Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Material Review and Acceptance interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Material Review and Acceptance Interview

Q 1. Describe your experience with Material Review and Acceptance processes.

My experience with Material Review and Acceptance (MRA) processes spans over 10 years, encompassing various industries including aerospace, automotive, and medical device manufacturing. I’ve been involved in every stage, from developing and implementing MRA plans to conducting inspections, resolving discrepancies, and managing associated documentation. I’ve worked with diverse materials, ranging from metals and composites to polymers and electronics, and am proficient in applying appropriate inspection techniques for each.

For example, in my previous role at a medical device company, I was responsible for the MRA of critical components used in implantable devices. This involved meticulous inspection using a variety of methods including visual inspection, dimensional measurement, and material testing, to ensure compliance with stringent regulatory requirements. Successfully implementing a robust MRA process there resulted in a significant reduction in defects and improved product quality.

Another significant project involved leading a team in the development of a new MRA system for a large aerospace manufacturer. This project involved streamlining existing processes, implementing new technologies (like automated inspection systems), and training personnel. The result was a more efficient and effective MRA process leading to substantial cost savings and improved turnaround times.

Q 2. Explain the difference between acceptance criteria and rejection criteria.

Acceptance criteria define the characteristics a material must possess to be deemed acceptable for use. These are pre-defined specifications based on design requirements, industry standards, and regulatory compliance. Rejection criteria, conversely, outline the characteristics that, if present, render the material unacceptable. These are often defined as limits outside the acceptable range or the presence of specific defects.

Think of it like this: imagine you’re baking a cake. Acceptance criteria might be: the cake must be fully baked, have a consistent texture, and be free of burnt areas. Rejection criteria might be: the cake is raw in the center, has significant cracks, or contains foreign objects. Meeting all acceptance criteria ensures a successful outcome, while any rejection criteria results in the product being discarded.

Q 3. What are the key elements of a robust Material Review and Acceptance plan?

A robust MRA plan requires several key elements to ensure effectiveness and efficiency. These include:

- Clearly Defined Acceptance Criteria: Detailed specifications for each material property (e.g., dimensions, chemical composition, mechanical properties) are crucial. These should be traceable to design requirements and relevant standards.

- Inspection Methods and Procedures: The plan must outline the specific inspection techniques (visual, dimensional, chemical, mechanical, etc.) to be used, along with detailed procedures to ensure consistency and accuracy.

- Testing Equipment and Calibration: The plan should identify the necessary testing equipment, including calibration schedules and procedures, to ensure the accuracy and reliability of measurements.

- Personnel Training and Qualification: Inspectors must be adequately trained and qualified to perform the specified inspections and interpret the results.

- Documentation and Traceability: Comprehensive documentation is essential, including inspection reports, certificates of compliance, and a complete audit trail for traceability.

- Non-Conformance Procedures: The plan should detail how to handle non-conforming materials, including procedures for investigation, corrective actions, and disposition decisions.

- Statistical Process Control (SPC): Implementing SPC can help monitor the process and identify potential issues early on, before they lead to widespread non-conformance.

Q 4. How do you handle discrepancies found during material inspection?

Discrepancies found during material inspection are addressed through a systematic process. First, the discrepancy is documented meticulously, including location, nature, severity, and photographic evidence. Then, the root cause of the discrepancy is investigated to determine if it’s a single incident or indicative of a larger problem in the manufacturing process. Following the investigation, a disposition decision is made based on the severity and root cause, following established procedures outlined in the MRA plan. Options include repair, rework, concession, or rejection. All actions taken are documented, and corrective actions are implemented to prevent recurrence.

For instance, if a slight dimensional deviation is found on a part, it might be acceptable if it falls within established tolerances and does not impact functionality. However, if a critical defect like a crack is found, the part would be immediately rejected. This process ensures that only conforming materials are used in the final product, contributing to overall quality and safety.

Q 5. What are the common methods for non-destructive testing (NDT)?

