Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Membrane Electrode Assembly (MEA) Handling interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Membrane Electrode Assembly (MEA) Handling Interview

Q 1. Describe the different types of MEAs and their applications.

Membrane Electrode Assemblies (MEAs) are the heart of fuel cells and electrolyzers, responsible for electrochemical reactions. Different types exist, primarily categorized by their membrane material and catalyst.

- Proton Exchange Membrane (PEM) MEAs: These are the most common, using a solid polymer electrolyte membrane (like Nafion) to conduct protons. Applications include fuel cell vehicles, stationary power generation, and portable devices. They offer high power density and efficiency but are sensitive to water management.

- Alkaline MEAs: These use an alkaline electrolyte, typically KOH, offering advantages in catalyst cost and tolerance to CO. Applications are expanding in areas like renewable energy storage and industrial applications, but they require careful management of CO2 contamination.

- High-Temperature MEAs: Operating at elevated temperatures (e.g., using solid oxide or molten carbonate electrolytes), these offer higher efficiency and potential for fuel flexibility (e.g., using biogas). They’re less common but gaining traction for large-scale power generation.

The choice of MEA type depends heavily on the specific application’s requirements – cost, efficiency, operating temperature, and fuel source.

Q 2. Explain the manufacturing process of an MEA.

MEA manufacturing is a complex process requiring precision and control. It typically involves several key steps:

- Catalyst Layer Deposition: Catalyst inks (containing platinum, platinum-alloy nanoparticles, or other catalysts) are deposited onto the gas diffusion layers (GDLs) using techniques like screen printing, spray coating, or doctor blading. The uniformity of this layer is crucial.

- Membrane Preparation: The polymer electrolyte membrane (PEM) is carefully handled and possibly treated to optimize its properties (e.g., hydration).

- Hot Pressing: The catalyst-coated GDLs and the membrane are meticulously aligned and hot-pressed under controlled temperature and pressure to create a strong, uniform, and intimate contact between layers. This process creates the MEA.

- Quality Control Checks: At each stage, rigorous quality control checks are performed using various methods such as microscopy, electrochemical impedance spectroscopy, and mechanical testing.

The entire process takes place in a controlled environment to avoid contamination and ensure consistent quality. Any deviation can significantly impact the MEA’s performance and lifespan.

Q 3. What are the key quality control parameters for an MEA?

Ensuring MEA quality is critical. Key parameters include:

- Membrane Thickness and Uniformity: Variations affect proton conductivity and performance.

- Catalyst Loading and Distribution: Optimal catalyst loading maximizes active surface area and electrochemical activity. Uniform distribution prevents inactive areas.

- GDL Porosity and Permeability: These control gas transport to the catalyst layer.

- Interfacial Contact Resistance: A high contact resistance between layers increases energy loss.

- Membrane Water Content: Optimal hydration is critical for proton conductivity.

These parameters are assessed through microscopy, electrochemical testing, and gas permeation measurements. Statistical Process Control (SPC) is often implemented to track and control the process effectively.

Q 4. How do you assess the performance of an MEA?

MEA performance is assessed using electrochemical techniques, focusing on key metrics:

- Power Density: The amount of power generated per unit area (W/cm2). This is a primary performance indicator.

- Voltage: The cell voltage at different current densities. This provides insights into the efficiency and internal losses.

- Current Density: The amount of current generated per unit area (A/cm2). Higher current density means higher power output.

- Electrochemical Impedance Spectroscopy (EIS): This technique allows detailed analysis of different components’ resistances and capacitances (e.g., membrane resistance, charge transfer resistance), providing valuable diagnostic information.

These measurements are carried out using a fuel cell test station under controlled conditions (temperature, humidity, gas flow rates). The data helps optimize MEA design and identify areas for improvement.

Q 5. What are the common defects found in MEAs and their causes?

Common MEA defects can significantly reduce performance. Some include:

- Pin Holes in the Membrane: These cause gas crossover (e.g., oxygen and hydrogen mixing), reducing efficiency and potentially causing safety issues. Causes include improper membrane handling or hot pressing.

- Non-Uniform Catalyst Distribution: Leads to uneven current density and reduced performance. This can result from poor catalyst ink preparation or deposition processes.

