Unlock your full potential by mastering the most common Log Hauling Knowledge interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Log Hauling Knowledge Interview

Q 1. Describe your experience with different types of log trailers and their suitability for various terrains and log sizes.

My experience encompasses a wide range of log trailers, from single-axle units ideal for smaller operations and less demanding terrain to heavy-duty, multi-axle trailers designed for massive log loads and challenging conditions. The choice of trailer depends critically on the size and weight of the logs, the terrain, and the distance of the haul.

- Single-axle trailers: Suitable for smaller logs and relatively smooth terrain. They are more maneuverable but have lower weight capacities.

- Tandem-axle trailers: Offer increased weight capacity and better stability than single-axle trailers, making them suitable for larger logs and slightly rougher terrain.

- Tri-axle and multi-axle trailers: These are the workhorses for substantial log loads and challenging terrains like steep inclines, rough forest roads, and muddy conditions. Their multiple axles distribute weight more evenly, preventing damage to roads and improving stability.

- Lowboy trailers: Designed for exceptionally large logs or loads that need a lower profile for easier loading and transportation over obstacles.

For instance, in mountainous regions with steep, winding roads, a tri-axle trailer with robust suspension is essential to ensure safe and stable transportation of heavy log loads. Conversely, smaller operations in flat, accessible areas might only require a single-axle trailer. The key is matching the trailer’s capabilities to the specific operational requirements.

Q 2. Explain the process of securing logs on a trailer to ensure safe transportation.

Securing logs on a trailer is paramount for safety. Improperly secured logs can shift during transit, leading to accidents. My process always involves a combination of techniques depending on log size and type:

- Proper placement: Logs are strategically positioned to distribute weight evenly, maximizing stability. Heavier logs are generally placed lower and closer to the trailer’s center of gravity.

- Binding: Chains or binders are used to tightly secure the logs to the trailer’s deck. These must be rated for the weight being hauled and secured correctly to prevent slippage. Multiple binding points are crucial, especially for larger loads.

- Dunnage: Wood blocks or other materials (dunnage) are strategically placed between logs to prevent shifting and reduce friction.

- Regular checks: Before and during transit, I regularly check the bindings and log placement to ensure everything remains secure. Stopping at safe locations for checks is crucial, especially on longer hauls.

Think of it like building a sturdy wall – you need the right materials (binders, dunnage), a strong foundation (even weight distribution), and regular checks to ensure it stays standing during a journey.

Q 3. What are the common safety regulations and procedures you follow during log hauling operations?

Safety is my top priority. I adhere strictly to all relevant regulations and company policies, including:

- Vehicle inspections: Thorough pre-trip inspections of the truck and trailer, checking brakes, lights, tires, and securing mechanisms.

- Load securement: Following established procedures for securing logs, as previously explained.

- Defensive driving: Maintaining a safe following distance, adjusting speed for road and weather conditions, and avoiding sudden maneuvers.

- Load limits: Never exceeding the legal weight limits or the trailer’s rated capacity.

- Personal Protective Equipment (PPE): Always wearing appropriate PPE, including high-visibility clothing, safety boots, and gloves.

- Communication: Maintaining clear communication with dispatch and other drivers, especially when operating in challenging conditions or on shared roadways.

Ignoring these safety regulations can have severe consequences, leading to accidents, injuries, and environmental damage. Following these established protocols is a non-negotiable commitment for me.

Q 4. How do you handle challenging weather conditions, such as snow or heavy rain, during log hauling?

Adverse weather conditions significantly impact log hauling safety and efficiency. My approach involves adapting my operations based on the specific challenge:

- Snow: Reduced speed, use of tire chains (where permitted and required), increased following distance, and careful navigation of icy patches. In extreme snowfall, hauling might be suspended altogether.

- Heavy rain: Reduced speed, increased following distance due to reduced visibility and slippery roads, and awareness of potential mudslides or washouts.

- High winds: Extra caution is needed, especially with high, unwieldy loads, as strong winds can affect trailer stability. In severe winds, operations may need to be halted.

- Fog: Reduced speed and the use of fog lights are crucial. If visibility drops below a safe threshold, operations are temporarily suspended.

Safety trumps all. If the conditions are too hazardous, I will not operate, prioritizing safety over schedules. Waiting out the storm is often the best and safest course of action.

Q 5. Describe your experience with different log loading techniques and equipment.