Non-destructive testing (NDT) methods allow us to inspect materials without causing damage. Common techniques include:

- Visual Inspection: A basic, yet critical method for detecting surface defects.

- Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal flaws.

- Radiographic Testing (RT): Uses X-rays or gamma rays to create images of internal structures and defects.

- Magnetic Particle Testing (MT): Detects surface and near-surface cracks in ferromagnetic materials.

- Liquid Penetrant Testing (PT): Detects surface-breaking flaws by using a dye that penetrates the cracks.

- Eddy Current Testing (ECT): Uses electromagnetic induction to detect surface and subsurface flaws in conductive materials.

The choice of NDT method depends on the material, the type of defect being sought, and the accessibility of the part.

Q 6. Explain your experience with different types of inspection methods (visual, dimensional, etc.).

My experience encompasses a wide range of inspection methods. Visual inspection is fundamental, requiring keen observation skills and knowledge of common defects. Dimensional inspection involves using various tools like calipers, micrometers, and coordinate measuring machines (CMMs) to verify dimensions against specifications. I’m experienced in using CMMs for complex geometries, ensuring accurate measurements and detailed reports. Chemical inspection might involve spectrographic analysis to verify material composition. Mechanical testing, such as tensile testing or hardness testing, assesses the material’s strength and durability. I am also proficient in using advanced optical inspection systems for high-precision measurements and detailed analysis of surface finishes.

For example, in a recent project involving carbon fiber composites, I combined visual inspection with ultrasonic testing to detect both surface imperfections and internal delaminations. This combined approach ensured a thorough evaluation of material quality.

Q 7. How do you ensure traceability throughout the MRA process?

Traceability throughout the MRA process is crucial for quality control and regulatory compliance. This is achieved through a robust documentation system linking every stage. Each material batch is identified with a unique lot number, and all inspection records are linked to this number. This ensures that the history of each material batch, from its origin to its final acceptance, is completely documented. This includes supplier documentation, incoming inspection reports, test results, and any non-conformance reports. Using a combination of paper-based and electronic systems, we ensure that this information is readily accessible and auditable. This traceability is vital not only for quality control but also for potential recalls or investigations.

Imagine a situation where a defective product is identified in the field. With a fully traceable system, we can easily determine the source of the problem, identify the specific batch of material involved, and take prompt corrective actions to prevent recurrence.

Q 8. Describe your experience with statistical process control (SPC).

Statistical Process Control (SPC) is a powerful methodology used to monitor and control processes by collecting and analyzing data. It helps us identify trends, variations, and potential problems before they significantly impact product quality. My experience with SPC involves utilizing control charts, such as X-bar and R charts, to track key process parameters. For instance, in a manufacturing setting, we might monitor the diameter of a machined part. By plotting the average diameter (X-bar) and the range of diameters (R) over time, we can quickly identify if the process is stable (within control limits) or if there’s a shift indicating a potential issue. If a point falls outside the control limits, or a pattern emerges (e.g., consistently increasing or decreasing trend), it signals a need for investigation and corrective action. I’m also experienced in using capability analysis to determine if a process is capable of meeting specified requirements.

In one project, we used SPC to reduce the defect rate in a welding process. By implementing X-bar and R charts for weld strength, we identified a correlation between electrode wear and inconsistent weld quality. Addressing electrode maintenance and replacement schedules directly improved the process capability and reduced defects by 30%.

Q 9. How do you document and report MRA findings?

Documenting and reporting MRA (Material Review and Acceptance) findings is crucial for maintaining traceability and ensuring corrective actions. My approach involves a comprehensive report including detailed descriptions of the non-conforming material, the inspection methods used, the test results, the root cause analysis findings (detailed in the next answer), and the disposition of the material (accepted, rejected, reworked, scrapped). This report is typically accompanied by supporting documentation like photographs, inspection reports, and test certificates. The findings are disseminated to relevant stakeholders through formal channels, often utilizing a structured reporting system with version control. This ensures transparency and accountability throughout the process.

