Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Monitoring and troubleshooting bailer tender equipment interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Monitoring and troubleshooting bailer tender equipment Interview

Q 1. Describe your experience troubleshooting hydraulic systems in baler tenders.

Troubleshooting hydraulic systems in baler tenders involves a systematic approach. I begin by assessing the symptoms – is there a complete lack of movement, slow response, or leaks? Then I check the obvious: fluid levels, filter conditions, and pressure gauges. Low fluid levels often point to leaks, which I’d locate using visual inspection and potentially dye testing. A clogged filter will restrict flow, causing slow response or complete failure. Pressure gauge readings help pinpoint issues within the system – abnormally high pressure suggests a blockage, while low pressure suggests a leak or pump malfunction.

For example, I once diagnosed a slow bale ejection issue by tracing a slow pressure build-up to a faulty hydraulic valve. Replacing the valve resolved the problem. I also utilize diagnostic tools like pressure transducers and flow meters to get precise readings and identify the source of the problem more quickly. Understanding the hydraulic schematic of the specific baler tender is crucial; it provides a road map for tracing fluid paths and identifying components.

Q 2. Explain the common causes of bale density issues and how you would diagnose them.

Bale density issues usually stem from problems with the baler’s compression mechanism or material feed rate. Low bale density might indicate insufficient pressure from the hydraulic rams, issues with the bale chamber’s compaction, or inconsistent material feeding. High bale density, on the other hand, could result from excessive pressure, leading to potential equipment damage or inconsistent bale size.

My diagnostic process involves checking the hydraulic pressure during the compression cycle, verifying the proper functioning of the compression rams and their related components, examining the material feed mechanism for blockages or inconsistencies, and also considering the type and moisture content of the material being baled. For instance, excessively wet material will compact poorly, resulting in low density. In one instance, I found a worn-out piston seal causing a significant drop in pressure, leading to low bale density. Replacing the seal immediately resolved the problem. Thorough inspection of the entire bale formation process is key.

Q 3. How do you identify and resolve electrical faults in a baler tender?

Identifying and resolving electrical faults in a baler tender involves a methodical approach. Safety is paramount – always disconnect power before working on electrical components. I begin by checking for blown fuses or tripped circuit breakers. Next, I use a multimeter to test voltage, current, and continuity in various circuits. Wiring diagrams are essential for tracing circuits and identifying potential issues. Loose connections, damaged wiring, and faulty sensors or switches are common culprits.

I’ve used a multimeter to pinpoint a faulty proximity sensor causing intermittent bale ejection failures. Replacing the sensor solved the issue. If a PLC is involved, error codes will help narrow down the problem area. Understanding the electrical schematic diagram and using appropriate safety measures is critical to efficiently and safely resolve electrical problems.

Q 4. What are the safety procedures you follow when maintaining baler tender equipment?

Safety is my top priority. Before any maintenance, I lock out and tag out the power supply to the baler tender. I always use appropriate personal protective equipment (PPE), including safety glasses, gloves, steel-toe boots, and hearing protection. I inspect the equipment for any potential hazards, such as hydraulic leaks or exposed wiring. If working at heights, I’d utilize proper fall protection equipment. I follow all manufacturer’s recommended safety procedures and guidelines, and if I encounter something unfamiliar or hazardous, I would consult the relevant documentation or seek assistance from a qualified colleague. Safety isn’t a checklist, it is an ongoing commitment.

Q 5. Describe your experience with preventative maintenance on baler tenders.

Preventative maintenance is crucial for maximizing uptime and minimizing breakdowns. My approach involves a scheduled maintenance program, including regular inspections, lubrication, and component replacements. I check hydraulic fluid levels and condition, inspect hoses and fittings for leaks or damage, lubricate moving parts according to the manufacturer’s recommendations, and inspect electrical connections for corrosion or looseness. I also test safety devices such as emergency stops and pressure relief valves.

I keep detailed maintenance logs documenting all work performed, including dates, actions taken, and any parts replaced. This helps identify patterns and predict potential problems before they become major issues. For example, regularly checking and replacing hydraulic filters prevents contamination and prolongs the life of the hydraulic system, which translates into significant cost savings and increased reliability.

Q 6. How do you troubleshoot PLC errors in a baler tender control system?

