Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Log Scaling Equipment Operation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Log Scaling Equipment Operation Interview

Q 1. Describe your experience with different types of log scaling equipment.

My experience encompasses a wide range of log scaling equipment, from basic manual tools like diameter tapes and scaling sticks to sophisticated electronic devices. I’m proficient with various types of calipers, both traditional and digital, that allow for precise diameter measurements. I’ve also extensively used laser-based log scanners which provide rapid and accurate volume estimations, even for irregularly shaped logs. Furthermore, I’m familiar with software systems that integrate with scanning equipment to generate detailed scaling reports. For example, I’ve worked with both the Smalian and Huber formulas using both manual and automated systems. My experience extends to using specialized equipment for scaling logs in challenging environments, such as those submerged in water or piled in complex stacks.

Q 2. What safety procedures do you follow when operating log scaling equipment?

Safety is paramount in log scaling. Before operating any equipment, I always conduct a thorough pre-operational inspection, checking for any damage or malfunctions. Personal Protective Equipment (PPE) is non-negotiable – this includes safety glasses, gloves, steel-toed boots, and high-visibility clothing. When working near heavy machinery or in areas with potential hazards, I follow all company safety protocols and utilize appropriate warning systems. I’m very familiar with the specific hazards associated with each type of equipment, such as the risk of pinched fingers with calipers or the potential for laser eye injury with scanners. I always maintain a safe distance from moving equipment and ensure that the work area is clear of obstructions. Regular safety training refreshes my understanding of best practices and helps me avoid potential accidents.

Q 3. How do you ensure accurate log measurements using various scaling methods?

Accurate log measurement depends on the chosen scaling method and the characteristics of the logs. For small-diameter logs, using a diameter tape or calipers is sufficient. For larger logs, I utilize a combination of diameter measurements at various points along the log and length measurement. I typically employ the Smalian or Huber formulas to calculate volume, depending on the log shape and the level of accuracy required. For complex shapes or damaged logs, more advanced techniques like segmenting the log into smaller, more regular sections might be necessary. Regardless of the method, meticulous attention to detail is crucial. For example, when using a diameter tape, I ensure it’s taut and correctly positioned to avoid measurement errors. I always double-check measurements and cross-reference them with different methods whenever possible to ensure accuracy. Modern electronic systems with advanced algorithms automate much of this process, but operator proficiency in data input and interpreting system outputs is still essential.

Q 4. Explain the process of calibrating log scaling equipment.

Calibrating log scaling equipment is a critical step in ensuring accuracy. Digital calipers and laser scanners require regular calibration to maintain precision. This usually involves comparing the equipment’s readings against a known standard, such as a precisely measured gauge block or a reference log of known dimensions. The calibration procedure is specific to each device and is outlined in the manufacturer’s instructions. I typically perform a calibration check before starting each work day and document all readings. Any discrepancies beyond the acceptable tolerance require adjustment or repair by a qualified technician. For manual measuring tools like diameter tapes, I check for stretching or damage. Proper calibration ensures consistency in measurement and minimizes errors in volume calculations, ultimately leading to more accurate scaling results.

Q 5. How do you handle challenging scaling situations, such as damaged or irregular logs?

Handling challenging scaling situations requires adaptability and experience. Damaged or irregular logs often necessitate a combination of techniques. For logs with broken sections, I carefully measure the remaining portions and estimate the missing volume based on the overall log shape. For heavily tapered logs, I take multiple diameter measurements to create a more accurate volume estimate. Irregularly shaped logs might require segmentation, breaking down the log into smaller, manageable sections, each measured separately and the volumes summed. Photographs are often taken to document the log’s condition for later verification. In some cases, I might refer to scaling guidelines or consult with a supervisor for complex scenarios. Accurate scaling of irregular logs involves more judgment and estimation, but methodical approaches minimize error.

Q 6. What are the common causes of errors in log scaling, and how do you mitigate them?

Errors in log scaling can stem from various sources. Inaccurate measurements due to improper use of equipment, such as a loose diameter tape, are common. Miscalculations using the scaling formulas or incorrect data entry into software systems are also potential pitfalls. Environmental factors like weather conditions affecting equipment performance (e.g., rain impacting laser scanners) can introduce errors. Operator fatigue and inconsistent techniques can also contribute to inaccuracies. To mitigate these errors, I emphasize meticulousness, regular calibration, proper use of equipment, double-checking measurements, and using appropriate scaling methods for different log shapes. Regular training and adherence to standardized procedures are crucial for minimizing errors and ensuring consistently reliable scaling results.