For example, I once prepared a report detailing non-conformance in a batch of raw materials due to contamination. The report detailed the observed contamination (foreign particles visible under magnification), the chemical analysis of the contaminant, photographs showing the contamination level, the testing procedure that identified the non-conformance, and a conclusion recommending the rejection of the affected batch.

Q 10. What is your experience with root cause analysis techniques?

Root cause analysis (RCA) is fundamental to preventing recurrence of quality issues. I am proficient in various RCA techniques, including the 5 Whys, Fishbone diagrams (Ishikawa diagrams), and Fault Tree Analysis. The 5 Whys method is a simple yet effective technique where you repeatedly ask ‘Why?’ to drill down to the root cause. The Fishbone diagram helps visualize potential causes categorized by factors like materials, methods, manpower, machinery, measurements and environment. Fault Tree Analysis is a more formal approach using Boolean logic to illustrate the combination of events that can lead to a failure. The choice of technique depends on the complexity of the situation.

For instance, when dealing with recurring weld defects, we employed a Fishbone diagram to identify potential causes. This revealed that inconsistent pre-heating of the base material was a significant contributor. Through targeted corrective actions, addressing the pre-heating process, we were able to eliminate the root cause and prevent further defects.

Q 11. How do you handle material rejection and non-conformance reports?

Handling material rejection and non-conformance reports involves a structured process. Upon receiving a non-conformance report, the first step is to verify the report’s accuracy through a thorough investigation. Then, depending on the severity and nature of the non-conformance, a Material Review Board (MRB) may convene to decide the appropriate disposition. Options include: rework, repair, scrap, concession (acceptance with certain stipulations), or rejection. The disposition decision is documented along with the justification. Throughout this process, I ensure compliance with established procedures, maintaining detailed records and communicating effectively with all relevant parties. In the case of supplier-related non-conformance, I initiate corrective actions with the supplier to prevent recurrence.

An example: A supplier provided a batch of components with dimensional inaccuracies. After verifying the non-conformance, the MRB decided that the components were still usable for a different application. This was documented as a concession, and the components were diverted to the alternative application.

Q 12. What are some common quality standards you are familiar with (e.g., ISO 9001)?

I am familiar with various quality standards including ISO 9001 (Quality Management Systems), AS9100 (Aerospace Quality Management Systems), and IATF 16949 (Automotive Quality Management Systems). These standards provide frameworks for establishing and maintaining quality management systems. My experience encompasses implementing, auditing, and maintaining systems compliant with these standards. Understanding these standards helps in establishing robust processes, procedures, and documentation to ensure product quality and customer satisfaction. Familiarity with these standards also facilitates effective communication and collaboration with clients and suppliers who operate under similar frameworks.

In a previous role, we implemented ISO 9001, leading to improved internal processes, better customer satisfaction, and increased efficiency.

Q 13. How do you prioritize materials for inspection based on risk?

Prioritizing materials for inspection based on risk is critical for efficient resource allocation. I employ risk-based inspection planning, considering factors such as criticality of the component, potential impact of failure, supplier history, and previous inspection results. A risk matrix can be used to categorize materials into high, medium, and low-risk categories. High-risk materials are inspected more frequently and thoroughly, while lower-risk materials may have less frequent or less rigorous inspections. This approach helps in focusing resources on areas that pose the greatest risk to product quality and safety.

For example, in the manufacturing of a medical device, critical components like the pump are categorized as high-risk and undergo rigorous 100% inspection, whereas less critical components are subject to sampling plans.

Q 14. What is your experience with using a Computerized Maintenance Management System (CMMS)?

My experience with Computerized Maintenance Management Systems (CMMS) is primarily focused on using the data they provide to support effective material review and acceptance. A CMMS can track equipment maintenance, which helps identify potential issues with equipment that might affect material processing. For example, if a machine consistently produces non-conforming parts, its maintenance history from the CMMS can help pinpoint the root cause (e.g., worn-out tooling or improper calibration). This data is incorporated into MRA investigations to assist in determining the disposition of materials impacted by the equipment malfunction. Although I don’t directly manage the CMMS, I’m adept at extracting relevant data to inform my MRA decisions.

