Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Molding Operation interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Molding Operation Interview

Q 1. Explain the difference between injection molding and blow molding.

Injection molding and blow molding are both plastic processing techniques, but they differ significantly in their method and the types of parts they produce. Imagine making a bottle versus a small gear.

Injection Molding: This process involves injecting molten plastic under high pressure into a closed mold cavity. The plastic fills the cavity, cools, and solidifies to form the part. Think of it like filling a cupcake tin with batter – the batter is the molten plastic, the tin is the mold, and the cooled cupcake is the finished part. Injection molding is ideal for creating complex, high-precision parts with intricate details, such as gears, electronic components, or automotive parts.

Blow Molding: In contrast, blow molding uses a heated plastic tube (parison) which is clamped within a mold. Air is then blown into the parison, forcing it to expand and conform to the mold cavity’s shape. This process is similar to blowing up a balloon inside a mold; the balloon is the parison, and the mold shapes the balloon into the desired form. Blow molding is excellent for manufacturing hollow objects like bottles, containers, and toys.

- Key Difference Summary: Injection molding creates solid parts from molten plastic injected under pressure, while blow molding creates hollow parts by inflating a heated plastic tube within a mold.

Q 2. Describe the process of setting up a molding machine.

Setting up a molding machine is a multi-step process that requires precision and attention to detail. Think of it as preparing a complex recipe – each step is crucial for the final outcome.

- Mold Installation: Carefully place the mold into the machine, ensuring proper alignment and secure clamping. This step is critical; misalignment can lead to defects.

- Material Selection and Loading: Select the appropriate resin pellets based on the part design and specifications. Load the hopper with the chosen material, ensuring a consistent flow to prevent starvation during the molding cycle.

- Machine Parameter Setting: This is the heart of the setup. Parameters such as injection pressure, injection speed, mold temperature, back pressure, and cooling time need to be carefully set based on the material properties and the part design. This often requires iterative adjustments during trial runs. Think of this as fine-tuning the recipe’s ingredients and cooking time.

- Cycle Test and Adjustment: Run several trial cycles to monitor the quality of the produced parts. Adjust parameters as necessary to achieve the desired dimensions, surface finish, and other quality characteristics. This iterative process ensures optimal performance.

- Safety Check: Before starting full production, thoroughly inspect the machine and its components for any potential hazards or malfunctions. Safety should always be a top priority.

Q 3. How do you troubleshoot a common molding defect like flash or short shots?

Flash and short shots are two common molding defects that require different troubleshooting approaches.

Flash: Flash is excess material that escapes from the mold cavity during the injection process. It’s like batter overflowing from the cupcake tin. It usually appears as thin, irregular lines along the parting line of the mold.

- Troubleshooting Flash:

- Check Clamp Pressure: Insufficient clamp pressure can allow the mold to open slightly during injection, leading to flash. Increase the clamp pressure to resolve this.

- Mold Condition: Inspect the mold for damage or wear, especially around the parting line. Replace or repair any damaged components.

- Material Viscosity: Too low viscosity can lead to flash. Adjust the melt temperature or choose a resin with higher viscosity.

Short Shots: Short shots occur when the mold cavity is not completely filled with plastic. This results in incomplete parts, with the plastic failing to reach the end of the cavity. Imagine only half of your cupcake batter filling the tin.

- Troubleshooting Short Shots:

- Injection Pressure and Speed: Low injection pressure or speed can lead to short shots. Increase these parameters, but avoid exceeding the machine’s capacity or causing damage.

- Gate Size: Restricted gate flow can prevent the mold from filling completely. Ensure an adequate gate size for the part design and material.

- Melt Temperature: Low melt temperature increases viscosity, hindering flow. Increase the melt temperature, but again, take care to avoid degradation of the plastic.

- Vent Issues: Air trapped in the mold can impede the flow of plastic. Improve venting in the mold by adding or adjusting venting channels.

Q 4. What are the key parameters to monitor during a molding cycle?

Monitoring key parameters during a molding cycle is critical for maintaining consistent part quality and optimizing the process. Think of it like monitoring the vital signs of a patient during surgery.

- Melt Temperature: Ensures consistent viscosity and flow.

- Mold Temperature: Affects the cooling rate and part shrinkage.

- Injection Pressure and Speed: Influences the mold fill and part density.

- Clamp Pressure: Prevents mold opening and flash formation.

- Back Pressure: Controls melt homogeneity and reduces degradation.

- Cycle Time: The time taken for the complete molding cycle, which includes injection, holding, cooling and ejection.

- Part Dimensions: Checks conformance to specifications.

- Weight: Ensures consistency in material usage.

Continuous monitoring of these parameters enables quick identification and rectification of any deviations, leading to increased efficiency and reduced scrap.

Q 5. Explain the role of mold temperature in the molding process.

Mold temperature plays a crucial role in determining the final properties and quality of molded parts. It directly influences the cooling rate of the molten plastic within the mold cavity.

Higher Mold Temperatures: Result in slower cooling, potentially leading to increased cycle times but also allowing for better flow and reduced stress within the part. This can be beneficial for complex geometries or materials prone to warping.

Lower Mold Temperatures: Result in faster cooling, leading to shorter cycle times but may also increase the likelihood of sink marks, warpage, or internal stresses. This approach is often preferred for thin-walled parts or when cycle time is critical.

The optimal mold temperature depends on several factors, including the type of resin, part geometry, and desired properties of the finished part. Experimentation and careful monitoring are essential to determine the ideal setting for each application. Think of it as choosing the right oven temperature for baking – too high and the cake burns, too low and it remains undercooked.

Q 6. How do you maintain and clean molding equipment?

Regular maintenance and cleaning are essential for ensuring the longevity and efficiency of molding equipment. Think of it as regularly servicing your car to prevent major breakdowns.

- Regular Cleaning: After each production run, remove any excess resin from the mold, sprue, and other machine components. Use appropriate cleaning solvents and follow the manufacturer’s recommendations.

- Mold Maintenance: Inspect the mold regularly for wear, tear, or damage. Repair or replace damaged components promptly to prevent defects or machine downtime. Regular polishing can improve the surface finish of the molded parts.

