Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Molding Machines interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Molding Machines Interview

Q 1. Explain the different types of molding processes.

Molding processes encompass various techniques to shape materials into desired forms using molds. The choice of process depends on factors like material properties, part complexity, production volume, and cost. Here are some key types:

- Injection Molding: The most common method, involving injecting molten material into a mold cavity under high pressure. It’s ideal for high-volume production of complex parts. Think of plastic bottles, car parts, or even smartphone casings.

- Compression Molding: Material is placed into a heated mold cavity, and then compressed to fill the mold. Often used for thermosetting plastics like fiberglass-reinforced polymers. Think of some electrical components or cookware handles.

- Transfer Molding: Similar to compression molding but the material is first preheated and transferred to the mold cavity, leading to more uniform part quality. This is employed in the production of some high-precision components.

- Blow Molding: Molten plastic is extruded into a tube (parison) which is then inflated inside a mold to form a hollow shape. Think of bottles, containers, and toys.

- Rotational Molding: Powdered or liquid plastic is placed inside a rotating mold. The mold’s rotation and heat cause the material to distribute evenly and form a hollow shape. This method creates large, hollow parts with even wall thickness, like kayaks or large storage tanks.

Q 2. Describe the operating principles of an injection molding machine.

An injection molding machine operates on a cyclical process. Imagine it as a highly precise and automated cookie-cutter for plastic. Here’s a breakdown:

- Clamping: The mold halves are tightly clamped together to prevent leakage during injection.

- Injection: Molten plastic, heated to a precise temperature, is injected at high pressure into the mold cavity. This is a crucial step, requiring carefully calibrated pressure and speed.

- Dwelling: The molten plastic is held under pressure for a specific time to allow complete filling and to compensate for material shrinkage.

- Cooling: The mold is cooled to solidify the plastic part within the cavity. The cooling time is precisely controlled to achieve desired material properties.

- Ejection: Once the plastic is solidified, the mold opens and ejector pins push the molded part out of the mold. We use highly engineered ejector pins to avoid damaging the molded product.

- Mold Closing: The mold closes, and the cycle repeats.

The entire process is controlled by sophisticated hydraulic and electronic systems, ensuring consistent product quality and high production rates.

Q 3. What are the common causes of molding defects?

Molding defects can be frustrating, but understanding their causes is key to prevention. These are some common culprits:

- Short Shots: Insufficient material filling the mold cavity, often due to low injection pressure, insufficient melt temperature, or mold restriction.

- Flashing: Molten plastic escaping between the mold halves, usually caused by insufficient clamping force or mold wear.

- Sink Marks: Surface depressions caused by uneven cooling or material shrinkage. This is commonly seen in thicker sections of the molded part.

- Warping: Distortion of the part after ejection, often due to uneven cooling or internal stresses. This issue can significantly impact part functionality and appearance.

- Weld Lines: Visible lines where two plastic flows merge. They might weaken the part and can be a cosmetic defect, depending on the part and the application.

- Burn Marks: Scorching of the plastic near the mold gate, often resulting from overheating.

Identifying the specific defect is the first step towards solving the issue.

Q 4. How do you troubleshoot a molding machine malfunction?

Troubleshooting a molding machine malfunction requires a systematic approach. Here’s a strategy:

- Safety First: Always ensure the machine is powered down and locked out before any maintenance or troubleshooting.

- Identify the Problem: Pinpoint the specific malfunction – is it a mechanical issue, a hydraulic problem, or an electrical fault? What are the error codes?

- Check the Obvious: Look for simple issues like material jams, loose connections, or insufficient coolant.

- Consult Manuals & Diagnostics: Use the machine’s operator manuals and diagnostic tools to guide your troubleshooting. Many modern machines have integrated systems for error detection.

- Systematic Elimination: If the problem is not immediately apparent, methodically check each component of the machine, systematically eliminating possibilities.

- Seek Expert Help: If you can’t resolve the issue, don’t hesitate to contact qualified service technicians or the machine manufacturer.

Maintaining detailed records of maintenance and troubleshooting efforts is crucial for preventing future issues.

Q 5. What safety procedures must be followed when operating molding machines?

Safety is paramount when operating molding machines. Always follow these procedures:

- Lockout/Tagout (LOTO): Before any maintenance or repair, perform LOTO procedures to ensure the machine is completely de-energized and cannot be accidentally restarted.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, hearing protection, and gloves. Heavy-duty work gloves are usually advised.

