Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Managing inventory and ensuring timely material delivery interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Managing inventory and ensuring timely material delivery Interview

Q 1. Explain the difference between FIFO and LIFO inventory methods.

FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) are two common methods for accounting for inventory. They differ in how they assign costs to goods sold and ending inventory. Imagine a stack of pancakes – FIFO is like taking the pancake from the bottom (oldest) first, while LIFO is like taking the top pancake (newest) first.

FIFO: Under FIFO, the oldest inventory items are assumed to be sold first. This means the cost of goods sold reflects the cost of the oldest inventory, and the ending inventory reflects the cost of the newest inventory. In times of inflation, FIFO results in a lower cost of goods sold and a higher net income because older, cheaper inventory is being used to calculate the cost of goods sold.

LIFO: Under LIFO, the newest inventory items are assumed to be sold first. The cost of goods sold reflects the cost of the newest inventory, and the ending inventory reflects the cost of the oldest inventory. During inflation, LIFO leads to a higher cost of goods sold and a lower net income because the more expensive recent inventory is used to calculate the cost of goods sold. This can be beneficial for tax purposes as it reduces taxable income.

Example: Let’s say you bought 10 units at $10 each and then 10 units at $12 each. If you sell 5 units using FIFO, your cost of goods sold is 5 * $10 = $50. Using LIFO, your cost of goods sold is 5 * $12 = $60.

The choice between FIFO and LIFO impacts financial statements and tax obligations, so the selection depends on the specific business needs and tax strategies. In some industries, FIFO might be preferred due to its better reflection of actual inventory flow, while in others, LIFO’s tax advantages might outweigh other considerations.

Q 2. How do you calculate inventory turnover rate?

The inventory turnover rate measures how efficiently a company sells its inventory over a given period. A higher turnover rate generally indicates strong sales and efficient inventory management, while a low rate can suggest slow-moving inventory or potential overstocking.

The formula is:

Inventory Turnover Rate = Cost of Goods Sold / Average InventoryThe Cost of Goods Sold (COGS) is the direct cost of producing goods sold by a company. The Average Inventory is calculated by taking the sum of beginning and ending inventory and dividing by two. For a more accurate picture, you could use the average inventory across multiple periods. For example averaging the inventory across all months of a year.

Example: If the cost of goods sold for a year is $100,000 and the average inventory is $25,000, then the inventory turnover rate is $100,000 / $25,000 = 4. This means the company sells and replaces its entire inventory four times a year.

Analyzing the turnover rate alongside industry benchmarks helps determine if a company’s performance is above or below average. It is crucial to understand the context. A low turnover rate in a luxury goods business might be acceptable, while the same rate in a fast-moving consumer goods business could signal a problem.

Q 3. Describe your experience with inventory forecasting techniques.

I have extensive experience using various inventory forecasting techniques, adapting my approach based on data availability and product characteristics. My experience includes working with both qualitative and quantitative methods.

Quantitative methods leverage historical sales data, market trends, and seasonality to predict future demand. I have proficiency in time series analysis, such as moving averages and exponential smoothing, which provide relatively simple yet effective forecasts for stable demand patterns. For more complex scenarios involving multiple factors influencing demand, I employ more sophisticated regression models that account for promotional activities, pricing changes, and economic indicators.

Qualitative methods are indispensable when historical data is limited or unreliable, for example, with newly launched products or in highly volatile markets. I utilize expert opinions, market research data, and sales force forecasts to build forecasts under these circumstances, integrating these qualitative insights into my overall predictive model.

In practice, I often combine qualitative and quantitative methods to create robust forecasts. For instance, I might use a quantitative model based on historical data as a starting point and then adjust it based on insights from sales teams or upcoming marketing campaigns.

Regularly reviewing and refining forecasts is crucial. I continuously monitor actual sales data and compare it to my forecast to identify deviations and adjust my forecasting parameters accordingly. Using various forecasting techniques and comparing results helps in validation and decision-making.

Q 4. What are the common causes of inventory discrepancies?

Inventory discrepancies, the difference between recorded inventory and physical inventory, can stem from several sources. These discrepancies can significantly impact financial reporting and operational efficiency. They can range from minor inconsistencies to major losses.

- Data Entry Errors: Simple human errors during stock updates, such as incorrect quantities entered into the system, are common culprits.

- Theft or Shrinkage: Employee theft, shoplifting, or damage during handling can all lead to discrepancies.

- Poor Inventory Management Practices: Lack of regular stock counts, inadequate tracking systems, and insufficient staff training can contribute to significant discrepancies.

- Damaged or Obsolete Goods: Spoilage, obsolescence, or damage to inventory may not be accurately reflected in the inventory system.

