The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Manual excavation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Manual excavation Interview

Q 1. Describe your experience with different hand tools used in manual excavation.

My experience with hand tools in manual excavation is extensive, encompassing a wide range of tools for various tasks. Think of it like a well-equipped toolbox for a meticulous craftsman. For digging, I’m proficient with shovels (round-point for breaking up compacted soil, square-point for moving loose material), post hole diggers (ideal for precise, cylindrical holes), and picks (for breaking up rocks and hardpan). For finer work, I utilize trowels, scoops, and hand rakes for shaping and cleaning. I’m also skilled in using levels and measuring tapes to ensure accuracy and precision in the excavation.

For example, on a recent project involving the installation of fence posts, I used a post hole digger to ensure perfectly sized holes for each post, preventing any instability. The round-pointed shovel was crucial in breaking up the hard clay soil before using the digger. Finally, a hand rake ensured a neat, level surface after completing the excavation.

Q 2. What safety precautions do you take when working near underground utilities?

Safety near underground utilities is paramount. Before any excavation begins, the first step is always thorough utility marking. We call in the utility companies – gas, electric, water, sewer – to mark the location of their underground lines. These markings are essential to avoid accidental damage, which could lead to serious injury or even death. I always maintain a safe distance from marked lines, typically more than the prescribed minimum. If a line is unclear or uncertain, I err on the side of caution and contact the utility company again. Hand digging is often preferred near marked lines to reduce the risk of damage. I also ensure that all team members are aware of the utility locations and adhere to strict safety procedures.

For instance, on one job, a gas line was marked unexpectedly close to our planned excavation. Instead of proceeding, we immediately contacted the gas company for clarification and adjusted the excavation plan accordingly. This proactive approach prevented a potentially catastrophic incident.

Q 3. How do you determine the appropriate depth for an excavation?

Determining the appropriate excavation depth depends entirely on the project’s requirements. It’s not a one-size-fits-all answer. For example, a foundation needs significantly more depth than a simple post hole. The project plans or specifications clearly indicate the required depth. I use measuring tapes and levels to ensure accuracy during excavation. If the plans aren’t detailed, I often consult with the project supervisor or engineer to clarify. Understanding the soil type is crucial too; a deeper excavation may be necessary in unstable soils to achieve the required stability.

Consider planting a tree: The depth depends on the tree’s size and root system. A small sapling needs a shallower hole than a mature tree. Therefore, the specified requirements and soil conditions dictate the final depth.

Q 4. Explain the process of shoring and bracing an excavation.

Shoring and bracing are crucial for preventing cave-ins, especially in deep excavations. The process starts with assessing the soil type and the excavation’s depth. Different soil types require different shoring techniques. For example, in cohesive soils (clay), simple trench boxes might suffice. In loose, granular soils (sand), more robust shoring systems are required, such as sheet piling or soldier piles with lagging.

The process typically involves installing the shoring system – whether it’s vertical supports, horizontal beams, or a combination – before excavation reaches a significant depth. Each stage of excavation requires careful monitoring of the shoring’s stability. Regular inspections ensure the safety of the excavation and the workers. Bracing adds extra support and increases the shoring’s load-bearing capacity.

Imagine building a tower of blocks: The shoring acts like the supporting structure, preventing the blocks (soil) from collapsing. Bracing adds extra support, like additional beams, to keep the tower stable.

Q 5. What are the signs of potential ground instability?

Recognizing signs of ground instability is crucial for preventing accidents. These signs can be subtle or obvious. Obvious signs include visible cracks in the soil, bulging or shifting earth, and water seeping into the excavation. Subtle signs may include recent rainfall saturating the ground, unusual soil behavior (e.g., unusually soft soil), and recent vibrations from nearby construction activities.

If I observe any of these signs, I immediately stop work and report them to the supervisor. Further investigation might be needed, perhaps involving a geotechnical engineer to assess the situation. Excavation might need to be stopped entirely until the instability is addressed, or alternative methods are employed. Ignoring these warnings can have severe consequences.

