Cracking a skill-specific interview, like one for Microcontroller Programming (8051, AVR), requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Microcontroller Programming (8051, AVR) Interview

Q 1. Explain the architecture of the 8051 microcontroller.

The 8051 microcontroller architecture is a Harvard architecture, meaning it has separate memory spaces for instructions and data. This allows for simultaneous fetching of instructions and data, improving efficiency. Let’s break down the key components:

- CPU: The central processing unit includes the ALU (Arithmetic Logic Unit) for calculations, registers for temporary data storage (like the Accumulator, B register, and others), and the program counter (PC) to track instruction execution.

- Memory: The 8051 has 4KB of internal ROM (Read-Only Memory) for program storage and 128 bytes of internal RAM (Random Access Memory) for data. It can also access external memory through address lines.

- I/O Ports: Four 8-bit I/O ports (P0, P1, P2, P3) provide interfaces for connecting to external devices like sensors, actuators, and displays. P0 is also used for external memory access.

- Timers/Counters: Two 16-bit timers/counters offer versatile timing and counting functionalities, crucial for tasks like generating pulses or measuring events.

- Serial Port: A UART (Universal Asynchronous Receiver/Transmitter) facilitates serial communication, allowing data exchange with other devices over a single wire.

- Interrupt System: The 8051 supports five interrupt sources, allowing it to respond to external events in a timely manner. This is essential for real-time applications.

Think of it like a small, efficient computer within a chip, designed for embedded applications where resource constraints are a significant factor. Each component works together to execute instructions and interact with the external world.

Q 2. Describe the different addressing modes of the 8051.

The 8051 supports several addressing modes, each offering different ways to specify the operand for an instruction. This flexibility simplifies programming and enhances code efficiency. Here are the most common:

- Immediate Addressing: The operand is included directly in the instruction.

MOV A, #55H(Moves the immediate value 55H into the Accumulator A). - Register Addressing: The operand is a register within the CPU.

MOV A, B(Moves the contents of register B into register A). - Direct Addressing: The operand’s address is specified directly in the instruction. This accesses data within the internal RAM.

MOV A, 20H(Moves the contents of memory location 20H into A). - Register Indirect Addressing: The operand’s address is stored in a register (typically R0 or R1).

MOVC A, @A+DPTR(Moves a code from the lookup table pointed by A+DPTR into the accumulator A). - Indirect Addressing: The operand’s address is stored in the memory location pointed by the register pair (R0 and R1).

- Relative Addressing: Used primarily for jump instructions (like JMP), where the offset is added to the program counter. This allows for efficient branching within code.

Choosing the appropriate addressing mode is crucial for writing optimized and efficient code. For instance, register addressing is the fastest, while immediate addressing is convenient for constant values.

Q 3. How does the 8051 handle interrupts?

The 8051 manages interrupts using a prioritized interrupt system. When an interrupt occurs, the CPU temporarily suspends its current task, saves the context (CPU registers), and jumps to a specific interrupt service routine (ISR) to handle the event. The priority levels determine which interrupt gets served first if multiple interrupts occur simultaneously.

- Interrupt Vector Table: The 8051 has a fixed interrupt vector table in the lower memory addresses. Each interrupt source has an associated address in this table that points to the start of its ISR.

- Interrupt Enable/Disable: Individual interrupts can be enabled or disabled using special control registers (like IE and IP). This allows selective control over which interrupts are responded to.

- Interrupt Priority: The 8051 prioritizes interrupts based on their assigned priority level. Higher-priority interrupts can interrupt lower-priority ones.

- Interrupt Return (RETI): After completing the ISR, the

RETIinstruction restores the CPU’s context and returns control to the interrupted program.

Imagine it like a phone system where calls (interrupts) are prioritized. A more important call (higher priority) can interrupt a less important one. Proper interrupt handling is crucial for real-time applications, ensuring timely responses to external events.

Q 4. Explain the Timer/Counter modes in the 8051.

The 8051’s two 16-bit timers/counters (Timer 0 and Timer 1) offer several modes of operation, enabling flexible timing and counting applications. These modes are controlled through specific bits in the timer control registers (TCON and TMOD).

- Mode 0: 13-bit timer mode: The timer increments continuously until it overflows, generating an interrupt.

- Mode 1: 16-bit timer mode: The timer functions as a 16-bit counter, allowing for longer timing intervals.

- Mode 2: 8-bit auto-reload timer mode: The timer counts up to a specified value, then automatically reloads the initial value, creating periodic interrupts.

- Mode 3: 16-bit auto-reload timer mode: Similar to Mode 2 but with a 16-bit counter, offering longer periods.

These modes are useful for various tasks. For example, Mode 2 is perfect for generating precise periodic pulses for driving a servo motor. Mode 1 is suitable for measuring the duration of an event. Selecting the right mode depends on the specific application requirements.

Q 5. How do you program serial communication (UART) on the 8051?

Serial communication on the 8051 using the UART involves configuring the baud rate, setting up the transmit and receive registers, and sending/receiving data byte by byte. Here’s a simplified explanation:

- Baud Rate: The baud rate (bits per second) needs to be configured in the serial port control register (SCON) and the Timer 1, often using a prescaler to achieve the desired rate.

- Transmitting Data: To transmit a byte, write the data to the transmit register (SBUF). The UART automatically transmits it serially.

- Receiving Data: The UART receives data serially and places it in the receive register (SBUF). A flag indicates when data is available.

- Interrupt Handling: Using interrupts greatly simplifies serial communication. Interrupt service routines can handle the sending and receiving of data without blocking the main program.

Consider a scenario where you need to send sensor data wirelessly. The 8051 could collect data from sensors and transmit it serially over a radio transceiver using the UART.

// Example code snippet (Illustrative, requires adaptation for specific hardware) void send_byte(unsigned char data) { while (!TI); // Wait for transmit interrupt flag SBUF = data; // Send data byte TI = 0; // Clear transmit interrupt flag }Q 6. What are the differences between the 8051 and AVR architectures?