- Poor Catalyst Layer Adhesion: Can cause delamination during operation, leading to increased contact resistance and performance degradation. Often caused by inadequate hot pressing or incompatible materials.

- GDL Defects: This can include poor porosity or hydrophobicity, hindering gas transport. This may be due to manufacturing irregularities or material defects.

Defect analysis usually involves microscopy (optical, SEM), electrochemical impedance spectroscopy, and destructive testing to identify the root cause and improve the manufacturing process.

Q 6. Explain the role of the catalyst layer in an MEA.

The catalyst layer is the heart of the MEA, where the electrochemical reactions occur. It typically consists of a high surface area catalyst (usually platinum or platinum alloys) supported on a conductive carbon material. This layer facilitates the following:

- Oxygen Reduction Reaction (ORR) at the Cathode: Oxygen is reduced to water, generating electrons.

- Hydrogen Oxidation Reaction (HOR) at the Anode: Hydrogen is oxidized to protons and electrons.

The catalyst’s activity, dispersion, and stability are critical for MEA performance and durability. Factors such as particle size, surface area, and catalyst support material strongly influence its efficiency. Careful control of the catalyst layer’s composition and structure is essential for optimizing the MEA’s overall performance.

Q 7. How do you handle and store MEAs to prevent degradation?

Proper handling and storage are crucial to prevent MEA degradation. Key considerations include:

- Humidity Control: MEAs must be kept at a specific humidity level (often ~50%) to maintain optimal membrane hydration. Too much or too little moisture can lead to degradation.

- Cleanliness: Avoid any contamination from dust, chemicals, or fingerprints, as this can affect performance. Wear gloves and work in a clean environment.

- Storage Temperature: Store MEAs in a cool, dry place at room temperature. Avoid extreme temperatures and direct sunlight.

- Protective Packaging: Store MEAs in suitable packaging (e.g., airtight containers with desiccant) to prevent exposure to moisture and contaminants.

- Avoid Bending or Mechanical Stress: The MEA is delicate. Avoid excessive bending or pressure that could cause damage to the layers.

Adhering to these practices can significantly extend the lifespan and maintain the performance of the MEAs, maximizing their efficiency and operational longevity.

Q 8. Describe the different types of membrane materials used in MEAs.

Membrane Electrode Assemblies (MEAs) utilize various membrane materials, each with unique properties impacting performance. The most common is the proton exchange membrane (PEM), typically made of perfluorinated sulfonic acid polymers like Nafion. These membranes selectively allow proton transport while blocking electron flow, crucial for fuel cell operation. Another type is the alkaline anion exchange membrane (AEM), which facilitates hydroxide ion transport. AEMs are gaining traction due to their potential for using non-precious metal catalysts. Finally, there are high-temperature PEMs, often based on phosphoric acid or other materials, that can operate at higher temperatures and offer improved performance characteristics compared to low-temperature PEMs. The choice of membrane depends on the specific application requirements, such as operating temperature, humidity, and desired power output.

- Nafion: The gold standard, known for its high proton conductivity and chemical stability.

- AEMs: Offer advantages in terms of cost and catalyst options, but often suffer from lower stability and durability.

- High-Temperature PEMs: Enable higher efficiency and potentially simpler system designs, but come with material challenges.

Q 9. What is the impact of humidity on MEA performance?

Humidity plays a critical role in MEA performance. Sufficient hydration of the PEM is essential for high proton conductivity. Think of the membrane as a sponge; it needs water molecules to facilitate proton transport. Low humidity leads to membrane dehydration, drastically reducing proton conductivity and resulting in decreased power output and increased cell resistance. Conversely, excessive humidity can lead to flooding of the gas diffusion layers, blocking access of reactant gases to the catalyst layer and impairing performance. Therefore, maintaining optimal humidity levels is crucial for efficient fuel cell operation. This is often achieved through careful control of the humidification system in the fuel cell stack.

Imagine trying to squeeze a dry sponge – it’s hard to get much water out. Similarly, a dehydrated membrane struggles to conduct protons effectively. Conversely, if the sponge is oversaturated it loses its ability to absorb more water. Similarly, the excess water in a flooded GDL blocks gas transport.