Troubleshooting PLC errors starts with reviewing the PLC’s error log. These logs usually contain codes that correspond to specific faults. I use the PLC programming software to access and interpret these error codes. Common issues include sensor failures, input/output module problems, and programming errors. A multimeter is useful for checking the signals to and from the PLC. I also check the physical connections to the sensors and actuators.

For example, a recurring error code might point to a short circuit in an output module which could be diagnosed by using the multimeter and checking the wiring. Once I identify the cause of the error, I can implement corrective actions – repairing or replacing faulty components, adjusting the PLC program, or checking the power supply to the PLC. Understanding the PLC’s ladder logic diagram is crucial for accurate diagnosis and repair.

Q 7. What are the common causes of bale size inconsistencies?

Bale size inconsistencies can result from several factors. Inconsistent material feed, malfunctions in the bale chamber’s mechanisms such as improper bale length detection, and problems with the bale ejection system can all contribute to this issue. Problems with the bale tying system (if applicable) can also lead to inconsistent bale sizes.

Diagnosing the problem begins by carefully observing the bale formation process. Are there periods of inconsistent material flow? Is the bale chamber properly cycling through its various stages? If a sensor is involved in the process, I’d check its calibration and functionality. Examining the bale ejection mechanism also plays a crucial role in identifying the root cause of the inconsistencies.

Q 8. Explain how you would diagnose and repair a jammed baler.

Diagnosing and repairing a jammed baler requires a systematic approach. First, I’d ensure the machine is completely shut down and locked out to prevent accidental injury. Then, I’d visually inspect the baler to pinpoint the jam’s location. Common jam points include the feed system, the compression chamber, and the bale ejection mechanism.

Possible causes and solutions:

- Feed System Jam: This often results from oversized or improperly shaped materials. Solution: Remove the obstruction manually, ensuring safety, and adjust the feed rate or pre-shred the material if necessary.

- Compression Chamber Jam: This can be caused by excessively dense material or mechanical failure within the chamber (e.g., broken needles or a damaged plunger). Solution: Carefully investigate the compression chamber, identifying and removing the blockage. Repair or replace damaged components.

- Bale Ejection Jam: This could be due to a binding mechanism, a clogged ejection chute, or a problem with the tying system. Solution: Examine the ejection mechanism for obstructions, lubricate moving parts if needed, and ensure the tying mechanism is functioning correctly. Replace worn or damaged parts as needed.

After addressing the immediate jam, I’d conduct a thorough inspection to identify any underlying causes of the malfunction, such as worn rollers, damaged belts, or other mechanical issues. Addressing these problems proactively prevents future jams.

Q 9. How do you perform a safety inspection on a baler tender?

A safety inspection of a baler tender involves a methodical check of several key areas. I’d start with a visual inspection for any obvious damage or wear and tear, checking for loose bolts, cracked components, or frayed wiring.

Key areas to check include:

- Guards and Shields: Ensure all guarding is in place and securely fastened to protect workers from moving parts.

- Emergency Stop System: Verify the emergency stop buttons and switches are functioning correctly and readily accessible.

- Hydraulic System: Check for leaks, damaged hoses, or low fluid levels.

- Electrical System: Inspect wiring for damage, ensuring proper grounding and insulation. Confirm the control panel is operational.

- Moving Parts: Carefully examine all moving parts for wear, damage, or misalignment. Check for proper lubrication.

- Tying System: Test the twine or wire tying system to ensure it’s functioning correctly and securely tying bales.

I’d also document the inspection findings, noting any required maintenance or repairs. A regular, documented safety inspection schedule is crucial for preventative maintenance and worker safety.

Q 10. What are the different types of balers and their unique maintenance needs?

Baler types vary widely depending on the application and material being processed. Common types include:

- Horizontal Balers: These are excellent for processing large volumes of consistently sized materials. Maintenance focuses on ensuring even material distribution, proper ram operation, and regular lubrication of the moving parts.

- Vertical Balers: Often used for smaller operations and varied material sizes. Maintenance involves regular inspection of the compression chamber for wear and tear and ensuring the tying mechanism is properly adjusted for different material types.

- Self-Tie Balers: Use an automatic tying system; maintenance includes regular knotter adjustments, twine/wire supply checks, and occasional knotter component replacement.

- Two-ram Balers: Increase production rate through alternating compression; maintenance requires careful attention to the synchronization of both rams and associated components.

