Cracking a skill-specific interview, like one for Mining Operations, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Mining Operations Interview

Q 1. Explain the different types of mining methods.

Mining methods are broadly categorized based on the location of the ore body and its accessibility. We primarily distinguish between surface mining and underground mining, each with various sub-methods.

- Surface Mining: This involves extracting ore from near the surface. Methods include:

- Open-pit mining: A large, open hole is excavated to access the ore. Think of the massive copper mines you see in pictures – that’s open-pit. This is cost-effective for large, shallow deposits.

- Strip mining: Overburden (the layer of rock and soil above the ore) is removed in strips to expose the ore seam. Common for coal and other horizontally layered deposits.

- Quarrying: Extraction of construction materials like stone and gravel. Often involves blasting and heavy machinery.

- Underground Mining: This is used for ore bodies located deep underground. Methods include:

- Room and pillar mining: Sections of ore are extracted, leaving pillars of ore to support the roof. It’s like making a honeycomb structure underground.

- Longwall mining: A continuous miner extracts ore in long panels, with the roof collapsing behind it. This method is highly efficient for large, flat seams.

- Sublevel stoping: Ore is extracted from horizontal levels, with the broken ore drawn to the bottom of the stope. This is adaptable to steeply dipping ore bodies.

- Block caving: A large block of ore is undercut to cause a controlled collapse, allowing the ore to be drawn from the bottom. It’s highly productive but requires careful planning.

The choice of mining method depends on several factors, including the geology of the ore body, its size and shape, the depth, the ore grade, environmental regulations, and economic considerations.

Q 2. Describe your experience with mine planning and scheduling software.

I have extensive experience with several mine planning and scheduling software packages, including MineSight, Deswik, and Datamine. My expertise spans from data input and geological modeling to scheduling optimization and production forecasting. For instance, in a previous role at a gold mine, I used MineSight to create a 3D geological model based on drill core data, then used this model to optimize the mine plan for maximum gold recovery and minimize waste removal. This involved developing production schedules that accounted for equipment availability, labor constraints, and potential geological risks. I’m proficient in using these programs to conduct sensitivity analyses and scenario planning, ensuring the mine plan remains flexible and adaptable to changing conditions. Furthermore, I’m comfortable with data extraction, reporting, and using the software to prepare presentations for senior management.

Q 3. How do you ensure safety compliance on a mining site?

Safety compliance is paramount in mining. My approach is multifaceted and proactive. It begins with a strong safety culture instilled through training, communication, and leadership. I employ a system that includes:

- Regular Safety Audits and Inspections: These identify potential hazards before they cause incidents. We use checklists and specialized software to track findings and ensure timely corrective actions.

- Comprehensive Training Programs: All personnel receive training relevant to their job roles, covering aspects like hazard recognition, safe work procedures, emergency response, and the use of personal protective equipment (PPE).

- Incident Investigation and Reporting System: A thorough investigation of every incident, regardless of severity, helps to identify root causes and prevent future occurrences. We use a structured system to record details, analyze findings, and implement corrective actions.

- Risk Assessments and Mitigation Plans: We conduct regular risk assessments to identify potential hazards and develop strategies to mitigate them. This involves understanding the specific risks at the site and implementing controls like engineering solutions, administrative controls, and PPE.

- Enforcement of Safety Rules and Regulations: Strict adherence to safety regulations is enforced through regular monitoring and disciplinary action when necessary. This creates an environment where safety is not optional.

My experience shows that a robust safety program not only protects workers but also improves operational efficiency by reducing downtime and lost production due to accidents.

Q 4. What are the key performance indicators (KPIs) you monitor in mining operations?

Key Performance Indicators (KPIs) in mining operations are crucial for monitoring efficiency and profitability. The specific KPIs vary depending on the type of mine and its goals, but some key ones include:

- Production Rate (tonnes/day or ounces/day): This measures the volume of ore extracted and processed.

- Ore Grade (%): This indicates the concentration of valuable minerals in the ore.

- Recovery Rate (%): This shows the percentage of valuable minerals extracted from the ore during processing.

- Operating Costs ($/tonne): This tracks the cost of mining and processing per unit of ore.

- Safety Performance (Lost Time Injury Frequency Rate – LTIFR): This crucial metric measures the number of lost-time injuries per million hours worked, indicating safety performance.

- Equipment Availability (%): This reflects the percentage of time that equipment is operational.

- Overall Equipment Effectiveness (OEE): This is a holistic measure of equipment performance, combining availability, performance, and quality.

- Unit Cost ($/oz or $/tonne): This crucial indicator combines production cost and production rates to express the cost of producing one unit.

Regular monitoring and analysis of these KPIs provide insights into operational effectiveness and help in identifying areas for improvement. For example, a drop in ore grade could trigger an investigation into geological variability, while high operating costs might indicate a need to optimize processes or equipment maintenance.

Q 5. Explain your understanding of ground control techniques.

Ground control techniques are vital for ensuring the stability of underground mine openings and preventing ground failures, such as rock bursts, falls of ground, and subsidence. These techniques aim to manage the stresses and strains within the rock mass. My experience encompasses a range of techniques, including:

- Support Systems: This includes installing rock bolts, wire mesh, and concrete or steel sets to reinforce the rock mass and prevent collapses. The type of support used depends on the geological conditions and the size and shape of the opening.

- Ground Reinforcement: Techniques like resin grouting, cement grouting, and cable bolting can improve the strength and stability of the rock mass.

- Stress Management: Understanding the in-situ stress field is crucial. Techniques like stress measurement and stress relief blasting can help to manage stress concentrations and reduce the risk of ground failure.

- Monitoring Systems: Regular monitoring of ground conditions using instruments like extensometers, convergence monitoring, and seismic sensors helps detect early signs of instability. This allows for proactive intervention and prevents major accidents.

- Sequential Mining Methods: The order in which ore is extracted significantly affects ground stability. Proper sequencing minimizes stress buildup and enhances ground control.

