Unlock your full potential by mastering the most common Maintain and troubleshoot equipment interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Maintain and troubleshoot equipment Interview

Q 1. Describe your experience with preventative maintenance procedures.

Preventative maintenance (PM) is all about proactively addressing potential equipment failures before they happen. It’s like getting regular check-ups at the doctor – much better than waiting for a heart attack! My experience spans various industries, including manufacturing and industrial automation. I’ve developed and implemented PM schedules for a wide range of equipment, from conveyor belts and robotic arms to complex PLC-controlled machinery. This involves creating detailed checklists specifying tasks like lubrication, cleaning, inspections, and component replacements, based on manufacturer recommendations and historical data. For instance, I implemented a PM schedule for a packaging line that reduced downtime by 30% in the first year by catching and fixing minor issues before they escalated into major breakdowns. My approach includes using CMMS software to schedule tasks, track completion, and generate reports to optimize maintenance intervals based on real-world data. It’s about understanding the equipment’s lifecycle and identifying potential failure points before they cause significant disruption.

Q 2. Explain your troubleshooting methodology when dealing with equipment malfunctions.

My troubleshooting methodology follows a structured approach, akin to a detective solving a case. It starts with gathering information: observing the malfunction, interviewing operators, checking error logs (if available), and reviewing historical maintenance records. Then, I systematically isolate the problem, employing techniques like visual inspection, testing individual components, and using diagnostic tools (multimeters, oscilloscopes etc.). I use a process of elimination, ruling out possible causes one by one. Documentation is critical at each step; clear and concise notes help others understand my process, and I can reference them later if the issue recurs. A recent example involved a sudden shutdown of a CNC machine. By systematically checking power supplies, control signals, and ultimately the machine’s controller, I pinpointed a faulty circuit board. Replacing the board restored functionality quickly, minimizing downtime. It’s essential to avoid jumping to conclusions; a methodical approach ensures the root cause is addressed, preventing repeated failures.

Q 3. How do you prioritize maintenance tasks in a high-pressure environment?

Prioritizing maintenance tasks in high-pressure environments requires a structured approach combining urgency and criticality. I use a risk-based prioritization system, ranking tasks based on the potential impact of failure and the likelihood of occurrence. Critical equipment with high failure consequences receives top priority, even if the maintenance task itself isn’t complex. For example, a malfunctioning safety system would always trump a less critical maintenance task, regardless of the schedule. I employ CMMS systems to visualize the work orders and their associated risks, facilitating clear decision-making. This requires good communication with operational teams to understand their immediate needs and concerns, ensuring alignment between maintenance and production goals. Flexible scheduling and efficient resource allocation are vital in these situations. Sometimes, this means re-allocating resources to address urgent issues, while maintaining the broader PM schedule as much as possible.

Q 4. What are your experience with different types of maintenance (preventive, predictive, corrective)?

My experience encompasses all three maintenance types: preventative, predictive, and corrective. Preventive maintenance, as discussed earlier, focuses on preventing failures. Predictive maintenance leverages data and technology (vibration analysis, infrared thermography) to predict potential failures before they occur, allowing for proactive intervention. Corrective maintenance addresses failures after they happen. Each type plays a crucial role. Preventive maintenance forms the backbone of a robust maintenance program, while predictive maintenance enhances its effectiveness, reducing unexpected downtime and optimizing resource allocation. Corrective maintenance is unavoidable; however, a strong preventative and predictive program minimizes its frequency. I’ve successfully integrated all three into comprehensive maintenance strategies in different settings, leading to significant improvements in equipment reliability and operational efficiency.

Q 5. How familiar are you with CMMS (Computerized Maintenance Management Systems)?

I’m highly familiar with CMMS (Computerized Maintenance Management Systems). My experience includes using various CMMS platforms to manage work orders, track maintenance activities, schedule PM tasks, manage inventory, and generate reports. I understand how to configure and customize these systems to meet specific needs. For example, I used a CMMS to implement a preventative maintenance program for a large manufacturing facility, resulting in a 25% reduction in unplanned downtime within six months. The software enabled efficient scheduling, parts management, and data analysis, leading to better decision-making and improved resource allocation. I am also adept at using CMMS data to identify trends, predict potential issues, and optimize maintenance strategies. Proficiency in CMMS is essential for efficient and data-driven maintenance management.