Think of it like seeing cracks in a building’s foundation – that’s a clear indication of structural instability and requires immediate attention.

Q 6. How do you handle unexpected obstacles during excavation?

Unexpected obstacles during excavation are common. These could range from buried rocks and debris to unexpected utility lines or underground structures. My approach is methodical and cautious. I always hand excavate around any unexpected obstacle to avoid damaging it. If it’s a utility line, I immediately stop work and contact the appropriate utility company. If it’s a large rock or obstruction, I’ll use the appropriate tools to remove or bypass it safely.

I meticulously document all unexpected finds, including their location and nature, and notify the supervisor immediately. Any changes to the excavation plan are carefully assessed and approved before proceeding. Safety and proper documentation are top priorities.

This methodical approach prevents costly delays and safety hazards.

Q 7. Describe your experience with different soil types and their impact on excavation.

Different soil types significantly impact excavation. Clay soils are cohesive and can be difficult to dig, requiring specialized tools and techniques. Sandy soils are loose and unstable, necessitating careful shoring and bracing. Rocky soils can be very challenging, often requiring specialized equipment like jackhammers or even blasting in some cases. Each soil type has unique characteristics that dictate the tools, methods, and safety precautions needed for excavation.

For example, I remember a project where we encountered extremely hard clay. A regular shovel wasn’t sufficient. We used picks and shovels together, breaking the soil into smaller pieces before removing them. In another project with sandy soil, we implemented a more robust shoring system to account for the increased risk of cave-ins. Understanding and adapting to the soil’s characteristics is key to a successful excavation.

Q 8. What are the OSHA regulations related to manual excavation?

OSHA (Occupational Safety and Health Administration) regulations for manual excavation are paramount for worker safety. They primarily focus on preventing cave-ins, a leading cause of death in trenching and excavation. These regulations, found in 29 CFR Part 1926 Subpart P, mandate protective systems based on soil type and depth. For example, trenches deeper than 5 feet generally require shoring, sloping, or a trench box to prevent collapse. The regulations also cover other hazards such as atmospheric monitoring for dangerous gases (like methane or hydrogen sulfide), proper access and egress from excavations, and the use of personal protective equipment (PPE) such as hard hats and high-visibility clothing.

Specific regulations detail requirements for inspections, competent persons overseeing the work, and emergency action plans. Failure to comply can result in significant fines and legal repercussions for employers.

- Soil Classification: OSHA emphasizes the importance of correctly classifying soil types to determine the appropriate protective systems. This often involves a professional assessment.

- Protective Systems: These include shoring (using supports to reinforce the sides of the excavation), sloping (cutting the sides of the excavation at an angle to reduce the risk of collapse), and trench boxes (protective structures placed inside the excavation).

- Emergency Action Plans: These plans detail procedures for responding to emergencies, including cave-ins, and ensuring the safety of workers.

Q 9. How do you ensure proper slope stability during excavation?

Ensuring proper slope stability is crucial for preventing cave-ins. The angle of repose, which is the steepest angle at which a soil can remain stable, is a key factor. This angle varies depending on the soil type – clay soils have a steeper angle than sandy soils. To ensure stability, we must slope the sides of the excavation at an angle less than the angle of repose. This means cutting back the sides of the excavation to create a gentler slope. The steeper the slope, the more likely a collapse is. For example, a stable slope for Type A soil (cohesive soil) might be 1:1 (meaning a one-foot horizontal to one-foot vertical slope), while a Type C soil (cohesionless soil) would require a much gentler slope, perhaps 1:1.5 or even flatter.

In addition to sloping, other techniques to improve stability include shoring, which uses supports like timber, metal, or hydraulic shoring systems to reinforce the sides, and benching (creating a series of horizontal steps along the sides of the excavation). Regular inspections and the presence of a competent person are also vital to maintain slope stability throughout the excavation process. We also use surveying equipment to accurately measure the slopes.

Q 10. Explain the importance of proper site preparation before excavation.