Q 7. Describe your experience with different log species and their scaling characteristics.

My experience spans various log species, each with unique scaling characteristics. For example, some species are more prone to taper than others, requiring more frequent diameter measurements. Others might have irregular shapes or knots that impact volume calculations. I am familiar with the typical dimensions and shapes of common species in my region, which aids in estimation for damaged or incomplete logs. Understanding the different densities of wood species is also important as it can influence the weight and value of the logs, although that’s not always a direct part of the scaling process itself. Knowledge of these species-specific characteristics improves my ability to apply the appropriate scaling methods and accurately estimate log volumes, ensuring fair and accurate timber valuation.

Q 8. How do you maintain log scaling equipment to ensure optimal performance?

Maintaining log scaling equipment is crucial for accurate measurements and efficient operations. It’s a multi-faceted process focusing on both the precision measuring tools and the supporting infrastructure.

Regular Calibration: All measuring tapes, calipers, and diameter tapes must be regularly calibrated against certified standards. This ensures readings remain accurate and minimizes errors in volume calculations. I typically calibrate my equipment every three months, or more frequently if I notice inconsistencies. For example, if a tape measure shows consistent differences from a verified standard, I would immediately replace it.

Cleaning and Maintenance: Keeping equipment clean prevents rust, corrosion, and damage. After each use, I clean all tools with a suitable solvent and store them properly to prevent accidental damage. This also helps with the longevity and overall lifespan of the equipment. Think of it like maintaining a precision instrument; care and attention lead to much longer usability.

Safety Checks: Regular safety inspections are essential. I routinely check for any wear and tear, ensuring the equipment is in good working order and meets all safety standards. This includes verifying the stability of any platforms or ladders used in the scaling process. The safety of both myself and the equipment are paramount.

Preventative Maintenance: I follow a preventative maintenance schedule, which includes lubricating moving parts and replacing worn components promptly. This is proactive to avoid unexpected equipment failures during critical scaling operations, leading to unnecessary downtime.

By adhering to this strict maintenance regimen, I ensure the accuracy and reliability of my measurements, leading to efficient and trustworthy log scaling operations.

Q 9. What software or systems are you familiar with for recording and managing log scaling data?

I’m proficient in several software and systems for managing log scaling data. My experience includes:

Spreadsheet Software (Excel, Google Sheets): I routinely use spreadsheets for data entry, calculations, and generating reports. This allows for customization and flexibility in data analysis.

Database Management Systems (DBMS): For larger-scale projects or when working with extensive datasets, I utilize DBMS such as Access or even cloud-based solutions like SQL Server to manage and analyze data efficiently. This ensures data integrity and easy retrieval.

Specialized Log Scaling Software: I have experience with several commercially available log scaling software packages. These programs often streamline data input, calculations, and report generation; they can significantly speed up the entire process. A good example of this is software which incorporates volume calculation formulas specific to different log shapes and species.

The choice of software depends heavily on the project’s size and complexity. For smaller projects, spreadsheets might suffice, whereas larger-scale projects often benefit from a robust database management system and specialized log scaling software.

Q 10. Explain your understanding of different log scaling rules and regulations.

Log scaling rules and regulations vary depending on the region and governing bodies involved. Understanding these nuances is critical for accurate and legally compliant scaling practices.

Regional Differences: Rules differ widely across countries, states, and even individual logging companies. Some areas might use specific scaling tables or formulas, while others may have different standards for log measurement and acceptable tolerances.

Species-Specific Rules: Regulations may also vary depending on the species of timber being scaled. Certain species might require more precise measurements or have specific rules regarding deductions for defects.

Log Grade and Quality: Log scaling often takes into account the quality of the timber. Rules dictate deductions for defects such as rot, knots, or splits, which affect the usable volume of the log. Understanding these quality criteria and how they factor into scaling is crucial.

Legal Compliance: Adherence to all local and national regulations is paramount to avoid penalties and ensure legal compliance. This includes keeping accurate records and using approved scaling methods.

Staying updated on the latest regulations requires continuous professional development and involvement in relevant industry associations. I regularly review updated rules and regulations to maintain my expertise.

Q 11. How do you interpret and apply scaling tables and formulas?

Scaling tables and formulas are the backbone of log volume calculations. They provide a standardized method for determining the volume of logs with varying shapes and dimensions.

Scaling Tables: These tables usually provide pre-calculated volumes for logs of different diameters and lengths. To use them, I’d measure the log’s diameter (often at both ends, then averaging), and its length, and then locate the corresponding volume in the table. For example, a table might show a volume of 10 cubic feet for a log with an average diameter of 12 inches and a length of 10 feet.