Unique maintenance needs vary by type. For example, horizontal balers often require more attention to the feed system, while vertical balers might necessitate more frequent adjustments to the compression chamber. Regular lubrication is crucial for all types to ensure smooth operation and prevent premature wear.

Q 11. Describe your experience with different types of bale tying systems.

My experience encompasses various bale tying systems, including twine and wire tying systems. Twine systems are generally more economical but may not offer the strength of wire for very dense bales. Wire systems are more robust but require more specialized tools and can be more costly.

Key aspects of my experience include:

- Troubleshooting knotting issues: Identifying and resolving issues such as inconsistent knotting, broken twine, or incorrect tension.

- System maintenance: Regular cleaning and lubrication of moving parts in the tying mechanism.

- Component replacement: Identifying worn or damaged components and ensuring timely replacement to prevent downtime.

- Different tying mechanisms: Experience with various types of knotters, including those employing different twine tensioning and knot-forming techniques.

I understand the importance of selecting the appropriate tying system for the specific baling application and material type. Understanding the strengths and limitations of each system is vital in preventing malfunctions and ensuring efficient operation.

Q 12. How do you handle a situation where a baler malfunctions during operation?

If a baler malfunctions during operation, my priority is safety. I’d immediately shut down the equipment using the emergency stop mechanism and lock it out to prevent accidental operation. I’d then assess the situation, identifying the nature of the malfunction. This might involve checking the control panel for error codes or visually inspecting the equipment.

Next steps depend on the malfunction:

- Minor issue: If it’s a simple problem (e.g., a minor jam), I would attempt to rectify the issue following established safety procedures.

- Major issue: For more complex malfunctions, I would consult the operation manual, troubleshoot based on error codes (if applicable), and if needed, contact a qualified technician for assistance.

- Safety concerns: If there is any indication of a safety hazard (e.g., hydraulic leak, electrical short), I’d ensure the area is secured and immediately notify appropriate personnel.

Thorough documentation of the malfunction, troubleshooting steps, and repairs undertaken is essential for future reference and preventative maintenance. Reporting the incident provides valuable data for continuous improvement.

Q 13. What is your experience with lubrication and maintenance schedules for balers?

Lubrication is crucial for the longevity and efficiency of balers. My experience includes developing and implementing effective lubrication schedules tailored to specific baler models and operating conditions.

Typical lubrication schedule elements include:

- Frequency: Daily, weekly, or monthly lubrication depending on the component and operating intensity.

- Lubricants: Using appropriate lubricants (greases, oils) for different components, considering factors such as temperature and load.

- Application methods: Using appropriate grease guns, oil cans, or specialized lubrication systems to ensure proper application.

- Inspection: Regularly inspecting lubricated components for signs of wear, leaks, or contamination.

I believe a proactive lubrication strategy minimizes friction, reduces wear and tear, and extends the lifespan of the baler, resulting in lower maintenance costs and fewer breakdowns. A well-documented lubrication schedule helps ensure consistent maintenance and facilitates quick identification of any lubrication-related problems.

Q 14. How do you interpret and act upon error codes displayed by a baler’s control system?

Interpreting error codes is a crucial skill for effective baler troubleshooting. I’m proficient in interpreting error codes displayed on various baler control systems. The process typically involves referring to the baler’s operational manual, which provides a detailed list of error codes and their corresponding causes and solutions.

Example: Suppose an error code like E03 is displayed, indicating a problem with the twine cutter. I’d refer to the manual to determine the likely cause (e.g., a sensor malfunction, a jammed cutter, or a low twine supply). I would systematically check these possibilities, carefully inspecting the cutter mechanism, verifying sensor functionality, and checking the twine supply.

Accurate interpretation of error codes significantly accelerates the troubleshooting process, minimizing downtime and facilitating quicker repairs. If the error code is unclear or the problem persists after addressing potential causes, I’d seek assistance from a qualified technician or the baler manufacturer.

Q 15. Explain your knowledge of various sensors and their role in baler operation.

Baler tenders rely heavily on various sensors to monitor their operation and ensure efficient bale production. These sensors provide crucial feedback to the control system, allowing for automated adjustments and preventing malfunctions.

Level Sensors: These sensors, often ultrasonic or capacitive, detect the fill level of the infeed hopper. This prevents overfilling and ensures a consistent material flow to the baler chamber. Imagine it like a fuel gauge in a car – it tells you when the hopper needs refilling.

