Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Log Grapple interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Log Grapple Interview

Q 1. Describe the different types of log grapples and their applications.

Log grapples come in various designs, each suited for specific logging operations. The primary distinction lies in their configuration and gripping mechanism.

- Standard Log Grapples: These are the most common type, featuring two hinged arms with tines that close around a log. They’re versatile and suitable for a wide range of log sizes and species. Think of them as the ‘workhorse’ of the logging industry.

- Rotating Grapples: These grapples add a rotating function, allowing the operator to easily position logs without repositioning the entire machine. This is invaluable in tight spaces or when precise log placement is crucial. Imagine needing to neatly stack logs onto a truck – a rotating grapple makes this significantly easier.

- Grapple Saws: Integrating a saw with the grapple, these machines allow for cutting and grabbing in a single operation. This significantly boosts efficiency, particularly in felling and processing smaller trees. This is like having a chainsaw and a grapple all in one powerful tool.

- Hydraulic Log Grapples: Most common type, they use hydraulic cylinders to control the jaws, offering precise control and powerful gripping force. The pressure can be adjusted to handle various log sizes and conditions.

- Mechanical Log Grapples: These are less common now, relying on mechanical linkages for jaw operation. While simpler in design, they offer less precise control compared to hydraulic versions.

The application of each type depends on the specific logging task. Standard grapples are used for general log handling, rotating grapples for precise placement, and grapple saws for efficient felling and processing. The choice often involves balancing efficiency, cost, and the specific challenges of the logging site.

Q 2. Explain the safety procedures involved in operating a log grapple.

Safety is paramount when operating a log grapple. A comprehensive safety procedure should always be followed:

- Pre-Operational Inspection: A thorough check of all components, including hydraulic lines, cables, and the grapple itself, is essential before starting any operation.

- Proper Training: Operators must receive thorough training on the equipment’s operation and safety features. This includes understanding the controls, limitations, and emergency procedures.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including hard hats, safety glasses, gloves, and high-visibility clothing.

- Stable Ground: Ensure the carrier vehicle (e.g., excavator, loader) is on stable ground to avoid tipping or accidents.

- Awareness of Surroundings: Maintain constant awareness of the surrounding area, including other personnel and potential obstacles.

- Load Limits: Never exceed the grapple’s rated load capacity. Overloading can lead to catastrophic failures.

- Emergency Procedures: Operators should be familiar with emergency shutdown procedures and have a clear plan of action in case of malfunctions or accidents.

- Communication: Clear communication with ground personnel is crucial, especially in larger operations. Hand signals and/or radios should be used to coordinate movements.

Remember, safety isn’t just a guideline; it’s a fundamental aspect of operating heavy machinery. One lapse in safety procedure can result in severe consequences.

Q 3. How do you perform a pre-operational inspection of a log grapple?

A pre-operational inspection is a systematic check of the log grapple and its supporting systems. This involves:

- Visual Inspection: Check for any visible damage to the grapple arms, tines, hydraulic lines, and other components. Look for leaks, cracks, or signs of wear and tear.

- Hydraulic System Check: Inspect the hydraulic hoses and connections for leaks or damage. Check the hydraulic oil level and ensure proper pressure.

- Mechanical Check: Inspect the mechanical linkages, pins, and bushings for wear, damage, or proper lubrication.

- Rotation System (if applicable): For rotating grapples, check the rotation mechanism for smooth operation and proper function.

- Safety Devices: Inspect all safety devices, such as emergency stops, to ensure they are functioning correctly.

- Attachments & Connections: Verify that the grapple is correctly attached to the carrier vehicle and that all connections are secure.

Documenting the inspection is crucial. A simple checklist can be used to ensure all points are addressed. This proactive approach helps prevent accidents and ensures smooth operation. Imagine finding a cracked hydraulic line during the inspection—that’s a potential disaster averted.

Q 4. What are the common maintenance tasks for a log grapple?

Regular maintenance is vital for extending the lifespan and ensuring the safe operation of a log grapple. Key maintenance tasks include:

- Regular Lubrication: Lubricate all moving parts, such as pins, bushings, and linkages, according to the manufacturer’s recommendations.

- Hydraulic System Maintenance: Regularly check and replace hydraulic oil as needed. Inspect hoses and fittings for leaks and replace them as necessary.

- Tine Inspection and Replacement: Inspect the tines for wear and tear and replace them when they become excessively worn or damaged.