Formulas: When precise calculations are needed, I use formulas to estimate volumes based on the log’s dimensions. Common formulas include:

Cylinder Formula (for relatively cylindrical logs): Volume = πr²h, where r is the average radius and h is the length.

Smalian’s Formula (accounts for taper): Volume = (A1 + A2) / 2 * h, where A1 and A2 are the cross-sectional areas at each end, and h is the length.

Application: In practice, I would select the appropriate table or formula based on the log’s shape and the accuracy needed. For instance, Smalian’s formula is more precise for tapered logs, while the cylinder formula is a quicker estimate for nearly cylindrical ones.

Q 12. How do you handle discrepancies between different scaling methods?

Discrepancies between different scaling methods can arise due to variations in measurement techniques, log shape irregularities, or differing interpretations of scaling rules. To resolve these, I follow a systematic approach:

Identify the Source of Discrepancy: I meticulously review the scaling data from each method, comparing the individual measurements (diameter, length) to pinpoint where differences originate.

Double-Check Measurements: I repeat measurements using each method to rule out simple errors. Precise and consistent measurement techniques are crucial for accurate scaling.

Assess Log Shape: Highly irregular log shapes can lead to different volume estimations depending on the scaling method used. For highly irregular logs, I might use more complex methods or averaging techniques to address this.

Consult Scaling Standards: If discrepancies persist, I consult the relevant scaling standards and regulations to ensure both methods adhere to the accepted rules and tolerances. Understanding the specific rules for the region and timber type is critical.

Documentation and Communication: I thoroughly document all measurements, methods used, and discrepancies encountered. This detailed record is essential for communication and resolution with clients or regulatory bodies.

The goal is to understand the reason for the discrepancy, not just to find a single ‘correct’ answer. Accurate record-keeping and a methodical approach are vital for building trust and ensuring transparency in my work.

Q 13. Describe your experience with volume calculations for different log shapes.

Accurate volume calculation for different log shapes is essential for precise scaling. My experience encompasses various methods tailored to different log geometries:

Cylindrical Logs: For logs approximating a cylinder, the simple cylinder volume formula (πr²h) is usually sufficient. However, even here, careful measurement of the average radius is crucial for accuracy.

Conical Logs (Tapered Logs): For tapered logs, Smalian’s formula ((A1 + A2) / 2 * h) provides a more accurate estimate by accounting for the change in cross-sectional area along the log’s length. However, for highly irregular taper, more complex methods might be necessary.

Irregular Logs: For irregularly shaped logs, I often employ techniques like dividing the log into smaller, more regular sections, calculating the volume of each section, and summing the results. Alternatively, advanced techniques like using three-dimensional laser scanning can provide extremely detailed volume estimates.

The selection of the appropriate method depends on the log’s shape, the required accuracy level, and the available tools and technologies. Accuracy is always the priority, and selecting the right method goes a long way towards achieving that goal.

Q 14. What are your experience with using laser scanners or other advanced technologies for log scaling?

I’ve had significant experience utilizing advanced technologies for log scaling, particularly laser scanners. These tools offer significant advantages over traditional methods.

Laser Scanners: Laser scanning provides highly accurate and detailed three-dimensional models of the logs. This allows for very precise volume calculations, even for highly irregular shapes, without the need for manual measurements. It eliminates errors inherent in manual methods and significantly increases efficiency. The data output can even be fed directly into scaling software for automation and reporting.

Data Processing and Analysis: The large datasets generated by laser scanners require efficient data processing and analysis techniques. I’m familiar with various software packages capable of handling this data and generating detailed reports. This includes programs that automatically identify defects, calculating net volumes after taking defects into account.

Integration with other systems: Laser scanner data can be readily integrated with other systems for comprehensive inventory management and tracking of log movement throughout the supply chain. The resulting data can provide valuable insights for optimization of production and resource management.

While traditional methods still hold value, especially in smaller-scale operations, advanced technologies like laser scanning are transforming the log scaling industry by enhancing accuracy, efficiency, and data management.

Q 15. How do you ensure the accuracy and reliability of your log scaling data?

Accuracy and reliability in log scaling are paramount. We achieve this through a multi-faceted approach, starting with meticulous equipment calibration. Before each scaling job, I rigorously check the measuring tapes and any electronic scaling tools for accuracy, using standardized calibration methods and referencing manufacturer guidelines. This involves comparing measurements against known standards and making adjustments as needed. For example, if my tape measure consistently reads 1cm short at the 10-meter mark, I record this offset and compensate for it during scaling.