Proper site preparation is foundational for safe and efficient excavation. It’s like laying the groundwork for a house – if the foundation is weak, the whole structure is at risk. Before any digging begins, a thorough site survey is essential to identify potential hazards, including underground utilities, buried objects, and unstable ground conditions. This often involves contacting utility companies to locate and mark underground lines (call-before-you-dig services) and performing a site reconnaissance to assess the terrain. Failure to locate underground utilities could lead to damaged lines, injuries, or even fatalities.

Site preparation also includes clearing the area of debris, vegetation, and any obstacles that could interfere with the excavation. Establishing a clear work area with appropriate access routes and designated areas for material storage ensures an organized and safer work environment. Finally, developing a detailed excavation plan that considers the soil type, depth, and protective systems required ensures a safe and controlled execution of the project.

Q 11. Describe your experience with different excavation methods (e.g., trenching, pitting).

My experience encompasses various excavation methods, primarily trenching and pitting. Trenching involves digging long, narrow excavations, typically for installing utilities like pipes or cables. I’m proficient in using various tools for trenching, from hand shovels and picks for smaller trenches to mechanized excavators for larger projects. Safety is always paramount in trenching, focusing on proper shoring or sloping techniques based on soil conditions and depth.

Pitting involves excavating larger, wider holes, often for foundations or other structural work. Here, the focus shifts to managing larger volumes of excavated material and ensuring the stability of the excavation’s walls. I’ve worked on numerous projects involving both manual and mechanized pitting techniques, adapting my approach based on project specifications and site conditions. Careful planning and execution, along with a keen eye for potential hazards, are essential in both methods.

Q 12. How do you manage waste materials generated during excavation?

Managing waste materials is a crucial part of responsible excavation. This involves separating materials based on their type (e.g., soil, rock, debris). Soil is often reused on-site for backfilling, but it’s vital to ensure it’s properly compacted to maintain stability. Other materials may need to be disposed of according to local regulations. Hazardous waste, such as asbestos or contaminated soil, requires specialized handling and disposal by licensed contractors to protect the environment and worker health. Proper documentation of waste management practices is key for compliance.

For example, I’ve worked on projects where we meticulously separated topsoil from subsoil, reusing the topsoil for landscaping after the project was complete. This not only saves money on disposal but also promotes sustainability. We also ensured that any debris or potentially hazardous materials were handled and disposed of responsibly, following all relevant environmental regulations.

Q 13. How do you identify and mitigate potential hazards during excavation?

Identifying and mitigating hazards during excavation is a continuous process. This begins with the pre-excavation site assessment, identifying potential hazards like underground utilities, unstable ground, or the presence of hazardous materials. During excavation, regular inspections are crucial to monitor for changes in soil conditions, water accumulation, or signs of instability. Atmospheric monitoring for dangerous gases is also vital, especially in confined spaces.

Mitigation strategies involve implementing appropriate protective systems, such as shoring, sloping, or trench boxes. Providing proper training to workers on hazard recognition and safe work practices, ensuring access to PPE and emergency equipment, and establishing clear communication protocols are also key. For example, if we encounter unexpected water inflow during excavation, we would immediately stop work, assess the situation, and implement measures to control the water before resuming. This could include pumping out the water or reinforcing the excavation walls.

Q 14. What is your experience with using surveying equipment in excavation?

My experience with surveying equipment in excavation is extensive. I’m proficient in using levels, total stations, and GPS equipment to accurately measure depths, slopes, and the dimensions of excavations. This is critical for ensuring that the excavation meets the design specifications and for verifying the stability of the slopes. Accurate surveying also helps to avoid over-excavation or under-excavation, saving both time and materials. For example, when constructing a trench for a pipeline, accurate level measurements are crucial to ensure that the trench has the correct gradient for proper drainage.

In addition to ensuring dimensional accuracy, surveying also plays a vital role in documenting the location of underground utilities and other subsurface features before and after excavation. This helps prevent damage to utilities and creates a comprehensive record of the excavation process. This documentation can be invaluable for future projects or maintenance work on the site.

