Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Log Loading and Transportation interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Log Loading and Transportation Interview

Q 1. Explain the different methods of log loading and their suitability for various terrain and log sizes.

Log loading methods vary significantly depending on terrain, log size, and available equipment. Think of it like choosing the right tool for the job – a small hand saw for delicate work, a chainsaw for larger tasks.

- Manual Loading: This involves using hand tools like tongs, peaveys (a type of cant hook), and skidders to load logs onto trucks. It’s best suited for smaller operations, difficult terrain where machinery can’t access, and smaller log sizes. Imagine a small logging crew working in a steep, mountainous area. Manual loading is their only feasible option.

- Mechanical Loading: This utilizes machinery such as grapple loaders, forwarders, and loaders mounted on excavators. These are efficient for larger volumes and various terrain, handling larger logs with ease. A grapple loader, for instance, can quickly pick up and place multiple logs simultaneously, ideal for flat terrain and larger-scale operations. However, swampy or extremely rocky terrain might still pose challenges.

- Aerial Loading: Helicopters or cable systems are used in areas inaccessible to ground-based equipment, such as steep slopes or dense forests. While highly effective in remote locations, this method is significantly more expensive. Think of logging operations in the remote mountains of British Columbia or Alaska; helicopters are often essential.

The choice of method depends on a cost-benefit analysis considering factors like terrain, log size, labor costs, equipment availability, and environmental impact.

Q 2. Describe the safety procedures you would implement during log loading operations.

Safety is paramount in log loading. We treat it not just as a procedure, but as a culture. My safety protocols would include:

- Pre-shift inspections: Thorough checks of all equipment, ensuring proper functionality and safety features are in place. Think brakes, lights, hydraulics, and any potential hazards identified.

- Designated safe zones: Clearly defined areas where personnel are to remain during loading operations to prevent accidents from moving equipment or logs.

- Personal Protective Equipment (PPE): Mandatory use of hard hats, safety glasses, high-visibility clothing, steel-toed boots, and hearing protection for all personnel on-site.

- Communication protocols: Established hand signals and radio communication for clear instructions and warnings. Miscommunication is a significant risk factor, so clear communication protocols are key.

- Emergency response plan: A detailed plan outlining procedures for accidents, including first aid, emergency contact information, and evacuation strategies.

- Training and competency: All personnel involved in loading operations must receive comprehensive training on safe operating procedures, hazard recognition, and emergency response.

Regular safety meetings and training reinforce these procedures, making safety an integral part of daily operations.

Q 3. How do you ensure efficient loading to maximize truck capacity and minimize damage?

Efficient loading maximizes profitability and minimizes waste. My approach focuses on careful planning and execution:

- Log sorting and segregation: Sorting logs by size and species to optimize truck space and prevent damage from incompatible log sizes. Imagine carefully stacking differently sized boxes in a truck to maximize available space.

- Load planning: Utilizing software or experience-based knowledge to plan load configurations, ensuring weight distribution and stability, minimizing shifting during transport.

- Secure placement and stabilization: Properly positioning logs to prevent shifting, using binders, chains, and dunnage to secure the load. Dunnage (protective material) prevents logs from rubbing and damaging each other.

- Regular monitoring: Checking load stability during loading, adjusting as needed to ensure secure transport.

- Continuous improvement: Regularly analyzing loading processes to identify areas for improvement in efficiency and safety.

By meticulously planning the loading process, we can significantly improve truck capacity, reduce transportation costs, and diminish the risk of log damage.

Q 4. What are the common types of log trucks and their specifications?

Log trucks are specialized vehicles designed for transporting logs. Common types include:

- Conventional log trucks: These trucks have a standard chassis with a long bed designed for carrying logs. They’re versatile but may have lower load capacity compared to other types.

- B-train or A-train log trucks: These use multiple trailers pulled by a single tractor, significantly increasing carrying capacity. They’re best suited for long distances and high volumes of logs.

- Lowboy trailers: These have a low-slung bed for carrying longer or larger logs, often used in conjunction with other trailer types.

- Bunker trailers: These enclosed trailers prevent log spillage and are ideal for shorter hauls, providing a safer and more secure method of transport.

Specifications vary widely based on the manufacturer, intended use, and local regulations, covering factors like gross vehicle weight (GVW), payload capacity, axle configuration, and trailer length. For example, a B-train might have a GVW of 100,000 lbs or more compared to a conventional truck’s considerably lower capacity. Understanding these specifications is crucial for safe and legal operation.

Q 5. Discuss your experience with load securing techniques and relevant regulations.

Load securing is crucial for safe and legal transportation of logs. I have extensive experience with various techniques, always adhering to relevant regulations. My experience covers:

- Proper use of binders, chains, and straps: I’m proficient in selecting the right type and number of securing devices based on log size, weight, and transportation distance. The placement and tensioning of these are equally important. Over-tightening can damage logs; under-tightening jeopardizes safety.

- Understanding of relevant regulations: I am familiar with local, state, and federal regulations regarding load securement, ensuring compliance with weight limits, overhang restrictions, and other safety requirements. These are often very specific and can change, so staying current is important.

