Cracking a skill-specific interview, like one for Material knowledge and embroidery techniques, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Material knowledge and embroidery techniques Interview

Q 1. Describe the different types of embroidery stitches and their applications.

Embroidery stitches are the fundamental building blocks of any embroidery design. They vary widely in appearance and function, impacting the texture, density, and overall aesthetic of the finished piece. Here are some key stitch types and their applications:

- Running Stitch: A simple stitch, ideal for outlining, creating lines, or filling in large areas quickly. Think of it as the pencil sketch of embroidery. I often use this as a base for more complex stitches.

- Backstitch: Creates a solid, neat line, often used for outlining or detailed work. Its strength makes it perfect for lettering or creating crisp edges. I’ve used this extensively in logos and monograms.

- Satin Stitch: Produces a smooth, glossy surface, perfect for filling in shapes or creating solid blocks of color. It’s like painting with thread; I frequently use it for floral designs and detailed images.

- French Knots: Small, decorative knots used to add texture and dimension, often used to represent small details like flower centers or eyes. Think of them as the sparkling details that bring a design to life.

- Chain Stitch: Creates a looped line, useful for outlining, adding texture, or filling areas. I use chain stitch to mimic vines or create a flowing effect.

- Cross Stitch: A simple X-shaped stitch, commonly used in counted-thread embroidery. It’s incredibly versatile and provides a distinct, easily recognizable texture. I frequently use it for folk art-inspired designs.

The choice of stitch depends heavily on the design, fabric, and desired effect. Experimenting with different combinations of stitches is key to developing a unique embroidery style.

Q 2. Explain the properties of various embroidery fabrics (e.g., cotton, linen, silk).

The fabric you choose significantly impacts the final look and feel of your embroidery. Different fabrics have unique properties that influence stitch visibility, thread tension, and overall durability:

- Cotton: A widely used fabric, cotton is durable, readily available, and easy to work with. Its smooth surface allows for crisp stitch definition. It’s a great all-around choice for beginners and experienced embroiderers alike. I frequently use cotton for projects that require durability, such as towels or clothing.

- Linen: Linen has a beautiful, slightly irregular texture that adds character to embroidery. Its strength and drape make it suitable for both fine detail work and larger projects. However, its tighter weave can sometimes be challenging for beginners. It’s a favorite for elegant designs where texture is desired.

- Silk: A luxurious fabric, silk is renowned for its sheen and drape. It’s ideal for delicate embroidery, but requires careful handling due to its delicacy. The subtle sheen enhances the beauty of embroidery threads. I reserve silk for high-end projects where the fabric itself is part of the design’s elegance.

Choosing the right fabric is crucial. The fabric’s weight, weave, and fiber content will affect how the stitches sit, making it essential to consider these factors before starting a project. For instance, a dense fabric might require a stronger thread to prevent the stitches from sinking.

Q 3. How do you select the appropriate thread for a specific embroidery project?

Thread selection is paramount to achieving the desired result. Several factors influence the appropriate thread choice:

- Fiber Content: Cotton, rayon, silk, and polyester are common embroidery thread materials. Cotton is a classic, durable choice; rayon offers luster; silk provides a luxurious sheen; and polyester offers high strength and vibrant color. I often use a blend depending on project requirements.

- Weight/Thickness: The weight of the thread must match the fabric and design details. Heavy threads are suitable for larger designs and coarser fabrics, whereas finer threads are used for finer details and lighter fabrics.

- Color: The color should harmonize with the fabric and overall design. I often use color charts to ensure consistent and accurate color matching.

- Design Complexity: Intricate designs may necessitate a finer thread for sharp details, while simpler designs can handle a heavier thread.

For example, for a delicate floral design on silk, I would choose a fine silk thread to maintain its elegance and prevent overpowering the fabric. However, for a bold design on denim, I would use a heavier cotton thread for durability and stitch definition.

Q 4. What are the advantages and disadvantages of different embroidery machines?

Embroidery machines offer speed and precision but come with their own sets of advantages and disadvantages:

- Home Embroidery Machines: These are affordable and convenient for smaller projects, but they often have limited features and stitching capabilities. Great for hobbyists or smaller-scale projects.

- Industrial Embroidery Machines: These machines are powerful and highly versatile, capable of handling large-scale projects with complex designs and high stitch densities. They are expensive but essential for large-volume production and detailed work. Perfect for businesses or those producing many embroidered items.

- Single-head vs. Multi-head: Single-head machines are more common and suitable for many types of projects, while multi-head machines significantly increase production speed and are used in mass production settings.

The choice depends entirely on your needs and budget. A home machine is ideal for personal projects, while industrial machines are essential for professional use. I’ve worked with both and understand their distinct strengths and limitations.

Q 5. Describe your experience with embroidery digitizing software.

I have extensive experience with various embroidery digitizing software, including Wilcom, Embird, and Pulse. Proficiency in this software allows for the creation of intricate and precise embroidery designs from digital artwork. I’m comfortable converting artwork into stitch files, adjusting stitch density, and optimizing designs for different embroidery machines. My skills extend to understanding color separation, underlay creation, and optimizing designs for various fabric types.

For example, I’ve used Wilcom to create complex logos for corporate apparel, carefully considering stitch density and thread count to guarantee excellent quality even with repeated washes. My experience allows me to troubleshoot and improve digital designs before they ever reach the embroidery machine, reducing waste and increasing efficiency.

