The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Log Purchasing interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Log Purchasing Interview

Q 1. Describe your experience negotiating log purchase contracts.

Negotiating log purchase contracts requires a deep understanding of market dynamics and strong negotiation skills. It’s not simply about price; it’s about securing a reliable supply of high-quality logs at a fair price, while mitigating risks. My approach involves thorough due diligence, including a careful review of the supplier’s reputation, logging practices, and financial stability. I begin by clearly defining our needs – species, volume, size specifications, and delivery timelines – and then engage in collaborative discussions with suppliers to find mutually agreeable terms. I leverage market data on current log prices and historical trends to support my offers and counter-offers. For example, during a period of high demand, I might negotiate longer-term contracts with guaranteed volumes to secure supply and protect against price spikes. Conversely, in a buyer’s market, I’d focus on competitive pricing and favorable payment terms. Successful negotiation involves finding a balance between cost and risk, often requiring compromise and creative solutions. I always ensure the contract clearly outlines all terms and conditions, including quality standards, payment schedules, and dispute resolution mechanisms.

Q 2. Explain your understanding of different log grading systems.

Log grading systems are essential for determining the quality and value of logs. Different systems exist, depending on the species, intended use (e.g., lumber, pulpwood), and geographical region. Some common systems include the American Lumber Standard Committee (ALSC) grading rules for lumber, which indirectly impacts log grading, and more specific systems used in pulp and paper production. These systems typically consider factors such as:

- Diameter and Length: Larger diameter and longer logs generally command higher prices.

- Species: Hardwoods like oak and maple are typically more valuable than softwoods like pine or fir.

- Defect Levels: Knots, rot, cracks, and other defects reduce the value of a log. Grading systems use scales or classifications to categorize the severity of defects.

- Straightness: Straight logs are preferred for lumber production.

- Shape and Form: Taper (the gradual decrease in diameter from base to top), crook (a bend in the log), and sweep (a gentle curve) influence grade and value.

Understanding these systems is crucial for accurate valuation and fair negotiation. For instance, a log graded as ‘high-grade’ according to the ALSC grading rules would fetch a higher price than a ‘low-grade’ log due to its superior potential for high-quality lumber. Experience enables me to quickly assess a log’s grade by visually examining for defects and measuring its dimensions.

Q 3. How do you assess the quality and quantity of log inventory?

Assessing log inventory involves a multi-step process combining physical inspection and data analysis. First, I conduct a thorough on-site assessment, visually inspecting logs for defects, measuring dimensions, and estimating volume using established methods. This often involves utilizing tools such as calipers, diameter tapes, and specialized software. Additionally, I may use scaling sticks or utilize 3D laser scanning technologies for precise volume calculations, particularly for large inventory. Second, I review available documentation, such as logging records, inventory reports, and chain-of-custody certificates, to verify the quantity and quality claims made by the supplier. Third, I often employ statistical sampling techniques to extrapolate data from a representative subset of the entire inventory, providing a cost-effective and efficient way to estimate the overall quantity and quality without needing to measure every single log. For example, instead of measuring every log in a large pile, I might take measurements from a predetermined number of logs strategically chosen to represent the pile’s overall characteristics. Finally, I meticulously cross-reference the physical measurements and documentation to identify any discrepancies and ensure the accuracy of the assessment. This comprehensive approach minimizes risks and helps ensure we purchase the required volume of the right quality.

Q 4. What are the key factors influencing log prices?

Log prices are influenced by a complex interplay of factors. Demand from downstream industries, such as lumber mills and pulp and paper plants, is a primary driver. Higher demand typically pushes prices up. Supply is another key factor. Factors influencing supply include weather conditions (affecting tree growth and logging operations), forest health, available logging infrastructure, and government regulations. The species of the log itself plays a crucial role, with rare and high-demand species commanding higher prices. Global market conditions, including economic growth and construction activity, also affect demand and hence pricing. Furthermore, transportation costs, logistical challenges, and the overall health of the economy impact prices. For example, a surge in housing construction could lead to increased demand for lumber, resulting in higher log prices. Conversely, a recession might decrease demand and lower prices.

Q 5. How do you manage risks associated with log purchasing, such as price volatility?