Q 6. Describe a time you successfully diagnosed and repaired a complex equipment failure.

One particularly challenging case involved a critical piece of process equipment experiencing intermittent shutdowns. Initial troubleshooting by others focused on superficial issues, offering only temporary fixes. I employed a systematic approach, starting with thorough documentation of the error messages and operational logs. I then meticulously analyzed sensor readings, electrical schematics, and hydraulic system parameters. I discovered that the intermittent shutdowns were due to a subtle, intermittent short circuit in a wiring harness, exacerbated by vibration. This wasn’t immediately apparent through standard diagnostics. The solution involved rerouting the affected section of the wiring harness and adding vibration dampening measures. This solved the problem permanently, avoiding significant production delays and demonstrating the importance of deep root-cause analysis and a methodical approach to complex failures.

Q 7. What safety procedures do you follow when maintaining equipment?

Safety is paramount in equipment maintenance. My adherence to safety procedures is unwavering. Before starting any task, I conduct a thorough risk assessment, identifying potential hazards and developing appropriate control measures. This includes using appropriate personal protective equipment (PPE) like safety glasses, gloves, hearing protection, and steel-toe boots. I follow lockout/tagout procedures to ensure equipment is de-energized before maintenance work begins, preventing accidental starts. I’m trained in the safe handling of hazardous materials and chemicals. Regular safety training and refresher courses keep my knowledge updated on best practices. I always prioritize safe working practices, and I encourage my team to do the same. I believe that a strong safety culture is fundamental to effective and sustainable maintenance operations.

Q 8. How do you handle conflicting priorities in your maintenance tasks?

Conflicting priorities are a daily reality in maintenance. I tackle this using a prioritization matrix. First, I assess the criticality of each task, considering factors like safety risks, production downtime costs, and regulatory compliance. For example, a malfunctioning safety system takes precedence over a minor cosmetic issue. Then, I factor in urgency – how quickly a task needs completion. This allows me to categorize tasks into four quadrants: urgent and critical, important but not urgent, urgent but not critical, and neither urgent nor critical. I focus on the urgent and critical first, schedule the important but not urgent, delegate where possible (if I have a team), and potentially defer the lower-priority tasks. Regular communication with supervisors and stakeholders is key to ensure everyone understands the prioritization and any potential delays.

For example, if we have a critical pump failure impacting a production line and a scheduled preventative maintenance task on a less critical machine, the pump repair will undoubtedly take priority. I’ll communicate the delay of the preventative maintenance, perhaps rescheduling it for a less busy period to minimize disruption.

Q 9. What are your experience with hydraulic and pneumatic systems?

I have extensive experience with both hydraulic and pneumatic systems, encompassing troubleshooting, maintenance, and repair. My experience with hydraulic systems includes diagnosing leaks using pressure gauges and dye testing, identifying faulty components like pumps, valves, and cylinders, and performing repairs including seal replacements and hose replacements. I’m familiar with different types of hydraulic fluids and their properties, and understand the importance of maintaining proper fluid levels and cleanliness.

With pneumatic systems, I’m adept at troubleshooting air leaks using specialized leak detectors, diagnosing problems with compressors, valves, actuators, and air treatment equipment. I understand the principles of pneumatic control circuits and can read and interpret pneumatic schematics. I’ve worked extensively on systems utilizing different types of pneumatic actuators, including linear cylinders and rotary actuators. In both hydraulic and pneumatic systems, I prioritize safety by following lock-out/tag-out procedures and adhering to all relevant safety regulations.

Q 10. How proficient are you in using diagnostic tools and equipment?

