Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Log Inventory Management interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Log Inventory Management Interview

Q 1. Describe your experience with various log inventory management systems.

My experience spans a variety of log inventory management systems, from simple spreadsheet-based tracking to sophisticated enterprise resource planning (ERP) systems integrated with GPS-enabled logging equipment. I’ve worked with systems like SAP, Oracle, and specialized forestry management software. Each system presents unique strengths and weaknesses depending on the scale of operations and specific needs. For instance, smaller operations might effectively utilize a spreadsheet system, while large companies benefit from the comprehensive data management and reporting capabilities of an ERP. My experience includes implementing, customizing, and troubleshooting these systems, ensuring seamless integration with other operational processes like harvesting, transportation, and sales.

For example, in a previous role, we migrated from a manual system to a cloud-based inventory management platform. This transition resulted in significant improvements in accuracy, efficiency, and real-time data visibility. The new system provided features such as automated log scaling, reduced manual data entry errors, and enhanced reporting capabilities, allowing us to make more data-driven decisions.

Q 2. Explain the process of log scaling and its importance in inventory management.

Log scaling is the process of accurately measuring the volume of logs. It’s crucial for inventory management because it forms the foundation for all subsequent calculations, including determining the value of the inventory, managing sales, and tracking profitability. Accurate scaling ensures that you’re not overestimating or underestimating your resources. There are several methods, including:

- Diameter and Length Method: This is the most common method, using a diameter tape to measure the small-end diameter and measuring the length of the log. Volume is then calculated using a formula (often involving a specific scaling factor for the type of log).

- Scribner Decimal C Scale: This is a more complex method using a specific table to calculate log volume based on diameter and length.

- Doyle Scale: Another scale, similar to Scribner, used for calculating log volume.

The importance of accurate scaling can’t be overstated. Inaccurate scaling can lead to significant financial losses due to miscalculations in sales, purchases, and inventory valuations. Imagine a sawmill underestimating the volume of logs received; this could lead to underpayment to suppliers and potential contract disputes.

Q 3. How do you ensure accurate log inventory tracking and reporting?

Ensuring accurate log inventory tracking and reporting involves a multi-pronged approach. It starts with accurate data collection at the point of harvest. This includes using reliable scaling methods, meticulously recording log dimensions, species, and quality grades. Then, using a robust inventory management system is key. This system should track log movement throughout the entire supply chain, from the forest to the mill or processing plant. Barcoding or RFID tagging can help automate this process, minimizing manual data entry errors. Regular physical inventory counts should be conducted and reconciled with the system’s records to identify and rectify discrepancies. Finally, the system should generate accurate and timely reports to track key metrics such as inventory levels, log movement, and sales.

For example, implementing a system of regular spot checks of inventory against the digital record helps catch errors early. We can then investigate the source of discrepancy and adjust processes to prevent it from happening again. Implementing a robust quality control protocol is also critical to prevent errors in data entry or data management.

Q 4. What metrics do you use to evaluate the efficiency of your log inventory processes?

Several key metrics evaluate the efficiency of log inventory processes. These include:

- Inventory Turnover Rate: This measures how quickly logs are processed and sold. A high turnover rate suggests efficient inventory management.

- Inventory Accuracy: The percentage of inventory records matching physical inventory. Higher accuracy indicates better control.

- Log Loss Rate: This tracks the percentage of logs lost due to damage, theft, or other reasons. A low loss rate is essential.

- Order Fulfillment Rate: Measures how effectively orders are met from available inventory. A high rate signifies efficient inventory planning.

- Carrying Costs: This represents the costs associated with storing and maintaining inventory. Efficient processes minimize these costs.

By monitoring these metrics regularly, we can identify areas for improvement and optimize inventory management strategies.

Q 5. How do you handle discrepancies between physical inventory and recorded inventory?

Discrepancies between physical and recorded inventory are inevitable, but prompt investigation and resolution are critical. The first step is to conduct a thorough recount of the physical inventory, meticulously verifying the data. Then, compare the physical count with the recorded inventory data, identifying the specific discrepancies. Possible causes include data entry errors, theft, damage, or inaccurate scaling. Investigate each discrepancy systematically. This might involve reviewing security footage, examining log movement records, and interviewing relevant personnel.

