Preparation is the key to success in any interview. In this post, we’ll explore crucial Molding Machine Troubleshooting interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Molding Machine Troubleshooting Interview

Q 1. Explain the common causes of short shots in injection molding.

Short shots, where the molded part is incompletely filled, are a common injection molding problem. Think of it like trying to fill a water balloon too quickly – you don’t get a perfectly full balloon.

- Insufficient Melt Volume: The most frequent cause. This happens when the injection pressure or speed is too low, the injection time is too short, or the melt flow rate is inadequate. Imagine trying to fill a large balloon with a tiny straw – it’ll take forever and might not even fill completely.

- Insufficient Back Pressure: This helps maintain consistent melt flow and prevent premature pressure drop in the mold. Low back pressure can lead to premature flow stoppage.

- Leakage in the Mold or System: Leaks in the mold itself, such as wear in the sprue bushing or gate, allow melt to escape before the part is fully formed. Imagine a hole in your water balloon – it won’t fill properly.

- Cooling Issues: Too-rapid cooling of the melt can cause premature solidification before the mold is completely filled. Like quickly cooling your water balloon with ice water, it freezes and doesn’t allow for expansion.

- Material Problems: High viscosity of the molten plastic or degraded material can restrict flow and lead to short shots.

- Gate Restriction: A small or partially clogged gate can restrict the melt flow into the mold cavity.

Troubleshooting involves systematically checking each of these areas, adjusting machine parameters, inspecting the mold for leaks, and evaluating the material.

Q 2. Describe the troubleshooting steps for a machine that is producing parts with excessive flashing.

Excessive flashing, where molten plastic escapes the mold cavity, is like having a poorly sealed container that leaks. It wastes material and creates defective parts.

- Clamp Tonnage Issues: Insufficient clamping force is a prime suspect. The mold doesn’t close tightly enough, allowing escape routes for the melt. This is like not screwing the lid of a jar tight enough, resulting in leakage.

- Mold Wear and Tear: Worn-out mold components, such as ejector pins or parting lines, can create gaps that allow the plastic to escape. Imagine an old, leaky container with cracks – it’s prone to leakage.

- Mold Temperature Issues: An excessively high mold temperature can reduce the viscosity of the plastic, making it easier to escape through small gaps. This is like having a very runny liquid in your container – it’ll leak easier.

- Injection Pressure Issues: Overly high injection pressure is another possible cause. Excessive pressure can force plastic through even small imperfections in the mold. This is like overfilling a container that already has a small gap; the pressure forces it out.

- Flash Land Problems: Improperly designed or worn flash lands – the areas where the mold halves meet – can allow flashing. This is like having an uneven seal on a container, causing leakage.

Troubleshooting involves careful inspection of the mold, checking the clamping force, adjusting injection pressure, monitoring mold temperature, and potentially repairing or replacing worn components.

Q 3. How do you identify and resolve issues related to air trapping in a mold?

Air trapping creates voids or bubbles within the molded part, weakening it and affecting its appearance. Think of trying to fill a container with a liquid that has already some air inside.

- Venting Issues: Insufficient venting in the mold allows air to become trapped. Think of a sealed container – there is no way for the air to escape.

- Mold Design Flaws: Poor mold design, like sharp corners or inadequate draft angles, can trap air. This is like creating small pockets in your container where air can hide.

- Injection Speed Issues: Injecting the melt too quickly can trap air before it has time to escape. This is like adding liquid too quickly; air doesn’t get a chance to exit.

- Material Properties: The material’s flow characteristics can impact air entrapment. Some materials are more prone to trapping air than others.

- Melt Temperature Issues: Incorrect melt temperature can influence the melt’s viscosity, affecting its ability to push air out of the mold cavity.

Resolving air trapping often involves improving venting by adding or enlarging vents in the mold, optimizing injection speed, adjusting melt temperature, or redesigning the mold to improve air flow. Careful mold design is crucial here.

Q 4. What are the key indicators of mold wear and tear, and how do you address them?

Mold wear is inevitable, leading to defects and reduced production efficiency. Think of an old, worn-out tool losing its precision.

- Parting Line Wear: The area where the two mold halves meet shows wear, leading to flash or misaligned parts. Visible damage or gaps are indicators.