Q 15. How do you maintain accurate records of excavation activities?

Maintaining accurate excavation records is crucial for safety, project management, and legal compliance. We utilize a multi-pronged approach. Firstly, a detailed excavation plan is created before work begins, specifying locations, depths, and anticipated soil conditions. This plan serves as our baseline.

During excavation, we maintain a daily log, meticulously documenting activities. This includes the date, time, location, depth reached, soil types encountered, any unforeseen obstacles (like utilities or rocks), equipment used, personnel involved, and any safety incidents. We use both handwritten logs, often bound into a site-specific notebook, and digital record-keeping using tablets or smartphones. Photos and videos of the excavation progress are integral components of our records, capturing the context of the daily log. Finally, all records are reviewed and signed off by the site supervisor before being archived, ensuring accountability and traceability.

For example, if we encounter an unexpected underground utility line, a detailed entry is made, including photos and the exact coordinates of the line. This prevents future accidents and facilitates effective communication with utility companies.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience working with a team during excavation projects.

Teamwork is paramount in manual excavation. My experience involves coordinating teams ranging in size from two to ten people. Effective communication is key. Before any work begins, a thorough briefing covers the plan, safety protocols, assigned tasks, and designated roles. Clear communication is maintained throughout the project through frequent check-ins and informal discussions.

On one project involving trenching near a historic building, I had to coordinate a team of three diggers with two spotters focused on trench stability. Each member understood their responsibilities: the diggers focused on precision, the spotters monitored wall integrity, and I ensured everyone followed safety measures. This collaborative approach ensured both efficiency and safety, resulting in the successful completion of the project without incident.

Q 17. How do you handle conflicts or disagreements with fellow workers?

Disagreements are inevitable on any project. My approach is to address them directly and professionally, prioritizing safety and project completion. I focus on active listening to understand each perspective, then facilitate a discussion aimed at finding a mutually agreeable solution. If the disagreement is safety-related, I have the authority to enforce the safest course of action.

For instance, if a worker disagrees with my decision on shoring a trench, I’ll clearly explain the safety risks and the relevant regulations, demonstrating why my approach is necessary. If the disagreement persists, I will escalate it to the site manager to find a resolution, always documenting the process to ensure transparency and accountability.

Q 18. What is your experience with backfilling and compacting excavated areas?

Backfilling and compaction are critical aspects of completing an excavation project, restoring the site to its original condition and preventing future settling. My experience encompasses various backfilling methods, from simple hand-shoveling to using mechanical equipment like excavators and compactors. I’m adept at selecting the appropriate backfill material based on the soil type and project requirements. Proper compaction ensures stability and minimizes the risk of future ground movement or damage to structures.

For example, when backfilling a trench, I would carefully layer the material and use a hand tamper or plate compactor to achieve optimal density, ensuring the layers are compacted to at least 95% of the Proctor density, depending on local requirements and the type of backfill being used. I always perform compaction tests to validate the effectiveness of the compaction process, documenting the results.

Q 19. How do you ensure the proper compaction of backfill material?

Proper compaction is crucial to prevent future settling and ensure the structural integrity of the surrounding area. It’s achieved through a combination of techniques and careful monitoring. The key is achieving the required density for the specific backfill material. This involves carefully layering the backfill, ensuring each layer is adequately compacted before adding the next. The choice of compaction equipment depends on the project scale and soil conditions. For small-scale projects, hand tampers might suffice. For larger projects, mechanical compactors such as plate compactors or vibratory rollers are used.

Before, during, and after the compaction process, I perform density tests using methods like the sand cone method or nuclear density gauge to verify that the desired density is being achieved and that there are no void areas. These test results are documented and retained.

Q 20. Describe your knowledge of different types of backfill materials.