A successful ground control strategy requires a detailed understanding of the geological conditions, the mining method used, and the potential for ground movement. I regularly utilize advanced geotechnical modeling and simulations to predict and mitigate potential ground control issues.

Q 6. How do you manage and mitigate geological risks in mining?

Geological risks in mining can significantly impact safety, production, and profitability. My approach involves a multi-stage process:

- Geological Mapping and Modeling: Thorough geological investigations, including drilling, sampling, and geophysical surveys, are essential for understanding the ore body’s geometry, structure, and lithology. We use this data to create detailed geological models, which are crucial for mine planning and risk assessment.

- Geotechnical Characterization: Rock mass properties, such as strength, fracturing, and permeability, are assessed through laboratory testing and field measurements. This informs the design of ground control measures and helps predict potential instability.

- Risk Assessment and Mitigation: We identify potential geological hazards such as faulting, jointing, groundwater inflows, and rock bursts. Then, we develop specific mitigation strategies, which could range from modifying the mining method, implementing additional ground support, or implementing water management plans.

- Contingency Planning: Developing contingency plans for dealing with unexpected geological conditions is crucial. This might involve alternative mining methods, extra ground support, or changes to the mine schedule.

- Continuous Monitoring: Regular monitoring of geological conditions, including ground movements, water levels, and stress changes, is vital to detect potential issues early and take appropriate corrective actions.

For example, during a project where we encountered unexpected high water pressures, we promptly implemented additional dewatering measures to prevent flooding and maintain safe working conditions.

Q 7. Describe your experience with mine ventilation systems.

Mine ventilation systems are critical for ensuring the safety and health of underground miners by controlling air quality, temperature, and airflow. My experience includes designing, implementing, and maintaining ventilation systems for various mining operations. This includes:

- Ventilation Planning and Design: This involves modeling airflow patterns using specialized software to determine the optimal placement of ventilation equipment, such as fans, ducts, and regulators, to achieve the required air quality and flow rates. The design considers factors like mine layout, geology, and environmental regulations.

- Equipment Selection and Installation: Selecting appropriate ventilation equipment, including fans, raises and shafts, airlocks and ventilation doors, based on capacity, efficiency, and durability is a key aspect. Proper installation and maintenance are essential for optimal performance.

- Monitoring and Control: Continuous monitoring of air quality parameters, including oxygen levels, methane concentrations, and temperature, is vital. We use sensors and monitoring systems to track these parameters and ensure compliance with safety regulations. We must have the ability to control the system remotely or through manual adjustments at the site.

- Maintenance and Optimization: Regular maintenance of ventilation equipment is crucial to ensure its longevity and efficient operation. This helps prevent equipment failures and maintains optimal airflow. We also perform optimization studies to improve efficiency and reduce energy consumption.

One project involved optimizing the ventilation system of a coal mine to reduce methane build-up and improve air quality. This involved installing additional ventilation fans and adjusting the airflow network based on detailed modeling and simulations, ultimately resulting in a significant improvement in miner safety and productivity.

Q 8. How do you optimize production efficiency in a mining operation?

Optimizing production efficiency in mining is a multifaceted challenge requiring a holistic approach. It’s not just about extracting more ore, but doing so safely, sustainably, and profitably. My strategy focuses on several key areas:

- Process Optimization: This involves analyzing the entire mining process, from exploration and drilling to extraction, processing, and transportation. We use data analytics to identify bottlenecks, inefficiencies, and areas for improvement. For example, by optimizing blast designs based on geotechnical data, we can improve fragmentation leading to higher throughput in crushing and milling.

- Equipment Maintenance and Reliability: Preventive maintenance is crucial. A robust maintenance program with predictive analytics, using sensor data to anticipate equipment failures, minimizes downtime. This also includes investing in modern, high-performance equipment that offers increased efficiency and lower operating costs.

- Technology Integration: Implementing automation and advanced technologies like autonomous haulage systems and remote operations can significantly enhance productivity and safety. For example, using GPS-guided drills reduces the time and cost associated with drilling operations.

- Workforce Training and Development: A well-trained and motivated workforce is essential. Continuous training programs focusing on best practices, safety procedures, and the use of new technologies ensure peak performance. In my previous role, we implemented a comprehensive training program that resulted in a 15% increase in overall productivity.

- Supply Chain Management: Efficient supply chain management is vital. This includes securing reliable suppliers for equipment, parts, and consumables, and optimizing logistics to ensure timely delivery. Delays in the supply chain can significantly impact production schedules.

Ultimately, the key to efficient production is a data-driven approach, continuous monitoring, and a culture of continuous improvement.

Q 9. Explain your experience with different types of mining equipment.

My experience encompasses a wide range of mining equipment, from surface mining to underground operations. I’m familiar with:

- Surface Mining Equipment: This includes excavators, loaders, haul trucks, drills (both rotary and percussion), and crushers. I’ve worked extensively with Caterpillar and Komatsu equipment, managing their maintenance and optimization. I’ve also been involved in selecting and implementing new equipment based on specific site requirements and production targets.

- Underground Mining Equipment: My experience includes working with various types of loaders, trucks, and drills used in both hard rock and soft rock mining. I’ve been involved in the operation and maintenance of both conventional and long-hole drilling equipment. I am also familiar with specialized equipment like roadheaders and continuous miners.

- Processing Equipment: I have experience with crushers, grinders, mills (ball, SAG, and rod), concentrators (flotation, gravity separation), and thickeners. Understanding the processing flow and its interaction with mining operations is critical for overall efficiency.

I’ve always been keen to stay updated with the latest technologies and equipment advancements. For example, I was involved in the successful implementation of a new automated drilling system that resulted in a significant reduction in drilling time and cost.

Q 10. How do you handle unexpected equipment failures in a mine?