- Machine Guards: Ensure all safety guards are in place and functioning correctly before operating the machine. Never bypass or remove safety guards.

- Emergency Shut-off: Familiarize yourself with the location and operation of the emergency shut-off switch.

- Training: Ensure all operators are properly trained on safe operating procedures and emergency response protocols before working with the machines.

- Regular Inspection: Regularly inspect the machine for any signs of wear, damage, or potential hazards.

Regular safety training and adherence to procedures significantly reduce the risk of accidents.

Q 6. Explain the role of clamping force in injection molding.

Clamping force is crucial in injection molding. It’s the force that holds the mold halves together during the injection process. Think of it as the grip strength needed to prevent the molten plastic from escaping the mold cavity under high pressure.

Insufficient clamping force leads to flashing (molten plastic escaping between the mold halves), resulting in defective parts. Excessive clamping force, on the other hand, can damage the mold and increase wear and tear on the machine. The optimal clamping force depends on several factors such as part design, material properties, and mold size. It’s a critical parameter that needs to be carefully controlled for consistent and high-quality production.

Q 7. What is the significance of melt temperature in the molding process?

Melt temperature is the temperature of the molten plastic during the injection process. It directly impacts several aspects of the molding process:

- Material Flow: An appropriate melt temperature is needed for proper material flow within the mold cavity. Too low, and the plastic will be too viscous and won’t fill the mold completely; too high, and it can lead to degradation or burning of the material. This temperature directly impacts the ability of the material to flow properly, filling all details of the mold.

- Part Properties: The melt temperature influences the final properties of the molded part, including its strength, stiffness, and surface finish. Precise control over the melt temperature is crucial to ensure that parts meet the required specifications.

- Cycle Time: The cooling time, and therefore the overall cycle time, is affected by the melt temperature. Higher melt temperatures can lead to faster cooling, but only if it doesn’t degrade the material properties.

Maintaining the correct melt temperature is essential for producing high-quality, consistent parts. This is often carefully managed by the injection molding machine’s computer controls.

Q 8. How do you adjust the injection pressure and speed?

Adjusting injection pressure and speed is crucial for controlling the quality of molded parts. Injection pressure dictates how forcefully the molten plastic is injected into the mold cavity, influencing part density and filling. Injection speed controls the rate at which the plastic enters the mold, impacting surface finish and potential for defects like weld lines.

These parameters are typically adjusted via the molding machine’s control panel, often a touchscreen interface. The specific controls will vary depending on the machine manufacturer and model, but common adjustments include:

- Injection Pressure: This is usually expressed in PSI (pounds per square inch) or bar. Increasing the pressure generally leads to denser parts, but excessive pressure can cause flash (excess material spilling over the mold) or damage the mold. You’d increase pressure if you’re seeing short shots (parts not completely filled) or air pockets.

- Injection Speed: This is often expressed as a percentage of the machine’s maximum speed or in millimeters per second. A slower injection speed promotes better surface finish and reduces the likelihood of weld lines (visible seams where molten plastic flows meet). However, excessively slow speeds can lead to longer cycle times. You’d decrease injection speed if you observe surface imperfections or weld lines.

Experienced molders often use a combination of pressure and speed adjustments to optimize the molding process. For instance, a high injection speed in the initial phase of filling can ensure rapid cavity filling, followed by a lower speed and higher pressure during the holding phase to compensate for material shrinkage and ensure complete filling.

Q 9. Describe the process of mold changeover.

Mold changeover is the process of removing one mold from a molding machine and replacing it with another. It’s a critical step in flexible manufacturing, enabling the production of different parts using the same equipment. It’s a process that requires precision and safety.

The steps generally include:

- Machine Shutdown and Cooling: Safely shut down the molding machine and allow the mold to cool completely to avoid burns or damage.

- Ejection of Remaining Parts: Carefully remove any parts remaining in the mold.

- Mold Removal: Using the appropriate lifting equipment (e.g., a crane or hoist), carefully remove the mold from the machine. This often involves releasing clamping mechanisms.

- Mold Cleaning: Clean the removed mold to remove any residual plastic or debris. This prevents contamination of the new mold.

- New Mold Installation: Carefully install the new mold, ensuring proper alignment and secure clamping.