Pressure Sensors: These measure the pressure within the pneumatic systems, crucial for controlling the ram’s movement and bale density. A drop in pressure might indicate a leak, a problem with the compressor, or a blockage in the lines.

Proximity Sensors: Used to detect the presence of materials or components, for example, sensing when a bale is ready to be ejected or ensuring proper positioning of the bale tying mechanism. They’re like the ‘eyes’ of the system.

Load Cells: These sensors measure the weight of the bale being formed, offering valuable data on bale density and consistency. Inconsistent weight can pinpoint issues with material density or the baling process itself.

Understanding how these sensors function and interpreting their readings is critical for proactive maintenance and quick troubleshooting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with pneumatic systems in baler tenders.

Pneumatic systems are the ‘muscles’ of a baler tender, providing the force needed to move the infeed system components. My experience encompasses troubleshooting various pneumatic issues, from minor leaks to major component failures.

Troubleshooting Leaks: I’ve used compressed air leak detectors, and my approach involves systematic checks of all air lines, fittings, and cylinders. Finding and repairing leaks is key to maintaining efficient operation and preventing unexpected shutdowns. For instance, I once traced a significant air leak to a loose fitting on a ram cylinder, requiring a simple tightening to resolve the issue.

Cylinder Maintenance: I’m proficient in inspecting and replacing pneumatic cylinders, including lubrication and cleaning procedures. A worn or damaged cylinder can result in inconsistent ram movement, affecting bale density and production.

Compressor Maintenance: I understand the importance of regular compressor maintenance, including oil changes and filter replacements, ensuring sufficient air pressure for all system components. A faulty compressor can bring the entire system to a grinding halt.

I always prioritize safety when working with pressurized air systems, following all relevant safety protocols and using appropriate personal protective equipment.

Q 17. How do you troubleshoot issues related to the infeed system of a baler?

Troubleshooting the infeed system begins with a visual inspection, then proceeds to systematic checks of individual components.

Visual Inspection: Look for blockages, damaged parts (e.g., conveyor belts, augers), or material build-up. A clogged auger is a common cause of infeed problems, easily remedied with clearing.

Motor Operation: Check if the infeed motors are operating correctly. Listen for unusual noises like grinding or whirring sounds. These could indicate mechanical issues that need repair.

Sensor Checks: Verify the level sensors are accurately detecting the material level and sending the appropriate signals to the control system. A faulty level sensor could lead to under or overfilling of the infeed hopper.

Pneumatic System: Inspect the pneumatic components involved in the infeed operation. A leak in the pneumatic system could lead to inconsistent material flow. I usually start with listening for air leaks and checking the pressure gauges.

Control System: Verify the control system is correctly managing the infeed process and that there are no errors within the logic.

A methodical approach, combining visual inspection with functional testing, will rapidly pinpoint the root cause of infeed problems.

Q 18. How would you determine the root cause of frequent bale breaks?

Frequent bale breaks indicate underlying problems in the baling process. My approach is to systematically investigate potential causes.

Bale Density: Excessive bale density can lead to breaks. Checking the pressure sensors and the baler’s settings is the first step. Perhaps the bale density needs adjustment.

Material Consistency: Inconsistent material (mix of large and small pieces, wet or dry material) is a frequent culprit. Analyzing the incoming material for uniformity and moisture content is essential.

Tying Mechanism: A malfunctioning twine or wire tying mechanism is another common reason. I’d inspect the twine feed, cutter, and knotting mechanism for any issues such as broken needles or jammed mechanisms.

Ram Movement: Problems with the ram’s operation – inconsistent pressure, speed, or timing – can cause poor bale formation and breaks. I’d check the pneumatic system for leaks or cylinder issues and review the ram’s movement during operation.

Careful analysis, combining operational data with physical inspection, usually reveals the root cause, leading to effective corrective actions. Sometimes, a simple adjustment to the bale density or a minor repair to the tying mechanism is all that’s required.

Q 19. What is your experience working with different types of baling materials?

My experience encompasses working with a wide variety of baling materials, including paper, cardboard, plastic films, textiles, and agricultural products. Each material presents unique challenges:

Paper and Cardboard: Relatively easy to bale, but requires careful attention to bale density to avoid excessive compaction, which can cause breaks.

