Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Low Voltage Cable Installation interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Low Voltage Cable Installation Interview

Q 1. Explain the difference between shielded and unshielded twisted-pair cables.

The key difference between shielded and unshielded twisted-pair cables lies in their susceptibility to electromagnetic interference (EMI) and radio frequency interference (RFI). Unshielded Twisted Pair (UTP) cables, commonly used in Ethernet networks, consist of pairs of wires twisted together to minimize interference. However, they offer no protection against external electromagnetic fields. Imagine it like a group of people chatting – they can hear each other clearly, but external noise might still affect their conversation.

Shielded Twisted Pair (STP) cables, on the other hand, have an additional layer of metallic shielding – often foil or braided wire – wrapped around the twisted pairs. This shielding acts as a barrier, preventing external electromagnetic fields from affecting the signal. Think of it like the same group of people now having a private room to chat, reducing the impact of external noise.

STP cables are generally more expensive and less flexible than UTP cables, making them a choice for applications requiring higher levels of noise immunity, such as industrial settings or environments with high levels of electromagnetic interference.

Q 2. Describe your experience with cable termination techniques (e.g., RJ45, BNC).

I have extensive experience in terminating various low-voltage cables, including RJ45 and BNC connectors. RJ45 termination, crucial for Ethernet networks, requires precision in crimping the wires to the connector according to the T568A or T568B wiring standard. Incorrect termination leads to connectivity issues. I’ve successfully terminated thousands of RJ45 connectors over my career, ensuring consistent and reliable network performance. I regularly use cable testers to verify connectivity after termination.

With BNC connectors, commonly used in coaxial cables for video surveillance or older network technologies, precise stripping and careful connection to the center conductor and the outer shield are critical. I meticulously follow the manufacturer’s instructions, paying attention to the proper impedance matching to avoid signal degradation. I always double-check the connections with a multimeter for continuity and proper grounding.

Q 3. What are the common types of low voltage cable used in commercial buildings?

Commercial buildings utilize a variety of low-voltage cables, each suited for specific applications. Some common types include:

- Unshielded Twisted Pair (UTP) cables: Used extensively for data networking (Ethernet), telephone systems, and other low-speed data transmission.

- Shielded Twisted Pair (STP) cables: Employed where EMI/RFI protection is critical, such as in industrial control systems or areas with high electromagnetic interference.

- Coaxial cables: Used for video transmission (CCTV systems), cable television distribution, and applications requiring higher bandwidth and longer distances compared to twisted pair.

- Fiber optic cables: Ideal for high-bandwidth applications like building-wide networks, data centers, and long-distance communication due to their superior speed and immunity to EMI/RFI.

- Control cables: These are typically multi-conductor cables used for various control systems, fire alarm systems, security systems, and building automation systems.

The choice of cable depends on factors such as bandwidth requirements, distance, environmental conditions, and the specific application.

Q 4. How do you troubleshoot a faulty network connection?

Troubleshooting a faulty network connection involves a systematic approach. I start with the basics:

- Visual inspection: Checking for loose or damaged cables, unplugged connectors, and any obvious physical damage.

- Testing connectivity: Using a cable tester to verify proper wiring and continuity in the cables. This quickly identifies problems at the cable level.

- Checking the network devices: Testing the network ports on computers, switches, and routers using ping commands to check basic network connectivity.

- Analyzing network configuration: Checking IP addresses, subnet masks, and default gateways to ensure correct network settings. Incorrect settings are a frequent cause of connectivity problems.

- Tracing the cable path: In larger installations, physically tracing the cable path to rule out breaks or other issues along its run can be necessary.

- Consult Network Diagrams and Documentation: Referencing accurately updated diagrams and documents helps to track down the connection path and identify related equipment.

By following this step-by-step process, I can quickly isolate the problem and implement the appropriate solution.

Q 5. What safety precautions do you take when working with low voltage cabling?

Safety is paramount when working with low-voltage cabling, even though it’s not as immediately dangerous as high-voltage work. My safety precautions always include:

- Proper Personal Protective Equipment (PPE): This includes safety glasses to protect my eyes from debris and gloves to protect my hands from cuts and abrasions during cable termination.

- Lockout/Tagout procedures: When working near energized equipment, I always adhere to lockout/tagout procedures to prevent accidental energization.

- Awareness of surroundings: I’m always cautious of my surroundings to avoid tripping hazards and potential injuries. I ensure the work area is clear and well-lit.

- Following Electrical Safety Codes: I always adhere to relevant electrical safety codes and regulations (such as NEC in the US or equivalent in other regions).

- Never working alone: Whenever possible, I always have a colleague present to ensure a second pair of eyes and assist in case of any incident.