In a previous role, analyzing CMMS data showed a correlation between the frequency of equipment maintenance and the rate of material defects. This led to an optimized maintenance schedule resulting in improved equipment performance and reduced material rejection.

Q 15. Describe your experience with supplier audits.

Supplier audits are a critical part of ensuring consistent product quality and compliance. My experience encompasses conducting both first-party (internal) and second-party (supplier) audits, focusing on evaluating the supplier’s quality management system (QMS) against relevant standards like ISO 9001 or industry-specific requirements. I’ve led audits assessing processes from raw material sourcing to finished goods inspection, encompassing areas like manufacturing processes, equipment calibration, documentation control, and personnel training. For example, during an audit of a supplier providing critical components for medical devices, I discovered a gap in their traceability system. This was addressed by recommending improvements to their labeling and documentation procedures, leading to better control and improved traceability. My audit reports are detailed, objective, and provide actionable recommendations for improvement.

I also leverage checklists and standardized audit procedures to maintain consistency across different suppliers. Following the audit, a formal report is issued to the supplier outlining findings, non-conformances, and recommended corrective actions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate MRA findings to stakeholders?

Communicating Material Review and Acceptance (MRA) findings effectively is crucial. My approach involves tailoring the communication to the audience and the severity of the findings. For minor issues, a brief email or informal meeting might suffice. However, for significant findings, I prepare a formal report which uses clear, concise language and avoids technical jargon whenever possible. This report will include a summary of the findings, their impact, proposed corrective actions, and a timeline for resolution.

Stakeholders I typically communicate with include the supplier, internal management (quality control, purchasing, engineering), and sometimes even the customer (depending on the severity and impact). I always encourage collaborative problem-solving, working with the supplier to implement CAPAs and to prevent recurrence. For instance, during a situation involving non-conforming materials, I held a conference call with representatives from the supplier, our quality control department, and the purchasing team, ensuring everyone understood the severity of the issue and their respective roles in resolving it. Visual aids such as charts and graphs are used to ensure easier comprehension of the presented data.

Q 17. Explain your experience with corrective and preventive actions (CAPA).

Corrective and Preventive Actions (CAPA) are vital for continuous improvement. My experience involves actively participating in the entire CAPA process, from identifying root causes of non-conformances to verifying the effectiveness of implemented corrective actions. I utilize various problem-solving tools like fishbone diagrams (Ishikawa diagrams) and 5 Whys to get to the root cause of the issue.

For example, when we found inconsistencies in the dimensions of a particular component, I led a team to investigate. We used a fishbone diagram to identify potential contributing factors (machine settings, operator skill, material variations) and then applied the 5 Whys to each factor to drill down to the root cause. We found that inadequate machine calibration was the primary issue. The CAPA implemented involved recalibrating the machines, revising operator training, and implementing regular monitoring procedures. Once completed, I verified the effectiveness of the CAPA through follow-up inspections and data analysis. Effective documentation is paramount, ensuring all steps, findings, and actions are thoroughly recorded and auditable.

Q 18. How do you manage multiple MRA tasks simultaneously?

Managing multiple MRA tasks simultaneously requires effective prioritization, planning, and organizational skills. I employ project management techniques, such as using task management software (e.g., Jira or Asana) to track progress, assign deadlines, and monitor overall performance. I break down complex tasks into smaller, manageable units, focusing on the most critical ones first.

Prioritization is done based on factors like the severity of the issue, potential impact on production, and customer deadlines. Regular review meetings help me to stay aligned with project timelines, to identify potential roadblocks early on and to adjust priorities as needed. Clear communication with all stakeholders is essential to keep everyone informed about the status of various tasks. Using visual tools like Kanban boards enhances the visibility of the workflow and helps in effective task allocation.