- Inspection and documentation: I always conduct thorough load inspections after securement, documenting the process to ensure safety and accountability. This also helps in case of audits or investigations.

- Use of dunnage: I utilize dunnage effectively to prevent log shifting and damage during transport. The correct type and placement of dunnage can significantly impact the stability and safety of the load.

My approach emphasizes a proactive and preventative mindset, ensuring the load is secured to withstand various conditions encountered during transportation. Failure to adequately secure a load can lead to accidents, property damage, and significant fines.

Q 6. How do you manage risks associated with weather conditions during log transportation?

Weather conditions are a major risk factor in log transportation. My risk management strategy includes:

- Weather monitoring: Continuous monitoring of weather forecasts before and during transportation, adjusting schedules or routes as necessary. This involves checking real-time weather updates and consulting with meteorological services.

- Route planning: Selecting routes that minimize exposure to adverse weather conditions, such as avoiding areas prone to flooding, high winds, or ice. Certain routes may be preferable in certain weather conditions.

- Load adjustment: Modifying load configurations to enhance stability in specific weather conditions, for example, reducing load size during high winds or heavy rain.

- Driver training: Providing drivers with training on handling vehicles in adverse weather conditions, emphasizing safe driving practices and emergency procedures.

- Communication protocols: Maintaining open communication between dispatchers, drivers, and operations teams, sharing relevant weather information and updating transport plans as needed.

By proactively monitoring and managing weather risks, we significantly reduce the likelihood of accidents and delays. Adaptability and quick decision-making are crucial in such situations.

Q 7. Explain your understanding of log scaling and its importance in transportation.

Log scaling is the process of measuring the volume of logs, typically expressed in cubic meters or board feet. It’s vital in several aspects of log transportation:

- Accurate payment calculations: Scaling provides an accurate basis for payment to loggers and ensures fair compensation. This is a crucial part of contract negotiations.

- Load planning and optimization: Knowing the volume of logs helps determine the number of trucks needed and optimizes load configurations for maximum efficiency.

- Inventory management: Scaling assists in tracking log inventory, assisting in accurate forecasting of supply and demand.

- Transportation cost estimation: Knowing the volume helps estimate fuel costs and transportation expenses, aiding in accurate budgeting.

- Compliance and regulations: Accurate scaling helps ensure compliance with regulations and forestry practices related to timber harvesting and transportation.

Methods vary from manual measurements using tapes and scales to modern technology employing laser scanning and automated systems. Regardless of the method, the accuracy of scaling directly impacts the financial aspects of the logging and transportation industry.

Q 8. How do you handle unexpected delays or breakdowns during log transportation?

Unexpected delays and breakdowns are unfortunately common in log transportation. My approach involves a multi-pronged strategy focusing on prevention, mitigation, and contingency planning. Prevention starts with rigorous vehicle maintenance schedules and driver training that emphasizes proactive identification of potential issues. For example, we regularly inspect trucks and trailers, checking tire pressure, brake systems, and load securing mechanisms. Drivers are trained to perform pre-trip inspections and report any concerns immediately.

Mitigation involves having a readily available network of support. This includes a list of trusted mechanics who can provide roadside assistance quickly. We also utilize GPS tracking systems to monitor vehicle locations and identify potential problems in real-time. If a breakdown occurs, we immediately dispatch a backup truck and crew, minimizing downtime and ensuring logs reach their destination as efficiently as possible. We also maintain detailed communication with clients, keeping them updated on the situation and projected delivery times.

Contingency planning involves having alternative routes and transportation options. For instance, if a road is closed due to an unforeseen circumstance, we have backup routes mapped out and readily available to our drivers. We also have relationships with other trucking companies that can assist if needed. This layered approach ensures business continuity and minimizes the impact of unforeseen delays.

Q 9. Describe your experience with log inventory management and tracking systems.

My experience with log inventory management and tracking systems is extensive. I’ve worked with both simple spreadsheet-based systems and sophisticated, integrated software solutions. The core principle is the same: accurate tracking of log volume, species, grade, location (both in the forest and during transport), and ultimate destination.

Spreadsheet systems, while simple, are prone to errors if not meticulously maintained. I’ve worked with more complex systems that integrate GPS tracking, barcode scanning, and real-time data updates. These systems offer far better accuracy and efficiency, allowing for precise inventory control and improved decision-making. For example, using a barcoded system, we can precisely track individual logs from the harvest site to the mill, providing complete traceability and minimizing loss or discrepancies. These systems also improve efficiency by automating tasks like order processing and scheduling, reducing manual workload and associated errors.

Regardless of the system used, effective inventory management requires strict adherence to standardized procedures. This includes regular physical inventory checks to validate the system data and reconcile any differences. A robust system offers reporting features that allow for analysis of inventory levels, trends, and potential bottlenecks. This is crucial for informed purchasing, production planning, and overall supply chain optimization.

Q 10. What are the key performance indicators (KPIs) you use to evaluate the efficiency of log loading and transportation operations?