- Machine Setup: Configure the molding machine settings (injection pressure, speed, temperature, etc.) for the new mold and material. This might involve changing process parameters saved in the machine’s memory.

- Testing: Run a few test shots to verify proper part formation, dimensional accuracy, and overall quality before full-scale production.

Proper documentation and standardized procedures are crucial to minimize downtime and ensure consistency during mold changeovers. A well-organized tool kit and readily available parts also speed up the process significantly. Think of it like changing a tire – a systematic approach minimizes errors and maximizes efficiency.

Q 10. How do you maintain and clean molding equipment?

Maintaining and cleaning molding equipment is essential for optimal performance, part quality, and equipment longevity. This involves both routine cleaning and scheduled preventative maintenance.

Cleaning:

- Regular Cleaning: Daily cleaning focuses on removing plastic residue from the mold, sprue, and nozzle. This prevents build-up that can lead to defects and machine damage. Compressed air and appropriate solvents are typically used.

- Mold Cleaning: Regular thorough cleaning of the mold itself is crucial. This can involve using specialized cleaning agents to remove burnt or stuck plastic.

- Machine Surfaces: Keep the machine’s external surfaces clean and free of debris to avoid accidents and ensure proper functionality.

Maintenance:

- Hydraulic System: Regular checks and maintenance of the hydraulic system, including oil changes and filter replacements, are critical for preventing leaks and ensuring consistent pressure.

- Heating and Cooling Systems: Monitor heating and cooling system performance. This includes checking temperature sensors and ensuring proper fluid flow.

- Electrical Systems: Regular inspection of electrical components and wiring prevents electrical failures.

Maintaining a detailed cleaning and maintenance log is essential for tracking work done and identifying potential issues before they become major problems.

Q 11. Explain the importance of preventative maintenance.

Preventative maintenance (PM) is proactive maintenance aimed at preventing equipment failures and extending its lifespan. It’s significantly more cost-effective than reactive maintenance (fixing problems after they occur). In molding, preventative maintenance reduces downtime, improves part quality, and enhances safety.

A good PM program includes:

- Regular Inspections: Scheduled inspections of all machine components, including hydraulics, electrics, and the mold itself. These checks identify potential problems early, allowing for timely repairs.

- Scheduled Lubrication: Regular lubrication of moving parts reduces friction and wear, preventing premature failure.

- Filter Changes: Regular replacement of hydraulic and air filters ensures clean fluids and air flow, preventing contamination and clogging.

- Calibration: Periodic calibration of temperature sensors and pressure gauges ensures accuracy and consistency.

Implementing a comprehensive PM program requires a detailed schedule and trained personnel. Think of it like regular car maintenance – regular oil changes and checkups prevent major breakdowns down the road, saving you time and money in the long run.

Q 12. What are the different types of mold materials?

Mold materials must withstand high temperatures, pressures, and the corrosive effects of molten plastics. The choice of material depends on the application, the type of plastic being molded, and the required mold lifespan.

Common mold materials include:

- Tool Steel: A widely used material, offering high strength, hardness, and wear resistance. Different grades of tool steel exist, offering varying properties for different applications.

- Pre-hardened Tool Steel: Provides good machinability and requires less post-processing compared to traditional tool steel. Good for less demanding applications.

- Aluminum: Lighter and easier to machine than steel. It’s often used for prototypes or molds with shorter lifespans. Less durable than steel.

- Beryllium Copper (BeCu): Offers high strength, excellent electrical conductivity, and good thermal conductivity. Used for molds requiring high precision and complex geometries.

- Maraging Steel: Very high strength and toughness. Used for large or complex molds requiring superior durability.

Choosing the right mold material is a crucial aspect of mold design. A poorly chosen material can lead to premature mold failure, increased downtime, and significant costs.

Q 13. How do you identify and address common mold problems?

Identifying and addressing mold problems requires a systematic approach. Common mold problems can range from cosmetic defects to severe mechanical failures.

Common Problems and Solutions:

- Short Shots: (Incomplete filling of the mold cavity) – Check injection pressure, speed, melt temperature, and potential mold restrictions.

- Flash: (Excess material leaking between mold halves) – Check mold clamping pressure, injection pressure, and mold parting lines.

- Sink Marks: (Indentations on the part’s surface) – Adjust melt temperature and injection pressure. Consider mold design improvements.

