Unlock your full potential by mastering the most common Mesh Count Selection interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Mesh Count Selection Interview

Q 1. What factors influence the selection of mesh count?

Mesh count selection is a crucial aspect of textile engineering, impacting various fabric properties. Several factors influence this choice. Primarily, the intended end-use dictates the required characteristics. A lightweight, breathable fabric for sportswear will demand a different mesh count than a durable, robust fabric for workwear.

- Fiber type and yarn structure: Thicker yarns, like those made from heavier fibers (e.g., cotton vs. polyester), will naturally yield a lower mesh count for the same level of density. Yarn twist also plays a role.

- Weave structure: Plain weave, twill weave, and other complex weaves influence the final mesh count and fabric properties. We’ll explore this further in a later answer.

- Desired fabric properties: Factors such as drape, breathability, durability, and opacity all directly influence the chosen mesh count. A more open weave (lower mesh count) allows for better breathability but sacrifices durability and opacity, for example.

- Manufacturing capabilities: The available machinery and production methods can limit the range of achievable mesh counts. Certain mesh counts might be easier or more cost-effective to produce than others.

- Cost: Higher mesh counts often equate to higher material and production costs.

Q 2. Explain the relationship between mesh count and fabric drape.

The relationship between mesh count and fabric drape is inversely proportional. Higher mesh counts generally result in stiffer, less drapey fabrics, while lower mesh counts create softer, more draping fabrics. Think of it like this: a tightly woven fabric (high mesh count) is like a tightly packed collection of threads, resisting bending and conforming to the body’s shape less readily. A loosely woven fabric (low mesh count) is like a loosely packed collection of threads, bending and flowing more easily.

For example, a high mesh count fabric might be used for a structured shirt, while a low mesh count fabric would be better suited for a flowing dress.

Q 3. How does mesh count affect the breathability of a fabric?

Mesh count significantly affects fabric breathability. Lower mesh counts generally mean more open weaves, resulting in better breathability. This is because air can easily pass through the larger gaps between the yarns. Conversely, higher mesh counts result in less breathability due to a tighter, denser weave that restricts airflow. This is analogous to a window screen: a screen with larger openings allows more air to pass through, just like a fabric with a lower mesh count.

Consider sportswear: athletic fabrics often utilize low mesh counts to promote ventilation and wicking, keeping the wearer cool and dry during exercise.

Q 4. Describe the difference between plain weave and twill weave in terms of mesh count.

Plain weave and twill weave are fundamental fabric structures that affect mesh count’s impact on fabric properties. In plain weave, the warp (lengthwise) and weft (crosswise) yarns interlace in a simple over-under pattern. This results in a relatively uniform structure, meaning the mesh count provides a consistent indicator of density and openness. A higher mesh count in plain weave implies a finer, denser fabric.

Twill weave, on the other hand, uses a more complex interlacing pattern, creating diagonal lines on the fabric’s surface. This structure means that the same mesh count in twill weave can result in a different density and openness compared to plain weave. The diagonal structure can add strength and durability, even at slightly lower mesh counts, compared to plain weave.

For example, a denim fabric (twill weave) can be quite durable even at a relatively low mesh count, while a plain weave shirt fabric might require a higher mesh count for comparable durability.

Q 5. How does mesh count impact the durability of a fabric?

Mesh count impacts fabric durability. Generally, higher mesh counts lead to more durable fabrics because the tighter weave provides greater resistance to abrasion, tearing, and pilling. The denser structure increases the overall strength of the fabric. Conversely, lower mesh counts tend to result in less durable fabrics that are more prone to damage.

Think of a fishing net: a net with a high mesh count (small holes) is more resistant to tearing than a net with a low mesh count (large holes). This analogy holds true for many textile applications. However, it’s important to consider the fiber type, as a high mesh count of a weaker fiber might still be less durable than a low mesh count of a stronger fiber.

Q 6. Explain the concept of GSM (grams per square meter) and its relationship to mesh count.

GSM (grams per square meter) is a measure of fabric weight, representing the mass of fabric per unit area. It’s closely related to but not directly proportional to mesh count. While a higher mesh count often implies a higher GSM due to increased yarn density, the type of yarn (fiber type, thickness, twist) significantly influences GSM. A high mesh count using fine yarns can have a lower GSM than a low mesh count using thick yarns.