My experience includes various log loading techniques and equipment. The method used depends largely on log size, terrain accessibility, and available resources:

- Grapple loaders: These are commonly used for loading logs directly from the logging site. A grapple claw on the end of a crane arm grabs and lifts logs onto the trailer.

- Front-end loaders: Efficient for loading smaller logs and shorter distances. These are versatile and commonly found in yards or near landing areas.

- Log loaders (self-loading trailers): These trailers have integrated cranes, allowing for efficient loading without requiring separate equipment. They increase efficiency, especially in areas with limited access.

- Manual loading (for smaller operations): In some situations, especially smaller operations, logs are manually loaded using equipment like skids and ramps.

The choice of equipment and technique is a critical aspect of efficient and safe log hauling. Choosing the right tools based on the site-specific conditions is essential.

Q 6. How do you ensure efficient loading and unloading of logs to minimize downtime?

Efficient loading and unloading directly affect profitability and safety. To minimize downtime, I focus on:

- Pre-planning: Coordinating with loading and unloading sites to ensure smooth transitions and avoid delays. Understanding the unloading process beforehand is important for pre-planning.

- Optimized loading patterns: Ensuring an even weight distribution and the correct placement of logs on the trailer to avoid shifting.

- Proper equipment and personnel: Having properly maintained equipment and a skilled team that is familiar with safe loading and unloading procedures.

- Communication: Maintaining clear communication with the loading and unloading crews to ensure a coordinated effort.

- Regular maintenance: Preventative maintenance on equipment minimizes breakdowns and reduces downtime.

Time is money. A well-organized and prepared operation with clear communication leads to faster loading and unloading and improves overall efficiency. Avoiding unnecessary delays and keeping operations flowing is crucial to making the entire hauling operation efficient.

Q 7. What are the common causes of log hauling accidents and how can they be prevented?

Log hauling accidents stem from various factors, most often preventable through careful planning and adherence to safety protocols:

- Improper load securement: Loose or incorrectly secured logs can shift during transit, leading to rollovers or cargo loss.

- Overloading: Exceeding weight limits increases the risk of accidents by making the vehicle unstable and affecting braking performance.

- Poor vehicle maintenance: Brake failure, tire blowouts, or other mechanical issues can lead to serious accidents.

- Driver fatigue and impairment: Tired or impaired drivers are more likely to make mistakes resulting in accidents.

- Adverse weather conditions: Inadequate preparation for inclement weather increases the risk of skidding, jackknifing, or other accidents.

Prevention involves a multi-pronged approach: regular vehicle maintenance, strict adherence to weight limits, proper load securement techniques, driver training and awareness, and adjusting operations to match prevailing weather conditions. By actively addressing these risk factors, we can significantly reduce the incidence of accidents in log hauling.

Q 8. Explain your experience with log scaling and measurement techniques.

Accurate log scaling is crucial for efficient log hauling and fair compensation. I’m experienced in several measurement techniques, including:

- Diameter Tape Measurement: This involves using a diameter tape to measure the small-end diameter of each log. Then, using pre-calculated tables or formulas (often specific to the species and region), we determine the log’s volume.

- Scribing: This more precise method involves marking the log’s length and diameter at multiple points to account for taper (the gradual narrowing of the log). This data is then used to calculate volume. I’m proficient with both manual scribing and using electronic measuring devices that automate the process.

- Log Scaling Software: I’m adept at using specialized software that integrates with GPS data and diameter measurements to create accurate scale tickets and volume calculations. This minimizes errors and streamlines the billing process. For example, I’ve used software that integrates with our fleet management system to automatically calculate the volume hauled by each truck.

My experience spans various log types and sizes, allowing me to accurately assess volume and ensure fair pricing for both buyers and sellers. I’ve worked on projects where precise scaling was critical for contractual agreements, and I’m always meticulous in ensuring accuracy.

Q 9. How do you plan and optimize log hauling routes for efficiency and cost-effectiveness?

Optimizing log hauling routes is vital for profitability. My approach combines route planning software with on-the-ground knowledge. I begin by analyzing factors such as:

- Distance and Terrain: Using mapping software and considering road conditions (paved vs. unpaved, steep grades, etc.), I identify the shortest and most practical routes.

- Load Weight and Truck Capacity: I ensure that routes are suitable for the weight and size of the loads, accounting for bridge weight limits and other road restrictions. This prevents costly delays and potential damage.