- Machine Lubrication: Follow the manufacturer’s lubrication schedule to ensure smooth operation and prevent premature wear of moving parts.

- Preventative Maintenance: Implement a preventive maintenance program that includes periodic inspections, component replacements, and adjustments. This reduces the risk of unexpected breakdowns and improves overall machine efficiency.

- Safety Precautions: Always follow established safety procedures when performing maintenance or cleaning tasks. Lockout/Tagout procedures should be adhered to before beginning any maintenance activities.

Q 7. Describe your experience with different types of molding resins.

My experience encompasses a wide range of molding resins, including thermoplastics and thermosets.

- Thermoplastics: I’ve worked extensively with materials like Polypropylene (PP), Polyethylene (PE), Polystyrene (PS), Acrylonitrile Butadiene Styrene (ABS), and Polycarbonate (PC). Each material exhibits unique properties regarding melt flow, strength, flexibility, and heat resistance. For example, PP is known for its flexibility and chemical resistance, making it suitable for containers and housings, while PC offers high impact strength and transparency, ideal for lenses or automotive components.

- Thermosets: My experience includes working with materials like Polyurethane (PU) and Epoxy resins. These materials undergo irreversible chemical changes during curing, resulting in strong and rigid parts. They are often used in applications requiring high strength and durability. For example, PU is frequently used in automotive parts due to its impact resistance and flexibility.

Understanding the unique properties of each resin is critical for selecting the appropriate material for a given application and optimizing the molding process parameters accordingly. Material selection heavily influences part quality, cost, and performance characteristics.

Q 8. What safety precautions do you follow while operating molding machinery?

Molding machinery presents inherent risks, so safety is paramount. My approach is multifaceted, beginning with rigorous adherence to all safety protocols outlined in the machinery’s operating manual and company’s safety regulations. This includes mandatory personal protective equipment (PPE), such as safety glasses, hearing protection, and steel-toed boots. Before operating any machine, I perform a thorough pre-operational inspection, checking for any loose parts, fluid leaks, or signs of malfunction. I never operate equipment if I’m unsure of its safety or if it needs maintenance. Furthermore, I’m trained in lockout/tagout procedures, ensuring that power is completely isolated before any maintenance or repair work. I regularly participate in safety training programs to stay updated on best practices and emerging hazards. For example, I recently completed training on the safe handling of plastics and the proper emergency shut-down procedures for our injection molding machine. I also promote a culture of safety by reporting any near misses or unsafe practices to my supervisor immediately.

Q 9. How do you ensure the quality of molded parts?

Ensuring the quality of molded parts involves a comprehensive approach, starting with the design and material selection. We use rigorous quality control checks at every stage of the process. This includes verifying the raw materials against specifications, ensuring consistent temperature and pressure settings within the machine, and conducting regular checks using dimensional measuring instruments such as calipers and micrometers to verify part dimensions. We also use visual inspection to check for defects such as sink marks, flash, or short shots. Statistical Process Control (SPC) techniques, which I’ll discuss further in the next question, play a significant role in monitoring and improving quality. Beyond the molding process itself, careful handling and storage of finished parts are crucial to prevent damage. For instance, we use appropriate packaging materials and stacking methods to avoid scratching or warping of the parts. To give a concrete example, during a recent production run, we noticed a slight increase in the number of parts with sink marks. Using our SPC data, we were able to trace the cause to a minor fluctuation in the melt temperature. By correcting this, we swiftly returned to acceptable quality levels.

Q 10. What is your experience with Statistical Process Control (SPC) in molding?

I have extensive experience with Statistical Process Control (SPC) in molding. SPC helps identify trends and variations in the molding process, allowing for proactive adjustments to maintain consistent quality. We use control charts, such as X-bar and R charts, to monitor key process parameters like melt temperature, injection pressure, and cycle time. By plotting these data points, we can readily identify any deviations from the established control limits. For instance, we use X-bar and R charts to monitor the wall thickness of molded parts. If a point falls outside the control limits, it signals a potential problem needing immediate attention. We then investigate the root cause, making adjustments as necessary. This might include recalibrating equipment, adjusting material properties, or even modifying the mold itself. Furthermore, we utilize capability analysis to determine the process’s ability to meet specific quality requirements. This helps us to establish process targets and identify areas for improvement. In one specific case, we were able to reduce the variation in part dimensions by 15% by implementing an SPC-driven improvement project focused on optimizing clamping pressure. This saved both material and labor costs.

Q 11. Explain the concept of cycle time reduction in molding.

Cycle time reduction is crucial for increasing productivity and profitability in molding. It focuses on minimizing the time required to complete one cycle of the molding process. Several strategies can achieve this. Optimizing the mold design itself can significantly reduce cycle time. For instance, using thinner walls, strategic gate placement, and efficient cooling channels can all decrease the time required for the part to cool and solidify. Process improvements, such as fine-tuning injection speed and pressure, can also improve efficiency. Implementing automated systems for material handling and part removal can further reduce cycle times. Improvements in machine maintenance and preventative measures are another key aspect. Finally, a lean manufacturing approach focused on streamlining the entire process, identifying and eliminating bottlenecks, can significantly improve cycle time. For instance, in a previous role, we implemented a new cooling system, which reduced our cycle time by 12%, leading to a substantial increase in production output without any loss in quality.

Q 12. How do you handle material waste in the molding process?

Material waste management is a crucial aspect of sustainable and cost-effective molding. Our strategy begins with careful planning and precise material handling to minimize material usage. We implement stringent quality control measures to reduce the number of defective parts that need to be discarded. We also employ various techniques to recycle and reuse excess material whenever possible. For example, regrind from the molding process can often be blended with virgin material, reducing waste and material costs. Furthermore, we conduct regular audits to identify areas where waste is generated and explore ways to improve efficiency. We maintain meticulous records of material usage and waste generation, allowing us to track progress and pinpoint areas for improvement. We also incorporate principles of lean manufacturing to identify and eliminate waste at each stage of the process. A recent initiative focused on optimizing material feed rates reduced our material waste by 8%, resulting in considerable cost savings.