Key performance indicators (KPIs) are essential for evaluating the efficiency of log loading and transportation operations. We focus on several key metrics:

- On-time delivery rate: This measures the percentage of loads delivered within the scheduled timeframe. A high percentage indicates efficient planning and execution.

- Transportation cost per unit: This KPI tracks the cost of transporting logs per unit of volume (e.g., cubic meter). Reducing this cost improves profitability.

- Log damage rate: This measures the percentage of logs damaged during transport. A low rate reflects effective handling and securing techniques.

- Vehicle utilization rate: This assesses how effectively our vehicles are being utilized. High utilization minimizes idle time and maximizes return on investment.

- Fuel efficiency: Monitoring fuel consumption per unit transported helps identify areas for improvement in driving practices and vehicle maintenance.

Regular monitoring and analysis of these KPIs allow us to identify bottlenecks, implement process improvements, and ultimately optimize the entire log transportation chain. For example, if the on-time delivery rate drops consistently, we might need to review our scheduling process or address vehicle maintenance issues.

Q 11. How do you ensure compliance with all relevant safety and environmental regulations?

Compliance with safety and environmental regulations is paramount in log loading and transportation. We maintain a comprehensive safety program that encompasses driver training, equipment maintenance, and adherence to all relevant local, state, and federal regulations. This includes regular safety inspections, ensuring all equipment meets operational standards and complies with emissions requirements.

Driver training is a critical aspect, covering safe driving practices, load securing techniques, and hazard awareness. We conduct regular safety meetings and provide ongoing training to keep drivers informed of updates to regulations and best practices. We maintain detailed records of all inspections, training, and incidents, which are vital for audits and regulatory compliance.

Environmental compliance is equally important. We adhere to regulations regarding erosion control, water quality, and waste disposal. We use environmentally friendly practices wherever possible, such as using biodegradable lubricants and minimizing fuel consumption. We also maintain open communication with regulatory agencies, ensuring we understand and meet all expectations.

Q 12. Describe your experience with different types of log handling equipment.

My experience encompasses a wide range of log handling equipment, from basic skidders and loaders to highly specialized machinery. I’m familiar with:

- Skidders: Used for dragging logs from the felling site to a landing area. I have experience with both cable and grapple skidders, understanding their strengths and limitations in different terrain conditions.

- Forwarders: These machines transport logs directly from the felling site to a landing or loading area, increasing efficiency compared to skidders. I understand the different types of forwarders and their suitability for specific logging operations.

- Loaders: These are crucial for loading logs onto trucks, and I’ve worked with various types, including knuckleboom loaders and wheeled loaders. I understand safe loading procedures and load securing methods.

- Log trucks: I have experience with various types of log trucks, including those equipped with different trailers and bunking systems. I’m familiar with their capacity and limitations.

Understanding the capabilities and limitations of each piece of equipment is crucial for optimizing efficiency and safety. Choosing the right equipment for a specific job is often the difference between a smooth operation and a costly delay.

Q 13. Explain your knowledge of weight restrictions and load limits for log transport.

Weight restrictions and load limits are critical for safety and compliance. These limits are determined by factors such as the vehicle’s gross vehicle weight rating (GVWR), axle weight limits, and bridge weight restrictions. The GVWR is the maximum allowable weight of the vehicle, including the truck, trailer, and load. Axle weight limits prevent damage to roads and bridges. Bridge weight restrictions are particularly important when traversing bridges with lower weight capacities.

We utilize precise weight scales to ensure loads remain within the legal limits. Overloading can lead to fines, accidents, and significant damage to infrastructure. We use load planning software to optimize load distribution and ensure that the weight is evenly balanced, minimizing stress on the vehicle and trailer. Accurate weight measurement and load planning are not only legally necessary but also crucial for maintaining safety and preventing costly accidents.

Accurate weight calculation and load distribution are essential to avoiding exceeding axle weight limits and other load restrictions. We train our drivers and loaders to understand and comply with these limits. We document all weight checks and any potential issues encountered.

Q 14. How do you communicate effectively with drivers, loaders, and other stakeholders?

Effective communication is the cornerstone of successful log loading and transportation operations. I utilize a multi-faceted communication strategy to ensure everyone is informed and working collaboratively. This includes:

- Regular meetings: We hold regular meetings with drivers and loaders to discuss upcoming jobs, safety procedures, and address any concerns.

- Two-way radios: Real-time communication using two-way radios allows for immediate responses to unexpected issues or changes in plans during transport.

- Dispatch software: Dispatch software facilitates efficient communication and tracking of vehicle locations, load status, and delivery times.

- Email and phone: For less urgent communication, email and phone calls are used to maintain a consistent flow of information.

- Written documentation: Clear and concise documentation of job assignments, delivery schedules, and any issues encountered minimizes misunderstandings and ensures accountability.

Open communication and mutual respect build trust and foster a collaborative work environment. Addressing concerns promptly and providing regular feedback are key to resolving conflicts and maintaining a high level of operational efficiency.

Q 15. What are the common challenges you face during log loading and transportation?