Even with low-voltage cables, a careless approach can still lead to accidents. Following these precautions minimizes risks and ensures a safe working environment.

Q 6. Explain the importance of proper cable labeling and documentation.

Proper cable labeling and documentation are crucial for efficient troubleshooting and maintenance. Imagine trying to repair a complex network system without knowing which cable goes where! It’s a nightmare scenario.

Clear labeling, usually with heat-shrink sleeves or labels with cable ID, function (e.g., ‘Network Main-A’), and destination, simplifies troubleshooting considerably. Accurate documentation, including network diagrams and cable schedules, provides a comprehensive overview of the entire cabling infrastructure. This helps technicians quickly identify the affected cable and related equipment in case of faults or during system upgrades.

In my experience, detailed and well-maintained documentation saves significant time and resources during troubleshooting and future maintenance, avoiding costly errors and downtime.

Q 7. Describe your experience with cable pulling techniques.

My experience with cable pulling encompasses various techniques, depending on the cable type, length, and the environment. I’ve worked with different pulling methods:

- Hand pulling: Suitable for short cable runs, hand pulling is simple and cost-effective but physically demanding for longer distances.

- Cable pulling equipment: For longer runs, I utilize cable pulling equipment such as winches, pulling grips, and lubricants. The choice of equipment depends on the cable size, distance, and the number of bends in the conduit. Proper lubrication is crucial to reduce friction and cable damage during pulling.

- Fish tapes: To navigate bends and obstacles in conduits, I’ll use fish tapes to guide the cable through the conduit before pulling it through with the chosen pulling equipment.

- Vacuum systems: I’ve also worked with vacuum systems for pulling cables in particularly challenging environments or where access is restricted.

Safety is paramount during cable pulling. I always ensure that the cable is properly secured, the pulling equipment is correctly set up, and the pulling force is controlled to prevent cable damage and equipment malfunction. It is important to regularly inspect the equipment for wear and tear.

Q 8. What is your experience with different cable management systems?

My experience encompasses a wide range of cable management systems, from simple cable trays and ladder racks to more complex structured cabling systems utilizing patch panels, fiber optic enclosures, and cable ties. I’m proficient in various methods of cable labeling and identification, ensuring traceability and ease of maintenance. For instance, in a recent data center project, we implemented a color-coded labeling system for different cable types and destinations, significantly improving troubleshooting time. I’ve also worked extensively with various cable support systems, selecting the appropriate system based on factors such as cable weight, environment, and accessibility requirements. This includes selecting between raceways, conduits, and even utilizing vertical cable management systems to maximize space in crowded environments.

- Cable Trays: Ideal for grouping similar cables, offering easy access and maintenance.

- Ladder Racks: Provide robust support for heavier cables and bundles.

- Structured Cabling: A standardized approach ensuring organization and future scalability.

- Conduit Systems: Offer superior protection against environmental factors and physical damage.

Q 9. How do you identify and resolve common cable faults?

Identifying and resolving cable faults requires a systematic approach. I begin with visual inspection, checking for obvious signs of damage like cuts, kinks, or exposed wires. Then, I use specialized testing equipment, such as a cable tester or tone generator, to pinpoint the exact location and nature of the fault. For instance, a continuity tester helps confirm a complete circuit, while a time-domain reflectometer (TDR) can locate short circuits or breaks within the cable.

Common faults I encounter include:

- Open circuits: A break in the cable causing a complete loss of signal. I would locate the break using a TDR and splice or replace the damaged section.

- Short circuits: An unintended connection between two conductors, resulting in signal degradation or equipment malfunction. I’d use a TDR to pinpoint the short and then repair or replace the affected cable.

- Ground faults: A connection between a conductor and ground, potentially leading to electrical shock or equipment damage. These are often identified through ground fault detectors.

In each case, careful documentation of the fault, the testing procedure, and the corrective actions taken is crucial for future reference and maintenance.

Q 10. What is your experience with fiber optic cable installation and termination?

My experience with fiber optic cable installation and termination is extensive. I’m familiar with various fiber types, including single-mode and multi-mode, and proficient in fusion splicing, mechanical splicing, and connector termination using various types of connectors such as SC, LC, and ST.

Fiber optic installation requires meticulous attention to detail. Proper cleaning of connectors is crucial to avoid signal loss. I use specialized cleaning tools and techniques to ensure optimal performance. Fusion splicing, for instance, requires careful alignment of the fibers to achieve the lowest possible loss. My experience includes working with fiber optic patch panels, cable management systems specifically designed for fiber optics, and the use of OTDR (Optical Time Domain Reflectometer) to test fiber optic cable continuity and locate faults. I’ve worked on numerous projects involving high-speed data transmission, ensuring optimal signal integrity.

