The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Material Procurement and Management interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Material Procurement and Management Interview

Q 1. Explain the difference between strategic and tactical procurement.

Strategic procurement focuses on the long-term, big-picture view of material acquisition, aligning purchasing decisions with the overall business strategy. It’s about optimizing the entire supply chain for maximum value and minimizing risk. Think of it like the architect designing a house – they consider the overall blueprint and long-term functionality. Tactical procurement, on the other hand, handles the day-to-day operational aspects of purchasing. It’s the project manager overseeing the construction, ensuring materials arrive on time and within budget. It focuses on efficiency and cost reduction in the short term.

- Strategic Procurement Examples: Negotiating long-term contracts with key suppliers, implementing a supplier relationship management (SRM) system, developing a global sourcing strategy, and identifying and mitigating supply chain risks.

- Tactical Procurement Examples: Placing purchase orders, managing inventory levels, resolving supplier delivery issues, and processing invoices.

The key difference lies in the time horizon and scope. Strategic procurement is proactive, anticipating future needs and shaping the supply chain, while tactical procurement is reactive, responding to immediate demands.

Q 2. Describe your experience with different sourcing strategies (e.g., competitive bidding, negotiation).

I’ve extensive experience employing various sourcing strategies, adapting my approach based on the specific needs of the project and the nature of the goods or services.

- Competitive Bidding: I’ve successfully used this for standardized goods and services where price is the primary driver. For example, when procuring office supplies, we issue a request for quotation (RFQ) to multiple vendors, evaluating bids based on price, quality, and delivery terms. The process ensures transparency and promotes healthy competition.

- Negotiation: This strategy works well for unique or complex purchases where a customized solution is required. For instance, when procuring specialized software or negotiating long-term contracts with a strategic supplier, strong negotiation skills are crucial to achieve favorable terms and conditions. I often employ techniques like integrative bargaining, focusing on creating value for both parties rather than just claiming value for myself.

- Reverse Auctions: I’ve used reverse auctions for volume purchases of commodities where multiple suppliers bid in real time, resulting in competitive pricing. This requires careful planning and management to ensure fairness and transparency.

- Supplier Relationship Management (SRM): Beyond individual transactions, I prioritize building strong, collaborative relationships with key suppliers. This ensures better communication, responsiveness, and a higher likelihood of securing favorable terms in the long run. It’s about more than just price; it’s about reliability and partnership.

My choice of sourcing strategy is always data-driven and carefully considered, balancing cost optimization with quality, risk mitigation, and long-term supplier relationships.

Q 3. How do you manage supplier relationships?

Managing supplier relationships is a crucial aspect of successful procurement. I believe in a collaborative approach, building partnerships based on mutual trust and respect. This goes beyond simply ordering materials; it involves open communication, regular performance reviews, and a commitment to continuous improvement.

- Communication: I maintain regular communication with key suppliers, utilizing various channels such as phone calls, emails, and regular meetings to discuss project updates, performance issues, and potential opportunities for collaboration.

- Performance Monitoring: I track key performance indicators (KPIs) such as on-time delivery, quality conformance, and responsiveness to ensure suppliers are meeting agreed-upon targets. This allows for timely intervention and improvement strategies when needed.

- Collaboration & Problem-Solving: I approach challenges proactively, working collaboratively with suppliers to identify root causes of problems and implement corrective actions. This collaborative approach strengthens the relationship and fosters innovation.

- Relationship Building: I foster strong relationships with key personnel at supplier organizations, attending industry events and building personal connections to ensure stronger communication and quicker responses to issues.

By investing in these relationships, I ensure reliable sourcing, timely delivery, and high-quality materials, ultimately contributing to the success of our organization.

Q 4. What are your preferred methods for supplier selection and evaluation?

Supplier selection and evaluation is a multi-stage process that I approach systematically to ensure we select the best partners.

- Pre-qualification: Initially, I screen potential suppliers based on criteria like financial stability, certifications (e.g., ISO 9001), and references. This weeds out unqualified candidates.

- Request for Information (RFI): For complex purchases, an RFI helps gather information and clarify requirements before issuing formal RFQs or RFPs.

- Request for Quotation (RFQ) / Request for Proposal (RFP): These documents formally solicit price quotes or detailed proposals from pre-qualified suppliers. Evaluation criteria are clearly defined and weighted to ensure fairness.

- Supplier Audits: On-site visits are often conducted to assess the supplier’s capabilities, quality systems, and overall operational efficiency. This provides a more hands-on understanding of their capabilities.

- Performance Monitoring and Evaluation: Post-selection, we continuously monitor supplier performance using KPIs and conduct regular reviews to identify areas for improvement and ensure continued adherence to contractual obligations. This process may include formal scorecards.

This systematic approach reduces risk, enhances transparency, and ultimately leads to the selection of reliable and high-performing suppliers.

Q 5. Explain your experience with RFQs (Request for Quotations) and RFPs (Request for Proposals).

RFQs and RFPs are vital tools in the procurement process.

- RFQ (Request for Quotation): An RFQ is used when the specifications of the required goods or services are clearly defined, and the focus is primarily on price comparison. It’s a concise document outlining the required items, quantities, and delivery timelines, requesting vendors to provide their best price. I ensure that all RFQs include clear specifications, terms and conditions, and a deadline for submission.

- RFP (Request for Proposal): An RFP is employed when the requirements are more complex, requiring a more detailed understanding of the vendor’s proposed solution, methodology, and capabilities. It often involves a more thorough evaluation process, possibly including presentations and demonstrations. For example, selecting a software provider would typically involve an RFP, where vendors outline their solutions, implementation plans, and pricing models.

I’ve managed numerous RFQ and RFP processes, ensuring clarity in requirements, transparency in evaluation, and adherence to deadlines. The success of these processes hinges on clear communication, comprehensive documentation, and a fair and consistent evaluation methodology.

Q 6. How do you ensure compliance with procurement policies and procedures?

Compliance with procurement policies and procedures is paramount. To maintain this, I employ a multi-pronged approach.

- Understanding Policies: I thoroughly understand and remain updated on all relevant procurement policies and procedures, ensuring all my actions align with legal and ethical standards.

- Training & Documentation: I participate in regular training sessions to stay updated on compliance requirements. All procurement activities are meticulously documented, including approvals, justifications, and relevant communications.

- Internal Controls: I use established internal controls throughout the procurement process, including segregation of duties, authorization levels, and regular audits. This helps identify and prevent deviations from established policies.

