Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Manual Screen Printing interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Manual Screen Printing Interview

Q 1. Describe the process of emulsion coating a screen.

Emulsion coating is the crucial first step in preparing a screen for screen printing. It involves applying a light-sensitive emulsion to the screen mesh, creating a stencil that will define your design. Think of it like creating a photographic negative for your print.

The process typically involves:

- Preparing the Screen: Thoroughly clean the screen to remove any dust, debris, or previous emulsion residue. A degreaser is often used.

- Mixing the Emulsion: Most emulsions require mixing before use, ensuring a consistent coating. Follow the manufacturer’s instructions carefully, as different emulsions have varying viscosity and sensitivity.

- Coating the Screen: Using a scoop coater or a trough, apply a thin, even layer of emulsion to both sides of the screen. This is best done in a darkroom or under a dim yellow light, as emulsion is photosensitive.

- Drying the Screen: Allow the emulsion to dry completely in a controlled environment, away from direct sunlight or excessive heat. This usually takes several hours. Over-drying can lead to cracking and under-drying can cause problems during exposure.

- Checking for Pinholes: Once dry, carefully inspect the coated screen for any pinholes, which can cause unwanted ink bleed. These can be fixed using a emulsion stop-off solution.

A smooth, even coating is critical for a sharp, clean print. Inconsistent emulsion application will inevitably lead to blurry or faded areas in the final print. I’ve found that practice makes perfect—it takes time to develop the steady hand needed for precise coating.

Q 2. Explain the difference between plastisol and water-based inks.

Plastisol and water-based inks are the two most common types of inks used in screen printing, each with distinct properties and applications. Choosing the right ink is crucial for achieving the desired look and feel of the final product.

- Plastisol Inks: These are PVC-based inks that require a curing process (usually with heat) to permanently adhere to the fabric. They’re known for their vibrant colors, opacity, and durability, making them ideal for garments and textiles that need to withstand frequent washing. However, they can be less environmentally friendly than water-based inks and require specialized equipment for curing.

- Water-Based Inks: These are environmentally friendly inks, often made from acrylic polymers. They require less curing time (air drying is often sufficient) and have a softer hand-feel, making them suitable for printing on sensitive materials or for eco-conscious projects. Water-based inks often offer a slightly less vibrant finish, however, and may require multiple coats to achieve full opacity.

In my experience, the choice between plastisol and water-based inks depends entirely on the project requirements. If durability and vibrant color are paramount, plastisol is the way to go. For eco-friendly applications or projects where a softer feel is desired, water-based inks are preferable. I’ve worked with both extensively and am comfortable switching between them based on the client’s needs.

Q 3. How do you achieve a sharp, well-defined print?

Achieving a sharp, well-defined print involves careful attention to detail throughout the entire process. It’s not just about one step, but rather a combination of factors working in harmony.

- Precise Emulsion Coating: An even coat of emulsion is crucial for preventing ink bleed. Uneven emulsion thickness can lead to fuzzy edges.

- Accurate Image Exposure: Proper exposure ensures the emulsion is completely hardened in the non-printing areas, preventing ink from seeping through. Too little exposure can lead to blocked areas, too much can cause thin lines.

- Meticulous Screen Cleaning: Removing all emulsion residue from the screen openings is essential. Leaving residue can clog the screen and lead to poor print quality.

- Optimal Screen Tension: A properly tensioned screen minimizes fabric stretching and ensures consistent ink deposit. A loose screen can cause a blurry image.

- Proper Ink Consistency: Using the right ink viscosity is important. Ink that is too thick can cause clogging, while ink that is too thin might lack opacity and definition.

- Off-Contact Printing: Maintaining a consistent distance (off-contact) between the screen and the substrate prevents the screen from dragging on the substrate, improving image sharpness and reducing print defects.

Think of it like baking a cake; every ingredient and step matters. A perfectly executed screen print is the result of carefully attending to every detail. I often find myself tweaking a small detail, like the off-contact setting, to get the best result.

Q 4. What are the different types of screens used in manual screen printing?

Screen selection is crucial in screen printing; it impacts print quality and efficiency. The choice depends on the project requirements, such as the material being printed on and the detail of the design.

- Polyester Mesh Screens: These are the most common type, known for their durability, excellent ink release, and versatility. They are available in different mesh counts (threads per inch), with higher counts being used for finer details.

- Nylon Mesh Screens: Offer good durability and sharpness, and are a less expensive alternative to polyester. However, they are generally less durable over time.

- Stainless Steel Mesh Screens: Extremely durable and resistant to harsh chemicals, ideal for industrial applications or repetitive printing of heavy designs. They’re more expensive but offer longevity.

The mesh count is critical. A lower mesh count (e.g., 43T) is better for larger, less detailed designs, while a higher mesh count (e.g., 156T) is better for finer details and sharper images. I usually choose the mesh count based on the design complexity and print area. For instance, a t-shirt design with sharp text might use a 110T or higher mesh, while a large, bold graphic might use a 68T or 43T.

Q 5. How do you troubleshoot a clogged screen?

A clogged screen is a frustrating problem, but often easily resolved with the right approach. The causes can range from dried ink to emulsion residue.

Troubleshooting steps:

- Identify the Clog: Determine if the clog is due to dried ink, emulsion residue, or other debris. Close inspection is key.