- Weld Lines: (Visible seams where plastic flows meet) – Reduce injection speed, optimize gate location, or consider better mold design.

- Burn Marks: (Discoloration or damage due to excessive heat) – Lower melt temperature, adjust mold cooling, or improve mold venting.

- Warping: (Distortion of the molded part) – Adjust mold temperature, optimize part design, or adjust cooling system settings.

Troubleshooting often involves careful observation of the molded parts and the molding process itself. Understanding the relationship between machine parameters and part quality is key to effectively addressing these issues. Keeping detailed records of adjustments and their outcomes is crucial for learning and improvement.

Q 14. What is the purpose of a sprue, runner, and gate?

The sprue, runner, and gate are integral components of the mold’s gating system. They control the flow of molten plastic from the injection nozzle into the mold cavity. Imagine them as a highway system for the plastic.

- Sprue: The main channel through which the molten plastic enters the mold. It’s the largest channel and connects the nozzle to the runner system.

- Runner: A network of channels that distributes the molten plastic from the sprue to individual gate locations in the mold.

- Gate: The small opening through which the molten plastic enters the mold cavity. The gate design influences the flow of the plastic and significantly affects the final part quality.

The design of the sprue, runner, and gate system is crucial. Poor design can lead to flow problems, weld lines, or air entrapment. Optimizing this system ensures efficient plastic flow and high-quality molded parts. Various gate types exist (e.g., tab gate, edge gate, hot runner), each offering different characteristics depending on the molded part and material.

Q 15. Describe the function of a cooling system in an injection molding machine.

The cooling system in an injection molding machine is crucial for solidifying the molten plastic after it fills the mold cavity. Think of it like rapidly cooling a hot liquid to form a solid shape. Without efficient cooling, the plastic wouldn’t harden properly, leading to deformed parts or incomplete molding cycles. The system typically uses water, chilled water, or oil circulated through channels within the mold. These channels, known as cooling lines, are strategically placed to ensure even cooling across the part. The temperature of the cooling medium is precisely controlled to achieve the desired cooling rate, affecting factors like cycle time and part quality. Insufficient cooling can lead to warping or sink marks in the molded part, while excessive cooling can cause internal stresses and cracking.

A typical system consists of a chiller unit to maintain the coolant temperature, a pump to circulate the coolant, and the cooling lines integrated into the mold itself. The temperature is monitored via sensors located near the mold, providing real-time feedback to the control system, enabling adjustments to optimize the cooling process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of cycle time in molding.

Cycle time in injection molding refers to the total time required to complete one molding cycle. It’s a critical parameter influencing productivity and profitability. Imagine it as the time it takes to bake a single cake from start to finish – the entire process. This cycle encompasses several stages: mold closing, injection (filling the mold with molten plastic), holding (maintaining pressure), cooling, mold opening, and ejection (removal of the molded part). Each stage contributes to the overall cycle time. Reducing the cycle time means producing more parts per hour, ultimately increasing output.

Several factors affect cycle time: the size and complexity of the part, the type of plastic used, the mold design (including the number and placement of cooling lines), and the machine’s clamping force and injection speed. Optimizing cycle time often involves fine-tuning these parameters, perhaps using simulation software to predict the effects of changes before implementing them in the actual machine. For example, increasing the cooling rate can significantly shorten the cycle, but this needs careful consideration to avoid stress cracking in the finished part.

Q 17. How do you measure and control the melt flow index (MFI)?

Melt flow index (MFI), also known as melt index, measures the ease with which a thermoplastic polymer can flow. Imagine squeezing toothpaste from a tube; a higher MFI means the toothpaste flows out more easily. It’s crucial for controlling the viscosity of the molten plastic during the injection molding process. A lower MFI indicates a higher viscosity (thicker consistency), while a higher MFI indicates a lower viscosity (thinner consistency).

MFI is measured using a standardized test method (ASTM D1238) with a melt indexer. This device extrudes a known amount of molten plastic through a precisely sized die under specific temperature and weight conditions. The amount of plastic extruded in a set time is then measured and reported as the MFI. Control is achieved by adjusting the processing temperature of the resin; higher temperatures generally result in a higher MFI. The material’s inherent properties also influence the MFI, so selecting the right resin grade is critical for consistent molding results. Careful control of the MFI ensures consistent flow behavior of the melt in the molding machine.

Q 18. What are the various types of resins used in molding?