Q 6. How do you troubleshoot common embroidery machine problems?

Troubleshooting embroidery machine problems requires a systematic approach. Here are some common issues and solutions:

- Thread breakage: Check for knots in the thread, ensure proper tension, and examine the thread path for obstructions.

- Skipped stitches: Adjust needle tension, check for bent needles, and clean the bobbin area. Inspect the machine’s feed dogs for any obstruction.

- Puckering/distortion: Adjust the stabilizer and hooping tension. Ensure the fabric is securely hooped. Check if the design is too dense for the fabric.

- Needle breakage: Use the correct needle type for the fabric and thread. Ensure the needle is inserted properly and is not bent.

Before tackling any issue, always consult the machine’s manual. Understanding its inner workings is crucial for effective diagnosis. Experience helps identify the root cause quickly, reducing downtime and improving efficiency. I’ve learned that meticulous attention to detail, from thread tension to the condition of the needle, is key to preventing most problems.

Q 7. Explain the process of creating an embroidery design from concept to production.

Creating an embroidery design from concept to production is a multi-step process:

- Concept Development: This stage involves brainstorming, sketching, and refining the design. The design’s purpose, target audience, and the final product’s use all play significant roles in the design’s creation.

- Digitalization: Using digitizing software, the design is converted into a stitch file containing instructions for the embroidery machine. This step often involves optimizing for stitch density, underlay, and color separation. This is where software expertise plays a crucial role.

- Testing & Refinement: A test run on a scrap fabric allows for identifying and correcting any flaws or imperfections in the design or stitch settings.

- Material Selection: The appropriate fabric, thread, and stabilizer are chosen based on the design’s complexity and desired outcome. This step utilizes my material knowledge and experience.

- Production: The final design is embroidered on the chosen fabric, following the optimized stitch file and using appropriate tension settings.

- Quality Control: The finished product is inspected for any defects before packaging or delivery. Maintaining quality control throughout the entire process is essential.

My experience allows me to streamline this process, ensuring efficient production while upholding the highest standards of quality. Each step is crucial, and a thorough understanding of each stage is key to creating beautiful and durable embroidery.

Q 8. How do you ensure consistent quality in embroidery production?

Maintaining consistent quality in embroidery production is paramount. It’s a multifaceted process that begins even before the needle touches the fabric. Think of it like baking a cake – you need precise measurements and consistent execution to achieve the perfect result.

- Standardization of Materials: Using high-quality, consistent materials is crucial. This includes selecting threads from the same dye lot, ensuring the stabilizer is appropriate for the fabric and design, and maintaining consistent needle and hoop tension. Inconsistent thread can lead to color variations, and improper stabilizer can result in puckering or distortion.

- Calibration and Maintenance: Regularly calibrating and maintaining embroidery machines is essential. This includes cleaning the machine, checking the tension of the threads, and ensuring the needle is sharp and appropriately sized for the thread and fabric. A poorly maintained machine can lead to skipped stitches, broken threads, and uneven stitching.

- Quality Control Checks: Implementing rigorous quality control checks at each stage of production is vital. This might involve inspecting the fabric for imperfections before embroidery, examining the stitching quality during the process, and performing a final inspection after completion to ensure consistency in stitch density, color accuracy and overall design execution. A visual inspection combined with a physical touch-check can reveal minor flaws that might be missed otherwise.

- Operator Training: Well-trained operators are key to consistent results. Consistent stitching speeds and pressure on the foot pedal impact the final quality of the embroidery. Regular training and feedback sessions can maintain high standards, minimizing errors and ensuring everyone is using the best practices.

Q 9. What are your methods for managing embroidery projects and deadlines?

Managing embroidery projects and deadlines effectively requires a structured approach. I use a project management system that combines careful planning with flexible adaptation. Imagine it as orchestrating a symphony – each instrument (task) needs to play its part at the right time for a harmonious outcome.

- Detailed Project Briefs: Each project begins with a detailed brief outlining the design, fabric, thread type, number of pieces, and the deadline. This clarifies expectations and avoids misunderstandings.

- Production Scheduling: I use project management software to create a detailed schedule, allocating specific time slots for each stage of the process: design digitization, fabric preparation, embroidery, and quality control. This timeline is shared with the team and updated regularly to reflect any changes.

- Communication and Collaboration: Open communication is vital. Regular updates with clients and the production team keep everyone informed of progress and any potential issues. This allows for early detection and resolution of problems, helping to avoid delays.

- Contingency Planning: Unexpected issues can arise – machine malfunctions, material shortages, or design changes. Having a contingency plan in place allows for flexibility and ensures that projects can still be completed on time, even with unforeseen circumstances. This could involve having backup machines or materials available.

Q 10. Describe your experience with different embroidery techniques (e.g., free motion, appliqué).

My experience encompasses a wide range of embroidery techniques, each offering unique creative possibilities. Think of them as different painting techniques – each adds its own texture and style to the artwork.

- Free Motion Embroidery: This technique allows for incredibly free-flowing designs, almost like drawing with thread. I’ve used it extensively to create intricate floral patterns and custom lettering on garments and home décor items. The key here is maintaining consistent hand-eye coordination and controlling the speed of the machine.