- Clean with appropriate solvent: If it’s dried ink, use a suitable solvent (consult the ink manufacturer’s recommendations). For plastisol inks, a plastisol cleaner is often necessary. For water-based inks, water might be sufficient.

- Use a screen cleaning brush: Gently work the brush through the clogged area, removing any loose material. Be careful not to damage the mesh.

- Pressure Washing: If the clog persists, consider using a pressure washer with a low-pressure setting to flush out the screen. Always test the pressure first in an inconspicuous area.

- Re-coat the area if necessary: For severe clogs or damage, it might be necessary to re-coat a small section of the screen with emulsion.

Prevention is always better than cure. Regular cleaning of the screen after each print run helps to avoid clogs. Also, storing screens properly, keeping them clean and away from dust, can significantly extend their life and reduce clogging issues. I’ve seen prints ruined by a minor clog, which emphasizes the importance of proactive screen maintenance.

Q 6. Explain the importance of proper screen tension.

Proper screen tension is paramount for achieving high-quality prints. It directly impacts the sharpness, registration, and consistency of the print. Think of it as the foundation of your printing process.

A properly tensioned screen:

- Reduces fabric stretching: A tight screen minimizes fabric distortion, leading to sharper images, especially important when printing on stretchy materials.

- Ensures consistent ink deposit: Consistent tension ensures uniform ink distribution across the screen, resulting in a more even print.

- Improves registration: Proper tension helps maintain accurate alignment of multiple colors, critical in multi-color prints.

- Minimizes screen sagging: Sagging can lead to uneven ink deposition and image distortion.

I typically use a tensionometer to ensure the screen is tensioned to the manufacturer’s recommended range. The process involves stretching the screen across the frame and securing it. Incorrect tension can lead to significant problems; under-tensioned screens are prone to sagging and inaccurate printing, while over-tensioned screens can easily break. Finding the sweet spot takes practice and experience.

Q 7. Describe your experience with different printing techniques (e.g., flood coating, off-contact printing).

I’ve extensive experience in various screen printing techniques, each contributing to different printing effects and outcomes. The right technique depends on factors like ink type, design detail, and the substrate.

- Flood Coating: This is the standard method, where ink is evenly spread across the screen before printing. It provides consistent ink coverage and is suitable for most designs.

- Off-Contact Printing: This involves setting a precise distance between the screen and the substrate. This minimizes the screen dragging against the fabric, which is especially valuable for printing sharp, detailed designs and for preventing ink smearing. Finding the right off-contact is crucial, often through careful adjustment and observation.

- Halftone Printing: This technique uses a halftone screen to create the illusion of continuous tones, crucial for reproducing photographic images or complex color gradients. It requires careful consideration of the screen’s angle and dpi settings.

My experience also extends to various printing styles, including layer printing, flash curing (for plastisol), and even techniques like stenciling for achieving unique effects. In one project, I used off-contact printing with a high mesh count to produce exceptionally sharp details in a limited-edition series of t-shirts. Mastering these various techniques has been key to my success in achieving diverse and high-quality screen prints.

Q 8. How do you clean and maintain your printing equipment?

Cleaning and maintaining screen printing equipment is crucial for consistent print quality and longevity. It’s a multi-step process that I meticulously follow after every print run, and also involves regular preventative maintenance.

- Immediately after printing: I thoroughly clean the squeegee with a suitable solvent, ensuring no ink residue remains. The screen itself gets a quick wipe-down to remove excess ink. This prevents ink from drying and hardening.

- Detailed screen cleaning: For deeper cleaning, I use a screen degreaser and a soft brush, paying attention to the mesh and the frame. This removes any stubborn ink build-up. I then rinse the screen thoroughly with water.

- Press maintenance: The printing press itself requires regular cleaning, removing ink spills and debris. I inspect all moving parts and lubricate them as needed, ensuring smooth operation.

- Preventative maintenance: This includes checking for loose screws, inspecting the condition of the screen clamps, and ensuring the press’s alignment is correct. This proactive approach prevents major issues down the line. For instance, I once avoided a major production delay by noticing a slightly bent screen clamp early on.

This systematic approach minimizes downtime, prolongs the life of my equipment, and guarantees high-quality prints every time. Thinking of it as a preventative maintenance program, not just a post-print clean-up, is key.

Q 9. What safety precautions do you take when using screen printing chemicals?

Safety is paramount when working with screen printing chemicals. I always adhere to strict safety protocols, starting with proper personal protective equipment (PPE).

- PPE: This includes nitrile gloves, safety glasses, and a respirator, especially when working with plastisol inks which contain volatile organic compounds (VOCs). The respirator protects me from inhaling harmful fumes.

- Ventilation: I ensure adequate ventilation in my workspace, either through open windows or a dedicated ventilation system. This helps to disperse fumes and minimize inhalation risks.

- Proper handling: I carefully handle all chemicals, avoiding spills and splashes. I always follow the manufacturer’s instructions on storage and disposal.

- Emergency preparedness: I have a readily available spill kit containing absorbent materials and neutralizing agents, in case of accidental spills. I am also familiar with emergency procedures and know where the nearest eyewash station is located.

- SDS Sheets: I consult the Safety Data Sheets (SDS) for each chemical I use. These sheets provide essential information on hazards, safe handling procedures, and emergency response measures.

