Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Marine Engineering and Ship Design interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Marine Engineering and Ship Design Interview

Q 1. Explain the difference between a single-screw and twin-screw propulsion system.

The primary difference between single-screw and twin-screw propulsion systems lies in the number of propellers used to drive the vessel. A single-screw system uses a single propeller located at the stern (rear) of the ship. This is the simplest and often most cost-effective arrangement, commonly found in smaller vessels and some larger cargo ships. Think of it like a single engine powering a car.

Conversely, a twin-screw system employs two propellers, usually one on each side of the stern. This configuration offers enhanced maneuverability and redundancy. If one propeller fails, the vessel can still operate, albeit at reduced speed and efficiency. Imagine a tugboat expertly maneuvering in a tight harbor – twin screws are crucial for that precision. Furthermore, twin screws allow for more efficient control in situations requiring precise directional changes, such as docking or navigating narrow channels.

In summary: Single-screw systems are simpler and cheaper, while twin-screw systems offer improved maneuverability and redundancy.

Q 2. Describe the principles of hydrostatic stability.

Hydrostatic stability refers to a ship’s ability to return to its upright position after being tilted or disturbed. It’s all about the interplay of buoyancy and gravity. The key principle is the metacenter – an imaginary point through which the buoyant force acts when the ship heels (tilts). If the metacenter is above the center of gravity (CG), the ship is considered positively stable; the restoring moment caused by buoyancy will right the ship. If it’s below the CG, the ship is unstable and will continue to capsize.

Imagine a rocking toy: its center of gravity is low, and its wide base ensures its metacenter is high above the CG. A ship’s design aims for a similar effect. Factors influencing hydrostatic stability include:

- Ship’s shape: A wider beam (width) increases stability.

- Distribution of weight: Lowering the CG improves stability.

- Water density: Changes in water density (e.g., saltwater vs. freshwater) affect buoyancy and therefore stability.

Understanding hydrostatic stability is crucial for ensuring a ship’s safety and preventing capsizing. Naval architects use sophisticated calculations and software to determine a ship’s stability characteristics before it’s even built.

Q 3. What are the various types of marine propellers and their applications?

Marine propellers come in various types, each suited for specific applications. Some common types include:

- Fixed-pitch propellers: The simplest type, with a fixed blade angle. Suitable for vessels with relatively constant speed requirements, like smaller cargo ships or fishing boats.

- Controllable-pitch propellers (CPP): Allow the blade angle to be changed while the propeller is rotating, providing excellent control over thrust and speed. Ideal for vessels requiring frequent speed and direction changes, like tugboats and cruise ships.

- Ducted propellers: The propeller is enclosed in a duct, enhancing efficiency and thrust, particularly at low speeds. Commonly found on smaller vessels and some specialized ships.

- Kort nozzles: A type of duct that improves propeller efficiency, especially in stern-mounted configurations. Frequently used in tugboats for increased bollard pull (thrust at zero speed).

- Voith Schneider Propellers (VSP): These unique propellers have rotating blades that can be independently adjusted, offering exceptional maneuverability in all directions, often seen on ferries and specialized workboats. These are crucial where precise maneuverability is vital.

The selection of a propeller type depends on factors like vessel type, speed requirements, maneuverability needs, and operating environment. A naval architect considers all these factors to optimize propulsion system efficiency and performance.

Q 4. Explain the function of a ballast system in a ship.

A ballast system is crucial for maintaining a ship’s stability and draft (depth in the water). It involves filling and emptying tanks within the ship with water. This controlled adjustment of weight distribution is vital for several reasons:

- Maintaining Stability: When a ship is lightly loaded or empty, ballast water adds weight low in the hull, lowering the center of gravity and increasing stability, preventing excessive rolling and pitching.

- Controlling Draft: Ballast water allows ships to adjust their draft to suit different water depths and load conditions. A deeper draft can be necessary in heavy seas for greater stability. Conversely, less draft might be needed for navigating shallower waterways.

- Trim Adjustment: By selectively filling or emptying ballast tanks, the ship’s trim (fore-to-aft balance) can be adjusted to optimize performance and handling.

Consider a large container ship: when empty, it needs ballast water to ensure sufficient stability. As it loads containers, ballast water is gradually removed to maintain an optimal draft and trim. The management of ballast water is crucial, especially regarding the spread of invasive species through the international transfer of ballast water – stringent regulations govern this aspect of shipping.

Q 5. How does a marine diesel engine work?

A marine diesel engine operates on the four-stroke principle, very similar to a car engine but built for greater reliability and power. The cycle is:

- Intake: The piston moves down, drawing air into the cylinder.

- Compression: The piston moves up, compressing the air to a high pressure and temperature.

- Power: Fuel is injected into the compressed air, causing it to ignite spontaneously (due to the high temperature and pressure). The resulting expansion forces the piston down, generating power.

- Exhaust: The piston moves up, expelling the burned gases from the cylinder.

Marine diesel engines are typically larger and more robust than automotive engines, designed to withstand harsh marine conditions. They often operate at lower speeds and higher torque for optimal efficiency in propelling large vessels. Large ships might use multiple diesel engines, sometimes connected to gears or generators to propel the ship or provide onboard power.

The reliability and longevity of marine diesel engines are paramount to ship operations. Regular maintenance and inspections are crucial for preventing failures at sea.

Q 6. Describe the different types of ship structures and their characteristics.

Ship structures are classified based on their hull form and overall design. Some key types are:

- Monohull: The traditional single-hull design, characterized by a single continuous hull, like most cargo ships and tankers.

- Catamaran: A vessel with two parallel hulls connected by a deck structure. Catamarans offer high stability and speed, making them suitable for passenger ferries and high-speed craft.

- Trimaran: Similar to a catamaran but with three hulls. Provides even greater stability and speed than catamarans but is more complex to build.