Managing price volatility in log purchasing is crucial for profitability. Several strategies can be employed. One key method is hedging using futures contracts or options, allowing us to lock in prices for future deliveries and mitigate the risk of price increases. Diversifying suppliers and sourcing logs from different geographical areas helps to reduce dependence on any single supplier or region and minimizes the impact of localized supply disruptions or price fluctuations. Another effective method is entering into long-term contracts with reliable suppliers, providing price stability over a defined period. Building strong relationships with suppliers enables better communication and potentially more favorable pricing terms, as the trust-based relationship can help navigate market volatility more effectively. Finally, accurately forecasting market trends through rigorous analysis of market data and economic indicators helps anticipate price shifts and adjust purchasing strategies accordingly.

Q 6. Explain your experience with sustainable forestry practices in log sourcing.

Sustainable forestry practices are paramount in log sourcing. I prioritize sourcing logs from suppliers who demonstrate a commitment to responsible forestry. This involves working with suppliers certified by organizations like the Forest Stewardship Council (FSC) or similar reputable bodies. These certifications ensure that logging operations adhere to strict environmental and social standards, including responsible forest management plans, reduced impact logging techniques, reforestation efforts, and protection of biodiversity. I also actively engage with suppliers to discuss their sustainability initiatives, verifying their commitment through on-site visits and inspections. My experience has shown that choosing sustainably sourced logs not only contributes to environmental protection but also reduces reputational risks and enhances the brand image of our company. It also reduces the likelihood of disruptions from government regulations or consumer boycotts related to unsustainable practices.

Q 7. Describe your process for identifying and selecting reliable log suppliers.

Identifying and selecting reliable log suppliers requires a thorough vetting process. I begin by conducting research into potential suppliers, considering their reputation, financial stability, and history of delivering quality products on time. I often review online resources, industry publications, and independent audits to assess their track record and commitment to sustainability. I directly contact references, including previous clients and industry professionals, to gather firsthand accounts of their experiences. Next, I perform on-site visits to the supplier’s operations to evaluate their logging practices, inventory management, and overall operational efficiency. This involves inspecting equipment, observing logging techniques, and assessing their adherence to safety standards. Crucially, I review their logging contracts and any relevant certification documentation to ensure that all processes are compliant with legal and ethical standards. Only after completing this rigorous process and confirming their capabilities and commitment to quality and sustainable practices, do we establish a formal business relationship. This thorough approach ensures that we partner with suppliers who can reliably provide the high-quality logs we need.

Q 8. How do you ensure timely delivery of logs to meet production demands?

Ensuring timely log delivery hinges on proactive planning and strong supplier relationships. It’s like orchestrating a complex symphony – each instrument (supplier, transportation, our production line) must play its part in perfect harmony.

- Predictive Modeling: We use historical data and production forecasts to anticipate log needs. This allows us to place orders well in advance, mitigating potential delays.

- Supplier Selection: We choose suppliers with proven track records of reliable delivery and efficient logistics. We prioritize those with sufficient capacity to meet our demands, even during peak seasons.

- Contractual Agreements: Our contracts with suppliers clearly specify delivery timelines and penalties for late deliveries. This provides a legal framework to ensure accountability.

- Real-time Tracking: We utilize GPS tracking systems to monitor shipments, allowing us to proactively address any potential delays. This is akin to having a GPS navigation system for our entire log supply chain.

- Inventory Buffer: Maintaining a strategic inventory buffer helps cushion unexpected delays or production surges. This provides a safety net, similar to having a spare tire in your car.

For example, during a recent project involving a large-scale construction site, we successfully predicted a potential timber shortage. By ordering logs two months in advance and diversifying our suppliers, we avoided a significant production bottleneck.

Q 9. How do you handle discrepancies between ordered and delivered log quantities or quality?

Discrepancies between ordered and delivered logs are addressed through a rigorous verification process and robust communication with suppliers. Think of it as quality control for a very large-scale construction project.

- Detailed Inspection: Upon arrival, every log shipment undergoes a thorough quality and quantity check. We verify species, dimensions, and the total volume against the purchase order.

- Documentation: All inspections are meticulously documented, including any discrepancies found. This creates an audit trail, allowing us to retrace any issues that may arise.

- Negotiation & Dispute Resolution: If discrepancies are discovered, we immediately contact the supplier to initiate a collaborative resolution. This usually involves reviewing the delivery notes, verifying weights at the loading point and our receiving area. In some cases, this may involve a 3rd party inspector.