Once the cause is identified, corrective actions should be implemented. This might involve retraining staff, improving data entry processes, enhancing security measures, or refining scaling techniques. It’s crucial to document the discrepancy, investigation, and resolution to prevent similar issues in the future.

Q 6. Describe your experience with inventory forecasting and demand planning for logs.

Inventory forecasting and demand planning for logs are crucial for optimizing inventory levels, ensuring timely supply to customers, and minimizing storage costs. This involves analyzing historical sales data, considering market trends, and anticipating future demand. Factors such as seasonal variations, construction activity, and global economic conditions need to be incorporated into the forecast. Statistical forecasting methods, such as time series analysis, can be employed to predict future demand with a certain degree of confidence. Furthermore, collaboration with key stakeholders, such as sawmill operators and customers, can provide valuable insights into future demand patterns. Regular review and adjustment of the forecast are vital to account for unexpected changes in the market.

For example, if we anticipate an increase in demand due to a major construction project, we can proactively increase our log inventory to meet the expected surge. This proactive approach helps avoid stockouts and ensures that we can fulfill customer orders promptly.

Q 7. Explain the role of quality control in log inventory management.

Quality control plays a vital role in log inventory management. It ensures that logs meet the required specifications and standards for their intended use. This starts with proper assessment of log quality during harvesting, considering factors like species, diameter, length, defects (knots, rot), and moisture content. Throughout the supply chain, quality checks should be conducted to identify and address any deterioration or damage. Rejected logs should be appropriately categorized and managed. This ensures that the inventory reflects the actual usable volume and value. Implementing a quality control system reduces losses from using damaged logs and enhances the overall efficiency and profitability of the operation.

For instance, establishing clear grading criteria and using consistent grading methods ensures that logs are categorized correctly and that customers receive the quality they expect. A robust quality control system can identify problems early, preventing the accumulation of low-quality logs, thus avoiding potential losses down the line.

Q 8. How do you manage log storage and handling to minimize losses?

Minimizing log losses requires a multi-pronged approach focusing on efficient storage and handling practices. Think of it like managing a high-value inventory – careful planning is crucial.

- Strategic Stacking: Logs should be stacked properly to prevent damage, using techniques like cribbing (placing smaller logs between larger ones for stability) and ensuring adequate ventilation to prevent fungal growth. Imagine building a tower of blocks – you wouldn’t just toss them randomly; you’d build it steadily and securely.

- Protection from the Elements: Logs are susceptible to degradation from sun, rain, and snow. Using tarps or storing them under cover is essential. Think of it like protecting valuable furniture from harsh weather – you wouldn’t leave a prized antique out in a downpour!

- Pest Control: Insects and fungi can significantly damage logs. Regular inspections and appropriate treatments are needed. This is similar to how a farmer protects their crops from pests to ensure a good yield.

- Inventory Management System: A robust system, such as a software-based inventory management system (discussed in question 3), helps track logs, reducing the chance of theft or misplacement.

Q 9. How do you address the challenges of log deterioration and spoilage?

Log deterioration and spoilage are significant challenges, often caused by biological agents (fungi, insects) and environmental factors (sun, rain). Addressing this involves proactive measures:

- Pre-harvest Treatments: Applying protective coatings or treatments to logs before storage can significantly reduce the risk of deterioration. This is like painting a wooden fence to protect it from the elements.

- Proper Drying: Rapid and efficient drying of logs is critical. This can involve techniques like air drying or kiln drying, reducing moisture content that encourages fungal growth. Imagine drying wet clothes quickly to prevent mildew.

- Regular Inspection: Frequent checks are crucial for early detection of deterioration signs (discoloration, insect infestations). This allows for timely intervention to minimize further damage – much like a doctor’s regular check-up to catch health problems early.

- Segregation of Damaged Logs: Quickly identifying and separating affected logs prevents the spread of damage to healthy ones. This is akin to isolating a sick person to prevent the spread of an illness.

Q 10. What software or technologies have you used for log inventory management?

I’ve had extensive experience with various software and technologies for log inventory management. They range from simple spreadsheet-based systems to sophisticated enterprise resource planning (ERP) solutions.

- Spreadsheet Software (Excel, Google Sheets): For smaller operations, spreadsheets can be effective for basic tracking of log quantities, locations, and grades. However, they lack the advanced features of dedicated software.