- SWATH (Small Waterplane Area Twin Hull): Features submerged hulls connected by a structure above the water. Offers superior stability in rough seas and a smoother ride, often used in military and research vessels.

Each type’s characteristics are dictated by its intended purpose and operating environment. A cargo ship will prioritize cargo capacity and fuel efficiency, while a passenger ferry will prioritize comfort and speed. The choice of structure involves considerations of stability, seakeeping, speed, construction cost, and overall efficiency.

Q 7. What are the key considerations in ship design for minimizing resistance?

Minimizing resistance is critical in ship design, directly impacting fuel efficiency and speed. Key considerations include:

- Hull Form Optimization: The shape of the hull is crucial. Hydrodynamic design principles focus on creating a streamlined hull form that reduces frictional resistance and wave-making resistance. This involves advanced computational fluid dynamics (CFD) simulations and model testing.

- Surface Finish: A smooth hull surface minimizes frictional resistance. Regular hull cleaning and the application of anti-fouling coatings are vital to reduce the build-up of marine organisms.

- Appliances and Appendages: The design of appendages like rudders, propellers, and shaft brackets should be optimized to reduce their drag. Careful placement and shaping minimize interference and improve efficiency.

- Bulbous Bow: Many modern ships feature a bulbous bow (a protrusion at the bottom of the bow), which modifies the wave pattern created by the hull, reducing wave-making resistance, especially at higher speeds.

- Propeller Design: Selecting the appropriate type and size of propeller maximizes thrust and minimizes propeller-induced drag.

These considerations involve a complex interplay of factors, and advanced techniques like CFD simulations and model testing in towing tanks are crucial for optimizing hull design and minimizing resistance. The goal is to achieve the most efficient vessel design possible for a given task.

Q 8. Explain the concept of metacentric height and its importance.

Metacentric height (GM) is a measure of a ship’s initial static stability. It’s the distance between the center of gravity (G) and the metacenter (M). The metacenter is the point of intersection between the line of action of the buoyant force and the centerline of the ship, when the ship is heeled (tilted) a small angle. A higher GM indicates greater initial stability, meaning the ship will resist heeling and return to its upright position more quickly after being disturbed.

Think of it like this: imagine a toy top. A top with a low center of gravity and a high metacenter (imagine a longer stem) is very stable and resists falling over. Conversely, a top with a high center of gravity and a low metacenter is easily knocked over. In ships, a sufficient GM is crucial for safe operation. An insufficient GM can lead to capsizing, especially in rough seas or with improper cargo loading.

In practice, naval architects carefully calculate GM during the design phase. This involves determining the ship’s center of gravity through weight calculations and the metacenter through hydrostatic calculations. GM is a key parameter in stability calculations, and regulations set minimum acceptable values depending on the ship type and intended operating conditions.

Q 9. How is ship stability affected by cargo loading?

Cargo loading significantly impacts ship stability. Improper cargo distribution can lead to a dangerously low GM, increasing the risk of capsizing. The key factors are:

- Center of Gravity (CG) Location: Heavier cargo placed high in the ship raises the CG, lowering GM. Conversely, placing heavy cargo low in the ship lowers the CG and increases GM.

- Cargo Shifting: Liquid cargo, for example, can shift during rolling motion, dramatically altering the CG and potentially leading to instability. This is why tankers have complex ballast and internal subdivision systems to mitigate this risk.

- Cargo Weight Distribution: Uneven cargo distribution can cause list (a permanent lean to one side), affecting stability and potentially causing stress on the hull. Proper weight distribution, as determined by load plans and trim calculations, is essential.

For example, a container ship carrying heavy containers high on deck may have a lower GM than one carrying the same total weight but with containers stowed lower. Careful planning and adherence to load plans, along with regular stability assessments are crucial to ensure the ship remains seaworthy and safe. Incorrect loading can be disastrous. The Herald of Free Enterprise disaster, partially attributed to improper loading and securing of vehicles, is a tragic example.

Q 10. Describe the different types of marine coatings and their purposes.

Marine coatings protect ship hulls and superstructures from corrosion, fouling (marine growth like barnacles and algae), and abrasion. Different types serve specific purposes:

- Anti-fouling coatings: These contain biocides that prevent marine organisms from attaching to the hull, reducing drag and improving fuel efficiency. Tributyltin (TBT) was commonly used but is now banned due to its environmental toxicity. Copper-based and silicone-based coatings are now more prevalent.

- Anti-corrosive coatings: These protect the metal substrate from rust and degradation. They can be zinc-rich primers, epoxy coatings, polyurethane coatings, or other specialized systems that provide a barrier between the metal and the seawater. The choice depends on factors like the substrate material, environmental conditions, and expected lifespan.

- Topcoats: Applied over anti-corrosive coatings, these provide additional protection from UV radiation, abrasion, and weathering. They often enhance aesthetics and provide a more durable finish.

- Specialized coatings: These include coatings designed for specific areas, such as ballast tanks to prevent corrosion in the presence of corrosive ballast water, or high-temperature coatings for engine rooms.

The application process is critical to coating performance. Proper surface preparation, including cleaning and blasting, is vital to ensure good adhesion and long-lasting protection. Incorrect application can lead to premature coating failure and increased maintenance costs.

Q 11. Explain the process of marine corrosion and its prevention.

Marine corrosion is the deterioration of ship materials (primarily steel) due to electrochemical reactions with the seawater environment. It’s a significant concern, leading to structural weakening, reduced lifespan, and increased maintenance costs. The process involves anodic and cathodic reactions:

- Anodic reaction (oxidation): Iron in the steel loses electrons and forms iron ions (Fe2+).

- Cathodic reaction (reduction): Oxygen in the seawater gains electrons, forming hydroxide ions (OH–).