Q 13. Describe your experience with mold maintenance and repair.

Mold maintenance and repair are critical for ensuring consistent production quality and extending mold lifespan. My experience encompasses preventative maintenance, routine inspections, and corrective repairs. Preventative maintenance includes regular cleaning, lubrication, and inspection of the mold components. We adhere to a scheduled maintenance program, and I personally conduct and oversee regular inspections, paying close attention to wear and tear on components like ejector pins and bushings. During routine inspections, I check for signs of erosion, corrosion, or damage. Corrective repair involves addressing issues such as broken components, leaks, or damage identified during inspections. My experience includes repairing molds using various techniques like welding, machining, and polishing. We maintain detailed records of all maintenance and repair activities, which help in tracking the mold’s health and predicting potential future issues. For instance, I recently identified a potential problem with a mold’s cooling system through preventative maintenance, preventing a costly production shutdown. I also collaborate with mold makers and suppliers to ensure timely repairs and component replacements.

Q 14. How do you interpret molding process data and identify trends?

Interpreting molding process data involves analyzing information collected from various sources, including sensors on the molding machines, quality control measurements, and material usage records. I’m proficient in using statistical software and data visualization tools to identify trends and patterns. For instance, I regularly review control charts to detect any shifts or trends in key parameters such as melt temperature, injection pressure, and cycle time. I also use data analysis techniques to investigate the root causes of variations or quality issues. A recent example involved identifying a correlation between increased ambient temperature and a rise in the number of rejected parts due to warping. By analyzing the data and applying engineering knowledge, we implemented a solution to maintain a more stable processing temperature, resulting in a significant reduction of rejected parts. My approach to data interpretation combines statistical analysis with a deep understanding of the molding process and engineering principles. This holistic approach allows for more accurate and actionable insights, driving process optimization and improvements.

Q 15. What is your experience with different types of molding machines (e.g., hydraulic, electric)?

My experience encompasses a wide range of molding machines, primarily hydraulic and electric. Hydraulic presses, known for their high tonnage capabilities, are essential for larger parts and tougher materials. I’ve extensively worked with machines ranging from 50 to 500 tons, managing their operation, maintenance, and troubleshooting. I’m proficient in setting up clamping force, injection pressure, and cycle times on these systems. Electric machines, while often offering more precise control and energy efficiency, require a different approach. My experience includes programming and optimizing servo-driven machines for various applications, paying close attention to energy consumption and part consistency. For instance, I successfully optimized an electric molding machine to reduce cycle time by 15% in a project involving high-precision medical components, ultimately increasing productivity significantly.

I understand the strengths and limitations of both types and can choose the appropriate machine based on the project requirements, considering factors like part size, material properties, required production volume, and budget constraints.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with automated molding systems.

My experience with automated molding systems is extensive. I’ve worked with fully automated lines incorporating robots for part removal, automated gating systems, and integrated quality control systems. This involves a deep understanding of PLC (Programmable Logic Controller) programming and robotic integration. In one project, we implemented a fully automated system for a high-volume production run of automotive parts. This reduced labor costs by 40% and minimized human error, resulting in improved part quality and consistency.

Automation also requires a keen eye for preventative maintenance, scheduling routine checks to minimize downtime. I regularly analyze production data to identify areas for improvement and optimize the entire automated process flow. Troubleshooting issues in an automated system requires systematic diagnostics, and my experience includes using diagnostic tools and working closely with automation engineers to swiftly resolve any unexpected issues, maintaining consistent high-level production.

Q 17. How do you ensure proper mold clamping pressure and tonnage?

Ensuring proper mold clamping pressure and tonnage is crucial for successful molding. Insufficient pressure can lead to flash (excess material escaping the mold), while excessive pressure can damage the mold or the part. I use a multi-pronged approach.

- Mold Design Review: I start by carefully reviewing the mold design to understand the required clamping force based on part geometry and material.

- Machine Calibration: Precise calibration of the molding machine is paramount. This involves using calibrated pressure gauges and load cells to accurately measure clamping force and tonnage.

- Material Properties: Understanding the material’s viscosity and flow characteristics is essential. Different materials require different clamping pressures.

- Monitoring and Adjustment: I continuously monitor clamping pressure and tonnage during production runs, making adjustments as needed based on real-time data and visual inspection of the parts.

For instance, I once identified a gradual decrease in clamping pressure over time, which led to an increase in flash defects. Through investigation, we discovered a problem with a hydraulic component. Replacing the component solved the issue and maintained consistent part quality.

Q 18. What is your experience with different types of mold materials (e.g., steel, aluminum)?

My experience includes working with various mold materials, including steel, aluminum, and specialized materials like beryllium copper. Steel offers high durability and temperature resistance, making it ideal for high-volume production and challenging materials. Aluminum is often preferred for its lighter weight and faster thermal transfer, leading to shorter cycle times – this is particularly beneficial when prototyping or manufacturing smaller batches. The choice of material depends on several factors, including the part’s complexity, required durability, cost considerations, and the material being molded.

I understand the properties and limitations of each material and can select the optimal material based on the specific application. For example, choosing beryllium copper for high-precision molds involving very thin walled parts due to its superior spring-back characteristics.

Q 19. How do you identify and address mold defects?

Identifying and addressing mold defects requires a systematic approach. I use a combination of techniques.

- Visual Inspection: This is the first step, carefully examining the molded parts for any surface imperfections, flash, sink marks, short shots, or warping.

- Dimensional Measurement: Precise measurements using calipers, CMM (Coordinate Measuring Machine), or other inspection tools are used to verify if parts meet specifications.

- Mold Analysis: If defects persist, a thorough inspection of the mold itself is conducted to identify potential issues such as wear and tear, damage to the mold cavity, or problems with the cooling system.

- Root Cause Analysis: After identifying the root cause, corrective actions are implemented, which might include mold repair, adjustments to molding parameters, or changes in material handling.

For instance, I once solved a recurring sink mark problem by optimizing the cooling channels within the mold, which improved heat dissipation and prevented material from solidifying too quickly.