Remember, safety isn’t just about following rules; it’s about making responsible choices every step of the way. A small misstep can have significant consequences.

Q 10. How do you register multiple colors in a multi-color print?

Registering multiple colors accurately in multi-color screen printing is crucial for achieving a crisp and aligned final product. This involves precise positioning of each screen to ensure perfect color overlap.

- Accurate artwork preparation: The artwork needs to be precisely separated into color layers. Each layer corresponds to a separate screen.

- Screen preparation: I carefully align registration marks (typically small crosshairs) on each screen with those on the substrate (e.g., t-shirt). Accurate exposure and emulsion coating is also vital for this.

- Using a registration system: This can be as simple as using tape and alignment pins or as advanced as a fully automated press with micro-registration systems. I typically use a combination of both depending on the job.

- Test prints: I always do test prints before the full run, adjusting screen placement as needed. Even minor adjustments can significantly affect alignment. This step has saved me from many a costly mistake!

- Microscopic adjustments: After each layer, the position of the screen may shift slightly, even with the best registration system. This is especially true for higher volume prints. Regular checks, sometimes even under a magnifying glass, can catch this very early.

Think of it like building a complex puzzle – each piece (color) must be in precisely the right place to complete the picture (design).

Q 11. What are the common causes of print defects and how do you address them?

Print defects are unfortunately common in screen printing, but understanding their causes allows for effective troubleshooting. Here are some of the most frequent issues and their solutions:

- Pin holes: These tiny holes in the stencil allow ink to bleed through, often caused by improper emulsion application or damage to the screen. Solution: Careful emulsion application, proper screen handling, and, if necessary, re-coating or replacing the screen.

- Halation: A blurry or fuzzy print, often caused by overexposure of the screen during the stencil creation process. Solution: Adjust exposure time during stencil making. Experimentation is key here.

- Off-register printing: Colors misaligned due to improper screen alignment. Solution: Utilize a reliable registration system and meticulously check alignment before each print run.

- Inconsistent ink deposit: Uneven ink coverage, often caused by incorrect squeegee pressure or angle. Solution: Adjust squeegee pressure and angle during printing, ensuring consistent, even strokes.

- Poor ink viscosity: Thick or thin ink can result in poor print quality. Solution: Adjust ink viscosity to the optimal level (explained further in another answer).

Troubleshooting often involves a process of elimination. Starting with visual inspection can guide you toward the root cause.

Q 12. Describe your experience with different types of printing meshes.

Different meshes offer varying levels of detail and ink deposit. I’ve worked extensively with several types:

- Low mesh count (e.g., 43T): Used for printing large, bold graphics or designs that require a significant amount of ink deposit. The larger openings allow more ink through. Think large bold lettering on a promotional t-shirt.

- Medium mesh count (e.g., 86T-110T): A versatile option suitable for a range of designs, offering a balance between detail and ink flow. This is probably my most commonly used range.

- High mesh count (e.g., 156T and above): Ideal for fine detail and halftone prints, where precise ink deposition is crucial. These meshes are very suitable for complex designs, including photography.

The choice of mesh depends heavily on the design complexity and desired print quality. High mesh counts are ideal for fine details, but require more careful ink handling to prevent clogging.

Q 13. How do you determine the appropriate ink viscosity for a given job?

Ink viscosity is crucial for achieving a clean and consistent print. It’s the thickness or thinness of the ink and affects the print’s sharpness, color vibrancy, and overall quality.

Determining the right viscosity is a combination of experience and experimentation. Factors like mesh count, design complexity, and ink type all play a role.

- Testing with a Zahn cup: This is a common method for measuring ink viscosity. I time how long it takes for a certain amount of ink to flow out of the cup, comparing the result to manufacturer’s recommendations.

- Visual inspection: I’ll often visually inspect the ink, checking its consistency and flow. Too thick and the ink will leave a rough print; too thin, and the image might lack definition.

- Test prints: I always conduct test prints using different viscosity levels to see which one produces the best results. This allows me to fine-tune the consistency for optimum results.

- Ink additives: Sometimes, I use ink additives – such as extenders or retarders – to adjust the viscosity. A retarder will slow the drying process; an extender will thin the ink.

Finding the sweet spot for viscosity is a learned skill, but consistent testing and observation are key.

Q 14. Explain the process of reclaiming a screen.

Reclaiming a screen involves removing the old emulsion and cleaning the mesh to reuse it. This is both cost-effective and environmentally friendly. It’s a process I perform routinely.

- Emulsion removal: I use a screen degreaser and a brush to loosen the old emulsion. Then, I carefully remove the emulsion using a high-pressure washer with warm water and a powerful spray nozzle. For stubborn emulsion, I may need to use an emulsion remover.

- Mesh cleaning: After emulsion removal, I thoroughly clean the mesh to remove any remaining residue. This often involves a combination of brushing, rinsing, and possibly using a specialized mesh cleaner.

- Inspection and repair: Once clean, I inspect the screen for any damage to the mesh or frame. I’ll repair any minor damage before recoating.

- Drying: The screen needs to be completely dry before applying new emulsion. I typically let it air dry completely.

Reclaiming screens not only saves money on buying new ones but also reduces waste. This is not only good for the environment but also a very important part of efficient screen printing operations.