Think of it like this: two fabrics can have the same GSM but vastly different mesh counts. One might be a tightly woven fabric using fine yarns, while the other could be a loosely woven fabric using thicker yarns. GSM gives you the weight; mesh count gives you an idea of weave density and openness. Both are essential for understanding fabric characteristics.

Q 7. How would you determine the appropriate mesh count for a sportswear application?

Determining the appropriate mesh count for sportswear involves considering several key factors:

- Activity level: High-intensity activities require highly breathable fabrics with lower mesh counts for better ventilation and moisture-wicking. Lower-intensity activities can tolerate higher mesh counts.

- Climate: Hot and humid climates demand lower mesh counts for better breathability, while cooler climates offer more flexibility in mesh count selection.

- Fabric function: Is the fabric primarily for moisture-wicking, sun protection, or insulation? Each function impacts the optimal mesh count. Moisture-wicking fabrics often use lower counts.

- Desired compression: Higher mesh counts can provide more compression, which might be desirable for some sports but not others.

- Durability requirements: Consider the fabric’s expected lifespan and the level of wear and tear it will face. Higher mesh counts offer better durability but may compromise breathability.

For example, a running shirt might use a very low mesh count for maximum breathability, while a compression legging might use a higher mesh count for support.

Often, a combination of mesh count and fabric construction (e.g., incorporating different weave structures in zones of the garment) is used to optimize performance. This iterative process typically involves prototyping and testing to achieve the desired properties.

Q 8. What are the limitations of using a high mesh count?

Using a very high mesh count, while seemingly beneficial for achieving finer detail and smoother surfaces, introduces several limitations. Firstly, it significantly increases production time and cost. The finer the mesh, the more complex and time-consuming the knitting or weaving process becomes. Secondly, high mesh counts can lead to weaker fabrics, particularly in knitted structures, as the thinner yarns used may be less durable. Finally, high mesh counts can sometimes result in difficulties during handling and finishing stages, leading to potential snagging or damage.

Think of it like trying to build a house with tiny Lego bricks – you can achieve incredible detail, but it takes much longer, costs more, and the structure might be less robust than one built with larger blocks.

Q 9. What are the limitations of using a low mesh count?

Conversely, using a low mesh count presents different challenges. The most obvious is a reduction in the detail and overall quality of the finished product. Low mesh counts result in a coarser, less refined texture that may not be suitable for certain applications. For example, a low mesh count in a shirt might make it feel scratchy against the skin. Additionally, low mesh counts can be less comfortable due to their lack of breathability. Finally, it might limit the garment’s ability to drape properly, leading to a stiff and less flattering appearance.

Imagine trying to paint a portrait with a very thick brush – you can get the basic shapes, but you’ll struggle to capture fine details and nuances.

Q 10. How does mesh count affect the cost of production?

Mesh count directly impacts the cost of production. Higher mesh counts require more yarn (increasing raw material costs), take longer to produce (increasing labor costs), and may necessitate more complex machinery and finishing processes (increasing overhead). For example, a high-mesh count fabric for a luxury sportswear line will obviously be more expensive to manufacture than a low-mesh count fabric for a basic t-shirt. The increased complexity of handling and manufacturing delicate, high-mesh count fabrics adds further to the expense.

This is a simple cost-benefit analysis: higher quality often means higher cost.

Q 11. Describe a situation where you had to make a decision regarding mesh count selection.

Recently, I was involved in a project to design a performance athletic shirt. We needed a fabric that was both lightweight and breathable, but also durable enough to withstand repeated washing and intense physical activity. Initially, the design team proposed a very high mesh count to maximize breathability. However, after conducting thorough testing and considering the budget, we opted for a slightly lower mesh count. While it sacrificed a minor degree of breathability, it ensured better durability and significantly reduced production costs without compromising the garment’s overall performance. This compromise prioritized a balance between quality and feasibility.

Q 12. What are the common industry standards for mesh count in different apparel types?