Q 20. Explain the importance of proper material handling in molding.

Proper material handling is crucial for efficient and successful molding. Improper handling can lead to contamination, degradation of material properties, and ultimately, defective parts. My approach involves:

- Material Storage: Materials are stored in a clean, dry environment, away from direct sunlight and extreme temperatures to prevent degradation. This includes proper labeling and rotation to ensure FIFO (First-In, First-Out) usage.

- Drying Procedures: For moisture-sensitive materials, I use appropriate drying equipment to ensure optimal moisture content before processing. This is crucial for achieving consistent part quality.

- Cleanliness: Maintaining cleanliness is paramount. This includes regular cleaning of the material hopper and feed system to prevent contamination.

- Material Flow: I make sure that the material flows smoothly and consistently into the molding machine to ensure uniform injection and prevent material starvation or degradation during the process.

I once traced a batch of defective parts to improperly dried resin which highlighted the crucial importance of proper material handling in molding operations.

Q 21. How do you handle unexpected equipment malfunctions?

Handling unexpected equipment malfunctions requires quick thinking and a systematic approach. My process typically involves:

- Safety First: The safety of personnel is the top priority. I immediately shut down the machine and assess the situation to ensure no one is at risk.

- Troubleshooting: I systematically troubleshoot the problem, checking for obvious issues like power outages, hydraulic leaks, or sensor malfunctions. I use diagnostic tools and logs provided by the machine to identify the root cause.

- Corrective Actions: Once the problem is identified, I implement the appropriate corrective actions. This could involve minor repairs, part replacement, or contacting external maintenance services.

- Preventative Maintenance: Following the resolution, I review the incident to identify any preventative maintenance measures that could avoid similar issues in the future. This might involve adjusting maintenance schedules or improving training protocols.

For example, during a night shift I once encountered an unexpected hydraulic failure. By quickly isolating the problem to a specific valve, I managed to minimize downtime by quickly replacing the valve and continuing production with minimal disruption.

Q 22. How do you contribute to a safe and productive work environment?

A safe and productive work environment is paramount in molding operations. My contribution starts with proactive adherence to safety protocols, including regular machine inspections, proper use of PPE (Personal Protective Equipment), and rigorous training for new team members. I actively participate in safety meetings, offering suggestions for improvement and ensuring everyone understands and follows established procedures. Beyond safety, I foster a collaborative atmosphere where open communication and mutual respect are valued. This includes actively listening to team members’ concerns, offering support, and celebrating successes together. A positive work environment significantly boosts morale and productivity, leading to fewer accidents and higher-quality output. For example, I once noticed a recurring near-miss incident related to a specific machine and initiated a process improvement that involved adding a safety guard and providing additional training. This resulted in a significant reduction in near-miss incidents and a boost in team confidence.

Q 23. Describe your experience with lean manufacturing principles in molding.

Lean manufacturing principles are fundamental to optimizing molding operations. My experience encompasses implementing 5S methodologies (Sort, Set in Order, Shine, Standardize, Sustain) to maintain a clean and organized workspace, reducing waste and improving efficiency. I’ve also been involved in value stream mapping, which helped identify and eliminate bottlenecks in the production process. For instance, in a previous role, we identified a significant delay in the material handling process. Using value stream mapping, we redesigned the layout of the facility and implemented a Kanban system for material replenishment. This resulted in a 15% reduction in lead time. Furthermore, I’m proficient in applying Kaizen (continuous improvement) techniques, such as conducting regular Gemba walks (going to the place where the work is done) to identify and address inefficiencies in real-time. This proactive approach ensures that the operation runs smoothly and wastes are continuously minimized.

Q 24. How do you improve cycle times and efficiency in a molding operation?

Improving cycle times and efficiency in molding involves a multi-pronged approach. Firstly, optimizing the molding process itself is crucial. This includes fine-tuning parameters like injection pressure, melt temperature, and holding time to ensure optimal part quality and minimize cycle time. Secondly, efficient mold design plays a critical role. Proper gating and venting strategies can significantly reduce filling time and prevent defects. Thirdly, preventative maintenance is essential for minimizing downtime. Regular inspections and scheduled maintenance prevent unexpected breakdowns that disrupt production. Finally, automation and robotics can significantly improve cycle times, especially in high-volume production. In a past project, we improved cycle time by 10% by optimizing injection parameters and implementing a robotic system for part removal. This resulted in significant cost savings and increased production output.

Q 25. What is your understanding of the different types of gating systems?

Gating systems are crucial for delivering molten plastic into the mold cavity. Several types exist, each with its advantages and disadvantages.

- Cold runner systems: The runner remains cold and the solidified plastic is removed and discarded after molding. This is simple and inexpensive, but material is wasted.

- Hot runner systems: Molten plastic is kept hot within the runner system, eliminating waste. This is more expensive but cost-effective for high-volume production.

- Submarine gating: The gate is located under the part, leaving a small, easily hidden sprue mark.

- Edge gating: The gate is located at the edge of the part. This is a simple, cost-effective method, but can leave a noticeable mark.

- Tab gating: A small tab of plastic connects the part to the runner, easily broken off.

Q 26. How do you manage and resolve conflicts in a team environment?

Conflict resolution is an important skill in a team environment. My approach involves active listening to all sides of the conflict, seeking to understand the root cause rather than focusing on assigning blame. I facilitate open communication by encouraging everyone to express their perspectives respectfully. I then work collaboratively to find a mutually acceptable solution, focusing on common goals and shared objectives. If necessary, I may suggest mediation or propose a compromise that addresses the concerns of all parties involved. Ultimately, the goal is to resolve the conflict effectively while preserving team cohesion and fostering a positive working relationship. For example, I once mediated a disagreement between two team members concerning the use of a particular molding machine. By focusing on the underlying resource constraints and identifying alternative solutions, I successfully resolved the conflict and prevented future recurrences.

Q 27. Describe a time you solved a complex molding problem. What was your approach?