Q 19. What is your experience with different types of measurement equipment?

Throughout my career, I have gained proficiency with a wide range of measurement equipment including:

- Optical Comparators: Used for precise dimensional measurements and comparing parts to specifications.

- Micrometers and Calipers: Standard tools for measuring linear dimensions.

- Coordinate Measuring Machines (CMMs): For precise three-dimensional measurements, commonly used for complex geometries.

- Surface Roughness Testers: For evaluating surface texture and finish.

- Spectrometers: Used for material analysis and composition determination.

My experience encompasses not only using this equipment, but also understanding the principles of metrology, calibration procedures, and the importance of maintaining equipment accuracy through regular calibration and verification. For example, while working on a project involving high-precision components, I ensured the CMM used was properly calibrated and validated according to ISO 10012-1 standards, which is crucial to maintain the reliability and integrity of the inspection results.

Q 20. Explain your knowledge of relevant industry regulations.

My knowledge of industry regulations is extensive, encompassing a range of standards depending on the industry. In the medical device industry, I am well-versed in regulations such as 21 CFR Part 820 (Quality System Regulation) and ISO 13485 (Medical Devices – Quality Management Systems). For aerospace applications, I’m familiar with AS9100 and relevant specifications such as those issued by the FAA.

Understanding these regulations helps in designing and implementing quality control systems that ensure compliance and minimize risks. This knowledge guides my audit procedures, MRA processes, and the development of CAPAs. Compliance requirements are always factored into my decision making, and I strive to stay up-to-date with any changes or revisions to these regulations.

Q 21. How do you ensure the accuracy and reliability of your inspection results?

Ensuring the accuracy and reliability of inspection results is paramount. This is achieved through a multi-pronged approach:

- Calibration and Validation: All measurement equipment must be calibrated regularly and traceable to national or international standards. Verification of the equipment’s accuracy is conducted prior to and after usage.

- Standard Operating Procedures (SOPs): Detailed SOPs are followed during each inspection to maintain consistency and minimize errors. These include instructions on equipment usage, sample selection, and data recording.

- Statistical Process Control (SPC): SPC techniques are utilized to monitor processes and identify trends, helping prevent deviations and ensuring consistent results. Control charts are used to detect abnormalities early on.

- Personnel Training: Inspectors are thoroughly trained on the use of equipment, inspection techniques, and interpretation of results. Their competence is assessed regularly.

- Audit Trails: A complete audit trail of all inspection activities is maintained to provide traceability and facilitate review. This includes data logging, signatures, and any deviations from standard procedures.

For example, we regularly audit our inspection processes and analyze data to identify any systemic issues that might affect the accuracy of our results. This proactive approach ensures that our inspection program remains robust and efficient.

Q 22. What are your strengths and weaknesses in relation to MRA?

My strengths in Material Review and Acceptance (MRA) lie in my meticulous attention to detail, my strong analytical skills, and my ability to effectively communicate complex technical information to both technical and non-technical audiences. I’m proficient in interpreting engineering drawings, specifications, and test reports to ensure materials meet required standards. I also excel at identifying and resolving discrepancies, proactively mitigating potential risks. A weakness I’m actively working on is delegation. While I can manage multiple MRA projects effectively, I sometimes struggle to fully trust others with critical tasks, preferring to handle everything myself. I’m addressing this by actively seeking opportunities to mentor junior team members and develop my delegation skills.

Q 23. Describe a situation where you had to make a difficult decision related to MRA.