The 8051 and AVR architectures, while both being 8-bit microcontrollers, have significant differences:

- Architecture: The 8051 uses a Harvard architecture (separate memory spaces for instructions and data), whereas many AVRs use a modified Harvard architecture (allowing some instruction and data sharing).

- Instruction Set: The 8051’s instruction set is relatively less efficient compared to the AVR’s RISC (Reduced Instruction Set Computing) architecture. AVRs typically execute instructions faster.

- Memory Organization: The 8051 has a more limited internal memory compared to many AVRs, which are available with a wider range of memory sizes.

- Peripherals: Both have timers, UARTs, and other peripherals, but the specific features and capabilities differ considerably. AVRs generally offer a richer set of peripherals and advanced features.

- Development Tools: Both architectures have good development tool support, but the AVR ecosystem is generally considered more modern and user-friendly.

Choosing between them depends on the project needs. The 8051 might be preferred for legacy projects or applications requiring a very small footprint. AVRs are often chosen for newer designs where performance, flexibility, and ease of development are prioritized. Imagine choosing a car – an 8051 might be like a reliable but older model, while an AVR might be a more modern and feature-rich car.

Q 7. Explain the concept of memory mapping in microcontrollers.

Memory mapping in microcontrollers defines how the microcontroller’s memory space is organized and accessed. Each memory location has a unique address, and the microcontroller uses these addresses to access instructions and data. This organization is crucial for efficient program execution and data management.

- Internal Memory: The microcontroller’s internal RAM and ROM have specific address ranges. For example, the 8051’s internal RAM occupies addresses 00H to 7FH.

- External Memory: If the microcontroller supports external memory, it’s also mapped into the address space. This allows accessing a larger memory pool.

- I/O Ports: I/O ports are also memory-mapped, meaning they are addressed like memory locations. Writing to these addresses controls the output pins, while reading from them gets the input values.

- Special Function Registers (SFRs): These registers control the microcontroller’s various peripherals and operations. They are assigned specific addresses within the memory map.

Understanding memory mapping is essential for writing efficient code and interacting with peripherals. For example, you need to know the addresses of the UART control registers to configure serial communication. Imagine a city map – the memory map is like a city’s address system, directing the microcontroller to the right locations for instructions and data.

Q 8. How do you handle external interrupts in the AVR?

Handling external interrupts in AVR microcontrollers involves configuring the microcontroller’s interrupt system to respond to signals from external devices. This is typically done by setting up the appropriate Interrupt Vector and enabling the interrupt source. AVRs have multiple interrupt sources, often connected to specific pins. Let’s break it down:

- Identifying the Interrupt Source: Each AVR has a specific pin or set of pins designated for external interrupts (INT0, INT1, etc.). You’ll need to consult the datasheet for your specific AVR chip to determine which pin(s) to use.

- Enabling the Interrupt: This usually involves setting a bit in the appropriate register. For example, setting the

INT0bit in theMCUCR(MCU Control Register) enables the INT0 interrupt. - Choosing the Interrupt Sense: You need to specify how the interrupt triggers. Common options are:

- Falling Edge: Interrupt triggers only when the signal transitions from HIGH to LOW.

- Rising Edge: Interrupt triggers only when the signal transitions from LOW to HIGH.

- Any Change: Interrupt triggers on any change in the signal level.

MCUCRfor INT0). - Writing the Interrupt Service Routine (ISR): This is the function that executes when the interrupt occurs. Within the ISR, you handle the event triggered by the external interrupt. Crucially, ISRs should be concise and avoid lengthy operations to minimize interrupt latency. Remember to re-enable the interrupt at the end of the ISR if necessary.

- Example (Conceptual):

// Enable INT0 interrupt, triggered on falling edge

MCUCR |= (1 << ISC01); // Set ISC01 for falling edge

GICR |= (1 << INT0); // Enable external interrupt INT0

// Interrupt Service Routine for INT0

ISR(INT0_vect) {

// Handle the interrupt event here

// ... your code ...

}

Think of it like a doorbell. The external device is like someone ringing the doorbell (the interrupt signal). The AVR’s interrupt system is like the circuitry inside your house that makes the bell ring, and the ISR is you answering the door and taking action (processing the interrupt).

Q 9. Describe the different timer/counter modes in AVR microcontrollers.

AVR timers/counters are incredibly versatile, offering various modes to suit different applications. They can be used for timing events, generating PWM signals, and more. The specific modes may vary slightly between different AVR families, but the general principles remain the same. Here are some common modes:

- Normal Mode: The counter increments from 0 to its maximum value (determined by the prescaler and timer size), then overflows and resets to 0. This mode is suitable for simple timing tasks.

- Clear Timer on Compare Match (CTC) Mode: The counter increments until it matches a value set in the Output Compare Register (OCR). When a match occurs, the counter is cleared to 0, triggering an interrupt. This allows for precise timing intervals.

- Fast PWM Mode: This mode generates a PWM signal where the output pin toggles between HIGH and LOW based on the value of the counter compared to the OCR. The duty cycle (the percentage of time the signal is HIGH) is controlled by the OCR value. This is widely used for motor control and dimming LEDs.

- Phase Correct PWM Mode: Similar to Fast PWM, but the counter counts up and then down, creating a smoother PWM signal with less ripple. This is preferred in applications sensitive to PWM signal noise.

- PWM Phase Frequency Correct Mode: A more advanced PWM mode that allows for independent control of the frequency and duty cycle.

Prescalers: In addition to the modes, AVRs use prescalers to divide the system clock frequency, allowing for precise control over the timer/counter speed and reducing CPU load. For instance, a prescaler of 64 divides the clock by 64, significantly slowing down the timer’s count rate. Each mode’s functionality is controlled through settings in specific registers (e.g., TCCR0A, TCCR0B, etc. for Timer/Counter0). The datasheet provides precise details on the register configurations for each mode.