Unexpected equipment failures are inevitable in mining. My approach to handling them is proactive and systematic:

- Rapid Response: Establishing a well-defined emergency response protocol is paramount. This involves clear communication channels, designated personnel, and pre-planned procedures for dealing with various equipment failures. The speed of response can significantly minimize the impact of the failure.

- Root Cause Analysis: Once the immediate issue is addressed, a thorough investigation is conducted to determine the root cause of the failure. This could involve analyzing maintenance records, inspecting the damaged equipment, and interviewing personnel. This prevents recurrence.

- Preventive Measures: Based on the root cause analysis, we implement preventive measures such as improved maintenance procedures, enhanced training for operators, or upgrades to the equipment. This proactive approach reduces future risks.

- Spare Parts Management: Maintaining an adequate inventory of critical spare parts is essential. This minimizes downtime caused by waiting for parts to arrive. Having a strategic spare parts management plan is critical.

- Contingency Planning: We develop contingency plans for handling major equipment failures. This includes identifying alternative equipment, securing repair services, and re-scheduling production to minimize disruptions.

A recent example involves a major haul truck breakdown. Our rapid response team was able to get the truck back online within 12 hours thanks to our well-stocked parts inventory and a skilled maintenance crew. The root cause analysis identified a faulty sensor, and we implemented preventative measures to avoid similar incidents in the future.

Q 11. Describe your experience with mine water management.

Mine water management is crucial for safety, environmental protection, and efficient operations. My experience involves:

- Water Collection and Treatment: Designing and implementing efficient systems for collecting, treating, and disposing of mine water is essential. This often includes dewatering systems, settling ponds, and water treatment plants that remove contaminants like heavy metals and suspended solids.

- Groundwater Monitoring: Continuous monitoring of groundwater levels and quality is vital to prevent environmental contamination and ensure the stability of the mine workings. We use various monitoring techniques, including piezometers and water quality sampling.

- Water Reuse and Recycling: Implementing strategies for reusing and recycling water reduces the environmental impact and operational costs. This might involve using treated mine water for dust suppression or industrial processes.

- De-watering Strategies: Understanding and implementing appropriate de-watering strategies are critical to maintain safe working conditions and prevent flooding in underground mines. This includes designing and maintaining effective pumping systems.

In a previous project, we implemented a water recycling system that reduced our fresh water consumption by 40%, significantly lowering our environmental impact and water costs.

Q 12. How do you ensure environmental compliance on a mining site?

Environmental compliance is non-negotiable. My approach involves:

- Regulatory Compliance: Staying abreast of all relevant environmental regulations and permits is crucial. This requires close collaboration with regulatory agencies and environmental consultants.

- Environmental Monitoring: Regular environmental monitoring programs are essential to track air and water quality, noise levels, and the impact on biodiversity. We use various monitoring methods, including air quality monitoring stations and water quality testing.

- Waste Management: Implementing a robust waste management plan, including the proper handling and disposal of mine tailings, is essential. This involves minimizing waste generation, recycling materials whenever possible, and using environmentally sound disposal methods.

- Rehabilitation Planning: Developing and implementing comprehensive mine rehabilitation plans is vital. This involves planning for the restoration of the site to a productive and ecologically sound state after mining operations cease.

- Stakeholder Engagement: Open communication and collaboration with local communities and other stakeholders are important for building trust and addressing environmental concerns. This could involve public meetings and community consultations.

In my experience, a proactive approach, combined with careful planning and transparent communication, is essential for maintaining high standards of environmental compliance.

Q 13. Explain your experience with mine waste management.

Mine waste management is a critical aspect of responsible mining. My experience involves:

- Tailings Management: Designing and implementing safe and environmentally sound tailings management systems is crucial. This includes selecting appropriate disposal methods (e.g., dry stacking, thickeners, paste backfill), managing water quality, and ensuring the long-term stability of tailings dams.

- Waste Rock Management: Proper management of waste rock, including its characterization and disposal, is important to minimize environmental impacts. This can involve methods such as selective backfilling, blending different waste rock types, and monitoring for potential acid mine drainage.

- Hazardous Waste Management: Handling and disposing of hazardous waste materials (e.g., chemicals, oils) in compliance with all relevant regulations is crucial. This involves specialized storage, transportation, and disposal procedures.

- Recycling and Resource Recovery: Exploring opportunities to recycle or recover valuable materials from mine waste can reduce environmental impacts and improve economic efficiency. We often collaborate with experts in material science to explore such opportunities.

In one project, we successfully implemented a paste backfill system for tailings management, significantly reducing the volume of tailings and improving the stability of the tailings storage facility. This project also involved developing strategies to recover some valuable materials from the waste rock.

Q 14. What are your strategies for cost reduction in mining operations?

Cost reduction in mining requires a multi-pronged approach focused on efficiency improvements and optimized resource allocation. My strategies include:

- Process Optimization: Improving the efficiency of the entire mining process, from exploration and drilling to processing and transportation, can significantly reduce operating costs. This involves identifying and eliminating bottlenecks, optimizing equipment utilization, and improving operational workflows.

- Technology Integration: Implementing new technologies like automated haulage systems, autonomous drilling, and predictive maintenance can significantly reduce labor costs and improve equipment reliability.

- Energy Efficiency: Mining operations are energy-intensive. Improving energy efficiency through measures like optimizing equipment performance, using renewable energy sources, and implementing energy-saving technologies can significantly reduce energy costs.

- Supply Chain Optimization: Negotiating favorable contracts with suppliers, optimizing logistics, and reducing inventory levels can significantly reduce procurement costs.

- Waste Reduction: Minimizing waste generation through improved process efficiency and waste recycling can reduce disposal costs and environmental impacts.

- Data-driven Decision Making: Utilizing data analytics to make informed decisions on equipment maintenance, resource allocation, and operational strategies can enhance efficiency and reduce overall costs.

For example, in a previous role, we implemented a new data-driven scheduling system that reduced equipment idle time by 15%, resulting in significant cost savings.