- Monitoring & Reporting: I regularly monitor compliance, utilizing reports and dashboards to identify any potential issues. Any non-compliance is reported promptly to management, and corrective actions are implemented.

- Use of Procurement Systems: I leverage procurement software and systems that incorporate built-in compliance features such as approval workflows, audit trails, and reporting capabilities. This helps minimize human error and enforce adherence to policy.

My commitment to compliance ensures that all procurement activities are ethical, transparent, and in line with organizational and regulatory standards.

Q 7. Describe your experience with contract negotiation and management.

Contract negotiation and management is a critical skill in procurement. My approach involves thorough preparation, strategic negotiation, and diligent monitoring.

- Preparation: Before any negotiation, I conduct thorough research, analyzing market conditions, competitor offerings, and the supplier’s financial position. I also establish clear objectives and priorities for the negotiation. A strong understanding of the supplier’s business is key.

- Negotiation Strategy: I employ a collaborative approach, aiming to achieve a win-win outcome. This involves identifying areas of common ground and creative solutions that satisfy both parties’ needs. I use active listening, persuasive communication, and a clear understanding of the supplier’s incentives.

- Contract Drafting & Review: I review and negotiate contract terms carefully, ensuring that all clauses protect the organization’s interests while maintaining a fair and balanced relationship with the supplier. Legal counsel is often involved in reviewing complex contracts.

- Contract Management: Post-signing, I monitor the performance of the contract, ensuring that the supplier is fulfilling its obligations and addressing any discrepancies promptly. I also use change management procedures to handle necessary modifications during the contract term.

My experience in contract negotiation and management has consistently resulted in favorable terms and long-term, mutually beneficial relationships with key suppliers. Clear communication and transparent processes are fundamental to this success.

Q 8. How do you manage risk in the procurement process?

Risk management in procurement is crucial for ensuring the smooth operation of a business and protecting its financial health. It involves proactively identifying, assessing, and mitigating potential problems throughout the entire procurement lifecycle, from sourcing to payment.

My approach is multifaceted:

- Supplier Risk Assessment: I thoroughly vet potential suppliers, evaluating their financial stability, production capacity, geographic location (considering political and environmental risks), and ethical practices. This might involve reviewing their financial statements, conducting site visits, and checking references.

- Contractual Risk Mitigation: Well-drafted contracts are essential. I incorporate clauses that address potential issues such as late delivery, quality defects, and price fluctuations. For example, a liquidated damages clause can specify financial penalties for non-compliance.

- Diversification of Suppliers: Relying on a single supplier exposes the business to significant risk. Diversification spreads the risk across multiple vendors, reducing vulnerability to disruptions caused by a single supplier’s failure.

- Inventory Management: Effective inventory management minimizes the risk of stockouts and obsolescence, which can disrupt production and lead to financial losses. Techniques like Just-In-Time (JIT) inventory can be crucial here.

- Continuous Monitoring: Regularly monitoring supplier performance, market trends, and geopolitical events is crucial to identifying and addressing emerging risks promptly. This might involve tracking key performance indicators (KPIs) and regularly reviewing contracts.

For example, during a recent project involving sourcing a specialized component, we anticipated potential supply chain disruptions due to geopolitical instability in the region where our primary supplier was located. We proactively identified and pre-qualified a secondary supplier in a different region, mitigating the risk of significant delays or production stoppages.

Q 9. How do you handle supplier performance issues?

Handling supplier performance issues requires a systematic and collaborative approach. My strategy focuses on communication, collaboration, and performance improvement plans.

- Identify and Document: Clearly define the performance issue, gathering concrete evidence like delivery delays, quality defects, or non-compliance with contractual obligations. Detailed documentation is crucial for future reference and escalation if necessary.

- Communication and Collaboration: I initiate open communication with the supplier, seeking to understand the root cause of the problem. Collaborative problem-solving is key. This often involves meetings, discussions, and joint analysis of the situation.

- Performance Improvement Plan (PIP): If the issues are significant, a formal PIP is developed in collaboration with the supplier. This outlines specific, measurable, achievable, relevant, and time-bound (SMART) goals and actions to address the performance gaps. Regular progress reviews are scheduled to monitor progress.

- Escalation and Remediation: If the supplier fails to meet the objectives outlined in the PIP, further action might be necessary, including reducing order volume, seeking alternative suppliers, or even terminating the contract. However, this is always a last resort.

In one instance, a supplier consistently missed delivery deadlines. Through open communication, we discovered they were facing capacity constraints due to unexpected demand. We collaborated to implement a phased delivery schedule, allowing them to manage their production more effectively while minimizing disruption to our operations.

Q 10. Explain your experience with inventory management techniques (e.g., FIFO, LIFO).

Inventory management techniques like FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) are critical for efficient inventory control and accurate cost accounting. The choice between them depends on the nature of the inventory and accounting practices.

- FIFO (First-In, First-Out): This method assumes that the oldest inventory is sold first. It’s ideal for perishable goods or items prone to obsolescence, as it minimizes the risk of spoilage or waste. The cost of goods sold (COGS) reflects the current market prices, resulting in a more accurate picture of profitability during inflationary periods.

- LIFO (Last-In, First-Out): This method assumes that the newest inventory is sold first. It’s less common than FIFO, especially in industries where inventory tracking is critical. LIFO can lower the taxable income during periods of inflation because the cost of goods sold reflects the most recent, higher costs, which can be beneficial for tax purposes but can skew the perceived profitability.

In my previous role, we used FIFO for our perishable food products, ensuring we minimized waste and maintained high product quality. For non-perishable items, a weighted-average costing method provided a balance between simplicity and accuracy.

Q 11. How do you optimize inventory levels to minimize costs and prevent stockouts?

Optimizing inventory levels is a balancing act between minimizing costs (holding costs, storage space, insurance, etc.) and preventing stockouts that disrupt production or sales. Several techniques can be employed:

- Demand Forecasting: Accurate demand forecasting is the cornerstone of effective inventory management. I utilize various forecasting methods, including statistical models and historical data analysis, to predict future demand and adjust inventory levels accordingly.

- Economic Order Quantity (EOQ): The EOQ model helps determine the optimal order quantity that minimizes the total inventory costs (ordering costs and holding costs). This requires careful consideration of factors like ordering costs, carrying costs, and demand rate.

- Safety Stock: Maintaining a safety stock buffer protects against unexpected demand fluctuations or supply chain disruptions. The level of safety stock is determined based on factors like lead times, demand variability, and service level requirements.