These reactions are accelerated by factors like salinity, temperature, dissolved oxygen, and the presence of corrosive contaminants. Different types of corrosion exist, including uniform corrosion (even across the surface), pitting corrosion (localized attack), and galvanic corrosion (between dissimilar metals).

Corrosion prevention involves various strategies:

- Protective Coatings: As discussed earlier, these provide a barrier between the steel and the seawater.

- Cathodic Protection: This involves using sacrificial anodes (e.g., zinc) that corrode preferentially, protecting the ship’s hull. Impressed current cathodic protection uses an external power source to provide electrons to the hull.

- Material Selection: Using corrosion-resistant materials like stainless steel or specialized alloys in critical areas can minimize corrosion.

- Design Considerations: Proper design, including good drainage and avoiding crevices where water can stagnate, reduces the risk of corrosion.

Regular inspections and maintenance are crucial for effective corrosion control. Early detection and timely repairs prevent major structural damage.

Q 12. What are the various types of marine fuels and their properties?

Marine fuels vary depending on the ship’s size, engine type, and environmental regulations. Key types include:

- Heavy Fuel Oil (HFO): A viscous, high-sulfur fuel widely used in large container ships and tankers due to its low cost. However, its high sulfur content contributes significantly to air pollution, leading to stricter regulations and increased use of exhaust gas cleaning systems (scrubbers).

- Marine Gas Oil (MGO): A distillate fuel with lower sulfur content than HFO, used in smaller ships and those operating in Emission Control Areas (ECAs). It’s cleaner-burning but more expensive.

- Liquefied Natural Gas (LNG): A cleaner-burning alternative to traditional fuels, with significantly lower emissions of greenhouse gases and sulfur oxides. Its use is growing, but requires specialized infrastructure and storage onboard.

- Liquefied Petroleum Gas (LPG): Another alternative fuel with lower emissions than HFO and MGO. Like LNG, it necessitates specialized storage and handling systems.

Fuel properties relevant to marine operations include:

- Sulfur content: This affects air pollution and compliance with environmental regulations.

- Viscosity: Affects fuel flow and atomization in the engine.

- Energy density: Determines the amount of energy per unit volume.

Selecting the appropriate fuel involves balancing cost, environmental impact, engine compatibility, and regulatory compliance. The transition towards cleaner fuels like LNG and LPG is underway, driven by environmental concerns and international regulations.

Q 13. Describe the principles of ship maneuvering and control.

Ship maneuvering and control involve skillfully using the ship’s propulsion system and rudder to achieve desired movements. This requires understanding hydrodynamic forces, propeller characteristics, and the ship’s response to rudder commands. Key principles include:

- Propulsion: The ship’s engines provide thrust, either through propellers or other propulsion systems. The magnitude and direction of thrust determine the ship’s speed and initial course.

- Rudder: The rudder provides directional control, creating hydrodynamic forces that steer the ship. The rudder’s effectiveness depends on speed, hull form, and water flow conditions.

- Hydrodynamic forces: These forces, including drag, lift, and added mass, influence the ship’s maneuvering characteristics. Understanding these forces helps predict the ship’s response to control inputs.

- Ship dynamics: This considers the ship’s response to control inputs, accounting for factors like inertia, yaw, pitch, and roll. Models are used to simulate ship behavior and assess maneuverability.

Maneuvering involves a complex interplay of rudder angle, engine speed, and the ship’s response to these actions. Skilled officers use these elements to perform maneuvers such as turning, docking, and maintaining a steady course in varying sea conditions. Advanced maneuvering systems and simulators enhance training and improve control in challenging environments. The Costa Concordia disaster serves as a stark reminder of the devastating consequences of inadequate maneuvering and decision-making.

Q 14. Explain the function of a rudder and its various types.

The rudder is a pivotal component for ship steering, providing directional control by creating hydrodynamic forces that counteract the ship’s momentum. It’s essentially a submerged airfoil, pivoting about a vertical axis. The rudder’s shape and size are carefully designed to maximize its effectiveness. Different types of rudders exist:

- Conventional Rudder: A simple, flat plate-like rudder with a streamlined shape. It’s cost-effective but can be less efficient at low speeds.

- High-lift Rudder: This type has a more complex shape, often incorporating a leading edge flap or a bulbous section at the leading edge, to increase lift and improve steering at low speeds. This is often found in larger ships.

- Skeg Rudder: A rudder supported by a skeg, a vertical extension of the hull. This provides increased structural support and reduces hydrodynamic forces on the rudder stock.

- Ducted Rudder: This rudder is housed in a duct, shaping the flow of water around the rudder and enhancing its effectiveness, especially at low speeds or during maneuvering. This is commonly used in vessels requiring better manoeuvrability.

The rudder’s operation is controlled by the ship’s steering gear, which uses hydraulic or electro-hydraulic systems. The angle of the rudder is adjusted by the helmsman or an automated steering system to maintain the desired course. The effectiveness of the rudder is affected by factors like the ship’s speed, water current, and the rudder’s condition. Regular inspections and maintenance are crucial for safe and efficient steering.

Q 15. How does a GPS system work in marine navigation?

A GPS (Global Positioning System) in marine navigation relies on a constellation of satellites orbiting the Earth. These satellites transmit signals containing precise timing information. A GPS receiver on a ship receives these signals from multiple satellites, using the time differences between the signals’ arrival to calculate the receiver’s position using trilateration. Think of it like drawing circles on a map – each satellite’s signal defines a circle representing possible locations, and the intersection of multiple circles pinpoints the ship’s location.

In simpler terms, imagine three friends standing at known points, each shouting at the same time. You hear them at slightly different times, and based on the speed of sound, you can determine how far you are from each friend. The intersection of these distances gives your location. GPS works similarly, but using radio waves and satellites instead of friends and sound.

Marine applications often incorporate GPS data with other navigational aids like charts and compasses for redundancy and increased accuracy, especially in challenging environments.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key safety regulations in marine engineering?