Q 11. Explain the difference between Cat5e, Cat6, and Cat6a cabling.

Cat5e, Cat6, and Cat6a are all twisted-pair copper cabling standards used for Ethernet networks, differing primarily in their bandwidth and performance capabilities. Think of it like comparing roads: Cat5e is a smaller two-lane road, Cat6 is a wider four-lane highway, and Cat6a is a superhighway with enhanced capabilities.

- Cat5e: Supports speeds up to 1 Gigabit Ethernet (1 Gbps) over shorter distances. It’s more cost-effective but has limitations in higher bandwidth applications.

- Cat6: Supports speeds up to 10 Gigabit Ethernet (10 Gbps) over shorter distances than Cat6a. It provides improved noise immunity compared to Cat5e.

- Cat6a: Supports speeds up to 10 Gbps over longer distances than Cat6. It offers superior performance and is better suited for high-bandwidth applications and future-proofing network infrastructure. The ‘a’ stands for ‘augmented’.

The key differences lie in the tighter twisting of the pairs, improved shielding, and overall better construction quality in Cat6 and Cat6a, allowing for higher frequencies and faster data transmission rates with less signal degradation.

Q 12. What is your experience with testing and certification of low voltage cabling?

Testing and certification of low-voltage cabling are critical to ensuring network performance and reliability. I’m experienced in using various test equipment, including cable testers, wire mappers, and optical time-domain reflectometers (OTDRs), to verify that the cabling installation meets industry standards.

My certifications include [mention specific certifications e.g., BICSI, TIA], which demonstrates my competency in this area. Typical testing procedures I follow include:

- Continuity Testing: Verifying the connection between ends of a cable.

- Wire Mapping: Identifying individual wires within a cable to verify correct pairing and termination.

- Length Measurement: Determining the length of the cable run for accurate documentation and future reference.

- Signal Attenuation and Return Loss Testing: Measuring signal loss and reflections in the cable, indicating potential issues.

- (For fiber optic) OTDR Testing: Detecting faults and measuring fiber length, ensuring proper performance.

Generating test reports that meet industry standards is a critical aspect of my work, providing a clear record of the cable’s performance and conformity to specifications.

Q 13. Describe your experience with working from blueprints or schematics.

Working from blueprints or schematics is an integral part of my job. I’m proficient in reading and interpreting various types of drawings, including electrical schematics, floor plans, and cable routing diagrams. I understand the symbols and notations used to represent different components and cable types. This ensures that the installation conforms to the project’s design specifications.

For example, in a recent office renovation, I used architectural blueprints to identify the location of data outlets and then developed a detailed cable routing plan, minimizing disruption to the building’s structure and ensuring that cables were routed discreetly and efficiently. I carefully coordinate with other tradespeople on site to ensure my work doesn’t clash with other installations like plumbing or HVAC systems.

Q 14. How do you handle difficult or unexpected situations during installation?

Handling unexpected situations during installation requires a calm and methodical approach. I always prioritize safety and begin by thoroughly assessing the situation. For example, encountering unexpected obstacles like a concealed pipe or a change in building structure requires flexible problem-solving. I carefully review the plans, consult with the project manager and other trades, and then develop an alternative solution that maintains the integrity and performance of the cabling system.

Open communication is crucial in such situations. Keeping stakeholders informed of progress, potential delays and alternative solutions ensures collaboration and prevents misunderstandings. Thorough documentation of the issue, the solution implemented, and any potential implications is vital.

Q 15. What software or tools are you proficient in using for cable installation?

For efficient and accurate low-voltage cable installation, I’m proficient in several software and tools. My expertise includes using AutoCAD for designing cable routes and layouts, ensuring optimal placement and minimizing interference. This allows for precise planning before any physical installation begins, reducing errors and rework. I also utilize cable management software like Bluebeam Revu for documenting the entire process, from initial designs to final as-built drawings, providing a clear and auditable record. This aids in future maintenance and troubleshooting. Finally, I’m skilled in using various testing equipment such as multimeters, cable testers, and tone generators to verify continuity, identify faults, and ensure the system’s overall integrity. Think of it like using a blueprint (AutoCAD) and a detailed checklist (Bluebeam Revu) along with a toolkit to build a perfect structure.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of connectors.

My experience with low-voltage connectors is extensive, covering a wide range of types depending on the application and cable type. For example, I routinely work with RJ45 connectors for network cabling, ensuring proper crimping and testing for optimal data transmission – think of it like meticulously connecting individual wires in a phone system to ensure each line works perfectly. I’m also proficient with BNC connectors for coaxial cables used in video surveillance systems, carefully paying attention to impedance matching to avoid signal loss. Similarly, I’m adept at using various terminal blocks for connecting wires to devices, ensuring secure and reliable connections. Understanding the specific requirements of each connector type and applying the right tools is crucial for a flawless installation, just like selecting the perfect screw for a given task to secure a solid join.