- Just-in-Time (JIT) Inventory: This approach aims to minimize inventory holding by receiving materials only when they are needed for production. It’s very efficient but requires a high degree of coordination with suppliers and reliable supply chains.

- Inventory Turnover Ratio: This KPI measures how efficiently inventory is managed. A higher turnover ratio generally indicates better inventory management, implying lower holding costs and quicker sales.

In a previous project, by implementing the EOQ model and refining our demand forecasting, we reduced our average inventory levels by 15% without compromising service levels, resulting in significant cost savings.

Q 12. Describe your experience with different purchasing systems or ERP software.

I have extensive experience with various purchasing systems and ERP software, including SAP Ariba, Oracle Procurement Cloud, and Coupa. My familiarity encompasses all aspects, from requisitioning and purchase order generation to supplier management and invoice processing.

These systems provide a centralized platform for managing the entire procurement process, improving efficiency, transparency, and control. They offer features like:

- e-Procurement: Streamlines the purchasing process through online catalogs, automated workflows, and electronic approvals.

- Supplier Relationship Management (SRM): Facilitates communication and collaboration with suppliers, allowing for performance monitoring and risk assessment.

- Contract Management: Supports the creation, execution, and monitoring of contracts, ensuring compliance and efficient contract lifecycle management.

- Reporting and Analytics: Provides valuable insights into procurement spending, supplier performance, and other key metrics.

In my experience, effective implementation of an ERP system requires careful planning, user training, and ongoing process optimization to fully realize its benefits.

Q 13. How do you track and measure procurement performance (KPIs)?

Tracking and measuring procurement performance is critical for continuous improvement and demonstrating value. I utilize several key performance indicators (KPIs) to monitor progress and identify areas for optimization.

- Purchase Order Cycle Time: Measures the time it takes to process a purchase order, from requisition to delivery. Reducing this time improves efficiency and responsiveness.

- Supplier On-Time Delivery Rate: Tracks the percentage of orders delivered on time by suppliers, indicating supplier reliability.

- Purchase Price Variance: Measures the difference between the budgeted price and the actual purchase price, highlighting opportunities for cost reduction.

- Inventory Turnover Rate: As mentioned earlier, this KPI assesses how efficiently inventory is managed.

- Procurement Cost as a Percentage of Revenue: Shows the overall cost of procurement as a proportion of revenue, providing a high-level view of procurement efficiency.

I regularly analyze these KPIs using dashboards and reporting tools to identify trends, areas for improvement, and the overall effectiveness of procurement strategies. This data-driven approach enables informed decision-making and continuous optimization of procurement processes.

Q 14. How familiar are you with different payment terms and their impact on cash flow?

Understanding different payment terms is crucial for managing cash flow effectively. Payment terms significantly impact a company’s liquidity and can influence relationships with suppliers.

- Net 30, Net 60, etc.: These terms specify the number of days after the invoice date that payment is due (e.g., Net 30 means payment is due 30 days after the invoice date). Longer payment terms provide more time to manage cash flow but can impact supplier relationships if not managed carefully.

- 2/10 Net 30: This offers a discount (e.g., 2%) if the invoice is paid within a shorter timeframe (e.g., 10 days), incentivizing early payment and improving cash flow for the supplier. It’s beneficial for both parties if utilized effectively.

- Advance Payment: Requires payment before goods or services are received, which shifts cash flow risk to the buyer. It’s often used for high-value purchases or when dealing with new or less reliable suppliers.

- Open Account: Payment is typically made after the goods are received and services rendered. This represents a higher credit risk for the supplier, often used in established business relationships with high trust.

Negotiating favorable payment terms is a key skill. The optimal terms depend on factors like supplier relationships, the strength of the buyer’s cash position, and industry standards. For example, by negotiating extended payment terms with a reliable supplier, we were able to improve our short-term cash flow, while still maintaining a strong relationship.

Q 15. How do you handle unexpected supply chain disruptions?

Handling unexpected supply chain disruptions requires a proactive and multi-faceted approach. It’s not about reacting to the problem, but anticipating potential issues and having contingency plans in place. Think of it like having a spare tire in your car – you hope you never need it, but it’s crucial to have when you do.

- Risk Assessment and Mitigation: Regularly assess potential disruptions, whether from natural disasters, geopolitical instability, or supplier issues. This involves identifying vulnerabilities in your supply chain and developing mitigation strategies. For example, diversifying suppliers, holding safety stock of critical materials, or establishing alternative sourcing options are all effective mitigations.

- Early Warning Systems: Implement systems to monitor key supply chain indicators. This might involve tracking supplier capacity, geopolitical events, or even social media sentiment related to your suppliers. Early warning gives you time to react and minimize the impact of disruptions.

- Strong Supplier Relationships: Nurturing strong relationships with suppliers is crucial. Open communication and collaboration allow you to identify potential problems early and work together to find solutions. For instance, during a recent shortage of a key component, we worked closely with our supplier to expedite production and secure alternative transportation.

- Agile Supply Chain Management: Adopt an agile approach, enabling you to quickly adapt to changing circumstances. This includes having flexible contracts, utilizing technology to optimize inventory, and fostering collaboration across your organization.

- Communication and Collaboration: Effective communication is essential during a disruption. Keep all stakeholders informed, from internal teams to customers, and work collaboratively to find solutions. Transparency is key to mitigating the negative impact on reputation and customer satisfaction.

In one instance, a major port strike threatened to disrupt our supply of raw materials. Because we had already identified this as a potential risk and established alternative shipping routes and a secondary supplier, we successfully mitigated the impact, avoiding any significant production delays.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of Total Cost of Ownership (TCO).

Total Cost of Ownership (TCO) is a comprehensive approach to evaluating the cost of an asset or procurement over its entire lifecycle, not just the initial purchase price. It’s like buying a car – you consider the initial price, but also fuel costs, maintenance, insurance, and potential resale value. A lower initial price doesn’t always translate to the lowest overall cost.

TCO includes factors like:

- Acquisition Costs: The initial price of the material, including taxes and transportation.

- Operating Costs: Costs associated with using the material, such as energy consumption, maintenance, and repairs.

- Disposal Costs: Costs associated with disposing of the material at the end of its life.

- Downtime Costs: Costs incurred due to delays or production stoppages caused by material failures or shortages.

- Quality Costs: Costs associated with defects, rework, and returns.

By considering all these factors, businesses can make more informed procurement decisions. For instance, a higher-priced material with a longer lifespan and lower maintenance costs might ultimately have a lower TCO than a cheaper alternative that requires frequent replacements or repairs. We use TCO analysis to compare different suppliers and material options to make optimal purchasing choices.