Beyond equipment, I maintain meticulous data recording practices. Every measurement is carefully documented, including species, diameter, length, and any deductions for defects. I double-check each entry before moving on, using a system of cross-referencing and visual verification. Think of it like a detective carefully examining every clue – no detail is too small. To further improve accuracy, I regularly compare my manual scaling estimates with the output of electronic scaling devices, looking for discrepancies and refining my methods based on those insights. Any deviations are noted and investigated, allowing for continuous improvement in my scaling technique.

Finally, I embrace the use of quality control checks. This might involve a random sampling of logs for re-measurement, or cross-referencing my data with the logs’ physical characteristics to confirm measurements. I believe in a continuous cycle of measurement, comparison, and refinement – it’s the only way to guarantee consistently high-quality data.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with data entry and report generation related to log scaling.

My experience with data entry and report generation extends across various software platforms and manual methods. I’m proficient in using specialized log scaling software, allowing for efficient data input and error minimization. This software often includes features like automated calculations, data validation checks, and customized report generation – a vast improvement over manual methods. For example, I’ve used software that automatically calculates volume based on entered dimensions, significantly reducing the risk of human error.

Even with software, I maintain a keen attention to detail during data entry. I always cross-check entries for accuracy against my field notes, ensuring that data consistency is maintained from the field to the final report. Furthermore, I have experience generating various reports, ranging from simple summaries to detailed analyses, tailored to the specific needs of clients and supervisors. These reports often include data visualizations, such as graphs and charts, making it easy to understand key metrics.

If software isn’t available, my experience with manual data entry ensures accuracy and legibility. For example, I’ve used well-organized spreadsheets and followed a standardized format for data recording, which allows for easy compilation and analysis even without sophisticated software. The key is consistency and attention to detail, no matter the method used.

Q 17. How do you communicate scaling data effectively to supervisors and clients?

Effective communication of scaling data is crucial. I prioritize clarity, conciseness, and visual aids. For supervisors, I provide concise summaries highlighting key metrics such as total volume, species breakdown, and any significant quality issues. I use clear and non-technical language unless specifically requested otherwise, and I’m always available to answer their questions and address their concerns. Imagine a quick, digestible summary that paints a clear picture of the job without overwhelming them with details.

For clients, my approach is more tailored. I offer detailed reports with comprehensive data, including precise measurements, calculations, and any relevant notes. I might also include visuals like charts or maps, making it easy for clients to visualize the data. For example, a chart showing the volume distribution across different log sizes can be more easily grasped than a raw data table. Client interactions often involve in-person presentations or virtual meetings where I discuss the findings and answer questions. This interactive approach makes it easier to grasp complex information and ensures that my communication matches the client’s level of technical expertise.

Q 18. What steps do you take to troubleshoot malfunctioning log scaling equipment?

Troubleshooting malfunctioning equipment is a regular part of the job. My approach is systematic and methodical. First, I isolate the problem by carefully examining the equipment for any visible damage or obvious malfunctions. Is the tape measure jammed? Is there a power issue with the electronic scaler? Simple issues are often quickly solved through basic maintenance, like replacing a battery or cleaning a sensor.

If the problem is more complex, I utilize my knowledge of the equipment’s specifications and manuals, systematically checking each component. I might test the connections, examine the wiring, or consult troubleshooting guides. If the problem persists, I document the issue thoroughly and contact the equipment manufacturer or a qualified technician for assistance. It’s crucial to follow safety procedures during troubleshooting, ensuring that the equipment is powered off before undertaking any repair or diagnostic work.

For example, if an electronic scaler isn’t powering on, I’d systematically check the battery, power cord, and then the internal circuitry, always prioritizing safety. The goal is efficient and effective troubleshooting that minimizes downtime and ensures accurate scaling can resume as soon as possible.

Q 19. Describe your experience with working in various weather conditions while operating log scaling equipment.

Operating log scaling equipment in various weather conditions is a common challenge. Extreme heat can lead to equipment malfunction and personal discomfort, while cold, wet conditions can make measurements inaccurate and increase safety risks. I mitigate these challenges with appropriate preparation and safety measures.

In extreme heat, I prioritize hydration, wear appropriate clothing, and take frequent breaks in shaded areas. I might also adjust my work schedule to avoid the hottest parts of the day. In cold, wet weather, I layer my clothing, use waterproof gear, and take precautions against slipping or falling on wet surfaces. I might also use specialized, weather-resistant equipment or make adjustments to my measuring techniques. Safety is always paramount; I would never operate equipment in conditions that pose an unacceptable risk to my safety or the accuracy of my work.