- Credit Adjustments: Depending on the nature and severity of the discrepancy, we negotiate credit adjustments or replacements. The goal is always a fair and mutually acceptable outcome.

- Supplier Performance Review: Persistent discrepancies lead to a review of the supplier’s performance. This includes exploring alternative suppliers to ensure the reliability of our supply chain.

For instance, we once received a shipment with a 10% shortfall in volume. Through careful documentation and negotiation, we secured a full credit adjustment from the supplier, preventing a significant financial loss.

Q 10. What software or tools do you use for log purchasing and inventory management?

We leverage a combination of software and tools for efficient log purchasing and inventory management. This integrated system helps us maintain transparency and optimize resource allocation.

- Enterprise Resource Planning (ERP) System: Our core system manages purchase orders, inventory tracking, and financial transactions. This provides a central hub for all log-related data.

- Supply Chain Management (SCM) Software: This tool helps us optimize logistics, track shipments in real-time, and manage supplier relationships. It’s like a central command center for our log supply chain.

- Inventory Management System (IMS): This system keeps a detailed record of log inventory, including location, species, and quality. This provides an always-up-to-date view of our inventory.

- Customised Databases: We maintain databases to store information such as supplier performance, log pricing data, and market trends. This helps us make informed purchasing decisions.

- Spreadsheet Software (Excel/Google Sheets): We use spreadsheets for data analysis and reporting, allowing us to identify trends and potential issues.

These tools work together seamlessly, providing us with a holistic view of our log purchasing and inventory management processes.

Q 11. Explain your experience with international log sourcing and import/export regulations.

International log sourcing is a complex undertaking, demanding a thorough understanding of import/export regulations and international trade practices. Navigating this landscape requires expertise in compliance and global logistics.

- Compliance with Regulations: We meticulously adhere to all relevant international and national regulations governing the import and export of timber products. This includes CITES (Convention on International Trade in Endangered Species) compliance, tariffs, and customs procedures.

- Due Diligence: We conduct thorough due diligence on international suppliers, including verifying their licenses and ensuring sustainable harvesting practices. This ensures ethical and legal sourcing.

- Logistics Management: We manage the entire shipping process, from port-to-port logistics to customs clearance, ensuring timely and cost-effective delivery. This involves coordinating with freight forwarders and customs brokers.

- Currency Fluctuations & Risk Management: We incorporate strategies to mitigate risks associated with currency fluctuations and global market volatility. This can involve hedging techniques and securing favorable payment terms.

- Building International Relationships: We nurture strong relationships with international suppliers and agents, developing a robust network of reliable contacts. This is crucial in navigating complex international markets.

In one instance, we successfully negotiated the import of a large quantity of sustainably sourced hardwood from Brazil, navigating complex import regulations and customs procedures without any delays or penalties.

Q 12. Describe a challenging log purchase negotiation and how you overcame it.

One particularly challenging negotiation involved securing a large volume of high-quality redwood during a period of high demand. The supplier was initially reluctant to commit to our price point.

- Understanding the Supplier’s Needs: We began by understanding the supplier’s constraints and priorities. We discovered they were facing increased transportation costs.

- Value-Based Negotiation: Instead of solely focusing on price, we presented a mutually beneficial proposal, including a long-term contract with guaranteed volume. This assured them of steady business.

- Building Rapport: We emphasized building a strong, long-term relationship rather than just focusing on a single transaction. This created trust and a collaborative environment.

- Creative Solutions: We explored alternative transportation options to help mitigate their increased costs, suggesting a more efficient route and introducing them to reliable trucking companies.

- Win-Win Outcome: The negotiation resulted in a price point that was acceptable to both parties, establishing a strong partnership that continues to this day.

This experience highlighted the importance of understanding the supplier’s perspective and finding creative solutions that benefit both parties.

Q 13. How do you forecast log demand and manage inventory levels?

Forecasting log demand and managing inventory levels requires a sophisticated approach that combines data analysis, market knowledge, and expert judgment. It’s like predicting the weather—there’s always an element of uncertainty, but you can improve accuracy with the right tools and data.

- Demand Forecasting: We utilize historical sales data, production schedules, and market trends to forecast future demand. This often involves using statistical modeling techniques.

- Inventory Optimization Models: We use software models to determine optimal inventory levels, balancing the cost of holding inventory against the risk of stockouts. These models take into account lead times, demand variability, and storage costs.