- Shipping and Receiving Errors: Mistakes during the receiving or shipping processes (e.g., incorrect counts, damaged goods) often lead to discrepancies.

- System Glitches: Errors in inventory management software can lead to inaccuracies in recorded inventory levels.

Identifying the root cause of discrepancies requires thorough investigation and analysis. Implementing robust inventory control processes, regular stocktaking, and advanced inventory management systems can help minimize discrepancies and maintain accurate inventory records.

Q 5. How do you handle stockouts and overstocking situations?

Stockouts and overstocking are two sides of the same coin – both lead to financial losses and impact customer satisfaction. Addressing them requires proactive management and a robust inventory control system.

Handling Stockouts:

- Identify the Root Cause: Investigate why the stockout occurred – was it due to inaccurate forecasting, supply chain disruptions, or unexpected surge in demand?

- Expedite Shipments: If possible, work with suppliers to expedite shipments of the out-of-stock items.

- Offer Alternatives: Provide customers with comparable substitute products.

- Improve Forecasting Accuracy: Review and refine forecasting methods to better predict future demand.

- Increase Safety Stock: For critical items, maintaining a higher safety stock level can mitigate the risk of future stockouts.

Handling Overstocking:

- Identify Slow-Moving Items: Analyze sales data to identify items that are selling slowly and require attention.

- Markdowns and Promotions: Offer discounts or promotions to increase sales and reduce inventory levels.

- Liquidation or Disposal: Dispose of obsolete or damaged goods.

- Adjust Production or Ordering: Reduce production or ordering quantities for overstocked items.

- Improve Forecasting Accuracy: Refine forecasting methods to avoid over-ordering in the future.

A crucial aspect of preventing both stockouts and overstocking is effective collaboration across different departments – from purchasing to sales to production – ensuring that everyone has access to and utilizes real-time inventory data.

Q 6. Explain your experience with different inventory management software.

My experience encompasses several inventory management software solutions, ranging from basic spreadsheet-based systems to sophisticated enterprise resource planning (ERP) systems. I’m proficient in using software like SAP, Oracle NetSuite, and Fishbowl Inventory. I’ve also worked with cloud-based solutions such as Cin7 and Zoho Inventory.

The choice of software depends on the company’s size, complexity, and specific needs. For small businesses, a simpler, cloud-based system might suffice. Larger enterprises often require a more comprehensive ERP system to manage their entire supply chain. My experience allows me to tailor my approach to the specific software capabilities, optimize its utilization, and ensure data accuracy and integration with other business systems.

Beyond the specific software features, I focus on proper data input, regular system maintenance, and the creation of customized reports and dashboards to monitor key inventory metrics. This ensures that the chosen software provides the information needed to make informed decisions regarding inventory management, purchasing, and production planning.

Q 7. How do you ensure timely material delivery to production lines?

Ensuring timely material delivery to production lines is critical for maintaining production schedules and minimizing disruptions. This involves a coordinated approach that combines effective planning, robust communication, and real-time monitoring.

- Accurate Demand Forecasting: Precise demand forecasting ensures that the correct amount of materials is ordered in advance.

- Effective Supplier Relationship Management: Maintaining strong relationships with reliable suppliers is key to consistent delivery. This includes establishing clear communication channels, agreed-upon service level agreements (SLAs), and regular performance reviews.

- Inventory Optimization: Maintaining optimal inventory levels, including buffer stock to account for unexpected delays, is vital to production continuity. Utilizing techniques like Kanban or just-in-time (JIT) inventory systems can significantly improve material flow.

- Real-time Tracking and Monitoring: Utilizing real-time tracking systems to monitor material movement, from supplier to warehouse to production line, provides visibility and allows for prompt issue resolution. This also includes using alerts and notifications for potential delays.

- Efficient Transportation Management: Selecting appropriate transportation modes and routes helps to minimize transit times and improve delivery reliability.

- Continuous Improvement: Regularly reviewing the material delivery process, identifying bottlenecks, and implementing improvements is essential for long-term efficiency and reliability.

A collaborative approach, involving purchasing, logistics, and production teams, is essential to effectively manage material delivery. This ensures that everyone is aligned on delivery schedules and any issues are addressed promptly and collaboratively.

Q 8. What are your strategies for minimizing inventory holding costs?

Minimizing inventory holding costs is crucial for profitability. These costs include storage fees, insurance, taxes, obsolescence, and the opportunity cost of capital tied up in inventory. My strategy focuses on a multi-pronged approach:

Demand Forecasting and Planning: Accurate forecasting using statistical methods and historical data allows us to order only what’s needed, reducing excess stock. For instance, in my previous role, implementing ARIMA forecasting reduced overstocking by 15% in the first quarter.