I’m highly proficient in using a wide range of diagnostic tools and equipment. This includes multimeters for electrical testing, oscilloscopes for analyzing waveforms, infrared cameras for detecting thermal anomalies (such as overheating components), vibration analyzers for detecting mechanical problems, and pressure gauges for hydraulic and pneumatic systems. I’m also experienced using specialized software for data acquisition and analysis, and can interpret data from various sensors to pinpoint the root cause of equipment malfunctions.

For instance, if a motor is failing, I would use a multimeter to check for voltage and current, an oscilloscope to analyze the motor’s waveform for irregularities, and a thermal camera to check for overheating. The combination of these diagnostic tools enables a thorough assessment and helps in identifying the precise issue – whether it’s a motor winding fault, a bearing problem, or a power supply issue.

Q 11. Describe your experience with electrical troubleshooting.

My electrical troubleshooting experience spans various aspects, from diagnosing simple circuit problems to troubleshooting complex PLC (Programmable Logic Controller) systems. I’m comfortable working with AC and DC circuits, understanding electrical schematics, and utilizing appropriate safety procedures. I’m proficient in using multimeters to check voltage, current, and resistance, and in tracing wires to identify breaks or shorts. Furthermore, I possess experience in troubleshooting motor control circuits, including starters, contactors, and overload relays. In PLC troubleshooting, I’m skilled in using programming software to diagnose faults in the logic, and in using diagnostic tools provided by the PLC manufacturer.

I remember once troubleshooting a production line shutdown caused by a faulty motor starter. Using a multimeter, I quickly identified a blown fuse, which was easily replaced. This prevented significant downtime and highlighted the importance of proactive maintenance and the effectiveness of basic diagnostic techniques.

Q 12. How do you manage your workload effectively?

Effective workload management is crucial. I use several strategies. First, I prioritize tasks as described earlier. Second, I create detailed daily or weekly schedules, breaking down larger tasks into smaller, manageable steps. Third, I utilize task management software or tools to track progress, set deadlines, and allocate time efficiently. I also proactively communicate with my team and supervisors to ensure that expectations are clear and that any potential bottlenecks are addressed promptly. This collaborative approach promotes efficiency and helps prevent unexpected delays.

For instance, if I have a major overhaul scheduled, I’ll break it down into stages: planning, parts procurement, disassembly, repair, reassembly, testing, and documentation. Each stage gets its own timeline and associated tasks, making the overall project more manageable and less daunting.

Q 13. How do you stay updated with the latest technologies in equipment maintenance?

Staying current with the latest technologies is vital. I regularly attend industry conferences and workshops, participate in online courses and webinars focused on equipment maintenance and new technologies, and actively read industry publications and journals. I also leverage online resources such as manufacturer websites and technical forums to access the latest information on troubleshooting techniques and best practices. Moreover, I encourage knowledge sharing within my team, fostering a culture of continuous learning and improvement.

For example, I recently completed a course on predictive maintenance using vibration analysis software. This new skill allows us to detect potential equipment failures before they occur, minimizing downtime and improving overall equipment effectiveness.

Q 14. Explain your understanding of root cause analysis.

Root cause analysis (RCA) is a systematic approach to identifying the underlying causes of problems, not just the symptoms. I typically use the ‘5 Whys’ technique – repeatedly asking ‘Why?’ to drill down to the root cause. Other methods I employ include fault tree analysis (FTA) which visually represents potential failure causes and their relationships, and fishbone diagrams (Ishikawa diagrams) which help brainstorm potential causes grouped by category (people, methods, materials, machines, environment, measurement). The goal is to move beyond simply fixing the immediate problem to preventing recurrence.

Imagine a conveyor belt stopping. The immediate problem is the belt’s stopped. The first ‘why’ might be ‘because the motor is not running.’ The second ‘why’ might be ‘because the circuit breaker tripped.’ The third ‘why’ might be ‘because of an overload.’ The fourth ‘why’ might be ‘because of an excessive load on the belt.’ The fifth ‘why’ might be ‘because of a buildup of material causing friction and excessive load.’ This final ‘why’ reveals the root cause, which could involve improving material handling procedures or adding a safety mechanism to prevent material buildup.

Q 15. How familiar are you with different types of sensors and their applications?