Q 10. Explain how to use ADC (Analog-to-Digital Converter) in an AVR.

The Analog-to-Digital Converter (ADC) is crucial for interfacing with analog sensors. In AVRs, you can convert analog voltages into digital values using the ADC module. Here’s a step-by-step guide:

- Reference Voltage Selection: Choose the voltage reference for the ADC. Common options include the AVCC (analog voltage supply) or an internal voltage reference. This is configured via the

ADMUXregister. - Input Channel Selection: Select the analog input pin to read from. Each AVR has multiple analog input pins. The pin selection is done by configuring the appropriate bits in the

ADMUXregister. - ADC Initialization: Set the ADC prescaler (to control the conversion speed) and enable the ADC using the

ADCSRAregister. A slower prescaler leads to more accurate readings but slower conversions. - Starting a Conversion: Initiate the conversion by setting the

ADSC(ADC Start Conversion) bit in theADCSRAregister. - Waiting for Conversion Completion: The ADC will automatically complete the conversion. You can poll the

ADIF(ADC Interrupt Flag) bit in theADCSRAregister to check for completion. Alternatively, you can enable ADC interrupts for a more efficient approach. - Reading the Conversion Result: Once the conversion is complete, read the digital value from the

ADCL(ADC Low) andADCH(ADC High) registers. The combined value provides the 10-bit (or less, depending on your configuration) digital representation of the analog voltage. - Example (Conceptual):

// Initialize ADC

ADMUX |= (1 << REFS0); // Select AVCC as voltage reference

ADCSRA |= (1 << ADEN) | (1 << ADPS2) | (1 << ADPS1) | (1 << ADPS0); // Enable ADC, set prescaler to 128

// Read from channel 0

ADMUX &= ~((1 << MUX3) | (1 << MUX2) | (1 << MUX1) | (1 << MUX0)); //Clear mux bits

ADCSRA |= (1 << ADSC); // Start conversion

while (!(ADCSRA & (1 << ADIF))); // Wait for conversion complete

uint16_t result = ADCL | (ADCH << 8); // Combine low and high bytes

Imagine the ADC as a translator converting an analog signal (like a temperature reading from a sensor) into a digital language the microcontroller can understand.

Q 11. How do you implement PWM (Pulse Width Modulation) using an AVR?

Pulse Width Modulation (PWM) is a technique for generating a variable DC voltage from a digital signal. In AVRs, this is commonly implemented using the timer/counter modules. Here’s how:

- Timer/Counter Selection: Choose a timer/counter module with a PWM mode (most AVRs have at least one). The choice depends on your desired frequency and resolution.

- Mode Selection: Configure the timer in the appropriate PWM mode (Fast PWM, Phase Correct PWM, etc.). The choice of mode affects the characteristics of the PWM signal.

- Prescaler Setting: Use the prescaler to set the desired PWM frequency. The frequency is determined by the system clock, the prescaler value, and the timer’s top value.

- Duty Cycle Control: Adjust the duty cycle (the percentage of time the output is HIGH) by changing the value of the Output Compare Register (OCR). The higher the OCR value, the higher the duty cycle.

- Output Pin Configuration: Configure the appropriate timer output pin to operate in PWM mode. This is usually done by setting bits in the timer control registers.

- Example (Conceptual):

// Configure Timer1 for Fast PWM mode

TCCR1A |= (1 << WGM11) | (1 << WGM10); // Set Fast PWM mode

TCCR1B |= (1 << WGM13) | (1 << WGM12) | (1 << CS11); // Set prescaler to 8

DDRB |= (1 << PB1); //Set PB1 as output

// Set the duty cycle (adjust OCR1A for desired duty cycle)

OCR1A = 200;

Think of PWM as controlling the brightness of an LED by rapidly switching it on and off. A higher duty cycle means the LED is on for a longer portion of each cycle, resulting in brighter light.

Q 12. Explain the SPI communication protocol and its implementation on AVR.

SPI (Serial Peripheral Interface) is a synchronous, full-duplex communication protocol used for short-distance communication between microcontrollers and peripherals. It’s often used for communication with sensors, displays, and other devices.

- Master/Slave Configuration: SPI communication involves a master device (usually the microcontroller) and one or more slave devices. The master device controls the clock signal and data transfer.

- Clock Signal: The master device generates the clock signal (SCK), which synchronizes the data transfer.

- Data Lines: MOSI (Master Out Slave In) and MISO (Master In Slave Out) lines are used to transfer data. The master sends data through MOSI, and the slave sends data back through MISO.

- Slave Select (SS): Each slave device has a dedicated slave select (SS) pin. The master activates a specific slave by pulling its SS pin LOW. When SS is HIGH, the slave is inactive.

- AVR Implementation: AVRs typically have dedicated SPI registers (e.g.,

SPCR,SPSR,SPDR) for configuring and controlling the SPI communication. - Example (Conceptual):

// Initialize SPI as master

SPCR |= (1 << SPE) | (1 << MSTR) | (1 << SPR0); //Enable SPI, master mode, clock prescaler = 64

// Send data

SPDR = data_to_send;

while (!(SPSR & (1 << SPIF))); // Wait for transmission complete

// Receive data

while (!(SPSR & (1 << SPIF))); // Wait for reception complete

received_data = SPDR;

Imagine SPI as a highly efficient conveyor belt carrying data back and forth between the master and slave devices, all perfectly synchronized.

Q 13. Describe the I2C communication protocol and its implementation on AVR.

I2C (Inter-Integrated Circuit) is a two-wire serial communication protocol used for short-distance communication between microcontrollers and peripherals. It’s known for its simplicity and low pin count.

- Two Wires: I2C uses only two wires: SDA (Serial Data) and SCL (Serial Clock). Both data and clock signals travel on these two wires.

- Master/Slave Architecture: I2C also uses a master/slave architecture, similar to SPI. The master initiates communication and addresses the desired slave device.

- Addressing: Each slave device has a unique 7-bit address. The master uses this address to select the target slave.