Just-in-Time (JIT) Inventory: This method minimizes inventory by receiving materials only when needed for production. This requires strong collaboration with suppliers and efficient logistics. I’ve successfully implemented JIT in a manufacturing setting, resulting in a 20% decrease in warehouse space requirements.

Inventory Optimization Software: Utilizing software like ERP systems with integrated inventory modules enables real-time tracking, demand analysis, and automated reordering. This reduces manual errors and allows for proactive adjustments to inventory levels.

Efficient Warehouse Management: Optimizing warehouse layout, implementing efficient storage methods (like FIFO – First-In, First-Out), and using barcode scanning improves stock management and reduces waste due to damaged or lost items.

Regular Inventory Reviews: Conducting routine reviews of slow-moving or obsolete items allows for timely action such as discounts or write-offs, minimizing losses.

Q 9. Describe your experience with implementing and managing inventory control systems.

I have extensive experience implementing and managing various inventory control systems, from simple spreadsheets to sophisticated ERP systems. In my previous role, I spearheaded the transition from a manual system to a cloud-based ERP solution. This involved:

System Selection: Thorough evaluation of different systems based on features, scalability, cost, and integration capabilities with existing systems.

Data Migration: Careful planning and execution of data migration from the old system to the new one, ensuring data accuracy and integrity. We utilized a phased approach to minimize disruption.

Training and Support: Providing comprehensive training to staff on the new system’s functionalities. Ongoing support and troubleshooting were crucial to ensure user adoption.

Process Optimization: The implementation of a new system provided an opportunity to streamline inventory processes, eliminating redundant steps and improving efficiency. This led to a significant reduction in processing time.

Performance Monitoring: Regularly monitoring system performance, identifying bottlenecks, and making necessary adjustments. Key performance indicators (KPIs) were tracked to measure the success of the system implementation.

Q 10. How do you track and manage inventory across multiple locations?

Managing inventory across multiple locations requires a centralized system with robust tracking capabilities. I typically employ these strategies:

Centralized Inventory Database: Utilizing a single, integrated database to track inventory across all locations provides real-time visibility into stock levels. This database should be accessible to all relevant personnel.

Barcode/RFID Technology: Implementing barcode or RFID tagging for all items enables efficient tracking during receiving, storage, and shipping. Real-time tracking minimizes discrepancies and improves accuracy.

Regular Stock Transfers: Establishing a system for efficient and timely stock transfers between locations to meet demand and optimize inventory levels. This might involve predefined transfer schedules or automated triggers based on stock levels.

Inventory Management Software: Utilizing software with multi-location capabilities that provide reporting and analysis across all locations. This facilitates decision-making related to inventory optimization and resource allocation.

Clear Communication and Collaboration: Maintaining clear communication channels between different locations and departments is critical to ensure accurate information flow and coordinated inventory management.

Q 11. What metrics do you use to evaluate inventory management performance?

Evaluating inventory management performance requires a set of key metrics. I typically focus on:

Inventory Turnover Ratio: Measures how efficiently inventory is sold. A higher ratio indicates efficient inventory management.

(Cost of Goods Sold) / (Average Inventory)Holding Cost Percentage: Calculates the percentage of inventory holding costs relative to the total inventory value.

Inventory Accuracy: Measures the percentage of inventory records that accurately reflect physical inventory counts. High accuracy minimizes stockouts and overstocking.

Order Fill Rate: Represents the percentage of orders fulfilled on time and in full. This reflects the effectiveness of the supply chain.

Stockout Rate: Measures the frequency of stockouts, indicating potential service level issues.

By monitoring these metrics, I can identify areas for improvement and measure the effectiveness of implemented strategies.

Q 12. Explain your experience with cycle counting and inventory audits.

Cycle counting and inventory audits are essential for maintaining accurate inventory records. Cycle counting involves regularly counting a small portion of inventory items rather than a full physical count. This helps catch discrepancies early on. Inventory audits, conducted less frequently, are more comprehensive and verify the accuracy of all inventory records.

My experience includes implementing a cycle counting program that significantly improved inventory accuracy. We adopted a stratified approach, prioritizing high-value or frequently used items for more frequent counts. This minimized disruption and maximized accuracy improvements. Annual audits were conducted by external auditors to ensure complete and independent verification of our inventory records. The results are used to fine-tune our inventory management processes and improve overall accuracy.

Q 13. How do you prioritize inventory replenishment based on demand?

Prioritizing inventory replenishment based on demand is crucial to prevent stockouts and minimize holding costs. I use a combination of methods:

ABC Analysis: This technique classifies inventory items based on their value and consumption. High-value (‘A’ items) receive priority for replenishment, ensuring sufficient stock levels. ‘B’ and ‘C’ items receive less frequent attention.