The world of molding resins is vast, but they can be broadly categorized into thermoplastics and thermosets. Thermoplastics, like those used for common plastic bottles, soften when heated and can be remolded repeatedly. Thermosets, such as epoxy resins, undergo an irreversible chemical change upon curing, hardening permanently into their molded shape.

- Thermoplastics: These include Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), Polystyrene (PS), Acrylonitrile Butadiene Styrene (ABS), Polycarbonate (PC), and Polyetheretherketone (PEEK). Each has unique properties like strength, flexibility, heat resistance, and chemical resistance, making them suitable for different applications.

- Thermosets: Examples are Epoxy, Phenolic, and Polyester resins. They offer superior strength and heat resistance compared to many thermoplastics but can’t be melted and reshaped.

The choice of resin depends on the desired properties of the final molded part and the molding process itself. For instance, ABS is commonly used for durable housings, while PC offers high impact resistance for safety critical components. Selecting the correct resin is paramount to achieving the desired performance characteristics in the final product.

Q 19. How do you ensure the quality of molded parts?

Ensuring the quality of molded parts is a multifaceted process involving meticulous attention to detail throughout the entire molding cycle. Imagine baking a cake – you need the right ingredients, temperature, and baking time to get a perfect result. Similarly, in molding, several steps contribute to quality control.

- Material Selection: Choosing the right resin with consistent properties.

- Mold Design and Maintenance: Proper design and regular inspection/maintenance of the mold to prevent defects like flash (excess material escaping the mold) or sink marks (indentations).

- Process Parameter Control: Precise control over injection pressure, temperature, and cooling rates.

- In-Process Monitoring: Using sensors to monitor key parameters in real time and detect anomalies.

- Post-Molding Inspection: Thorough visual inspection for defects and dimensional accuracy. Statistical Process Control (SPC) helps analyze the data and detect trends indicating potential problems.

- Testing: Mechanical testing (tensile strength, impact resistance) to verify that the molded parts meet the required specifications.

Employing a robust quality control system throughout the process is essential for maintaining consistent part quality and minimizing waste. Implementing a well-defined quality management system, perhaps ISO 9001, provides a framework to accomplish this.

Q 20. Explain the use of different types of tooling in molding.

Tooling in injection molding encompasses the molds used to shape the molten plastic. Different tooling types are employed depending on factors like part complexity, production volume, and material properties.

- Single-cavity molds: Produce one part per molding cycle; simple, cost-effective for low-volume production.

- Multi-cavity molds: Produce multiple parts simultaneously; boosts productivity for high-volume applications.

- Family molds: Produce multiple different parts in a single mold; efficient for manufacturing several components.

- Insert molds: Use inserts within the mold to create intricate features or embed metal components in the plastic parts.

- Overmolding molds: Mold one plastic over another, such as molding plastic onto a metal core.

The selection of tooling is a critical decision impacting the cost and efficiency of the molding process. Factors to consider are the number of cavities, the need for inserts or overmolding, the material’s thermal properties, and the desired part accuracy and surface finish. The tooling’s design must be optimized for manufacturability and maintainability, contributing significantly to the long-term success of the process.

Q 21. What is the difference between hot runner and cold runner molds?

The primary difference between hot runner and cold runner molds lies in how the molten plastic is delivered to the mold cavities. Imagine a cake baking – the hot runner is like having a pipe directly supplying the batter to each individual cake cup, while the cold runner requires you to pour a large batch of batter into a tray and let it distribute amongst the cups.

Hot runner molds use heated manifolds and nozzles to keep the plastic molten within the mold, eliminating the need for runners (the channels that carry the melt to the cavities) to be cut off the finished parts. This reduces material waste and improves cycle time, but increases the initial tooling cost. Cold runner molds, on the other hand, require the plastic to flow through runners that solidify and must be removed from the molded parts as excess material. This results in material waste and added post-processing steps, but the initial tooling cost is usually lower. The choice between hot and cold runner molds depends largely on the production volume and the acceptable level of material waste. High-volume production usually justifies the higher initial investment of hot runner molds to save on material and labor costs.

Q 22. How does automation play a role in modern molding processes?

Automation is revolutionizing modern molding processes, significantly improving efficiency, consistency, and product quality. Think of it as having a highly skilled, tireless worker constantly monitoring and adjusting the machine.