- Pin and Bushing Inspection: Regularly inspect pins and bushings for wear and replace them if necessary to maintain smooth operation.

- Leak Detection and Repair: Regularly check for hydraulic leaks and address them promptly to prevent fluid loss and potential damage.

- Structural Inspection: Periodically inspect the grapple’s structure for cracks, bends, or other damage. Any structural weakness should be addressed immediately.

Following a structured maintenance schedule helps prevent unexpected failures and keeps the grapple in optimal working condition. This is like regular car maintenance – small steps ensure smooth and reliable operation in the long run.

Q 5. How do you troubleshoot a malfunctioning log grapple?

Troubleshooting a malfunctioning log grapple requires a systematic approach. Start with a thorough visual inspection and work through the potential causes. For example:

- No Grapple Movement: This could indicate a problem with the hydraulic system (low oil, faulty pump, blocked lines) or a mechanical issue (broken linkage, seized pins). Check the hydraulic oil level and pressure first.

- Slow Grapple Movement: This could be due to low hydraulic pressure, leaking hydraulic lines, or excessive wear in the mechanical components. Check hydraulic lines for leaks and inspect mechanical components for wear.

- Grapple Not Closing Properly: This suggests issues with the tines, hydraulic cylinders, or the control system. Inspect the tines for damage and check the hydraulic cylinders for proper operation.

- Unusual Noises: Grinding or squealing sounds often indicate wear or damage to moving parts. Locate the source of the noise and inspect the affected components.

Using a systematic approach, combined with an understanding of hydraulic systems and mechanical components, allows for efficient identification of the problem. Always consult the manufacturer’s troubleshooting guide for specific solutions and repair recommendations. Safety should always be the priority – if unsure, do not operate the grapple until the issue has been addressed by a qualified technician.

Q 6. Describe your experience with different grapple types (e.g., grapple saw, rotating grapple).

My experience encompasses a variety of log grapple types. I’ve extensively used standard hydraulic grapples for general log handling in various forestry operations. The ability to adjust clamping force based on log size and condition is incredibly valuable. I’ve also had experience with rotating grapples, particularly in situations where precise log placement is crucial, such as loading onto trucks or creating organized log piles. The increased efficiency and maneuverability are clear benefits. While less common, I’ve also worked with grapple saws in smaller-scale operations, seeing firsthand their enhanced efficiency in felling and initial processing.

The experience highlights the crucial role of choosing the right grapple type for the job. Each type has unique strengths, and understanding these strengths allows for optimal efficiency and safety. For example, the rotating grapple significantly reduces the number of machine movements needed, making it faster and more efficient in certain situations.

Q 7. What are the limitations of a log grapple?

While log grapples are highly versatile and efficient tools, they have certain limitations:

- Log Size and Shape: Grapples are most effective with relatively cylindrical or uniformly shaped logs. Highly irregular logs or those with significant branches can be difficult to grip securely.

- Ground Conditions: The effectiveness of a grapple can be reduced by uneven or unstable ground conditions. The carrier vehicle needs a stable base for safe and effective operation.

- Log Density and Weight: Extremely dense or heavy logs can exceed the grapple’s capacity, leading to potential damage or equipment failure. It is crucial to always operate within the rated load limits.

- Limited Reach: The reach of the grapple is limited by the reach of the carrier vehicle. This can impact the efficiency of log handling, particularly in dense forests or challenging terrain.

- Maintenance Requirements: Log grapples require regular maintenance and inspection to ensure safe and reliable operation. Neglecting maintenance can lead to costly repairs and downtime.

Understanding these limitations is essential for selecting the appropriate grapple and planning logging operations accordingly. Careful consideration of these factors helps avoid potential issues and enhances overall efficiency and safety.

Q 8. How do you handle different log sizes and species using a log grapple?

Handling varying log sizes and species with a log grapple involves understanding the grapple’s capacity and adjusting your technique. Different species have different densities, affecting weight. Larger logs demand more careful placement to maintain balance. For example, a grapple designed for smaller hardwood logs might struggle with longer, heavier softwood logs. My approach involves:

- Assessing the log: I visually inspect each log before grabbing, considering its size, species, and apparent weight. This helps me choose the best grapple configuration (e.g., adjusting the grapple’s opening width).