Key safety regulations in marine engineering are numerous and vary depending on the flag state (the country under whose laws the ship operates) and the type of vessel. However, some overarching principles include adherence to the International Maritime Organization (IMO) conventions, such as the SOLAS (Safety of Life at Sea) convention. SOLAS mandates standards for hull integrity, fire protection, life-saving appliances, and communication systems.

Other critical regulations involve:

- Crew Certification and Training: Ensuring seafarers possess the necessary qualifications and undergo regular training to handle emergencies.

- Maintenance and Inspection: Regular inspections and maintenance of essential equipment, such as lifeboats, engines, and safety systems, are vital. This often involves documented evidence of inspections and repairs.

- Pollution Prevention: Strict regulations exist regarding the prevention of oil spills, ballast water management, and discharge of waste into the ocean.

- Cargo Handling and Securing: Safe and secure handling of cargo to prevent accidents and loss of life or property.

- Navigation and Communication: Proper navigation practices and effective communication systems are crucial for collision avoidance and safe voyage management.

Failure to comply with these regulations can lead to significant penalties, including fines, detention of vessels, and reputational damage for the ship owner and operator.

Q 17. Explain the different types of marine communication systems.

Marine communication systems are crucial for ensuring the safety and efficient operation of ships. These systems can be broadly categorized as follows:

- Very High Frequency (VHF) Radio: Used for short-range communication between ships and shore stations. This is often used for routine communication, distress calls, and coordinating activities with harbor authorities.

- Inmarsat: A global satellite communication system offering various services, including voice, data, and fax. Inmarsat is essential for communication in remote areas where VHF is not effective.

- Global Maritime Distress and Safety System (GMDSS): An integrated system ensuring distress alerts can be transmitted effectively worldwide, using various technologies like satellite EPIRBs (Emergency Position Indicating Radio Beacons) and VHF.

- Automatic Identification System (AIS): A system for automatically transmitting and receiving information about ships’ identity, position, and course. This improves collision avoidance and situational awareness.

- Long Range Identification and Tracking (LRIT): A satellite-based system used for tracking the positions of ships, particularly in international waters. This aids in enforcing safety regulations and security measures.

The choice of communication system depends on factors such as range, required data throughput, and cost. Modern ships typically employ a combination of these systems for redundancy and flexibility.

Q 18. Describe the principles of underwater acoustics.

Underwater acoustics is the science of sound propagation in water. It’s governed by the same principles as sound in air, but with significant differences due to water’s higher density and different properties. Sound travels much faster in water than in air (approximately 1500 m/s in seawater compared to 343 m/s in air).

Key principles include:

- Sound Speed Variation: The speed of sound in water varies with temperature, salinity, and pressure. These variations can cause sound waves to refract (bend) and create acoustic shadow zones.

- Absorption: Sound energy is absorbed by water, resulting in signal attenuation (weakening) with distance. The amount of absorption depends on frequency, with higher frequencies being absorbed more quickly.

- Scattering: Sound waves are scattered by inhomogeneities in the water column, such as marine organisms or suspended particles. This scattering can reduce the clarity of the signal.

- Refraction: Sound waves bend as they pass through regions of different sound speed. This affects how far a signal can travel and its direction.

These principles are essential for designing sonar systems for navigation, fish finding, and underwater communication. Understanding how sound behaves in water is critical for optimizing these systems’ performance.

Q 19. How does an automatic identification system (AIS) work?

The Automatic Identification System (AIS) is a crucial safety and navigational tool. It’s a radio-based system that allows ships to automatically broadcast their identity, position, course, and speed to other nearby vessels and shore-based stations.

Each ship equipped with AIS has a transponder that regularly transmits messages containing:

- MMSI (Maritime Mobile Service Identity): A unique alphanumeric identifier for the ship.

- Position (latitude and longitude): The ship’s current location obtained from GPS.

- Course and speed over ground: The direction and speed at which the ship is traveling.

- Navigational status: Information indicating the ship’s current operational status (e.g., underway, at anchor).

Other vessels and shore stations equipped with AIS receivers can pick up these messages, displaying the information on their navigational charts or displays, providing a real-time picture of the surrounding marine traffic. This significantly enhances collision avoidance and situational awareness, improving overall maritime safety.

Q 20. What are the environmental considerations in ship design?

Environmental considerations in ship design are increasingly critical due to growing concerns about climate change and marine ecosystem protection. These considerations encompass various aspects:

- Reduced Greenhouse Gas Emissions: Designing ships with improved fuel efficiency, using alternative fuels (e.g., LNG, hydrogen), and incorporating energy-saving technologies are key goals.

- Ballast Water Management: Minimizing the introduction and spread of invasive species via ballast water discharge is achieved through effective treatment systems.

- Noise Pollution: Reducing underwater noise produced by ships’ propellers and machinery to minimize disruption to marine life. This may involve using quieter propeller designs and noise reduction measures.

- Waste Management: Implementing efficient and environmentally friendly systems for handling sewage, garbage, and other ship-generated waste.

- Air Emissions: Minimizing emissions of sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter (PM) through improved engine technology and emission control systems.

- Hull Design for Reduced Resistance: Optimized hull forms can reduce fuel consumption and subsequently lower emissions.

Compliance with international regulations like MARPOL (International Convention for the Prevention of Pollution from Ships) is crucial for addressing these environmental concerns.

Q 21. Explain the concept of hull vibration and its mitigation.

Hull vibration in ships is caused by various sources, such as propeller excitation, engine vibrations, and wave impacts. Excessive vibration can lead to fatigue damage, noise pollution, and discomfort for passengers and crew.

The principles behind hull vibration are complex and involve structural dynamics. The hull acts as a complex structure with various natural frequencies. When an excitation force (like propeller thrust) matches one of these frequencies, resonance occurs, causing large amplitude vibrations.