- Traffic Patterns and Potential Delays: I consider peak traffic hours and potential road closures to minimize travel time and fuel consumption. I’ve utilized real-time traffic data from apps to avoid congestion hotspots.

- Delivery Schedules and Priorities: Route optimization also considers the urgency of deliveries and the need to prioritize certain customers or contracts.

For example, on a recent project, I implemented a route optimization strategy that reduced our hauling costs by 15% by utilizing a more efficient route network and consolidating loads more effectively.

Q 10. Describe your experience with GPS tracking and fleet management systems in log hauling.

GPS tracking and fleet management systems are indispensable for efficient log hauling. I have extensive experience using systems that provide:

- Real-time Location Tracking: This allows me to monitor the progress of each truck, ensuring timely deliveries and identifying any deviations from the planned route.

- Driver Behavior Monitoring: Some systems track speed, idling time, and harsh braking/acceleration. This data helps improve driver safety, reduce fuel consumption, and minimize wear and tear on equipment.

- Maintenance Scheduling: Many systems offer alerts for scheduled maintenance, reducing downtime and ensuring the longevity of our vehicles. I’ve used this feature to proactively schedule maintenance and avoid costly unexpected breakdowns.

- Fuel Consumption Monitoring: Tracking fuel efficiency helps identify inefficiencies and potential mechanical issues. For instance, a sudden increase in fuel consumption might signal a problem requiring attention.

Through these systems, I’m able to optimize our fleet operations, enhance safety, and improve the overall efficiency of our log hauling operations. I am proficient in several leading fleet management software applications, which allow the analysis of large amounts of data for continuous improvement.

Q 11. How do you handle unexpected delays or breakdowns during log hauling operations?

Unexpected delays and breakdowns are inevitable in log hauling. My approach involves a proactive and reactive strategy:

- Preventive Maintenance: Regular maintenance significantly reduces the likelihood of breakdowns. I ensure all equipment undergoes thorough inspections and scheduled servicing.

- Emergency Response Plan: We have a detailed plan for handling breakdowns, including contacting roadside assistance, arranging for repairs, and finding alternative transportation if necessary. This plan specifies contact details, procedures, and alternative options for transportation of logs.

- Communication: Immediate and transparent communication with dispatchers, clients, and drivers is crucial. I inform stakeholders about the delay and provide estimated times for resolution. This minimizes disruptions and keeps everyone informed.

- Problem-Solving: In case of a breakdown, I work to assess the situation, diagnose the problem, and find the most efficient solution for repair or replacement, considering factors like availability of parts and repair personnel.

For instance, on one occasion, a truck experienced a tire blowout in a remote area. Our pre-planned emergency response ensured a rapid replacement and minimized the delay. Effective communication with the client prevented any significant impact on the delivery schedule.

Q 12. What are your methods for maintaining log hauling equipment and ensuring its optimal performance?

Maintaining log hauling equipment is paramount for safety and efficiency. My approach includes:

- Regular Inspections: Daily pre-trip inspections are mandatory. This includes checking tire pressure, fluid levels, brakes, lights, and other critical components.

- Scheduled Maintenance: We follow a strict maintenance schedule based on hours of operation or mileage. This includes oil changes, filter replacements, and other routine tasks.

- Preventive Repairs: Addressing minor issues promptly prevents them from escalating into major breakdowns. We maintain a detailed log of all maintenance and repairs.

- Driver Training: Drivers receive training on proper equipment operation and maintenance. They’re also instructed to report any unusual noises or performance issues immediately.

Investing in preventative maintenance has significantly reduced our downtime and repair costs over the years. A well-maintained fleet leads to safer operations and greater cost efficiency.

Q 13. Describe your experience with load balancing and weight distribution in log hauling.

Proper load balancing and weight distribution are critical for safety and efficiency. Improperly loaded trucks can lead to accidents, damage to roads, and increased fuel consumption.

- Load Planning: Before loading, I plan the weight distribution to ensure even balance across the truck’s axles. This might involve strategically placing heavier logs closer to the center of gravity.

- Securement: Logs must be securely fastened to prevent shifting during transport. We use chains, binders, and other appropriate securing devices according to industry best practices and regulations.

- Weight Limits: We strictly adhere to weight limits set by regulations and the truck’s specifications. Overloading can lead to serious consequences and legal penalties.

- Technology: Some trucks utilize load-measuring systems that help drivers optimize weight distribution and ensure compliance with weight restrictions.