Plastic Films: Can be difficult to handle due to their tendency to slip and cling. Appropriate adjustments to the infeed system and the bale density are often needed.

Textiles: Can be bulky and require specific settings to ensure uniform bale density and avoid entanglement in the tying mechanism.

Agricultural Products: Moisture content is a major factor affecting bale density and quality. This requires adjusting bale density and sometimes even pre-drying the material to achieve ideal results.

Adaptability and the ability to quickly adjust the baler to handle various materials are crucial skills for a successful baler tender technician.

Q 20. Describe your experience with using diagnostic tools on baler tenders.

Modern baler tenders often have sophisticated diagnostic tools incorporated into their control systems. My experience includes using these tools for:

Error Code Analysis: Interpreting error codes displayed on the control panel to identify specific faults within the system. For example, a specific code might point to a malfunctioning sensor or a problem in the hydraulic system.

Data Logging: Reviewing logged data, such as pressure readings, sensor inputs, and motor performance, to identify trends and anomalies. This is like having a detailed medical history for the baler – it shows the pattern of its health over time.

Network Diagnostics: For balers with network connectivity, I can utilize network diagnostics tools to check the communication between various components and troubleshoot connectivity issues.

Besides these on-board tools, I’m also familiar with using external diagnostic equipment such as multimeters, pressure gauges, and specialized tools to check the system’s electrical and pneumatic components more thoroughly. Combining onboard data with hands-on testing provides a holistic diagnostic approach.

Q 21. Explain how you would perform a basic mechanical adjustment on a baler.

Basic mechanical adjustments on a baler might include tightening loose bolts, adjusting belt tension, or lubricating moving parts. Before performing any adjustment, safety must be the top priority.

Power Down: Always ensure the baler is completely powered down and locked out before any maintenance or adjustments.

Safety First: Wear appropriate safety equipment, including gloves and safety glasses.

Identify the Issue: Carefully determine the specific problem requiring adjustment. For example, a loose bolt on a conveyor might cause material jams, or loose belts might lead to slippage and poor performance.

Correct Adjustment: Make the appropriate adjustment. If adjusting a belt tension, for instance, use the appropriate tools to achieve the correct level of tension, as specified in the machine’s manual.

Test and Inspect: Once the adjustment is made, ensure the baler operates as expected, watching for any unusual behaviors.

A well-maintained baler will typically require only minor mechanical adjustments. Proper lubrication and periodic inspections will prevent more serious repairs. Remember that always referring to the equipment’s operating manual is crucial for proper adjustments and maintenance.

Q 22. How familiar are you with different types of baler rams and their maintenance?

Baler rams are the heart of a baling system, responsible for compressing the material. They come in various types, each with its own maintenance considerations. The most common are hydraulic rams, which use hydraulic pressure to create the force. These require regular checks of hydraulic fluid levels, pressure, and for leaks. Then there are mechanical rams, often using a system of gears and levers. Their maintenance focuses on lubrication, wear and tear on moving parts, and ensuring proper alignment. Finally, some modern systems use electric rams, which are often less maintenance-intensive but require regular inspections of electrical connections and motor functionality.

- Hydraulic Rams: Think of these like a giant syringe. Regularly checking the fluid level is like checking the syringe’s liquid level – it ensures proper operation. Leaks are equivalent to a hole in the syringe. We need to identify and seal them immediately to maintain pressure.

- Mechanical Rams: This is more like a complex set of gears in a clock. Each part needs lubrication to function smoothly and prevent wear. Proper alignment of the gears is vital to maintain the compression force consistently.

- Electric Rams: These are like a powerful electric motor driving a piston. Here, the focus shifts to electrical components: checking for loose wires, ensuring the motor is properly cooled, and monitoring its power consumption.

Maintenance involves scheduled lubrication, leak checks (for hydraulic systems), visual inspections for wear and tear, and regular functional tests to ensure the ram is operating within its specified parameters.

Q 23. Describe a time you had to troubleshoot a complex baler problem.