- Ejector Pin Wear: Worn ejector pins can cause damage to parts, resulting in scratches or deformed features. Pins might be bent or broken.

- Cavity Wear: Erosion or scratches in the mold cavity cause surface imperfections on molded parts. This is seen as consistent defects on the part surface.

- Gate Wear: Wear on the gate can lead to short shots or flow issues. A gate that is too large or eroded will allow for leakage.

- Cooling Channel Clogging: Clogged cooling channels affect temperature control and part quality. This could be identified by uneven part cooling.

Addressing mold wear involves regular inspections, preventative maintenance such as polishing and chrome plating, and in severe cases, replacement of worn components.

Q 5. Explain the process for diagnosing and repairing a hydraulic leak in a molding machine.

Hydraulic leaks are serious, resulting in loss of pressure, reduced efficiency, and potential safety hazards. Think of a punctured water hose – it loses its pressure.

- Visual Inspection: Thoroughly inspect hydraulic lines, fittings, and cylinders for signs of leaks. Leaks can be obvious, but also small and subtle.

- Pressure Testing: Isolate sections of the hydraulic system and check for pressure drops, indicating leakage points. This requires specialized equipment.

- Leak Detection Dye: Add a fluorescent dye to the hydraulic fluid to help pinpoint leaks under ultraviolet light. This provides a precise location of the leak.

- Repair or Replacement: Repair leaks by tightening fittings, replacing seals, or repairing or replacing damaged components. This may require specialized tools and knowledge.

Safety is paramount when diagnosing and repairing hydraulic leaks. Always follow safety protocols, shut down the machine, and relieve pressure before attempting any repairs. Depending on the severity of the leak, it might require a qualified technician.

Q 6. Describe your experience with troubleshooting electrical issues in molding machines.

Troubleshooting electrical issues in injection molding machines requires a systematic approach and safety precautions. It’s like diagnosing a complex circuit in a computer.

- Safety First: Always disconnect power before working on any electrical components. Lockout/Tagout procedures are essential.

- Visual Inspection: Check for loose connections, frayed wires, burnt components, or other visible damage. Start by visually inspecting for any obvious problems.

- Circuit Testing: Use multimeters and other electrical testing equipment to check for voltage, current, and continuity in circuits. Test different components based on the observed issues.

- Component Replacement: Replace faulty components like relays, sensors, switches, or motor drives. Faulty components may need to be replaced.

- PLC Programming: Electrical issues can also stem from the PLC program. This often requires detailed knowledge of PLC programming to diagnose the issues.

My experience includes diagnosing and resolving issues related to motor control, sensor malfunctions, and PLC programming errors. I’m comfortable using various electrical testing equipment and applying appropriate troubleshooting methods.

Q 7. How do you troubleshoot issues related to inconsistent melt temperature?

Inconsistent melt temperature directly impacts part quality, leading to defects and inconsistencies. Think of baking a cake; inconsistent oven temperature leads to a poorly baked cake.

- Heater Issues: Check for faulty heaters, heater controllers, and wiring issues. This could be a malfunctioning heater, a thermostat that’s off, or wiring issues.

- Temperature Sensor Issues: Faulty temperature sensors provide inaccurate readings, leading to improper temperature control. A faulty sensor will misrepresent the temperature to the control system.

- Material Flow Issues: Issues with material flow, such as insufficient material or blockage, can affect melt temperature consistency. Poor material flow can affect the heat distribution.

- Cooling System Issues: An improperly functioning cooling system can affect melt temperature regulation. This will create inconsistent cooling of the melt.

- Control System Issues: Problems with the machine’s control system, such as PID controller settings, can cause inconsistencies. This usually requires adjustments of the controller settings.

Troubleshooting inconsistent melt temperature involves systematic checking of the heating system, sensors, material flow, cooling system, and control system settings, adjusting parameters as needed to ensure stability.

Q 8. What are the common causes of weld lines in injection molded parts, and how can they be minimized?

Weld lines, also known as knit lines, are visible imperfections in injection molded parts where two flows of molten plastic meet and fuse. They’re often weaker than the surrounding material and can affect the part’s aesthetics. Several factors contribute to their formation:

- Multiple injection points: The most common cause. When a part is too complex to fill from a single point, multiple gates are needed, resulting in weld lines where the flows merge.