Q 15. How do you manage and motivate a team in a mining environment?

Managing and motivating a mining team requires a multifaceted approach focusing on safety, communication, and recognition. In my experience, it starts with fostering a strong safety culture. This isn’t just about adhering to regulations; it’s about embedding safety into every aspect of the work, from daily briefings to hazard identification and reporting. Open communication is crucial. I utilize regular team meetings, both formal and informal, to ensure everyone feels heard and involved in decision-making processes. This includes soliciting feedback on procedures and acknowledging contributions. I also believe strongly in recognizing and rewarding achievements, both large and small. This could be through formal awards, public acknowledgment, or simply a sincere thank you. I’ve found that celebrating successes boosts morale and reinforces positive behaviors.

For example, during a challenging project involving the installation of a new ventilation system, I implemented daily ‘huddle’ meetings where the team could openly discuss challenges, share ideas, and celebrate small wins. This improved communication and fostered a sense of collaboration, ultimately leading to the successful and timely completion of the project.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with mine permitting and regulatory compliance.

My experience with mine permitting and regulatory compliance spans over 15 years, encompassing various stages from initial exploration through operational phases and closure planning. I’m proficient in navigating complex environmental regulations, including those related to air and water quality, waste management, and land reclamation. I’ve successfully managed the preparation and submission of permit applications, interacting extensively with regulatory bodies such as the [Insert relevant regulatory body, e.g., Mine Safety and Health Administration (MSHA) or equivalent]. This involves ensuring complete and accurate documentation, conducting environmental impact assessments, and implementing robust environmental monitoring programs.

One notable project involved obtaining a complex permit for an open-pit mine in a sensitive ecological area. This required a comprehensive environmental impact assessment, detailed reclamation plan, and extensive community engagement. Through meticulous preparation and transparent communication with the regulatory agency, we successfully obtained the necessary permits within the stipulated timeframe, minimizing project delays.

Q 17. How do you handle conflicts or disagreements within a mining team?

Handling conflicts within a mining team requires a proactive and fair approach. I believe in addressing disagreements promptly and directly, fostering an environment where open discussion is encouraged. My strategy involves active listening to all parties involved, ensuring everyone feels understood before attempting to find common ground. I facilitate discussions, ensuring that all perspectives are considered. When necessary, I mediate, helping the team identify the root cause of the conflict and collaboratively develop solutions. Impartiality is paramount; I aim to ensure a fair resolution that considers the needs and concerns of all parties involved. In some cases, involving HR or senior management might be necessary for more complex or escalated issues.

For example, a conflict arose between the blasting crew and the geology team regarding the accuracy of blast designs. Through facilitated discussion, we identified a lack of clear communication protocols as the root cause. We implemented a new system for data sharing and feedback, which prevented similar conflicts in the future.

Q 18. Explain your experience with mine reclamation and closure planning.

Mine reclamation and closure planning are critical components of responsible mining. My experience encompasses developing and implementing detailed reclamation plans that meet or exceed regulatory requirements. These plans include site rehabilitation, topsoil management, re-vegetation strategies, and water management solutions. I’ve been involved in various stages, from early-stage planning and budgeting to on-site implementation and post-closure monitoring. This includes conducting environmental baseline studies, establishing monitoring protocols, and assessing long-term environmental liabilities.

In one project, we developed a comprehensive reclamation plan for a large open-pit mine that involved restoring the site to a productive grassland ecosystem. This plan included detailed specifications for topsoil storage and replacement, seed selection tailored to the local climate, and a long-term monitoring program to ensure successful revegetation. This was crucial in securing environmental permits and ensuring the long-term sustainability of the project.

Q 19. How do you use data analytics to improve mining operations?

Data analytics plays a transformative role in enhancing mining operations. We leverage data from various sources, including geological surveys, operational sensors, and maintenance records, to optimize various aspects of mining activities. This includes predictive maintenance, optimizing blasting parameters, improving extraction rates, and reducing operational costs. We utilize various techniques such as statistical modeling, machine learning, and data visualization to identify patterns, trends, and anomalies that can be used to inform decision-making. For example, by analyzing sensor data from heavy equipment, we can predict potential failures and schedule maintenance proactively, minimizing downtime and improving equipment lifespan. Similarly, analyzing geological data helps in optimizing blast designs, reducing waste, and improving the recovery of valuable minerals.

Example: Using regression analysis to predict ore grade based on geological data.

Q 20. Describe your experience with implementing new technologies in mining.

I have extensive experience implementing new technologies in mining operations, focused on enhancing safety, efficiency, and sustainability. This includes the integration of autonomous haulage systems (AHS), the adoption of advanced drilling technologies such as automated drilling rigs, and the implementation of digital twin technology for mine modelling and simulation. The implementation process typically involves a phased approach: initial assessment of technology suitability, pilot testing, comprehensive training for personnel, and ongoing monitoring and evaluation. This requires close collaboration with technology vendors, internal stakeholders, and regulatory bodies. The benefits are significant; AHS, for example, can improve safety by reducing the risk of human error and improve efficiency through optimized haulage routes and reduced downtime.

One specific example involves the implementation of a real-time monitoring system for ground stability. This system employs sensors and advanced analytics to provide early warning of potential ground instability, significantly improving safety and enabling proactive intervention.

Q 21. How do you ensure the quality control of mined materials?

Ensuring the quality control of mined materials is crucial for profitability and meeting customer specifications. Our quality control process starts at the exploration phase, with rigorous sampling and assaying to establish ore grade and mineral content. During extraction, we employ rigorous monitoring and sampling protocols to ensure that the material being extracted meets the predetermined quality standards. This includes regular quality checks at various stages of the process, including crushing, grinding, and concentration. We use advanced analytical techniques, such as X-ray fluorescence (XRF) and inductively coupled plasma mass spectrometry (ICP-MS), to precisely determine the composition of the mined materials. We also maintain comprehensive records and documentation to track quality throughout the entire process. Non-conforming materials are carefully managed and either reprocessed or disposed of according to established procedures. Regular audits and internal reviews are conducted to ensure the ongoing effectiveness of our quality control system.

