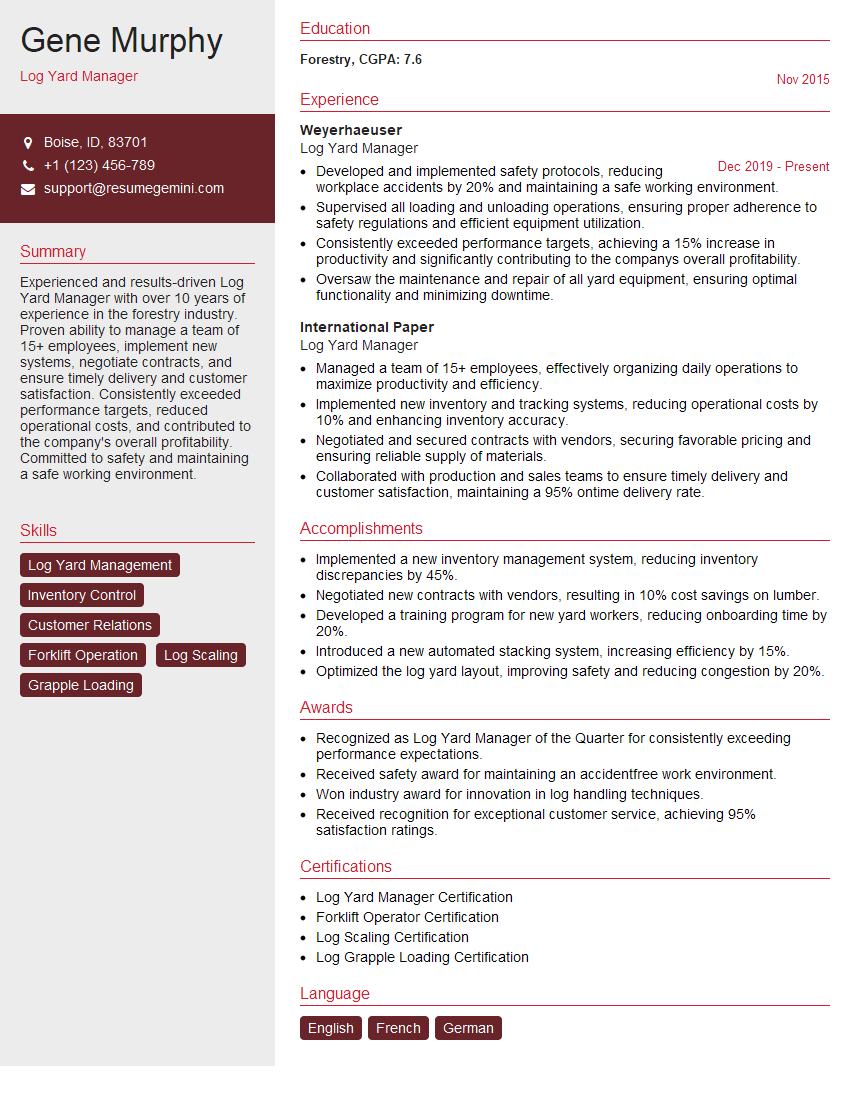

Mastering Log Grader principles opens doors to rewarding careers in the forestry and lumber industries, offering opportunities for growth and specialization. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored specifically to Log Grader roles are available to help you craft your application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good