Q 17. What is your understanding of grounding and bonding in low voltage systems?

Grounding and bonding are critical safety aspects in low-voltage systems, preventing electrical shock and ensuring signal integrity. Grounding connects the system to earth, providing a path for fault currents to safely flow to the ground, preventing dangerous voltage buildup. Bonding connects various metallic components together to equalize their electrical potential. This prevents voltage differences between the components, minimizing the risk of electric shock. Imagine it like a safety net – grounding provides the essential ground connection, preventing hazardous voltages, while bonding ensures that all connected parts are at the same electrical potential, removing any voltage differences that might lead to problems.

For instance, in a data center, proper grounding and bonding are paramount. A grounded rack ensures that any potential faults are quickly and safely conducted to earth. The various components within the rack are bonded to prevent voltage differentials that could damage sensitive equipment. Failing to implement this correctly could lead to data loss or even equipment failure due to unforeseen electrical surges.

Q 18. How do you manage your time and prioritize tasks during installation projects?

Effective time management is crucial in cable installation projects. I typically begin with a thorough review of the project specifications and blueprints, creating a detailed schedule that breaks down the tasks into manageable chunks. This involves estimating the time needed for each step, considering factors like cable routing, connector installation, and testing. I use a combination of project management software and a physical checklist to track progress and ensure deadlines are met. Prioritization involves tackling critical tasks first—those that impact subsequent steps—and allocating resources effectively. For instance, if there’s a crucial connection that needs to be made before other systems can be integrated, I prioritize that connection. This approach allows me to stay focused and organized throughout the installation process, minimizing delays and maintaining project quality.

Q 19. Explain your experience with working in confined spaces or at heights.

I have significant experience working in confined spaces and at heights, always prioritizing safety. When working in confined spaces, I ensure adequate ventilation, wear appropriate personal protective equipment (PPE) such as respirators and harnesses, and use appropriate lighting. I also follow all safety protocols and communicate regularly with my team. In scenarios involving heights, I always use appropriate fall protection equipment, such as harnesses and safety lines, and follow strict safety guidelines. Before starting any work at height, I inspect all equipment and the workspace for hazards. Remember, safety is paramount. One lapse in judgment could mean a significant risk. The proper use of safety equipment is never optional.

Q 20. What is your understanding of NEC codes related to low voltage cabling?

My understanding of the National Electrical Code (NEC) concerning low-voltage cabling is comprehensive. I’m familiar with the relevant articles that address installation requirements for various low-voltage systems, including fire alarm, security, data communication, and power-limited fire alarm circuits. For instance, I adhere strictly to Article 725 for Class 2 and Class 3 circuits, ensuring proper cable routing, grounding, and bonding practices. I understand the requirements for cable separation from higher voltage circuits and the appropriate use of cable trays and conduits. Compliance with the NEC is crucial for safety and ensures the installation meets industry standards, preventing potential hazards and ensuring the system’s longevity. Regular updates on NEC changes are part of my ongoing professional development.

Q 21. How do you ensure the quality and integrity of your work?

Ensuring quality and integrity is central to my work ethic. I begin with meticulous planning and preparation, including thorough cable routing and design. During installation, I meticulously follow industry best practices and adhere to the NEC standards. Throughout the process, I perform regular testing and inspection using appropriate tools to verify continuity, signal quality, and overall system integrity. Once completed, I provide detailed documentation, including as-built drawings and test results, which helps with any future maintenance or troubleshooting. This approach, coupled with a commitment to continuous learning and staying updated on industry advancements, ensures that my work consistently meets the highest standards of quality and reliability. Think of it like building a house; each step, from the foundation to the final touches, has to be carefully planned and executed to create a robust and long-lasting structure.

Q 22. Describe your experience working with different types of building materials.

My experience spans a wide range of building materials, from the common like drywall and plaster to more specialized materials such as concrete, metal studs, and various types of flooring. Understanding the properties of each material is crucial for safe and efficient cable installation. For example, when working with concrete, I use specialized diamond-core drills to avoid cracking the structure while creating pathways for conduits. With drywall, I employ careful cutting techniques to minimize damage and ensure a clean finish. Different materials require different approaches to cable routing and fixing, and I have consistently adapted my methods to achieve optimal results while maintaining building integrity.

- Drywall: Requires precise cutting to avoid cracking and ensures a seamless finish after installation.

- Concrete: Demands specialized tools like diamond core drills for precise conduit placement, minimizing structural damage.

- Metal Studs: Necessitates the use of appropriate fasteners to securely attach cables and conduits.