For example, in heavy rain, I might use a rain cover for my measuring tape to prevent water damage and ensure accurate readings. Adaptability and preparation are key to safely and efficiently working through varying weather conditions.

Q 20. How do you prioritize tasks when dealing with multiple scaling assignments?

Prioritizing tasks with multiple scaling assignments requires effective planning and organization. I use a combination of techniques to ensure efficiency and meet deadlines. First, I carefully review all assignments, noting deadlines, log volume, location, and any special requirements. I then prioritize based on deadlines – urgent jobs come first. Next, I consider the location of the assignments, grouping jobs geographically to minimize travel time.

A crucial aspect of prioritization involves assessing the complexity of each assignment. A large, complex scaling job might require more time than several smaller, simpler ones, even if their deadlines are similar. I often use scheduling software or tools to visualize tasks and track progress, making it easier to manage multiple assignments simultaneously. This may include creating daily or weekly schedules that allocate specific time slots to each task.

For instance, I might prioritize a rush order for a small volume of high-value logs ahead of a larger, less time-sensitive job to meet the client’s urgent need. Flexibility and adaptability are key, and I am always prepared to adjust my schedule based on unforeseen circumstances or changes in priorities.

Q 21. How do you adapt your scaling techniques to different log sizes and types?

Adapting scaling techniques to different log sizes and types is fundamental to accurate scaling. For small-diameter logs, I use precise measuring tools and meticulous techniques to minimize measurement error. I’m careful to account for log shape and any irregularities, ensuring that my measurements are as accurate as possible. Larger logs often require different techniques, possibly involving the use of specialized equipment or more advanced scaling methods.

Different species of trees also require consideration. The density of wood, potential defects, and the shape of the log can all impact the scaling method and the accuracy of measurements. I am familiar with various scaling rules and formulas for different species, allowing me to choose the most appropriate method for each scenario. For example, I might use different scaling methods for a straight, cylindrical log compared to a tapered or crooked one. I may also adjust my technique to account for knots, rot, or other defects to accurately assess the usable volume of the log.

Essentially, my approach is one of continuous adaptation and precision. I choose the right tools, techniques, and formulas to ensure that my scaling process consistently delivers accurate results, regardless of the log size or species.

Q 22. Explain your understanding of the environmental impact of logging and how it relates to accurate scaling.

Accurate log scaling is crucial for minimizing the environmental impact of logging. Sustainable forestry practices rely heavily on precise measurements to ensure that harvesting doesn’t exceed the sustainable yield of a forest. Inaccurate scaling can lead to over-harvesting, resulting in deforestation, habitat loss, soil erosion, and increased carbon emissions. Conversely, under-estimating timber volume can lead to inefficient resource management and missed economic opportunities.

For example, if a logger consistently underestimates the volume of timber harvested, they might clear-cut more area than necessary to meet their quota, causing greater environmental damage than if accurate measurements were used. Accurate scaling allows for better planning of logging operations, minimizing disturbance to sensitive ecosystems and ensuring that regeneration efforts are adequately funded based on actual harvest quantities.

Moreover, accurate scaling supports sustainable certification programs like the Forest Stewardship Council (FSC), which sets standards for responsible forest management. These certifications rely on precise data to verify compliance, showcasing the critical link between precise scaling and responsible environmental stewardship.

Q 23. What is your experience with working independently and as part of a team in log scaling operations?

Throughout my career, I’ve effectively worked both independently and collaboratively within log scaling teams. Independent work often involves fieldwork: using scaling tools like diameter tapes, Biltmore sticks, and electronic scaling devices to individually measure logs in remote locations. This requires strong problem-solving skills, resourcefulness, and meticulous attention to detail, as I’m responsible for the accuracy of my own data collection.

Teamwork is essential when dealing with large-scale logging operations. I’ve collaborated with fellow scalers, supervisors, and logging crews to ensure data consistency, coordinate measurements across different areas, and resolve discrepancies. Efficient team communication and clear data-sharing protocols are key to maintaining accurate records and minimizing errors. For instance, I’ve participated in cross-checking measurements with colleagues to ensure the consistency and reliability of our data, a crucial part of maintaining the integrity of our reporting.

Q 24. Describe a time when you had to solve a problem related to log scaling equipment or data.

During a particularly heavy rainfall, the software on our electronic scaling device malfunctioned, causing inaccurate measurements. This threatened to significantly delay our operation and potentially compromise the accuracy of the entire project.