Industry standards for mesh count vary considerably depending on the apparel type and intended use. There aren’t strict, universal standards, but general guidelines exist. For example, fine hosiery might use mesh counts in the hundreds or even thousands, while heavier-duty fabrics like those used in workwear might utilize much lower counts. Similarly, sheer fabrics will require higher counts than heavier, more opaque ones. Sportswear often lies somewhere in the middle, balancing breathability, durability, and cost. Specific counts are always determined based on the fabric type (knit or woven), yarn type, desired drape and texture, and end-use requirements.

- Hosiery: High mesh counts (e.g., 100+)

- T-shirts: Moderate mesh counts (e.g., 20-40)

- Workwear: Lower mesh counts (e.g., 10-20)

- Sportswear: Varies widely depending on specific needs.

Q 13. How do you handle inconsistencies in mesh count during quality control?

Inconsistencies in mesh count are a significant quality control concern. We use a multi-stage approach. Firstly, we implement stringent quality checks during the raw material sourcing process. This includes verifying the yarn specifications and confirming the consistency of the supplied materials. Secondly, throughout the production process, regular inspections are carried out using calibrated measuring instruments. These include visual checks and often more sophisticated methods like digital image analysis to quantify mesh consistency across the fabric. Any inconsistencies beyond pre-defined tolerances trigger corrective actions, which may range from adjusting machine settings to rejecting entire batches of fabric. Finally, statistical process control (SPC) techniques are used to monitor and analyze data, helping identify and address recurring issues early on.

Q 14. Explain the process of calculating the required mesh count based on design specifications.

Calculating the required mesh count isn’t a single formula but a process combining design specifications, material properties, and manufacturing capabilities. It begins with understanding the design intent – drape, opacity, strength, breathability, etc. Then, we consider the chosen yarn type and its properties (thickness, strength, elasticity). Next, we consider the desired aesthetic. Finally, we test several prototypes using different mesh counts, evaluating their performance against the design objectives. This iterative process combines both technical calculations based on yarn properties and practical experimentation. Software tools can aid in simulating the fabric behaviour, providing a valuable starting point.

It’s crucial to consider factors like the intended use and expected wear and tear. There is no single answer, and the selection process requires expertise and iterative testing.

Q 15. What are some of the software tools or techniques used to analyze mesh count?

Analyzing mesh count often involves a combination of software and hands-on techniques. Software tools, particularly those used in CAD (Computer-Aided Design) for textiles, can simulate fabric drape and behavior based on the mesh count. This allows designers to predict the final product’s properties before production. These programs often allow for inputting various parameters, including fiber type, weave structure, and mesh count, to predict the resulting fabric characteristics.

Beyond software, physical testing methods play a crucial role. This includes using a mesh count measuring device – essentially a magnifying glass with a calibrated grid – to directly count the threads per inch (or centimeter) in both the warp (lengthwise) and weft (widthwise) directions. Microscopes can also be used for more precise measurements, especially with fine fabrics. Additionally, experienced textile professionals often rely on their tactile sense – feeling the fabric’s density and hand to get a general understanding of the mesh count.

For example, a CAD program might allow the user to input a mesh count of 150×150 and simulate the resulting fabric’s weight, drape, and breathability, whereas a physical measurement of a sample using a mesh counter would confirm the accuracy of the manufacturing process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How does mesh count affect the printing quality of a fabric?

Mesh count directly impacts fabric printing quality in several ways. A higher mesh count (more threads per inch) results in a finer, denser fabric. This finer structure provides a smoother printing surface, allowing for sharper image resolution and greater detail in the printed design. The ink sits better on the smoother surface, resulting in clearer lines and reduced bleeding or blurring. Conversely, a lower mesh count, resulting in a coarser fabric, tends to produce a less sharp, potentially blurry print due to the coarser surface that makes it more challenging for ink to adhere uniformly.

Think of it like painting on a canvas: a fine-grained canvas allows for intricate details, while a coarse-grained one will produce a less defined image. The same principle applies to fabric printing. A fabric with a mesh count of 300×300 will generally yield superior print quality compared to one with a mesh count of 100×100.

Q 17. How do you communicate mesh count specifications to suppliers?