Different backfill materials have varying properties, impacting compaction and long-term stability. Common types include: native soil (the soil excavated from the site), engineered fill (compacted granular materials like gravel or crushed stone), and select fill (specially chosen materials to meet specific requirements). The choice of material depends on factors such as the purpose of the backfill, the surrounding environment, and local regulations.

For instance, native soil may be suitable for simple backfilling where minimal stability is required. However, for areas requiring significant stability, like supporting structures, engineered fill would be preferred due to its superior compaction characteristics and load-bearing capacity. Understanding these differences is essential for choosing the correct material and achieving the necessary compaction.

Q 21. How do you handle difficult soil conditions, such as rock or clay?

Handling difficult soil conditions requires specialized techniques and equipment. Rock requires specialized tools like jackhammers, or even blasting (depending on size and location) to break it up. Clay, with its tendency to shrink and swell, needs careful attention to moisture content during excavation and backfilling. Often, additional shoring or support is necessary to prevent cave-ins, especially in trenches. The approach depends entirely on the specific soil characteristics and the nature of the excavation.

For example, I’ve encountered situations where large boulders needed to be carefully removed using appropriate equipment. To handle expansive clay, we used specific drainage techniques during backfilling to prevent moisture accumulation. Always employing the most suitable methods for the situation is paramount to maintain both safety and project efficiency.

Q 22. Explain your experience with using hand-held power tools in excavation.

My experience with handheld power tools in excavation is extensive. I’m proficient with a variety of tools, including jackhammers for breaking up hard ground, small electric breakers for more delicate work, and various types of saws for cutting through pipes or other obstructions. Safety is paramount; I always ensure the tools are in good working order, wear appropriate personal protective equipment (PPE) like safety glasses, hearing protection, and gloves, and follow all manufacturer safety guidelines. For instance, on a recent project involving a particularly dense rock formation, using a jackhammer with the correct bit type and working in short bursts with frequent breaks proved crucial for both efficiency and preventing operator fatigue and injury. Proper maintenance, including regular cleaning and lubrication, is essential to prolong tool life and ensure safe operation.

Q 23. What are the different types of hand digging tools and their applications?

Hand digging tools are fundamental in manual excavation and each serves a specific purpose. Some of the most common include:

- Shovels: Round-point shovels are ideal for loose soil; square-point shovels are better for moving heavier materials like clay or gravel.

- Pickaxes: Used to break up rocks and hard ground, employing both a pointed and bladed end for various tasks.

- Trowels: Smaller, more precise tools, useful for fine-tuning excavations and working in confined spaces.

- Post hole diggers: Specifically designed for digging cylindrical holes for fence posts and similar applications.

- Mattocks: Combines features of an axe and pickaxe, offering both chopping and digging capabilities.

The choice of tool depends heavily on the soil type, the required depth and width of the excavation, and the overall project goals. For example, a round-point shovel would be perfect for digging a shallow drainage ditch in soft soil, while a pickaxe would be needed to break up a rocky area before trenching.

Q 24. Describe your experience with working in confined spaces during excavation.

Working in confined spaces during excavation requires extra caution and planning. I have extensive experience working in trenches, utility vaults, and other restricted areas. The biggest concern is the risk of suffocation due to lack of ventilation or the presence of hazardous gases. Before entering a confined space, I always ensure adequate ventilation is in place, using either natural ventilation or mechanical ventilation such as fans. I also use gas detectors to monitor for hazardous gases, such as methane or carbon monoxide. In addition, a safety harness with a lifeline is a must in case of emergency. For example, during a recent project where we were excavating around a gas line in a narrow trench, continuous monitoring with gas detectors was essential, as well as having a safety officer on standby above ground in case of any incident.

Q 25. How do you ensure the safety of yourself and others while working in a trench?

Trench safety is paramount. My approach involves several key elements:

- Protective Systems: Implementing appropriate trench support systems like shoring, sloping, or shielding depending on soil conditions and trench depth. This prevents collapse.

- PPE: Ensuring everyone wears appropriate personal protective equipment (PPE), including hard hats, safety glasses, high-visibility clothing, and sturdy work boots.