During a recent project involving the procurement of a specialized alloy for aerospace components, we received a shipment with inconsistencies in the material’s chemical composition. The supplier’s initial report indicated the deviation was minor and within acceptable tolerances. However, my analysis, using statistical process control (SPC) techniques, revealed a concerning trend indicating a potential risk of structural failure. This contradicted the supplier’s assessment. The difficult decision was whether to accept the shipment and mitigate the risk through enhanced component testing or reject the entire shipment causing project delays and potential cost overruns. After carefully evaluating the risks and benefits of both options, and consulting with engineering and project management, I opted to reject the shipment. This decision, while initially met with some resistance, ultimately prevented potential catastrophic failures down the line and reinforced our commitment to quality. The extra testing we ultimately implemented, while adding expense, gave us confidence that our quality expectations were met.

Q 24. How do you stay updated on the latest MRA best practices and technologies?

Staying updated on MRA best practices and technologies is crucial. I actively participate in professional organizations like ASQ (American Society for Quality) and attend relevant conferences and webinars. I subscribe to industry journals like Quality Progress and regularly review online resources and technical publications from organizations such as ASTM International and ISO. Furthermore, I maintain a network of contacts within the industry, engaging in peer-to-peer learning and knowledge exchange. This multi-faceted approach ensures I remain at the forefront of industry advancements.

Q 25. What is your experience with using quality management systems (QMS)?

I have extensive experience with Quality Management Systems (QMS), particularly ISO 9001. I’ve been involved in the implementation, auditing, and continuous improvement of QMS in various organizations. My experience includes developing and maintaining MRA procedures within the QMS framework, ensuring compliance with regulatory requirements and industry standards. This involves documenting MRA processes, creating and maintaining controlled documents, and conducting internal audits to verify compliance. For example, I helped implement a digital MRA system that reduced processing time by 40% and improved traceability of materials.

Q 26. How do you handle pressure and tight deadlines in an MRA environment?

Handling pressure and tight deadlines in an MRA environment requires a structured and proactive approach. I utilize project management techniques, such as prioritizing tasks based on criticality and urgency, and employing effective time management strategies. Clear communication with stakeholders is key—keeping them informed of progress and potential challenges. I also focus on efficient workflows and automation where possible, using software tools to streamline tasks and reduce manual effort. For instance, utilizing automated inspection reports allows me to immediately highlight any issues.

Q 27. Explain your experience with data analysis and reporting in relation to MRA.

My experience with data analysis and reporting in MRA involves using statistical methods to analyze inspection data, identify trends, and assess the effectiveness of MRA processes. I’m proficient in using software tools like Minitab and Excel to create charts and graphs that visualize key performance indicators (KPIs), such as defect rates and acceptance rates. This data helps to identify areas for improvement and support data-driven decision-making. For example, I once used statistical analysis to show a correlation between a particular supplier and an increase in defects, leading to corrective actions with that supplier.

Q 28. Describe your experience with different types of materials and their specific inspection requirements.

My experience encompasses a wide range of materials, including metals (ferrous and non-ferrous), polymers, composites, and ceramics. Each material has unique inspection requirements based on its properties and intended application. For example, metals may require visual inspection, dimensional checks, chemical analysis, and mechanical testing, while polymers might necessitate testing for tensile strength, elongation, and impact resistance. My understanding extends to specific industry standards and regulations applicable to each material type, ensuring compliance and minimizing risk. I am well-versed in using various inspection techniques, including non-destructive testing (NDT) methods like ultrasonic testing (UT) and radiographic testing (RT), when required.

Key Topics to Learn for Material Review and Acceptance Interview

- Material Specifications and Standards: Understanding and interpreting engineering drawings, specifications, and industry standards (e.g., ASME, ASTM) to ensure materials meet required quality.

- Inspection Techniques and Methods: Familiarizing yourself with various inspection methods like visual inspection, dimensional measurement, non-destructive testing (NDT) techniques (e.g., ultrasonic testing, radiography), and their practical applications in material verification.

- Quality Control Procedures: Mastering the implementation and documentation of quality control procedures, including sampling plans, inspection reports, and non-conformance reports. Understanding root cause analysis and corrective actions.

- Material Testing and Analysis: Understanding the purpose and interpretation of various material tests (e.g., tensile strength, hardness, impact resistance) and how these results inform acceptance criteria.