- Inventory Management Software (e.g., SAP, Infor): These specialized systems offer comprehensive features, including tracking, reporting, and analysis of log inventory. They can integrate with other systems for enhanced efficiency. One example is automated alerts for low stock levels or expiring logs.

- Custom-built Databases: For larger companies or those with unique requirements, a custom-built database can provide a tailored solution for log inventory management. This often allows for better integration with specific equipment and logistics.

Q 11. Describe your experience with RFID or barcode technology in log tracking.

RFID (Radio-Frequency Identification) and barcode technology are invaluable tools for efficient log tracking. I’ve used both extensively.

- Barcodes: These are relatively inexpensive and easy to implement, providing a unique identifier for each log. However, they require line-of-sight scanning, making them less efficient in cluttered yards.

- RFID: RFID tags offer superior tracking capabilities, allowing for remote identification of logs even without direct line of sight. This improves efficiency and accuracy, particularly in large storage yards. Imagine scanning a pallet of logs without having to manually check each one. The data is immediately accessible, improving real-time inventory visibility.

- Integration with Software: Both barcode and RFID systems integrate seamlessly with inventory management software, providing real-time updates and reducing manual data entry.

Q 12. How do you optimize log transportation and logistics to minimize costs?

Optimizing log transportation and logistics is essential for minimizing costs. It involves a strategic approach involving several key elements:

- Route Optimization: Utilizing route planning software to determine the most efficient routes, minimizing fuel consumption and travel time. This is similar to using GPS navigation to find the fastest route to a destination.

- Load Planning: Efficiently loading trucks to maximize space and reduce the number of trips needed. This is like packing a suitcase – you want to fit everything in as efficiently as possible.

- Transportation Mode Selection: Choosing the most cost-effective transportation mode based on distance, volume, and urgency. This might involve truck, rail, or barge transportation, depending on the specific circumstances.

- Real-time Tracking: Using GPS tracking to monitor shipments in real-time, enabling proactive response to potential delays or issues.

Q 13. Explain your understanding of different log grading systems.

Log grading systems classify logs based on various factors affecting their value and use. Different systems exist depending on the species and intended use of the wood.

- Visual Grading: This relies on visual assessment of characteristics like diameter, length, straightness, and the presence of defects. Experienced graders use their knowledge and experience to assess the quality.

- Mechanical Grading: This employs automated systems that measure and assess logs based on pre-defined criteria. This approach enhances consistency and objectivity.

- Standards: Various standards and guidelines exist for log grading, depending on the region and species. Examples include the Canadian Lumber Standards and the American Lumber Standard Committee grades.

- Impact on Value: The grade significantly impacts the price of the logs. Higher-grade logs fetch higher prices due to their superior quality and suitability for specific applications.

Q 14. How do you manage seasonal fluctuations in log supply and demand?

Managing seasonal fluctuations in log supply and demand requires a proactive approach incorporating several strategies:

- Demand Forecasting: Accurate forecasting helps anticipate market changes and adjust inventory levels accordingly. This is analogous to a store owner stocking up on holiday items in anticipation of increased demand.

- Strategic Sourcing: Diversifying sources and establishing strong relationships with suppliers ensures a steady supply even during peak seasons. Think of it like having multiple suppliers for a product to avoid reliance on just one.

- Inventory Management: Efficient inventory management allows for flexibility in managing surplus or shortfalls by strategic stockpiling during low demand and controlled release during peak times. This is like having a reserve supply of goods to manage periods of high demand.

- Pricing Strategies: Dynamic pricing strategies, adjusting prices based on supply and demand fluctuations, can optimize profitability throughout the year. This is like adjusting prices for seasonal products based on the time of year.

Q 15. How do you integrate log inventory management with other supply chain processes?

Integrating log inventory management with other supply chain processes is crucial for efficient operations. It’s not just about tracking logs; it’s about aligning inventory levels with harvesting schedules, transportation logistics, and mill processing capacity. Think of it like a well-oiled machine – each part needs to work in harmony.

Procurement and Harvesting: Log inventory management systems should directly integrate with harvesting plans. This ensures that the right volume and type of logs are harvested and delivered, avoiding overstocking or shortages. For example, if the system predicts a high demand for specific log types in the next quarter, procurement can adjust harvesting schedules accordingly.

Transportation and Logistics: Integration with transportation management systems allows for real-time tracking of log shipments, optimizing routes, and minimizing transportation costs. Knowing the exact location and status of each log shipment allows for better planning and prevents delays.