Communicating mesh count specifications to suppliers requires precision and clarity. The standard method is to specify the count in threads per inch (TPI) or threads per centimeter (TPC) for both the warp and weft directions. This is typically written as a ratio, for example, 150x150 TPI or 60x60 TPC. This unambiguous notation avoids confusion. It’s crucial to include tolerance levels to account for slight variations in manufacturing. For instance, one might specify 150x150 TPI +/- 5, indicating an acceptable range of 145 to 155 threads per inch in both directions.

Beyond the numerical specification, it is beneficial to include a clear description of the fabric type (e.g., polyester mesh, nylon mesh) and any other relevant information, like the weight and construction method of the fabric. Samples can be invaluable for ensuring that both parties are on the same page about the desired texture and quality. Detailed technical drawings or specifications might be part of the process, especially for complex designs.

Q 18. How would you explain the concept of mesh count to someone without a technical background?

Imagine a woven fabric like a grid. Mesh count simply refers to how many threads are packed into each inch (or centimeter) of this grid, both horizontally and vertically. A higher mesh count means more threads, resulting in a denser, finer fabric, much like a higher resolution image has more pixels. A lower mesh count results in a coarser, more open fabric. Think of a mosquito net versus a heavy-duty canvas: the mosquito net has a high mesh count for preventing tiny insects, while the canvas has a much lower count for strength and durability.

So, the mesh count determines how tightly woven the fabric is, directly impacting its texture, strength, and other properties.

Q 19. What are the consequences of selecting an inappropriate mesh count?

Selecting an inappropriate mesh count can lead to a cascade of negative consequences, impacting both the aesthetic and functional aspects of the final product.

- Poor Print Quality: Using a low mesh count for a high-resolution print will result in a blurry, indistinct image.

- Reduced Durability: A mesh count that is too low for the intended application might lead to a weak or easily torn fabric.

- Inadequate Breathability: A mesh count that is too high might produce a fabric that lacks breathability, crucial for certain apparel or industrial applications.

- Increased Costs: Using a much higher mesh count than necessary can lead to unnecessary expense and production delays.

- Unsatisfactory drape and feel: Incorrect mesh selection will lead to suboptimal draping capabilities and texture of the final product

For example, choosing a low mesh count for a sportswear application would compromise the fabric’s breathability and durability, leading to customer dissatisfaction.

Q 20. How do different fiber types impact the selection of mesh count?

Fiber type significantly influences mesh count selection. Different fibers have varying strengths, thicknesses, and elasticities. A stronger fiber like nylon can support a higher mesh count than a weaker fiber like cotton without compromising the fabric’s integrity. Thicker fibers naturally result in a lower mesh count for a given fabric weight, as they take up more space in the weave. The elasticity of the fiber also plays a role; a highly elastic fiber might allow for a looser weave (lower mesh count) while still maintaining sufficient strength and flexibility.

For instance, a high-performance sportswear fabric might utilize a high mesh count of nylon or polyester for breathability and durability, while a cotton shirt might have a much lower mesh count to ensure comfort and a suitable drape. Careful consideration of the fiber’s properties is essential for selecting the appropriate mesh count to achieve the desired balance of strength, flexibility, and other characteristics.

Q 21. Describe the challenges in selecting mesh count for fabrics with complex patterns.

Selecting mesh count for fabrics with complex patterns presents several challenges. The intricacy of the design dictates how tightly the threads need to be woven to maintain the pattern’s clarity and structural integrity. A too-low mesh count might lead to distortion or loss of detail in the pattern. Conversely, a too-high mesh count could make the pattern overly rigid and might increase production costs and time.

Furthermore, the pattern itself might require variations in mesh count within the fabric itself to balance strength and flexibility in different areas. This could necessitate more complex manufacturing processes and necessitate careful coordination between the designer and the manufacturer to ensure the pattern is accurately reproduced. Digital simulation tools become particularly useful in managing such challenges, as they allow for the assessment of pattern clarity and structural stability at various mesh counts before committing to production.

Q 22. What are some common errors to avoid when selecting a mesh count?

Selecting the right mesh count is crucial for the final product’s quality and performance. Common errors include:

- Ignoring the end-use application: Choosing a mesh count unsuitable for the garment’s purpose. For instance, using a low mesh count for a high-performance athletic shirt will result in poor breathability and support. A high mesh count might be unnecessary and costly for a simple tote bag.