- Start/Stop Conditions: Communication begins with a start condition and ends with a stop condition. These conditions are generated by the master by manipulating the SDA line.

- Acknowledgment (ACK): The slave sends an acknowledgment (ACK) bit after receiving data to indicate successful reception.

- AVR Implementation: AVRs usually don’t have dedicated I2C hardware. You’ll typically use bit-banging (direct manipulation of the SDA and SCL pins using software) or a dedicated I2C library to implement I2C communication.

- Example (Conceptual – Bit-Banging, requires significant detail for complete implementation):

// Illustrative snippet: Bit-banging requires detailed bit manipulation

// for start, stop, data transfer, and ACK handling. A library is highly recommended.

// This is simplified and incomplete for illustration.

PORTC |= (1 << PORTC0); //SCL HIGH

PORTC &= ~(1 << PORTC1); //SDA LOW (Start condition)

Imagine I2C as a simple, two-way street for communication, where the master device sends the address of the house (slave device) it wants to communicate with and then sends and receives data.

Q 14. What are the advantages and disadvantages of using assembly language for microcontroller programming?

Assembly language programming offers fine-grained control over the microcontroller’s hardware, but it comes with trade-offs.

- Advantages:

- Performance: Assembly language directly manipulates the microcontroller’s registers and instructions, resulting in highly optimized code with the best possible execution speed. This is crucial in time-critical applications.

- Hardware Access: Direct access to hardware resources (memory locations, peripherals) is unparalleled, providing complete control over system operations.

- Code Size: Assembly code tends to be compact, saving valuable memory space in resource-constrained microcontrollers.

- Disadvantages:

- Complexity: Writing and debugging assembly code is more time-consuming and error-prone than using higher-level languages. You need a deep understanding of the microcontroller’s architecture.

- Portability: Assembly code is highly platform-specific. Code written for one microcontroller is typically not portable to another.

- Development Time: Development cycles are generally longer compared to higher-level languages. This increases the project’s overall cost.

- Maintainability: Assembly code can be very difficult to understand and maintain, especially for large projects.

Consider this analogy: Assembly language is like building a house from scratch using individual bricks. It takes more time and effort, but you have complete control over every aspect of the structure. Higher-level languages are like using prefabricated modules – faster construction, but less control.

Therefore, the choice between assembly and higher-level languages often depends on the project’s requirements. For time-critical applications needing optimal performance or extreme memory limitations, assembly might be the best option. However, for most projects, the advantages of higher-level languages in terms of development speed, maintainability, and portability outweigh the performance gains of assembly.

Q 15. What are the advantages and disadvantages of using C language for microcontroller programming?

C is a popular choice for microcontroller programming due to its structured nature, ability to access hardware directly, and efficient code generation. Let’s look at its advantages and disadvantages:

- Advantages:

- Structure and Portability: C’s structured programming approach leads to more readable, maintainable, and portable code compared to assembly. This means code can often be reused across different microcontroller families with minimal modification.

- Hardware Access: C allows direct manipulation of hardware registers and memory locations, making it ideal for low-level programming tasks crucial in microcontrollers.

- Efficiency: C compilers for microcontrollers produce efficient machine code, optimizing for size and speed, which is vital for resource-constrained devices.

- Extensive Libraries: Many libraries support common microcontroller tasks (like I2C communication or SPI), accelerating development.

- Disadvantages:

- Complexity: While structured, C can be more complex than simpler languages, potentially leading to errors if not handled carefully. Memory management, for instance, requires vigilance.

- Debugging: Debugging C code on a microcontroller can be challenging compared to higher-level languages, requiring specific tools and techniques.

- Potential for Errors: Direct memory access and pointer manipulation can introduce subtle and hard-to-find errors if not done meticulously.

For example, in an AVR project I worked on, using C allowed me to easily interface with an external sensor through SPI, while the structured approach made the code far easier to maintain than if I had used assembly.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you debug microcontroller code?

Debugging microcontroller code requires a multi-pronged approach. The best methods depend on the microcontroller and available tools, but common techniques include:

- Hardware Debuggers: Tools like JTAG (Joint Test Action Group) or SWD (Serial Wire Debug) interfaces allow real-time monitoring and control of the microcontroller’s execution. Breakpoints can be set, variables inspected, and program flow traced step-by-step. I frequently use a JTAG debugger with my AVR projects to identify memory corruption issues or infinite loops. This provides a much more powerful debugging experience compared to using just LEDs.

- Simulators: Simulators replicate the microcontroller’s behavior in software. This allows testing and debugging code without needing the physical hardware, which is particularly helpful during early development stages or when testing scenarios that might damage the physical hardware.

- Logic Analyzers and Oscilloscopes: For hardware-related problems, logic analyzers provide detailed views of signals on various pins. Oscilloscopes are useful for checking analog signals and timing-related issues.

- Print Statements (printf debugging): While less precise, strategically placed

printfstatements (where supported by the development environment) can help track variable values and execution flow. This is often a quick first step to identify the general area of a problem. - Code Review and Static Analysis: Peer review of the code and employing static analysis tools can identify potential errors before even running the code.

For instance, in a recent 8051 project, I used a combination of JTAG debugging and printf statements to pinpoint a race condition causing unpredictable behavior. The JTAG debugger allowed me to see the exact point of failure, while the printf statements helped to confirm the state of critical variables.

Q 17. Explain the concept of real-time operating systems (RTOS) in the context of microcontrollers.

A Real-Time Operating System (RTOS) is a specialized operating system designed for real-time applications. In the context of microcontrollers, it manages tasks, resources, and timing constraints to ensure predictable and timely responses to events. Think of it as a tiny, highly efficient operating system tailored for embedded devices. Instead of a general-purpose OS like Windows or macOS, an RTOS prioritizes deterministic behavior.

- Task Scheduling: RTOSes schedule tasks based on priorities, deadlines, or other criteria. This ensures that critical tasks are executed first, even when multiple tasks compete for resources.