- Inadequate melt flow: Insufficient melt flow can lead to slow filling and weak fusion at the weld line.

- Mold design flaws: Poorly designed gates, runners, or cooling channels can create flow imbalances and increase the likelihood of weld lines.

- Material properties: Some materials are more prone to visible weld lines than others.

- Processing conditions: High melt temperatures or injection pressures might improve fusion, but can also negatively impact part quality.

Minimizing weld lines involves a multi-pronged approach:

- Optimal gate location and design: Strategic placement of gates can minimize the length and visibility of weld lines. Subtle changes in gate design can significantly improve flow.

- Mold temperature control: Maintaining consistent mold temperature ensures uniform melt flow.

- Injection pressure and speed adjustments: Carefully adjusting these parameters can help achieve a balance between complete filling and minimized weld line formation.

- Material selection: Some materials are naturally less prone to weld line formation.

- Part design optimization: Simplifying the part design to allow filling from fewer gates can greatly reduce weld lines. This often requires collaboration with design engineers.

For instance, I once worked on a project where a complex part had significant weld lines. By redesigning the gate location and optimizing the injection parameters, we successfully reduced the weld lines’ visibility and improved the part’s strength.

Q 9. Explain the process for calibrating and maintaining a molding machine’s pressure sensors.

Calibrating and maintaining pressure sensors in a molding machine is crucial for accurate process control and consistent part quality. The process typically involves these steps:

- Preparation: Disconnect the power to the machine for safety. Consult the machine’s manual to identify the sensor location and access points.

- Verification: Using a calibrated pressure gauge, compare the readings from the machine’s sensors against the gauge’s measurements. This is usually done at multiple pressure points within the sensor’s range.

- Calibration: If discrepancies exist, the sensor needs calibration. This might involve adjusting the sensor’s internal settings or even replacing it. Calibration procedures vary depending on the sensor’s type, and proper training is essential.

- Documentation: Meticulously document all calibration steps, including date, time, readings, and any corrective actions. This ensures traceability and helps track sensor performance over time.

- Regular maintenance: Regular inspection of the sensors for any damage, dirt or debris is critical. Cleaning sensors and checking their wiring connections will help ensure long-term accuracy.

An example of a calibration procedure would involve using a deadweight tester, which provides a known and precise pressure, to check the sensor’s accuracy. Any deviation from the expected reading indicates the need for adjustment or replacement.

Q 10. How do you identify and troubleshoot problems related to the clamping system of an injection molding machine?

The clamping system is vital for holding the mold halves together during injection. Troubleshooting clamping system issues usually starts with a visual inspection for:

- Hydraulic leaks: Check hydraulic lines and cylinders for leaks. A slow leak can lead to insufficient clamping force.

- Mechanical issues: Inspect tie bars, toggle mechanisms, and other mechanical components for wear, damage, or misalignment. Unusual noises often indicate mechanical problems.

- Sensor malfunctions: Check the sensors that monitor clamp position and pressure. A faulty sensor can lead to incorrect clamping force.

- Hydraulic pressure problems: Insufficient hydraulic pressure will affect clamping force. This requires checking the hydraulic pump, accumulator, and related components.

If a problem is identified, I would approach troubleshooting systematically. For example, if there’s a hydraulic leak, I would first try to identify the source of the leak, and then repair or replace the damaged component. If the problem is due to a faulty sensor, I would either recalibrate the sensor or replace it. If the problem is caused by insufficient hydraulic pressure, I would investigate the reasons for that and rectify them. Documentation of every step and findings is vital for future reference and preventing similar problems.

Q 11. Describe your experience with troubleshooting problems related to the screw and barrel of an injection molding machine.

The screw and barrel are the heart of the injection molding machine, responsible for melting and conveying the plastic. Troubleshooting problems in this area requires a thorough understanding of material properties and processing parameters. Common problems include:

- Screw wear: Excessive wear can lead to reduced plasticizing efficiency and inconsistent melt flow. This can manifest as poor part quality, short shots, or excessive pressure drops.

- Barrel wear or corrosion: Wear on the barrel’s internal surface can cause similar issues to screw wear. Corrosion can be caused by material degradation or improper cleaning.

- Insufficient plasticizing: Insufficient heat or mixing can result in incomplete melting and uneven flow, producing defects like short shots or inconsistent part weight.