- Increased Efficiency: Automated systems handle tasks like material handling, injection, clamping, and ejection, reducing manual labor and cycle times. For example, robotic arms can quickly transfer molded parts to the next stage of production, eliminating bottlenecks.

- Improved Consistency: Automation minimizes human error, resulting in parts with more uniform dimensions and properties. Precise control over parameters like injection pressure, temperature, and clamping force ensures consistent quality across the entire production run.

- Enhanced Quality Control: Automated systems often incorporate vision systems and sensors to perform real-time quality checks. Defective parts are immediately identified and rejected, preventing flawed products from reaching the customer.

- Data Acquisition and Analysis: Modern molding machines are equipped with sophisticated data acquisition systems. This data provides insights into process performance, allowing for proactive adjustments and predictive maintenance, reducing downtime and maximizing uptime.

For instance, an automated injection molding system might incorporate a robotic system for part removal, a vision system for quality inspection, and a sophisticated control system for managing the entire process, resulting in significantly higher throughput and consistent quality compared to a manually operated system.

Q 23. What are the environmental considerations in plastics molding?

Environmental considerations are paramount in plastics molding due to the industry’s impact on resource consumption and waste generation. Sustainable practices are crucial for minimizing environmental footprint.

- Material Selection: Choosing recycled or bio-based plastics reduces reliance on virgin materials derived from fossil fuels. The use of sustainable materials is a significant step towards reducing carbon emissions and promoting a circular economy.

- Energy Efficiency: Optimizing machine settings and using energy-efficient equipment minimizes energy consumption during the molding process. Implementing energy-saving measures, like using heat recovery systems, significantly reduces energy costs and greenhouse gas emissions.

- Waste Reduction: Minimizing material waste through efficient mold design and process optimization is essential. Implementing strategies to reclaim and reuse excess materials minimizes waste sent to landfills.

- Emissions Control: Controlling emissions from the molding process is vital. This involves using proper ventilation systems and employing technologies to capture and treat volatile organic compounds (VOCs) released during molding.

- End-of-Life Management: Addressing the end-of-life management of plastic products through design for recyclability and developing effective recycling infrastructure is crucial to prevent plastic waste accumulation in landfills and the environment.

A company might, for example, invest in a machine using recycled PET flakes to produce food containers, simultaneously reducing landfill waste and using a sustainable material. This holistic approach minimizes the environmental impact across the entire product lifecycle.

Q 24. Explain the concept of statistical process control (SPC) in molding.

Statistical Process Control (SPC) is a powerful methodology used to monitor and control the molding process to ensure consistent product quality. Think of it as a detective constantly looking for patterns and inconsistencies within the production process.

SPC relies on collecting and analyzing data from the molding machine. Control charts, like X-bar and R charts, are used to graphically display this data, showing the process mean and variability over time. By monitoring these charts, we can identify trends and patterns that signal potential problems before they lead to significant product defects. Control limits are established based on historical data, and any data points falling outside these limits indicate a process that is out of control, requiring immediate investigation and corrective actions.

For example, if the wall thickness of a molded part consistently deviates from the target value over several cycles, indicated by points outside the control limits on an X-bar chart, this indicates a potential problem. This could be due to variations in material viscosity, injection pressure, or mold temperature, all requiring further investigation and adjustment.

SPC is not just about detecting problems; it also helps optimize the process. By identifying and addressing small variations before they escalate, SPC ensures that the molding process remains stable and consistently produces high-quality parts.

Q 25. How do you interpret process parameters from machine data?

Interpreting process parameters from machine data involves understanding the relationship between machine settings and the resulting product quality. This requires a deep understanding of the molding process and the specific machine being used.

Machine data typically includes parameters like:

- Injection Pressure: Too high, and you risk part deformation; too low, and you might have insufficient filling.

- Melt Temperature: Incorrect temperature can lead to inconsistent flow and poor surface finish.

- Mold Temperature: This influences cooling rate and part shrinkage.

- Clamp Force: Insufficient clamping can cause flash, while excessive force can damage the mold.

- Cycle Time: Monitoring cycle time helps identify bottlenecks and areas for process optimization.

I use data analysis tools and statistical methods to identify trends and patterns in this data. For example, a sudden increase in cycle time might indicate a problem with the cooling system, while a consistent drift in injection pressure could point to a leak in the hydraulic system. By analyzing these trends, I can diagnose the root cause of the problem and implement corrective actions.