Mill Processing: Connecting inventory management with the mill’s production schedule ensures that the right logs are available when needed. This minimizes downtime and maximizes efficiency. For instance, if the mill requires a specific log diameter, the system can prioritize the delivery of logs meeting that criteria.

Sales and Order Fulfillment: The system should enable accurate sales forecasting based on inventory levels and demand. This ensures that sales commitments can be met reliably.

Effective integration often involves using enterprise resource planning (ERP) systems or specialized supply chain management (SCM) software that can connect various modules and data sources.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with inventory optimization techniques (e.g., ABC analysis).

Inventory optimization is key to minimizing storage costs and maximizing profitability in log management. ABC analysis is a valuable technique I frequently use. It categorizes inventory items based on their value and consumption rate.

A-items: These are high-value, high-consumption items (e.g., rare hardwood species). They require tight control and frequent monitoring to ensure availability and prevent losses.

B-items: These are medium-value, medium-consumption items. They require moderate control and monitoring.

C-items: These are low-value, high-consumption items (e.g., common softwoods). They require minimal control, focusing on efficient bulk purchasing and storage.

I’ve used ABC analysis to prioritize inventory efforts, focusing on A-items to minimize risks and optimize storage for B and C items. For example, in one project, we implemented a more rigorous tracking system for A-items, resulting in a 15% reduction in inventory shrinkage.

Beyond ABC analysis, I’m also experienced with techniques like Economic Order Quantity (EOQ) calculations to determine optimal order sizes and Just-in-Time (JIT) inventory management to minimize storage costs by receiving materials only when needed. These techniques are tailored to the specific characteristics of log inventory, considering factors like spoilage, degradation, and seasonal demand.

Q 17. How do you ensure compliance with environmental regulations in log management?

Compliance with environmental regulations is paramount in log management. This involves careful consideration of several key areas:

Sustainable Harvesting Practices: Ensuring that logging operations adhere to sustainable forestry guidelines and certification schemes like the Forest Stewardship Council (FSC) is critical. This involves tracking the origin of logs, ensuring compliance with reforestation plans, and avoiding harvesting in protected areas.

Waste Management: Proper management of logging residues and waste is crucial to minimize environmental impact. This includes proper disposal or recycling of waste wood and the prevention of soil erosion.

Water Management: Minimizing the impact of logging operations on water resources is vital. This includes protecting water bodies from sedimentation and pollution.

Air Quality: Controlling air emissions from equipment and processing facilities is important. Regular maintenance and use of cleaner technologies contribute to air quality compliance.

I ensure compliance through regular audits, maintaining detailed records of logging operations, and working closely with regulatory agencies. For example, I’ve implemented a tracking system that monitors the volume and origin of each log, enabling us to quickly identify and address any non-compliance issues. We’ve also invested in technologies to optimize fuel consumption and reduce emissions.

Q 18. What are the key challenges in managing log inventory in a remote location?

Managing log inventory in remote locations presents unique challenges:

Accessibility: Reaching remote areas can be difficult and expensive, impacting transportation costs and delivery times. This necessitates robust planning and reliable transportation networks.

Security: Remote locations are more susceptible to theft and vandalism, requiring enhanced security measures. This might involve security personnel, surveillance systems, and robust inventory tracking systems.

Infrastructure: Limited infrastructure in remote areas can impact storage, processing, and communication capabilities. This may necessitate investing in specialized storage facilities and communication technologies.

Weather Conditions: Extreme weather events can damage logs and disrupt transportation, requiring resilient storage facilities and contingency plans.

Monitoring and Control: Remote monitoring systems and regular site visits are necessary to track inventory levels, detect damage, and maintain overall control.

In my experience, implementing remote sensing technologies, like drones for inventory assessment and GPS tracking for transportation, is crucial. Robust communication systems and well-trained local personnel are also vital to overcome the limitations of remote operations.

Q 19. How do you handle damage or loss claims related to log inventory?

Handling damage or loss claims requires a systematic approach:

Documentation: Maintain meticulous records of log inventory, including detailed descriptions, quantity, quality, and location. Photographs and video evidence can be crucial.

Investigation: Thoroughly investigate the cause of damage or loss, identifying potential contributing factors such as weather events, transportation accidents, or theft.