- Appliqué: Appliqué is a technique where fabric shapes are sewn onto a base fabric to create a dimensional effect. I’ve combined appliqué with embroidery to create stunning three-dimensional designs, adding texture and depth to my work. Precise cutting and placement of the appliqué fabric are essential to achieve clean lines and a professional finish.

- Chain Stitch Embroidery: This simple yet versatile stitch is fantastic for creating outlines, filling areas, and adding textural details. Its repetitive nature makes it ideal for creating larger-scale patterns, and the stitch length is easily adjustable for various effects. I have used this technique extensively for both detailed designs and larger, bold statements.

- Satin Stitch Embroidery: This technique creates smooth, lustrous surfaces, perfect for solid color blocks or detailed filled areas. Achieving a high-quality satin stitch requires careful attention to machine tension and thread selection to prevent puckering or gaps in the stitching.

Q 11. How do you determine the appropriate stabilizer for a given embroidery project?

Choosing the right stabilizer is critical for achieving professional-looking embroidery; it’s like choosing the right foundation for a building. The wrong stabilizer can ruin the project by causing puckering, distortion, or even tearing of the fabric.

My selection process considers several factors:

- Fabric Type: Lightweight fabrics require lightweight stabilizers, while heavier fabrics may need a heavier-duty stabilizer to prevent distortion. For example, delicate silks would require a soft cut-away stabilizer, whereas a heavy denim might use a tear-away.

- Design Density: Dense designs require more support than sparse ones. A heavier stabilizer is necessary for densely packed designs to prevent puckering and maintain the stitch quality.

- Embroidery Technique: Different techniques require different types of stabilizer. Appliqué often needs a combination of stabilizers for optimal results. Free motion embroidery, however, often benefits from a cutaway stabilizer for easier removal.

- Stitch Type: Certain stitches, such as satin stitches, require more support than others. Choosing the right stabilizer ensures these stitches are crisp and clean without pulling or distorting the fabric.

I often use a combination of stabilizers for intricate designs or when working with difficult fabrics, for instance using a wash-away stabilizer as an underlying layer for extra support, topped with a tear-away stabilizer for easier removal post-embroidery.

Q 12. Explain your knowledge of different types of embroidery thread (e.g., rayon, polyester).

Embroidery threads come in a wide variety of materials, each with unique properties influencing the look and feel of the finished product. Think of them like different types of paint – each adds a different texture and vibrancy to the artwork.

- Rayon: Rayon threads are known for their beautiful sheen and luster. They offer a wide range of vibrant colors, but they’re less durable than polyester threads, making them unsuitable for high-wear items. They are ideal for projects where aesthetic appeal is prioritized over durability.

- Polyester: Polyester threads are very strong, durable, and colorfast, making them a good choice for items that will be frequently washed or handled. They have a slightly less lustrous finish than rayon, but their durability outweighs this for many applications.

- Cotton: Cotton embroidery threads are a natural fiber choice, offering a softer hand and a matte finish. They are ideal for projects that emphasize a natural, rustic look.

- Metallic Threads: These threads add a touch of glamour and shimmer. However, they can be more challenging to work with as they are more prone to breakage and require careful handling. They are best used sparingly to accentuate designs.

The choice of thread depends on the project’s requirements – durability, desired look, and the budget. For instance, I would use rayon thread for a delicate wedding dress embroidery but polyester for a durable children’s clothing design.

Q 13. How do you calculate the cost of an embroidery project?

Calculating the cost of an embroidery project involves several factors, similar to calculating the cost of any other product – materials, labor, and overhead. Think of it like calculating the cost of a customized cake – ingredients, baker’s time, and the cost of running the bakery all contribute to the final price.

- Materials Cost: This includes the cost of the fabric, thread, stabilizer, needles, and any other supplies needed. The quantity of materials used will directly influence this cost.

- Labor Cost: This covers the time spent on design digitization, fabric preparation, embroidery, and finishing. I calculate my labor cost based on an hourly rate or a per-piece rate depending on project complexity.

- Machine Usage: While less prominent than other costs, the hourly operational cost of machinery needs to be factored in. This cost includes electricity, regular maintenance, and depreciation of the equipment.

- Overhead: This encompasses the costs of running my business, such as rent, utilities, and insurance. This is a percentage added to the total cost to cover these expenses.

- Profit Margin: Finally, I add a profit margin, accounting for my business’s profitability and market competitiveness.

I use a spreadsheet to track these costs for each project, enabling accurate pricing and transparent cost breakdown for clients.

Q 14. How do you handle customer requests or design changes during the embroidery process?

Handling customer requests and design changes during the embroidery process requires clear communication and a flexible approach. It’s about collaboration and finding creative solutions, much like adapting a recipe to suit specific dietary needs.

- Open Communication: I maintain clear communication channels with clients to ensure that they are informed about the progress of their project and any potential challenges. This proactive communication minimizes surprises and misunderstandings.

- Feasibility Assessment: When a client requests a design change, I assess its feasibility, considering the impact on the project timeline and budget. Sometimes, a seemingly small change can significantly impact the workload and timeline.

- Alternative Solutions: I may propose alternative solutions that achieve the desired effect more efficiently or economically. This shows that I am thinking proactively and am invested in their project’s success.

- Revised Quotes and Timelines: If changes require additional work or affect the existing timeline, I will provide a revised quote and update the project schedule accordingly, keeping clients updated on the changes in real-time.