My familiarity with sensors is extensive, encompassing various types and their applications in industrial settings. I’m proficient in working with sensors across diverse technologies. For instance, I’ve extensively used photoelectric sensors for object detection in automated assembly lines, where they precisely trigger actions based on light beam interruption. Proximity sensors, both inductive and capacitive, are crucial in my work for detecting the presence of objects without physical contact; this is vital for preventing collisions in robotic systems or ensuring safety in machinery. I’m also experienced with temperature sensors (thermocouples, RTDs) for monitoring equipment operating temperatures and preventing overheating, and pressure sensors for managing fluid systems and detecting leaks or pressure drops. My experience also includes working with flow sensors to monitor fluid movement in pipelines and level sensors to detect the level of liquids or solids in tanks.

Understanding the nuances of each sensor type – their strengths, weaknesses, and calibration requirements – is critical. For example, the choice between an inductive and capacitive proximity sensor depends heavily on the material properties of the object being detected. Similarly, selecting the right temperature sensor depends on the temperature range and accuracy requirements. I’m well-versed in selecting, installing, troubleshooting, and calibrating these various sensors to ensure optimal system performance and reliability.

Career Expert Tips:

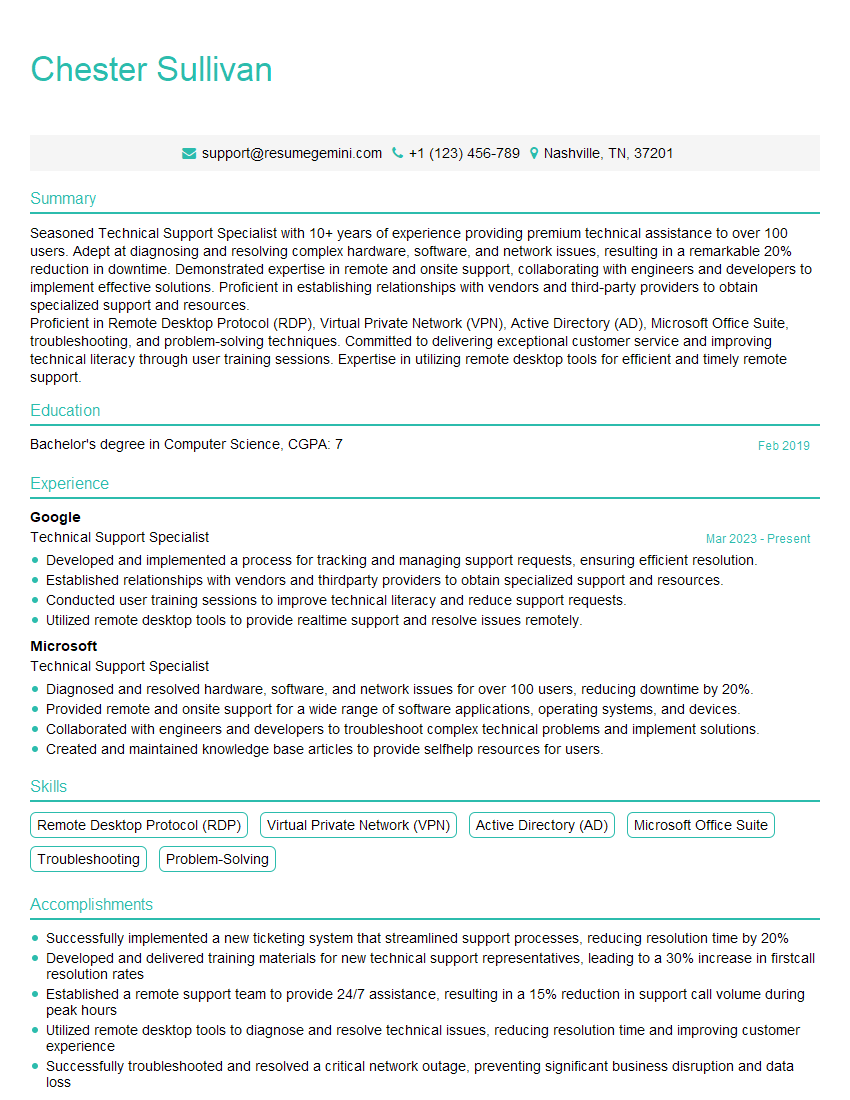

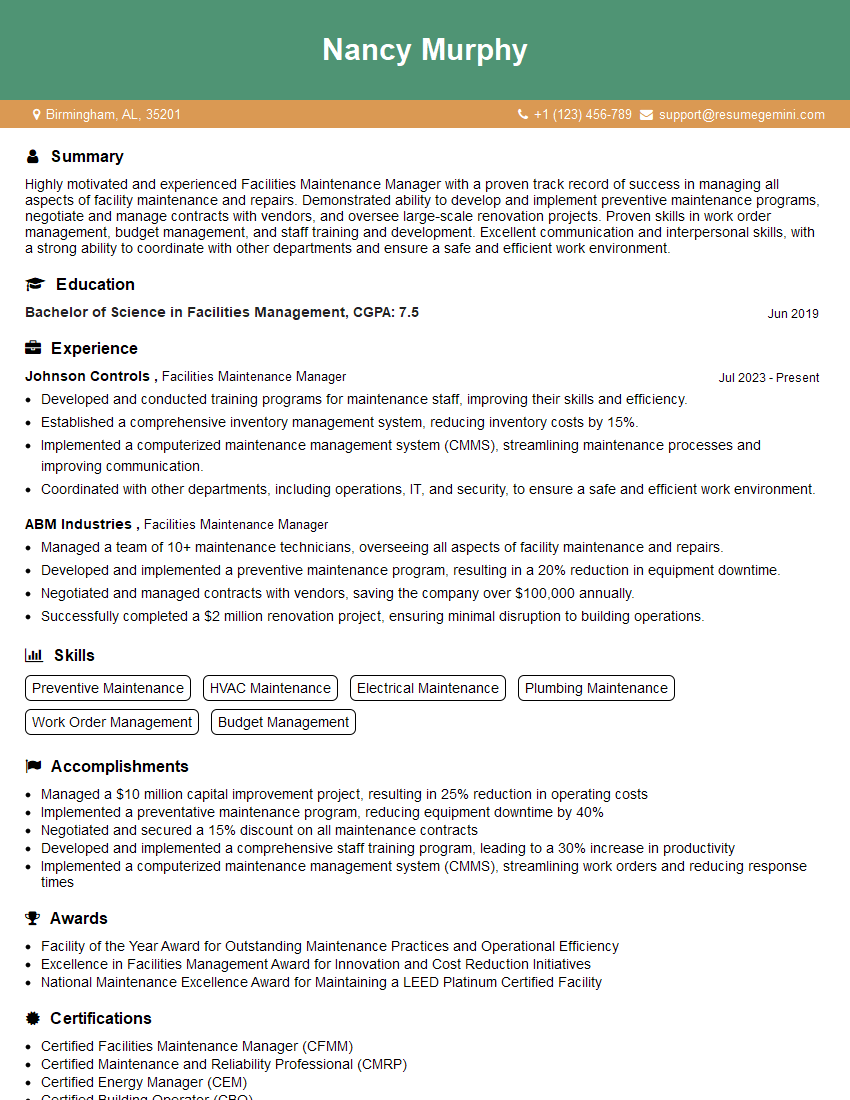

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with PLC programming and troubleshooting.

I possess significant experience in PLC programming and troubleshooting, primarily using Allen-Bradley and Siemens PLCs. My expertise includes designing, implementing, and debugging PLC programs for various industrial automation applications. This involves working with ladder logic, function block diagrams, and structured text. For example, I’ve developed PLC programs to control complex manufacturing processes, including automated assembly lines, robotic systems, and material handling systems.

Troubleshooting PLCs requires a systematic approach. My strategy involves carefully examining the PLC program for logical errors, checking input and output signals, and using diagnostic tools to isolate the problem. One memorable instance involved a production line shutdown due to a faulty sensor. By systematically tracing the signals back from the output to the input, I identified a miswired sensor, quickly resolving the issue and minimizing production downtime. I am also skilled in using various diagnostic tools including monitoring software to inspect PLC communication and program execution.