Insurance Claims: File insurance claims promptly, providing all necessary documentation to support the claim. This includes inventory reports, damage assessments, and police reports if theft is involved.

Third-Party Liability: If the damage or loss is due to a third party (e.g., a transportation company), pursue compensation from them.

Prevention: Implement measures to prevent future damage or loss, such as improved storage facilities, enhanced security, and more robust transportation protocols.

For example, in a case involving storm damage, we used detailed photographic evidence and meteorological reports to substantiate our insurance claim, resulting in full compensation for the lost logs. The incident also prompted us to implement a more robust early warning system for extreme weather events.

Q 20. Describe your experience with using data analytics to improve log inventory management.

Data analytics plays a vital role in improving log inventory management. By analyzing historical data and real-time information, we can gain valuable insights to optimize processes and reduce costs.

Predictive Modeling: Using historical data on log demand, prices, and weather patterns, I develop predictive models to forecast future inventory needs. This helps in making informed purchasing and harvesting decisions.

Inventory Optimization: Analyzing data on inventory turnover, storage costs, and spoilage rates allows for optimizing inventory levels and minimizing losses.

Performance Monitoring: Tracking key performance indicators (KPIs) like inventory accuracy, order fulfillment rates, and transportation efficiency allows for identifying areas for improvement.

Anomaly Detection: Using data analytics to detect anomalies in inventory levels, such as unusually high shrinkage or discrepancies in stock counts, can help identify potential problems early on.

In one project, we used machine learning to develop a predictive model for log demand, which resulted in a 10% reduction in inventory holding costs and a 5% increase in sales.

Q 21. How do you communicate inventory status and forecasts to stakeholders?

Effective communication of inventory status and forecasts to stakeholders is crucial for successful log inventory management. This involves using a variety of methods tailored to different audiences.

Regular Reporting: I create regular reports summarizing inventory levels, key performance indicators, and forecasts. These reports are distributed to relevant stakeholders through email or shared dashboards.

Visualizations: Using charts and graphs to visualize inventory data makes it easier for stakeholders to understand trends and patterns.

Meetings and Presentations: I conduct regular meetings with stakeholders to discuss inventory status and forecasts, allowing for open dialogue and addressing any concerns.

Inventory Management System Access: Providing access to the inventory management system allows stakeholders to monitor inventory levels in real-time.

Alert Systems: Setting up alert systems to notify stakeholders of critical events such as low inventory levels or potential delays ensures timely responses.

For example, I utilize a customized dashboard that provides real-time visibility of inventory levels, allowing stakeholders, from mill managers to sales teams, to make informed decisions based on the latest data. This transparency improves collaboration and minimizes potential disruptions in the supply chain.

Q 22. Explain your understanding of the importance of accurate log measurement.

Accurate log measurement is the bedrock of efficient log inventory management. It’s crucial for several reasons: It ensures accurate costing, allowing for precise pricing and profitability analysis. Without precise measurements, we risk underselling our inventory or overestimating our profits. Secondly, it facilitates efficient inventory tracking. Knowing the exact volume of logs allows for better forecasting of supply and demand, reducing waste from spoilage or overstocking. Finally, accurate measurement is essential for operational efficiency. It ensures that logging operations, transportation, and processing are planned effectively, minimizing delays and logistical challenges.

For example, inaccurately measuring the diameter of logs can lead to miscalculations in volume, resulting in significant financial losses over time. Imagine a sawmill relying on inaccurate measurements – they could end up with insufficient material for a production run or excess logs that need storage, incurring additional costs.

Q 23. How do you manage risk associated with fluctuations in log prices?

Managing risk associated with fluctuating log prices requires a multi-pronged approach. First, we utilize hedging strategies, such as futures contracts, to lock in prices for future deliveries. This helps mitigate the risk of price increases. Second, we diversify our log sourcing to reduce dependence on a single supplier or region, minimizing the impact of localized price shocks. Third, we maintain a robust financial model that accounts for potential price volatility. This allows for informed decision-making and proactive adjustments to our operational strategies. Finally, we constantly monitor market trends and conduct thorough price analysis to anticipate potential price fluctuations.

For instance, during periods of high price volatility, we might prioritize purchasing logs from regions with more stable pricing, even if it means slightly higher transportation costs. This strategic approach helps us navigate uncertain market conditions and protect our profitability.

Q 24. Describe your experience with implementing new log inventory management systems.