My approach to troubleshooting involves checking several aspects:

- Visual inspection: A visual inspection of the screw and barrel can reveal wear or damage. Close attention should be given to the flighting and barrel surface for scoring or discoloration.

- Temperature monitoring: Monitoring barrel temperature zones is essential for detecting inconsistencies and potential overheating.

- Melt flow analysis: This helps assess plasticizing efficiency and identify potential issues.

- Pressure monitoring: Consistent pressure fluctuations can indicate a problem with the screw or barrel.

In one instance, I diagnosed a production issue involving inconsistent part weights. By meticulously analyzing pressure and temperature profiles, along with a visual inspection of the screw, we discovered a minor crack in the barrel, which was causing the fluctuations and leading to inadequate plasticizing.

Q 12. What are the safety procedures you follow when troubleshooting molding machinery?

Safety is paramount when troubleshooting molding machinery. My standard safety procedures always include:

- Lockout/Tagout (LOTO): Before any work, the machine must be completely shut down and locked out, using LOTO procedures to prevent accidental start-up.

- Personal Protective Equipment (PPE): Appropriate PPE such as safety glasses, gloves, and hearing protection must be worn at all times.

- Proper training: Only trained and authorized personnel should undertake troubleshooting activities.

- Risk assessment: Assessing potential hazards before starting any work is crucial. This involves identifying potential risks and implementing control measures to minimize them.

- Emergency procedures: Familiarizing oneself with the machine’s emergency shutdown procedures and knowing the location of safety equipment is essential.

- Proper handling of materials: Handling hot parts and molten plastic requires careful procedures and appropriate tools.

I always follow the company’s safety regulations and adhere to best practices to ensure the safety of myself and others around me. Prioritizing safety is non-negotiable.

Q 13. How do you interpret and use process parameters (pressure, temperature, time) to diagnose molding problems?

Process parameters like pressure, temperature, and time are critical for diagnosing molding problems. Analyzing these parameters provides insights into various aspects of the molding process:

- Pressure: Injection pressure, holding pressure, and clamping pressure are vital indicators of melt flow, packing, and mold closure. Inconsistent pressure may point to problems with the hydraulic system, mold sealing, or screw performance.

- Temperature: Barrel, nozzle, and mold temperatures affect melt viscosity and flow. Uneven temperatures can lead to part defects like warping, sink marks, or weld lines.

- Time: Injection time, holding time, and cooling time impact the part’s properties. Excessive or insufficient time in any of these stages can result in defects.

By closely monitoring and analyzing these parameters, I can pinpoint the root cause of many molding problems. For example, if I observe consistently low injection pressure, it might indicate a problem with the hydraulic system or the screw. If the cooling time is insufficient, it might cause warping in the finished part. A systematic approach to data analysis, often using statistical process control (SPC) charts, allows for early detection and effective solutions.

Q 14. Describe your experience using various diagnostic tools (e.g., pressure gauges, temperature sensors, thermocouples).

I have extensive experience using various diagnostic tools for troubleshooting injection molding machines. These include:

- Pressure gauges: Essential for measuring hydraulic and melt pressure at various points in the machine, providing insights into hydraulic system performance and melt flow characteristics.

- Temperature sensors and thermocouples: Precise measurement of barrel, nozzle, and mold temperatures is critical for diagnosing thermal-related issues, like uneven heating or insufficient cooling.

- Melt flow index (MFI) testers: Measuring the melt flow index of the material helps determine its processability and identify potential material-related problems.

- Data acquisition systems (DAS): DAS allows for simultaneous monitoring and recording of multiple process parameters, aiding in identifying trends and patterns associated with specific defects. This helps build a comprehensive picture of the molding process over time.

- Visual inspection tools: Microscopes or magnifying glasses are sometimes needed to examine minute details of the molded parts for defects such as short shots, weld lines, burn marks, or other imperfections.

My proficiency in using these tools helps me accurately diagnose problems and implement effective solutions. For example, using a thermocouple to carefully map mold temperature profiles helped me identify a cold spot in a mold, causing warping in the finished part. The ability to integrate information from multiple tools is what facilitates successful troubleshooting in complex situations.

Q 15. How familiar are you with different types of molding machines (e.g., horizontal, vertical, two-plate)?