- Documentation: I meticulously document all design changes, along with the associated cost and timeline implications. This ensures clear transparency and prevents future misunderstandings.

Q 15. What are your strategies for maintaining embroidery equipment?

Maintaining embroidery equipment is crucial for longevity and consistent high-quality results. My strategy involves a multi-pronged approach focusing on preventative maintenance, regular cleaning, and careful storage.

Preventative Maintenance: This includes regularly lubricating moving parts like the machine’s needle bar and hook assembly, according to the manufacturer’s instructions. Ignoring this can lead to premature wear and tear.

Cleaning: After each embroidery session, I meticulously clean the machine’s bobbin case, removing lint and thread buildup. This prevents jams and ensures smooth operation. I also regularly clean the feed dogs and the area around the needle plate. Think of it like cleaning a sewing machine – regular maintenance prevents bigger problems.

Storage: When not in use, I cover the machine to prevent dust accumulation. I also store bobbins and needles in designated containers, protecting them from damage and loss. Proper storage is paramount to prevent accidental damage or rusting of metal parts.

Professional Service: I schedule annual professional servicing to ensure everything is operating at peak efficiency. This often includes a thorough cleaning, lubrication, and inspection by a qualified technician to catch issues before they escalate.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with color matching in embroidery.

Color matching in embroidery requires a keen eye for detail and a solid understanding of color theory. My experience involves a combination of digital and physical techniques.

Digital Matching: I utilize embroidery design software with advanced color palettes and tools to accurately match pantone numbers or thread manufacturer’s color charts. This ensures consistency across multiple projects and allows for precise adjustments.

Physical Matching: This involves comparing thread samples to the fabric and adjusting them until the color is a perfect match. I often use lighting boxes to ensure consistency in viewing the colors under different light conditions. It’s often a process of trial and error with different threads to achieve that ideal match.

Example: I once had to match a very specific shade of teal for a client’s logo. Using my software, I identified the closest match from a variety of manufacturers’ thread charts. Then, I physically checked it with the fabric, and made subtle adjustments until it seamlessly integrated with the design.

Q 17. How do you ensure the dimensional stability of embroidered garments?

Maintaining dimensional stability in embroidered garments is critical for preventing distortion and ensuring the finished product looks its best. My approach combines fabric selection with appropriate embroidery techniques.

Fabric Choice: I carefully select fabrics known for their stability, such as tightly woven cottons, linens, or stable knits. Avoid highly textured or loosely woven fabrics which can easily distort during embroidery.

Pre-treatment: Pre-washing the fabric helps to pre-shrink the material and prevent any shrinkage after embroidery, leading to consistent size. This is especially important for natural fibers.

Stabilizer Selection: The right stabilizer is essential. I choose stabilizers appropriate for the fabric weight and embroidery design. Cut-away stabilizers are great for detailed work, tear-away stabilizers for less dense work and wash-away is ideal for delicate fabrics.

Tension Control: Proper machine tension is crucial. Incorrect tension can cause puckering or distortion. I always check and adjust tension settings during the embroidery process. Practice and observation are key to mastering tension.

Hooping Technique: The way the fabric is hooped is crucial for preventing puckering. I ensure the fabric is taut and evenly distributed within the hoop to avoid uneven tension during the stitching process.

Q 18. What is your experience with different types of fabric finishes and their impact on embroidery?

Fabric finishes significantly impact embroidery results. Different finishes influence the fabric’s absorbency, texture, and drape, all of which affect how the embroidery looks and feels.

Mercerized Cotton: This finish gives cotton a lustrous sheen and enhances its strength, making it ideal for detailed embroidery. The fibers are smoother and less prone to damage.

Pre-shrunk Fabrics: Essential to prevent shrinkage after embroidery, ensuring the final product’s dimensions remain consistent.

Water-resistant Finishes: These finishes can affect thread adhesion and may require a specific stabilizer or embroidery techniques to get optimum results.

Softened Finishes: These softer finishes impact the texture of the finished embroidery, making it softer to the touch. However, they might require a denser stitching technique or a different stabilizer to prevent damage to the soft fiber structure.

Example: Embroidering on a fabric with a stiff finish, like some types of linen, may require a heavier stabilizer and slightly more tension to prevent the fabric from pulling away from the needle.

Q 19. Explain your knowledge of embroidery design software and its functionalities.

I’m proficient in several embroidery design software packages, including industry-standard options like Wilcom EmbroideryStudio and Embird. These programs offer a wide array of functionalities.

Digitizing: Creating embroidery designs from scratch, including outlining and filling stitch types. I can design intricate patterns, logos, and lettering.

Editing: Modifying existing designs, adjusting stitch density, changing colors, and optimizing designs for different fabric types.

Color Separation: Separating the design into different thread colors for efficient embroidery production.

Stitch Type Selection: Selecting appropriate stitch types for different areas of the design, optimizing for quality, speed, and fabric type. This would include choosing fill stitches like satin stitch, or decorative stitches like chain stitch for borders.

Import/Export: Working with various file formats to exchange designs with other programs or embroidery machines.

Q 20. How familiar are you with different types of embroidery hoops and their uses?

I’m familiar with a variety of embroidery hoops, each suited for specific needs and fabric types.

Circular Hoops: The most common type, suitable for a wide range of projects. They come in different sizes for various design dimensions.

Square Hoops: Ideal for designs with straight lines and sharp corners, reducing the chance of distortion.