- Competent Person: Having a designated competent person inspect the trench regularly throughout the excavation process to identify potential hazards.

- Communication: Establishing clear communication between workers in the trench and those above ground.

- Emergency Plan: Developing a pre-planned emergency response strategy including readily available rescue equipment and clear evacuation procedures.

- Daily Inspections: Daily inspections to check for signs of instability in the trench walls or other hazardous conditions.

For example, on one project, we encountered unstable soil. We immediately stopped work and implemented a shoring system before resuming excavation. Continuous monitoring and communication were key to a safe outcome.

Q 26. What are the signs of trench collapse and how do you prevent them?

Trench collapse is a serious hazard and can have fatal consequences. Warning signs include:

- Visible cracks or bulging in the trench walls.

- Sinking or settling of the trench floor.

- Changes in soil moisture or texture.

- Recent heavy rainfall or unusual ground vibrations.

Prevention involves careful assessment of soil conditions before excavation begins, selecting appropriate support systems based on those conditions, and continuous monitoring during the excavation process. Properly sloped trenches or appropriately installed shoring significantly reduce the risk of collapse. Understanding soil types and their behavior is crucial; for example, saturated clay is significantly more prone to collapse than dry, sandy soil. Implementing a robust inspection and monitoring plan is essential to detect any early signs of instability and react accordingly.

Q 27. How do you conduct a pre-excavation site assessment?

A pre-excavation site assessment is critical for safety and efficiency. My approach includes:

- Identifying underground utilities: Using one-call centers or other methods to locate buried utilities like gas lines, water pipes, and electrical cables.

- Assessing soil conditions: Examining the soil to determine its type, stability, and moisture content.

- Checking for previous excavations or fill material: Identifying areas that may be unstable due to prior construction or disturbance.

- Reviewing relevant site plans and documents: Ensuring compliance with local regulations and identifying potential hazards outlined in project plans.

- Identifying environmental concerns: Determining the presence of hazardous materials or environmental sensitivities.

This thorough assessment allows me to select appropriate excavation techniques and safety measures, preventing costly delays and potential accidents. For instance, discovering a previously unknown gas line during a site assessment allowed us to modify our excavation plan and implement additional safety protocols, avoiding a potentially dangerous situation.

Q 28. Explain your experience with different types of excavation support systems.

My experience encompasses various excavation support systems:

- Shoring: Using timber, steel, or aluminum supports to reinforce trench walls, providing stability and preventing collapse. This is commonly used in unstable soil conditions.

- Sloping or benching: Cutting back the sides of the trench at an angle to create a self-supporting slope, suitable for certain soil types and trench depths.

- Shielding: Utilizing trench boxes or other protective structures to enclose workers within a safe space. These are often used in very unstable soils or where the trench depth makes other techniques impractical.

The selection of the appropriate support system is heavily dependent on soil type, trench depth, and surrounding conditions. For example, in sandy soil, sloping or shoring would be needed. In very unstable clay, trench boxes might be the most appropriate solution. Understanding the strengths and limitations of each system is critical for selecting the safest and most effective method for a given project.

Key Topics to Learn for Manual Excavation Interview

- Safety Regulations and Procedures: Understanding and applying relevant OSHA and other safety regulations for manual excavation, including trenching, shoring, and slope protection. This includes recognizing and mitigating potential hazards.

- Soil Classification and Properties: Knowing how to identify different soil types (e.g., clay, sand, gravel) and their impact on excavation methods and stability. This includes practical application in selecting appropriate excavation techniques.

- Excavation Techniques and Tools: Familiarity with various hand tools and methods used in manual excavation, including shoveling, digging, and proper use of safety equipment. This includes understanding the limitations of manual excavation versus mechanized methods.

- Trenching and Shoring Methods: Understanding the principles of trench shoring and the different types of shoring systems (e.g., sloping, benching, shoring boxes). This involves applying appropriate shoring based on soil conditions and trench depth.