For example, we implemented a real-time XRF system at the crushing plant which allowed for immediate analysis of the ore grade, enabling us to make adjustments to the extraction process in real-time and maximize the yield of high-grade ore.

Q 22. Explain your understanding of mine surveying techniques.

Mine surveying is crucial for accurately mapping and modeling the subsurface geology and the mine workings themselves. It provides the essential data for safe and efficient extraction of resources. Techniques encompass a range of methods, chosen based on the specific mining environment and objectives.

- Traditional Surveying: This involves using instruments like theodolites, levels, and total stations to measure angles, distances, and elevations. This data is then used to create detailed plans and sections of the mine.

- GPS Surveying: Global Positioning System technology offers increased speed and accuracy, particularly in open-pit mining, for establishing control points and monitoring ground movement.

- Underground Surveying: This is more complex, requiring specialized techniques to overcome challenges like limited visibility and difficult terrain. Gyrotheodolites and laser scanners are commonly employed.

- 3D Laser Scanning: This technology creates a highly detailed point cloud model of the mine environment, capturing complex geometries with exceptional precision. It’s useful for both planning and monitoring.

- Photogrammetry: Using overlapping photographs to create 3D models, it’s valuable for mapping inaccessible areas or monitoring surface changes.

For example, in an underground coal mine, precise surveying ensures that tunnels are correctly aligned and that sufficient support structures are in place to prevent collapses. In an open-pit operation, it aids in optimizing the excavation process and managing waste rock disposal. Accurate surveying directly impacts safety, efficiency, and profitability.

Q 23. How do you manage and mitigate risks associated with mining explosives?

Managing and mitigating risks associated with mining explosives requires a rigorous and multi-layered approach focusing on safety procedures, training, and regulatory compliance. It starts with proper selection of explosives based on the rock type and mining method.

- Risk Assessment: A thorough risk assessment identifies potential hazards like accidental detonation, misfires, and environmental damage. This leads to the development of a comprehensive safety plan.

- Training and Competency: All personnel involved in handling explosives must receive extensive training and demonstrate competency before undertaking any tasks. Regular refresher training is crucial.

- Storage and Handling: Secure storage facilities, following strict regulations, are vital. Careful handling procedures, including the use of appropriate PPE, must be adhered to at all times.

- Blasting Design: The design of the blast itself is crucial. Factors like the amount of explosives used, the placement of blast holes, and the type of initiation system must be carefully considered to minimize risks and maximize efficiency. This often involves sophisticated software modeling.

- Emergency Response Plan: A detailed emergency response plan must be in place, regularly practiced, and readily accessible to all personnel. This plan outlines procedures for handling various scenarios, including accidents and misfires.

- Regulatory Compliance: All operations must strictly adhere to local, national, and international regulations regarding the use and handling of explosives.

For instance, a miscalculation in blast design could lead to flyrock, causing damage or injury. Poor storage practices could result in an explosion. A well-implemented safety program proactively mitigates these risks.

Q 24. What is your experience with different types of blasting techniques?

My experience encompasses various blasting techniques, selected based on the specific geological conditions, mining method, and desired outcome.

- Conventional Blasting: This involves the use of detonating cord or electronic detonators to initiate a series of explosives charges. It’s suitable for a wide range of applications but can be less precise than other methods.

- Pre-split blasting: Used to create smooth, controlled fractures in the rock face, reducing damage to the surrounding rock and minimizing flyrock. This is commonly employed in quarrying and open-pit mining.

- Smooth blasting: Aims to create a smooth, flat surface after blasting, improving safety and reducing the need for secondary breakage. This requires careful planning and precise execution.

- Directional blasting: This technique involves carefully controlling the direction and energy of the blast to minimize vibration and damage to nearby structures or sensitive environments. It is very crucial near populated areas or environmentally sensitive sites.

- Mass blasting: Used for large-scale excavations where high volumes of rock need to be removed quickly. Requires careful control to avoid excessive vibration and ground movement.

In one project, we utilized pre-split blasting in a quarry to create a smooth, vertical face, reducing the need for secondary drilling and blasting and enhancing safety for the workers.

Q 25. Describe your experience with mine transportation and logistics.

Mine transportation and logistics are critical for efficient and cost-effective mine operations. It involves the safe and timely movement of materials, personnel, and equipment within and from the mine site.

- Haulage Systems: This includes trucks, conveyor belts, rail systems, and even aerial trams, depending on the mine’s size, topography, and production capacity. Selection depends on factors such as distance, volume, and terrain.

- Fleet Management: Efficient fleet management involves tracking vehicle location, maintenance schedules, and fuel consumption to optimize operations and reduce downtime.

- Traffic Management: Safe and efficient movement of vehicles and personnel within the mine site requires careful planning and control of traffic flow, especially in confined underground environments.

- Material Handling: Efficient material handling ensures that ore and waste rock are moved effectively and safely throughout the mine, from extraction to processing and disposal.

- Supply Chain Management: The entire supply chain, from procurement of materials and equipment to delivery of the final product, must be effectively managed to ensure uninterrupted operations.

In a previous role, we optimized the haulage system by implementing a new fleet management system, which reduced downtime by 15% and improved fuel efficiency by 10%, significantly impacting the overall cost of operations.

Q 26. How do you ensure the security of a mining operation?

Ensuring the security of a mining operation is multifaceted and crucial, encompassing physical security, cybersecurity, and personnel safety. It involves protecting assets, people, and sensitive information from theft, sabotage, and other threats.

- Physical Security: This includes perimeter fencing, access control systems (e.g., gates, security checkpoints), and surveillance systems (CCTV cameras, motion detectors) to prevent unauthorized entry and deter criminal activity.