- Market Analysis: We continuously monitor market conditions, including lumber prices and supply chain disruptions, to adjust our forecasts and inventory strategies as needed.

- Supply Chain Visibility: We maintain clear visibility into our supply chain to anticipate potential disruptions and make adjustments to our inventory plans.

- Regular Inventory Reviews: We conduct regular inventory reviews to assess actual stock levels against forecasts and make adjustments as necessary.

By combining these methods, we aim to minimize inventory holding costs while ensuring sufficient stock to meet production demands. Regular review and adaptation is crucial.

Q 14. How do you maintain relationships with key log suppliers?

Maintaining strong relationships with key log suppliers is critical to ensuring a reliable and cost-effective supply of high-quality logs. Think of it as cultivating a garden – you need to nurture the plants to ensure a bountiful harvest.

- Regular Communication: We maintain open and frequent communication with our key suppliers, sharing information and building trust.

- Fair and Transparent Pricing: We strive for fair and transparent pricing practices, ensuring that our suppliers receive a reasonable profit margin.

- Long-Term Contracts: Where feasible, we negotiate long-term contracts with reliable suppliers, providing them with price certainty and reducing risk.

- Collaborative Problem Solving: We work collaboratively with our suppliers to address any challenges or issues that may arise, fostering a mutually beneficial partnership.

- Performance Evaluation: We regularly evaluate supplier performance based on factors such as quality, delivery time, and overall service, providing feedback to help them improve.

- Mutual Respect: We treat our suppliers with respect and recognition, valuing their expertise and contribution to our business.

By fostering strong, collaborative relationships, we ensure a reliable supply of logs, enabling us to meet our production goals and maintain profitability.

Q 15. What are your strategies for cost reduction in log purchasing?

Cost reduction in log purchasing is a multifaceted strategy demanding a keen eye for detail and market understanding. It’s not about sacrificing quality, but optimizing the entire process.

Negotiating favorable prices: Building strong relationships with multiple suppliers allows for competitive bidding and leveraging market fluctuations. I always negotiate based on volume, quality, and delivery terms. For example, securing long-term contracts with reliable suppliers often leads to discounted rates.

Optimizing transportation: Efficient routing and choosing the right mode of transport (truck, rail, barge) significantly impacts costs. I analyze factors like distance, road conditions, and fuel prices to minimize transportation expenses. For instance, consolidating shipments from multiple suppliers in a single region can drastically reduce per-unit transport costs.

Strategic log selection: Understanding species availability and market demand helps make informed decisions. Choosing locally sourced logs reduces transportation costs and minimizes environmental impact, thereby offering a cost advantage in the long run. Moreover, selecting logs based on their suitability for specific end-products reduces waste and enhances profitability.

Inventory management: Careful planning and forecasting prevent overstocking, reducing storage costs and minimizing the risk of log degradation. Implementing a robust inventory management system with real-time tracking and forecasting capabilities can contribute significantly to cost savings.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different log species and their applications.

My experience spans a wide range of log species, each with unique properties and applications. Understanding these nuances is crucial for effective log purchasing.

Douglas Fir: Known for its strength and durability, it’s ideal for structural lumber, construction, and heavy-duty applications. I’ve sourced significant quantities of Douglas Fir for large-scale construction projects.

Pine: Various pine species offer different characteristics. Southern Yellow Pine is strong and versatile, suitable for framing, decking, and furniture. White Pine is softer and more easily worked, ideal for interior finishes and crafts. I’ve worked with both, carefully selecting species based on the client’s specific needs.

Redwood: Highly resistant to rot and decay, it is prized for outdoor applications like decking, fencing, and siding. Its natural beauty also makes it a popular choice for interior finishes. I’ve personally overseen the procurement of Redwood for a high-end residential project.

Hardwoods (Oak, Maple, etc.): These are valued for their strength, beauty, and durability, making them suitable for furniture, flooring, and fine cabinetry. The selection within hardwood species requires careful consideration of grain, color, and other aesthetic factors.

I always prioritize understanding the specific application of the logs before making a purchase, ensuring the right species is selected to meet the requirements efficiently and effectively.

Q 17. Explain your understanding of log transportation logistics and costs.

Log transportation logistics are a critical factor in overall cost and efficiency. Understanding this involves more than just the cost per mile.