One time, a baler was experiencing inconsistent bale density. Initially, the operators suspected a problem with the ram, but after thorough inspection, everything appeared to be functioning normally. We meticulously checked the hydraulic system, the ram’s alignment, and even the electrical connections (despite it being a purely mechanical system). The issue turned out to be a much more subtle problem: worn-out bale chamber linkage components. These components were responsible for maintaining the even compression of the material. While the ram itself was working perfectly, it couldn’t efficiently compress the material because the chamber wasn’t aligned properly. We replaced these linkage components, and the bale density immediately returned to normal. This highlighted the importance of examining the entire system, not just individual components, when troubleshooting.

Q 24. How do you prioritize maintenance tasks for optimal baler performance?

Prioritizing maintenance tasks hinges on a risk-based approach. We start by identifying critical components that, if they fail, could cause significant downtime or safety hazards. This might include hydraulic systems, the main ram, and safety interlocks. These receive top priority for inspections and preventative maintenance. We then move to less critical components, such as lubrication points, which have scheduled lubrication based on manufacturer recommendations and usage. Finally, there are minor components such as wire harnesses and exterior panels that can be addressed during scheduled maintenance. This structured approach helps maintain optimum performance and safety while keeping costs in check. The frequency of these tasks also depends on the production volume and the age of the machine; higher volume and older machines necessitate more frequent checks.

Q 25. What are your skills in using schematics and manuals for baler maintenance?

I’m highly proficient in using schematics and manuals. Schematics provide a visual representation of the entire system’s layout, helping to identify component locations, connections, and interdependencies. This allows for quick identification of the affected areas during troubleshooting. The manuals offer detailed information on individual components, their functions, maintenance procedures, and troubleshooting steps. I use them in conjunction with each other, mapping the information from the manual to the physical components on the equipment. For instance, if a hydraulic leak is found, the schematic helps locate the source and the manual suggests the appropriate repair or replacement procedure. This combination allows for accurate diagnosis and efficient repair.

Q 26. How do you ensure the safety of yourself and others while performing maintenance?

Safety is paramount. Before starting any maintenance, I always follow the lockout/tagout procedure to de-energize any electrical systems and isolate the hydraulic system. This prevents accidental energization or activation while working on the equipment. I use personal protective equipment (PPE) appropriate for the task, including safety glasses, gloves, and hearing protection. I also ensure the work area is clear of obstructions and properly lit. Additionally, if the task is complex or involves significant risk, I would involve another skilled technician for assistance to ensure a second set of eyes on the task.

Q 27. What are your experience with automated baling systems?

My experience with automated baling systems includes working with PLC-controlled systems (Programmable Logic Controllers) and advanced sensor-based equipment. I’m familiar with troubleshooting issues related to PLC programming, sensor malfunction (such as bale density sensors or material level sensors), and automated bale ejection mechanisms. This also includes understanding the integration of the baler with other automated systems within a larger production line. Troubleshooting in these systems involves a deep understanding of both mechanical and electrical systems and frequently requires the use of diagnostic software for PLC troubleshooting and data analysis from sensors.

Q 28. Describe your experience with preventative maintenance programs.

My experience with preventative maintenance programs involves developing and implementing comprehensive schedules based on manufacturer recommendations, usage patterns, and risk assessments. This includes setting up regular lubrication cycles, visual inspections, and functional testing of critical components. We also maintain detailed records of all maintenance activities, including parts replacements, repairs, and any issues encountered. This data allows us to identify trends, predict potential failures, and optimize the maintenance schedule for maximum efficiency. Furthermore, I’m adept at using computerized maintenance management systems (CMMS) for scheduling, tracking, and reporting maintenance activities.

Key Topics to Learn for Monitoring and Troubleshooting Bailer Tender Equipment Interview

- Hydraulic Systems: Understanding hydraulic pressure, flow rates, and troubleshooting common hydraulic leaks and malfunctions in bailer tender equipment. Practical application: Diagnosing a slow bale ejection cycle by analyzing hydraulic pressure readings.

- Electrical Systems: Familiarity with electrical schematics, motor controls, sensor diagnostics, and troubleshooting electrical faults. Practical application: Identifying the root cause of a malfunctioning bale density sensor and replacing it.

- Mechanical Systems: Knowledge of mechanical components like gears, chains, belts, and bearings; understanding wear and tear, preventative maintenance, and troubleshooting mechanical failures. Practical application: Performing routine inspections to identify and replace worn-out drive belts to prevent unexpected breakdowns.

- Safety Procedures: Thorough understanding and adherence to all safety regulations and procedures related to operating and maintaining bailer tender equipment. Practical application: Correctly using lockout/tagout procedures before performing maintenance.