Log loading and transportation present numerous challenges, often intertwined and dependent on various factors. These can be broadly categorized into operational, logistical, and environmental concerns.

- Operational Challenges: These include efficient loading techniques to maximize truck capacity while ensuring load stability and safety. Uneven terrain at harvesting sites can complicate loading, and the varying sizes and shapes of logs require skilled planning and execution. For example, improperly loaded logs can shift during transport, leading to accidents or delays. Weather conditions, especially heavy rain or snow, can significantly impact access to logging sites and road conditions.

- Logistical Challenges: Finding and coordinating suitable trucking services, managing driver schedules, and navigating complex permitting and regulatory requirements are crucial logistical hurdles. Accurate tracking of logs throughout the entire supply chain is essential, and delays at any point can impact the entire operation. For instance, a single unforeseen road closure can disrupt an entire day’s schedule.

- Environmental Challenges: Minimizing the environmental impact of logging operations is paramount. This involves adhering to regulations related to soil erosion, water quality, and forest protection. Sustainable logging practices, efficient transportation routes to reduce fuel consumption, and careful handling to minimize damage are key considerations. For example, using specialized equipment to minimize soil compaction during loading is crucial for responsible forestry.

Addressing these challenges requires a proactive and adaptable approach, combining technology, skilled personnel, and careful planning.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your problem-solving approach to addressing delays or logistical issues.

My problem-solving approach to delays or logistical issues is systematic and data-driven. I utilize a five-step process:

- Identify the Root Cause: Thoroughly investigate the delay. This involves gathering data from various sources – GPS tracking, driver logs, communication records – to pinpoint the specific cause. Was it a mechanical failure? Traffic congestion? Unforeseen weather conditions? A simple example: If a truck is late, I investigate whether the delay is due to a mechanical problem or traffic.

- Assess the Impact: Evaluate the consequences of the delay on the entire operation. Will it affect downstream processes? Are there penalties for late delivery? This helps prioritize the response.

- Develop Solutions: Brainstorm potential solutions tailored to the root cause. This could include rerouting trucks, deploying alternative transport, coordinating with clients for schedule adjustments, or even engaging emergency repair services.

- Implement the Solution: Execute the chosen solution efficiently and monitor its effectiveness. This often involves close collaboration with the drivers and other stakeholders.

- Document and Learn: Document the entire process, including the cause of the delay, the implemented solution, and its effectiveness. This allows for continuous improvement and prevents similar issues in the future. Analyzing past delays helps us anticipate and mitigate similar problems.

Q 17. How do you maintain accurate records of log transportation and delivery?

Maintaining accurate records is crucial for transparency, accountability, and efficient operation. We utilize a combination of electronic and paper-based systems.

- Electronic Systems: Transportation Management Systems (TMS) are employed to track shipments, record delivery confirmations, and generate detailed reports. These systems often integrate with GPS tracking to provide real-time location data and delivery status updates. For instance, our TMS logs the origin, destination, driver, date and time of pickup, and time of arrival at the destination of each shipment.

- Paper-Based Systems: While electronic records are predominant, paper-based documentation like bills of lading, delivery receipts, and inspection reports are maintained as a backup and for regulatory compliance. These documents are diligently stored and archived for easy retrieval.

- Data Validation: Regular checks and reconciliation of data between electronic and paper-based systems ensure data integrity and accuracy. We use automated data validation checks to flag any inconsistencies.

This dual approach ensures that we always have a reliable record of every log’s journey, from harvest to final delivery. This meticulous record-keeping is vital for both internal operational efficiency and for external stakeholders such as clients and regulatory bodies.

Q 18. What is your experience with GPS tracking and fleet management systems?

I have extensive experience with GPS tracking and fleet management systems. These technologies are integral to our operations, providing real-time visibility and enhancing efficiency.

- GPS Tracking: We use GPS tracking devices in all our trucks to monitor their location, speed, and other relevant data. This allows us to optimize routes, track deliveries in real-time, and respond quickly to unforeseen circumstances. For example, if a truck experiences a mechanical breakdown, we can immediately dispatch roadside assistance.

- Fleet Management Systems: We use fleet management software that integrates with the GPS data, providing comprehensive reports on fuel consumption, driver behavior, vehicle maintenance, and overall fleet performance. This enables data-driven decision-making for improving fuel efficiency, reducing maintenance costs, and ensuring driver safety.

- Data Analysis: The data collected from these systems is analyzed to identify areas for improvement in routing, scheduling, and overall logistics. We can use the data to identify consistently delayed routes, for instance, and adjust our logistics accordingly.

The integration of GPS and fleet management systems is crucial for our ability to manage our fleet effectively and provide our clients with reliable and timely delivery services.

Q 19. Explain your familiarity with different types of log species and their handling requirements.

Understanding different log species and their handling requirements is fundamental to safe and efficient transportation. Different species vary significantly in density, strength, and susceptibility to damage.