My experience encompasses a wide range of molding machine types. I’m very familiar with horizontal, vertical, and two-plate molding machines, understanding their unique operational characteristics and common failure points. Horizontal machines, for example, are often used for larger parts and require specific attention to clamping force and mold alignment. Vertical machines excel in high-speed, high-volume production of smaller parts, with troubleshooting often centering around ejection mechanisms and nozzle issues. Two-plate machines, while simpler, require careful attention to mold design and material flow. My understanding extends to the nuances of each type, including their control systems and hydraulic/pneumatic components.

- Horizontal: Think of these as the workhorses for larger, more complex parts. Troubleshooting often involves checking platen parallelism and clamping force.

- Vertical: Ideal for high-speed production of smaller items. Ejection system failures and nozzle issues are common challenges.

- Two-Plate: Simpler in design, but precision is key. Mold design and material flow are crucial aspects for successful operation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience troubleshooting problems related to material degradation or discoloration.

Material degradation and discoloration are significant problems in molding. Troubleshooting involves a systematic approach. First, I’d analyze the affected material, checking for signs of oxidation, thermal degradation, or contamination. This often involves examining the material’s properties before and after processing, including melt flow index (MFI) testing. Then, I investigate the molding process itself. Is the material being subjected to excessive heat? Is there insufficient venting in the mold? Are there any contaminants in the machine or the material itself? For example, discoloration can be caused by thermal degradation (too high a melt temperature) or contamination from previous batches or the machine’s components (e.g., residues in the barrel or nozzle). I’ve had instances where seemingly minor factors like inconsistent drying of hygroscopic materials led to considerable discoloration and brittleness.

My approach involves careful observation, material testing, and analysis of the process parameters to pinpoint the exact cause. This is followed by implementing corrective actions such as adjusting processing parameters, cleaning the machine thoroughly, and ensuring proper material handling and storage.

Q 17. How do you maintain detailed records of troubleshooting activities and repairs?

Maintaining detailed records is crucial for effective troubleshooting and preventative maintenance. I utilize a combination of methods. A computerized maintenance management system (CMMS) tracks all maintenance activities, repairs, and part replacements, providing a central repository of information. I also maintain physical logs including detailed notes on troubleshooting steps, observations, measurements, and outcomes for each issue. Photographs and even short videos can be invaluable for documenting the problem and solution. This detailed documentation allows for efficient problem solving in the future and facilitates identifying trends or patterns that may indicate underlying systemic issues within the molding process or the equipment itself. For example, a detailed log might note the date, time, problem description (e.g., ‘Cycle time increase on machine #3’), steps taken, parts replaced, and the final resolution. This creates a valuable historical record for continuous improvement.

Q 18. How do you prioritize troubleshooting tasks based on urgency and impact on production?

Prioritization is critical. I use a system that considers both urgency and impact. I employ a matrix prioritizing tasks based on the severity of the problem and its potential effect on production. For example, a complete machine shutdown (high urgency, high impact) takes precedence over a minor cosmetic defect (low urgency, low impact). A partially functioning machine with reduced output (medium urgency, medium impact) would fall somewhere in between. Using this matrix helps ensure that resources are allocated effectively to maximize production uptime and minimize losses. Regularly scheduled preventative maintenance tasks are also included in the schedule to reduce the frequency of major repairs and unscheduled downtime.

Q 19. Describe a time you had to troubleshoot a complex molding machine problem. What was your approach?

One time, we experienced inconsistent part quality on a high-speed vertical injection molding machine. Parts were exhibiting warping and sink marks. My initial approach was systematic: I began by ruling out obvious issues. The material was fresh and properly dried, and the mold temperature was within specification. I then meticulously checked the mold itself for any wear or damage—finding none. The next step was analyzing the machine’s process parameters: injection pressure, speed, hold time, and cooling time. It turned out that the hold pressure was fluctuating, causing inconsistent filling of the mold cavity. By carefully examining the pressure readings and hydraulic system, we discovered a small leak in a pressure regulator. Replacing the regulator instantly solved the problem and restored consistent part quality. This experience reinforced the value of systematic troubleshooting, beginning with the simplest checks and progressively moving to more complex system components.

Q 20. What preventative maintenance steps do you recommend for molding machines?