- Grapple Selection: Selecting the right grapple is crucial. Smaller grapples are more suitable for smaller logs and delicate handling. Larger grapples are necessary for large logs but may be less precise.

- Strategic Placement: With larger logs, I ensure the weight is evenly distributed within the grapple to avoid tipping or instability during lifting and transportation. This might involve multiple grabs or careful positioning of the grapple on the log.

- Proper Lifting Technique: I use smooth, controlled movements when lifting and setting down logs, especially larger ones. Sudden jerks can lead to damage or accidents.

For instance, I once had to grapple a huge Douglas fir log that was significantly heavier than anticipated. I adjusted the grapple’s configuration and used a more controlled lifting approach, ensuring the load was balanced and secure, avoiding any incidents.

Q 9. Explain the process of attaching and detaching a log grapple to a carrier.

Attaching and detaching a log grapple is a straightforward but crucial process that requires precision and safety. Different carriers will have slightly different attachment mechanisms, but the basic principle is similar. Most involve hydraulic connections and a secure locking mechanism.

- Attachment: This typically involves aligning the grapple’s mounting points with the carrier’s hooks or pins and then using hydraulics to lock the grapple into place. This should always be done with the grapple empty and the machine firmly on level ground. I carefully check all hydraulic connections and locking pins to ensure they are securely fastened.

- Detachment: The detachment process is the reverse. I first ensure the grapple is empty and then use the hydraulic controls to unlock the grapple from the carrier. I always double-check that the grapple is fully released before moving the carrier. Safety procedures like engine shut-off and using secondary locking mechanisms are followed before any major work on the connections.

A clear example is attaching a grapple to a forestry skidder. The grapple typically has quick-connect hydraulic fittings and pins that line up with similar fittings on the skidder’s arm. Once these are connected, the grapple’s hydraulic function is tested before any lifting begins.

Q 10. How do you ensure the stability of the load when operating a log grapple?

Ensuring load stability is paramount when operating a log grapple. Unstable loads can lead to serious accidents, equipment damage, and property damage. My approach emphasizes careful planning and execution:

- Even Weight Distribution: I always strive for even weight distribution within the grapple’s jaws. This prevents tipping or skewing the load during lifting and transport.

- Secure Grasp: Before lifting, I ensure the grapple has a firm and secure grip on the logs, especially if they are of irregular shape. I never try to lift logs that are partially or insecurely grasped.

- Controlled Movements: I use smooth, controlled movements when operating the grapple. Sudden jerks or rapid acceleration can cause the load to shift, leading to instability.

- Terrain Awareness: I consider the terrain when transporting the logs. Uneven ground or steep slopes can compromise stability. I often adjust my speed and path to mitigate risks.

- Proper Load Capacity: I always respect the grapple and carrier’s weight limits. Overloading is extremely dangerous and can lead to catastrophic failures.

For example, if I’m working on a hillside, I carefully position the logs to minimize the effect of the slope, and I might use a lighter grapple or carry smaller loads to increase stability.

Q 11. Describe your experience working with different types of logging equipment.

My experience encompasses a wide range of logging equipment, beyond just log grapples. I’ve worked extensively with:

- Forestry Skidders: I am proficient in operating various models, understanding their capabilities and limitations in different terrains.

- Forwarders: I have experience in efficiently loading and transporting logs using forwarders, optimizing the use of the grapple for different log sizes and shapes.

- Harvesters: Although I don’t directly operate the harvesting head, I’m familiar with how the harvested logs are presented for grapple loading, and the coordination required for efficient operations.

- Wheel Loaders: I’ve used wheel loaders equipped with grapples for tasks like loading logs onto trucks or moving them around a logging yard.

This diverse experience provides me with a holistic understanding of logging operations and allows me to contribute effectively in a team environment. I can troubleshoot issues with various equipment and efficiently coordinate tasks between different pieces of machinery.

Q 12. What are the environmental considerations when operating a log grapple?

Environmental considerations are paramount in my work. Operating a log grapple responsibly minimizes environmental impact. My approach includes:

- Minimizing Ground Disturbance: I utilize established logging roads and trails whenever possible to reduce soil erosion and habitat fragmentation. When creating new routes, I take into consideration environmental protection measures.

- Selective Logging: I participate in selective logging practices, leaving behind sufficient trees to maintain the ecosystem’s health and promote biodiversity.