- Cybersecurity: Protecting critical infrastructure and data from cyberattacks is increasingly important. This involves implementing robust cybersecurity measures such as firewalls, intrusion detection systems, and regular security audits.

- Personnel Security: Background checks, training on security protocols, and awareness programs are essential to prevent insider threats and ensure that personnel are aware of potential security risks.

- Emergency Response: A well-defined emergency response plan is needed to handle security incidents, including evacuation procedures, communication protocols, and coordination with external emergency services.

- Risk Assessment: Regular security assessments are vital to identify vulnerabilities and update security measures accordingly. This is an iterative process.

For example, we implemented a multi-layered security system in a remote mining operation, including perimeter surveillance, access control, and cybersecurity measures, significantly reducing the risk of theft and sabotage.

Q 27. Explain your understanding of mine health and safety regulations.

Mine health and safety regulations are stringent and designed to protect workers from the inherent risks associated with mining. These regulations cover various aspects of mine operations, and vary by jurisdiction but share common goals.

- Ground Control: Regulations cover the management of ground stability, including the use of support systems to prevent roof and wall collapses.

- Ventilation: Adequate ventilation is crucial to prevent the buildup of harmful gases and dust, ensuring breathable air for workers.

- Hazard Identification and Risk Assessment: Systematic identification and assessment of hazards are mandatory, with control measures implemented to mitigate the risks.

- Personal Protective Equipment (PPE): Regulations mandate the use of appropriate PPE, such as hard hats, safety glasses, respirators, and protective clothing, to minimize the risk of injury.

- Emergency Response: Mines must have comprehensive emergency response plans, including procedures for handling various emergencies such as fires, explosions, and medical emergencies.

- Training and Competency: Workers must receive adequate training on safe work practices, and their competency must be regularly assessed.

Non-compliance can result in significant penalties, including fines, suspension of operations, and even criminal prosecution. Understanding and adhering to these regulations is not only legally required but also essential for creating a safe and healthy work environment.

Q 28. Describe your experience with developing and implementing a mine safety program.

Developing and implementing a mine safety program requires a systematic and comprehensive approach. It begins with a detailed risk assessment, identifying potential hazards and assessing their likelihood and severity. This then informs the design of safety procedures and control measures.

- Risk Assessment and Hazard Identification: A thorough risk assessment is the foundation of any effective safety program. It involves identifying all potential hazards, assessing their risks, and prioritizing control measures. This often involves using standardized risk assessment methodologies.

- Safety Procedures and Control Measures: Based on the risk assessment, specific safety procedures and control measures are developed and implemented. These may involve engineering controls (e.g., safety guards, ventilation systems), administrative controls (e.g., training programs, work permits), and personal protective equipment (PPE).

- Training and Competency: All personnel must receive adequate training on safe work practices and emergency procedures. Regular refresher training is crucial to maintain competency and awareness of safety procedures.

- Emergency Response Plan: A well-defined emergency response plan is essential for dealing with accidents and emergencies. The plan should outline clear procedures for handling various scenarios, including evacuation procedures, communication protocols, and first aid response.

- Monitoring and Auditing: Regular monitoring and auditing of the safety program are critical to ensure its effectiveness. This may involve safety inspections, audits, and incident investigations to identify areas for improvement.

- Communication and Consultation: Effective communication and consultation with workers are vital. Open communication channels and opportunities for feedback ensure that workers are involved in the development and implementation of the safety program.

In a previous role, I led the implementation of a new mine safety program, which resulted in a significant reduction in the number of accidents and injuries. This involved a combination of improved training, updated safety procedures, and a strengthened safety culture.

Key Topics to Learn for Mining Operations Interview

- Mining Methods: Understanding various extraction techniques (open-pit, underground, etc.), their suitability for different ore bodies, and associated environmental impacts. Consider practical applications like selecting the optimal method for a specific geological setting and budgeting considerations.

- Mine Planning & Design: Explore mine layout, resource estimation, scheduling, and production optimization. Practical application involves analyzing geological data to create a feasible and profitable mine plan, addressing potential challenges like ground stability.

- Health & Safety: Mastering relevant regulations, risk assessment methodologies, and emergency response procedures. Practical application includes developing and implementing safety protocols to minimize workplace incidents and ensure compliance.

- Equipment & Technology: Familiarize yourself with various mining equipment (e.g., excavators, haul trucks, drills) and their operation, maintenance, and technological advancements (e.g., automation, remote operation). Consider practical scenarios like troubleshooting equipment malfunctions or optimizing equipment utilization.

- Environmental Management: Understand environmental regulations, reclamation techniques, and sustainable mining practices. Practical application includes developing and implementing an environmental management plan that minimizes the environmental footprint of mining operations.

- Project Management in Mining: Gain knowledge of project lifecycle, cost control, risk management, and stakeholder communication within a mining context. Explore practical applications like managing project timelines and budgets effectively.

- Data Analysis & Reporting: Develop skills in analyzing production data, identifying trends, and generating reports for management. Consider practical scenarios like using data analysis to optimize production efficiency or identify areas for improvement.