Preventative maintenance is crucial for maximizing molding machine uptime and minimizing unexpected failures. I recommend a comprehensive program including:

- Regular lubrication: All moving parts require regular lubrication schedules, following the manufacturer’s recommendations.

- Hydraulic system checks: Inspecting fluid levels, filters, and pressure gauges regularly to detect potential leaks or contamination.

- Electrical system inspection: Checking wiring, connections, and safety devices to prevent electrical hazards.

- Mold maintenance: Regular cleaning, inspection for wear, and timely repairs are essential.

- Barrel and screw cleaning: Periodically cleaning the barrel and screw to remove accumulated material and prevent degradation.

- Temperature monitoring and calibration: Ensuring accurate temperature control is critical for consistent part quality.

- Scheduled downtime: Including dedicated time for thorough inspections and preventative maintenance tasks.

A well-defined PM schedule, tailored to the specific machine and its operating conditions, is essential. It significantly reduces the risk of unexpected failures and extends the machine’s lifespan.

Q 21. How do you identify and address the root cause of recurring molding problems?

Recurring problems require a root cause analysis (RCA) approach. This goes beyond simply fixing the immediate symptom and aims to identify and eliminate the underlying cause. I usually follow these steps:

- Data collection: Gathering comprehensive data about the problem, including frequency, severity, and any contributing factors.

- 5 Whys analysis: Repeatedly asking ‘Why?’ to drill down to the root cause. For example, ‘Why is the part warping?’ ‘Because the cooling is uneven.’ ‘Why is the cooling uneven?’ ‘Because the cooling lines are clogged.’

- Fishbone diagram: Using a cause-and-effect diagram to visually represent potential causes and their relationships. This helps in brainstorming.

- Corrective actions: Implementing permanent solutions to address the root cause, not just the symptoms.

- Verification: Monitoring the system after implementing corrective actions to verify their effectiveness.

By systematically investigating the root cause and implementing effective solutions, we can prevent the recurrence of the problem and improve overall process reliability.

Q 22. What are your experiences with different types of plastics and their molding characteristics?

My experience encompasses a wide range of plastics, each with unique molding characteristics requiring tailored approaches. For example, polypropylene (PP) is known for its relatively low melt viscosity, making it suitable for thin-walled parts but prone to warping if not carefully cooled. In contrast, polycarbonate (PC) possesses high melt viscosity, demanding higher injection pressures and temperatures to achieve complete filling, but it offers superior impact resistance. I’ve worked extensively with ABS (Acrylonitrile Butadiene Styrene), known for its good balance of properties and ease of processing, as well as polystyrene (PS) which is easier to mold but less durable. Understanding the melt flow index (MFI), the glass transition temperature (Tg), and the crystallization behavior of each plastic is crucial for optimizing the molding process and preventing defects like short shots, sink marks, or warpage. I’ve successfully troubleshooted issues arising from material degradation, inappropriate processing parameters, and material incompatibility.

- Polypropylene (PP): Prone to warping; requires precise cooling control.

- Polycarbonate (PC): High melt viscosity; needs higher injection pressure and temperature.

- ABS: Good balance of properties; relatively easy to mold.

- Polystyrene (PS): Easy to mold, but less durable.

Q 23. Describe your proficiency in reading and interpreting schematics and blueprints related to molding machines.

Reading and interpreting schematics and blueprints is fundamental to my work. I’m proficient in understanding hydraulic schematics, identifying component locations (e.g., valves, pumps, sensors), tracing fluid flow paths, and diagnosing potential problems based on the design. I can effectively use electrical schematics to troubleshoot wiring issues, trace signal paths, and identify faulty components within the control system. My experience includes working with both 2D and 3D CAD drawings, allowing me to visualize the machine’s physical layout and understand the interaction between different components. For instance, I once used schematics to pinpoint a leak in the hydraulic system by tracing the fluid lines and identifying a faulty valve based on pressure readings. This led to a quick repair minimizing downtime.

I am comfortable with various notations and symbols used in industrial drawings and can easily identify specific components, such as pressure transducers, proximity sensors, and actuators, and understand their roles within the larger system. I consider myself adept in interpreting and using this information to solve complex problems.

Q 24. What experience do you have with PLC programming and troubleshooting in the context of molding machines?