My first step was to ensure the safety of the equipment and personnel, as working with malfunctioning technology in wet conditions presents safety hazards. Then, I systematically troubleshooted the device, checking its power source, connections, and software updates. Simultaneously, I contacted our technical support team for assistance. While waiting for their guidance, I switched to manual scaling methods using traditional tools as a backup, ensuring a minimal disruption to the logging process. The technical support team remotely diagnosed and rectified the software issue, and we were able to seamlessly integrate the digital data with the manually collected data. This ensured that we met our deadlines without compromising the data’s accuracy.

Q 25. How do you stay updated on new technologies and techniques in log scaling?

Staying current in log scaling requires continuous learning. I actively participate in professional development workshops and conferences offered by organizations like the Society of American Foresters. These events offer updates on the latest technologies, scaling techniques, and industry best practices. I also subscribe to relevant industry journals and publications, keeping abreast of advancements in software, equipment, and measurement standards. Furthermore, I actively participate in online forums and communities where scalers share experiences and insights, expanding my knowledge base.

For instance, I recently learned about the increased use of LiDAR (Light Detection and Ranging) technology for timber volume estimation, which offers more efficient and accurate measurements than traditional methods in certain situations. I am always looking for opportunities to integrate these new technologies into my workflow where appropriate.

Q 26. How do you ensure the safety of yourself and others while performing log scaling operations?

Safety is paramount in log scaling. My daily routine includes conducting thorough pre-operation checks on all equipment, ensuring that everything is functioning correctly and safely. I always wear appropriate personal protective equipment (PPE), including safety boots, high-visibility clothing, and hard hats, especially in areas with heavy machinery. I strictly adhere to all safety regulations and company protocols, which include maintaining awareness of my surroundings, especially when working near heavy equipment and felled logs.

I actively communicate with colleagues and logging crews, ensuring clear lines of communication to prevent accidents. For example, if I identify a potential hazard, I immediately alert the relevant personnel and take corrective measures to mitigate the risk. Regular safety training and awareness programs are critical to maintaining a safe working environment and are practices that I consistently prioritize.

Q 27. What are your salary expectations for this role?

My salary expectations are commensurate with my experience and skills, and in line with the industry standard for experienced log scaling professionals in this region. I am open to discussing a specific salary range based on the full details of the position and the company’s compensation package.

Q 28. What are your long-term career goals in the field of log scaling?

My long-term career goals involve becoming a leading expert in log scaling, potentially specializing in the application of advanced technologies like LiDAR and remote sensing in timber volume estimation. I aim to contribute to the development and implementation of innovative and sustainable forestry practices. I also envision myself mentoring and training new professionals, ensuring a skilled and knowledgeable workforce for the future of this vital industry.

Key Topics to Learn for Log Scaling Equipment Operation Interview

- Equipment Knowledge: Understanding the various types of log scaling equipment (e.g., scanners, tapes, calipers), their functionalities, and limitations. This includes knowing the principles behind each method of measurement.

- Safety Procedures: Demonstrating a thorough understanding of safety protocols, including pre-operational checks, personal protective equipment (PPE) usage, and emergency response procedures specific to log scaling operations.

- Data Collection and Analysis: Explaining the process of accurate data collection using different equipment, and how to analyze this data to determine log volume, grade, and other relevant metrics. Understanding potential sources of error and how to minimize them is crucial.

- Log Scaling Techniques: Mastering various log scaling techniques, including understanding the differences between different scaling methods and their applications in various situations (e.g., different tree species, log sizes, and terrain).

- Software Proficiency: Familiarity with software commonly used in log scaling, including data entry, reporting, and potentially data analysis tools. Highlighting your ability to learn new software quickly will be beneficial.

- Problem-Solving and Troubleshooting: Describing your approach to identifying and resolving equipment malfunctions, data inconsistencies, and other operational challenges. Provide examples showcasing your analytical skills and ability to think critically under pressure.

- Environmental Awareness: Demonstrating an understanding of environmental considerations related to log scaling, such as sustainable forestry practices and minimizing environmental impact.