I’ve worked on projects with challenging terrain requiring particularly careful load planning and securing to maintain stability and prevent accidents. The safety of our drivers and the protection of public roads are paramount in our load management approach.

Q 14. How do you communicate effectively with dispatchers, foresters, and other stakeholders?

Effective communication is the cornerstone of successful log hauling operations. My approach emphasizes:

- Clear and Concise Communication: I use clear, unambiguous language, avoiding jargon whenever possible. I confirm all instructions and information to prevent misunderstandings.

- Regular Updates: I provide regular updates to dispatchers, foresters, and clients on the progress of hauling operations, including any potential delays or issues.

- Multiple Communication Channels: I utilize various communication channels, such as radio, phone, and email, to ensure timely delivery of information, even in areas with limited cell service. For example, two-way radios are crucial in remote locations.

- Active Listening: I pay close attention to instructions and concerns from stakeholders. This helps address issues proactively and build strong working relationships.

Open and honest communication fosters trust and collaboration, ultimately leading to more efficient and successful log hauling projects. I value building positive relationships with all stakeholders involved.

Q 15. What is your approach to dealing with challenging or difficult work situations?

My approach to challenging work situations hinges on a structured, proactive methodology. First, I thoroughly analyze the problem, identifying root causes and potential contributing factors. This often involves gathering data, consulting with colleagues, and reviewing past experiences. Then, I develop a plan of action, outlining specific steps to mitigate the problem. This plan includes setting realistic goals and timelines. Crucially, I prioritize communication throughout the entire process. Keeping everyone informed, from my crew to management, ensures transparency and fosters collaboration. Finally, I rigorously evaluate the effectiveness of the implemented solutions, adapting my approach as needed to optimize outcomes. For instance, when faced with a particularly challenging terrain during a log haul, I wouldn’t just plow through; I’d re-assess the route, perhaps utilizing different equipment or seeking alternative paths to ensure safety and efficiency.

I firmly believe that even setbacks provide valuable learning opportunities. By carefully analyzing what went wrong, I can refine my methods and prevent similar issues from arising in the future. This continuous improvement cycle is integral to my success in log hauling.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of relevant transportation regulations and permits for log hauling.

Understanding and adhering to transportation regulations is paramount in log hauling. This involves familiarity with federal, state, and local laws governing vehicle weight limits, load securement, driver qualifications (such as CDL requirements and hours of service), and permits for oversized or overweight loads. Specific regulations vary significantly by jurisdiction, so I always consult the relevant authorities to ensure compliance. This includes obtaining the necessary permits – which might include special permits for routes with low bridges or narrow roads – and ensuring my vehicles and loads are compliant with all safety standards. For instance, proper load securing is crucial; improperly secured logs could result in serious accidents and legal ramifications. Regular vehicle maintenance, to ensure compliance with brake and lighting regulations, is also a critical part of maintaining legal compliance.

Q 17. How do you ensure compliance with environmental regulations during log hauling operations?

Environmental compliance is a top priority in my log hauling operations. This begins with adhering to regulations concerning erosion control, particularly on logging roads. Proper road maintenance, including the use of erosion control techniques like ditching and culverts, minimizes soil runoff and sediment pollution. I also strictly follow guidelines for managing stormwater runoff to prevent contamination of waterways. Careful planning of routes minimizes environmental impact by avoiding sensitive areas. Furthermore, I implement strategies to prevent the spillage of fuel or oil from our heavy equipment. Regular maintenance and proper fueling procedures minimize the risk of leaks. Ultimately, environmental responsibility is not just about compliance; it’s about being a good steward of the land and minimizing our overall footprint during every haul.

Q 18. Describe your experience with different types of logging roads and their impact on log hauling.

Experience with various logging road types is essential for efficient and safe log hauling. I’ve worked on everything from well-maintained, gravel roads to rough, muddy trails. Well-maintained roads significantly reduce travel time and minimize equipment wear and tear. However, even well-maintained roads can present challenges, such as steep inclines or sharp curves that require careful maneuvering and speed control. Rough, unmaintained roads drastically increase the risk of equipment damage and accidents. In these situations, specialized equipment might be necessary, such as heavy-duty trucks with increased ground clearance, and careful route planning is crucial. The condition of the road directly affects fuel consumption; rougher roads necessitate slower speeds and increase fuel use. For example, a muddy logging road requires a much slower pace, affecting overall efficiency compared to hauling on a paved road.