Q 17. How do you ensure the quality of procured materials?

Ensuring the quality of procured materials is paramount. It directly impacts product quality, customer satisfaction, and overall profitability. A multi-pronged approach is needed, starting even before the procurement process begins.

- Supplier Selection: Rigorous supplier selection is critical. We evaluate potential suppliers based on their quality management systems (e.g., ISO 9001 certification), past performance, and references. We conduct thorough audits to assess their capabilities and compliance with our quality standards.

- Material Specifications: Clear and detailed material specifications must be defined upfront. These specifications should cover all relevant aspects, including chemical composition, physical properties, and tolerances. Any ambiguity can lead to quality issues.

- Incoming Inspection: Incoming inspection is crucial for verifying that received materials meet the specified requirements. This involves conducting tests and inspections to identify any defects or non-conformances before they are used in production.

- Quality Control throughout the Supply Chain: Quality control isn’t limited to incoming inspection. We maintain close communication and collaboration with suppliers to monitor quality throughout the entire supply chain. Regular performance reviews and corrective actions are essential.

- Continuous Improvement: We continuously strive to improve our quality control processes. This involves analyzing quality data, identifying root causes of defects, and implementing corrective and preventive actions.

For example, we recently implemented a new automated inspection system that significantly improved the speed and accuracy of our incoming inspection process, resulting in fewer defects reaching the production floor.

Q 18. Describe your experience with implementing cost-saving initiatives in procurement.

Implementing cost-saving initiatives in procurement requires a strategic approach, focusing on both efficiency and effectiveness. It’s not just about finding the cheapest option but also optimizing the entire procurement process.

- Negotiation and Contract Management: Skilled negotiation with suppliers is key. We leverage our purchasing power to secure better pricing and payment terms. Effective contract management ensures that we comply with contractual obligations while optimizing cost and mitigating risks.

- Supply Base Optimization: Reducing the number of suppliers can streamline the procurement process and improve leverage. However, this must be balanced with risk mitigation; we avoid over-reliance on a single supplier.

- Process Automation: Automating tasks such as purchase order generation, invoice processing, and supplier communication can reduce administrative costs and improve efficiency. E-procurement systems play a crucial role here.

- Inventory Management: Optimizing inventory levels can significantly reduce storage costs and minimize obsolescence. We use techniques like Just-in-Time (JIT) inventory management to minimize holding costs.

- Value Engineering: Value engineering involves identifying opportunities to reduce costs without compromising quality or functionality. This might involve finding alternative materials, redesigning components, or streamlining processes.

In one project, we implemented a new e-procurement system that automated the purchase order process, reducing processing time by 50% and saving significant administrative costs. We also successfully negotiated a long-term contract with our primary supplier, securing a 15% discount on raw materials.

Q 19. How do you stay updated on industry trends and best practices in procurement?

Staying updated on industry trends and best practices is crucial for any procurement professional. The field is constantly evolving, with new technologies, strategies, and regulations emerging regularly.

- Professional Organizations: Membership in professional organizations like the Institute for Supply Management (ISM) provides access to valuable resources, networking opportunities, and industry publications.

- Industry Publications and Journals: Regularly reading industry publications and journals keeps you informed about the latest trends, research, and best practices.

- Conferences and Workshops: Attending industry conferences and workshops offers opportunities to learn from experts, network with peers, and gain insights into new technologies and approaches.

- Online Resources and Webinars: Numerous online resources, webinars, and podcasts provide valuable information on various aspects of procurement.

- Networking: Networking with other procurement professionals through industry events, online forums, and professional organizations provides access to valuable insights and perspectives.

I personally subscribe to several industry publications, attend at least two major procurement conferences annually, and actively participate in online forums and networking events to stay ahead of the curve.

Q 20. Explain your experience with e-procurement systems.

E-procurement systems have revolutionized the procurement process, improving efficiency, transparency, and cost savings. These systems automate many manual tasks, enabling better tracking, analysis, and control of the procurement cycle.

My experience with e-procurement systems encompasses:

- Implementation and Configuration: I have been involved in the implementation and configuration of several e-procurement systems, including selecting the appropriate software, customizing it to our specific needs, and training users.

- Process Automation: E-procurement systems automate tasks such as purchase order creation, approvals, and invoice processing, significantly reducing manual effort and errors.

- Supplier Portal Management: I have experience managing supplier portals, facilitating communication and collaboration with suppliers, and enabling online purchase order placement and tracking.

- Data Analytics and Reporting: E-procurement systems provide valuable data on procurement activities, enabling data-driven decision-making and performance monitoring. I regularly analyze this data to identify trends, improve efficiency, and negotiate better deals with suppliers.

- Integration with ERP Systems: Successfully integrating e-procurement systems with Enterprise Resource Planning (ERP) systems provides a seamless flow of information across the organization.

In a previous role, we implemented a new e-procurement system that reduced our procurement cycle time by 40%, improved invoice processing accuracy, and provided valuable insights into our spending patterns.

Q 21. How do you manage ethical considerations in procurement?

Ethical considerations are paramount in procurement. Maintaining integrity and transparency is vital for building trust with suppliers, customers, and stakeholders. Unethical practices can have severe legal and reputational consequences.

- Conflict of Interest Management: We have strict policies in place to address potential conflicts of interest. Employees are required to disclose any potential conflicts, and procedures are in place to mitigate any risks.

- Fair and Competitive Bidding: We ensure that all procurement processes are fair and transparent, with equal opportunities for all qualified suppliers. We avoid favoritism or collusion.

- Compliance with Regulations: We strictly comply with all relevant regulations and laws, including those related to bribery, corruption, and anti-trust.

- Sustainable Procurement Practices: We increasingly prioritize sustainable procurement practices, considering environmental and social impacts throughout the supply chain. This includes selecting suppliers committed to environmental responsibility and ethical labor practices.

- Transparency and Accountability: We maintain transparent and accountable procurement practices. Our procedures are documented, and regular audits ensure compliance with our ethical guidelines.

We recently implemented a new supplier code of conduct, requiring our suppliers to adhere to strict ethical standards regarding labor practices, environmental protection, and anti-corruption measures. This commitment to ethical procurement enhances our reputation and strengthens relationships with our valued partners.

Q 22. Describe a time you had to negotiate a challenging contract.