I possess extensive experience with PLC programming and troubleshooting, specifically using Siemens and Allen-Bradley PLCs. I’m proficient in ladder logic programming, troubleshooting PLC programs using diagnostic tools, and modifying programs to optimize machine performance. My expertise extends to identifying and resolving issues related to input/output (I/O) signals, timer and counter functions, and communication protocols used in molding machines. For example, I once resolved a production halt caused by a faulty sensor by using the PLC’s diagnostic capabilities to pinpoint the erroneous signal, then adjusting the program’s input conditions to compensate. I also have experience programming safety relays and ensuring compliance with relevant safety standards.

// Example ladder logic code snippet (illustrative): IF (Sensor_1) THEN Output_1 := TRUE; ELSE Output_1 := FALSE; END_IF; This simple example shows how I would use PLC code to control an output based on a sensor input. In a real-world scenario, this could be controlling a clamp, ejector, or other critical component of the molding machine.

Q 25. Describe your familiarity with different types of mold designs and their associated troubleshooting needs.

My familiarity with mold designs extends to various types, including hot runner molds, cold runner molds, and multi-cavity molds. Each design presents unique troubleshooting challenges. For instance, hot runner molds require understanding the temperature control system and troubleshooting issues related to nozzle leaks or inconsistent melt flow. Cold runner molds, while simpler, can still experience issues such as air trapping or improper venting. Multi-cavity molds introduce complexities related to ensuring consistent filling and part quality across all cavities. I’m experienced in identifying problems such as flash, short shots, sink marks, and weld lines, and diagnosing their root causes in relation to mold design. I understand the importance of proper mold venting, parting line design, and cooling systems in achieving high-quality parts consistently. I’ve worked with mold designers to implement improvements, such as modifying cooling channels to address warpage or adding additional vents to reduce air trapping.

Q 26. How do you ensure the safety of yourself and others when working with molding machinery?

Safety is my paramount concern. I rigorously follow all safety protocols, including lockout/tagout procedures before performing any maintenance or repair on molding machinery. I’m trained in identifying and mitigating potential hazards, such as pinch points, high-pressure hydraulic lines, and electrical hazards. I ensure the proper use of personal protective equipment (PPE), such as safety glasses, gloves, hearing protection, and steel-toed shoes. I regularly inspect machinery for safety concerns and report any issues immediately. Moreover, I actively promote a safety-conscious work environment by training others and fostering open communication about potential hazards. Before any work commences, I always perform a thorough risk assessment. This is essential to identify potential hazards and devise appropriate control measures. This proactive approach has always been my priority and is a cornerstone of my work philosophy.

Q 27. How do you stay up-to-date on the latest technologies and best practices in molding machine troubleshooting?

Staying current in this rapidly evolving field requires a multi-faceted approach. I actively participate in industry conferences and workshops, attending seminars and webinars to learn about the latest technologies and best practices. I regularly review technical publications, journals, and online resources to keep abreast of advancements in molding machine design and troubleshooting techniques. I also maintain professional networks with other engineers and technicians, engaging in discussions and sharing best practices. Furthermore, I continually seek opportunities for professional development, including pursuing certifications to enhance my skills and knowledge base. This commitment to continuous learning allows me to offer my clients the most advanced and effective solutions to their challenges.

Q 28. What are your salary expectations?

My salary expectations are commensurate with my experience and expertise in the field, and I’m open to discussing a competitive compensation package that reflects my value to your organization. I am confident that my skills and experience will contribute significantly to your team’s success.

Key Topics to Learn for Molding Machine Troubleshooting Interview

- Hydraulic Systems: Understanding hydraulic pressure, flow control, and troubleshooting common hydraulic failures (leaks, low pressure, overheating). Practical application: Diagnosing and resolving a hydraulic pump malfunction leading to inconsistent clamping force.

- Pneumatic Systems: Knowledge of air pressure regulation, cylinder operation, and troubleshooting pneumatic components (valves, actuators). Practical application: Identifying and repairing a faulty air pressure regulator causing inconsistent ejection of molded parts.

- Electrical Systems: Familiarity with motor controls, sensors, PLCs (Programmable Logic Controllers), and troubleshooting electrical circuits. Practical application: Diagnosing and repairing a faulty proximity sensor causing cycle interruptions.

- Molding Process Understanding: Comprehensive knowledge of the injection molding process, including material properties, cycle parameters, and their impact on part quality. Practical application: Adjusting process parameters to eliminate short shots or flash.