- Hardwoods vs. Softwoods: Hardwoods like oak and maple are denser and stronger, requiring more robust handling techniques to prevent breakage during loading and transportation. Softwoods like pine and fir are more susceptible to bending and scratching, necessitating careful stacking and securing to minimize damage.

- Moisture Content: The moisture content of logs significantly affects their weight and handling. Wet logs are heavier and more prone to slippage, requiring additional care during loading and securing. This also impacts the type of truck required – we may need heavier-duty trucks for wetter logs.

- Log Size and Shape: Log dimensions influence the loading and securing strategies employed. Longer logs require more careful planning to ensure stability and prevent overhang, while smaller logs may require different packing techniques to maximize space utilization.

- Species-Specific Handling: Certain species have unique handling requirements. For example, some species are more prone to splitting or insect infestation and may require special protective measures during transport.

Our team is trained to identify different species and apply appropriate handling techniques. This ensures logs arrive at their destination in optimal condition, minimizing damage and maximizing value.

Q 20. How do you manage the allocation of resources for efficient log transportation?

Efficient resource allocation is key to minimizing costs and maximizing throughput. We employ a multi-faceted approach.

- Route Optimization: We leverage GPS technology and route planning software to determine the most efficient routes, considering factors like distance, road conditions, and traffic patterns. This minimizes fuel consumption and transportation time.

- Load Planning: Careful load planning maximizes truck capacity while ensuring safety and stability. This avoids the need for multiple trips, reducing fuel consumption and transportation costs.

- Truck and Driver Scheduling: We use scheduling software to optimize truck and driver assignments, ensuring efficient utilization of resources. This involves considering factors like driver availability, truck maintenance schedules, and delivery deadlines.

- Real-time Monitoring: Real-time monitoring of truck locations and deliveries allows us to dynamically adjust schedules and resource allocation as needed. If a delay occurs, we can instantly re-allocate resources to minimize disruption.

- Maintenance Scheduling: Preventative maintenance schedules for our trucks minimize downtime and ensure optimal fleet performance. This avoids unexpected breakdowns and delays.

By systematically optimizing these aspects, we strive for maximum efficiency and minimize resource wastage in our log transportation operations.

Q 21. Describe your experience with contract negotiations and managing log haulage contracts.

Negotiating and managing log haulage contracts is a critical aspect of our business. My experience involves several key elements:

- Contract Structure: I am familiar with various contract types, including fixed-price contracts, cost-plus contracts, and performance-based contracts. The choice depends on the specific project and risk tolerance. For example, fixed-price contracts offer price certainty but require careful estimation, while cost-plus contracts offer more flexibility but expose us to potential cost overruns.

- Pricing Strategies: I am adept at developing pricing strategies that reflect the costs involved, including fuel, labor, maintenance, and insurance, while ensuring competitiveness. Understanding market rates and factoring in potential risks are crucial.

- Risk Management: Contracts need to address potential risks, such as fuel price fluctuations, weather delays, and equipment breakdowns. We use contract clauses to allocate risk appropriately and mitigate potential losses.

- Performance Monitoring: I actively monitor contract performance, using key performance indicators (KPIs) like on-time delivery rates and adherence to safety regulations. Regular communication with contractors is vital to addressing any issues promptly.

- Dispute Resolution: I am experienced in handling disputes arising from contract breaches, utilizing negotiation and mediation where possible. However, I am also prepared to escalate matters to legal channels if necessary.

Effective contract negotiation and management are essential for ensuring a smooth and profitable log transportation operation. By understanding all facets of the contract and maintaining strong relationships with our contractors, we ensure successful completion of projects and minimize disputes.

Q 22. What are your strategies for optimizing routes and minimizing transportation costs?

Optimizing routes and minimizing transportation costs in log hauling requires a multi-faceted approach. It’s not just about finding the shortest distance; it’s about finding the most efficient route, considering factors like road conditions, weight limits, bridge clearances, and even traffic patterns.

My strategies begin with leveraging Geographic Information Systems (GIS) software and route optimization tools. These tools allow me to input various parameters – the origin point(s), destination(s), weight of the load, truck dimensions, and even real-time traffic data – to generate the most cost-effective route.

- Real-time tracking and adjustments: I utilize GPS tracking on our trucks to monitor their progress and make adjustments on the fly if unexpected delays or road closures arise. This proactive approach helps avoid significant time and fuel losses.

- Consolidation of loads: Whenever feasible, I coordinate loads to maximize truck capacity. This reduces the number of trips required, leading to significant fuel savings and lower labor costs. For example, if we have several smaller loads heading to a similar destination, combining them into one larger load is significantly more efficient.

- Negotiating favorable fuel contracts: Securing bulk fuel purchases at discounted rates is a crucial cost-saving measure that directly impacts the bottom line.

- Regular maintenance to improve fuel efficiency: Ensuring our trucks are properly maintained and regularly serviced improves fuel efficiency and reduces the risk of breakdowns, minimizing downtime and associated costs.

For instance, in one project, by optimizing routes using GIS software and consolidating loads, we reduced transportation costs by 15% within the first quarter.

Q 23. How do you handle incidents or accidents involving log transportation?