Q 10. Explain the concept of gas diffusion layers (GDLs) in MEAs.

Gas Diffusion Layers (GDLs) are porous components in MEAs that facilitate the transport of reactant gases (hydrogen and oxygen) to the catalyst layer and the removal of water and byproducts. They act as a bridge, connecting the flow fields to the catalyst layer. A typical GDL is made of a carbon fiber paper or cloth treated with a hydrophobic polymer (like PTFE) to control water management. The hydrophobic treatment prevents flooding by directing liquid water away from the catalyst layer while maintaining a gas pathway. The porous structure ensures that the gases can diffuse efficiently, while the electronic conductivity allows electrons to be transported. A well-designed GDL is key to achieving high performance in a fuel cell.

Think of a GDL as a highway system for gases and electrons. The porous structure allows for smooth flow of gases to the catalyst, while the hydrophobic treatment ensures that water doesn’t clog the roads. The electronic conductivity is like the power lines that carry the electrons.

Q 11. How do you troubleshoot performance issues in an MEA?

Troubleshooting MEA performance issues involves a systematic approach. First, thoroughly examine the cell voltage and current density curves (polarization curves). A significant drop in voltage at low current densities often points to issues with the membrane (high resistance) or contact resistance. Decreased performance at high currents indicates issues with mass transport – potentially flooding or insufficient reactant supply. Visual inspection for cracks or pinholes in the MEA can also provide clues. Measuring the gas flow rates and pressure drops helps to identify limitations in gas supply. Electrochemical Impedance Spectroscopy (EIS) can pinpoint the sources of resistance within the MEA. Finally, comparing performance with a known good MEA can help isolate the problem.

- Analyze polarization curves: Identify voltage drops indicating high resistance or mass transport limitations.

- Visual inspection: Check for cracks or pinholes.

- Gas flow and pressure: Verify sufficient reactant supply.

- EIS measurements: Pinpoint resistance sources.

- Comparative testing: Compare against a known good MEA.

Q 12. Describe the various methods for MEA characterization.

MEA characterization involves various techniques to assess its performance and properties. Polarization curves, as mentioned before, measure voltage versus current density to evaluate overall performance. Electrochemical Impedance Spectroscopy (EIS) provides insights into different resistance components (e.g., ohmic, charge transfer, mass transport). Water uptake measurements determine the membrane’s hydration level. Gas permeability testing assesses the GDL’s ability to transport gases. Scanning Electron Microscopy (SEM) and other microscopic techniques analyze the MEA structure and catalyst layer morphology. These combined techniques give a comprehensive understanding of MEA performance and its underlying mechanisms.

Q 13. What are the safety precautions when handling MEAs?

Handling MEAs requires careful attention to safety. MEAs are delicate and susceptible to damage from handling. Always wear clean nitrile gloves to avoid contamination with fingerprints or other substances. Work in a clean environment to minimize particulate contamination. Avoid scratching or bending the MEA. Proper storage conditions are critical. MEAs should be stored in a dry, controlled environment to prevent degradation. Some MEA materials may be sensitive to certain chemicals, so be aware of the specific MEA materials.

Q 14. How does temperature affect MEA performance?

Temperature significantly impacts MEA performance. Higher temperatures generally lead to increased reaction kinetics and proton conductivity, resulting in higher power output. However, there are limitations. Excessive heat can degrade the membrane and catalyst materials, reducing their lifespan and performance. Also, at very high temperatures, water management becomes more challenging, potentially leading to drying or flooding. Therefore, operating within an optimal temperature range is crucial to balance performance and durability. Each MEA material and catalyst has its own optimal operating temperature range.

Think of it like cooking an egg. You need heat to cook it, but too much heat will burn it. Similarly, with an MEA, increased temperature enhances performance, but extreme temperatures can damage it.

Q 15. Explain the importance of proper MEA assembly procedures.

Proper MEA assembly is paramount to achieving optimal fuel cell performance and durability. Think of it like building a finely tuned engine – if even one component is misaligned or improperly installed, the entire system suffers. Improper procedures can lead to defects such as gas leaks, poor contact between components, and uneven current distribution, all resulting in significantly reduced power output and efficiency.