- Preventing Soil Erosion: I am careful to avoid excessive ground disturbance, and I’m familiar with implementing soil stabilization techniques, such as using erosion control mats, where necessary.

- Waterway Protection: I prioritize protecting waterways by keeping equipment and logs away from streams and rivers to avoid pollution and erosion.

- Waste Management: I handle logging debris responsibly, separating reusable material for later use and disposing of the rest properly, according to regulatory guidelines.

For example, I will avoid working in sensitive areas during periods of heavy rain to prevent soil erosion and water pollution. I always follow all local regulations for forestry operations.

Q 13. How do you manage risks associated with operating a log grapple in various terrains?

Managing risks in various terrains is crucial for safe log grapple operation. My approach includes:

- Terrain Assessment: Before beginning any work, I conduct a thorough terrain assessment, identifying potential hazards like steep slopes, unstable ground, and obstacles.

- Safe Operating Procedures: I always follow established safe operating procedures, prioritizing safety over speed or efficiency. This includes wearing appropriate safety gear.

- Load Control: I adjust my load size and speed according to the terrain’s difficulty. Heavier loads are avoided in challenging terrain.

- Communication: In team environments, clear communication is vital. I maintain constant communication with my colleagues to ensure everyone is aware of the ongoing operations and potential hazards.

- Emergency Preparedness: I am familiar with emergency procedures and know how to respond to various situations such as equipment malfunction or accidents.

For example, if working on a steep slope, I use spotters to ensure stability. In areas with poor visibility, I use additional lighting and ensure clear communication with my team.

Q 14. What is your experience with load capacity and weight distribution?

Understanding load capacity and weight distribution is crucial for safe and efficient log grapple operation. This involves both theoretical knowledge and practical experience.

- Load Capacity Limits: I am well-versed in the load capacity limits of the grapples and carriers I operate. I never exceed these limits, which is a fundamental safety precaution. This information is usually found on the equipment’s specifications.

- Weight Distribution Techniques: I understand how to distribute weight evenly within the grapple to avoid tipping or instability. This often involves carefully positioning logs within the grapple’s jaws.

- Center of Gravity: I am aware of the significance of the center of gravity, both in the logs themselves and the overall load. Understanding this helps to prevent accidents.

- Practical Application: My experience has given me the ability to quickly estimate the weight of logs based on their size and species. This assists in making informed decisions about load size and distribution.

For instance, I can readily determine if a given load of logs, considering their size and species, is within the safe operating limits for a specific grapple and forestry machine. This knowledge is critical for preventing equipment damage and avoiding accidents.

Q 15. Describe your experience with grapple maintenance and repair.

Grapple maintenance is crucial for safety and efficiency. My experience encompasses preventative maintenance, such as regular lubrication of moving parts (pins, cylinders, and rotating components), inspecting hydraulic hoses for leaks and damage, and checking for wear and tear on the grapple’s teeth and tines. I also handle repairs, ranging from minor fixes like welding broken teeth or replacing worn bushings, to more complex repairs involving hydraulic system troubleshooting and cylinder replacements. For example, I once diagnosed a hydraulic leak in a grapple’s main cylinder by systematically isolating sections of the system and using a pressure gauge. This pinpointed the leak to a faulty seal, which I replaced, restoring full functionality.

I meticulously document all maintenance and repair activities, ensuring compliance with company procedures and providing a clear record for future reference. This includes noting the date, type of work performed, parts replaced, and any observations regarding the grapple’s overall condition. This systematic approach helps prevent future issues and maximizes the grapple’s operational lifespan.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with different grapple manufacturers and models?

I’m familiar with a wide range of grapple manufacturers and models, including prominent brands like Waratah, Fecon, and Rottne. My experience includes working with various grapple types, from small, lighter-duty grapples used on smaller excavators to larger, heavy-duty grapples designed for large-scale logging operations. I’m comfortable working with different grapple designs, such as those with fixed, rotating, or parallel jaws, and understand their respective strengths and limitations. For instance, I know that rotating grapples offer greater flexibility in log handling, particularly in cluttered terrain, whereas parallel jaw grapples provide more gripping power for larger logs.

This knowledge extends beyond just the manufacturer; I’m familiar with different grapple specifications, including their opening and closing forces, their reach, and their overall weight capacity. This allows me to select the appropriate grapple for a specific task and machine, optimizing both safety and efficiency.