Q 19. How do you assess the risks associated with different log hauling routes and terrains?

Risk assessment is a crucial element of every log haul. This involves carefully evaluating the route, terrain, weather conditions, and the load itself. Factors like steep inclines, sharp turns, narrow bridges, and potential hazards like rockslides or flooding are all carefully considered. I use topographic maps, satellite imagery, and local knowledge to identify potential risks. Weather conditions, especially rain or snow, can significantly increase the risk of accidents. The size and weight of the load also play a critical role; a heavier load will require more careful planning and maneuvering. I always develop contingency plans, considering alternative routes or strategies to mitigate potential problems. For example, if a route is particularly hazardous, I’d prioritize hauling smaller loads or employing extra support vehicles.

Q 20. What are your strategies for managing fuel efficiency and reducing operational costs?

Managing fuel efficiency and reducing operational costs are intertwined goals that I actively pursue. Strategies include optimizing routes to minimize mileage, using fuel-efficient vehicles and equipment, and employing proper driving techniques like avoiding excessive idling and maintaining appropriate speeds. Regular vehicle maintenance, including proper tire inflation and engine tuning, plays a significant role in fuel economy. Another important aspect is load planning. Optimizing the weight and distribution of the load minimizes fuel consumption. Careful monitoring of fuel usage data helps identify areas for improvement, allowing for proactive adjustments to operational procedures. Implementing technologies such as GPS tracking can enhance route optimization and fuel management. For example, by carefully studying historical fuel data, I’ve identified particular road segments where fuel consumption was unexpectedly high. Analysis revealed a need for route adjustments, resulting in a noticeable reduction in fuel costs.

Q 21. Describe your experience with using different types of heavy equipment used in log hauling.

My experience encompasses a range of heavy equipment used in log hauling. This includes various types of logging trucks, from smaller single-axle units to large, heavy-duty tandem and tri-axle trucks capable of carrying substantial loads. I’m proficient in operating different types of trailers designed for log hauling, including those with bunks, dollies, and specialized attachments for different log sizes and configurations. I’m also familiar with various types of skidders, loaders, and forwarders used in the initial stages of log extraction. Each piece of equipment has its own characteristics and operational requirements. Knowing how to properly operate and maintain this equipment is critical for efficiency and safety. For example, understanding the limitations of a specific truck’s weight capacity and maneuverability is vital to prevent accidents and equipment damage. Additionally, my experience extends to using specialized equipment for challenging terrain, such as articulated trucks for navigating difficult logging roads.

Q 22. What is your experience with maintaining accurate log hauling records and documentation?

Maintaining accurate log hauling records is crucial for operational efficiency, regulatory compliance, and financial accountability. My experience involves meticulously documenting every aspect of a haul, from the initial loading at the logging site to the final delivery at the mill. This includes:

- Pre-haul documentation: Recording the species, volume (using scaling methods like Smalian’s formula or Scribner’s rule), and grade of logs, along with the origin and destination. I use digital logging software to ensure accuracy and easy access to data.

- During-haul documentation: Recording truck identification number, driver’s information, departure and arrival times, any delays encountered (e.g., weather, road closures), and fuel consumption. GPS tracking provides real-time location data and supports accurate mileage calculations.

- Post-haul documentation: Confirming log delivery, documenting any damage sustained during transport, and generating comprehensive reports for clients and internal review. These reports help analyze efficiency, identify areas for improvement, and aid in cost management.

For instance, on one occasion, detailed records helped resolve a discrepancy in log volume reported by the mill, eventually proving our accurate initial measurements and preventing a financial loss for the company.

Q 23. Explain your knowledge of different log species and their handling requirements.

Understanding different log species and their handling requirements is paramount to preventing damage and ensuring efficient transportation. Different species possess varying densities, strengths, and susceptibilities to damage. For example:

- Hardwoods (e.g., oak, maple): These are denser and stronger, requiring robust handling and secure fastening to prevent cracking or splitting during transport. Overloading trucks carrying hardwoods should be avoided as these logs are prone to shift during transit.

- Softwoods (e.g., pine, fir): Generally lighter and more flexible, they require careful stacking to prevent bending or crushing. Proper load distribution is essential, as softwoods are more susceptible to damage from uneven pressure.

- Special considerations: Some species are more prone to insect infestation or fungal decay, requiring specific transportation methods to minimize risks. For example, logs susceptible to blue stain should be transported quickly to prevent discoloration.