In a previous role, we experienced a recurring problem with warping in a specific part. Initial troubleshooting focused on adjusting the mold temperature and injection pressure, but the issue persisted. My approach involved a systematic investigation. We started by reviewing the mold design for potential flaws. We then carefully analyzed the part’s geometry and material properties to identify any contributing factors. Using a combination of Finite Element Analysis (FEA) simulation and physical testing, we discovered that the part’s design was inherently prone to warping due to uneven cooling. To resolve this, we redesigned the part to incorporate ribs and changed the cooling channels within the mold. The combination of FEA analysis, design modification, and thorough testing resulted in a significant reduction in part warping, improving product quality and reducing waste.

Q 28. What are your salary expectations?

My salary expectations are commensurate with my experience and skills in the molding industry. Based on my qualifications and the responsibilities of this role, I am targeting a salary range of [Insert Salary Range Here]. I am open to discussing this further and believe that my contributions will quickly justify the investment.

Key Topics to Learn for Molding Operation Interview

- Molding Processes: Understand the various molding techniques (injection molding, compression molding, blow molding, etc.), their applications, and advantages/disadvantages. Be prepared to discuss the specifics of each process in detail.

- Material Science: Demonstrate knowledge of different plastics and their properties (e.g., thermoplastics vs. thermosets). Be able to discuss how material selection impacts the molding process and final product quality.

- Mold Design and Construction: Familiarize yourself with mold components, design considerations (gating, venting, cooling), and common mold design software. Discuss troubleshooting and maintenance of molds.

- Machine Operation and Maintenance: Understand the operation of molding machines (injection molding machines, etc.), including setup, parameters, and troubleshooting common machine issues. Be prepared to discuss preventative maintenance procedures.

- Quality Control and Assurance: Discuss quality control techniques used in molding operations, including inspection methods, statistical process control (SPC), and defect analysis. Showcase your problem-solving skills related to quality issues.

- Safety Procedures and Regulations: Demonstrate a strong understanding of safety protocols and regulations within a molding operation environment, including machine guarding, personal protective equipment (PPE), and hazard identification.

- Process Optimization and Improvement: Be prepared to discuss methods for improving efficiency, reducing cycle times, and minimizing waste in a molding operation. Showcase your problem-solving abilities through examples.