The process typically involves meticulously layering the components – the gas diffusion layers (GDLs), the catalyst layers, and the membrane – with precise control over pressure and alignment. Any imperfections introduced during this delicate process directly translate to performance losses. For example, wrinkles in the membrane or uneven catalyst layer deposition can create high-resistance regions, acting like bottlenecks that impede proton transport and electron flow, diminishing the overall cell efficiency.

- Cleanliness: Maintaining a clean environment is critical to avoid contamination which could affect the performance of the MEA. Even microscopic particles can severely impact performance.

- Controlled Pressure: Applying the right amount of pressure during the hot-pressing process is crucial for ensuring good contact between the layers without damaging them. Too little pressure leads to poor contact, and too much can damage the membrane.

- Precise Alignment: Accurate alignment of the layers is important to ensure uniform current distribution and prevent gas leaks.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe different MEA testing methods (e.g., electrochemical impedance spectroscopy).

Several methods exist to characterize MEA performance. Electrochemical Impedance Spectroscopy (EIS) is a powerful technique to analyze the various resistances and capacitances within the MEA. It’s like giving the fuel cell a detailed health check, identifying bottlenecks. EIS applies a small AC signal and measures the system’s response. The resulting impedance spectrum provides insights into the different processes occurring within the MEA, such as charge transfer resistance, mass transport limitations, and membrane resistance. This data allows us to pinpoint specific areas for improvement.

Other important methods include:

- Polarization curves (I-V curves): These measure the cell voltage as a function of current density, revealing overall performance and identifying voltage losses.

- Cyclic Voltammetry (CV): This technique probes the electrochemical activity of the catalyst layer, providing insights into the electrocatalytic properties of the material.

- Durability tests: These involve prolonged operation under specific conditions to evaluate the MEA’s long-term stability.

Q 17. What is the role of the electrolyte in an MEA?

The electrolyte in an MEA, typically a proton exchange membrane (PEM), plays a vital role in conducting protons from the anode to the cathode while blocking electron flow. It’s the heart of the fuel cell, acting as a selective barrier. Think of it as a one-way street for protons. Electrons are forced to travel through the external circuit, generating electricity. The electrolyte’s properties, such as proton conductivity, water uptake, and chemical stability, directly affect the performance and durability of the MEA. A high-performing electrolyte is crucial for efficient proton transport and minimizing ohmic losses.

The choice of electrolyte depends on several factors, including operating temperature and the specific fuel cell application. Different types of electrolytes include PEMs (like Nafion), alkaline membranes, and solid oxide electrolytes.

Q 18. How do you evaluate the long-term durability of an MEA?

Evaluating long-term durability is crucial for MEA development. We subject MEAs to accelerated stress tests under various conditions to simulate real-world operation over an extended period, often greatly compressed. These tests might include:

- Potential Cycling: Repeatedly cycling the cell potential between high and low values to simulate start-stop operation.

- Load Cycling: Alternating between high and low current densities, mimicking real-world power demands.

- Temperature Cycling: Exposing the MEA to varying temperatures to simulate fluctuating conditions.

- Humidity Cycling: Changing the relative humidity to mimic different operating environments.

By monitoring performance parameters (voltage, current, impedance) over these tests, we can understand degradation mechanisms and identify ways to improve the MEA’s lifespan. For example, observing a significant increase in resistance over time could indicate catalyst degradation, while a voltage drop might suggest membrane degradation.

Q 19. Explain the concept of polarization curves in MEA testing.

Polarization curves, also known as I-V curves, are graphs plotting the cell voltage (V) against the current density (I). They provide a comprehensive overview of MEA performance. These curves reveal different voltage loss mechanisms within the fuel cell, allowing us to identify areas for improvement. The curve is typically divided into three regions:

- Activation Polarization: This initial region shows slow voltage drop at low current densities due to the sluggish kinetics of the electrochemical reactions at the catalyst surface.

- Ohmic Polarization: A linear region reflecting resistance to the flow of ions and electrons within the MEA (membrane resistance, contact resistance, etc.).