- Overlooking fabric type: Different fabrics behave differently. A mesh count that works well for nylon might not be suitable for polyester, affecting drape, strength, and durability.

- Neglecting manufacturing constraints: The chosen mesh count must be compatible with available knitting or weaving machinery and techniques. Trying to produce a very fine mesh count with equipment not designed for it leads to inconsistencies and defects.

- Failing to consider dimensional stability: The mesh count influences how the fabric stretches and retains its shape. An unsuitable mesh count may lead to sagging, distortion, or unwanted shrinkage after washing.

- Not accounting for cost implications: Higher mesh counts generally mean higher production costs, potentially impacting profitability if not carefully considered in relation to the product’s value proposition.

Q 23. How do you verify the accuracy of the mesh count provided by a supplier?

Verifying a supplier’s mesh count claim involves a multi-pronged approach:

- Requesting detailed specifications: The supplier should provide precise documentation including the exact count (e.g., 20 x 20), yarn type and denier, and construction method (knitted or woven).

- Sample testing: Obtain fabric samples and conduct independent testing using a calibrated mesh counter or microscope. This involves physically counting the number of warp and weft threads per inch or centimeter.

- Microscopic analysis: A higher-level verification can use microscopic imaging techniques to analyze the yarn structure and density, confirming the reported mesh count and detecting irregularities.

- Checking past performance: Review the supplier’s track record with other clients. References and past project data can indicate their reliability in providing accurate mesh specifications.

- Third-party audits: Engaging a neutral third-party inspection agency to independently verify mesh counts can offer additional assurance and mitigate risks.

Q 24. What are some industry best practices for mesh count selection?

Industry best practices for mesh count selection emphasize a holistic approach:

- Clearly defined specifications: Establish precise requirements in the design phase, specifying mesh count, fabric type, performance expectations, and tolerances.

- Thorough testing and prototyping: Conduct tests on prototypes to evaluate the selected mesh count’s suitability for the intended application under various conditions.

- Collaboration with suppliers: Work closely with suppliers to leverage their expertise and assess the feasibility of the chosen mesh count within their production capabilities.

- Documentation and traceability: Maintain detailed records of mesh count selection, testing results, and any necessary adjustments throughout the production process.

- Continuous improvement: Regularly review the mesh count selection process to identify areas for optimization based on feedback and performance data.

Q 25. How does environmental sustainability factor into mesh count considerations?

Environmental sustainability is increasingly important in mesh count selection. Higher mesh counts often require more raw materials, increasing the environmental footprint. Considerations include:

- Material selection: Prioritizing recycled or sustainably sourced yarns reduces the environmental impact.

- Reducing waste: Optimized production processes and precise mesh count selection minimize fabric waste during cutting and sewing.

- Durability and longevity: Choosing a mesh count that leads to a durable garment extends its lifespan, reducing the need for frequent replacements.

- End-of-life considerations: Selecting fabrics and mesh counts that facilitate recycling or biodegradability contributes to a circular economy.

- Carbon footprint analysis: Evaluate the entire supply chain to identify opportunities for reducing greenhouse gas emissions associated with the production of mesh fabrics.

Q 26. What are the trade-offs between mesh count, cost, and performance?

There’s a delicate balance between mesh count, cost, and performance.

- Higher mesh count = higher cost: More yarn is needed, increasing material costs and potentially labor costs. More intricate knitting or weaving processes may also be required.

- Higher mesh count = potentially better performance: This translates to finer fabrics with improved breathability, drape, and sometimes strength (depending on the yarn used). However, this benefit plateaus at a certain point. Excessive density may lead to diminished breathability or stiffness.

- Lower mesh count = lower cost: Less material and simpler production processes translate into cost savings.

- Lower mesh count = potentially lower performance: Could result in less breathable, less durable fabrics with poorer drape and aesthetics.

The optimal mesh count is the sweet spot that balances performance requirements with cost constraints. This requires careful analysis and trade-off assessment.

Q 27. How does mesh count affect the comfort of the final garment?

Mesh count significantly impacts garment comfort.