I have extensive experience in implementing new log inventory management systems, including both on-site and cloud-based solutions. My approach typically begins with a thorough needs assessment, identifying pain points in the existing system and aligning the new system with business objectives. This involves close collaboration with stakeholders across departments, including logging, transportation, and accounting. The implementation process itself involves careful planning, data migration, thorough testing, and comprehensive training for all users. Post-implementation, ongoing monitoring and performance analysis are crucial to optimize the system and address any emerging issues.

In one project, we replaced a legacy system with a modern cloud-based solution. The new system improved accuracy, reduced manual data entry errors, and allowed real-time tracking of inventory across multiple locations. This resulted in a significant reduction in operational costs and improved decision-making capabilities.

Q 25. How do you prioritize tasks and manage workload in a fast-paced log inventory environment?

In a fast-paced log inventory environment, effective task prioritization is essential. I use a combination of techniques, including the Eisenhower Matrix (urgent/important), to categorize tasks and focus on high-impact activities first. Additionally, I employ project management methodologies, such as Agile, breaking down larger projects into smaller, manageable tasks. Regular review and adjustment of priorities, based on changing circumstances, are key. Effective time management techniques, including time blocking and delegation where appropriate, further enhance my ability to handle workload effectively.

For example, if a large order needs immediate fulfillment, that task will naturally take precedence over less time-sensitive tasks like inventory auditing. By constantly monitoring deadlines and assessing priorities, I can ensure efficient resource allocation and timely completion of crucial tasks.

Q 26. How do you collaborate with different departments to ensure effective log inventory management?

Effective log inventory management requires seamless collaboration across various departments. I foster this by maintaining open communication channels, regularly attending interdepartmental meetings, and actively participating in collaborative problem-solving sessions. I ensure that everyone understands the importance of accurate data entry and timely information sharing. I leverage technology, such as shared databases and project management software, to facilitate information flow and ensure transparency. Building strong relationships with colleagues in different departments is crucial for effective collaboration and achieving common goals.

For instance, I work closely with the transportation department to schedule efficient log deliveries, minimizing transportation costs and ensuring timely supply to the mills. Collaboration with the accounting department is crucial for accurate cost tracking and financial reporting.

Q 27. What are your strategies for continuous improvement in log inventory management?

Continuous improvement in log inventory management is an ongoing process. I employ several strategies, including regular performance reviews of the inventory management system, identifying areas for improvement based on key performance indicators (KPIs). We conduct data analysis to identify trends and patterns, enabling proactive adjustments to optimize processes. I encourage a culture of innovation and experimentation within the team, exploring new technologies and best practices in the industry. Benchmarking against industry leaders helps identify areas where we can further optimize our processes. Participation in relevant industry conferences and professional development programs keeps our team abreast of the latest advancements in log inventory management.

For example, by analyzing historical data, we might identify patterns in seasonal demand and adjust our inventory levels accordingly, minimizing storage costs and preventing stockouts.

Q 28. Describe a time you had to solve a significant problem related to log inventory management.

In one instance, we experienced a significant discrepancy in our log inventory due to a software glitch that miscalculated the volume of logs in several storage yards. This resulted in inaccurate inventory reports and potential supply chain disruptions. To solve this, I immediately assembled a cross-functional team comprising IT specialists, inventory managers, and logging personnel. We first isolated the source of the error in the software, identifying a coding flaw that affected the volume calculations. While the IT team addressed the coding issue, we conducted a physical inventory count to verify the actual log volume. This painstaking process involved detailed measurements and careful record-keeping. Once the software was fixed, we reconciled the physical count with the updated system data. This incident highlighted the importance of regular system audits and the need for robust data validation procedures.

Key Topics to Learn for Log Inventory Management Interview

- Log Inventory Fundamentals: Understanding different log types (e.g., transactional, error, audit), their structure, and purpose within a system.

- Data Structures and Algorithms: Exploring efficient data structures (e.g., hash tables, trees) and algorithms for searching, sorting, and analyzing large log datasets. Practical application: optimizing log retrieval and analysis times.

- Log Storage and Retrieval: Examining various log storage solutions (e.g., centralized log management systems, cloud-based storage) and strategies for efficient data retrieval based on specific queries or criteria.