Negotiating contracts, especially challenging ones, requires a strategic approach combining strong analytical skills, effective communication, and a deep understanding of the market. One particularly challenging negotiation involved securing a critical raw material, titanium alloy, for a high-profile aerospace project. The supplier, initially unwilling to compromise on their high price, citing increased raw material costs, had a near-monopoly on the specific alloy we needed.

My strategy focused on several key aspects. First, I thoroughly researched alternative suppliers, even those with less ideal lead times or slightly inferior materials, to leverage as negotiation leverage. Second, I highlighted the long-term value of our partnership, emphasizing potential future contracts for substantial volumes. Third, I presented a detailed breakdown of our cost analysis, demonstrating the unreasonableness of their initial pricing compared to market rates and the potential for long-term collaboration. Ultimately, we reached an agreement 15% below their initial offer by demonstrating flexibility and mutual benefit. We agreed on a staggered payment plan, mitigating their immediate cash flow concerns while safeguarding our budget. This situation underscored the importance of thorough preparation, relationship building, and a win-win approach in complex negotiations.

Q 23. How do you handle conflicting priorities in procurement?

Conflicting priorities in procurement are a common occurrence, often arising from competing demands for budget, quality, delivery time, and supplier relationships. My approach prioritizes a structured framework for resolving these conflicts. It starts with clearly defining the priorities of each stakeholder – engineering, production, finance – and documenting the relative importance of each factor for each project. I use a prioritization matrix, weighing factors like criticality, potential impact on project timeline, and financial implications.

For instance, if a project requires a specific high-quality material with a tight deadline but has a constrained budget, I might explore cost-saving measures without compromising quality or timeliness. This could involve negotiating more favorable payment terms, exploring alternative, equally suitable materials from different suppliers, or optimizing order quantities. Transparency and clear communication are key; keeping all stakeholders informed of the decision-making process and rationales prevents misunderstandings and builds trust.

Q 24. Describe your experience with different types of contracts (e.g., fixed price, cost-plus).

My experience spans a variety of contract types, each suited to different procurement scenarios. Fixed-price contracts are best suited for projects with well-defined scopes and minimal anticipated changes. The price is set upfront, providing cost certainty, but requires meticulous upfront planning as changes can be costly. I’ve used these extensively for standard components with reliable specifications.

Cost-plus contracts are preferred when the project scope is uncertain or involves complex, innovative work. The supplier is reimbursed for their costs plus a predetermined markup. This offers flexibility but demands rigorous cost tracking and management to prevent cost overruns. I utilized this model for research and development projects where uncertainty was high.

Time and materials contracts are suitable for smaller projects or service agreements, where the final scope isn’t fully defined upfront. The supplier is paid for the time spent and materials used. Careful monitoring is crucial to prevent scope creep. I have used this type for consulting or maintenance services.

Understanding the strengths and weaknesses of each contract type is vital to selecting the optimal choice for each specific situation, aligning risk and reward appropriately. This requires careful contract review and negotiation to mitigate potential risks.

Q 25. How do you ensure timely delivery of materials?

Ensuring timely delivery of materials involves a proactive, multi-faceted approach encompassing supplier relationship management, robust inventory control, and effective risk mitigation. My strategy begins with selecting reliable suppliers with proven track records of on-time delivery. This involves thorough supplier audits and performance evaluations, incorporating metrics like on-time delivery percentage and lead time consistency into the supplier selection process.

Beyond supplier selection, I employ a robust inventory management system, utilizing techniques such as Just-in-Time (JIT) inventory to optimize stock levels and minimize storage costs while preventing stockouts. Regular communication and close monitoring of purchase orders are essential, proactively identifying potential delays and implementing corrective actions. This includes utilizing project management software to track shipments and proactively address potential supply chain disruptions. Finally, having contingency plans in place to manage unforeseen events, like natural disasters or supplier-side issues, is crucial to maintain timely delivery.

Q 26. How do you manage procurement budgets effectively?

Effective procurement budget management requires a combination of meticulous planning, proactive cost control, and continuous monitoring. My approach begins with developing a detailed budget encompassing all anticipated material costs, considering factors like quantity, pricing, lead times, and potential variations. I leverage historical data, market analysis, and supplier quotes to create a realistic budget, incorporating contingency for unforeseen events.

Proactive cost control measures include negotiating favorable pricing with suppliers, implementing cost-saving strategies such as bulk purchasing or leveraging strategic partnerships. Regular monitoring of expenditures against the budget ensures early detection of any variances, allowing for prompt corrective action. Using procurement software with robust reporting capabilities enables detailed tracking and analysis of spending patterns, identifying areas for optimization. This ensures transparency and accountability, promoting efficient budget utilization.

Q 27. Describe your experience with Lean principles in procurement.

Lean principles, focusing on eliminating waste and maximizing efficiency, are highly relevant to procurement. I’ve implemented several Lean practices to optimize our procurement processes, resulting in significant improvements in cost, lead time, and quality. One example is the implementation of a Kanban system to manage our inventory. This visual system signals when materials need to be reordered, reducing excess inventory while preventing stockouts.

Another key application is value stream mapping, a tool used to analyze and improve the flow of materials from supplier to end-user. By mapping out the entire process, we identified bottlenecks and inefficiencies in our procurement cycle, which allowed us to streamline processes and reduce lead times significantly. We also implemented 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to organize our procurement workspace, improving efficiency and reducing search times for documents and information. By consistently applying Lean principles, we have improved the overall efficiency and effectiveness of our procurement processes, leading to significant cost savings and improved supplier relationships.

Key Topics to Learn for Material Procurement and Management Interview

- Sourcing Strategies: Understand various sourcing methods (e.g., global sourcing, single sourcing, dual sourcing), their advantages and disadvantages, and how to select the optimal strategy based on business needs and risk tolerance.

- Supplier Relationship Management (SRM): Learn how to build and maintain strong relationships with suppliers, negotiate favorable contracts, and manage supplier performance effectively. Consider practical applications like performance metrics and conflict resolution.

- Inventory Management Techniques: Explore different inventory control methods (e.g., JIT, EOQ, MRP) and their practical applications in optimizing inventory levels, minimizing costs, and preventing stockouts or overstocking. Discuss scenarios requiring different techniques.

- Procurement Processes: Master the entire procurement cycle, from requisition to payment, including purchasing processes, order management, and invoice processing. Consider potential bottlenecks and solutions.

- Cost Reduction Strategies: Understand various methods for reducing procurement costs, such as negotiating better prices, optimizing logistics, and improving efficiency in the procurement process. Consider examples of cost-saving initiatives.