My experience includes working with a wide range of species and adapting my handling procedures accordingly. I regularly consult industry best practices and stay updated on the latest handling recommendations to optimize safety and reduce damage.

Q 24. Describe your experience with managing a log hauling team and ensuring their safety.

Managing a log hauling team effectively involves strong leadership, clear communication, and a relentless focus on safety. This includes:

- Pre-trip inspections: Ensuring all equipment is in proper working order, including trucks, trailers, and winches. Drivers receive training on safe operating procedures and pre-trip inspection checklists.

- Safety training: Regular safety meetings and refresher courses covering hazard identification, risk mitigation, and emergency response protocols. This includes training on safe load securing techniques and defensive driving.

- Communication: Maintaining open lines of communication with drivers, providing regular updates, addressing concerns promptly, and fostering a culture of mutual respect and teamwork. Using communication technologies to ensure all team members are coordinated effectively.

- Performance monitoring: Tracking driver performance, identifying areas needing improvement, and providing necessary coaching and support. Using metrics such as on-time delivery rates, accident rates, and fuel efficiency to evaluate performance.

For example, I implemented a new driver training program that reduced our accident rate by 15% in the first year. This involved hands-on training sessions, coupled with ongoing mentorship and regular performance reviews.

Q 25. What are your strategies for preventing log damage during transportation?

Preventing log damage during transportation requires a multifaceted approach focusing on proper loading, secure fastening, and careful driving. My strategies include:

- Proper loading techniques: Logs should be carefully stacked and distributed evenly to maintain balance and minimize shifting during transit. The use of proper dunnage to distribute weight is essential.

- Secure fastening: Using appropriate binders, chains, and other securing devices to prevent logs from moving or falling. The number and placement of the fasteners depend on the type of log, size of the load and prevailing transportation conditions.

- Careful driving: Avoiding sudden braking, sharp turns, and excessive speed to minimize stress on the load and reduce the risk of damage. Drivers should be trained on safe driving practices and adherence to speed limits.

- Weather considerations: Adjusting transportation schedules to avoid extreme weather conditions such as rain, snow, or high winds, which can increase the risk of accidents or damage.

For instance, I’ve found that using specialized log bunks designed to minimize friction and better distribute weight results in significantly less damage to the logs during transit.

Q 26. How do you handle situations involving damaged logs or equipment during transportation?

Handling situations involving damaged logs or equipment requires prompt action, thorough documentation, and adherence to established procedures. My approach includes:

- Assessment of the damage: Determining the extent of the damage to both the logs and equipment. Taking photographs and documenting everything to create an accurate account of the situation.

- Safety first: Prioritizing the safety of personnel involved by securing the area and ensuring no further risk to individuals exists.

- Reporting and communication: Reporting the incident to the appropriate personnel, including supervisors, clients, and insurance companies. Clear communication is essential to ensure all parties are informed.

- Investigation and analysis: Investigating the cause of the damage to identify areas for improvement in future operations and prevent recurrence. Documentation helps determine the exact events that led to the incident.

- Remedial actions: Taking appropriate remedial actions, such as repairing or replacing damaged equipment or logs, and implementing corrective measures to prevent future incidents.

For example, in a situation involving a damaged trailer, I coordinated with maintenance personnel for prompt repairs, ensuring minimal downtime and avoiding delays in log deliveries.

Q 27. Describe your understanding of the principles of load stability and its impact on safety.

Load stability is paramount to safe log hauling. An unstable load can shift during transit, leading to accidents, damage to logs, and potential injury. Understanding the principles involves considering:

- Center of gravity: The load’s center of gravity should be kept as low as possible to improve stability. This means careful consideration of log placement and weight distribution.

- Load distribution: Logs should be evenly distributed across the trailer to prevent imbalance and reduce the risk of shifting. Using proper dunnage to spread the weight evenly is vital.

- Securing methods: Appropriate and sufficient binding, chains, and other securing devices must be used to prevent movement during transit. Over tightening of bindings can also cause damage, so careful use is important.

- Road conditions: Drivers should adjust their driving behavior based on road conditions. Reduced speeds and cautious maneuvering are critical on uneven or rough terrain.

An analogy would be stacking blocks: if the blocks aren’t evenly balanced and firmly secured, they’ll topple. The same principle applies to log hauling. A well-balanced, securely fastened load reduces the risk of accidents and damage significantly.