- Utility Location and Avoidance: Knowledge of safe practices for locating and avoiding underground utilities (e.g., gas lines, electrical cables, water pipes) before and during excavation. This includes understanding the importance of calling 811 (or your local equivalent).

- Emergency Procedures: Being prepared for potential emergencies such as cave-ins, equipment malfunctions, or injuries. This includes knowledge of emergency response protocols and communication procedures.

- Site Preparation and Clean-up: Understanding the procedures for preparing the excavation site, including clearing debris and ensuring proper access. This also covers the importance of safe and efficient site cleanup after completion.

Next Steps

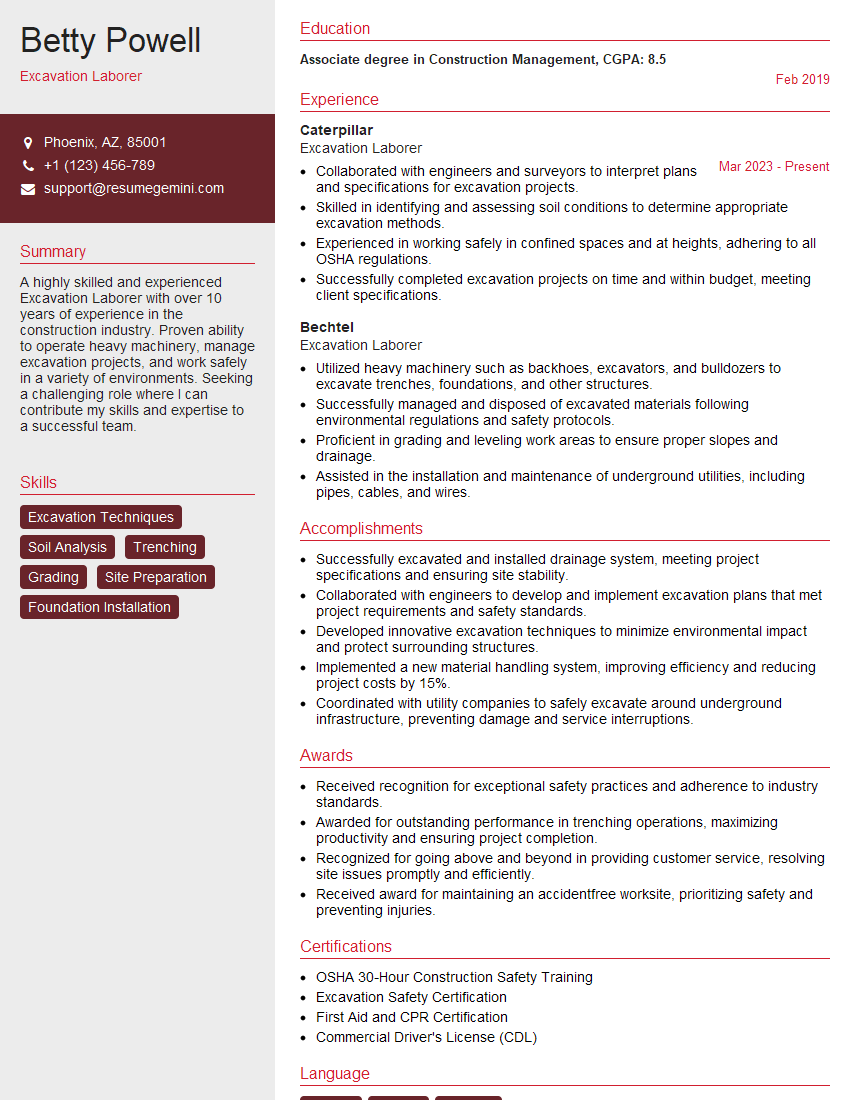

Mastering manual excavation techniques is crucial for a successful and rewarding career in construction and related fields. It demonstrates a strong commitment to safety and a practical understanding of essential groundwork. To significantly boost your job prospects, crafting an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of the manual excavation industry. Examples of resumes specifically designed for manual excavation positions are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good