In addition to looking at individual parameters, I look at the correlations between them. For example, a change in melt temperature might affect injection pressure and cycle time. Understanding these correlations helps in determining the most effective adjustments to optimize the process.

Q 26. Describe your experience with different types of molding machines (e.g., injection, blow, rotational).

My experience encompasses a wide range of molding machines, including injection molding, blow molding, and rotational molding. Each process presents unique challenges and requires specialized knowledge.

- Injection Molding: This is the most common type, used for high-volume production of complex parts. My experience includes working with various injection molding machines, from small benchtop models to large, high-tonnage machines, and troubleshooting issues related to mold design, material selection, and process optimization. I am proficient in programming and operating these machines, as well as performing preventative maintenance.

- Blow Molding: I’ve worked with both extrusion blow molding and injection blow molding processes, creating hollow parts such as bottles and containers. My expertise extends to understanding the relationships between parison parameters, blow pressure, and final product quality.

- Rotational Molding: This process is ideal for producing large, hollow parts. My experience includes working with various sizes of rotational molding machines and understanding the impact of rotation speed, mold temperature, and resin viscosity on the final product.

I am familiar with the specific challenges of each process and have extensive experience in selecting the appropriate machine and process parameters based on the product design and material requirements.

Q 27. How do you handle emergencies or unexpected situations during machine operation?

Handling emergencies or unexpected situations requires a calm, systematic approach. My first priority is always safety.

My approach follows these steps:

- Assess the situation: Immediately identify the nature of the problem and any immediate safety hazards. This might involve shutting down the machine, evacuating personnel, or isolating the affected area.

- Isolate the problem: Determine the source of the problem. Is it a hydraulic leak? A faulty sensor? An electrical issue? This might involve checking gauges, sensors, and other critical components.

- Implement temporary fixes: If possible, implement temporary fixes to minimize downtime. This might involve bypassing a faulty component or using a backup system. Safety should always come first.

- Contact support: If the problem is beyond my expertise, I’ll contact the machine manufacturer or a qualified technician for assistance. I document all observations and data to aid troubleshooting.

- Perform root cause analysis: Once the problem is resolved, I conduct a thorough root cause analysis to prevent similar incidents in the future. This might involve reviewing maintenance logs, adjusting operating parameters, or improving safety procedures.

For example, if a hydraulic leak is observed, I’d immediately shut down the machine and contact maintenance to repair the leak. A thorough inspection of the hydraulic system would then be carried out to prevent further incidents. Documentation of the event is vital, including the date and time, the type of fault, the actions taken, and any subsequent analysis to ensure preventative measures are in place.

Q 28. Describe a time you had to troubleshoot a complex molding machine problem.

I once encountered a complex issue with an injection molding machine where parts were consistently exhibiting sink marks. Sink marks are indentations on the surface of a molded part indicating that the material didn’t fully fill the mold cavity. This was costing us a large amount of scrap.

My troubleshooting involved:

- Data Analysis: I reviewed process parameters and machine data, noticing no significant variations in injection pressure, melt temperature, or mold temperature. The initial suspicion was an issue with mold design.

- Visual Inspection: I carefully inspected the mold, discovering that a small vent channel was partially blocked with resin debris. This blockage restricted the flow of air, preventing proper venting during the molding cycle.

- Corrective Action: The blocked vent channel was cleared, and a preventative maintenance procedure was implemented to regularly check for such blockages.

- Process Optimization: After clearing the vent, I also made minor adjustments to the injection speed and holding pressure to further optimize the filling of the mold cavity.

This resolved the issue of sink marks. Through careful analysis and a systematic approach, I not only solved the immediate problem but implemented preventative measures to minimize the risk of similar issues occurring in the future. This case highlights the importance of thorough mold maintenance and the benefits of preventative measures.

Key Topics to Learn for Molding Machines Interview

- Machine Types & Processes: Understand the differences between injection molding, blow molding, compression molding, and other common processes. Be prepared to discuss the advantages and limitations of each.

- Material Science & Properties: Demonstrate knowledge of various plastics and their properties (e.g., thermoplastics, thermosets). Discuss how material selection impacts the molding process and final product quality.

- Mold Design & Construction: Explain the key components of a mold, including the cavity, core, runner system, and ejector pins. Discuss different mold designs and their applications.