- Risk Management in Procurement: Identify and mitigate potential risks associated with procurement, such as supply chain disruptions, supplier default, and quality issues. Develop strategies for risk assessment and mitigation.

- Contract Negotiation and Management: Develop strong negotiation skills and understand the legal aspects of contract management. Practice creating and reviewing contracts, including key terms and conditions.

- Technology in Procurement: Familiarize yourself with procurement software and technologies (e.g., ERP systems, e-procurement platforms) and their impact on efficiency and cost savings. Consider the benefits and challenges of implementing new technologies.

- Ethical Considerations in Procurement: Understand and adhere to ethical principles in procurement, such as transparency, fairness, and compliance with regulations. Discuss scenarios requiring ethical decision-making.

Next Steps

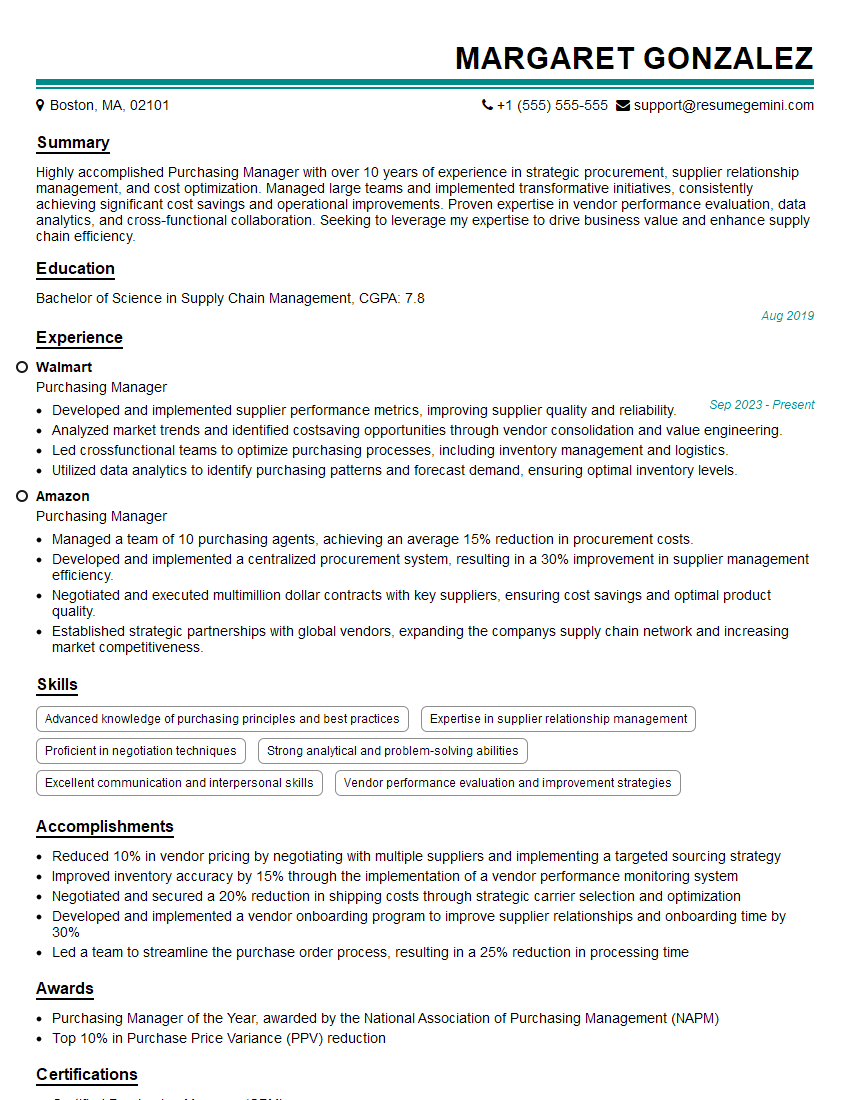

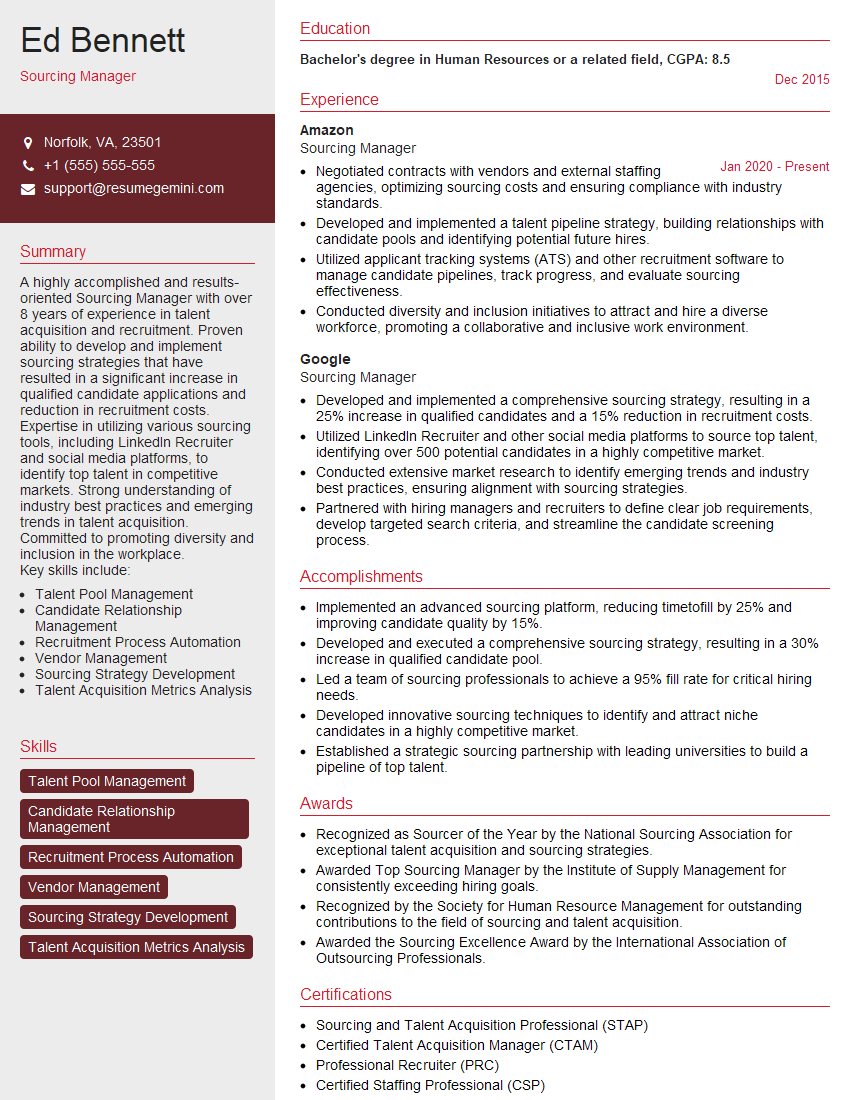

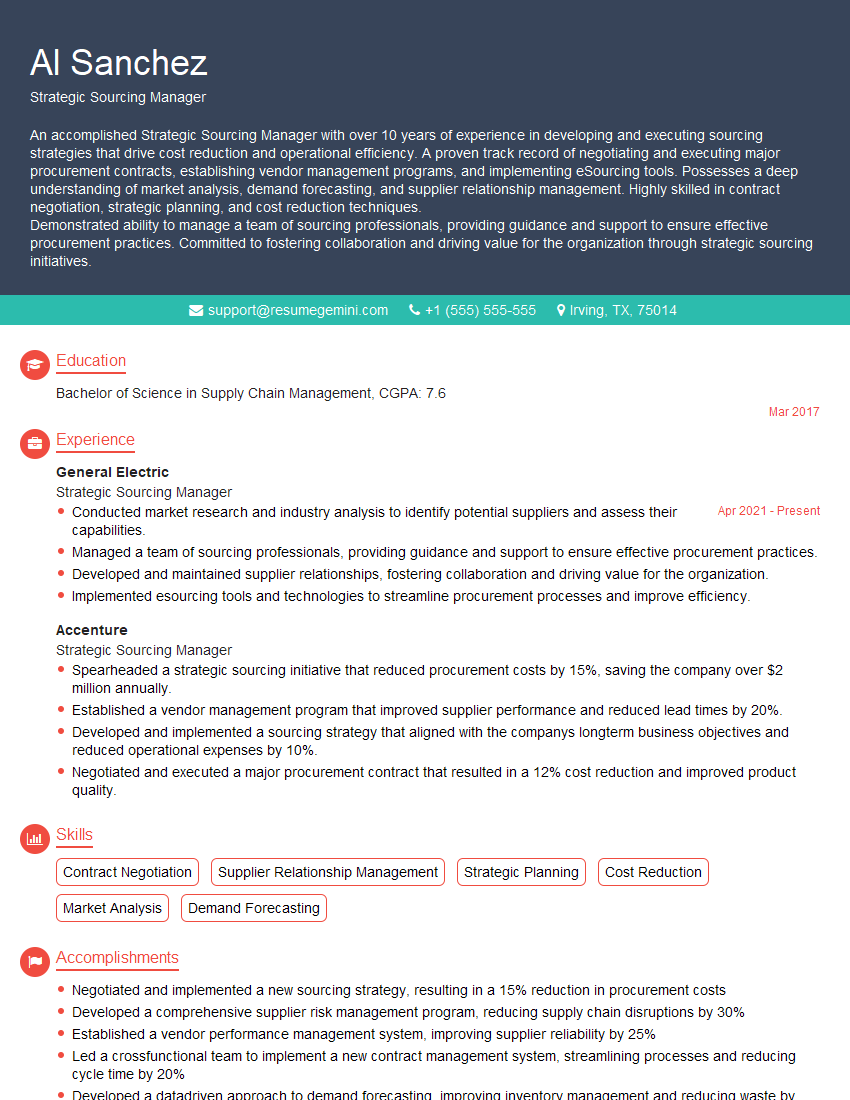