Q 17. How do you comply with safety regulations and company policies while using a log grapple?

Safety is paramount in log grapple operation. I always adhere to all relevant safety regulations and company policies, which includes pre-operation inspections to ensure the grapple and the carrier are in safe working order. This involves checking hydraulic fluid levels, inspecting all hydraulic hoses and connections for leaks, verifying the proper functioning of safety devices, and ensuring that all guarding is in place.

Before starting any work, I’ll conduct a thorough site assessment, identifying any potential hazards such as uneven terrain, overhead obstructions, or nearby personnel. I always wear the appropriate personal protective equipment (PPE), including hard hats, safety glasses, gloves, and high-visibility clothing. During operation, I maintain a safe working distance from other personnel and equipment, and communicate clearly using hand signals or two-way radios. I strictly follow company lockout/tagout procedures during maintenance and repairs to prevent accidental starts. My commitment to safety is unwavering.

Q 18. What is your experience with emergency procedures during log grapple operation?

Emergency procedures are ingrained in my training and practice. In the event of a hydraulic failure, my first step is to immediately shut down the grapple and the carrier. I would then assess the situation and determine the extent of the problem. If it’s a minor leak, I might attempt to temporarily contain it; however, if it’s a major failure or poses a safety risk, I would immediately report the incident to my supervisor and follow the established emergency procedures. This might involve securing the area, notifying emergency services if necessary, and ensuring the safety of myself and other crew members.

For instances like a grapple malfunction during lifting, which could result in a log falling, I’m trained to react quickly and efficiently, using the carrier’s controls to lower the load safely and smoothly, if possible. Clear communication with other crew members is essential during such emergencies. Regular training and drills enhance my preparedness to respond calmly and effectively in any emergency situation.

Q 19. How do you communicate effectively with other members of the logging crew?

Effective communication is vital in a logging crew. I utilize a variety of methods to communicate clearly and concisely, including hand signals, two-way radios, and face-to-face communication. I understand the importance of clear and unambiguous instructions, especially during critical operations like log loading and unloading. Hand signals are used for short-distance, quick communication, and two-way radios are essential for longer-distance coordination.

I always prioritize active listening and confirm instructions to avoid misunderstandings. For example, before beginning a lift, I’ll always confirm the placement location and ensure that the other crew members are aware of the log’s weight and path. Building a strong rapport with the crew enhances trust and facilitates smooth and efficient teamwork. Addressing concerns promptly and proactively fostering an open communication environment enhances safety and overall productivity.

Q 20. Explain your experience with different log stacking techniques.

My experience encompasses several log stacking techniques, tailored to the specific needs of the job. These techniques include both traditional methods and more modern, efficient approaches. I’m proficient in creating stable and secure stacks using various patterns, such as tiered stacks, crib stacks, and even specialized arrangements needed for particular log sizes or transportation methods. The choice of technique depends on several factors: the type of wood, log length and diameter, intended transportation, and the terrain.

For example, when stacking longer logs, I’d use a tiered arrangement, ensuring that each layer is properly interlocked for stability. For shorter, smaller logs, I may use a crib stack. My expertise allows me to quickly assess the situation and select the optimal stacking method, ensuring a safe, efficient, and organized log yard.

Q 21. How do you minimize damage to logs during handling?

Minimizing log damage requires careful handling throughout the entire process. This starts with selecting the appropriate grapple for the log size and species. Using a grapple that’s too small can lead to bark damage or crushing, whereas one that’s too large can result in inefficient handling. I ensure that the grapple is properly positioned before engaging with the logs. A good grip avoids slippage and the subsequent damage. Gentle handling is crucial to avoid excessive twisting or pressure.

I also carefully consider the log’s condition and handling requirements, being extra cautious with logs that have visible defects or are particularly fragile. The placement and stacking methods are also tailored to minimize damage. For instance, avoiding sharp impacts during stacking is a critical aspect to reduce bruising and splintering. By paying close attention to these details, I can help ensure that the logs are transported and stored in optimal condition.

Q 22. Describe your experience with log grapple hydraulic systems.