- Breathability: Higher mesh counts generally improve breathability, crucial for athletic wear or hot climates. Lower counts might feel stuffy or retain heat.

- Drape and texture: The mesh count affects how the fabric hangs and feels against the skin. A very high count might feel stiff, while a very low count may feel too loose or flimsy.

- Softness: The type of yarn and its fineness are important along with the mesh count. A high mesh count with a coarse yarn might not be as comfortable as a lower count with a finer, softer yarn.

- Support: In certain applications like swimwear or athletic gear, higher mesh counts can provide better support and shape retention.

Ultimately, the ideal mesh count for comfort depends on the garment’s purpose, material type, and intended use.

Q 28. How has technology changed the way mesh count is selected and analyzed?

Technology has revolutionized mesh count selection and analysis:

- Automated mesh counters: Digital mesh counters provide accurate and rapid measurements, replacing manual counting, reducing errors, and increasing efficiency.

- Image analysis software: Software can analyze microscopic images of fabric to determine mesh count, yarn diameter, and other structural characteristics with high precision.

- Simulation and modeling: Computer simulations can predict fabric behavior based on mesh count, yarn properties, and other parameters, allowing for virtual prototyping and optimization before physical production.

- 3D knitting and weaving technologies: Advanced manufacturing processes allow for greater control and flexibility in producing complex mesh structures, enabling highly customized mesh counts for specific applications.

- Data analytics: Collecting and analyzing data on mesh count, performance, and consumer feedback helps inform future mesh count selections and optimize design parameters.

Key Topics to Learn for Mesh Count Selection Interview

- Understanding Mesh Count: Defining mesh count, its units (ends/inch and courses/inch), and the relationship between count and fabric properties like drape, weight, and strength.

- Fabric Construction and Mesh Count: Exploring how different weaving and knitting techniques influence the final mesh count and its impact on the fabric’s characteristics. This includes understanding plain weaves, twill weaves, and knit structures.

- Relationship between Mesh Count and Application: Analyzing how mesh count selection directly impacts the suitability of a fabric for specific applications, such as sportswear, filtration, medical textiles, or industrial uses. Consider factors like breathability, durability, and filtering efficiency.

- Mesh Count and Quality Control: Understanding the importance of consistent mesh count for product quality and identifying methods for measuring and controlling mesh count during manufacturing.

- Industry Standards and Specifications: Familiarizing yourself with relevant industry standards and specifications related to mesh count and fabric testing.

- Problem-Solving Scenarios: Practice analyzing scenarios where incorrect mesh count selection could lead to product defects or performance issues. Develop a structured approach to troubleshooting and decision-making in mesh count selection.

- Advanced Concepts (Optional): Explore more advanced topics like the influence of yarn type and twist on mesh count and the relationship between mesh count and cost-effectiveness.