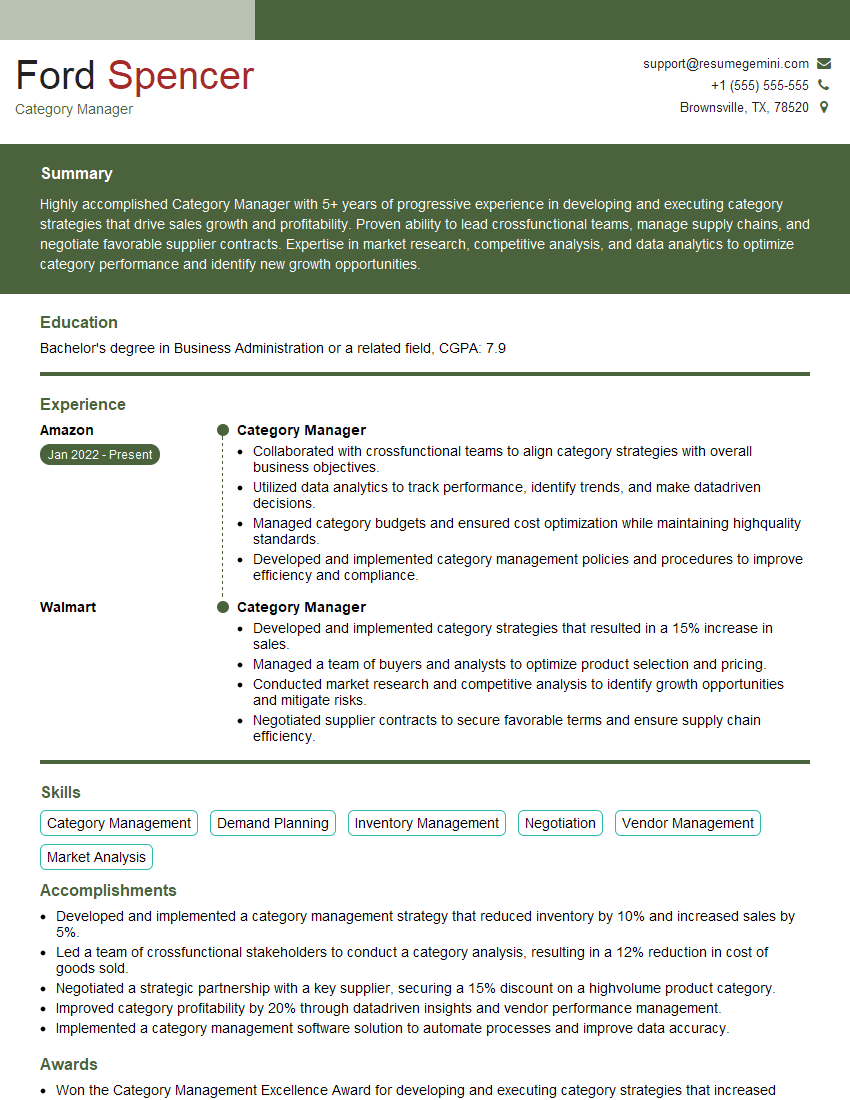

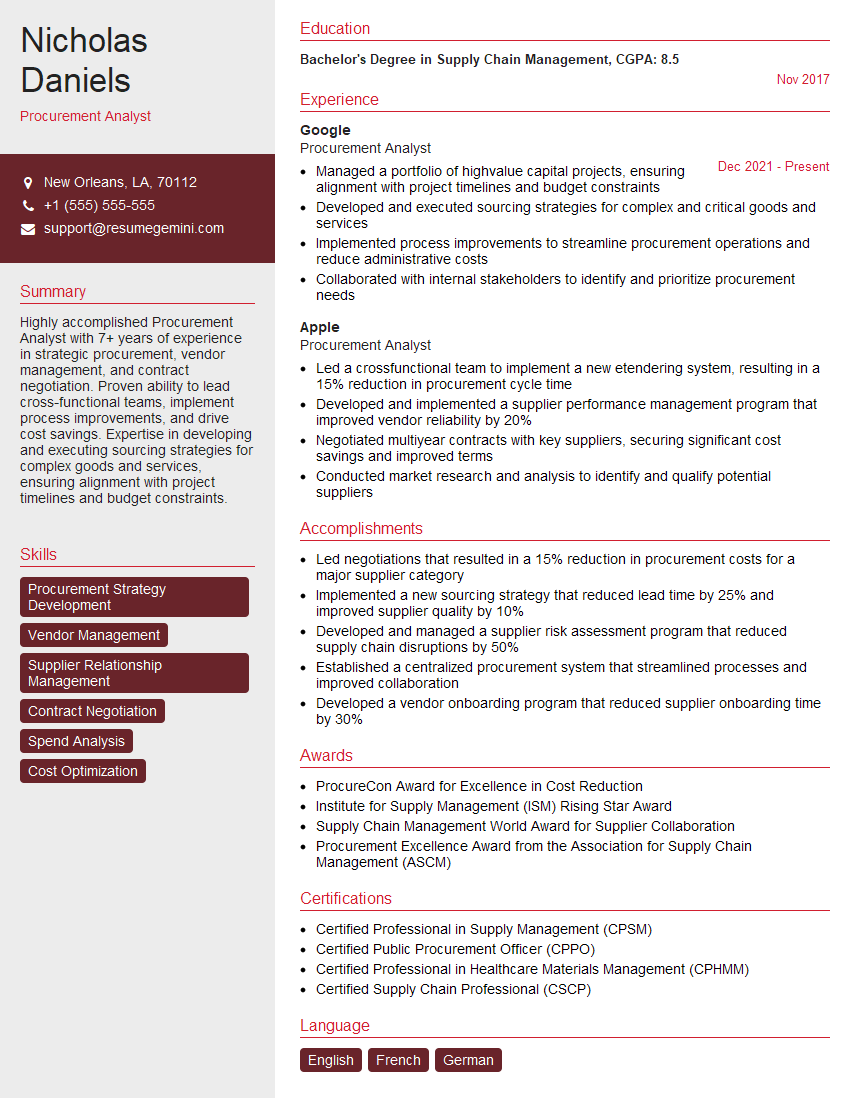

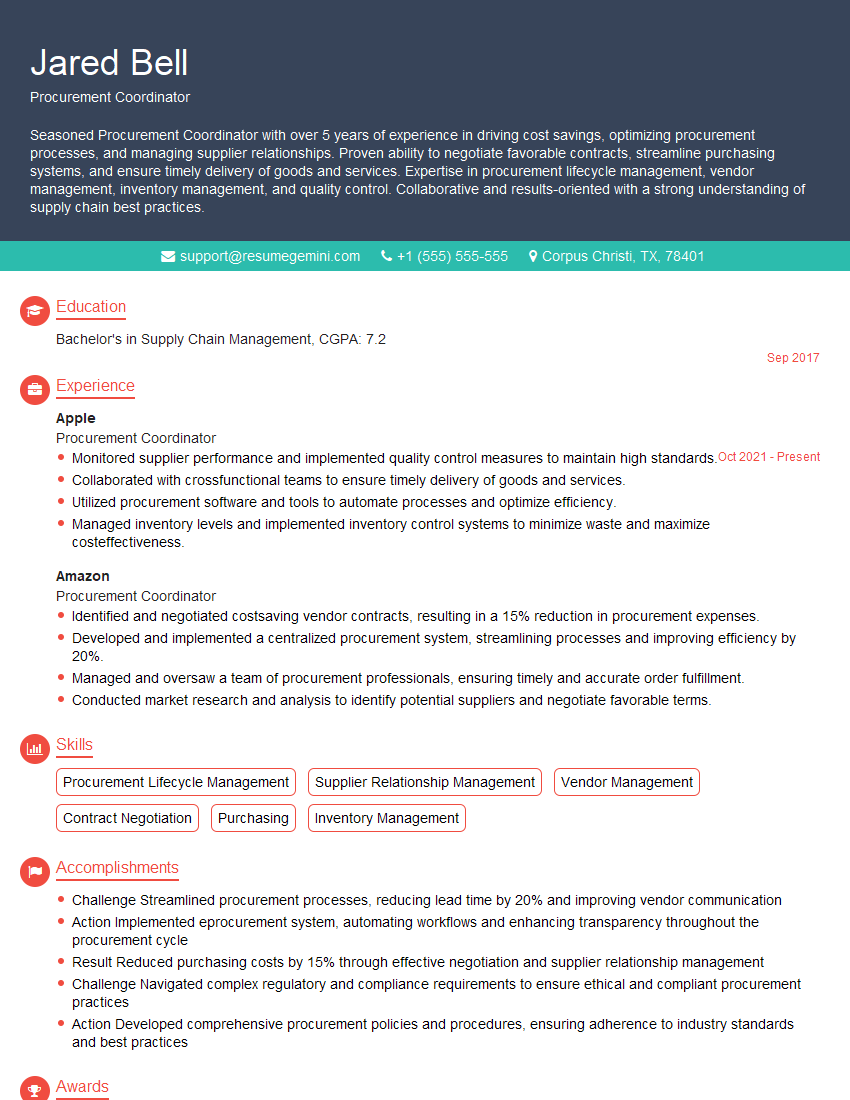

Mastering Material Procurement and Management opens doors to exciting career opportunities with significant growth potential. A strong understanding of these principles will make you a highly valuable asset to any organization. To enhance your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Material Procurement and Management are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good