Next Steps

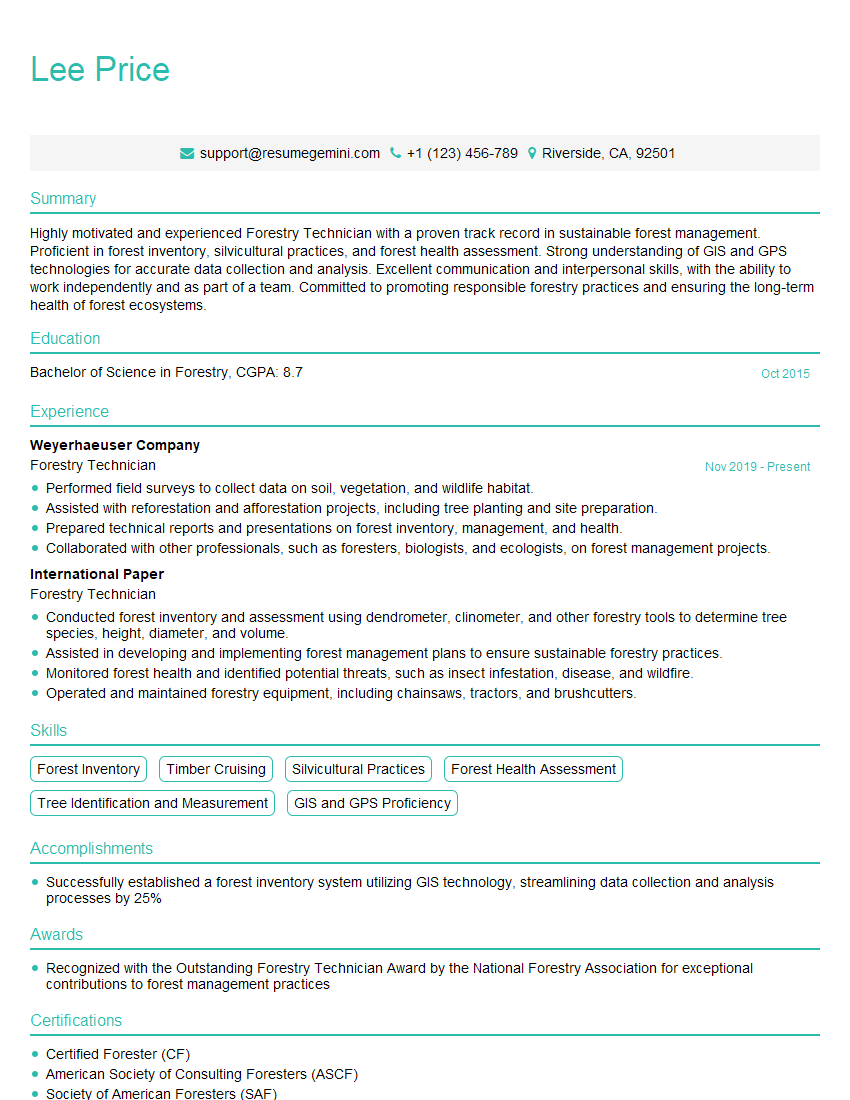

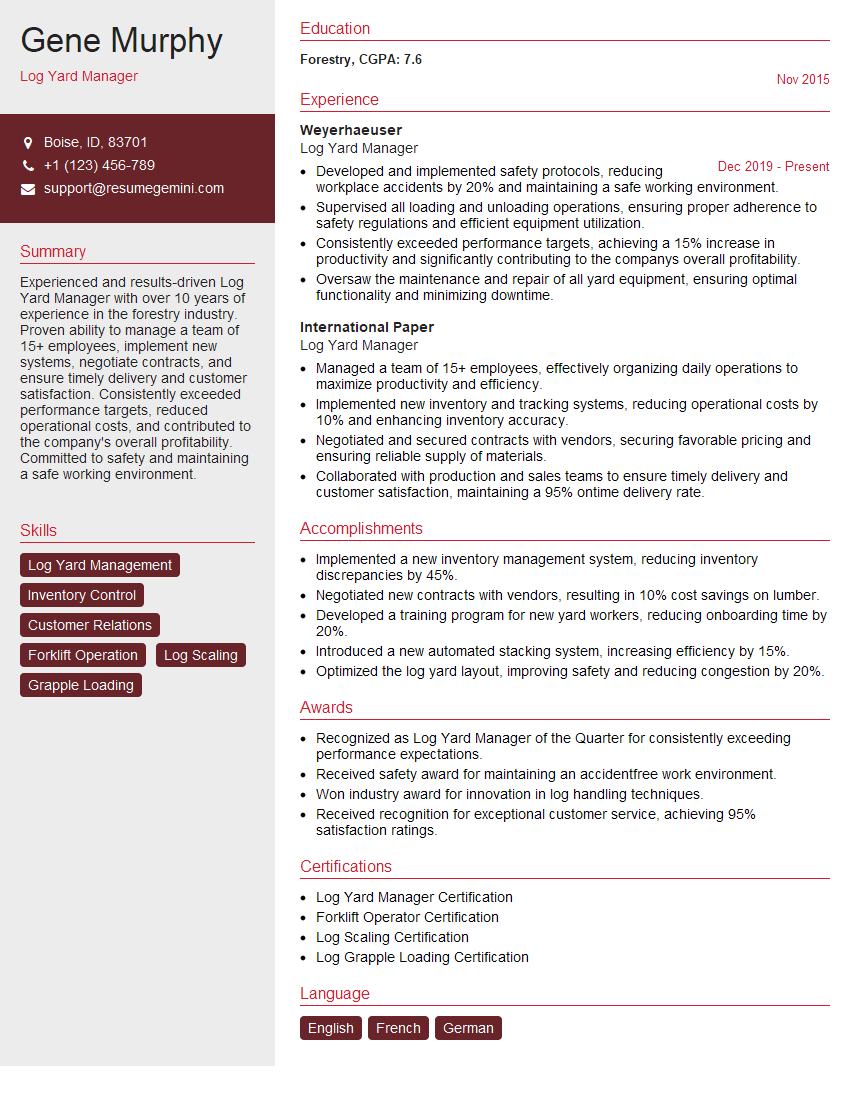

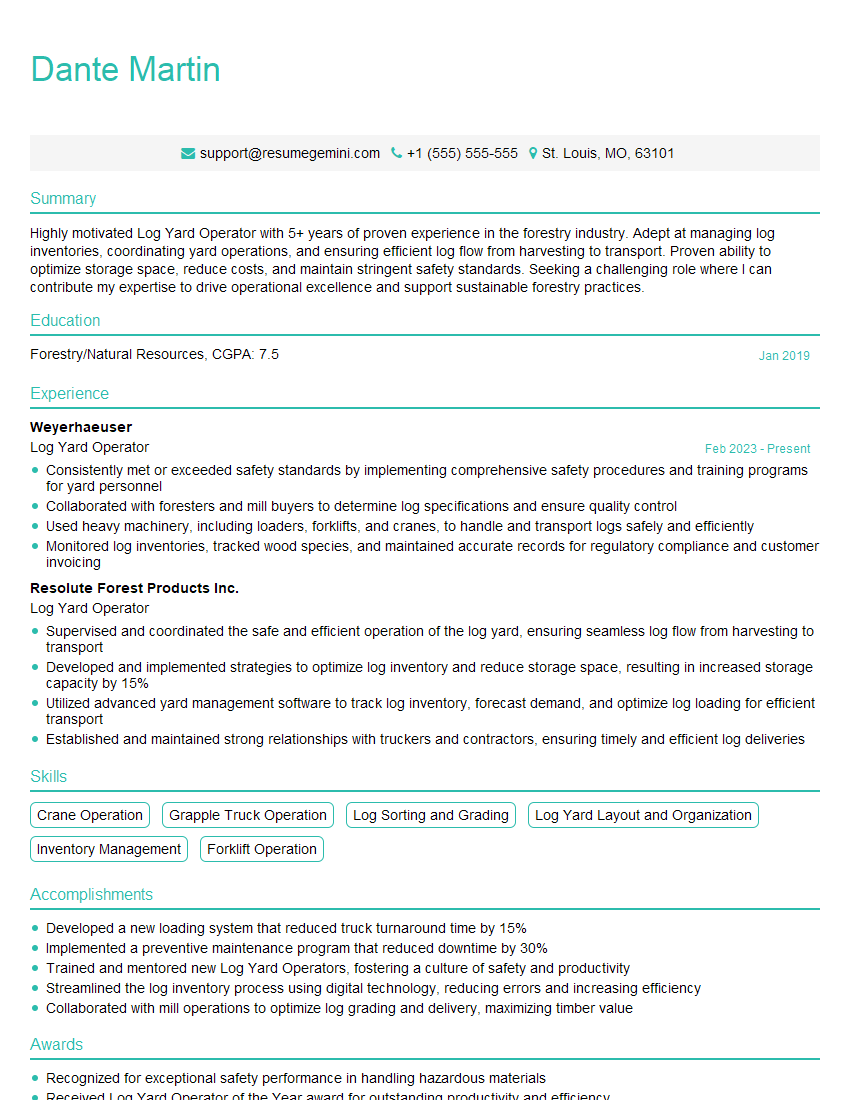

Mastering Log Scaling Equipment Operation opens doors to a rewarding career with excellent growth potential within the forestry and timber industries. To significantly increase your chances of landing your dream job, a well-crafted, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you create a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Log Scaling Equipment Operation are available to help guide your process. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good