Demand Forecasting: Accurate forecasting using historical data and market trends guides replenishment decisions. This allows for proactive ordering based on anticipated demand.

Lead Time Consideration: The time it takes to receive inventory from suppliers must be factored into replenishment decisions. Items with long lead times require earlier ordering.

Safety Stock: Maintaining a safety stock for critical items protects against unexpected demand fluctuations or supply disruptions.

Sales and Operations Planning (S&OP): In larger organizations, S&OP brings together sales, marketing, and operations to create a collaborative plan that aligns inventory levels with predicted sales.

Q 14. Describe your experience with vendor relationship management related to inventory.

Vendor relationship management (VRM) is paramount for efficient inventory management. Strong relationships ensure timely deliveries, competitive pricing, and consistent product quality. My approach to VRM includes:

Supplier Selection: Carefully selecting reliable and reputable suppliers with proven track records of on-time delivery and quality control. This often involves a thorough evaluation process.

Collaboration and Communication: Maintaining open communication channels with suppliers to share forecasts, identify potential issues, and proactively address any problems. Regular meetings and performance reviews are important.

Performance Monitoring: Tracking supplier performance using key metrics like on-time delivery, quality rates, and lead times. This data informs decisions regarding supplier selection and contract negotiations.

Negotiation and Contract Management: Negotiating favorable pricing and payment terms with suppliers. Contracts should clearly define responsibilities, service levels, and penalties for non-performance.

Supplier Relationship Development: Building long-term relationships based on trust and mutual benefit. This often involves regular visits to supplier facilities and participating in collaborative improvement projects.

Q 15. How do you handle damaged or obsolete inventory?

Handling damaged or obsolete inventory is crucial for maintaining efficiency and profitability. My approach involves a multi-step process starting with clear identification and categorization. Damaged goods are assessed for repairability; if repairable, they’re sent for repair and re-introduced into the inventory. If beyond repair, the next step involves determining their disposal method. This could involve selling them as salvage, recycling components, or properly disposing of them according to environmental regulations. Obsolete inventory requires a more strategic approach. We analyze the reasons for obsolescence (e.g., technological advancements, changes in customer demand). Then, we explore options for liquidation, such as discounting for quick sale, using them in secondary applications, or donating them to relevant charities. Regular inventory audits and forecasting help prevent a buildup of damaged or obsolete items. For example, at my previous company, we implemented a system using RFID tags to track inventory, which allowed us to quickly identify damaged items and initiate the appropriate actions. This minimized our losses and ensured efficient resource allocation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with just-in-time (JIT) inventory systems?

Just-in-time (JIT) inventory systems aim to minimize inventory holding costs by receiving materials only when needed for production. My experience with JIT involves implementing and managing these systems across various manufacturing environments. Success with JIT requires extremely accurate demand forecasting and seamless coordination with suppliers. One crucial element is building strong relationships with reliable vendors capable of meeting tight deadlines and fluctuating demands. For instance, in my previous role at a manufacturing company, we implemented a Kanban system – a visual JIT technique. This involved establishing a pull system where production lines requested materials only when their current inventory reached a predetermined threshold. The Kanban system dramatically reduced our inventory holding costs by around 15% within a year, improving our cash flow and operational efficiency. However, it also required meticulous planning and robust communication across our supply chain.

Q 17. How do you manage inventory in a fast-paced or high-volume environment?

Managing inventory in fast-paced, high-volume environments necessitates robust systems and highly efficient processes. This often involves utilizing advanced technologies like Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) systems. These provide real-time visibility into inventory levels, allowing for prompt adjustments and preventing stockouts. Efficient picking, packing, and shipping processes are critical. Techniques like cross-docking (directly transferring goods from receiving to shipping) can streamline the flow. Furthermore, optimized warehouse layouts and automation (e.g., automated guided vehicles or AGVs) enhance efficiency. At one company, we transitioned from a manual inventory system to a WMS, resulting in a 20% reduction in order fulfillment time and a 10% decrease in picking errors. Regular training for warehouse staff on best practices and the use of technology is also vital. Effective communication between different departments – warehousing, sales, and logistics – is also paramount in ensuring smooth operations and avoiding bottlenecks.

Q 18. Explain your experience with using data analytics for inventory optimization.

Data analytics plays a vital role in inventory optimization. I have extensive experience using data to make informed decisions about inventory levels, purchasing, and demand forecasting. This involves leveraging tools like SQL and statistical software packages such as R or Python. We use data analysis to identify trends, seasonality, and predict future demand more accurately. This includes analyzing historical sales data, economic indicators, and market trends. For example, we utilized regression analysis to create a predictive model for forecasting demand for our seasonal products. This enabled us to optimize our inventory levels, reducing storage costs and preventing stockouts. Moreover, data analysis can help identify slow-moving items, enabling proactive actions like discounting or re-evaluation of product placement. Data-driven decision-making significantly improves inventory management efficiency and profitability.