Q 15. What is the importance of proper squeegee pressure and angle?

Proper squeegee pressure and angle are paramount to achieving consistent and high-quality screen prints. Too little pressure, and you’ll get a weak, faded print with incomplete ink transfer. Too much pressure, and you risk pushing ink under the stencil, causing bleed or clogging the screen. The angle is equally crucial; a skewed angle leads to uneven ink deposition, resulting in variations in print density.

Imagine painting a wall: you wouldn’t use a feather-light touch, nor would you press so hard you gouge the paint. Similarly, finding the ‘sweet spot’ in squeegee pressure and angle is essential. A typical starting point is a 45-degree angle, but this can be adjusted slightly based on the ink viscosity and mesh count of the screen. I usually start with a test print to fine-tune the pressure and angle for optimal results.

For example, printing on a highly absorbent fabric like cotton might require slightly more pressure than printing on a smoother, less absorbent material like polyester. The angle might need tweaking based on the design’s complexity, too. A large, solid area may benefit from a slightly more aggressive angle and pressure than a design featuring fine lines and details.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage ink consistency throughout a printing run?

Maintaining consistent ink viscosity is critical for uniform printing throughout a run. Ink thickens over time due to evaporation and settling, and this change directly affects print quality. I use several methods to manage ink consistency. Firstly, I always stir the ink thoroughly before each printing session and periodically throughout the run. I use a specialized ink stirrer to ensure even distribution.

Secondly, I use ink retarders or humectants to slow down evaporation and keep the ink workable for longer periods. The type of retarder depends on the type of ink, for instance, plastisol inks have different requirements than water-based inks. Thirdly, I utilize a pressure-regulated airbrush to add small amounts of ink solvent to thin out the ink if it becomes overly viscous. Adding solvent gradually is crucial to avoid drastically altering the ink’s properties.

Finally, I always cover unused portions of the ink to prevent excessive evaporation. In larger printing projects, I utilize airtight containers or specially designed ink-mixing buckets that seal off the top area where the evaporation primarily occurs. Regularly checking the ink’s consistency and making adjustments as needed is part of my standard procedure; it’s proactive maintenance that guarantees a clean and consistent final product.

Q 17. What are your strategies for efficient production and minimizing waste?

Efficient production and waste minimization are critical for profitability and sustainability in screen printing. My strategies focus on optimization at every stage. This starts with careful pre-production planning, including precise artwork preparation and accurate screen creation. Using emulsion efficiently and minimizing screen waste are key considerations. I carefully plan my screen arrangements to make best use of the available printing space, preventing unnecessary material waste.

During the printing process, I focus on minimizing ink waste. This includes using the appropriate amount of ink for each print, employing techniques such as flood strokes to prevent ink from pooling and wasting the material. For cleanup, I use proper cleaning solutions and separate my waste components, ensuring responsible disposal. I keep a detailed inventory of my materials, which ensures we avoid over-ordering supplies while ensuring we have sufficient materials to complete the printing job without delays.

I continually strive to improve my processes, which includes tracking my waste generation and identifying areas for improvement. For example, I experimented with different ink-saving techniques and found that using a lower-mesh count screen could reduce ink usage without affecting print quality for certain designs. Data tracking provides actionable feedback to improve my efficiency and minimize waste generation.

Q 18. How do you handle color matching and consistency across multiple prints?

Color matching and consistency across multiple prints demand precision and attention to detail. I use a color management system to ensure accuracy, starting with accurate color separations in the artwork. Using Pantone Matching System (PMS) colors provides a standardized method for color specification, which reduces color variations between different prints.

Before starting the printing run, I always print test strips to verify color accuracy against the Pantone reference. If there are any discrepancies, I adjust the ink mixtures to achieve the desired color precisely. During the run, I regularly monitor the color consistency of the prints. This often includes visually checking the prints, and occasionally using a spectrophotometer, a tool that measures the exact color values, to ensure precise consistency. If I notice slight variations in color, it might be due to temperature changes, ink viscosity alterations, or even the substrate itself.

For instance, certain fabrics might absorb ink differently, resulting in subtle color variations. For complex multi-color prints, I frequently use a color chart as a visual reference to ensure I am consistently hitting the target color for each color separation. I also consistently maintain the same printing pressure and squeegee angle to maintain print quality. This multi-faceted approach guarantees consistent and accurate color reproduction across all prints, regardless of the size or quantity of the order.

Q 19. Describe your experience with different types of substrates (e.g., cotton, polyester).

My experience encompasses a wide range of substrates, each demanding a unique approach. Cotton, for example, is highly absorbent and requires inks with good penetration and adhesion. I typically use plastisol inks for cotton, ensuring adequate curing time to prevent cracking or fading. Polyester, on the other hand, is a more challenging substrate because of its smooth surface and lower absorbency. For polyester, I often adjust the pressure and angle of the squeegee and opt for inks formulated for synthetic fabrics to ensure proper adhesion.

Other substrates I’ve worked with include blends of cotton and polyester, requiring a balance between penetration and adhesion properties; nylon, which needs specialized inks for a durable print; and even more unconventional materials such as wood or metal, each with its unique surface characteristics that need appropriate inks and techniques. For instance, while plastisol is a popular ink for many applications, for printing on dark garments using water-based inks may be more suitable.