Next Steps

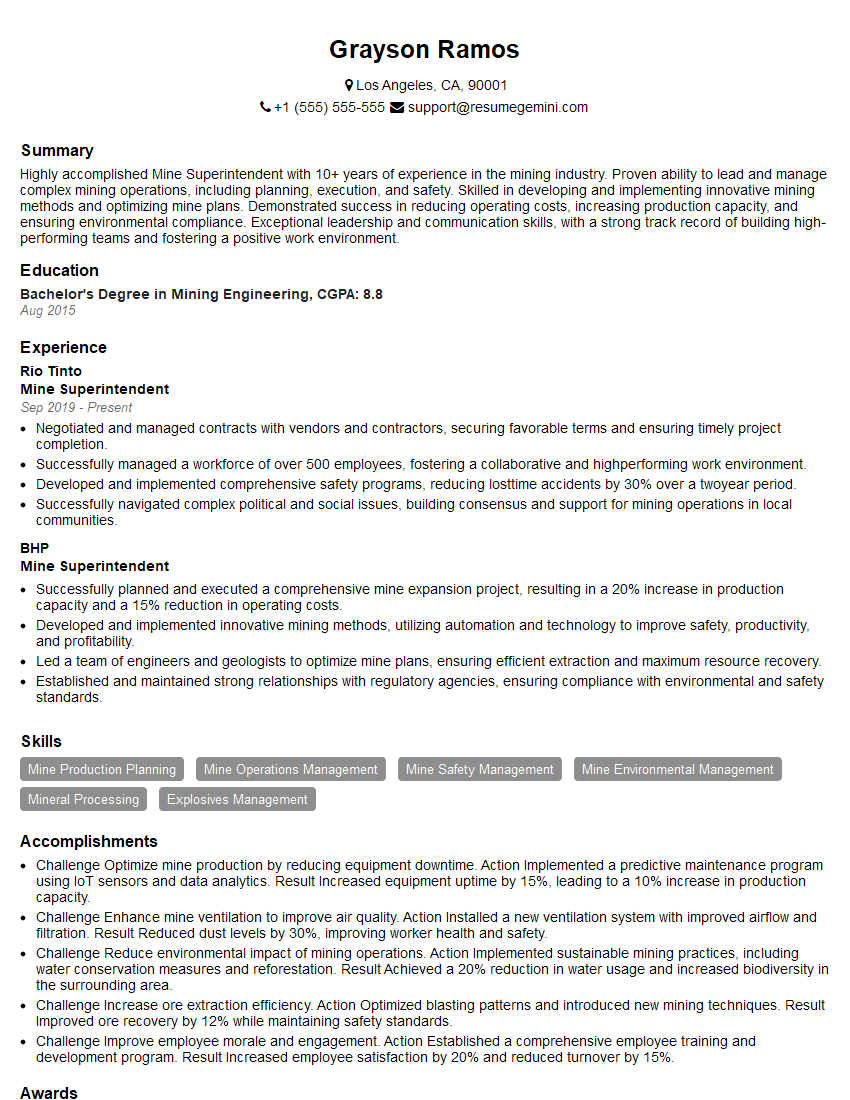

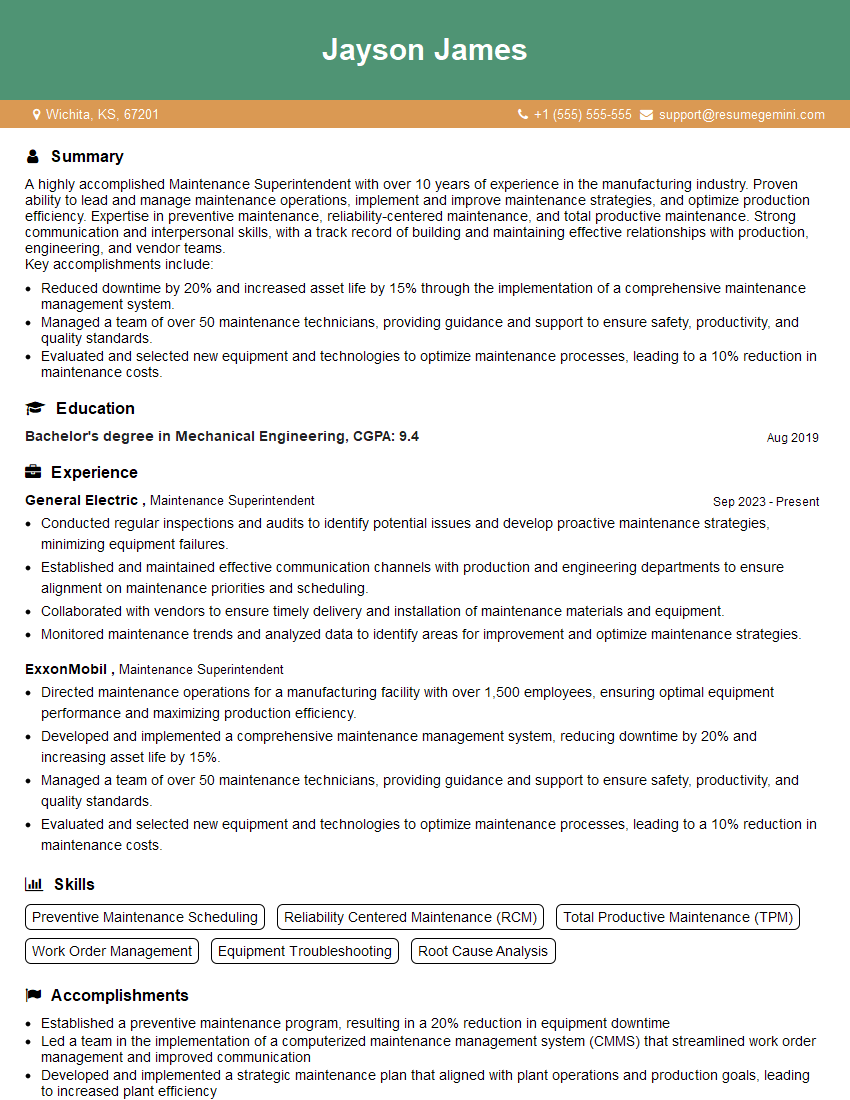

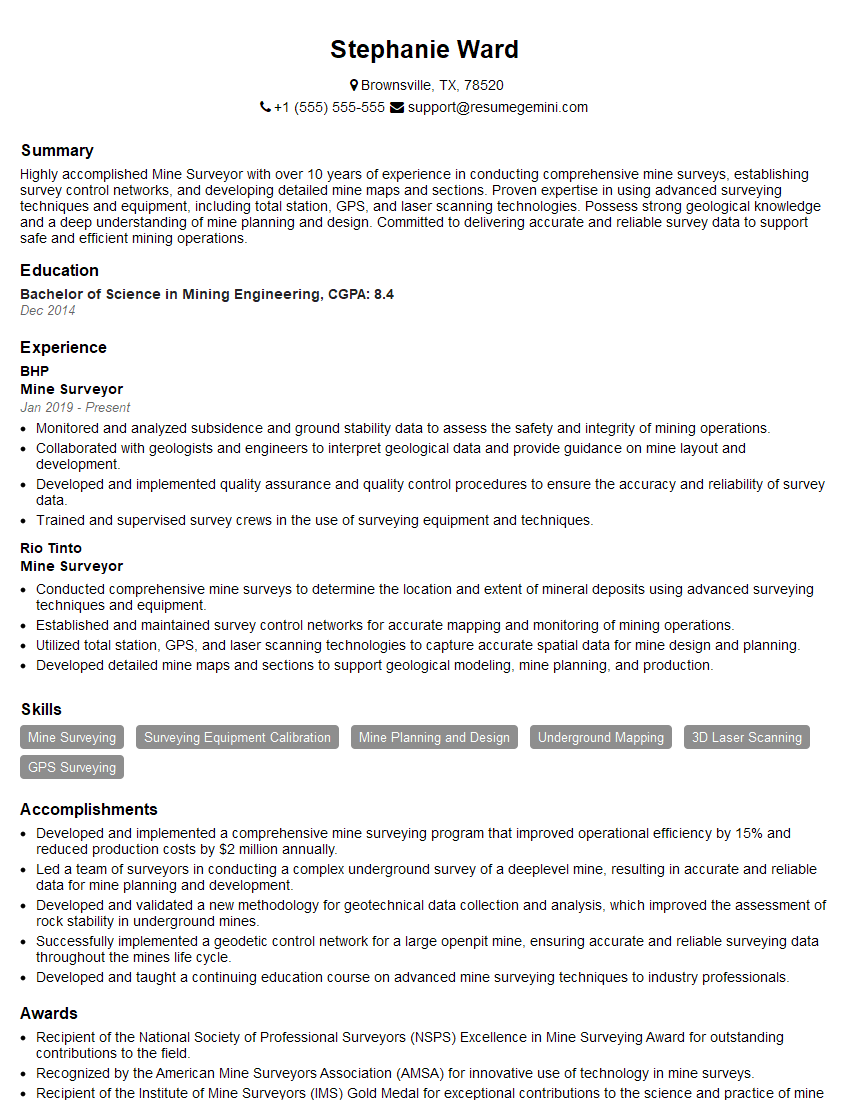

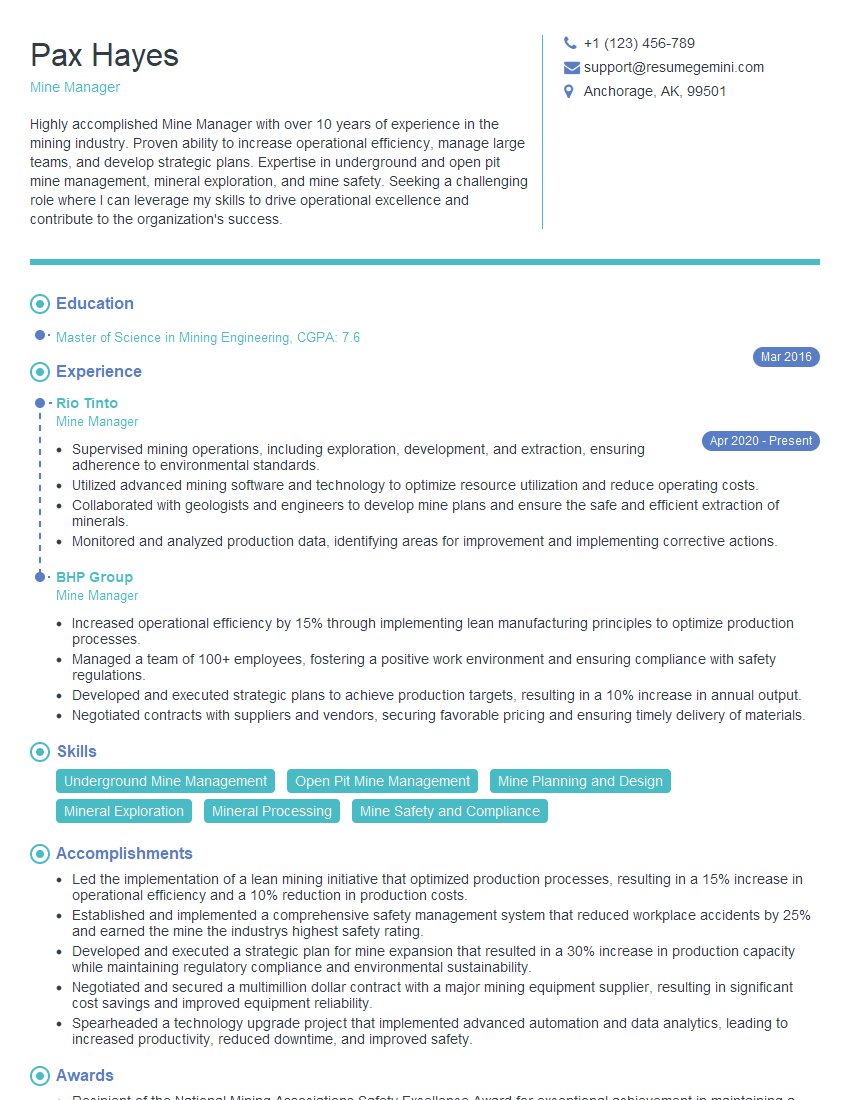

Mastering Mining Operations is crucial for career advancement in this dynamic industry. A strong understanding of these key areas demonstrates your technical expertise and problem-solving abilities, making you a highly competitive candidate. To maximize your job prospects, it’s essential to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Mining Operations to guide you through the process. Invest the time to craft a compelling resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good