- Resource Management: They manage shared resources like memory and peripherals to prevent conflicts and ensure data integrity. Multiple tasks can safely share the same hardware resources without causing unexpected issues.

- Inter-Process Communication (IPC): Mechanisms like semaphores, mutexes, and message queues enable communication and synchronization between different tasks within the RTOS.

- Interrupt Handling: RTOSes integrate with the microcontroller’s interrupt system, allowing efficient handling of external events without disrupting the main program flow.

Imagine a microcontroller controlling a robot arm. An RTOS can manage tasks such as monitoring sensor inputs, controlling motors, and communicating with a computer, all with precise timing and prioritization. A task controlling safety might have the highest priority, ensuring immediate action if a hazard is detected.

Q 18. What are the different types of memory used in microcontrollers?

Microcontrollers utilize various types of memory, each with specific characteristics and purposes:

- Flash Memory: Non-volatile memory used to store the program code. It retains its contents even when the power is turned off. Flash memory can be programmed and erased in blocks.

- RAM (Random Access Memory): Volatile memory used to store data and variables during program execution. Its contents are lost when the power is removed. Access to RAM is much faster than to Flash.

- EEPROM (Electrically Erasable Programmable Read-Only Memory): Non-volatile memory that can be programmed and erased electrically in individual bytes. It’s slower than RAM but allows for persistent data storage, typically used for configuration settings or calibration data.

- Register Files: Small, fast memory locations within the microcontroller’s CPU. Registers are used for temporary storage during program execution and interact directly with the ALU (Arithmetic Logic Unit).

In an AVR microcontroller, for example, the program code resides in Flash memory, variables are stored in RAM, and configuration settings might be kept in EEPROM. Understanding the characteristics and limitations of each memory type is crucial for efficient and reliable code.

Q 19. Explain the concept of watchdogs in microcontrollers.

A watchdog timer is a hardware timer within a microcontroller that is used to detect and recover from program failures. Imagine it as a safety net for your program.

It functions by periodically resetting a counter. The program must periodically ‘kick’ or reset this counter before it expires. If the counter expires, it means the program has stalled or crashed, and the watchdog automatically resets the microcontroller, restarting the system. This prevents the system from becoming unresponsive and ensures a level of fault tolerance.

Use Cases:

- Software Glitches: Watchdogs prevent a program stuck in an infinite loop from indefinitely locking up the system.

- Hardware Failures: They can detect hardware failures, such as memory corruption or clock glitches, by triggering a reset.

- External Event Handling: A watchdog can be used in conjunction with a sensor to trigger an action if a predetermined condition (e.g., no signal for a specified time) is not met.

In a real-world scenario, a watchdog timer might be crucial in an industrial control system to guarantee the safe operation of machinery. If the main control loop freezes, the watchdog timer will reset the system, minimizing the risk of damage or injury.

Q 20. How do you handle power management in embedded systems?

Power management in embedded systems is crucial for extending battery life and reducing energy consumption. Strategies include:

- Low-Power Modes: Microcontrollers offer various low-power modes (sleep, idle, etc.) that reduce power consumption when processing is not required. Careful selection and use of these modes are key.

- Clock Management: Reducing the microcontroller’s clock frequency lowers power consumption. Dynamic clock frequency scaling allows adapting the clock speed to the current workload.

- Peripheral Power Management: Turning off unused peripherals conserves energy. Many peripherals have power-down modes that can be enabled selectively.

- Power-Saving Techniques in Code: Optimizing code to reduce execution time and minimize the use of power-hungry operations can significantly impact power consumption.

- Hardware Power Management ICs: Dedicated power management integrated circuits (PMICs) can efficiently manage power distribution and optimize battery charging and discharging.

In a battery-powered sensor node, for example, the microcontroller might spend most of its time in a low-power sleep mode, waking up only periodically to collect data and transmit it wirelessly. Careful selection and configuration of low-power modes is crucial for maximizing battery lifetime.

Q 21. Describe your experience with different development tools for 8051/AVR microcontrollers.

My experience with 8051 and AVR microcontroller development tools spans various integrated development environments (IDEs), compilers, and debuggers.

- 8051: I’ve extensively used Keil µVision IDE along with its 8051 compiler. I’ve also worked with some open-source alternatives like SDCC (Small Device C Compiler) for projects where licensing wasn’t a primary concern. For debugging, I’ve used both hardware debuggers (through JTAG) and simulator-based debugging techniques.

- AVR: For AVR microcontrollers, I’m proficient with Atmel Studio (now Microchip Studio) and its AVR-GCC compiler. I find this IDE particularly well-suited for AVR development and its integration with the debugging tools is seamless. I have also experience with using various Atmel-ICE JTAG debuggers. For smaller projects, I occasionally prefer the command-line compilation process with AVR-GCC combined with a makefile.

My experience includes utilizing different programming techniques, including interrupt handling, timer management, and working with various peripherals in both architectures. I’m adept at optimizing code for size and speed, crucial for resource-constrained embedded systems.

Q 22. How do you ensure the reliability and robustness of your embedded code?

Ensuring reliable and robust embedded code involves a multi-pronged approach focusing on preventative measures and rigorous testing. Think of it like building a sturdy house – you wouldn’t skip the foundation or ignore potential weather damage!

Defensive Programming: This is paramount. It means anticipating potential errors (like invalid user input or unexpected sensor readings) and incorporating checks to handle them gracefully. Instead of assuming data is always valid, explicitly validate it. For example, always check array bounds before accessing elements to prevent crashes.

Modular Design: Break down complex tasks into smaller, manageable modules. This makes code easier to understand, test, and maintain. Think of it as assembling a house from pre-fabricated parts rather than building everything from scratch on site.

Code Reviews: Peer reviews are invaluable. A fresh pair of eyes can often spot subtle bugs or design flaws that the original author might have missed. It’s like having a quality control inspector check your house’s construction.