The choice of ink and printing techniques is critical; selecting the wrong ink can result in poor print quality, color variations, or even ink bleeding. Understanding the properties of each substrate and selecting the right ink and technique is crucial for achieving a professional and high-quality print. Experience has taught me to always perform thorough substrate testing and prepare test prints before undertaking a large-scale project, which minimizes risk and ensures optimal print quality.

Q 20. How do you prepare your artwork for screen printing?

Artwork preparation is a crucial step. I begin with high-resolution artwork, typically provided as a vector file (AI, EPS, or SVG) for scalability without quality loss, or as a high-resolution raster file (TIFF or PSD) at at least 300 DPI. I then prepare the artwork for separation, ensuring the correct color modes (CMYK for process printing, spot colors for PMS). The file needs to be separated into individual films for each color, ensuring that every element is placed precisely to avoid registration problems during the printing process.

For this, I use specialized software like Adobe Illustrator or Photoshop. Accuracy is critical here; any errors in the artwork will directly translate to flaws in the final print. I meticulously check the artwork for sizing, color accuracy, and detail before creating the separation films. These films then serve as guides during the screen-making process, where each color separation gets its own screen. Additionally, I often create a ‘proof’ print using a lower-quality method to ensure design and color accuracy before committing to the full-scale printing run. This step helps identify any potential problems early and prevents wasted materials or time.

For example, subtle details may require adjustments in the artwork to ensure they print cleanly. I may also adjust the stroke weight or add bleed to ensure elements don’t get lost during the screen printing process. Thorough artwork preparation significantly impacts the efficiency and quality of the final product, preventing costly mistakes and rework down the line.

Q 21. How do you diagnose and solve problems with screen registration?

Screen registration problems, where different color layers don’t align correctly, are a common challenge in multi-color printing. Diagnosing these issues involves a systematic approach. First, I check the alignment of the screens themselves. Are they accurately positioned on the printing press? Are the clamps holding them securely and preventing any movement? Any misalignment here will cause registration problems.

Next, I examine the alignment of the artwork separations. Were the separations prepared correctly and accurately in the design software? Even small inaccuracies in the artwork’s alignment can result in misregistration during printing. If the screens and artwork are correctly aligned, then I check the printing process itself. Is the pressure and speed consistent across all screens? Are the screens properly tensioned, to prevent sagging or misalignment during the print process? Uneven pressure or inconsistent print speed can lead to registration issues.

Troubleshooting involves adjusting screen position, re-checking artwork accuracy, and refining the printing technique as necessary. In some cases, I might need to remake screens if they show imperfections. For example, if I notice one color consistently shifting to one side, it indicates that there is a consistent problem during the printing process rather than an issue with the artwork itself. By systematically checking each stage of the process, I can isolate the root cause and implement a solution to ensure correct registration in subsequent prints. Accuracy and attention to detail are key in preventing and resolving registration issues.

Q 22. What is your experience with spot color vs. process color printing?

Spot color and process color printing represent two fundamentally different approaches to color reproduction in screen printing. Spot color involves using pre-mixed inks, each with a unique color designation (like Pantone colors), to achieve specific hues. Think of it like using crayons – you select the exact color you need. Process color, on the other hand, uses a combination of four base inks – Cyan, Magenta, Yellow, and Key (black, or K) – to create a wider range of colors through overprinting. It’s like mixing paint to get a precise shade.

In my experience, spot color is ideal for projects requiring consistent and accurate color reproduction across different print runs, particularly when matching a corporate logo or brand identity. The color remains true to the Pantone specification, regardless of minor variations in printing conditions. Process color offers greater flexibility and allows for smoother gradients and more complex color transitions, but can be more challenging to maintain consistent color accuracy between runs due to the inherent variations in ink mixing and overprinting. I’ve had to use both extensively, and choosing between them usually depends on the client’s needs and the complexity of the design.

For example, I recently printed a series of t-shirts with a company logo. Using the company’s Pantone-specified spot color ensured the logo looked exactly as intended across all shirts, a must-have for brand consistency. In contrast, another project involved a vibrant landscape design where the subtle gradations of color were best achieved with process color printing.

Q 23. Describe your understanding of halftone screens and their impact on print quality.

Halftone screens are essential in screen printing for reproducing images with continuous tone, like photographs or detailed artwork, using only dots of ink. A halftone screen is a mesh pattern created digitally, where varying dot sizes and densities simulate different levels of shade and tone. The finer the screen (measured in lines per inch or lpi), the smoother and more detailed the image appears, but also the more challenging it is to print cleanly. A coarser screen, with fewer lines per inch, is more forgiving but lacks the sharpness of finer screens.

The impact of the halftone screen on print quality is significant. A properly selected screen resolution ensures a balance between detail and print clarity. Too fine a screen can lead to clogging of the mesh, resulting in blurry or broken images. Too coarse a screen will produce a visibly pixelated or muddy print. Choosing the correct screen ruling depends on the type of artwork, the mesh count of the screen, and the printing technique. I usually consider the level of detail in the artwork; a highly detailed photograph may require a higher lpi screen than a simple line drawing.

For instance, I once worked on a project that involved printing highly detailed photographic images on fabric. Selecting a 150 lpi screen provided a great balance between image sharpness and print quality. On the other hand, a simpler design, such as a bold logo print, only needed a 60 lpi screen for excellent results without clogging issues.