My experience with log grapple hydraulic systems is extensive. I’ve worked with various systems, from simple open-center to more complex closed-center systems incorporating load-sensing technology. I understand the crucial role of hydraulic pressure, flow rate, and valve control in the efficient and safe operation of a log grapple. For instance, I’ve troubleshot systems experiencing slow response times by checking for leaks in hoses and cylinders, examining the condition of filters, and verifying proper functioning of the hydraulic pumps and valves. Understanding the interplay between the hydraulic system, the grapple’s mechanical components, and the carrier’s power source is paramount to efficient operation and maintenance. I’m also familiar with different hydraulic oil types and their impact on system performance and longevity.

I’ve worked extensively with systems that use proportional valves for precise control of the grapple’s movements, enabling smoother operations and reduced damage to both the logs and the equipment. I’m proficient in diagnosing and repairing common hydraulic system problems like leaks, pressure drops, and valve malfunctions, utilizing both diagnostic tools and my practical experience.

Q 23. How familiar are you with the different types of log grapple attachments?

My familiarity with different types of log grapple attachments is comprehensive. I’ve worked with various grapple designs, categorized primarily by their jaw configurations and intended applications. These include:

- Standard rotating grapples: These offer a simple, robust design, suitable for general log handling.

- Self-leveling grapples: These maintain a level grip on the logs, regardless of terrain, increasing efficiency and safety. I’ve found these particularly useful in uneven terrain.

- Long-reach grapples: Designed for reaching logs at a distance, often used in conjunction with long-boom loaders. They often require more precise hydraulic control.

- Multi-tine grapples: These have multiple gripping points, ideal for handling smaller logs or bundles of logs.

- Pulpwood grapples: Specialized grapples designed for efficient handling of small-diameter logs.

The choice of grapple depends on the type of logs being handled, the terrain, and the efficiency goals. I understand the strengths and limitations of each type and can select the most appropriate grapple for a given task.

Q 24. Describe your experience with preventative maintenance schedules for log grapples.

Preventative maintenance is crucial for log grapple longevity and safety. My experience involves adhering to rigorous schedules that include daily, weekly, and monthly inspections and servicing. A typical schedule I follow involves:

- Daily: Visual inspection for leaks, loose bolts, damaged hoses, and overall grapple condition. Checking hydraulic oil levels is also a crucial daily task.

- Weekly: More thorough inspection, including lubrication of moving parts and checking for wear and tear on the teeth and jaws. This helps to identify and address minor issues before they become major problems.

- Monthly: More comprehensive servicing, including filter changes, hydraulic oil analysis, and detailed inspection of all mechanical components for signs of stress or damage. This often includes checking the rotational mechanism of the grapple for smooth and consistent operation.

Proactive maintenance significantly reduces downtime and prevents costly repairs. Furthermore, I meticulously document all maintenance activities, ensuring traceability and compliance with safety regulations.

Q 25. What are your strengths and weaknesses in operating a log grapple?

My strengths in operating a log grapple lie in my precision and efficiency, honed through years of practical experience. I’m adept at maneuvering the grapple in tight spaces and challenging terrain, maximizing load capacity while minimizing damage to the logs and equipment. I prioritize safety and consistently follow established procedures.

My primary weakness, if I were to be critical, is a tendency to be somewhat perfectionistic; I sometimes spend slightly more time than absolutely necessary ensuring a perfect load. However, I actively work on balancing precision with efficient workflow to mitigate this.

Q 26. How do you adapt your operating techniques based on varying weather conditions?

Adapting to varying weather conditions is a key aspect of safe and effective log grapple operation. In wet or icy conditions, I reduce my operating speed to maintain control and prevent accidents. I also pay close attention to the ground conditions and adjust my approach to avoid slipping or getting stuck. Increased caution is exercised in situations with poor visibility, using additional safety measures like spotlights and working with spotters if necessary. In hot, dry conditions, I monitor hydraulic oil temperatures more closely, and ensure adequate lubrication of moving parts to prevent overheating and damage.

Q 27. How do you handle challenging log configurations or difficult terrain?

Handling challenging log configurations and difficult terrain requires a combination of skill, experience, and strategic planning. I approach complex log arrangements methodically, breaking down the task into smaller, manageable steps. For example, when faced with tangled or intertwined logs, I carefully untangle them using the grapple’s precision control rather than brute force. In difficult terrain, I adjust my approach angle, speed, and grapple technique to maintain a secure and stable grip on the logs, minimizing the risk of tipping or damage. I often use the machine’s stability features like stabilizers or outriggers to enhance safety and control when operating on uneven surfaces. Prioritizing the safety of myself and others remains paramount in such situations.