Static Analysis Tools: These automated tools can detect potential issues in your code before you even compile it. Think of them as automated pre-construction inspections.

Unit and Integration Testing: Thorough testing is crucial. Unit tests verify individual modules, while integration tests check how modules interact. Imagine this as testing individual parts of the house (e.g., plumbing, electrical) and then the whole house systems (e.g., heating, ventilation).

Error Handling: Implement robust error handling mechanisms, such as try-catch blocks (where applicable) and status flags. This allows the system to recover from errors or at least report them meaningfully, preventing catastrophic failures.

By combining these techniques, you can significantly increase the reliability and robustness of your embedded code, creating a system that’s resilient to unexpected events and errors.

Q 23. Explain your experience with different debugging techniques for embedded systems.

Debugging embedded systems can be challenging due to limited resources and real-time constraints. My experience spans various techniques:

Hardware Debuggers (e.g., JTAG, SWD): These are essential for low-level debugging. They allow single-stepping through code, examining registers, setting breakpoints, and inspecting memory. I’ve used these extensively with AVR microcontrollers, using tools like Atmel Studio’s debugging capabilities and external debuggers.

Print Statements (printf debugging): Simple but effective for basic debugging. Strategic placement of

printfstatements (or their microcontroller-specific equivalents) can provide valuable insights into the program’s execution flow. This is like placing sensors throughout a house to monitor its state.Logic Analyzers: These tools capture digital signals over time, providing a visual representation of data bus activity. They are particularly helpful for understanding timing-related issues or low-level hardware interactions, like investigating why a peripheral isn’t responding.

Oscilloscope: Useful for examining analog signals and verifying the behavior of hardware components connected to the microcontroller. Imagine using an oscilloscope to check the voltage levels of your house’s electrical system.

Simulators: Simulators allow you to run your code in a virtual environment before deploying it to the actual hardware. This helps catch many errors early, reducing the time spent debugging on the real hardware. This is akin to using a virtual model of your house to check the design before construction.

Software Tracing: Recording program execution in detail. Some microcontroller architectures (and debugging tools) support detailed tracing that can help pin down intermittent or hard-to-reproduce bugs. This is a more advanced technique like using comprehensive monitoring throughout the construction process of a house.

The choice of debugging technique often depends on the complexity of the problem and the available tools. I usually start with simpler methods like print statements and then move to more advanced tools if necessary.

Q 24. How would you approach designing a state machine for a microcontroller application?

Designing a state machine for a microcontroller application involves defining distinct states, transitions between those states, and actions performed within each state. It’s a structured approach that simplifies complex control logic. Think of it like a flowchart for your microcontroller’s behavior.

Here’s a typical approach:

Identify States: Determine the different operating modes or conditions of your system. For example, in a simple traffic light controller, states might be Red, Yellow, and Green.

Define Transitions: Specify the conditions that cause transitions between states. For example, the traffic light might transition from Green to Yellow after a timer expires.

Specify Actions: Determine the actions performed within each state. In our example, the Green state might activate a Green light, while the Yellow state activates a Yellow light.

Implement the State Machine: This can be done using various techniques. A common approach is using a switch-case statement (or a similar construct) in your code. Each case represents a state, and the code within each case performs the actions associated with that state. Transitions are handled by checking conditions and updating the current state variable.

Example (Conceptual C code):

enum State {RED, YELLOW, GREEN};

State currentState = RED;

void trafficLight() {

switch (currentState) {

case RED:

// Turn on red light

// ...

if (timerExpired()) currentState = GREEN;

break;

case YELLOW:

// Turn on yellow light

// ...

if (timerExpired()) currentState = RED;

break;

case GREEN:

// Turn on green light

// ...

if (timerExpired()) currentState = YELLOW;

break;

}

}

State machines are incredibly useful for managing complex interactions and improving code readability. They are particularly effective in applications requiring clear and predictable behavior, like motor control, data acquisition, and communication protocols.

Q 25. Describe a challenging microcontroller project you have worked on and the solutions you implemented.

One challenging project involved designing a wireless sensor network for environmental monitoring. The challenge stemmed from the need for low-power consumption, long-range communication, and reliable data acquisition in a remote, harsh environment. We used 8051 microcontrollers due to their low power consumption and availability of suitable RF modules.

The major hurdles were:

Power Management: We had to carefully optimize the microcontroller’s power consumption to extend battery life. This involved techniques like using low-power sleep modes, carefully managing clock speeds, and minimizing unnecessary computations.

Long-Range Communication: Standard RF modules had limited range. To overcome this, we implemented a multi-hop communication protocol, where sensor nodes relayed data to each other to reach the base station. This involved managing routing tables and ensuring robust error detection and correction.

Data Reliability: Data loss was a major concern. To address this, we implemented data redundancy and error-checking mechanisms. We also developed sophisticated data filtering to identify and discard spurious readings.

Solutions implemented included:

Custom Power Management routines: These routines dynamically adjusted the microcontroller’s clock speed and sleep modes based on sensor activity and communication needs.

A robust multi-hop routing protocol: This protocol ensured data delivery even with node failures. It included features like path discovery, automatic rerouting, and acknowledgement mechanisms.

Cyclic Redundancy Check (CRC): We used CRC to detect data corruption during transmission.

The project was a success, resulting in a reliable, low-power sensor network capable of collecting data over extended periods in challenging conditions. It highlighted the importance of careful system design, efficient resource management, and robust error handling in embedded systems development.

Q 26. How do you handle memory constraints in microcontroller programming?

Microcontrollers have limited memory, so efficient memory management is critical. It’s like budgeting for a small apartment – you need to be mindful of what you keep and how you use it.

Code Optimization: Writing concise and efficient code is the first step. This includes avoiding unnecessary variables, loops, and function calls. Using compiler optimization flags can also help.

Data Structures: Choosing the right data structures is important. For example, using arrays instead of linked lists can save memory if the size is known at compile time. If you need to frequently add or remove elements, linked lists might be more appropriate.