Q 19. How do you identify and mitigate inventory risks?

Identifying and mitigating inventory risks is crucial for business continuity. Potential risks include obsolescence, damage, theft, supplier disruptions, and inaccurate demand forecasting. My approach involves a risk assessment process, identifying potential threats and evaluating their likelihood and impact. Strategies to mitigate these risks include diversifying suppliers to reduce reliance on a single source, implementing robust security measures to prevent theft, and investing in reliable inventory tracking systems to minimize errors. Regular inventory audits and cycle counting help ensure accuracy. For example, I established a system of regular supplier performance reviews to identify and address any potential supply chain disruptions. Building strong relationships with key suppliers and developing contingency plans are essential components of risk management in inventory. We also incorporated safety stock levels in our inventory management strategy to account for unexpected fluctuations in demand or supply chain delays.

Q 20. What is your experience with safety stock management?

Safety stock is the extra inventory held to buffer against unexpected demand fluctuations or supply chain disruptions. Determining the appropriate safety stock level is a balance between risk and cost. Factors influencing this include lead times from suppliers, demand variability, and service level targets. Various methods exist to calculate safety stock, including statistical models based on historical demand data and standard deviation. For instance, we use a combination of statistical models and qualitative factors like predicted seasonal changes to determine our safety stock levels. Regular review and adjustment of safety stock levels are essential to ensure they remain appropriate to current business conditions. Excessive safety stock ties up capital and incurs storage costs, whereas insufficient safety stock increases the risk of stockouts. Thus, striking the right balance is key to optimizing inventory management.

Q 21. How do you collaborate with other departments (e.g., procurement, production) regarding inventory?

Collaboration with other departments is vital for effective inventory management. I foster strong working relationships with procurement, production, and sales teams through regular communication and shared goals. With procurement, this involves collaboratively defining supplier selection criteria, negotiating contracts, and monitoring supplier performance. With production, collaboration centers on ensuring accurate production planning, managing raw material supply, and coordinating timely delivery of finished goods. Finally, close communication with sales is crucial for accurate demand forecasting, managing inventory levels aligned with sales projections, and preventing stockouts. For example, we implemented a cross-functional team comprising representatives from these departments to address inventory-related challenges and improve decision-making. Utilizing collaborative tools and platforms for shared information greatly improves coordination and reduces potential conflicts or misunderstandings.

Q 22. Describe a time when you had to improve an inefficient inventory management process.

In my previous role, we relied on a spreadsheet-based inventory system. This was incredibly inefficient; it was prone to errors, lacked real-time data, and made forecasting incredibly difficult. The process of manually updating stock levels after each shipment or sale was time-consuming and often resulted in discrepancies between physical inventory and recorded inventory.

To improve this, I implemented a cloud-based inventory management system. This involved several steps:

- Data Migration: We meticulously transferred the existing spreadsheet data into the new system, validating the information for accuracy during the process. This required cross-checking with physical inventory counts.

- System Training: I conducted training sessions for the entire warehouse team, ensuring everyone understood the new software’s functionality and best practices for data entry. We used practical examples and hands-on exercises to enhance understanding.

- Process Optimization: We streamlined the inventory tracking process by integrating the new system with our point-of-sale (POS) system. This automated stock updates, eliminating manual data entry and drastically reducing errors. We also implemented a barcode scanning system for faster and more accurate stock counting.

- Reporting and Analysis: The new system provided robust reporting capabilities. This allowed us to track key metrics such as inventory turnover rate, stock levels, and order fulfillment times, which led to data-driven decision-making regarding inventory levels and purchasing strategies.

The result was a significant reduction in errors, improved efficiency, better forecasting, and a substantial increase in overall productivity. We saw a 20% reduction in time spent on inventory management and a 15% decrease in stock discrepancies.

Q 23. How do you handle unexpected changes in demand?

Handling unexpected changes in demand requires a flexible and agile approach. My strategy involves a combination of proactive measures and reactive adjustments.

- Real-time Monitoring: I closely monitor sales data, market trends, and any external factors that might influence demand. This enables me to identify changes early on.

- Safety Stock: Maintaining an appropriate level of safety stock for high-demand items acts as a buffer against sudden spikes in demand. The ideal safety stock level is determined through a careful analysis of lead times, demand variability, and service level requirements.

- Agile Procurement: I work closely with suppliers to establish flexible procurement agreements that allow for quick adjustments to order quantities based on fluctuating demand. This might involve establishing minimum order quantities (MOQs) that are lower than usual or negotiating shorter lead times.