- Plaster: Requires careful planning to avoid damaging the fragile material during drilling and routing.

Q 23. What is your experience with installing and troubleshooting security systems?

I have extensive experience installing and troubleshooting various security systems, including CCTV, access control, and intrusion detection systems. My work involves selecting appropriate cabling (e.g., shielded twisted pair for video transmission, multi-core cables for access control), running cables through structured cabling systems, terminating cables with appropriate connectors, and configuring network components. Troubleshooting often involves using testing equipment like multimeters and network analyzers to identify faults in the cabling, connectors, or network devices. For instance, I once solved a problem where intermittent camera outages were caused by a faulty connection within a poorly shielded cable run, requiring me to reroute a section of the cable to resolve the issue.

- CCTV: Expertise in coaxial cable, fiber optic cable, and IP network installation and troubleshooting.

- Access Control: Experienced in low-voltage wiring for door access readers, control panels and electromagnetic locks.

- Intrusion Detection: Proficiency in installing and troubleshooting various sensor types and their associated cabling.

Q 24. What is your experience with installing and troubleshooting AV systems?

My experience with AV systems encompasses installation and troubleshooting of audio and video distribution systems in various settings. This includes working with different cabling types (HDMI, CAT6, fiber optic), configuring equipment (projectors, amplifiers, audio mixers), and integrating systems with control interfaces. I’m proficient in using signal testing equipment to identify and resolve signal loss or interference. For instance, in a recent project involving a large conference room, I successfully resolved a significant audio delay by identifying and correcting a grounding issue in the cable infrastructure.

- HDMI: Experience in high-definition video distribution using HDMI cabling, ensuring signal quality.

- CAT6/CAT5e: Knowledge of using twisted-pair cabling for network-based audio and video transmission.

- Fiber Optic: Experience with long-distance audio/video transmission through fiber optic cables.

Q 25. Describe your experience with working on large-scale projects.

I have been involved in several large-scale projects, including a recent multi-building campus-wide network upgrade that involved the installation of hundreds of kilometers of fiber optic and copper cabling. Managing such projects demands meticulous planning, effective coordination with other trades, and adherence to stringent deadlines. My role often involves creating detailed cable routing diagrams, managing material procurement, and overseeing a team of technicians. I am proficient in using project management software to track progress, identify potential delays, and ensure that the project is completed on time and within budget.

Working on these large projects has honed my ability to handle complex logistical challenges and communicate effectively with multiple stakeholders.

Q 26. What is your experience with working as part of a team?

Teamwork is essential in cable installation. I thrive in collaborative environments and have a proven track record of working effectively within teams of varying sizes. My approach emphasizes clear communication, shared responsibility, and mutual respect. I am comfortable taking on leadership roles when necessary, guiding team members and ensuring that all aspects of the project are completed to a high standard. I believe in fostering a positive and supportive work environment where everyone feels valued and empowered to contribute their skills and expertise.

For example, during a recent project with a tight deadline, I worked closely with the electrical team to coordinate our activities, preventing conflicts and ensuring a smooth workflow.

Q 27. How do you stay up-to-date with the latest technologies and industry standards?

Staying current in this rapidly evolving field is critical. I achieve this through a multi-pronged approach: I regularly attend industry conferences and workshops, participate in online training courses, and actively engage with professional organizations like BICSI (Building Industry Consulting Service International). I also subscribe to industry publications and actively follow relevant blogs and online forums. This ensures I stay abreast of the latest advancements in cabling technologies, safety standards (like NEC and IEC), and best practices.

Continuous learning allows me to enhance my skills, adopt new techniques, and improve the quality of my work.

Q 28. Describe a challenging cable installation project and how you overcame the challenges.

One particularly challenging project involved installing a complex fiber optic network in a historic building with limited access and intricate architectural features. The building’s age presented numerous obstacles, including fragile walls and restricted access points. We faced difficulties in navigating the existing infrastructure while minimizing disruption to the building’s historical integrity.

To overcome these challenges, we adopted a phased approach, carefully planning each stage of the installation. We used advanced fiber optic testing equipment to precisely locate and identify cable paths, and we collaborated closely with historical preservation specialists to ensure minimal damage to the building. We also implemented rigorous quality control measures to guarantee the network’s performance and reliability. Through meticulous planning, effective teamwork, and creative problem-solving, we successfully completed the project on time and to the client’s satisfaction.

Key Topics to Learn for Low Voltage Cable Installation Interview

- Cable Selection and Specifications: Understanding different cable types (coaxial, fiber optic, twisted pair), their applications, and how to choose the right cable for specific projects. This includes knowledge of voltage ratings, shielding, and impedance.