Route optimization: Using GPS tracking and route planning software to identify the most efficient routes, considering factors like traffic, road conditions, and bridge weight limits. I frequently use specialized software to model different transport options and choose the most cost-effective solution.

Mode selection: Choosing between truck, rail, or barge transport depends on factors like distance, volume, and accessibility. Rail is often more economical for long distances and large volumes, while trucking is more flexible for shorter distances and smaller shipments. Barge transport is often the most cost-effective option for transporting large quantities over water.

Load optimization: Maximizing truck or railcar capacity to reduce the number of trips required and minimizing empty miles. I consistently monitor load plans to ensure maximum efficiency.

Insurance and permits: Securing appropriate insurance coverage and obtaining necessary permits for transportation. This mitigates risk and ensures legal compliance.

I meticulously track transportation costs, including fuel, driver wages, maintenance, and insurance, to ensure transparency and identify areas for potential improvement.

Q 18. How do you assess the financial viability of a log purchase?

Assessing the financial viability of a log purchase requires a thorough analysis of several key factors.

Market price analysis: Researching current market prices for the specific log species and size required. I rely on multiple sources for price information to get a comprehensive picture.

Log quality assessment: Inspecting logs for defects such as knots, rot, and insect damage, which can impact yield and value. I use standardized grading systems to accurately assess log quality.

Transportation costs: Calculating transportation costs, including fuel, tolls, and driver wages, to determine the total landed cost. As mentioned earlier, I utilize route optimization software to accurately estimate these costs.

Processing costs: Estimating the costs of milling and processing the logs into lumber or other products. I work closely with mills to get accurate estimates of processing costs.

Projected revenue: Estimating the revenue generated from the sale of the finished products based on market prices and yield estimates. I often use sophisticated models to predict these factors.

By carefully analyzing these factors, I can develop a detailed financial model to determine the profitability of a log purchase. This model allows for scenario planning and sensitivity analysis to assess risks and potential returns.

Q 19. What are your methods for ensuring the legality and sustainability of sourced logs?

Ensuring the legality and sustainability of sourced logs is paramount. My approach involves a multi-layered strategy.

Chain of custody certification: Working with suppliers who have obtained chain of custody certification from reputable organizations, such as the Forest Stewardship Council (FSC) or the Programme for the Endorsement of Forest Certification (PEFC). This verifies that the logs come from legally harvested and sustainably managed forests.

Due diligence: Thoroughly investigating the origin of the logs, verifying harvesting permits, and ensuring compliance with all relevant laws and regulations. I request and review all relevant documentation from suppliers to ensure full transparency and compliance.

Species identification: Verifying the species of the logs to prevent the purchase of endangered or illegally harvested species. I employ experienced professionals for species identification in cases of uncertainty.

Third-party verification: Using independent third-party verification services to audit the supply chain and ensure compliance with sustainability standards. This adds an extra layer of assurance and safeguards against illegal activities.

My commitment to sustainable sourcing ensures not only legal compliance but also promotes environmental responsibility and contributes to the long-term health of our forests.

Q 20. How do you handle supplier performance issues?

Handling supplier performance issues requires a proactive and collaborative approach.

Regular communication: Maintaining open and frequent communication with suppliers to address concerns early on. I schedule regular meetings to discuss performance and identify potential challenges.

Performance monitoring: Tracking key performance indicators (KPIs) such as delivery times, quality, and compliance with agreed-upon terms. I use a detailed tracking system to monitor performance and identify trends.

Performance improvement plans: Developing and implementing performance improvement plans with underperforming suppliers, providing support and guidance to address deficiencies. This collaborative approach often yields positive results.

Contingency planning: Having backup suppliers in place to mitigate the impact of supplier failures. Diversifying supply sources reduces reliance on any single supplier.

Contractual remedies: Using contractual mechanisms such as penalties and termination clauses as a last resort to address serious and persistent performance issues. I always ensure the contracts clearly outline responsibilities and penalties for non-performance.

My approach focuses on building strong relationships with suppliers, fostering mutual trust, and working collaboratively to achieve mutually beneficial outcomes.

Q 21. How do you ensure compliance with relevant industry standards and regulations?

Compliance with industry standards and regulations is essential for responsible log purchasing. My approach is multifaceted.