Handling incidents or accidents during log transportation requires a swift and organized response, prioritizing safety and minimizing environmental impact. My approach follows a structured protocol:

- Immediate Response and Safety Assessment: The first step is to ensure the safety of all personnel involved. This involves securing the accident site, contacting emergency services (police, paramedics, fire department as needed), and assessing the extent of any injuries or environmental damage (e.g., fuel spills).

- Notification and Documentation: We immediately notify relevant authorities, including the insurance company and any regulatory bodies. Detailed documentation is crucial, including photographs, witness statements, and a comprehensive accident report.

- Log Salvage and Site Cleanup: Depending on the severity of the accident, we coordinate the safe salvage of the logs and the thorough cleanup of the site to mitigate any environmental concerns. This might involve specialized equipment like heavy-duty wreckers and environmental cleanup crews.

- Investigation and Preventative Measures: Following the incident, a thorough investigation is conducted to determine the root cause and implement preventative measures to avoid similar accidents in the future. This could include driver retraining, equipment upgrades, or route adjustments.

One example involved a rollover accident. Our immediate response ensured no injuries, and swift action prevented a significant environmental impact. The post-incident investigation led to the implementation of driver training focusing on challenging terrain navigation, reducing risks in the future.

Q 24. Describe your experience with maintaining equipment and ensuring its safe operation.

Maintaining equipment and ensuring its safe operation is paramount in the log hauling industry. It’s not just about keeping trucks running; it’s about preventing accidents and maximizing uptime. My strategy focuses on:

- Preventive Maintenance Schedules: We adhere to rigorous preventive maintenance schedules for all equipment, including trucks, trailers, and loading equipment. This involves regular inspections, oil changes, tire rotations, and other necessary servicing based on manufacturer recommendations and usage patterns.

- Regular Inspections: Daily pre-trip inspections are mandatory for all drivers, checking for any mechanical issues, tire pressure, and other safety-critical components. These inspections are thoroughly documented.

- Driver Training and Responsibilities: Drivers receive comprehensive training on equipment operation, safety procedures, and preventative maintenance checks. They are responsible for reporting any potential issues immediately.

- Investing in High-Quality Equipment: Investing in well-maintained, reliable equipment reduces the risk of breakdowns and costly repairs. This is a long-term cost-saving approach.

- Data-Driven Maintenance: We use telematics data to monitor truck performance, identify potential issues early on, and schedule maintenance proactively. For example, monitoring fuel consumption can indicate potential mechanical problems before they escalate into major failures.

Over the years, our proactive approach to equipment maintenance has resulted in significantly reduced downtime and improved safety records, proving that investment in maintenance is an investment in efficiency and safety.

Q 25. What is your experience with using load planning software?

My experience with load planning software is extensive. I’ve used several different software packages, from simple spreadsheet-based systems to sophisticated cloud-based solutions. These tools are invaluable for optimizing load placement, securing cargo, and ensuring efficient transportation.

I’m proficient in using software that allows me to:

- Create 3D models of loads: Visualizing the load before transportation helps avoid issues related to weight distribution, stability, and securement.

- Calculate center of gravity: This ensures optimal weight distribution to prevent rollovers and improve fuel efficiency.

- Generate load securement plans: The software helps determine the appropriate number and placement of tie-downs and other securing devices.

- Optimize load capacity: Maximizing load capacity within legal limits ensures cost-effectiveness.

- Generate reports: Tracking key metrics like load weight, dimensions, and transportation time allows us to identify areas for improvement.

For instance, in a recent project, using load planning software allowed us to increase load capacity by 10% without compromising safety, resulting in significant cost savings and fewer trips.

Q 26. How do you ensure the timely delivery of logs to their destination?

Ensuring timely delivery of logs requires careful planning and execution, encompassing several key aspects:

- Accurate Scheduling and Planning: This involves creating detailed delivery schedules, taking into account factors like harvest schedules, mill capacity, and transportation times. This often requires coordinating with multiple stakeholders.

- Real-Time Tracking and Communication: Using GPS tracking allows us to monitor the location and progress of each load in real-time. This enables proactive responses to unexpected delays, such as traffic congestion or equipment malfunctions.

- Efficient Loading and Unloading Procedures: Well-defined loading and unloading procedures are crucial to minimize delays at both origin and destination points. This often involves using specialized equipment and techniques.

- Route Optimization: As discussed previously, selecting the optimal route minimizes travel time and reduces the risk of delays.

- Maintaining Good Relationships with Stakeholders: Strong communication and coordination with suppliers, mills, and other stakeholders are essential for ensuring seamless operations and timely deliveries.

For example, by implementing a real-time tracking system and improving communication protocols, we improved on-time delivery rates by 18% in a six-month period.

Q 27. Explain your knowledge of different log grading systems and their applications.

Understanding different log grading systems is essential for determining log value and optimizing their use. Several systems exist, but they all aim to classify logs based on their quality and suitability for different applications.

Common grading systems consider factors such as:

- Species: Different tree species have varied properties, affecting their suitability for different products.