Mitigation techniques include:

- Optimized Propeller Design: Using propellers with reduced cavitation and improved blade geometry can minimize vibration generation.

- Engine Mounting and Isolation: Using vibration dampeners and flexible mounts to isolate engine vibrations from the hull.

- Structural Modifications: Reinforcing or modifying the hull structure to alter its natural frequencies and avoid resonance.

- Active Vibration Control: Employing active systems that counteract vibrations using sensors and actuators.

- Passive Vibration Control: Using passive devices such as tuned mass dampers to absorb vibrational energy.

The choice of mitigation method depends on the specific causes and severity of the vibration, and a comprehensive approach often combines several techniques to achieve effective vibration control.

Q 22. Describe the different types of marine engines and their applications.

Marine engines are the heart of any vessel, powering propulsion and onboard systems. Several types exist, each suited to different applications:

- Diesel Engines: The most common type, offering high efficiency and reliability. They range from small, slow-speed engines in smaller vessels to massive, high-speed engines in large container ships and tankers. Slow-speed, two-stroke engines are particularly efficient for large vessels, while medium-speed four-stroke engines find applications in a broader range of ship types.

- Gas Turbines: Used primarily for high-speed applications, such as fast ferries and naval vessels, where their high power-to-weight ratio is advantageous. They are generally less fuel-efficient than diesel engines for continuous operation.

- Steam Turbines: Less common nowadays, but still used in some older vessels and specialist applications like nuclear-powered ships. They utilize steam generated from boilers to drive turbines.

- Electric Propulsion: An increasingly popular option, particularly for environmentally conscious designs. It involves using electric motors powered by generators (often diesel-driven) to propel the ship. This allows for better efficiency and control, potentially incorporating hybrid systems for optimized performance.

- Hybrid Propulsion Systems: Combining different power sources like diesel and electric motors, allowing for optimized performance and potentially reducing emissions depending on the operational profile. This strategy offers flexibility and efficiency depending on whether the vessel is at cruising speed or maneuvering in port.

The choice of engine type depends heavily on factors like vessel size, speed requirements, operational profile (e.g., long voyages vs. short trips), environmental regulations, and budget.

Q 23. What is the role of a marine surveyor?

A marine surveyor is a vital part of the maritime industry, acting as an independent expert assessing the condition, value, and seaworthiness of vessels. Their role encompasses a wide spectrum of activities:

- Condition Surveys: Thoroughly inspecting a ship’s hull, machinery, equipment, and structure to determine its overall condition and identify potential defects or maintenance needs. This is often required before purchase, sale, or insurance renewal.

- Valuations: Estimating the market value of a vessel based on its condition, age, and market trends. This is critical for insurance, sale, and financing purposes.

- Damage Surveys: Investigating damage to a vessel after an accident or incident, determining the cause, extent of damage, and associated costs of repair.

- Insurance Surveys: Assessing the risks associated with insuring a vessel and ensuring it meets the insurer’s requirements.

- Compliance Surveys: Verifying that a vessel complies with relevant safety regulations and international conventions.

Marine surveyors require extensive knowledge of shipbuilding, marine engineering, and maritime law to perform their duties effectively. They act as neutral third parties, providing objective assessments to different stakeholders in the maritime industry. Think of them as the doctors for ships, ensuring they are fit for purpose and safe.

Q 24. Explain the principles of hydrodynamics and their application to ship design.

Hydrodynamics is the study of how fluids (like water) behave when in motion, particularly their interaction with solid bodies, like ships. Understanding hydrodynamics is paramount in ship design for optimizing performance and efficiency.

- Resistance: Ships experience resistance as they move through water. This resistance is composed of frictional resistance (due to water viscosity), wave-making resistance (due to waves generated by the hull), and pressure resistance (due to the shape of the hull).

- Propulsion: Efficient propulsion requires careful consideration of propeller design and its interaction with the hull. The propeller generates thrust to overcome resistance.

- Maneuverability: Hydrodynamics plays a crucial role in the design of a ship’s rudder and other control surfaces to ensure safe and efficient maneuvering. The shape of the hull influences its response to the rudder and its overall responsiveness.

- Seakeeping: The ability of a ship to handle waves and rough seas is significantly influenced by its hull form and hydrodynamics. This involves analyzing motions such as rolling, pitching, and heaving.

Applying these principles allows naval architects to design hulls that minimize resistance, maximize propulsion efficiency, and enhance seakeeping qualities. Computational Fluid Dynamics (CFD) is a powerful tool used to simulate and predict hydrodynamic behavior before the actual construction of the ship.

Q 25. Describe the different types of sea fastening systems.

Sea fastening systems secure cargo and equipment during transit, preventing damage and ensuring safety. Different systems cater to different cargo types and environmental conditions:

- Lashing: Using strong straps or chains to secure cargo to the deck or bulkheads. This is common for containers, vehicles, and other large items.

- Wedging: Filling gaps between cargo pieces with wooden wedges or similar materials to prevent movement. This is often used for timber or other irregularly shaped cargo.

- Blocking and Bracing: Using wooden blocks or other supports to create a rigid structure around the cargo, preventing shifting. This is effective for heavy or oddly-shaped cargo.

- Dunnage: Using materials like wood or plastic to create a level surface and prevent damage to cargo. This protects the goods from abrasion and impact.

- Container Securing Systems: Specialized systems designed for securing shipping containers on deck, utilizing twist locks and other mechanisms.

The choice of sea fastening system depends on factors such as the type of cargo, its weight and dimensions, the expected sea conditions during transit, and the vessel’s design. Proper sea fastening is crucial for preventing cargo damage, vessel damage, and ensuring the safety of crew.

Q 26. How is the structural integrity of a ship assessed?

Assessing a ship’s structural integrity is a complex process, involving a combination of methods:

- Initial Design and Analysis: Finite Element Analysis (FEA) is used extensively during the design phase to simulate stresses and strains under various loading conditions (waves, cargo weight, etc.).