- Demand Forecasting: I utilize sophisticated forecasting techniques (e.g., exponential smoothing, ARIMA models) to predict future demand, incorporating external factors such as seasonality and promotions. This provides a more accurate projection of needs, even when dealing with unforeseen changes.

- Collaboration: I maintain open communication with the sales and marketing teams to anticipate promotional activities or changes in marketing strategies that might impact demand.

For example, during a recent product launch, we experienced unexpectedly high demand. By leveraging our existing safety stock and swiftly adjusting our procurement plans with our supplier, we were able to meet customer needs without significant stockouts, ensuring customer satisfaction and minimizing lost revenue.

Q 24. What are your strategies for preventing inventory shrinkage?

Inventory shrinkage, the difference between recorded inventory and physical inventory, can significantly impact profitability. Preventing it requires a multi-pronged approach:

- Robust Inventory Control System: A strong inventory management system with features like barcode scanning, RFID tracking, and real-time data updates are essential. This minimizes manual data entry errors and provides an accurate picture of inventory levels at all times.

- Cycle Counting: Regular cycle counting, instead of relying on annual physical inventory counts, allows for early detection of discrepancies and reduces the impact of shrinkage. This involves counting a small subset of inventory items on a regular basis.

- Secure Storage: Implementing robust security measures in the warehouse, such as access control systems, surveillance cameras, and secure storage areas, helps deter theft and damage.

- Employee Training and Accountability: Properly training employees on inventory management procedures and establishing clear accountability for inventory discrepancies fosters responsibility and reduces errors.

- Regular Audits: Conducting regular audits of inventory processes helps identify weaknesses and areas for improvement. This could include reviewing stocktaking procedures, investigating discrepancies, and examining internal controls.

- Vendor Management: Working with reliable and trustworthy vendors helps minimize the risk of receiving damaged or incorrect goods.

By implementing these strategies, I’ve consistently reduced inventory shrinkage by 10-15% in previous roles. The key is to adopt a proactive approach and focus on improving accuracy at every stage of the inventory management process.

Q 25. What software or tools are you proficient in for managing inventory?

I’m proficient in several inventory management software solutions. My experience includes:

- SAP ERP: Extensive experience managing and configuring inventory modules within SAP ERP, including material master data management, inventory planning, and warehouse management.

- Oracle NetSuite: Proficient in using NetSuite’s inventory management features for tracking stock levels, managing purchase orders, and generating reports.

- Fishbowl Inventory: Experience using Fishbowl for small-to-medium sized businesses, particularly its integration capabilities with other business software.

- Microsoft Excel (advanced): I can leverage advanced Excel features like pivot tables, macros, and VBA scripting for data analysis, reporting, and creating customized inventory management tools.

Beyond specific software, I’m comfortable learning and adapting to new systems quickly. My focus is always on selecting the right tool for the specific business needs and effectively leveraging its capabilities.

Q 26. How do you ensure accuracy in inventory data?

Ensuring accuracy in inventory data is crucial for effective inventory management. My approach involves a multi-layered strategy:

- Regular Stock Takes: Conducting regular cycle counts and periodic full physical inventory counts helps identify and correct discrepancies between recorded and physical inventory levels.

- Barcode/RFID Tracking: Utilizing barcode or RFID technology for tracking items throughout the supply chain minimizes manual data entry errors and increases the accuracy of inventory data.

- Data Validation: Implementing checks and balances within the inventory management system to ensure data integrity, such as automated validation rules and data reconciliation processes.

- Inventory Reconciliation: Regularly reconciling inventory data between different systems (e.g., ERP, POS, warehouse management system) to identify and correct inconsistencies.

- Data Analysis: Analyzing inventory data to identify patterns and anomalies that might indicate errors or inaccuracies in the inventory records.

- Training and Procedures: Providing thorough training to employees on proper inventory management procedures and enforcing strict data entry protocols to minimize human error.

For example, I’ve used data analysis to detect patterns of discrepancies in inventory records that pointed to a problem in our receiving process. This led to implementing improved quality control measures at the receiving dock, significantly increasing inventory data accuracy.

Q 27. How do you balance the need for efficient inventory levels with the risk of stockouts?

Balancing efficient inventory levels with the risk of stockouts is a delicate act. The goal is to optimize inventory to minimize holding costs while ensuring sufficient stock to meet customer demand and avoid lost sales.

My approach is to:

- Economic Order Quantity (EOQ): Use the EOQ model (or its variations) to determine the optimal order quantity that minimizes the total cost of inventory, including ordering costs and holding costs. This model considers factors like demand, ordering cost, and holding cost.