Q 24. How do you maintain accurate color reproduction?

Maintaining accurate color reproduction in screen printing requires a meticulous approach, starting from the design stage itself. This involves a multi-step process including color proofing, accurate ink mixing, consistent printing pressures and using color management systems.

First, I always work with high-resolution digital files and ensure proper color profiles are used during the design phase. Color proofs, using methods like Pantone color matching systems or digital proofs from reliable printers, are crucial for verifying the intended colors before actual printing. Precise ink mixing, using calibrated scales and measuring devices, is essential to achieve consistent color throughout the entire print run. During the printing process itself, I pay close attention to ink viscosity, squeegee pressure and speed to avoid inconsistent ink deposit, that would affect the color.

Furthermore, regular calibration and maintenance of printing equipment are also paramount. I always use a color management software that profiles my printers and inks to ensure color accuracy.

For example, in a recent project printing custom artwork for a clothing line, using a calibrated Pantone color guide alongside a color management software allowed me to accurately match the client’s specified color palette across several print runs. Color variations were minor and well within acceptable industry standards.

Q 25. Explain your experience with different curing methods (e.g., flash cure, oven cure).

Curing, or drying, the ink after printing is critical for achieving a durable and long-lasting print. Flash curing and oven curing are two common methods. Flash curing uses a rapid-heating element (usually infrared lamps) to partially dry the ink immediately after printing, preventing smudging and allowing for quick turnaround. It’s like a quick blast of heat to set the ink enough for handling. Oven curing, on the other hand, uses a controlled temperature oven to fully cure the ink over a longer period. This method is essential for achieving optimal ink adhesion and durability, especially for plastisol inks, often necessary for garments.

My experience involves using both extensively. Flash curing is ideal for high-volume projects where speed is important and when layering colors, ensuring that each layer is dry before the next is applied. Oven curing provides a more thorough curing process resulting in a more durable, long lasting result, particularly important for plastisol inks printed on fabrics that will be washed frequently. I usually select the curing method based on the ink type, the substrate, and the client’s requirements. Sometimes a combination of both methods provides the best results.

For instance, I used flash curing when printing a large number of simple designs on promotional t-shirts. The speed of flash curing enabled us to meet the tight deadline. A different project involving detailed artwork on durable fabric required oven curing to ensure the prints would withstand multiple washes without cracking or peeling.

Q 26. How do you perform quality control checks throughout the printing process?

Quality control is an ongoing process in screen printing, not a single event. I implement checks at various stages:

- Pre-press: This includes verifying the accuracy of film positives, checking screen tension and ensuring proper mesh count selection to match the design requirements.

- During Printing: Continuous monitoring of ink consistency, squeegee pressure, and print registration (alignment of colors) is crucial. I regularly inspect prints for defects such as pinholes, smears, and misregistration.

- Post-Printing: After printing, a thorough inspection of the final products is done to ensure the colors are accurate, the image quality is satisfactory, and that there are no printing defects. I also include a visual inspection under varying lighting conditions.

- Documentation: Maintaining detailed records of ink mixes, screen mesh counts, printing parameters, and any encountered issues is vital for consistent quality and troubleshooting purposes. This allows me to replicate successful jobs and resolve problems efficiently.

I have a set of checklists and quality control standards that helps maintain consistency. For instance, in a recent large order, implementing a regular quality check at each step prevented a significant amount of waste and ensured a high-quality final product.

Q 27. What are your experience and skills in using specialized screen printing equipment?

My experience encompasses a wide range of screen printing equipment, including automatic and manual presses, exposure units, washout booths, and various types of dryers and curing systems. I am proficient in operating and maintaining these pieces of equipment.

I’m skilled in using different types of screen printing presses, from smaller manual presses ideal for smaller projects and prototypes, to larger, more automated presses for high-volume production. My experience also extends to different types of screens, including those made from various mesh counts and materials, suitable for a variety of applications and print techniques.

I’m familiar with different exposure units and understand the importance of proper exposure time and intensity in creating high-quality screens. In addition, I’m proficient in using washout booths for cleaning screens efficiently and effectively, a crucial step in extending the screen life and maintaining printing quality. My experience also includes working with different curing systems, ensuring that the appropriate curing method is used for each job to ensure colorfastness and durability of the printed product. Through years of practice and troubleshooting I’ve developed a strong working knowledge of their optimal operations and maintenance.

For example, my experience working with large automatic presses on a significant order for a major retailer demonstrates my ability to handle high-volume production while ensuring high-quality results. The efficiency in using these machines translates directly to faster turnaround times and reduced costs.

Key Topics to Learn for Manual Screen Printing Interview

- Screen Preparation: Understanding emulsion application, coating techniques, and exposure processes for achieving crisp, clean images. Practical application includes troubleshooting uneven emulsion coats and addressing exposure issues.

- Image Creation & Film Positives: Familiarizing yourself with different film types and their properties, as well as the importance of accurate image scaling and preparation for screen printing. Practical application includes creating and preparing film positives for various designs and color separations.

- Ink Mixing & Color Matching: Understanding the properties of various inks (plastisol, water-based, etc.), proper mixing techniques, and achieving consistent color matches. Practical application includes troubleshooting color inconsistencies and understanding ink viscosity.