- Non-Destructive Testing (NDT): Various NDT techniques, such as ultrasonic testing, radiographic testing, and magnetic particle inspection, are used to detect flaws or defects in the ship’s structure without causing damage.

- Regular Inspections and Surveys: Ships undergo regular inspections and surveys (both during operation and in dry dock) to detect any signs of deterioration, corrosion, or damage. These inspections are guided by classification society rules and regulations.

- Monitoring Systems: Advanced vessels may incorporate structural health monitoring systems using sensors to continuously track stresses and strains in critical areas of the hull.

- Thickness Measurements: Regular measurements of the thickness of plating and other structural members help assess the level of corrosion and remaining structural life.

The goal is to ensure the ship’s structure can withstand the stresses encountered throughout its operational life. Failure to maintain structural integrity can have catastrophic consequences, leading to accidents and significant financial losses. Classification societies play a crucial role in setting standards and overseeing structural integrity assessments.

Q 27. What are the different stages of ship design and construction?

Ship design and construction is a multi-stage process:

- Conceptual Design: Initial feasibility studies, defining the ship’s purpose, size, and overall characteristics.

- Preliminary Design: Developing detailed plans, including hull form, propulsion system, and general arrangement.

- Detailed Design: Producing detailed engineering drawings and specifications for all ship components and systems.

- Construction: Building the ship according to the detailed design, involving multiple stages like steel cutting, assembly, outfitting, and testing.

- Sea Trials: Testing the ship’s performance and systems at sea to ensure it meets specifications.

- Delivery and Commissioning: Transferring ownership to the client and putting the ship into operation.

Each stage involves various specialists, including naval architects, marine engineers, and other skilled professionals. Effective coordination and communication are crucial throughout the process to ensure the ship is delivered on time and within budget, while meeting all performance and safety requirements.

Q 28. Explain the role of CFD analysis in ship design.

Computational Fluid Dynamics (CFD) analysis is a powerful tool used to simulate the flow of fluids around a ship’s hull. It allows naval architects to predict hydrodynamic performance and optimize the design before building a physical model or the actual vessel.

- Resistance Prediction: CFD can accurately predict the resistance a ship will experience at various speeds, helping to optimize the hull form for fuel efficiency.

- Propulsion System Optimization: CFD can analyze the interaction between the propeller and the hull, allowing for improved propeller design and minimizing energy loss.

- Maneuvering Analysis: CFD can simulate a ship’s maneuvering characteristics, helping to optimize the design of rudders and other control surfaces.

- Seakeeping Analysis: CFD can predict how a ship will behave in waves, aiding in the design of a seaworthy hull that minimizes motions in rough seas.

- Propeller Cavitation Analysis: CFD can help designers reduce or avoid propeller cavitation, a phenomenon that reduces efficiency and can cause damage to the propeller.

By employing CFD, designers can identify potential issues early in the design process, reducing the need for costly modifications and improving the overall performance and efficiency of the ship. It’s a crucial element of modern ship design, bridging the gap between theoretical understanding and practical applications.

Key Topics to Learn for Marine Engineering and Ship Design Interviews

- Hydrostatics and Stability: Understanding buoyancy, stability criteria, and the impact of cargo loading on ship behavior. Practical application includes calculations for safe loading and ballast conditions.

- Propulsion Systems: Knowledge of different propulsion types (e.g., diesel engines, gas turbines, electric propulsion), their operational principles, and maintenance. Practical application involves troubleshooting engine malfunctions and optimizing fuel efficiency.

- Ship Design and Construction: Familiarity with various ship types, their structural design considerations (e.g., material selection, stress analysis), and construction methods. Practical application includes understanding the design process from initial concept to final construction.

- Marine Regulations and Safety: Thorough understanding of relevant international maritime regulations (e.g., SOLAS, MARPOL) and safety procedures. Practical application includes ensuring compliance with regulations and mitigating safety risks.

- Fluid Mechanics and Thermodynamics: Solid grasp of fundamental principles related to fluid flow, heat transfer, and energy conversion within marine systems. Practical application involves analyzing system performance and optimizing efficiency.

- Automation and Control Systems: Understanding the role of automation in modern ships, including engine room automation and navigational systems. Practical application includes troubleshooting and maintaining automated systems.

- CAD Software and Ship Design Tools: Proficiency in relevant CAD software (e.g., AutoCAD, SolidWorks) used in ship design and 3D modeling. Practical application includes creating and interpreting ship designs using these tools.