- Diameter and Length: These dimensions determine the volume and potential yield of lumber.

- Defect levels: Knots, rot, and other defects reduce the value and usability of logs.

- Straightness: Straight logs are generally more valuable as they yield higher-quality lumber.

Examples of Grading Systems:

- Visual Grading: This is a traditional method where experienced graders assess logs based on visual inspection. This is subjective but relies on expertise and experience.

- Numerical Grading Systems: These systems use numerical scales to quantify log quality based on specific attributes, offering a more objective approach.

Knowledge of these systems allows for accurate pricing, efficient sorting, and optimization of log utilization in various manufacturing processes. For example, knowing that certain logs are better suited for plywood versus structural lumber helps optimize production and maximize profits.

Q 28. Describe your approach to continuously improving the efficiency and safety of log loading and transportation processes.

Continuously improving efficiency and safety in log loading and transportation is an ongoing process. My approach involves:

- Data Analysis and Performance Monitoring: Regularly analyzing key performance indicators (KPIs) such as on-time delivery rates, accident rates, fuel consumption, and maintenance costs helps identify areas for improvement.

- Technology Adoption: Embracing new technologies such as telematics, load planning software, and driver assistance systems enhances efficiency and safety.

- Employee Training and Development: Providing regular training to drivers and other personnel on safety procedures, equipment operation, and best practices is crucial for accident prevention.

- Safety Audits and Reviews: Conducting regular safety audits and reviews helps identify potential hazards and implement corrective measures.

- Benchmarking and Best Practices: Staying up-to-date on industry best practices and benchmarking against top performers in the field helps us identify opportunities for improvement.

- Continuous Feedback Loops: Open communication channels and feedback mechanisms encourage continuous improvement, allowing for proactive responses to challenges and suggestions for enhancements.

For example, a recent review of our fuel consumption data led to the implementation of driver training on fuel-efficient driving techniques, resulting in a 5% reduction in fuel costs.

Key Topics to Learn for Log Loading and Transportation Interview

- Log Yard Management: Understanding efficient log stacking, sorting, and inventory management techniques. Practical application includes optimizing yard space and minimizing handling time.

- Loading Techniques: Mastering various loading methods (e.g., grapple loaders, loaders with forks) and their suitability for different log types and transport vehicles. This includes understanding safe loading practices and load securing.

- Transportation Logistics: Planning efficient transport routes, considering factors like road conditions, weight limits, and permit requirements. Practical applications involve optimizing delivery schedules and minimizing fuel consumption.

- Equipment Maintenance and Safety: Knowledge of routine maintenance procedures for loading and transportation equipment, as well as adhering to safety regulations and protocols. This involves understanding preventative maintenance and identifying potential hazards.

- Regulations and Compliance: Familiarity with industry regulations concerning load securing, weight limits, and transportation permits. This includes understanding environmental regulations related to logging and transport.

- Supply Chain Optimization: Understanding the entire supply chain from forest to mill, and how efficient log loading and transportation contribute to overall efficiency. Practical applications involve identifying bottlenecks and proposing solutions.

- Cost Management: Analyzing and controlling costs associated with log loading, transportation, and related activities. This includes fuel costs, maintenance, and labor.

- Problem-Solving and Decision-Making: Demonstrating the ability to troubleshoot issues that may arise during loading or transportation, such as equipment malfunctions or unexpected delays. This includes developing contingency plans.