Magnetic Hoops: Offer convenience, particularly for smaller or delicate projects, but can be less stable than traditional hoops.

Frame Hoops: These are often larger and more robust than standard hoops, providing improved stability and are particularly good for large designs or very heavy fabrics.

Choosing the Right Hoop: The selection depends on factors such as the fabric type, design size, and level of detail. For instance, heavier fabrics need robust hoops to prevent distortion.

Q 21. Describe your process for creating a sample for embroidery design approval.

Creating a sample for embroidery design approval involves a methodical process aimed at ensuring client satisfaction and accurate representation of the final product.

Initial Consultation: A thorough discussion with the client to understand their requirements, including fabric type, design details, and desired stitch density.

Design Creation: Developing the embroidery design using suitable software, incorporating the client’s feedback and incorporating appropriate stitch types and color palettes.

Fabric Selection and Preparation: Choosing an appropriate fabric that closely matches the client’s intended final product, pre-treating as needed, ensuring that it’s clean and free from defects.

Stabilizer Selection: Carefully selecting the correct stabilizer to ensure design integrity and prevent distortion during the embroidery process.

Embroidery and Finishing: Producing the sample embroidery using suitable machines, following proper tension and stitch settings. The sample must be finished to a high standard, carefully considering how the edges and any excess stabilizer are dealt with.

Client Presentation: Presenting the sample to the client under appropriate lighting conditions, allowing them to examine the quality, color, and stitch consistency closely.

Feedback and Revisions: If the client requests revisions, using feedback to modify the design and create an updated sample until the client is entirely satisfied.

Q 22. What are your skills in hand embroidery techniques?

My hand embroidery skills encompass a wide range of techniques, from basic stitches like running stitch, backstitch, and satin stitch to more intricate ones such as French knots, seed stitch, and various forms of surface embroidery. I’m proficient in working with diverse materials, including silk, linen, cotton, and wool, adapting my stitch choices to best suit the fabric and design. For example, I’ve used delicate seed stitch to create intricate floral details on a fine silk scarf, while employing a robust backstitch for lettering on a durable canvas bag. My expertise extends to creating unique textures and dimensional effects using techniques like padded satin stitch and raised work. I’m also skilled in free-motion embroidery, allowing for greater artistic freedom and expressive designs.

Q 23. How do you address design limitations when working with embroidery machines?

Design limitations with embroidery machines often arise from factors like hoop size, stitch density limitations, and the machine’s capabilities regarding thread types and colors. To overcome these, I employ several strategies. First, I carefully plan my designs, segmenting larger pieces into manageable sections that fit within the hoop. I then digitally edit designs, simplifying intricate details or adjusting them to optimize stitch density for the chosen fabric. If a complex design necessitates multiple hoopings, I meticulously plan stitch placement to ensure seamless transitions between sections. Color limitations are addressed by strategically selecting color palettes and utilizing techniques like blending to create the desired visual effect. Finally, understanding the machine’s limitations is key. I always test stitch designs on a sample fabric before committing to the final piece to avoid costly mistakes and ensure the final product matches the design vision.

Q 24. What are your strategies for managing time constraints in embroidery production?

Managing time constraints in embroidery production requires meticulous planning and efficient workflow. I begin with a realistic project timeline, breaking down the task into manageable phases, from design and digitization to production and quality control. Prioritization of tasks based on deadlines and complexity is crucial. For instance, if multiple projects are underway, I may focus on the most time-sensitive ones first, allocating resources accordingly. I utilize time-saving techniques like bulk prepping (pre-cutting fabric and organizing threads) and streamlining the machine setup process. This allows me to maximize machine uptime and reduce unnecessary delays. Automation, wherever possible, is also implemented to speed up repetitive tasks. Finally, regular monitoring of progress against the schedule allows for quick identification and resolution of any potential bottlenecks.

Q 25. Explain your experience with large-scale embroidery projects.

I have extensive experience with large-scale embroidery projects, including the creation of custom wall hangings for a hotel lobby, requiring precise execution and coordination of numerous embroidery panels. For this project, detailed planning was paramount, ensuring consistent design and color across all panels. We employed a systematic approach to digitization and production, breaking the design into multiple manageable sections. Careful quality control was integrated throughout, with regular checks during each phase to maintain consistency and address any errors promptly. Effective communication between team members, and a focus on efficient resource allocation, were also instrumental in successfully delivering this large-scale project within the set timeframe and budget. Another notable example was the creation of a large logo for a corporate event that needed many identical pieces. Using a combination of bulk production techniques and rigorous quality checks ensured uniformity across all pieces.

Q 26. How do you stay updated on the latest trends and technologies in the embroidery industry?

Staying current in the embroidery industry requires a multifaceted approach. I regularly attend industry trade shows and workshops, networking with other professionals and learning about new technologies and trends firsthand. I subscribe to industry publications and follow leading embroidery artists and companies on social media. Online platforms and forums offer valuable insights into new techniques, software, and materials. I also actively seek out educational opportunities, including online courses and webinars, which expand my knowledge base and refine existing skills. Experimentation with new threads, fabrics, and software is also a critical part of staying ahead of the curve. I strive to maintain a curious and inquisitive mindset, ensuring that my skillset remains relevant and competitive.

Q 27. What are your methods for quality control in embroidery production?