Next Steps

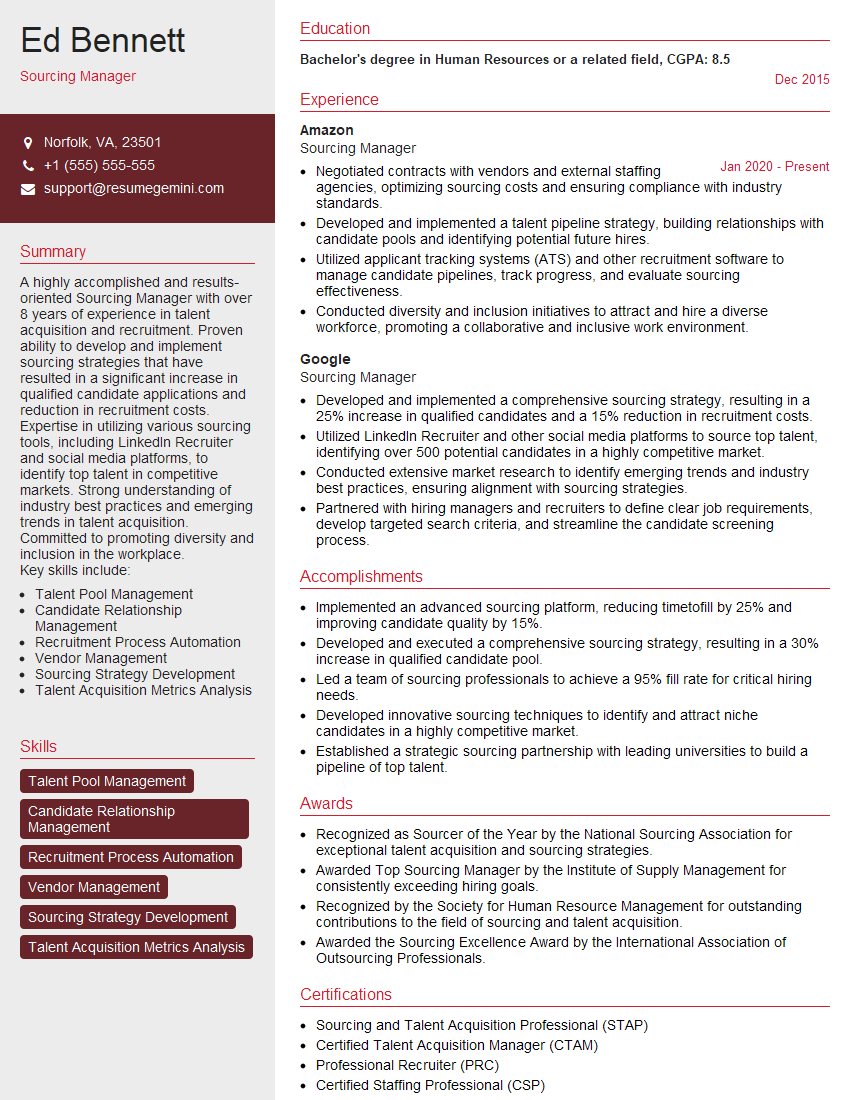

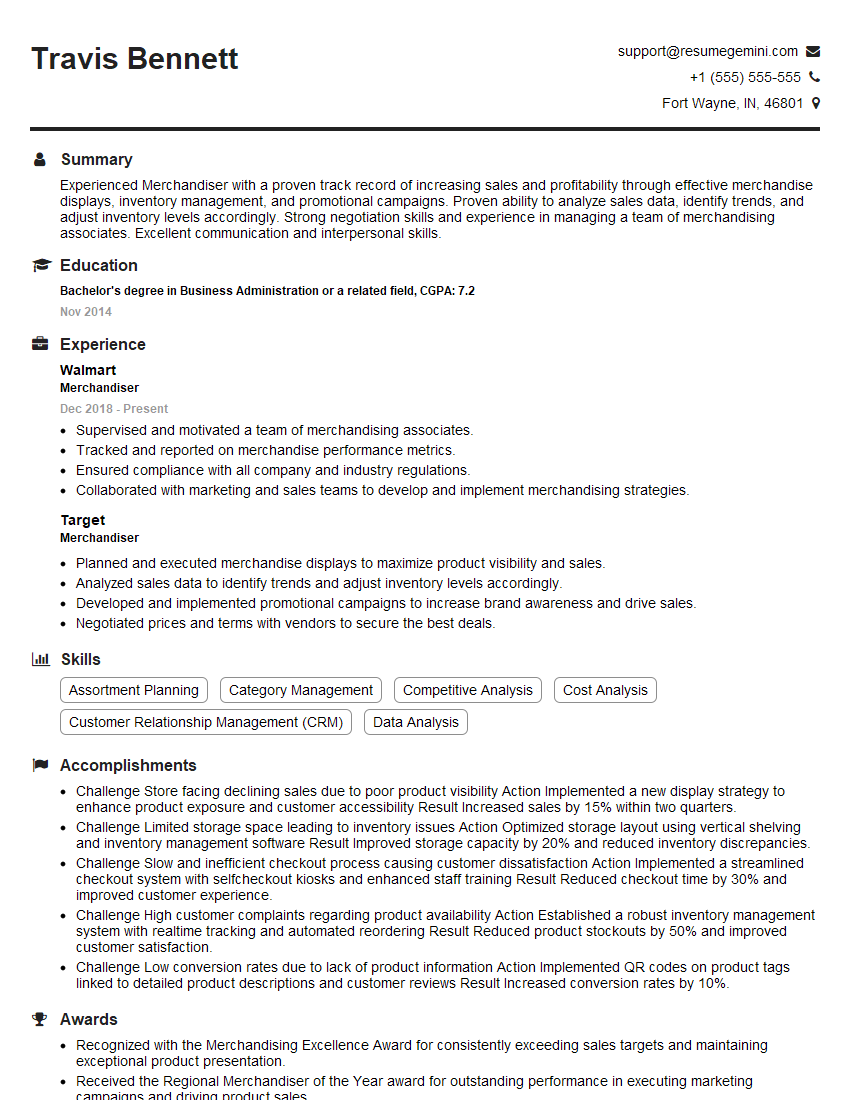

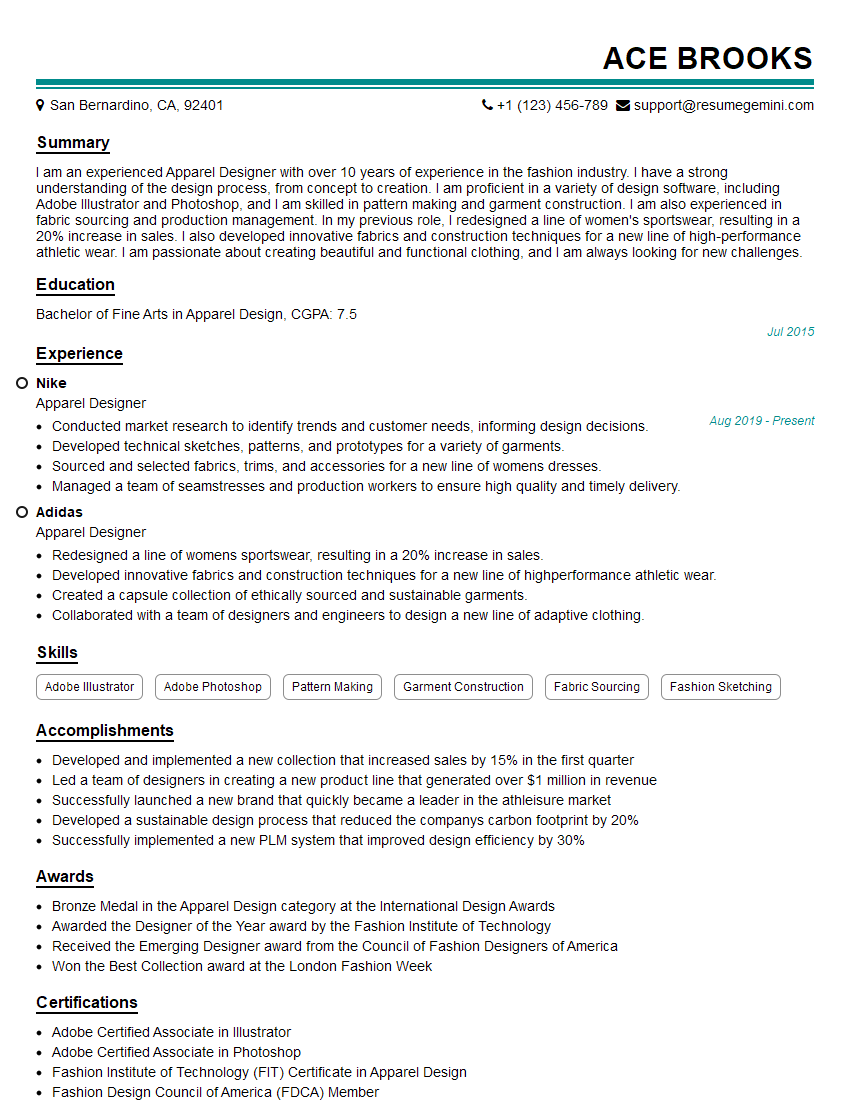

Mastering mesh count selection is crucial for advancing your career in textiles, manufacturing, and related fields. A strong understanding of this fundamental concept demonstrates technical expertise and problem-solving skills highly valued by employers. To significantly boost your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and effective resume. Examples of resumes tailored to Mesh Count Selection are available to provide you with guidance and inspiration. Take the next step towards your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good