Q 28. What is your experience in dealing with emergency situations or accidents during log hauling?

Experience with emergency situations and accidents involves a structured response rooted in safety and regulatory compliance. My approach focuses on:

- Immediate response: Securing the scene, assessing the situation, and providing any necessary first aid. Calling emergency services if required.

- Safety procedures: Following established safety protocols, including notifying relevant parties (e.g., supervisors, authorities). Traffic control is vital if the incident involves a road closure.

- Documentation: Thorough documentation of the incident, including photographs, witness statements, and details of any injuries or damage. This is vital for insurance claims and accident investigations.

- Investigation: Cooperating fully with any investigations into the accident’s cause, contributing information gathered from various sources to determine causation.

- Post-incident review: Reviewing the incident to identify areas for improvement in safety procedures and prevent future occurrences. This is essential for ongoing development of risk management protocols.

In one instance, I successfully managed a rollover accident, ensuring the safety of the driver and coordinating with emergency services and regulatory bodies to handle the situation efficiently and safely.

Key Topics to Learn for Log Hauling Knowledge Interview

- Log Harvesting Techniques: Understanding various felling methods, pre-harvest planning, and the impact on timber quality and safety.

- Equipment Operation and Maintenance: Familiarity with different types of log hauling equipment (e.g., skidders, forwarders, trucks), their operational procedures, and preventative maintenance schedules. Practical experience troubleshooting common mechanical issues will be beneficial.

- Log Transportation and Logistics: Knowledge of efficient loading, securing, and transporting logs, including understanding regulations and safety protocols for road transport and load limits.

- Safety Regulations and Procedures: Deep understanding of all relevant safety regulations, including personal protective equipment (PPE) requirements, hazard identification, and emergency response procedures. Demonstrating a proactive safety-first mindset is crucial.

- Environmental Considerations: Awareness of sustainable forestry practices, minimizing environmental impact during log hauling, and adhering to environmental regulations.

- Efficiency and Productivity: Understanding strategies to optimize log hauling operations, minimizing downtime and maximizing output while maintaining safety standards. This includes route planning and efficient equipment utilization.

- Legal and Regulatory Compliance: Knowledge of relevant permits, licenses, and regulations pertaining to log harvesting and transportation, as well as weight limits and road usage restrictions.