Knowledge of regulations: Staying up-to-date on all relevant local, national, and international laws and regulations related to forestry, logging, and transportation. I subscribe to industry publications and actively participate in professional development activities to stay abreast of the latest regulations.

Documentation review: Thoroughly reviewing all relevant documentation from suppliers, including harvesting permits, transportation permits, and chain-of-custody certificates. I maintain meticulous records of all documentation received and reviewed.

Audits and inspections: Conducting regular audits and inspections of supplier operations to verify compliance. I may also utilize independent third-party audit services for comprehensive assessments.

Training and education: Providing training to my team on relevant regulations and best practices to ensure consistent compliance throughout the organization. Regular training sessions keep our team informed and up-to-date.

Continuous improvement: Continuously evaluating our compliance programs and implementing improvements to enhance effectiveness and prevent future violations. We regularly assess our compliance processes and identify opportunities for optimization.

My commitment to compliance not only ensures legal adherence but also builds trust with stakeholders, including customers, regulators, and the communities where we operate.

Q 22. Describe your experience with different types of log contracts (e.g., fixed price, cost-plus).

Log purchasing contracts vary significantly, each with its own risk and reward profile. Two common types are fixed-price and cost-plus contracts.

Fixed-price contracts: In these, the price per unit (e.g., cubic meter) of logs is agreed upon upfront. This provides price certainty for the buyer, protecting against market fluctuations. However, the seller bears the risk of rising costs. For example, if the cost of harvesting increases unexpectedly, the seller might absorb the loss. This type of contract is best suited for stable market conditions where accurate volume forecasting is possible.

Cost-plus contracts: Here, the buyer reimburses the seller for all costs incurred in supplying the logs, plus a predetermined markup or profit margin. This shifts the price risk to the buyer, who might face unexpected cost increases. However, it incentivizes the seller to efficiently manage costs, as their profit is directly tied to cost control. This contract works well when there’s significant uncertainty around harvesting costs or log availability.

My experience encompasses negotiating and managing both types of contracts, adapting the chosen approach to the specific circumstances and risk appetite of the purchasing organization. For instance, I’ve used fixed-price contracts for routine purchases of readily available species from established suppliers. For more specialized or less predictable log types, cost-plus contracts have offered a more appropriate level of flexibility and risk sharing.

Q 23. How do you use market data to inform your log purchasing decisions?

Market data is crucial for making informed purchasing decisions. I utilize various sources, including industry publications, government reports on timber production and harvests, and real-time market intelligence platforms.

My analysis focuses on several key indicators:

Price trends: Identifying upward or downward trends in log prices for different species and regions helps determine optimal purchasing timing. For instance, a projected price increase might justify purchasing earlier, even if inventory space is limited.

Supply and demand: Understanding current and projected supply levels relative to demand helps assess potential shortages or surpluses. This informs negotiation strategies and helps avoid overpaying in a tight market.

Competitor activity: Monitoring competitor purchasing behavior can reveal valuable market insights and help anticipate future price movements.

I use this data to build predictive models, estimating future log prices and availability. This allows for proactive purchasing strategies and minimizes the risk of supply disruptions or excessive costs.

Q 24. What are your strategies for managing inventory risk and spoilage?

Inventory management and spoilage prevention are critical for profitability. My strategies involve a combination of proactive measures:

Precise forecasting: Accurate demand forecasts minimize overstocking, reducing spoilage risk. This involves careful analysis of production schedules and market projections.

Efficient storage: Proper storage conditions are essential. This includes selecting appropriate storage yards, ensuring adequate ventilation, and utilizing protective treatments to minimize decay and insect infestations. For instance, proper stacking and covering logs reduces exposure to rain and sun.

FIFO (First-In, First-Out) system: Implementing a FIFO system ensures that older logs are processed first, reducing the risk of spoilage. This is crucial for logs susceptible to deterioration.

Regular inspections: Periodic inspections allow for early detection of spoilage and pest infestations, enabling timely intervention and mitigating losses.

By implementing these strategies, I aim to maintain an optimal inventory level that balances supply needs with minimizing waste due to spoilage or degradation. This involves constant monitoring and adaptation to changing market conditions and potential supply chain disruptions.

Q 25. Explain your understanding of different log measurement methods.

Accurate log measurement is fundamental to fair pricing and efficient inventory management. Several methods are employed:

Scribner Decimal C-Scale: This is a widely used volume estimation method based on a formula applied to diameter and length measurements. It’s relatively quick but can be less accurate than other methods, especially for irregular log shapes.