- Concentration Polarization: A steep voltage drop at high current densities representing limitations in reactant supply to the catalyst layers due to mass transport limitations.

Analyzing the shape and slope of the polarization curve helps to diagnose problems like catalyst activity, membrane conductivity, or mass transport limitations, ultimately guiding optimization efforts.

Q 20. What are the challenges in scaling up MEA manufacturing?

Scaling up MEA manufacturing presents several challenges. Maintaining consistency in the quality and performance of MEAs at a larger scale is difficult. Think of it like baking a cake – you can easily make a perfect cake for a few people, but scaling up to feed a large crowd requires precise control over every aspect of the process. The main challenges include:

- Uniformity: Ensuring consistent coating thickness and composition across large areas is crucial for uniform performance.

- Defect Control: Minimizing defects like pinholes or delamination becomes more critical at larger scales.

- Cost-Effectiveness: Scaling up production must be done while maintaining cost-effectiveness.

- Automation: Automation of the various steps is essential for high throughput and reproducibility.

Advanced manufacturing techniques like roll-to-roll processing and inkjet printing are being developed to address these issues, enabling cost-effective and high-throughput MEA production.

Q 21. How do you optimize the performance of an MEA?

Optimizing MEA performance involves a multi-faceted approach. It’s an iterative process of refinement, testing, and analysis. Improving performance often involves optimizing the individual components and their interactions. Key strategies include:

- Catalyst Optimization: Using high-performance catalysts with increased active surface area and improved durability.

- Membrane Selection: Choosing membranes with high proton conductivity, low permeability to fuel gases, and good chemical stability.

- GDL Optimization: Selecting GDLs with high porosity, good gas permeability, and appropriate hydrophobicity for effective gas transport.

- Layer Thickness and Composition: Optimizing the thickness and composition of the catalyst layers and other components to improve mass transport and reduce resistance.

- Operating Conditions: Adjusting operating parameters like temperature, pressure, and humidity to enhance performance.

The optimization process often involves a combination of experimental and computational approaches, utilizing techniques like Design of Experiments (DOE) to systematically explore the parameter space and identify optimal conditions.

Q 22. Explain the effect of different catalyst loadings on MEA performance.

Catalyst loading significantly impacts MEA performance. Think of it like this: the catalyst (typically platinum) is the engine of the fuel cell, facilitating the electrochemical reactions. Higher catalyst loading generally leads to higher power output and improved performance at higher current densities. This is because more active sites are available for the reactions to occur. However, increasing the catalyst loading beyond a certain point yields diminishing returns. This is due to factors like mass transport limitations – the reactants struggle to reach all the catalyst sites, and increased cost of precious metals.

For example, in a PEM fuel cell, increasing platinum loading on the cathode might boost its oxygen reduction reaction (ORR) kinetics, resulting in a higher cell voltage at a given current. But excessively high loading can lead to inefficient use of platinum and increased costs without proportionate performance gains. Optimizing catalyst loading is crucial for achieving the best balance between performance, cost, and durability. We often use experimental techniques like polarization curves and electrochemical impedance spectroscopy to determine the optimal loading for a given application and MEA design.

Q 23. What are the environmental considerations in MEA manufacturing and disposal?

Environmental considerations in MEA manufacturing and disposal are paramount. The manufacturing process involves the use of various chemicals, including solvents and precious metals like platinum, which can be harmful if not managed properly. Wastewater treatment is crucial to mitigate the environmental impact of these chemicals. Moreover, the responsible sourcing of materials, such as ensuring that the platinum used isn’t derived from conflict zones, is gaining significant importance.

At the end of life, MEA disposal poses a challenge. The presence of precious metals necessitates recycling to recover valuable resources and prevent environmental pollution. Developing environmentally friendly MEA materials and exploring closed-loop recycling systems are active areas of research. This includes exploring alternative catalysts that reduce our reliance on precious metals.

Q 24. Discuss different MEA designs and their advantages/disadvantages.

MEA designs vary significantly, impacting performance and cost. A common design is the ‘conventional’ MEA, where the catalyst layers are directly coated onto the membrane. This offers simplicity and cost-effectiveness but can have limitations in mass transport.