- Squeegee Techniques & Print Pressure: Mastering proper squeegee angles, pressure, and speed to achieve consistent and high-quality prints. Practical application includes understanding how these factors impact print registration and ink lay-down.

- Troubleshooting & Problem Solving: Identifying and resolving common issues such as pinholes, clogged screens, and misregistration. This includes understanding the root causes of printing defects and implementing corrective measures.

- Health & Safety: Understanding and adhering to safety regulations and best practices related to ink handling, screen cleaning, and proper disposal of materials. This includes recognizing potential hazards and utilizing appropriate safety equipment.

- Different Printing Methods: Familiarity with various manual screen printing techniques, such as flood printing and halftone printing, and their applications. This includes understanding the advantages and limitations of each method.

- Substrate Preparation & Selection: Understanding the properties of different printing substrates (e.g., cotton, polyester, etc.) and proper preparation techniques for optimal ink adhesion and print quality. This includes understanding how substrate choices impact ink selection and printing techniques.

Next Steps

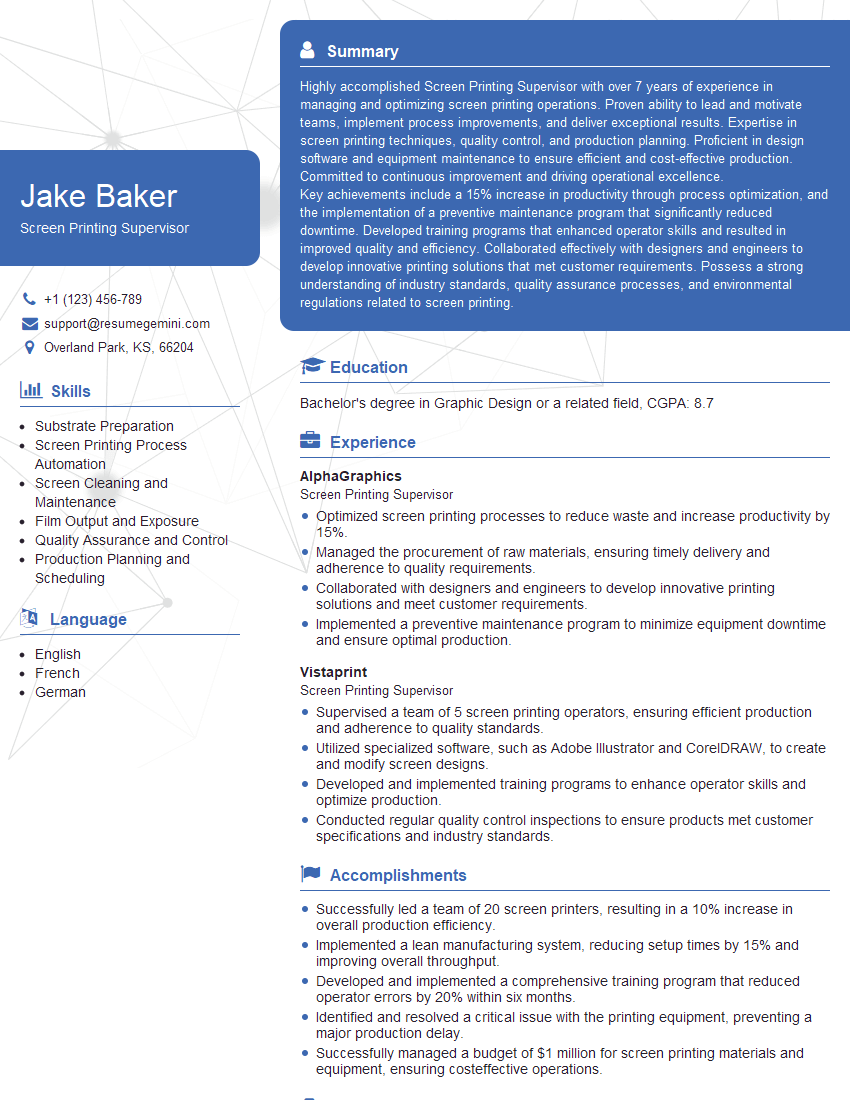

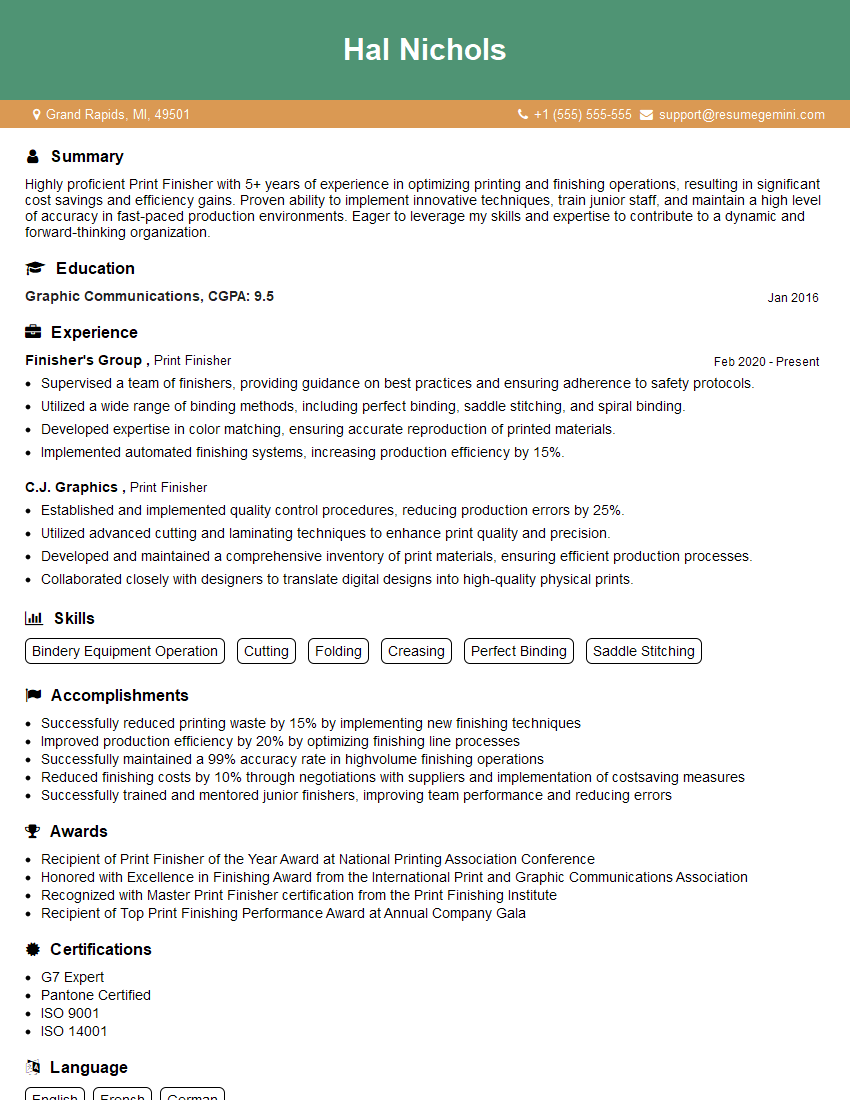

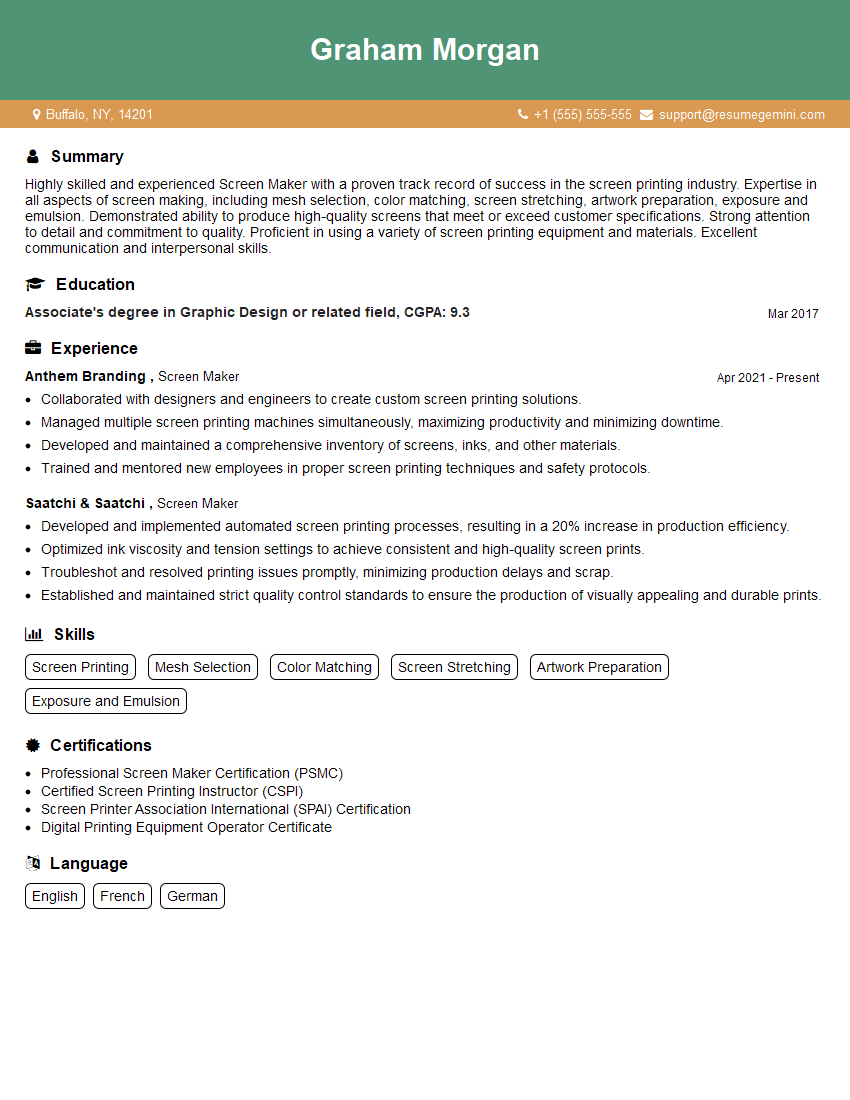

Mastering manual screen printing opens doors to exciting opportunities in the creative industries, from apparel design to fine art. To maximize your job prospects, focus on building an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you craft a professional and impactful resume. They provide examples of resumes tailored specifically to the manual screen printing field to help guide you. Invest time in creating a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good