- Regulatory Compliance: Knowledge of relevant industry regulations and compliance requirements related to material acceptance and traceability.

- Problem-Solving and Decision-Making: Developing your ability to identify and troubleshoot material discrepancies, make informed decisions based on available data, and propose effective solutions.

- Communication and Teamwork: Understanding the importance of clear and concise communication with engineers, suppliers, and other stakeholders. Highlighting experience in collaborative problem-solving within a team environment.

Next Steps

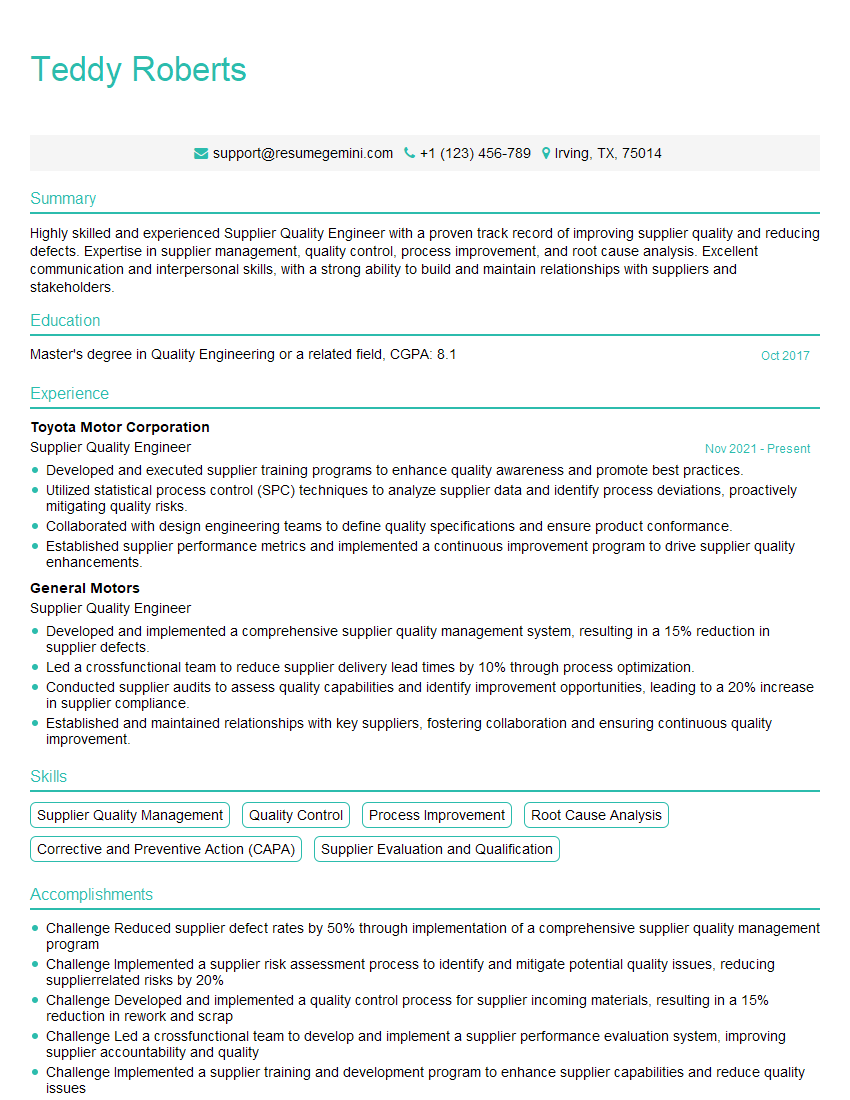

Mastering Material Review and Acceptance opens doors to exciting career advancements in manufacturing, engineering, and quality control. A strong understanding of these principles significantly enhances your value to any organization. To maximize your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. We provide examples of resumes tailored specifically to Material Review and Acceptance roles to guide you through the process. Invest time in creating a strong resume – it’s your first impression to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good