- Process Parameters & Optimization: Understand the influence of factors like injection pressure, temperature, clamping force, and cycle time on the quality and efficiency of the molding process. Be ready to discuss troubleshooting techniques for common process issues.

- Quality Control & Inspection: Describe methods used to ensure the quality of molded parts, including visual inspection, dimensional measurement, and material testing. Be familiar with common defects and their causes.

- Automation & Robotics: Discuss the role of automation in modern molding operations, including robotic handling, automated material feeding, and process monitoring systems.

- Maintenance & Troubleshooting: Explain common maintenance procedures and troubleshooting strategies for molding machines. Demonstrate your understanding of preventative maintenance and its importance.

- Safety Procedures & Regulations: Highlight your awareness of safety protocols and regulations relevant to operating and maintaining molding machines.

Next Steps

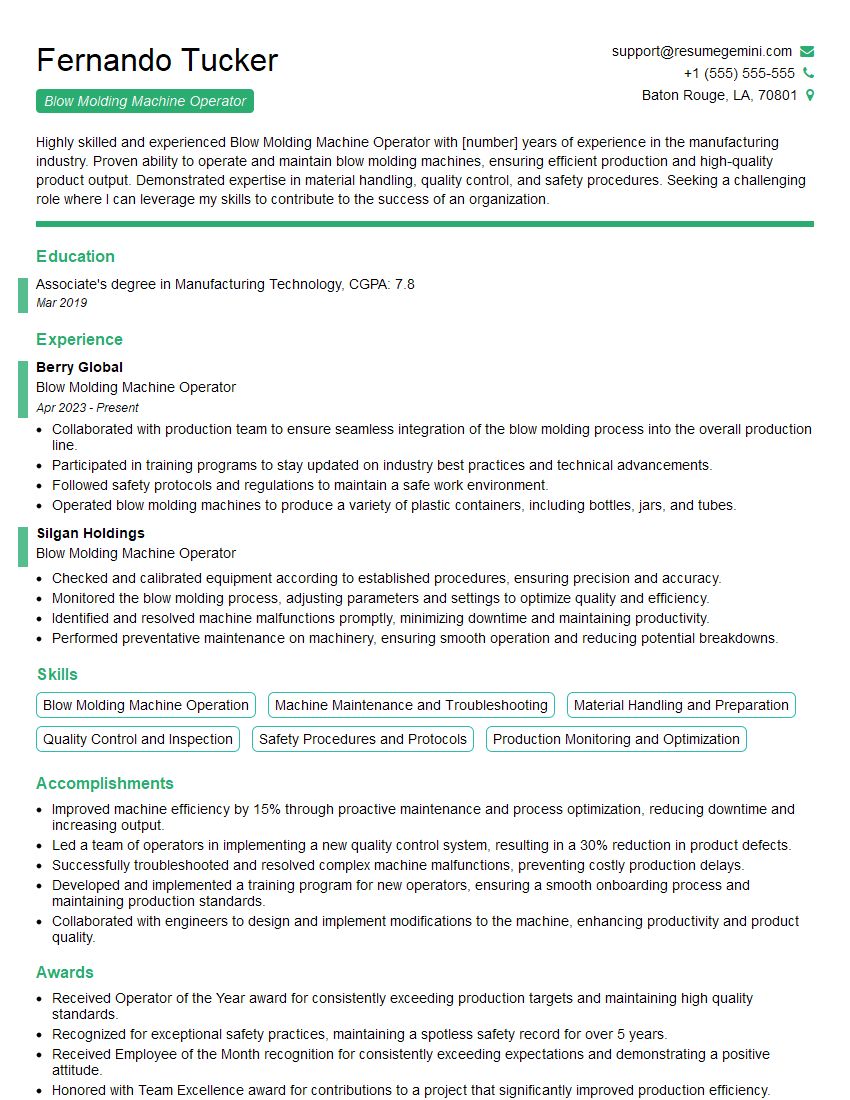

Mastering the intricacies of molding machines significantly enhances your career prospects in manufacturing, providing a strong foundation for advancement and specialization. To unlock your full potential, a well-crafted resume is essential. An ATS-friendly resume increases your visibility to potential employers. We strongly encourage you to use ResumeGemini to build a professional and impactful resume that showcases your skills and experience in Molding Machines. ResumeGemini provides examples of resumes tailored to the specific requirements of this field, helping you present yourself effectively to recruiters.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good