Alternatively, we have ‘gas diffusion layer (GDL)-integrated’ MEAs where the GDL is already incorporated into the structure during manufacturing. This can enhance mass transport and improve performance but adds complexity to the manufacturing process. We also see various designs focusing on improving water management, such as using microporous layers (MPLs) to optimize water transport within the MEA. The choice of design depends on the specific application requirements and the trade-offs between performance, cost, and manufacturing complexity.

- Conventional MEA: Simple, cost-effective, but may have mass transport limitations.

- GDL-integrated MEA: Improved mass transport, higher performance, more complex manufacturing.

- MPL-enhanced MEA: Optimized water management, improved durability, but requires specialized manufacturing techniques.

Q 25. How do you interpret data from MEA testing?

Interpreting MEA testing data involves analyzing various electrochemical parameters. The most common are polarization curves (I-V curves), which show the relationship between cell voltage and current density. A high open-circuit voltage (OCV) indicates good sealing and low leakage currents, while a steep slope in the polarization curve suggests low internal resistance. Electrochemical Impedance Spectroscopy (EIS) provides information on the different resistances and capacitances within the MEA, highlighting areas for improvement.

For example, a high charge-transfer resistance from EIS could indicate a need for a higher catalyst loading or a more efficient catalyst. By combining data from polarization curves and EIS with other characterization techniques, we can gain a comprehensive understanding of the MEA’s performance and identify limitations.

Q 26. What are the latest advancements in MEA technology?

Recent advancements in MEA technology focus on enhancing performance, durability, and cost-effectiveness. This includes the development of non-platinum group metal (PGM)-free catalysts to reduce reliance on expensive platinum. Significant progress is being made in developing highly active and stable PGM-free catalysts based on earth-abundant materials. Another area of focus is the development of advanced membrane materials with enhanced proton conductivity, improved chemical stability, and reduced methanol crossover (in Direct Methanol Fuel Cells). Research also focuses on innovative MEA designs and manufacturing techniques to minimize costs and improve scalability.

Q 27. Describe your experience with different MEA fabrication techniques.

My experience encompasses various MEA fabrication techniques, including decal transfer, screen printing, and spray coating. Decal transfer offers excellent control over catalyst layer thickness and uniformity, particularly suitable for high-performance MEAs. Screen printing is a cost-effective method suitable for large-scale production but may have limitations in achieving fine catalyst layer structures. Spray coating offers flexibility in terms of materials and patterns but requires precise control of the spraying parameters to ensure consistency. Each method has its own advantages and disadvantages; the choice depends on factors like desired performance, production scale, and budget constraints. I’ve worked extensively on optimizing these techniques to enhance MEA quality and consistency.

Q 28. How do you ensure the consistency of MEA performance in mass production?

Ensuring consistent MEA performance in mass production requires a multifaceted approach. Firstly, rigorous quality control at each stage of the manufacturing process is crucial. This starts with meticulous control of the raw materials, including the membrane, catalyst inks, and GDLs. We use statistical process control (SPC) methods to monitor key parameters during the fabrication process and identify deviations early on.

Secondly, automation and precise control of fabrication parameters are essential for consistency. For instance, using automated dispensing systems for catalyst ink application ensures uniform layer thickness and reduces human error. Finally, regular performance testing of the MEAs is crucial to verify that the desired performance specifications are consistently met. We utilize a combination of techniques such as statistical process control and automated quality checks at every step of production to ensure high consistency.

Key Topics to Learn for Membrane Electrode Assembly (MEA) Handling Interview

- MEA Structure and Components: Understand the layers of an MEA (catalyst layer, membrane, gas diffusion layer), their individual functions, and how they interact.

- MEA Manufacturing Processes: Familiarize yourself with common MEA fabrication techniques, including hot-pressing, spraying, and doctor blading. Understand the impact of each process on MEA performance.

- MEA Characterization Techniques: Learn about methods used to evaluate MEA performance, such as electrochemical impedance spectroscopy (EIS), polarization curves, and single-cell testing. Be prepared to discuss the significance of key performance indicators (KPIs).

- MEA Handling and Storage Protocols: Understand the importance of proper handling to avoid damage, contamination, and degradation. Know best practices for storage and transportation.