- Installation Techniques: Mastering proper cable routing, termination techniques (e.g., crimping, soldering), and connector selection for various low-voltage systems. Practical experience with different installation methods in various environments (residential, commercial) is crucial.

- Troubleshooting and Diagnostics: Developing skills in identifying and resolving common low-voltage system problems, including signal loss, interference, and connectivity issues. This requires a strong understanding of testing equipment and diagnostic procedures.

- Safety Regulations and Codes: Familiarity with relevant safety standards and building codes related to low-voltage cable installation. This includes understanding proper grounding techniques and working safely with electrical systems.

- Network Infrastructure: Understanding basic networking principles and how low-voltage cabling supports various network topologies (e.g., star, bus). This includes familiarity with concepts like data transmission rates and network protocols.

- Project Planning and Management: Demonstrating an understanding of project planning, including estimating materials, scheduling tasks, and adhering to deadlines. This encompasses skills in reading blueprints and following specifications.

- Communication and Teamwork: Highlighting your ability to communicate effectively with colleagues, supervisors, and clients, and your ability to work collaboratively as part of a team.

Next Steps

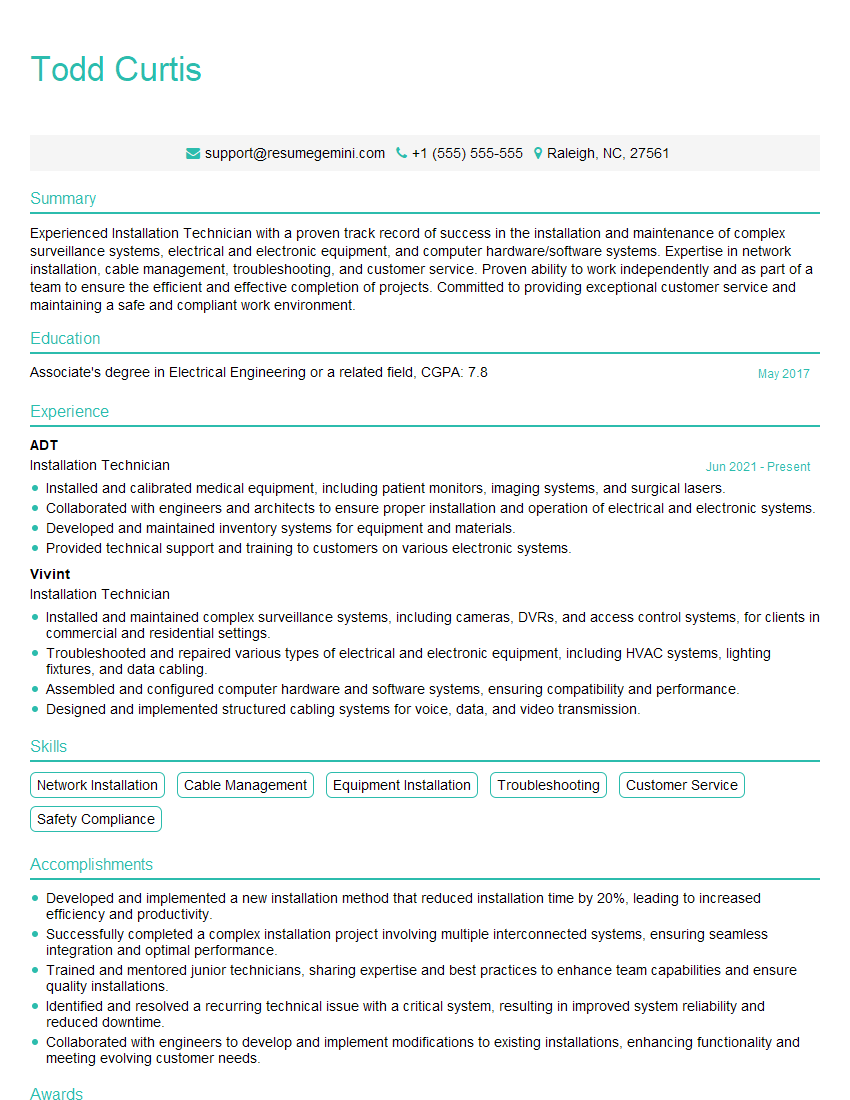

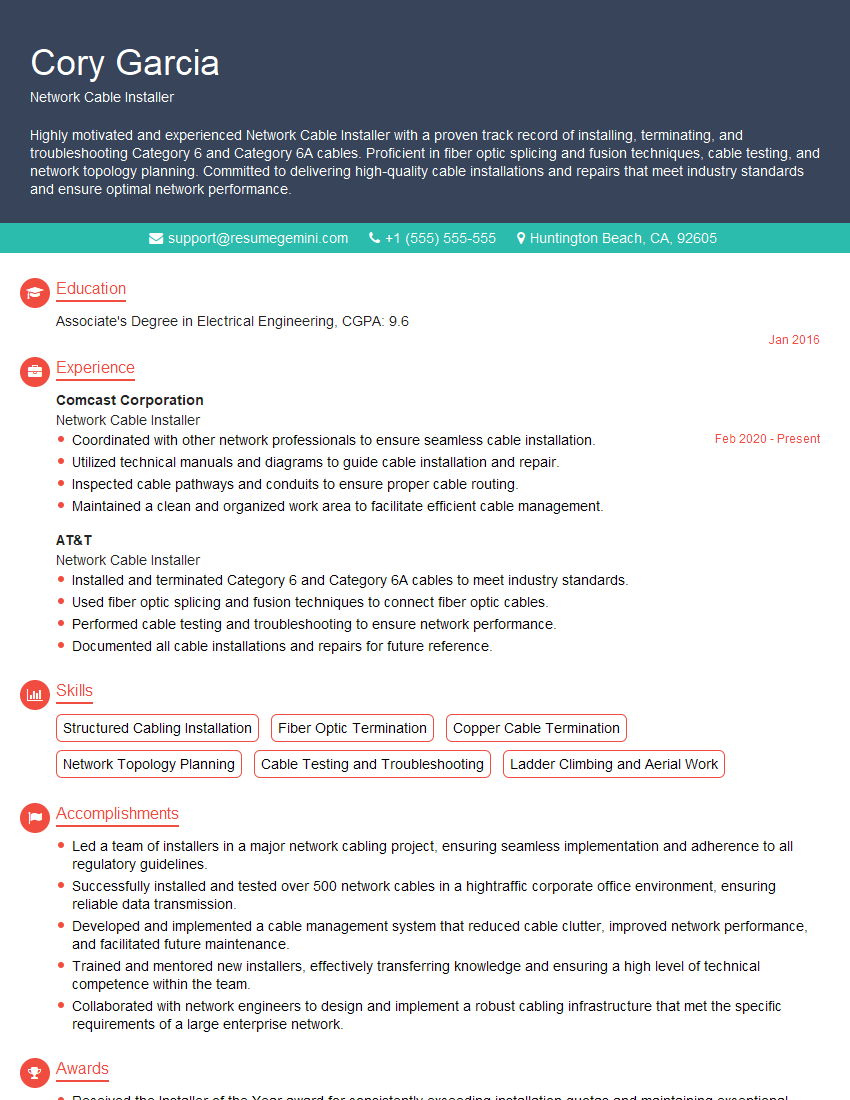

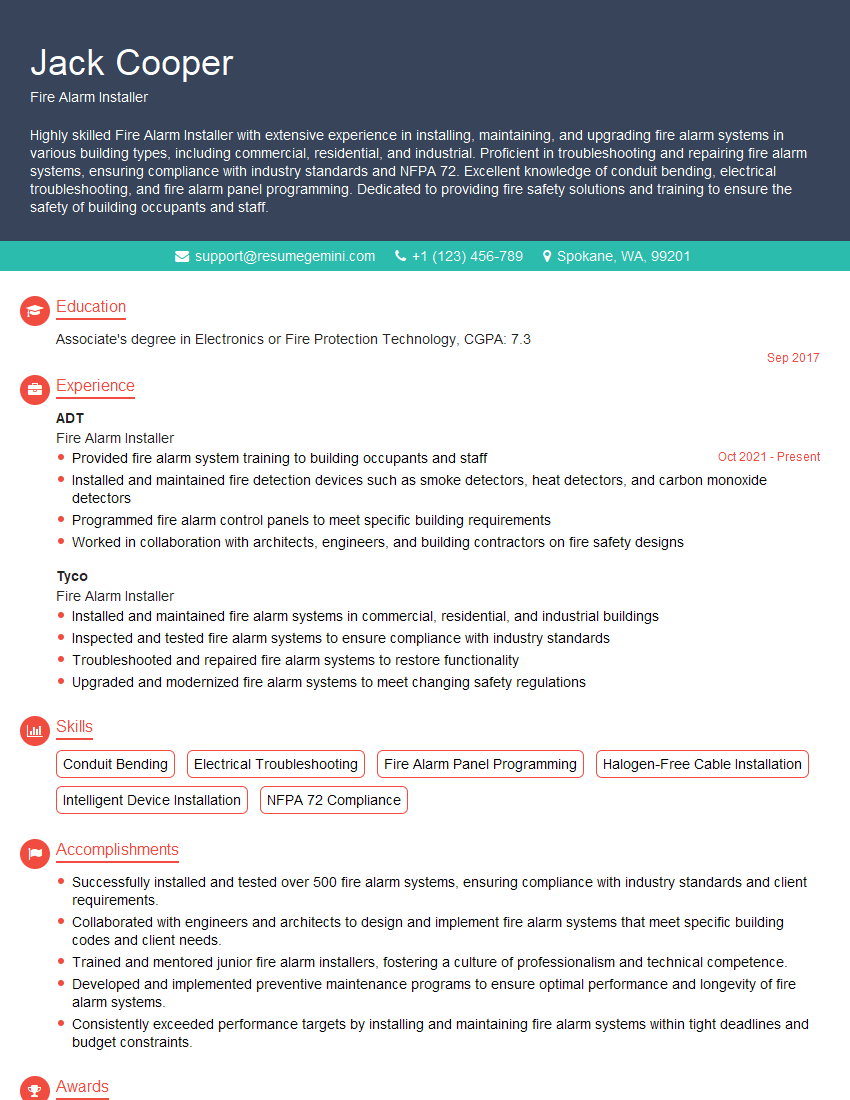