Next Steps

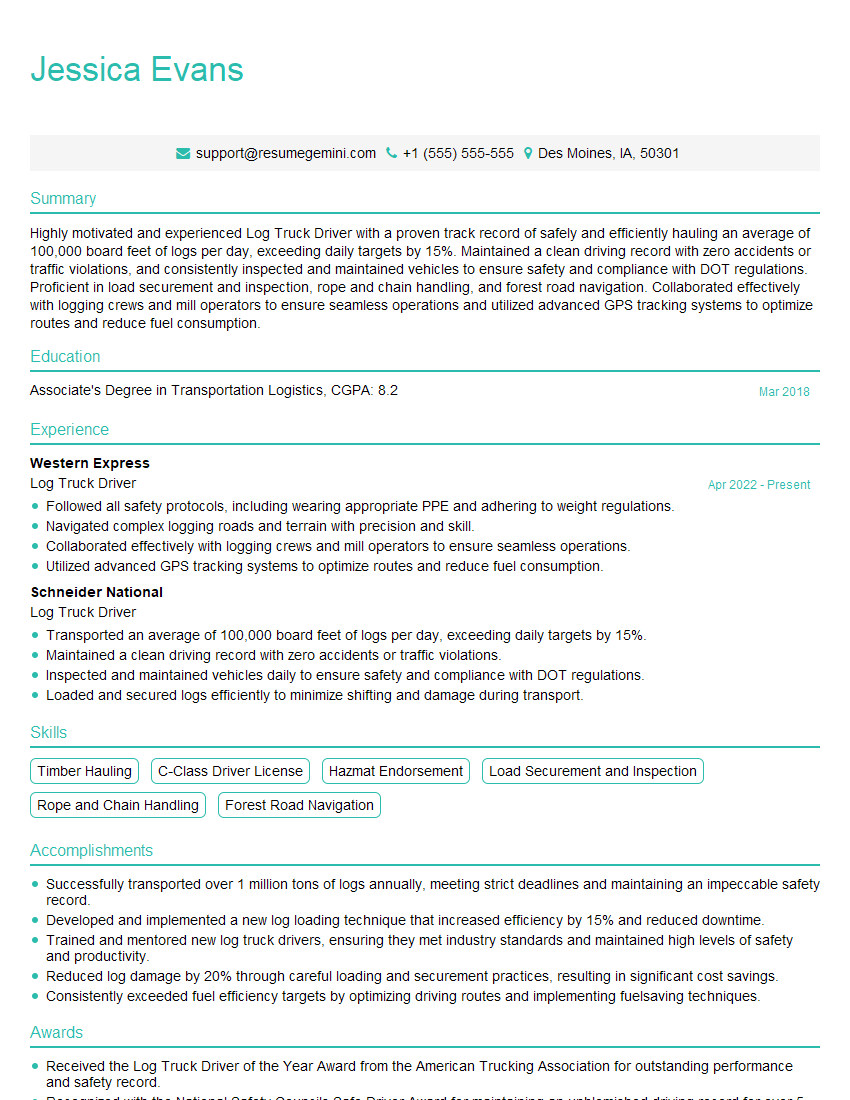

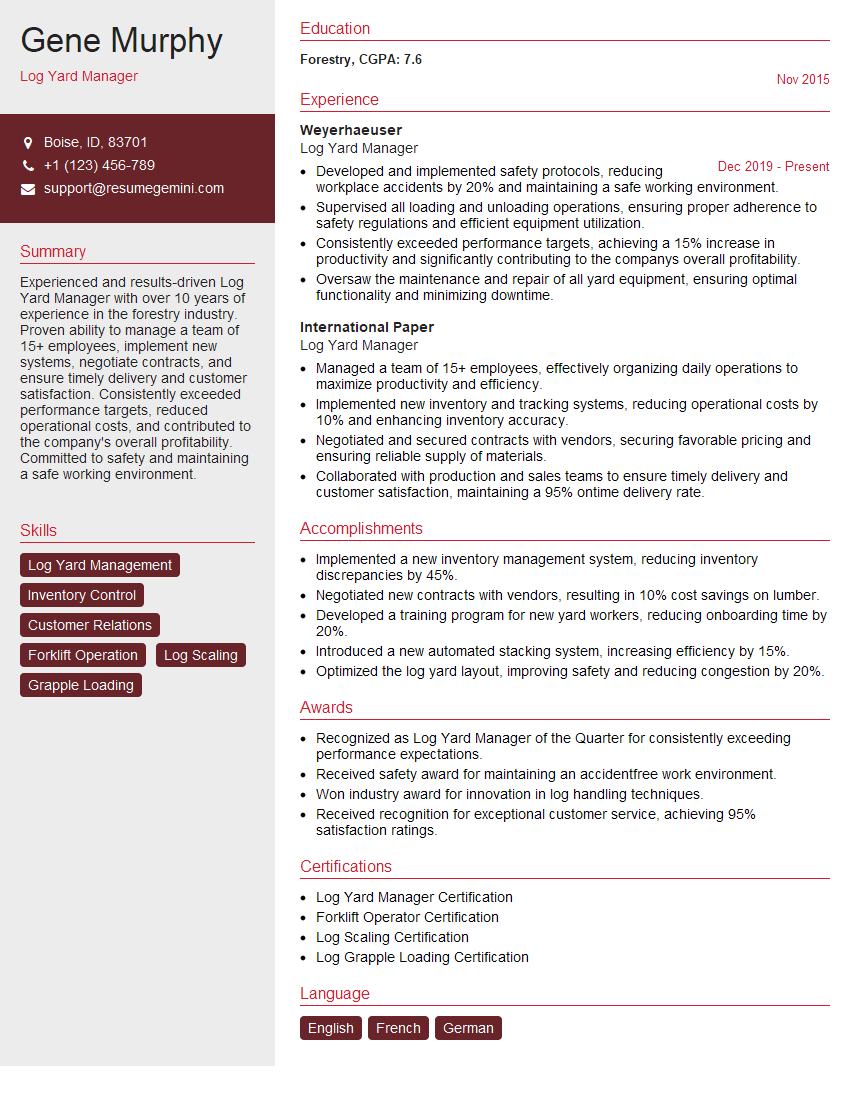

Mastering log hauling knowledge is essential for career advancement in the forestry industry, opening doors to higher-paying roles and increased responsibility. A strong understanding of these topics demonstrates your commitment to safety, efficiency, and sustainable practices. To significantly boost your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Log Hauling Knowledge are available to guide you. Invest the time to craft a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good