- Troubleshooting Common MEA Issues: Develop your problem-solving skills related to identifying and resolving issues such as low performance, leaks, and degradation. Practice analyzing data to pinpoint the root cause of problems.

- Safety Procedures in MEA Handling: Familiarize yourself with safety regulations and protocols associated with handling potentially hazardous materials and equipment used in MEA processing.

- Quality Control and Assurance in MEA Production: Understand the importance of quality control measures throughout the MEA lifecycle, from material selection to final testing and validation.

Next Steps

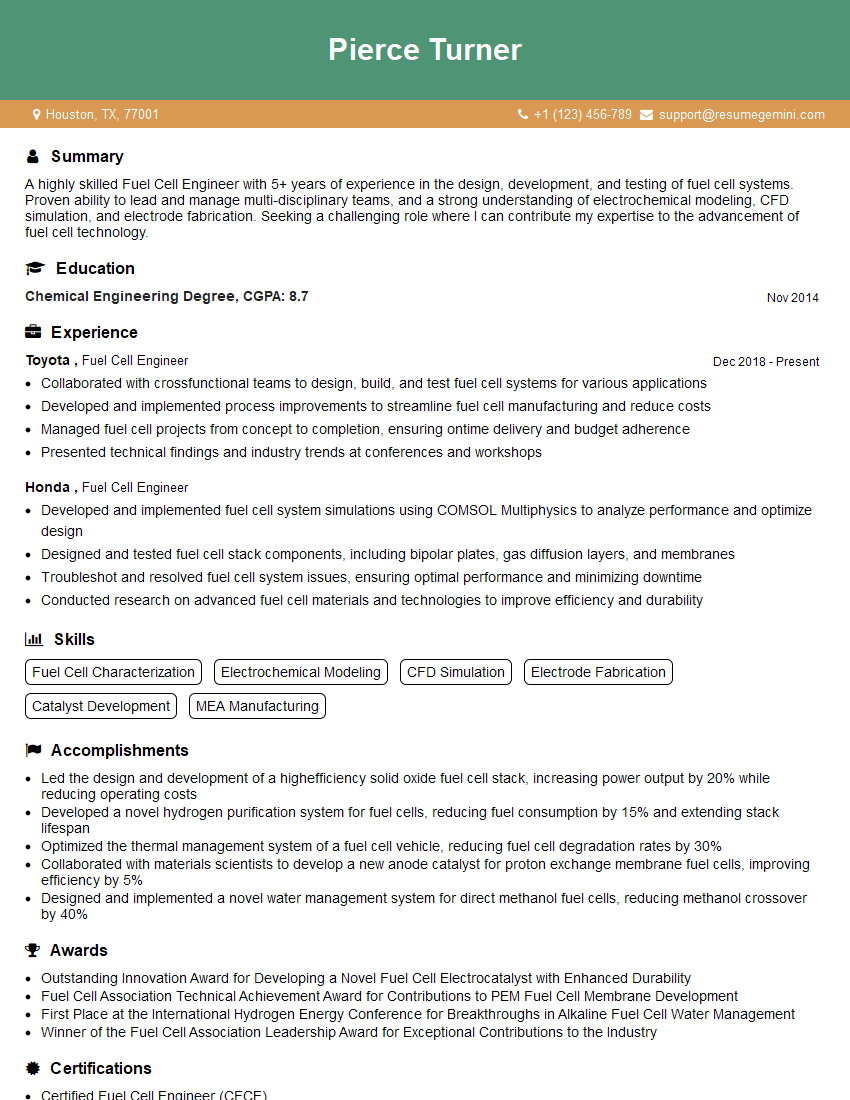

Mastering Membrane Electrode Assembly (MEA) Handling opens doors to exciting opportunities in the rapidly growing fuel cell and electrolyzer industries. A strong understanding of MEA technology is highly sought after by employers, significantly enhancing your career prospects. To maximize your chances of landing your dream role, focus on crafting a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini can help you build a professional resume that stands out from the competition. ResumeGemini provides examples of resumes tailored to Membrane Electrode Assembly (MEA) Handling, offering valuable guidance and inspiration as you build your own. Invest time in creating a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good