Doyle Log Rule: Another common method that uses a table to determine volume based on diameter and length. It tends to underestimate the volume of larger logs.

International 1/4-inch Rule: This provides a more precise volume calculation, using more precise measurements and accounting for log taper. It’s more accurate than simpler methods like Doyle but requires more time and effort for measurement.

Electronic Measurement Devices: Modern technology uses scanners and lasers to accurately determine log volume and shape. These devices significantly increase measurement accuracy and efficiency, though they require an initial investment.

My experience includes using all these methods, selecting the most appropriate approach based on the specific situation – the species, log size, urgency of purchase and availability of technology. Accuracy and consistency are paramount to ensure fair transactions and accurate inventory tracking.

Q 26. How do you deal with unforeseen circumstances, like unexpected log shortages?

Unexpected log shortages require immediate and decisive action. My approach involves a multi-pronged strategy:

Assess the impact: First, determine the severity of the shortage and its potential impact on production schedules.

Explore alternative sources: This could involve contacting secondary suppliers, exploring different log species as substitutes, or even adjusting production plans to minimize reliance on the affected logs.

Negotiate with existing suppliers: Discussions with existing suppliers may uncover hidden capacity or allow for expedited deliveries at a potentially higher cost.

Monitor market conditions: Closely track price fluctuations and availability to anticipate future supply issues and make informed decisions.

Diversify supply chains: Over-reliance on a single supplier increases vulnerability to shortages. Establishing relationships with multiple suppliers from diverse geographic locations helps mitigate this risk.

In a past scenario, a sudden storm damaged a significant portion of a supplier’s harvest. By quickly identifying alternative suppliers and negotiating with existing ones for priority delivery, we minimized production disruptions. The key is proactive planning and maintaining strong relationships across the supply chain to navigate such challenges effectively.

Q 27. What are your strategies for building and maintaining strong supplier relationships?

Strong supplier relationships are essential for a reliable and cost-effective log supply. My approach emphasizes mutual trust, transparency, and fair dealing:

Open communication: Regular communication keeps both parties informed about market conditions, production schedules, and potential challenges.

Fair pricing and negotiation: Negotiations should be fair, recognizing the importance of mutual profitability. Avoid squeezing suppliers to the point that they compromise quality or sustainability practices.

Long-term partnerships: Building long-term partnerships fosters trust and provides greater stability in supply. This creates incentives for both parties to collaborate on mutually beneficial goals.

Support sustainable practices: Promoting sustainable forestry practices benefits both the supplier’s long-term viability and the environment. This strengthens the relationship and contributes to responsible sourcing.

I’ve fostered strong relationships with several suppliers over many years, resulting in preferential treatment during periods of high demand and access to premium quality logs. These partnerships are invaluable for navigating market volatility and securing a reliable log supply.

Q 28. Describe your experience with using data analytics to improve log purchasing efficiency.

Data analytics significantly enhances log purchasing efficiency. I leverage data to optimize various aspects of the process:

Predictive modeling: Statistical models, using historical data on log prices, supply, and demand, help predict future market trends, informing purchasing decisions and optimizing inventory levels. This involves using software like R or Python with statistical packages.

Supplier performance analysis: Data analysis on supplier delivery times, quality of logs, and pricing helps identify top-performing suppliers and improve contract negotiations.

Inventory optimization: Data-driven insights help optimize inventory levels, minimizing storage costs and spoilage. Techniques such as ABC analysis, which categorizes inventory items based on their value and usage, assist with this process.

Cost analysis: Analyzing data on transportation costs, harvesting costs, and other relevant expenses helps identify areas for cost reduction and improve profitability.

Example: Using regression analysis to predict log prices based on historical data and market indicators.

By integrating data-driven insights, I’ve consistently improved the efficiency and profitability of log purchasing operations. This includes reducing purchasing costs by 5-10% and minimizing inventory losses.

Key Topics to Learn for Log Purchasing Interview

- Market Analysis & Pricing Strategies: Understanding timber market dynamics, price fluctuations, and developing effective pricing strategies for different log types and qualities.

- Log Grading & Quality Assessment: Mastering the techniques for evaluating log quality, including species identification, defect assessment, and volume calculations. Practical application: Knowing how to interpret grading scales and their impact on pricing.