Memory Allocation Strategies: Dynamic memory allocation should be used cautiously. It’s better to use static allocation whenever possible to avoid fragmentation and runtime errors. If dynamic allocation is necessary, use memory management libraries carefully and check for memory leaks.

Code Reuse: Reusing code modules reduces overall code size. This avoids redundancy, especially for common tasks.

Data Compression: If possible, compress data before storing it in memory. Lossless compression techniques are appropriate for preserving data integrity, while lossy compression might be used in situations where a slight loss of fidelity is acceptable.

Memory Mapping: Understanding how memory is organized in the microcontroller is essential. Using memory efficiently requires knowledge of the different memory spaces (e.g., RAM, ROM, Flash) and how they are accessed. Memory mapping can also allow for direct manipulation of hardware peripherals within certain memory address ranges.

By applying these strategies, you can maximize the use of available memory and create a functional application within the constraints of the target microcontroller.

Q 27. Explain your understanding of different clock sources for microcontrollers.

Microcontrollers use various clock sources to regulate their internal operations. Choosing the right source is crucial for performance, power consumption, and accuracy.

Internal RC Oscillator: This is a simple, on-chip oscillator built using a resistor-capacitor network. It’s the most common and simplest source, but its frequency is not very accurate, typically +/-1%. This is like having a basic timer that’s reasonably accurate but not precise.

External Crystal Oscillator: This uses a quartz crystal to generate a more stable and accurate clock signal. Crystals provide higher accuracy (e.g., +/-0.01%) and are commonly used when precise timing is needed.

Ceramic Resonator: A cheaper alternative to crystals, offering somewhat better accuracy than RC oscillators. They are more sensitive to temperature changes. Think of it as a middle-ground solution with moderate accuracy and cost.

PLL (Phase-Locked Loop): A PLL multiplies the frequency of an existing clock source, enabling higher operating frequencies. It’s often used to generate higher-speed clocks from a lower-frequency crystal. A PLL is like a gear system that increases the speed of the clock signal.

The choice of clock source depends on the application’s requirements. For applications requiring precise timing, such as real-time systems or communication protocols, a crystal oscillator is usually preferred. For simpler applications where high accuracy isn’t critical, an internal RC oscillator might suffice, trading accuracy for simplicity and low power consumption.

Q 28. Describe the process of selecting the appropriate microcontroller for a specific application.

Selecting the appropriate microcontroller involves carefully considering several factors. Think of it like choosing the right tool for a job—you wouldn’t use a hammer to screw in a screw.

Processing Power: Consider the computational demands of your application. Do you need a fast processor for complex algorithms, or will a simpler, lower-power microcontroller suffice?

Memory: How much program memory (Flash) and data memory (RAM) do you need? This depends on the size of your code and the data your application needs to store.

Peripherals: Does your application require specific peripherals (e.g., ADC, DAC, UART, SPI, I2C)? Make sure the microcontroller has the necessary interfaces to communicate with the other components in your system.

Power Consumption: Low-power consumption is crucial for battery-powered applications. Check the microcontroller’s power specifications to ensure it meets your needs.

Cost: The microcontroller’s cost is an important factor, particularly for high-volume applications.

Development Tools and Support: Ensure that adequate development tools (compilers, debuggers, IDEs) and community support are available for the chosen microcontroller.

Package and Form Factor: The physical size and packaging of the microcontroller must be compatible with your application’s constraints.

Often, a trade-off is required. For example, a high-performance microcontroller might have greater power consumption, while a low-power option might have less processing power. Careful evaluation of the requirements and constraints is key to selecting the optimal microcontroller for your specific application.

Key Topics to Learn for Microcontroller Programming (8051, AVR) Interview

- Architecture and Registers: Understand the internal architecture of both 8051 and AVR microcontrollers, including registers, memory organization (RAM, ROM, Special Function Registers), and addressing modes. Practice accessing and manipulating these registers.

- Instruction Set and Assembly Programming: Become proficient in reading and writing assembly code for both architectures. Focus on understanding instruction timing and the impact on program execution speed.

- Peripheral Interfacing: Master interfacing with common peripherals such as timers/counters, UART, SPI, I2C, ADC, and DAC. Be prepared to discuss the configuration and programming of these peripherals in both 8051 and AVR contexts.

- Interrupt Handling: Understand interrupt vectors, priority levels, and interrupt service routines (ISRs). Practice writing efficient and robust ISR code to handle external events.

- Real-Time Programming Concepts: Grasp the principles of real-time systems, including timing constraints, scheduling, and multitasking. Be prepared to discuss how these concepts apply to microcontroller programming.

- C Programming for Microcontrollers: Demonstrate proficiency in using C to program microcontrollers, including memory management, pointer manipulation, and efficient code optimization techniques specifically tailored for resource-constrained environments.

- Practical Application and Problem Solving: Be ready to discuss projects you’ve worked on, highlighting your problem-solving skills and your ability to apply your knowledge to real-world applications. Consider examples involving embedded systems design, sensor integration, or control systems.

- Debugging and Troubleshooting: Describe your approach to debugging microcontroller code, including the use of debugging tools and techniques. Be prepared to discuss common errors and how you’ve solved them.