Next Steps

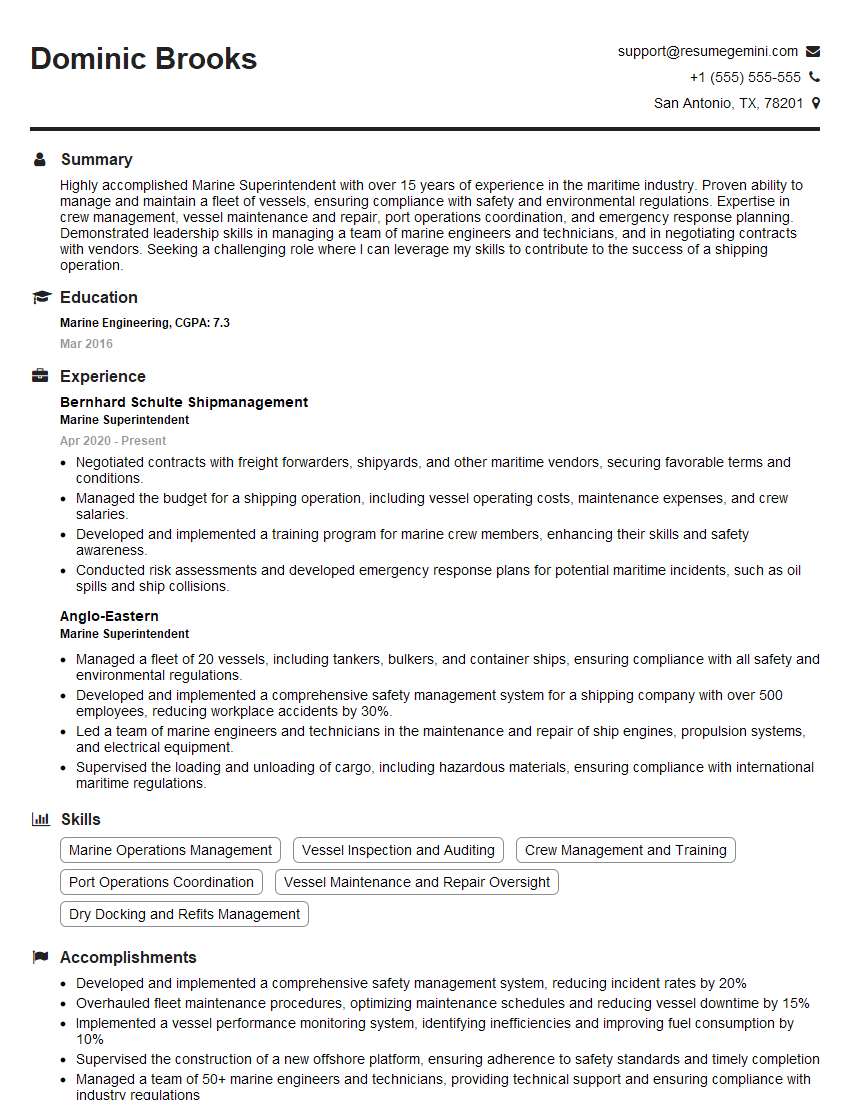

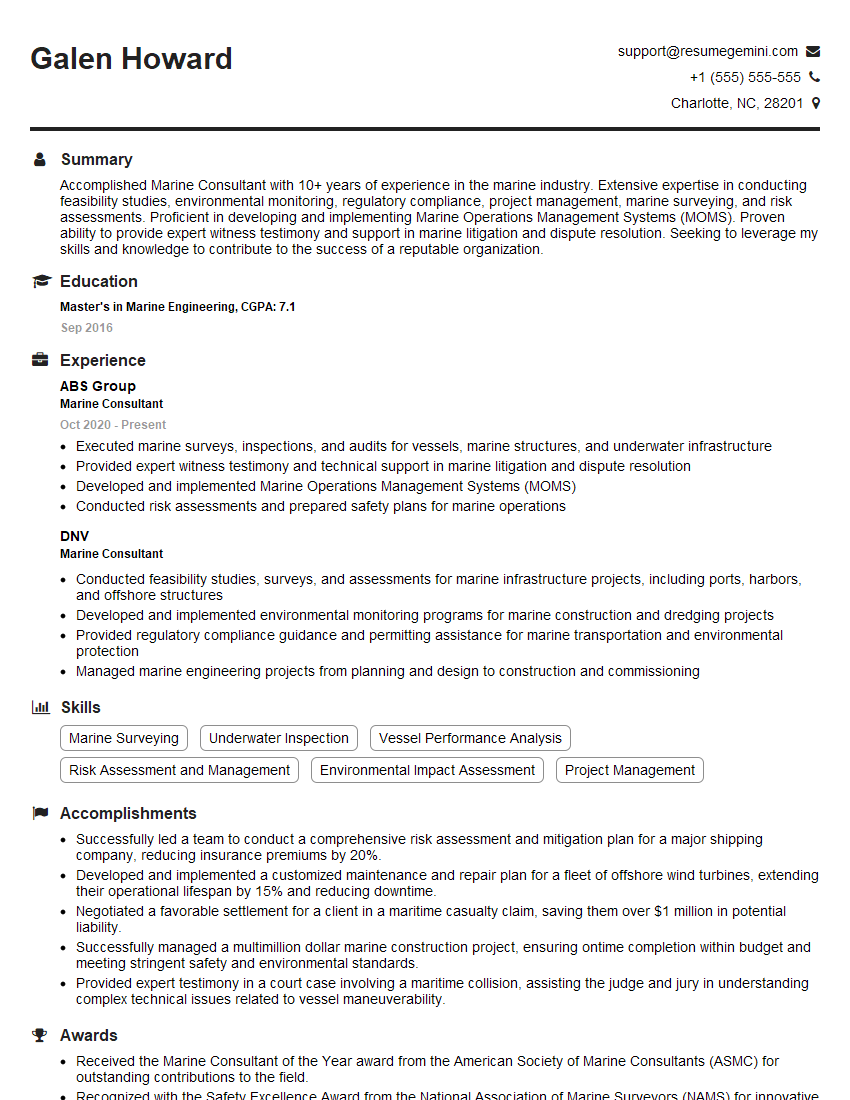

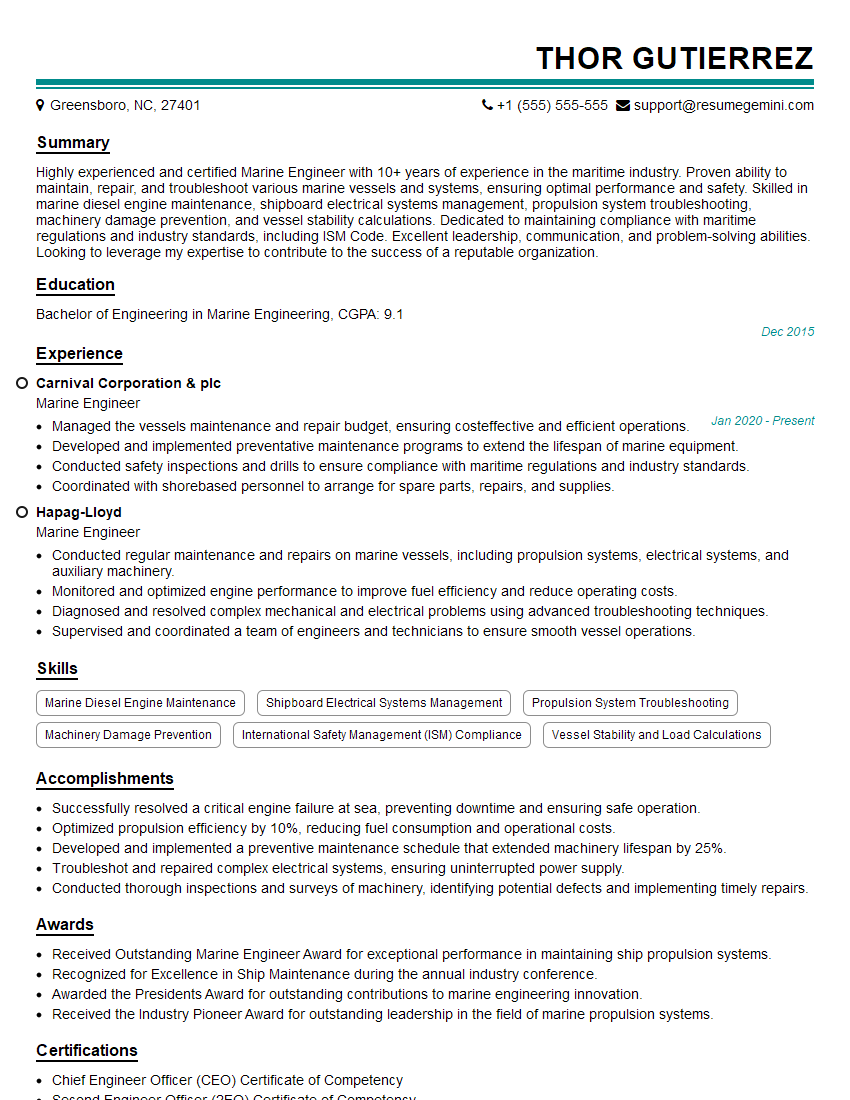

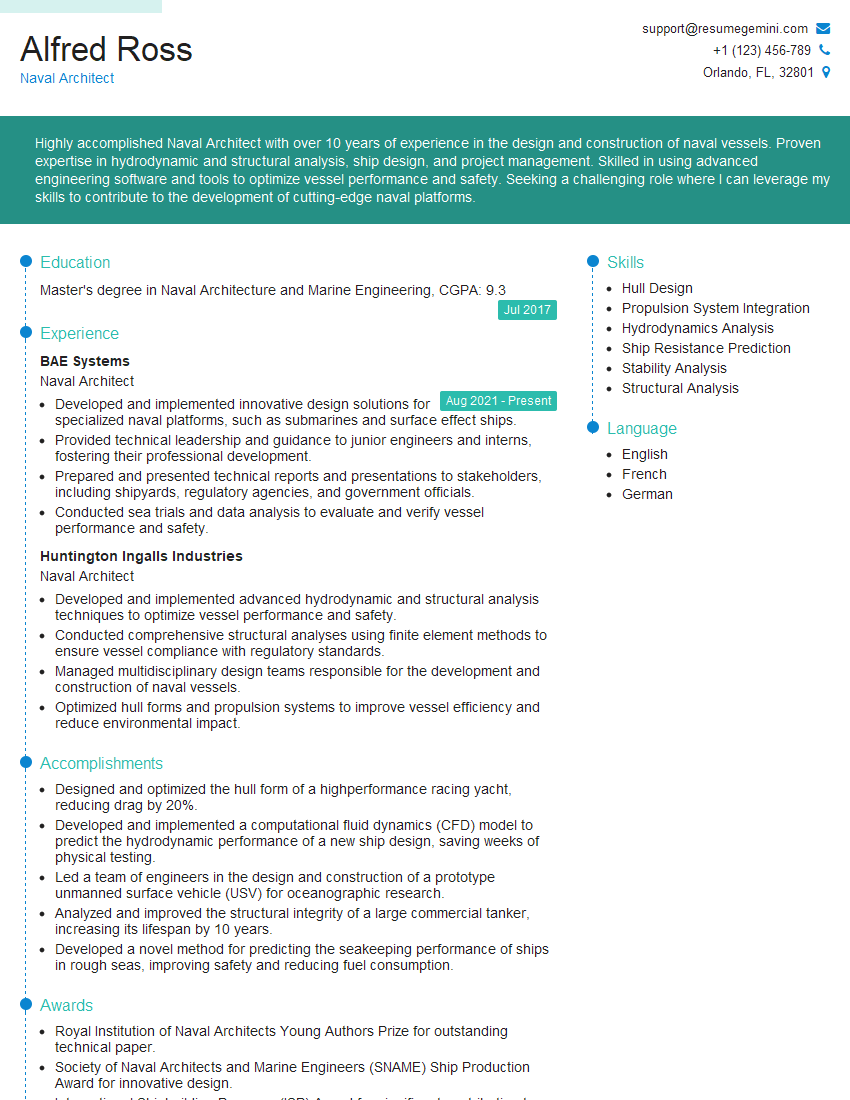

Mastering Marine Engineering and Ship Design opens doors to a rewarding career with diverse opportunities for growth, from design and construction to operations and management. To significantly boost your job prospects, creating a strong, ATS-friendly resume is crucial. This ensures your application gets noticed by recruiters and hiring managers. We highly recommend using ResumeGemini, a trusted resource that helps you build a professional and impactful resume. ResumeGemini offers examples of resumes tailored to Marine Engineering and Ship Design, providing you with a head start in showcasing your skills and experience effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good