- Contract Negotiation & Procurement: Developing strong negotiation skills to secure favorable contracts with landowners and suppliers, including understanding contract terms and conditions.

- Supply Chain Management: Understanding the entire process from harvesting to delivery, including logistics, transportation, and inventory management. Practical application: Optimizing transportation routes and minimizing costs.

- Sustainable Forestry Practices: Demonstrating knowledge of responsible logging practices, environmental regulations, and sustainable forest management principles.

- Risk Management & Mitigation: Identifying and mitigating potential risks associated with log purchasing, such as price volatility, market fluctuations, and supply chain disruptions. Practical application: Developing contingency plans for unexpected events.

- Financial Analysis & Budgeting: Understanding the financial aspects of log purchasing, including cost analysis, budgeting, and profitability calculations.

- Technology & Data Analysis: Utilizing software and data analysis techniques to optimize purchasing decisions and improve efficiency. Practical application: Analyzing historical data to predict future market trends.

Next Steps

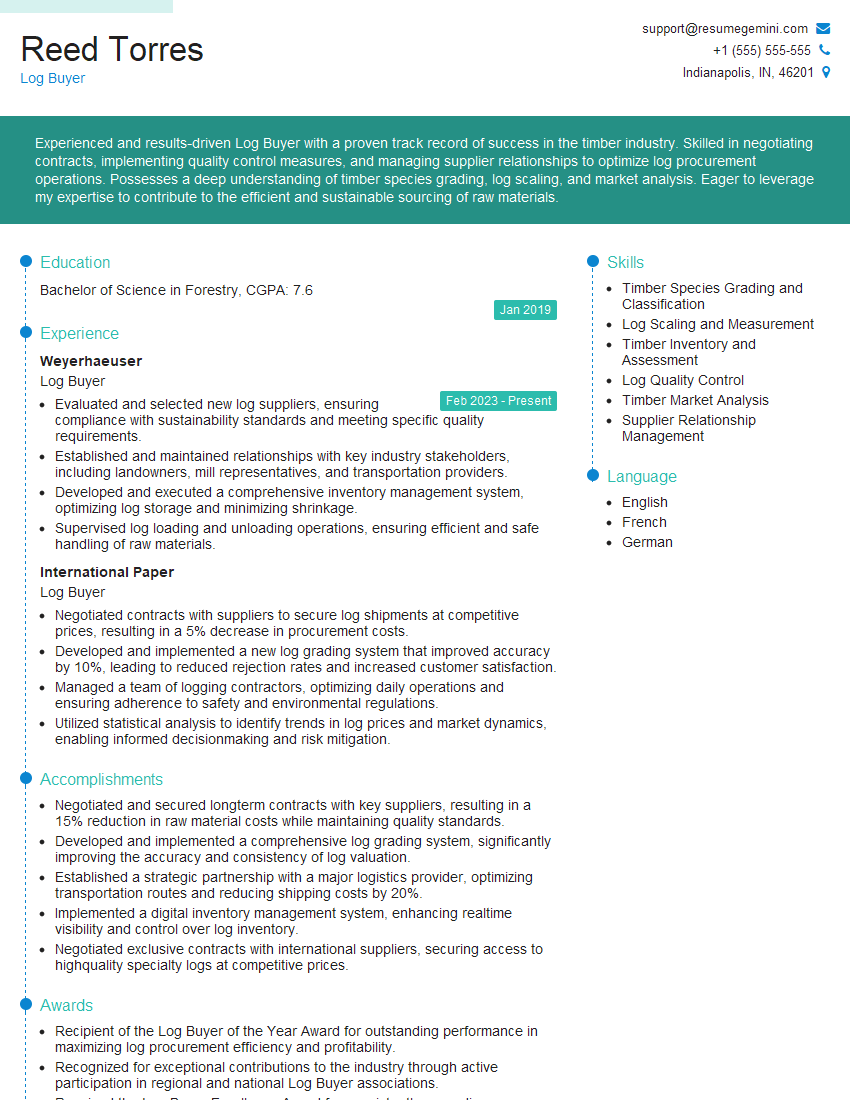

Mastering log purchasing opens doors to rewarding careers in the forestry and timber industries, offering opportunities for growth and specialization. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of log purchasing roles. Examples of resumes tailored to Log Purchasing are available to help guide your resume development.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

good