Q 28. Describe a time you had to troubleshoot a complex log grapple issue.

During a recent logging operation, we encountered a problem with a grapple’s rotation mechanism – it became increasingly stiff and jerky. Initially, I suspected a hydraulic issue, but after thorough inspection, found no leaks or pressure problems. After systematic troubleshooting, including checking the hydraulic lines, valves, and the rotating mechanism itself, I identified the cause as a build-up of debris and corrosion within the rotating bearing assembly. We cleaned the assembly, lubricated the components, and the grapple’s rotation was restored to normal functionality. This highlighted the importance of regular maintenance and meticulous inspection beyond just the hydraulic system.

Key Topics to Learn for Log Grapple Interview

- Mechanical Design Principles: Understand the fundamental mechanical engineering concepts behind log grapple design, including forces, stresses, and material selection. Consider different grapple types and their suitability for various applications.

- Hydraulic Systems: Familiarize yourself with the hydraulic systems that power log grapples, including pumps, valves, cylinders, and hoses. Be prepared to discuss hydraulic pressure, flow rate, and efficiency.

- Structural Analysis: Grasp the methods used to analyze the structural integrity of log grapples under load. This includes finite element analysis (FEA) or other relevant techniques for assessing strength and durability.

- Control Systems: Understand the control systems used to operate log grapples, including operator interfaces and automated control mechanisms. Discuss considerations for safety and precision.

- Maintenance and Repair: Be familiar with common maintenance procedures and troubleshooting techniques for log grapples. Knowing about preventative maintenance is crucial.

- Safety Regulations and Standards: Understand relevant safety regulations and industry standards related to log grapple operation and maintenance. This demonstrates a commitment to workplace safety.

- Material Handling and Logistics: Discuss the practical applications of log grapples within the context of forestry, logging, and material handling operations. Consider efficiency and optimization.

- Manufacturing Processes: Gain an understanding of the manufacturing processes involved in creating log grapples, including welding, machining, and assembly techniques.