- Preventive Maintenance: Understanding scheduled maintenance procedures, lubrication techniques, and the importance of proactive maintenance to minimize downtime. Practical application: Developing and implementing a preventative maintenance schedule for a specific molding machine.

- Troubleshooting Techniques: Systematic approaches to fault diagnosis, including using diagnostic tools, interpreting error codes, and utilizing troubleshooting charts. Practical application: Applying a structured troubleshooting methodology to identify the root cause of a recurring molding defect.

- Safety Procedures: Understanding and adhering to all relevant safety regulations and procedures when working with molding machinery. Practical application: Implementing lock-out/tag-out procedures before performing maintenance.

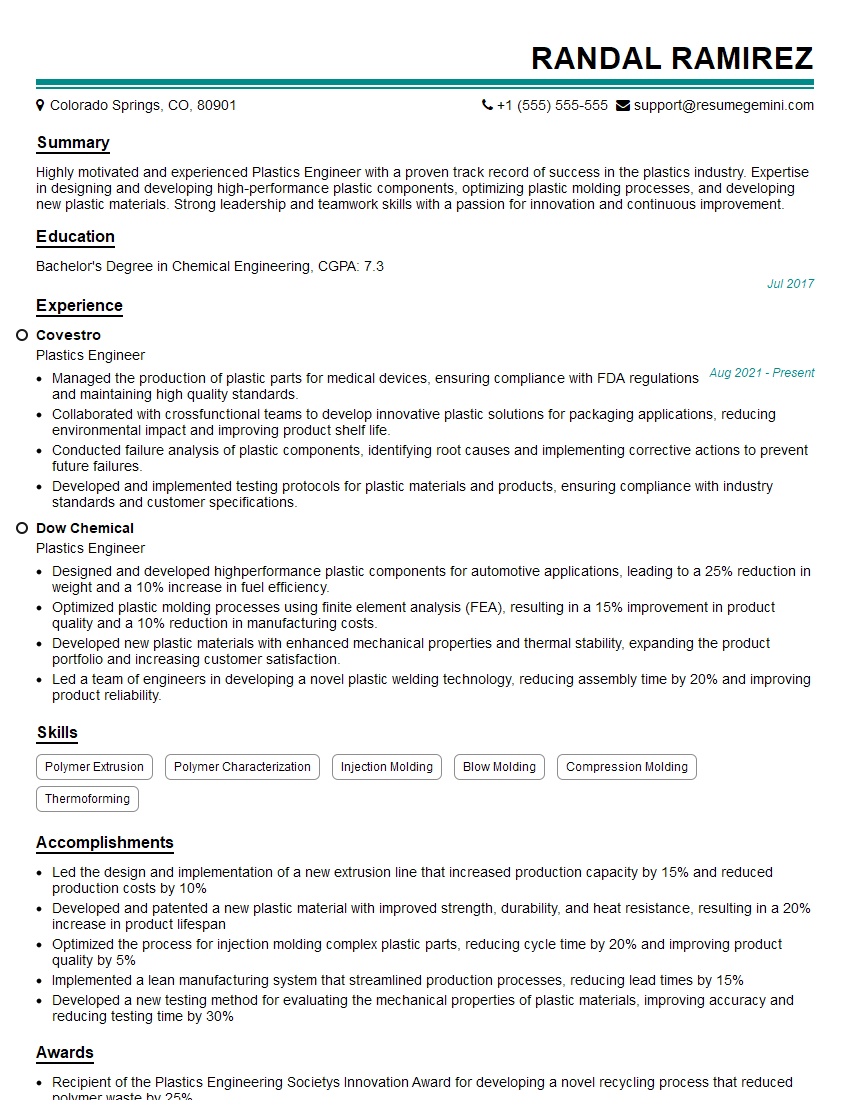

Next Steps

Mastering Molding Machine Troubleshooting is crucial for career advancement in manufacturing. A deep understanding of these systems allows you to become a highly valued asset, leading to increased responsibility and earning potential. To enhance your job prospects, invest time in creating a strong, ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Molding Machine Troubleshooting are available to guide you, showcasing best practices for presenting your qualifications effectively. Take this opportunity to present yourself in the best possible light and land your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good