Example Ladder Logic Code Snippet (Illustrative): //IF Sensor_1 IS ON THEN Conveyor_1 Starts //XIC Sensor_1 OTE Conveyor_1 Q 17. How do you document your maintenance activities?

My maintenance documentation follows a rigorous and standardized format to ensure clarity and traceability. I utilize a Computerized Maintenance Management System (CMMS), which allows for detailed record-keeping. Each maintenance activity is documented with a unique identification number, a clear description of the work performed, the date and time of the task, the equipment involved, parts used (with serial numbers if applicable), and the technician’s signature. I also include preventative maintenance schedules for each piece of equipment and use a checklist to make sure every point is covered. Photographs and videos are frequently included to document the equipment’s condition before, during, and after maintenance. Furthermore, any unusual observations or problems encountered are meticulously recorded, which aids in future troubleshooting and identifying potential equipment failures.

Q 18. What are your experience with welding and fabrication?

My experience with welding and fabrication is substantial. I’m proficient in various welding techniques, including MIG, TIG, and stick welding, and I’m comfortable working with different materials such as steel, aluminum, and stainless steel. I’ve undertaken numerous projects involving the fabrication of custom components, repair of damaged equipment, and modification of existing structures. For example, I once fabricated a custom support structure for a conveyor system using MIG welding, ensuring both structural integrity and alignment precision.

Beyond welding, my fabrication skills encompass cutting, grinding, drilling, and the use of various hand and power tools. I understand the importance of safety protocols in these processes, consistently adhering to safety standards and wearing appropriate personal protective equipment (PPE). This blend of welding and fabrication skills is invaluable in resolving equipment malfunctions that demand on-site fabrication of replacement parts or modifications to existing equipment.

Q 19. How do you ensure the accuracy of your maintenance records?

The accuracy of maintenance records is paramount. To ensure accuracy, I use a multi-pronged approach. First, I employ a detailed checklist for each task, minimizing the chance of errors or omissions. Second, I cross-reference information from different sources whenever possible – for example, comparing sensor readings with maintenance logs. Third, regular audits of the records are conducted to ensure consistency and identify potential discrepancies. Finally, the CMMS itself has built-in checks and balances to maintain data integrity. Any corrections or updates to records are documented with explanations, maintaining a complete audit trail. This meticulous process guarantees the reliability and accuracy of the information, which is critical for efficient maintenance scheduling, budgeting, and compliance.

Q 20. What is your experience with inventory management for maintenance parts?

My experience with inventory management for maintenance parts involves utilizing a CMMS to track parts, their location, and their usage history. I participate in regular inventory audits to ensure that the recorded quantities match the physical inventory. I work closely with procurement to manage stock levels, minimizing storage costs while avoiding stockouts that can lead to equipment downtime. We use a combination of methods including Minimum/Maximum levels and Just-in-Time (JIT) inventory systems depending on the criticality and usage frequency of a particular part. This system allows for accurate forecasting of future needs and optimizes procurement strategies.

For critical parts, we have a system for expedited ordering to minimize downtime in case of unexpected failure. A well-managed inventory system directly reduces costs by preventing unnecessary purchases, reducing storage requirements, and minimizing downtime due to stockouts. Regular analysis of parts usage helps to identify opportunities for cost savings or streamlining of the procurement process.

Q 21. How do you collaborate with other team members to ensure efficient maintenance operations?

Effective collaboration is vital for efficient maintenance operations. I actively participate in team meetings to discuss upcoming tasks, share information about equipment issues, and coordinate work schedules. I utilize the CMMS to communicate with other team members, assigning tasks, updating progress, and sharing relevant documentation. Open communication is key; I ensure everyone is informed about potential disruptions or changes in plans. I’m always willing to assist colleagues, sharing my knowledge and expertise to solve problems collaboratively. A team approach ensures that maintenance tasks are completed efficiently and effectively, minimizing downtime and maximizing equipment uptime.