Quality control is an integral part of my embroidery process. It begins with careful selection of high-quality materials, ensuring consistent thread tension, and optimizing stitch settings for the chosen fabric. I conduct regular checks at every stage of production, starting with design digitization, to ensure the design is accurately translated to the embroidery machine. Throughout the embroidery process, I visually inspect the work for inconsistencies such as skipped stitches, thread breaks, or puckering. I employ specific tools to assess stitch density and fabric integrity. A final, comprehensive inspection is performed before packaging the finished product, meticulously examining for imperfections. Documentation of these checks ensures traceability and accountability. This multi-layered approach to quality control contributes to customer satisfaction and maintaining a high standard of work.

Q 28. How do you handle unexpected challenges during the embroidery process?

Unexpected challenges in embroidery are inevitable. For instance, thread breakage during a large project requires a calm and methodical response. I always keep extra spools of thread on hand and am adept at quickly identifying and rectifying the cause of breakage (e.g., thread tension issues, faulty needles). Other challenges might involve unforeseen fabric irregularities or machine malfunctions. My approach involves troubleshooting the issue systematically, isolating the problem, and implementing a solution. If the problem is beyond my expertise, I consult with experienced technicians or colleagues for support. Open communication with the client is essential when facing unexpected delays or alterations to the original design. Prioritizing problem-solving while maintaining open communication ensures the project remains on track, minimizing disruptions and upholding professional standards.

Key Topics to Learn for Material Knowledge and Embroidery Techniques Interview

- Fiber Types and Properties: Understanding natural (cotton, silk, linen, wool) and synthetic (polyester, nylon, rayon) fibers; their characteristics (strength, drape, texture, absorbency), and suitability for different embroidery techniques and projects.

- Fabric Structures: Knowledge of weaves (plain, twill, satin), knits, and non-woven fabrics; how fabric structure impacts embroidery results (e.g., stitch density, fabric stability).

- Embroidery Stitches: Mastery of various embroidery stitches (e.g., running stitch, backstitch, satin stitch, French knots, chain stitch); understanding their applications and suitability for different fabrics and designs.

- Embroidery Techniques: Familiarity with different embroidery techniques like freehand embroidery, machine embroidery, appliqué, and cross-stitch; understanding their advantages and limitations.

- Thread Selection: Choosing the appropriate thread type (e.g., cotton, rayon, silk) and weight based on the fabric and desired embroidery effect; understanding thread properties and their impact on the finished product.

- Design and Pattern Transfer: Methods for transferring patterns onto fabric (e.g., tracing, water-soluble pens, projector); creating original designs and adapting existing patterns for embroidery.

- Finishing Techniques: Proper methods for finishing embroidered projects (e.g., trimming threads, pressing, blocking); techniques for enhancing the longevity and presentation of the final product.

- Troubleshooting: Identifying and resolving common embroidery problems (e.g., thread breakage, puckering, uneven stitches); understanding the cause-and-effect relationship between materials, techniques, and outcomes.

- Color Theory and Application: Understanding color theory principles and their practical application in embroidery projects; choosing and combining colors effectively to achieve a desired aesthetic.

- Sustainability and Ethical Sourcing: Awareness of sustainable practices in textile and embroidery industries; understanding the importance of ethical sourcing of materials.