Next Steps

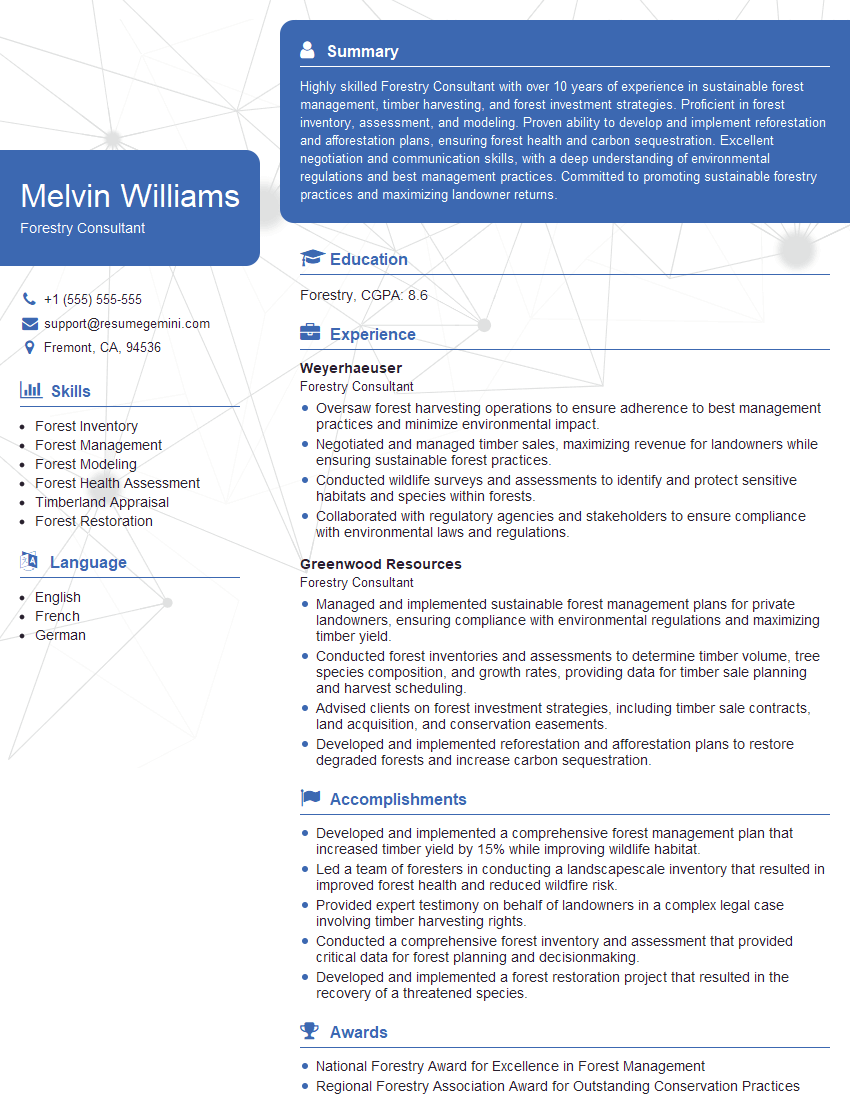

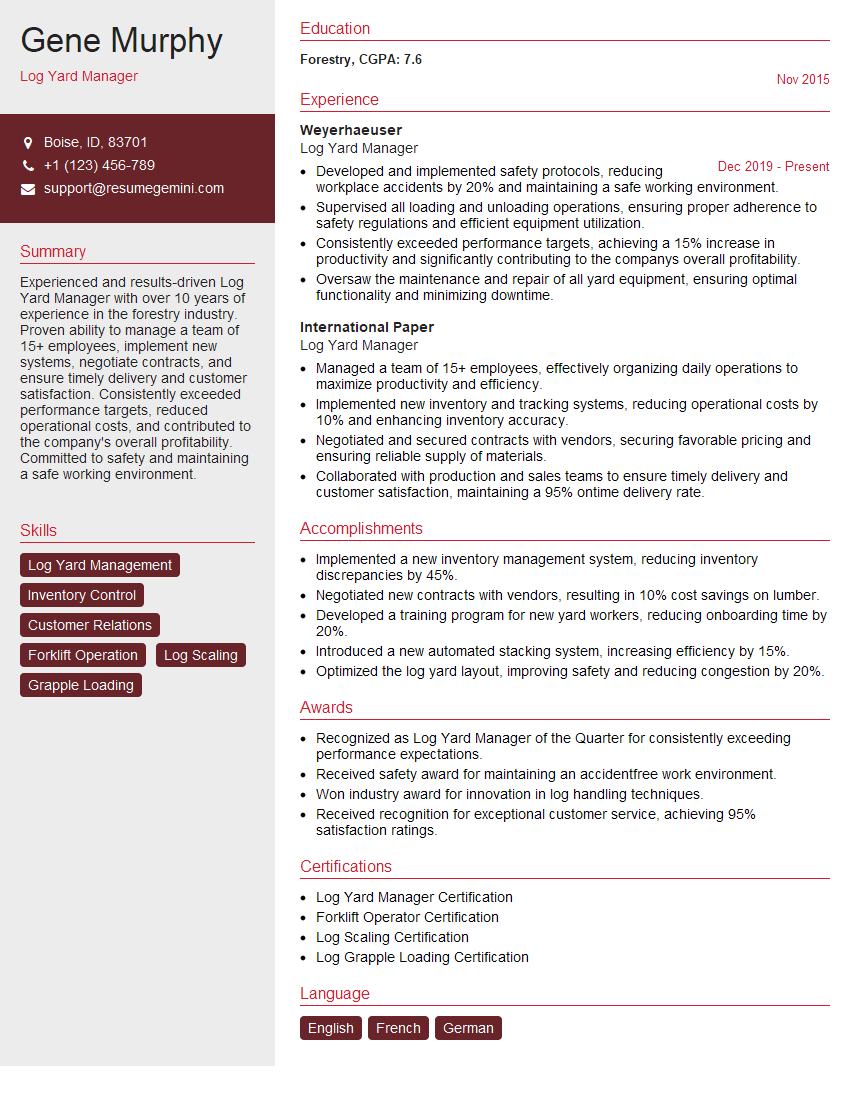

Mastering the intricacies of Log Grapple technology significantly enhances your career prospects in the forestry, logging, and heavy machinery sectors. It opens doors to specialized roles with higher earning potential and greater responsibility. To maximize your chances of landing your dream job, creating a compelling and ATS-friendly resume is essential. We highly recommend using ResumeGemini, a trusted resource, to build a professional resume that showcases your skills and experience effectively. Examples of resumes tailored to Log Grapple positions are available to help you create a winning application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good