- Troubleshooting Techniques: Mastering systematic troubleshooting methods, including using diagnostic tools, interpreting error codes, and identifying the root cause of malfunctions. Practical application: Using a diagnostic code reader to pinpoint the origin of a system error and implement the appropriate solution.

- Preventive Maintenance: Knowledge of routine maintenance schedules, lubrication procedures, and component inspection techniques to minimize downtime and extend equipment lifespan. Practical application: Developing and implementing a preventative maintenance schedule for optimal equipment performance.

- Data Interpretation & Reporting: Ability to collect, analyze, and interpret data from machine sensors and logs to identify trends and potential issues. Practical application: Using machine data to predict potential component failures and schedule timely maintenance.

Next Steps

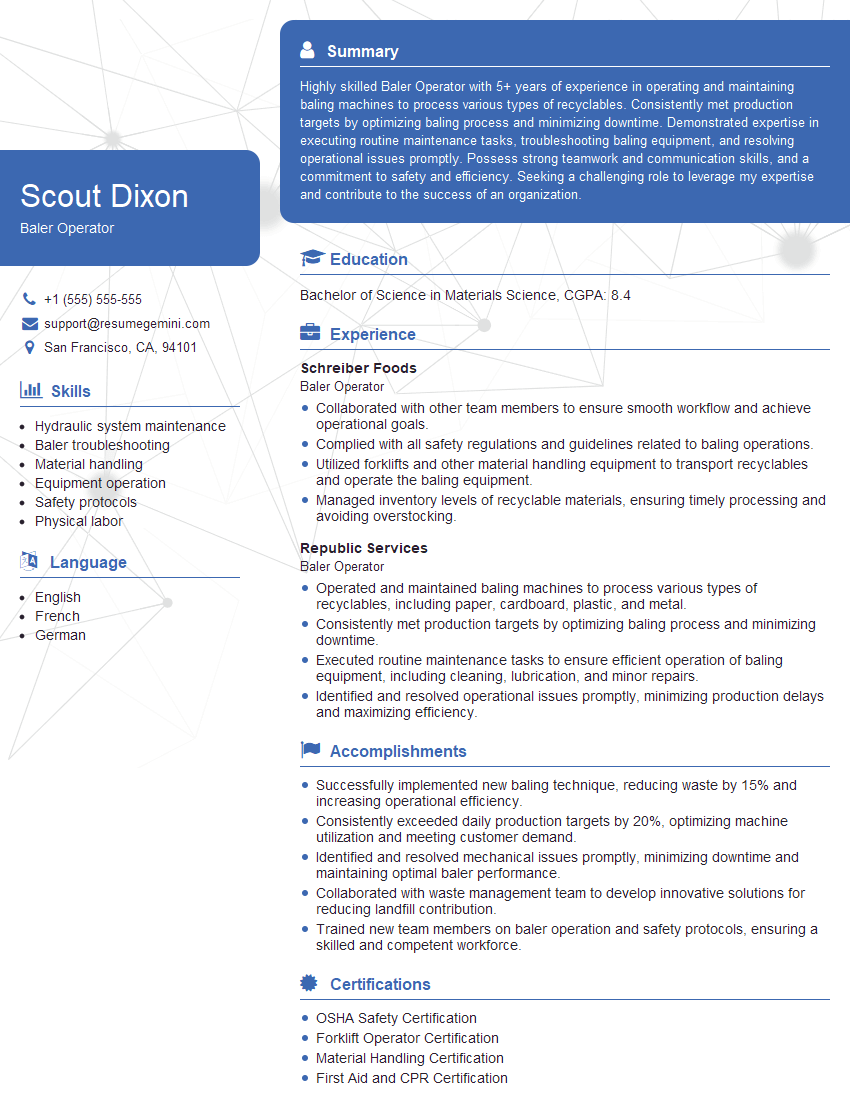

Mastering the monitoring and troubleshooting of bailer tender equipment is crucial for career advancement in the manufacturing and recycling industries. This skillset demonstrates your technical expertise, problem-solving abilities, and commitment to efficiency and safety. To significantly enhance your job prospects, focus on building an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you craft a professional and impactful resume. Examples of resumes tailored to Monitoring and Troubleshooting Bailer Tender Equipment are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good