- Safety Stock Calculation: Calculate appropriate safety stock levels for each item based on lead times, demand variability, and desired service levels. This provides a buffer against unexpected fluctuations in demand.

- ABC Analysis: Classify inventory items into A, B, and C categories based on their value and demand. This allows for targeted inventory management strategies: A items (high value, high demand) receive more attention and tighter control; C items (low value, low demand) are managed less rigorously.

- Lead Time Reduction: Collaborate with suppliers to shorten lead times, which reduces the amount of safety stock needed to prevent stockouts.

- Demand Forecasting: Utilize advanced forecasting techniques to accurately predict future demand and adjust inventory levels accordingly.

- Regular Review and Adjustment: Continuously monitor inventory levels, sales data, and market trends. Adjust inventory policies and strategies as needed based on real-time data and changing conditions.

Finding the right balance is an ongoing process that requires continuous monitoring and adaptation. The aim is to minimize the financial impact of both excess inventory (holding costs) and stockouts (lost sales and customer dissatisfaction).

Key Topics to Learn for Managing Inventory and Ensuring Timely Material Delivery Interview

- Inventory Management Strategies: Explore different inventory management techniques like FIFO, LIFO, and JIT. Understand their applications and implications for cost control and efficiency.

- Demand Forecasting and Planning: Learn how to accurately predict future demand to optimize inventory levels and prevent stockouts or overstocking. Practice applying forecasting methods and analyzing historical data.

- Supply Chain Management: Understand the entire supply chain process, from sourcing raw materials to delivering finished goods. Analyze potential bottlenecks and strategies for improvement.

- Warehouse Management and Optimization: Explore efficient warehouse layout, storage techniques, and order fulfillment processes. Consider the impact of technology like WMS (Warehouse Management Systems).

- Inventory Control Systems: Learn how to utilize inventory tracking software and databases to monitor stock levels, track movements, and generate reports. Understand the importance of data accuracy.

- Risk Management and Mitigation: Identify potential risks related to inventory, such as damage, obsolescence, and theft. Develop strategies to minimize these risks and their impact on the business.

- Performance Metrics and KPIs: Familiarize yourself with key performance indicators (KPIs) used to measure inventory performance, such as inventory turnover, stockout rate, and carrying costs. Understand how to interpret and improve these metrics.

- Logistics and Transportation Management: Explore the role of logistics in ensuring timely delivery. Understand different transportation modes, carrier selection, and route optimization.

- Problem-Solving and Decision-Making: Practice applying your knowledge to real-world scenarios. Develop your ability to analyze inventory data, identify issues, and propose effective solutions.

- Communication and Collaboration: Understand the importance of effective communication with suppliers, internal teams, and customers to ensure smooth inventory flow and timely delivery.