Constructive feedback is essential; I actively seek feedback from my colleagues and provide feedback in return, aiming for continuous improvement. This collaborative approach fosters a positive and supportive work environment, resulting in higher quality maintenance and greater overall efficiency.

Q 22. Describe your experience with interpreting technical drawings and schematics.

Interpreting technical drawings and schematics is fundamental to effective equipment maintenance. It’s like having a blueprint for the machine – understanding it allows for accurate troubleshooting and repair. My experience spans various types, from basic isometric drawings showing overall equipment layout, to complex electrical schematics detailing wiring diagrams and control systems, and even detailed exploded views showing individual component assemblies.

For instance, when troubleshooting a malfunctioning conveyor belt system, I’d first consult the schematic to trace the power supply, identify the motor control circuit, and locate any sensors or safety interlocks. This allows me to systematically check each component, eliminating potential failure points. I’m proficient in using CAD software to view and manipulate these drawings, and I’m comfortable interpreting various symbology standards used across different industries. I regularly use my knowledge of blueprint reading to prevent mistakes and ensure repairs are carried out safely and correctly, optimizing downtime and maintenance costs.

Q 23. How do you handle situations where you don’t know the solution to a problem?

When faced with an unfamiliar problem, my approach is systematic and collaborative. Think of it like solving a detective mystery. First, I gather as much information as possible – observing the equipment’s behavior, reviewing maintenance logs, and discussing the issue with colleagues. I then leverage online resources, technical manuals, and even manufacturer support to research potential causes.

If the problem persists, I don’t hesitate to escalate the issue to a senior technician or engineer. This isn’t about admitting defeat; it’s about ensuring the problem gets resolved efficiently and effectively. In fact, many of my most significant learning experiences have stemmed from these collaborative problem-solving sessions. The goal is always to gain knowledge and improve my skillset, ultimately enhancing my ability to tackle future challenges independently.

Q 24. How do you prioritize safety in your maintenance practices?

Safety is paramount in equipment maintenance. It’s not just a policy; it’s a mindset. My approach to safety is proactive, not reactive. Before starting any task, I conduct a thorough risk assessment, identifying potential hazards and implementing appropriate control measures. This includes using lockout/tagout procedures (LOTO) to de-energize equipment, wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection, and ensuring the work area is clear of obstructions.

For example, before working on a high-voltage electrical panel, I would always follow the strict LOTO procedures, verify the absence of power with a multimeter, and double-check with a colleague before starting any work. I also emphasize teamwork and communication; if I see a colleague taking unnecessary risks, I’ll intervene and correct them. Safety isn’t just my responsibility; it’s everyone’s responsibility.

Q 25. What are your experience with different types of machinery (e.g., pumps, motors, compressors)?

My experience encompasses a wide range of machinery, including pumps (centrifugal, positive displacement), various types of electric motors (AC, DC, servo), and air compressors (reciprocating, screw, centrifugal). I’m familiar with their operation, common failure modes, and preventative maintenance procedures. For example, I’ve extensively worked on troubleshooting problems in centrifugal pumps, ranging from seal leaks to cavitation issues, using my understanding of fluid dynamics and pump curves to diagnose the problem. Similarly, I’m comfortable diagnosing electrical faults in AC motors using multimeter readings and performing motor winding resistance tests.

I have also worked extensively with hydraulic and pneumatic systems, understanding their components (cylinders, valves, actuators), and troubleshooting techniques. My practical experience includes performing predictive maintenance using vibration analysis techniques, thermal imaging, and oil analysis to detect potential problems before they cause significant downtime. This proactive approach saves costs and improves system reliability.

Q 26. How do you manage your time effectively during maintenance tasks?

Effective time management during maintenance tasks is crucial for maximizing efficiency and minimizing downtime. I use a combination of techniques, including planning, prioritization, and execution. Before commencing a task, I create a detailed work plan, breaking down the job into smaller, manageable steps. This includes gathering necessary tools and materials beforehand to avoid delays. I prioritize tasks based on their urgency and impact, focusing first on critical issues that could affect production.