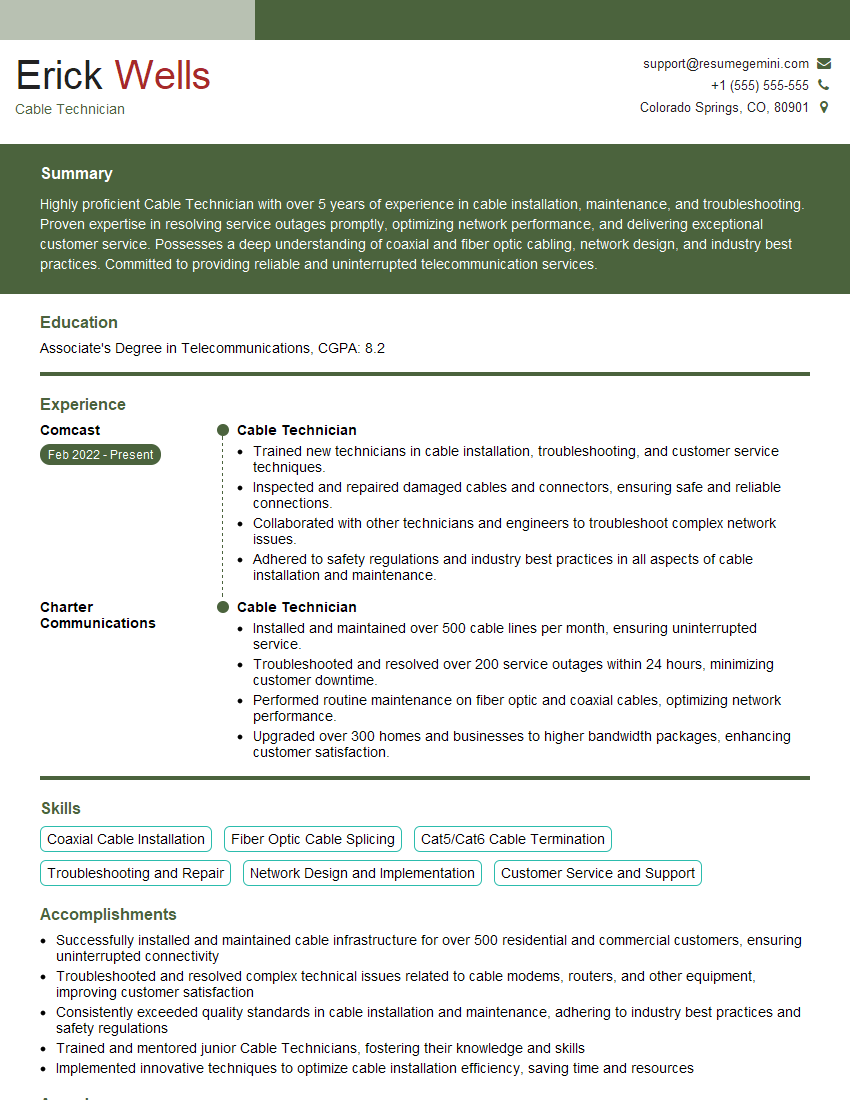

Mastering Low Voltage Cable Installation opens doors to rewarding careers in telecommunications, security systems, and home automation. A strong foundation in these skills significantly enhances your job prospects and allows you to pursue advanced roles and higher earning potential. To maximize your chances of landing your dream job, it’s vital to create a resume that effectively showcases your qualifications to Applicant Tracking Systems (ATS). ResumeGemini is a trusted resource to help you build a professional, ATS-friendly resume that highlights your skills and experience. We provide examples of resumes tailored to Low Voltage Cable Installation to help guide you in creating your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good