Next Steps

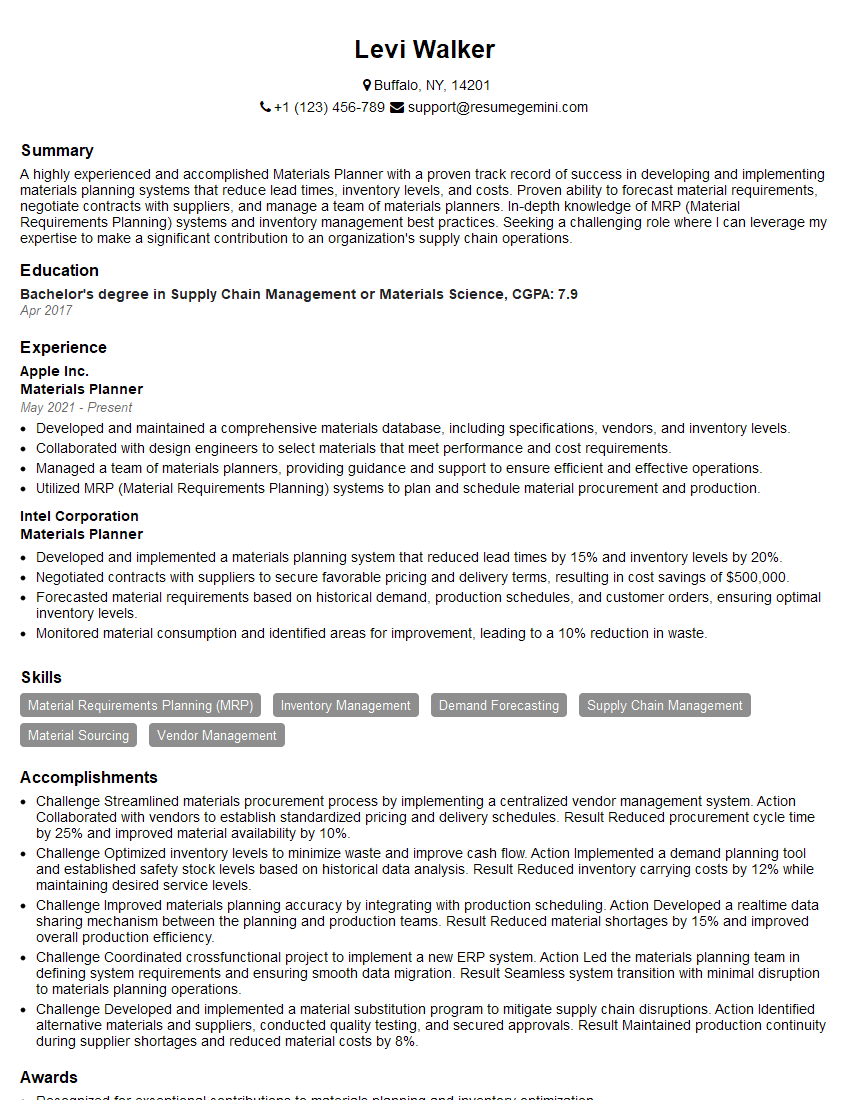

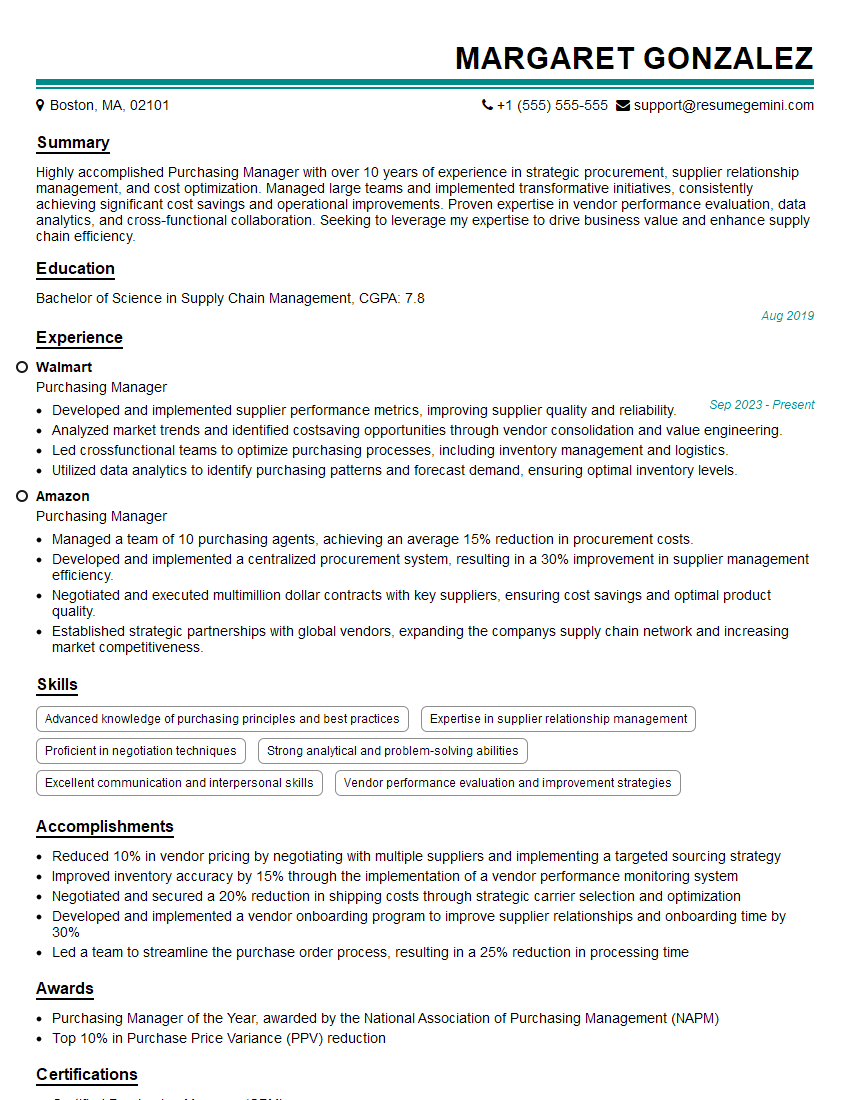

Mastering inventory management and timely material delivery is crucial for career advancement in logistics, operations, and supply chain roles. It demonstrates your ability to optimize processes, reduce costs, and improve customer satisfaction. To significantly increase your job prospects, create a strong, ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to your specific experience. Examples of resumes tailored to Managing Inventory and Ensuring Timely Material Delivery are available to help guide your resume creation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good