For example, if a critical pump fails, that takes priority over a less urgent preventative maintenance task. I also track my progress, using checklists and reporting systems to ensure adherence to schedules and identify potential bottlenecks. Using standardized procedures and proper documentation further streamlines my workflow, leading to greater efficiency in my maintenance operations.

Q 27. Describe your experience with regulatory compliance and safety standards.

I’m thoroughly familiar with various regulatory compliance and safety standards relevant to equipment maintenance, such as OSHA (Occupational Safety and Health Administration), NFPA (National Fire Protection Association), and industry-specific regulations. I ensure all work is carried out in strict adherence to these regulations, following established safety procedures and using appropriate documentation. This includes maintaining detailed maintenance logs, ensuring proper labeling of equipment, and participating in safety training programs.

For example, my experience includes working in environments with hazardous materials, where I’ve strictly adhered to safety protocols related to handling, storage, and disposal. This awareness extends to ensuring all equipment inspections, repairs, and calibrations are properly documented and compliant with regulatory requirements. My commitment is to maintain a safe and efficient work environment that adheres to all relevant safety and compliance regulations.

Q 28. What are your long-term career goals related to equipment maintenance?

My long-term career goals involve becoming a recognized expert in industrial equipment maintenance, possibly specializing in predictive maintenance techniques using advanced technologies like IoT sensors and AI-powered diagnostic tools. I aspire to lead a team of maintenance professionals, mentoring and training others, and contributing to the development of innovative maintenance strategies that improve efficiency, safety, and overall equipment reliability. I’m also interested in pursuing certifications and advanced training to stay abreast of the latest technologies and best practices in the field.

Ultimately, I aim to make a significant contribution to optimizing industrial operations through reliable and sustainable equipment maintenance practices. This involves a continuous pursuit of knowledge, innovation, and teamwork, all while maintaining the highest safety standards.

Key Topics to Learn for Maintain and Troubleshoot Equipment Interview

- Preventive Maintenance Schedules: Understanding the importance of routine maintenance, developing and implementing effective schedules, and recognizing the impact of preventative measures on equipment lifespan and operational efficiency.

- Troubleshooting Methodologies: Applying systematic approaches to diagnose equipment malfunctions, including using diagnostic tools, interpreting error codes, and isolating faulty components. Practical application includes describing your experience with specific troubleshooting techniques on different types of equipment.

- Safety Procedures and Regulations: Demonstrating knowledge of relevant safety protocols, lockout/tagout procedures, and compliance with industry standards. This includes explaining how you prioritize safety in your maintenance work.

- Equipment-Specific Knowledge: Thorough understanding of the equipment you’ve maintained, including its operational principles, common failure points, and required maintenance tasks. Be prepared to discuss specific equipment types and your experience with them.

- Record Keeping and Documentation: Maintaining accurate and detailed records of maintenance activities, repairs, and parts used. This demonstrates organizational skills and accountability.

- Repair and Replacement Techniques: Demonstrating proficiency in repairing or replacing faulty components, using appropriate tools and techniques, and ensuring proper functionality after repairs.

- Cost-Effectiveness and Optimization: Highlighting your ability to minimize downtime, reduce repair costs, and optimize maintenance strategies to improve overall efficiency.

- Communication and Teamwork: Describing your experience collaborating with colleagues, reporting maintenance issues, and communicating effectively with supervisors or clients.

Next Steps

Mastering the art of maintaining and troubleshooting equipment is crucial for career advancement in many fields. Proficiency in this area demonstrates valuable skills such as problem-solving, technical expertise, and a commitment to safety and efficiency. To significantly boost your job prospects, it’s essential to create a resume that effectively communicates your abilities to Applicant Tracking Systems (ATS). ResumeGemini is a trusted resource that can help you craft a compelling and ATS-friendly resume highlighting your relevant experience and skills. Examples of resumes tailored to the “Maintain and troubleshoot equipment” field are available within ResumeGemini to help guide you. Take the next step in your career journey – invest in building a powerful resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good