Next Steps

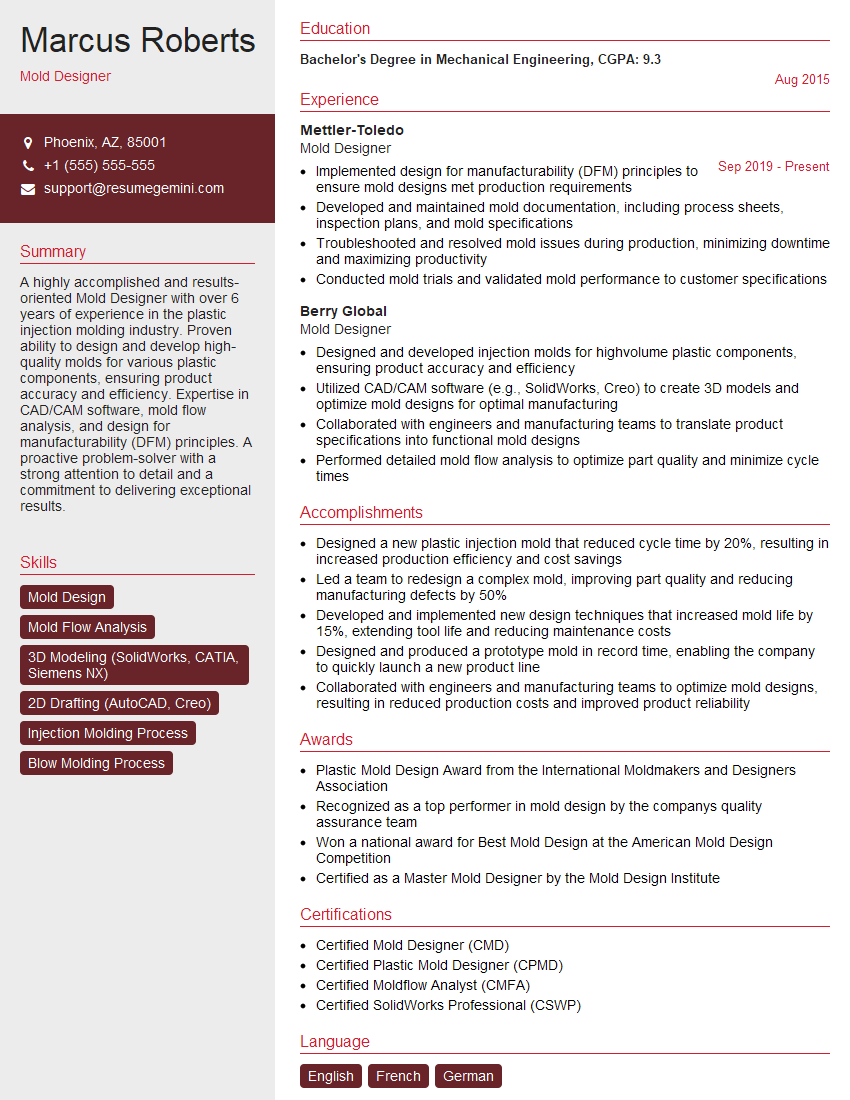

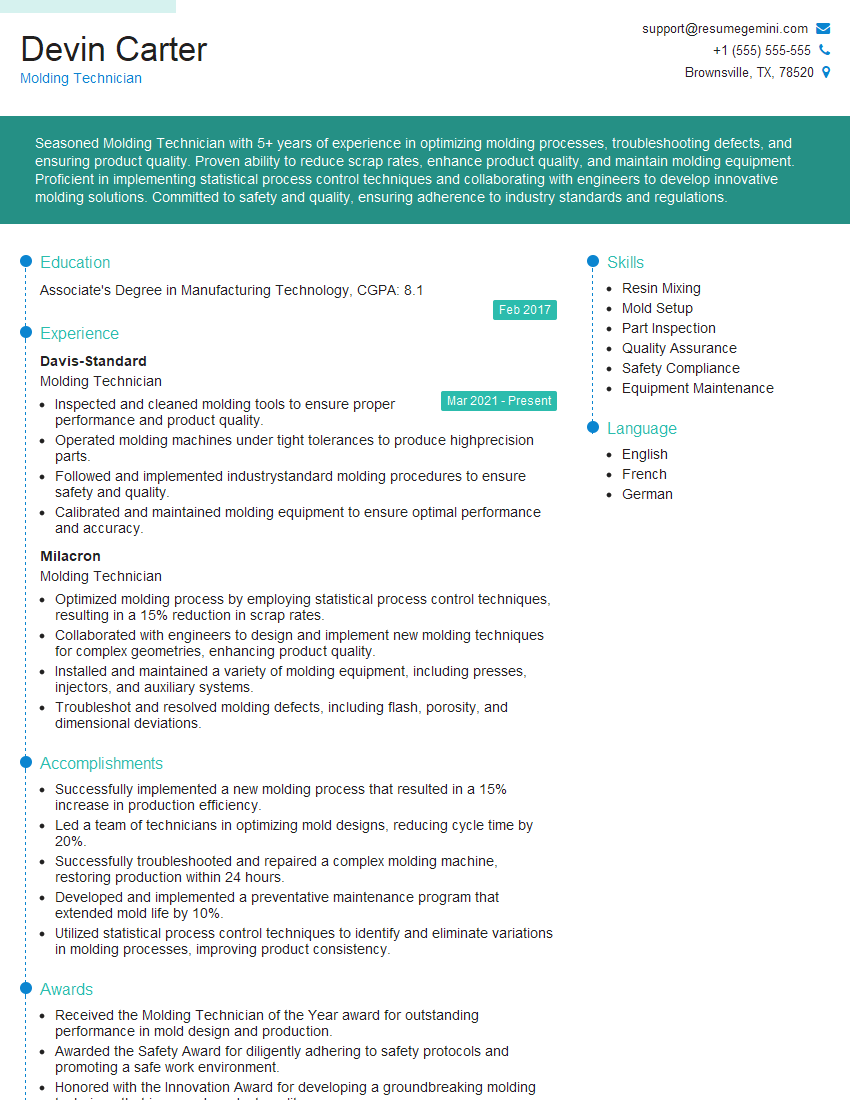

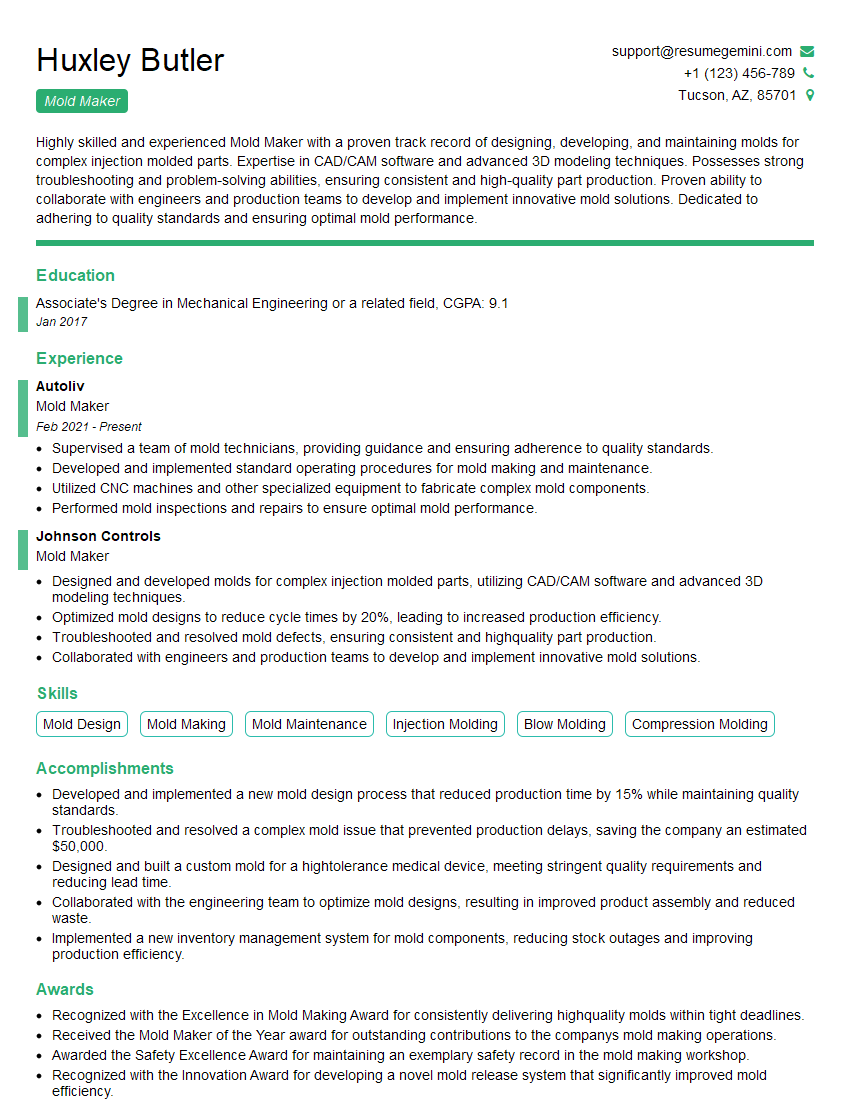

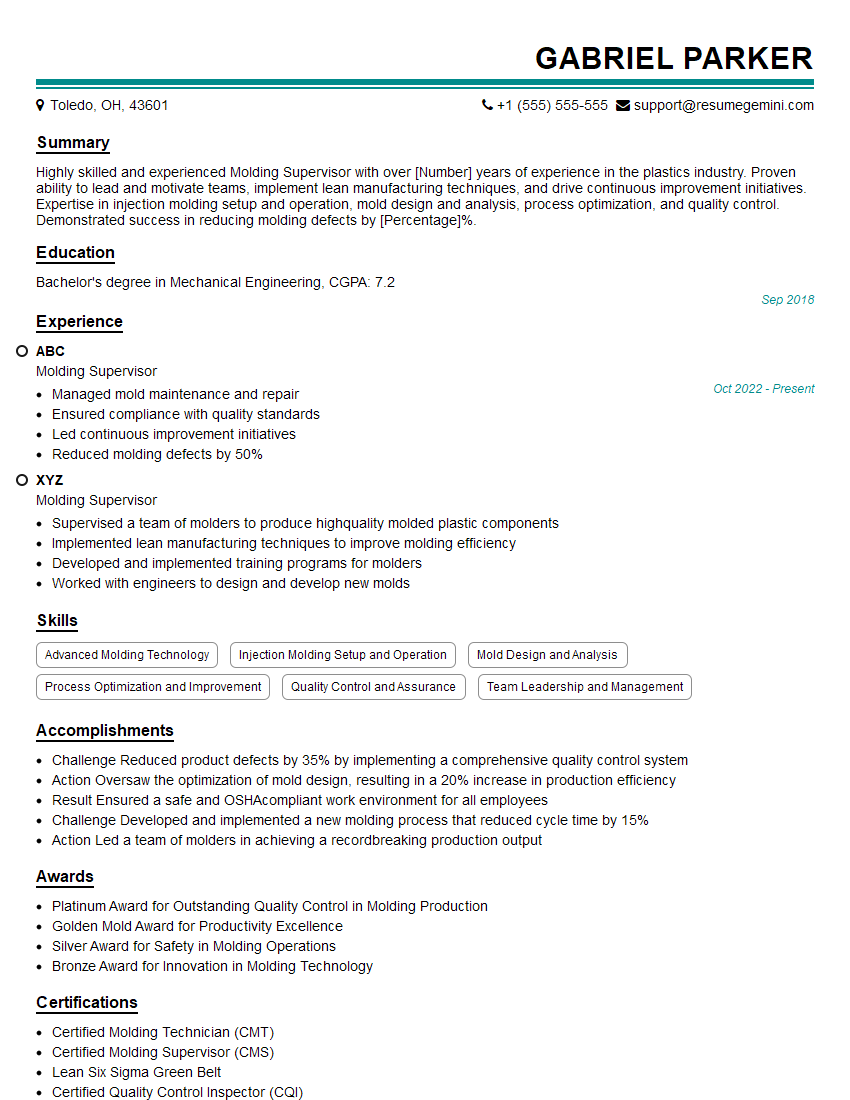

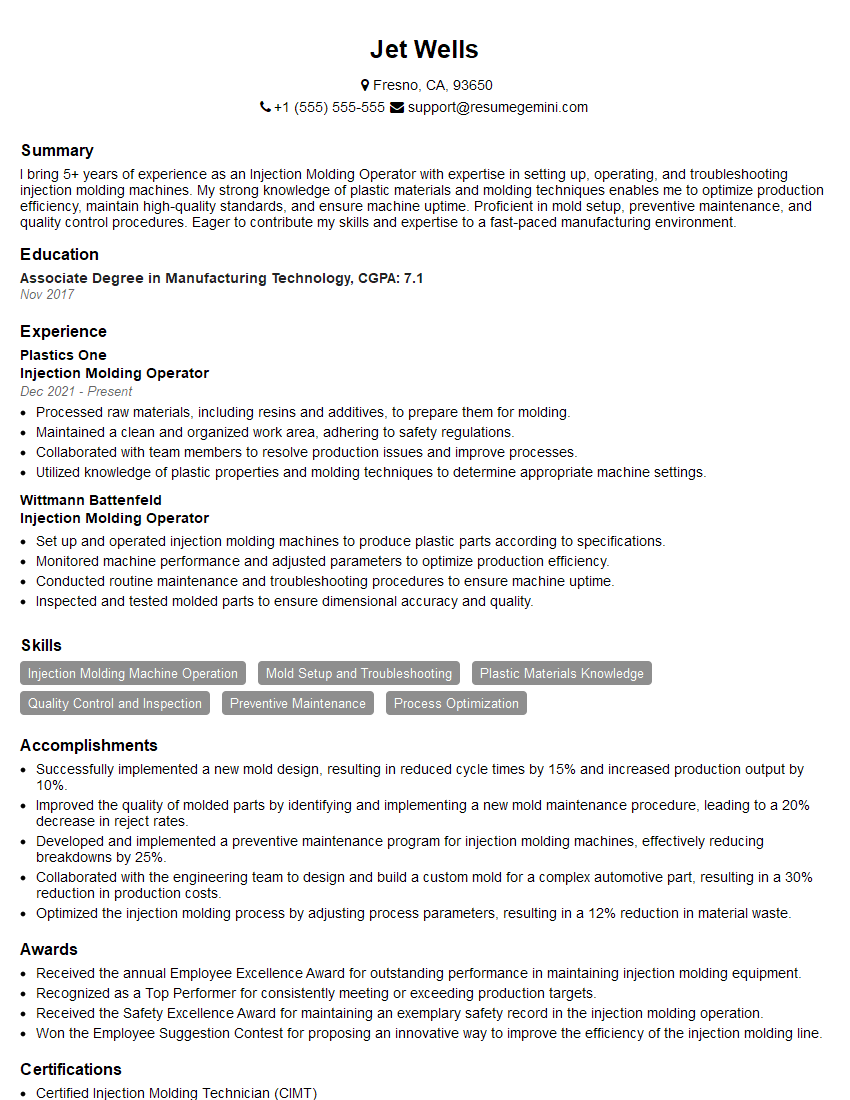

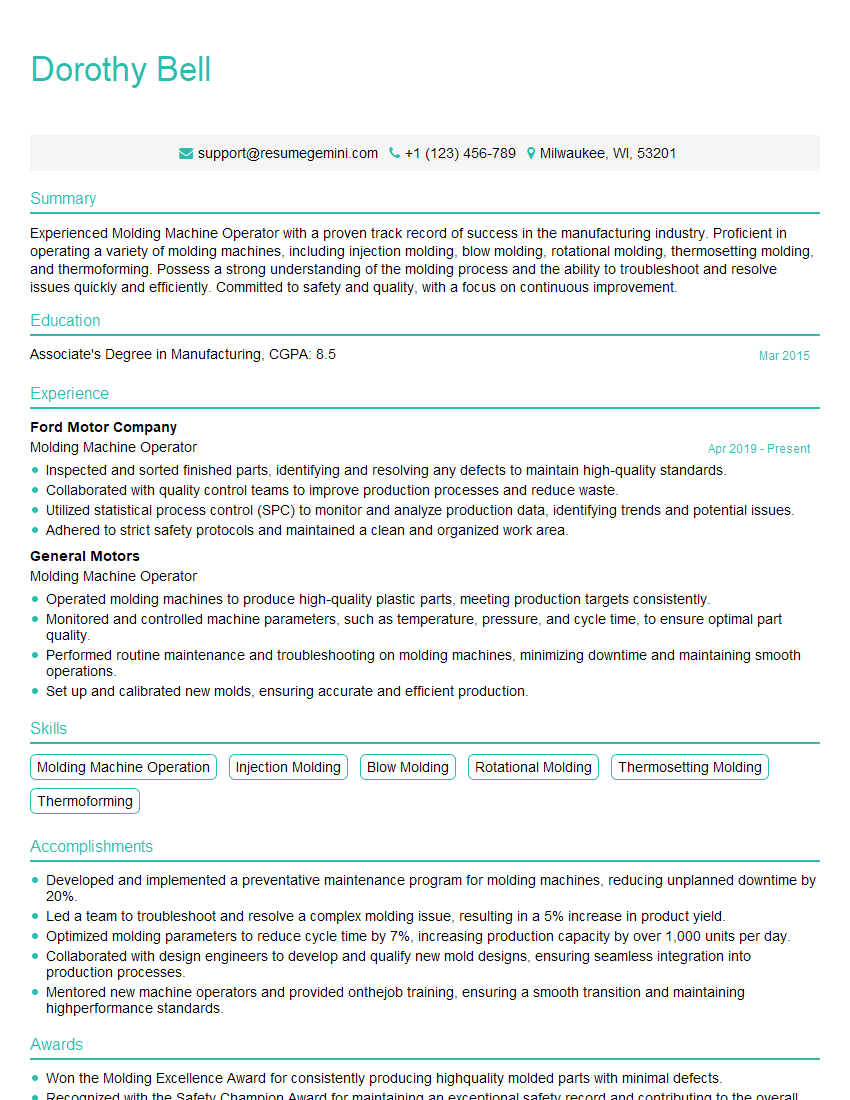

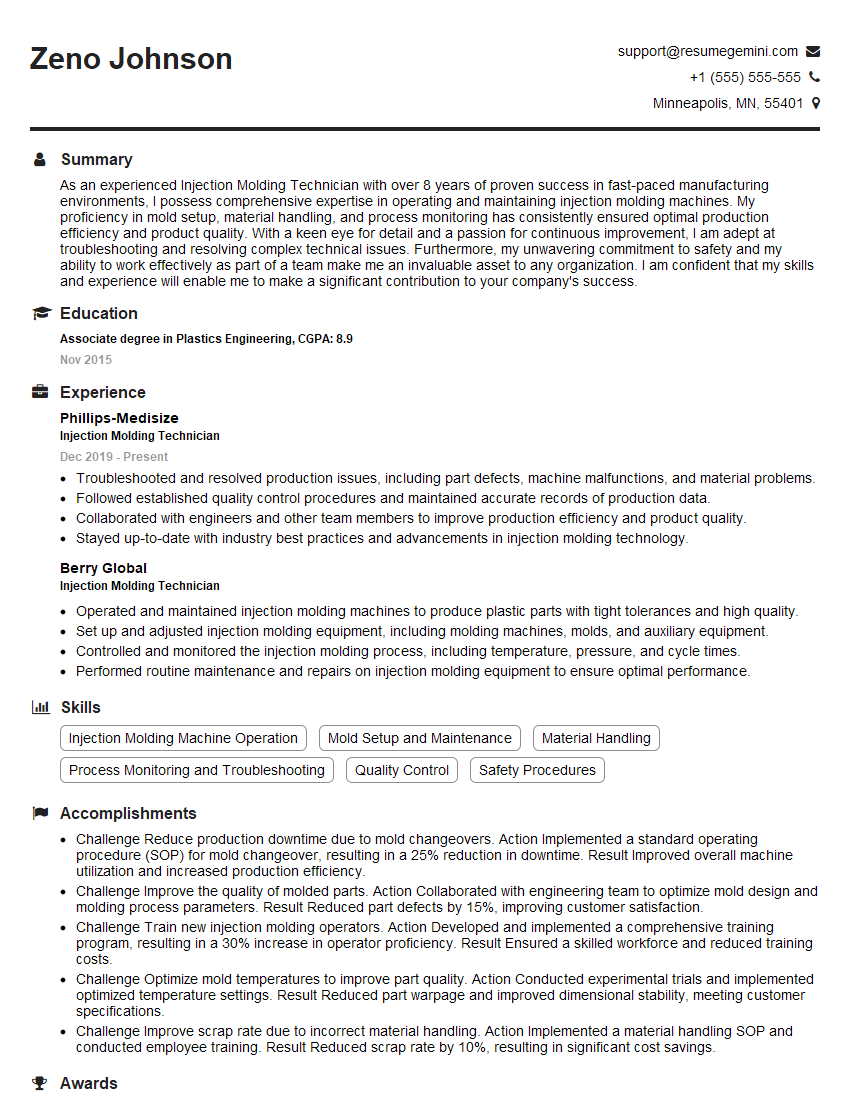

Mastering Molding Operation principles opens doors to rewarding and challenging career opportunities within manufacturing and related industries. A strong understanding of these concepts positions you for advancement and increased earning potential. To maximize your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your skills and experience. Examples of resumes tailored to Molding Operation are available within ResumeGemini to guide you through the process. Invest in your future by crafting a compelling resume that showcases your expertise – it’s the first step towards your next exciting opportunity.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good