Next Steps

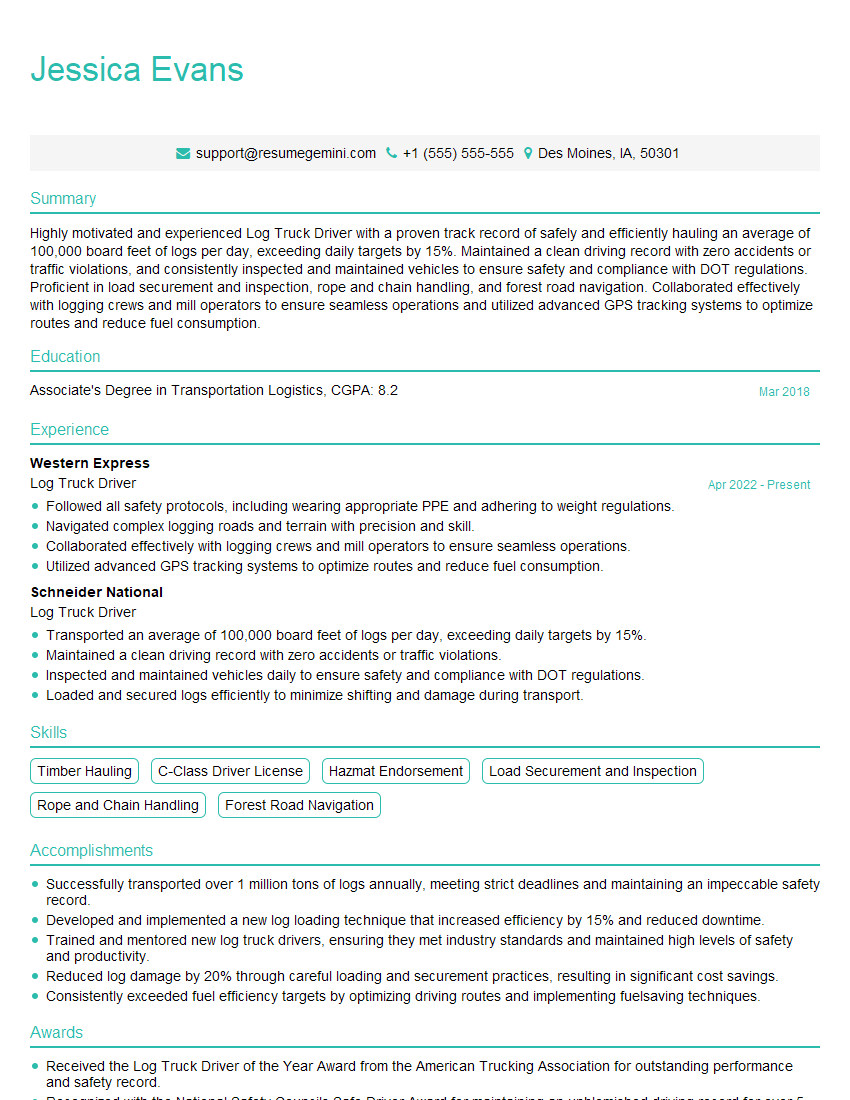

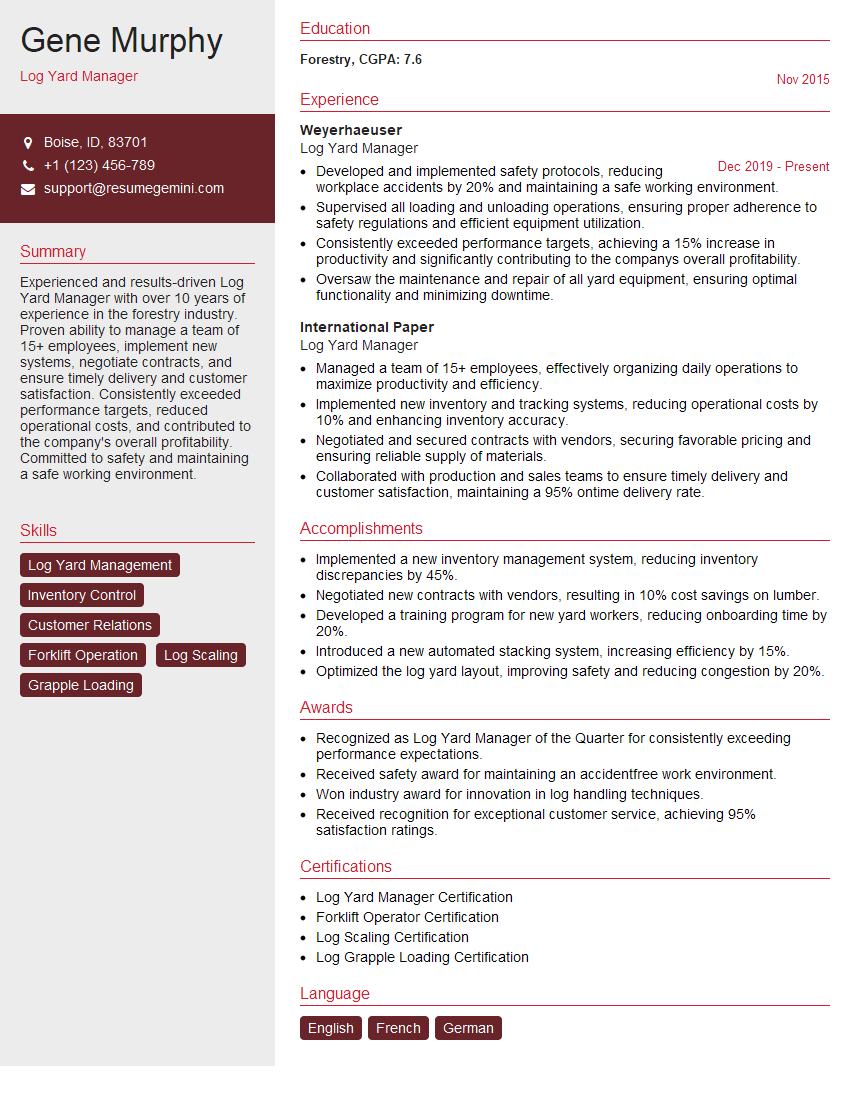

Mastering Log Loading and Transportation opens doors to rewarding careers with excellent growth potential within the forestry and timber industries. To maximize your job prospects, it’s crucial to present your skills effectively. Building an ATS-friendly resume is key to getting your application noticed by recruiters. We highly recommend using ResumeGemini to craft a professional and impactful resume that highlights your qualifications. ResumeGemini offers numerous examples of resumes tailored specifically to the Log Loading and Transportation field, helping you showcase your expertise and land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good