Next Steps

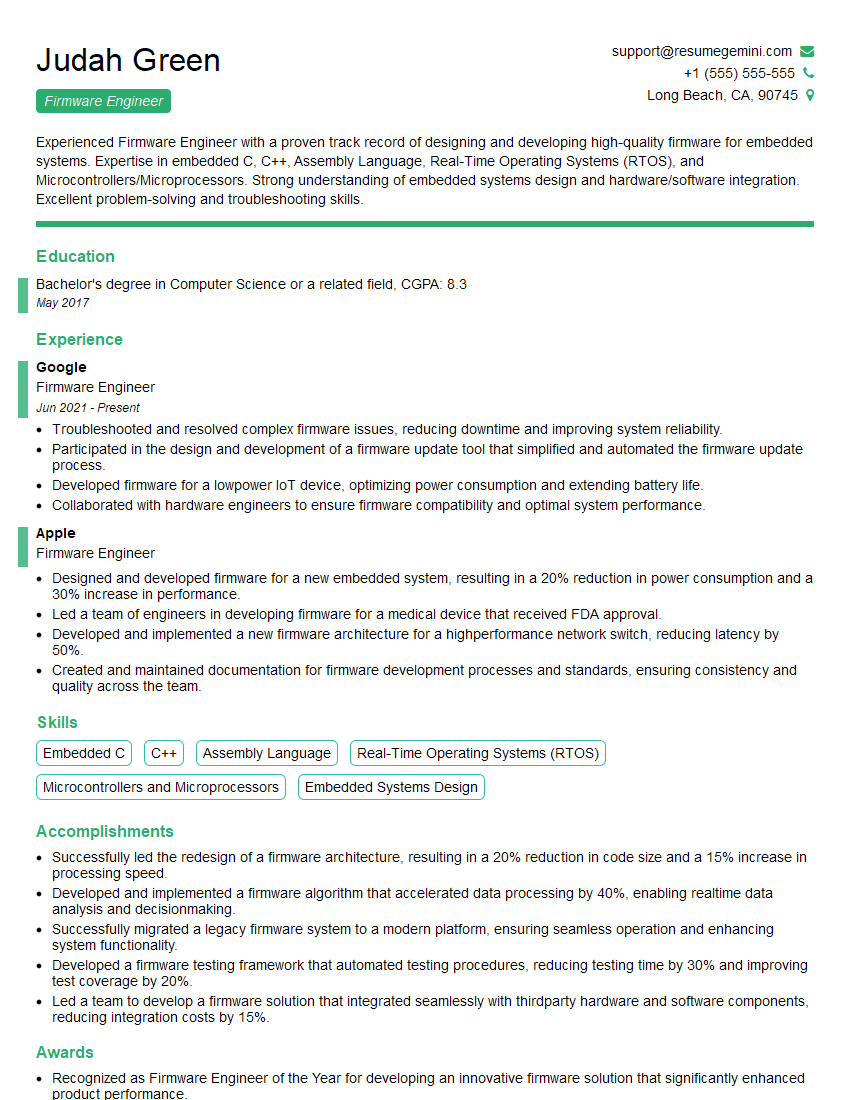

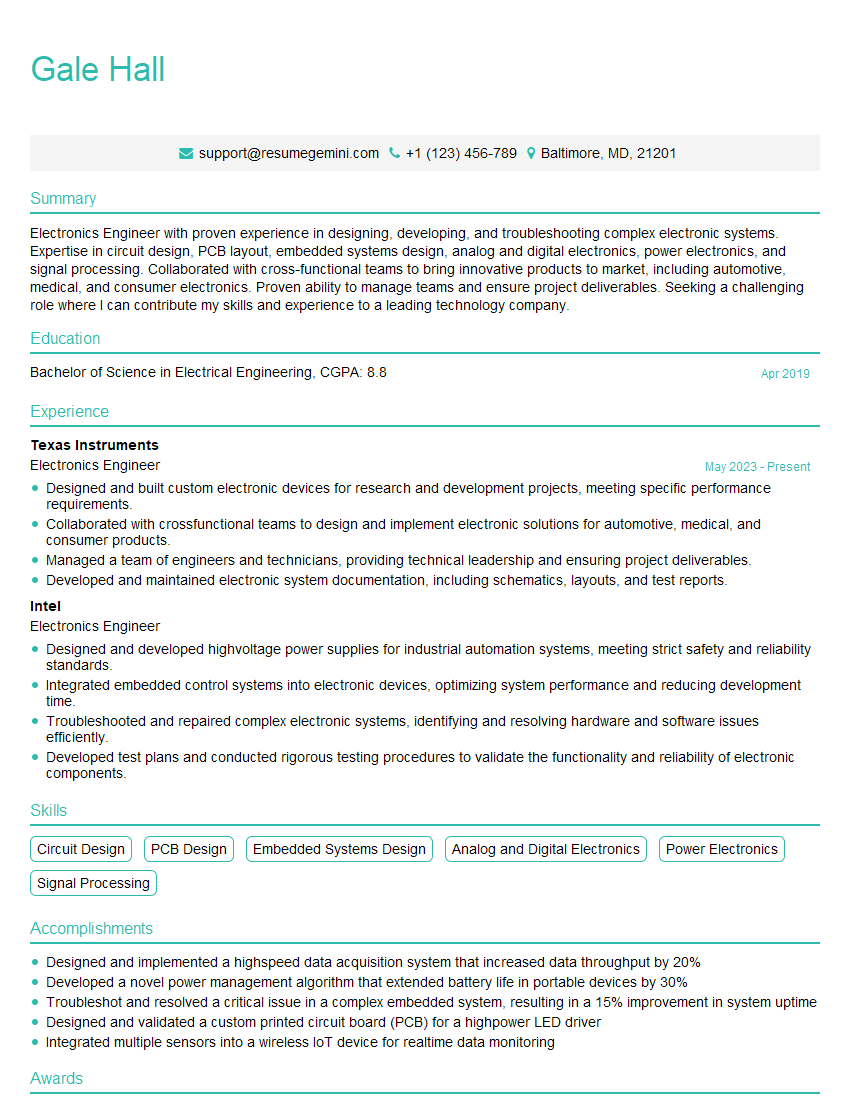

Mastering microcontroller programming (8051 and AVR) opens doors to exciting career opportunities in embedded systems, automation, and robotics. It demonstrates a crucial skillset highly valued by employers. To maximize your job prospects, focus on crafting a compelling and ATS-friendly resume that showcases your expertise effectively. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience in the best possible light. Examples of resumes tailored to Microcontroller Programming (8051, AVR) roles are available to provide you with inspiration and guidance.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good