Next Steps

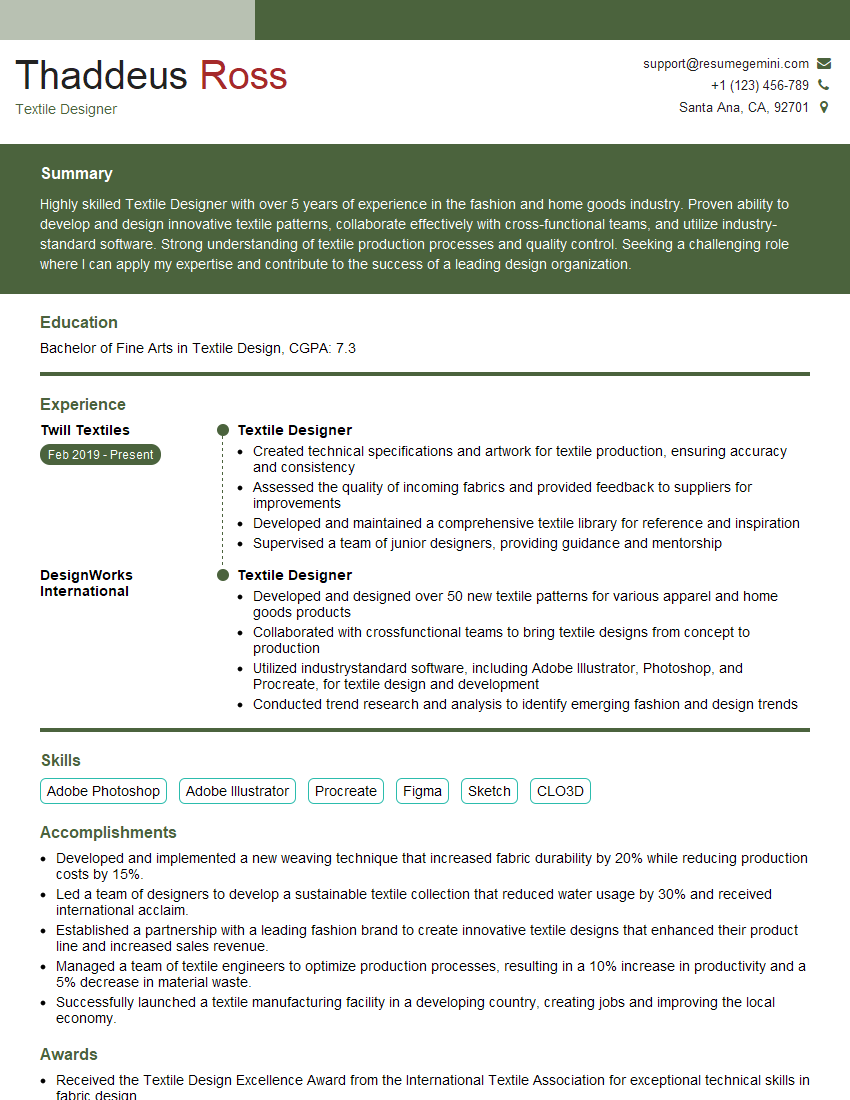

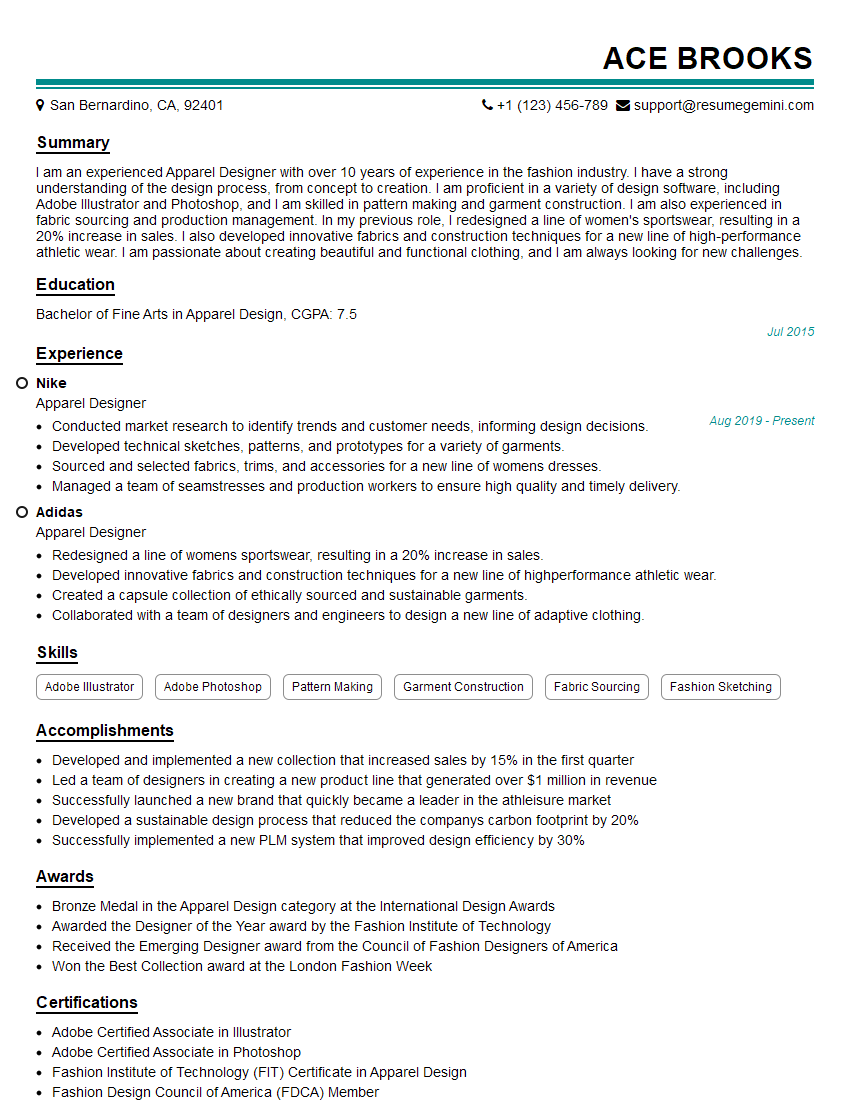

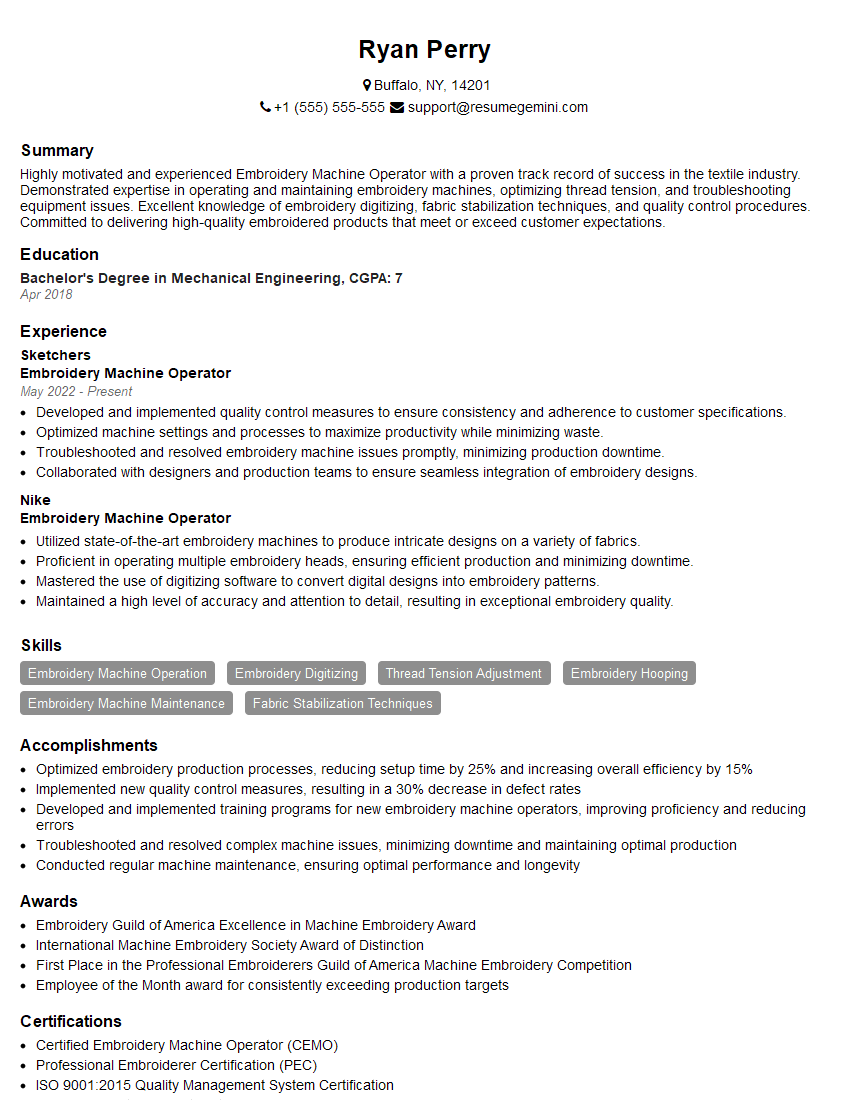

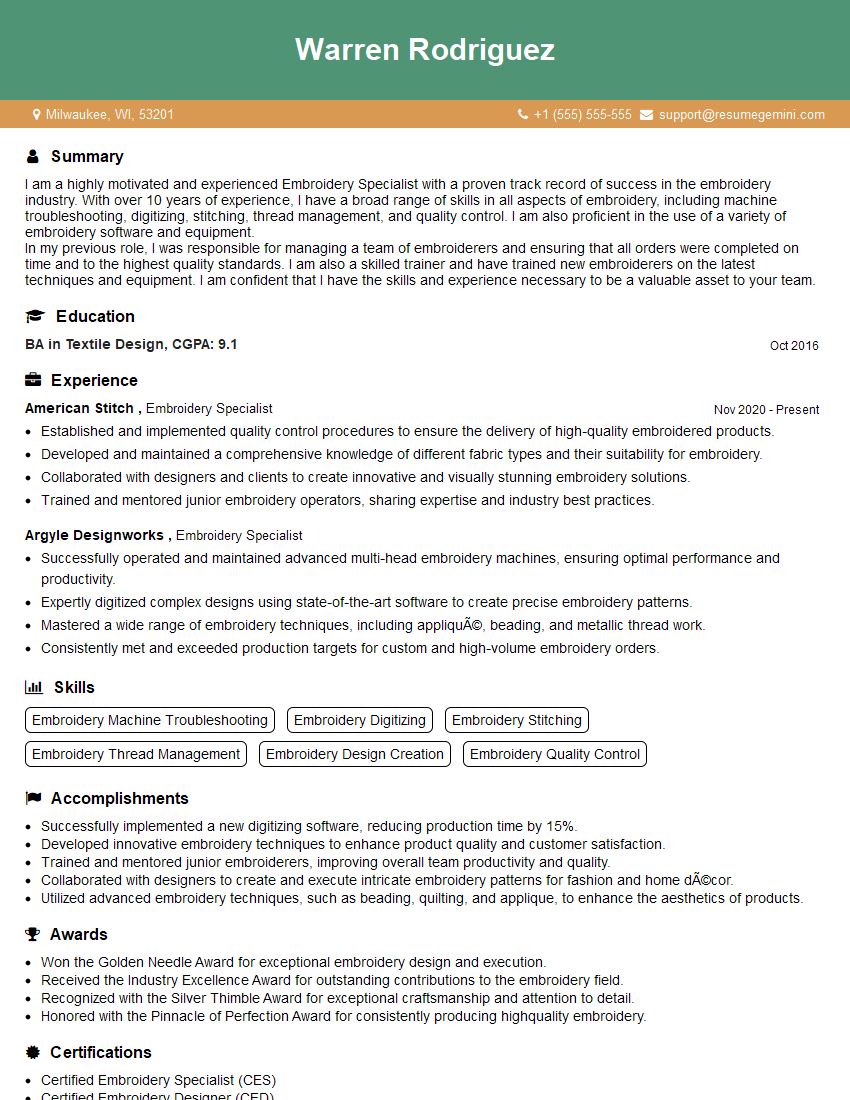

Mastering material knowledge and embroidery techniques is crucial for career advancement in the textile and fashion industries. A strong understanding of these topics demonstrates your expertise and problem-solving abilities, making you a highly desirable candidate. To maximize your job prospects, focus on building an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you create a professional and impactful resume tailored to the specific requirements of your target roles. Examples of resumes tailored to material knowledge and embroidery techniques are available to guide you in this process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good