- Log Aggregation and Analysis: Understanding techniques for aggregating logs from multiple sources, correlating events, and applying analytical methods to identify patterns, anomalies, and potential issues. Practical application: troubleshooting system failures and improving performance.

- Log Monitoring and Alerting: Implementing real-time monitoring systems to track log activity, detect critical events, and trigger automated alerts based on predefined thresholds or patterns.

- Security and Compliance: Addressing security considerations related to log management, including data encryption, access control, and compliance with relevant regulations (e.g., GDPR, HIPAA).

- Log Rotation and Retention Policies: Defining efficient strategies for managing log storage capacity by implementing appropriate rotation and retention policies.

- Performance Optimization: Techniques for optimizing log processing and analysis performance, minimizing resource consumption and maximizing efficiency.

- Troubleshooting and Problem-Solving: Developing a systematic approach to identifying and resolving issues related to log management systems, analyzing log data to pinpoint root causes.

Next Steps

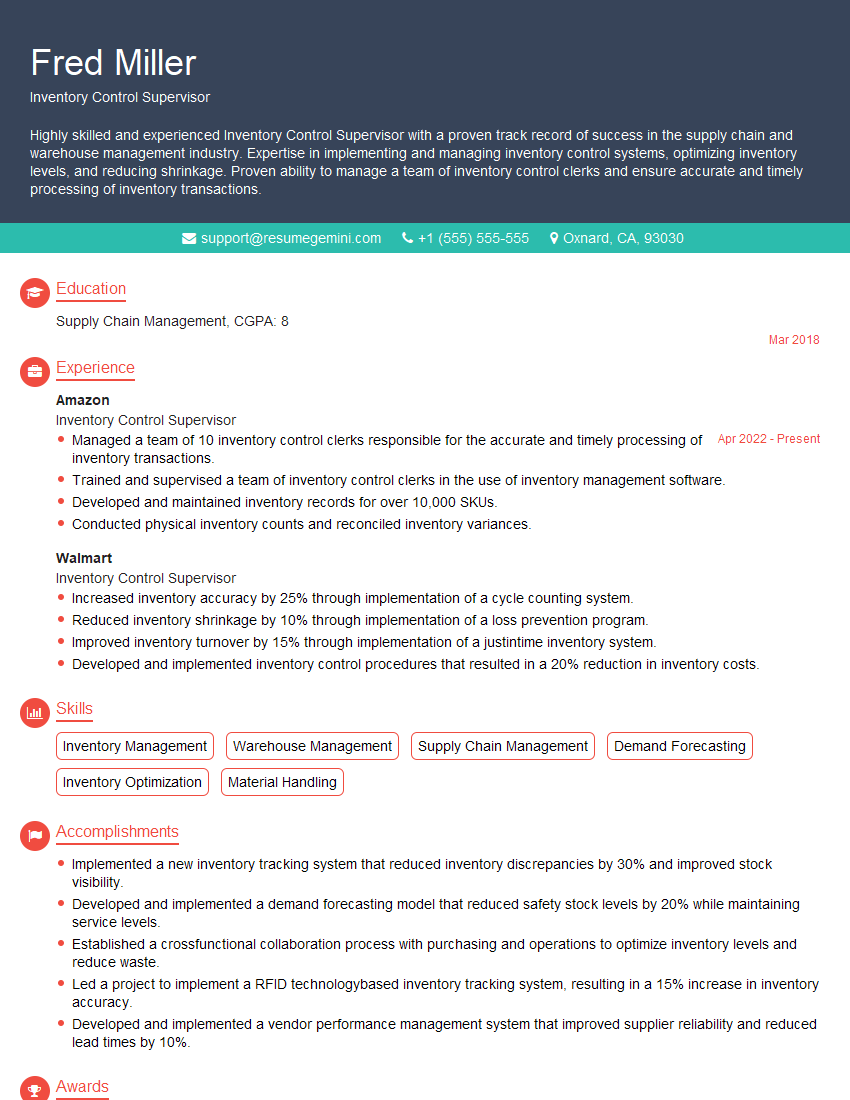

Mastering Log Inventory Management is crucial for career advancement in IT operations, system administration, and DevOps roles. Strong skills in this area demonstrate your ability to manage large datasets efficiently, identify potential problems proactively, and ensure system stability and security. To significantly improve your job prospects, creating an ATS-friendly resume is essential. Use ResumeGemini as your trusted resource to build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Log Inventory Management are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good