Are you ready to stand out in your next interview? Understanding and preparing for Musical Instrumentation Skills interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Musical Instrumentation Skills Interview

Q 1. Describe your experience with different types of wood used in instrument construction.

Wood selection is crucial in instrument making, as different species offer unique tonal qualities, durability, and workability. For example, spruce is prized for its responsiveness and lightness, often used for the soundboards of guitars and violins, while maple provides strength and clarity, frequently found in violin backs and necks. Rosewood, known for its rich, warm tone, is often used in guitar fingerboards and bodies. Ebony, prized for its density and hardness, is a popular choice for fingerboards due to its durability and smooth surface. Mahogany offers a balance of warmth and projection, commonly used in guitar bodies and necks. The choice depends heavily on the instrument type, desired sound, and budget. I’ve personally worked extensively with spruce, maple, and rosewood, experimenting with different grades and drying techniques to achieve optimal results.

- Spruce: Light, resonant, ideal for soundboards.

- Maple: Strong, bright tone, used in backs and necks.

- Rosewood: Warm, rich tone, frequently used in bodies and fingerboards.

- Ebony: Hard, durable, common in fingerboards.

- Mahogany: Versatile, balance of warmth and projection.

Q 2. Explain the process of voicing a piano.

Voicing a piano is a complex process involving the precise adjustment of each individual hammer to achieve a balanced and expressive tone across the entire keyboard range. It’s a delicate art requiring years of experience and a keen ear. The process generally involves adjusting the hammer’s height, voicing, and its felt. This affects the hammer’s impact on the strings and thus the timbre and dynamics of the note. Too hard a hammer blow will result in harsh, bright tones while too soft yields muffled, indistinct ones. We start by assessing the overall tonal balance, then proceed to regulate hammer height, meticulously tweaking each hammer to ensure consistent volume and timbre across the keyboard. Then comes the crucial voicing of the felt, using specialized tools to precisely shape and refine the hammer’s surface to remove harshness, add warmth or brightness and provide consistent tone. The whole process is iterative; I might repeatedly adjust a hammer and its felt several times, before its tone aligns with the overall tonal balance. Every piano is unique, so voicing requires constant adjustment and fine-tuning, guided by experience and the specific character of the instrument.

Q 3. How do you troubleshoot a malfunctioning valve on a trumpet?

Troubleshooting a malfunctioning trumpet valve involves systematically checking several potential problems. A sticking valve often results from dirt, corrosion, or damage to the valve’s components, such as the valve guides, springs, or the valve casing itself. First, I’d visually inspect the valve for any obvious signs of damage or obstruction. Then I would carefully remove the valve and clean it thoroughly with appropriate solvents and lubricants. Often, a simple cleaning will resolve the issue. If cleaning doesn’t work, I’d inspect the valve casing and guides for damage or wear, potentially requiring replacement or lapping. I also check the valve spring tension; a weak or broken spring will cause sluggish operation. Finally, I would check for valve alignment, as misalignment can severely impact valve function. It is important to work methodically and carefully, as trumpet valves are delicate and easily damaged. Sometimes, it’s simply the need for proper lubrication – a little valve oil can make all the difference!

Q 4. What are the common issues encountered in repairing string instruments?

Common issues in string instrument repair include cracks in the wood, loose joints, bridge problems, and neck alignment. Cracks in the body or neck often require careful glueing and clamping for repair. Loose joints, caused by changes in humidity, can be re-glued and reinforced. Bridge problems, such as cracks or instability, may require replacing the bridge or adjusting its positioning. Neck alignment is critical for playability; a poorly aligned neck may require adjustment or even resetting. Other common issues include damaged soundposts, worn fingerboards, and loose pegs. I’ve seen many instruments that have suffered from humidity-related damage, so educating owners about proper instrument care is vital. Preventing damage is often easier than fixing it.

Q 5. Describe your experience with setting up and maintaining a drum kit.

Setting up and maintaining a drum kit involves ensuring proper tuning, head tension, cymbal placement, and overall stability. Tuning involves adjusting the tension of drumheads to achieve the desired pitch using tuning keys. Consistent head tension is crucial for even tone and responsiveness. Cymbal placement influences sound projection and playing comfort; I typically help drummers position cymbals based on their playing style and preferences. The stability of the kit is also important, checking for any loose components or wobbly stands and fixing them accordingly. Regular maintenance involves cleaning and protecting the drums and hardware from damage, such as cleaning the drums with appropriate drum cleaners and using protective coatings to prevent tarnishing.

Q 6. How do you identify and repair cracks in a wooden instrument?

Repairing cracks in a wooden instrument requires careful attention to detail and a steady hand. The process starts with a thorough cleaning and assessment of the damage. Small cracks might be repaired using wood glue and clamping, ensuring even pressure for proper bonding. Larger cracks, particularly those running along the grain, are often more challenging and may necessitate inlaying additional wood to stabilize the structure before gluing. In all cases, using the appropriate glue for the wood type is paramount to prevent future problems. For larger repairs, I sometimes employ specialized techniques like adding cleats or dowels to enhance structural stability, keeping the repair invisible to the naked eye while ensuring its strength. Patience and precision are key; rushing the repair process can lead to further damage.

Q 7. Explain the process of fretting a guitar.

Fretting a guitar is a crucial step in its construction and setup, requiring precision and expertise. It involves carefully installing frets into the fingerboard slots to ensure proper intonation and playability. First, the frets are carefully fitted into their slots, ensuring they are perfectly seated and aligned. Then, they are hammered down using specialized tools until they are level with the fingerboard. After installation, the frets are leveled using specialized files and sanding tools to create a perfectly even playing surface. Once leveled, the fret ends are dressed to create a clean and smooth finish and reduce the risk of injury. Finally, polishing the frets completes the process, leaving the frets smooth, ready for strings and offering an enhanced playing experience. The entire process is critical to the guitar’s playability and intonation – a poorly fretted guitar will be difficult to play and will be out of tune.

Q 8. What are the different types of finishes used on musical instruments, and their advantages/disadvantages?

Musical instrument finishes protect the instrument, enhance its appearance, and can even affect its tone. Several types exist, each with its own set of advantages and disadvantages.

- Lacquer: A thin, transparent coating offering good protection against scratches and environmental damage. It’s relatively durable and allows the wood’s natural grain to show through. However, it can be susceptible to cracking or chipping with significant impact. Many high-end guitars and violins use lacquer.

- Polyurethane: A thicker, more durable finish offering superior protection against scratches and moisture. It provides a very hard, glossy surface but can sometimes mask the wood’s natural beauty and may feel less ‘organic’ to the touch. Often used on less expensive instruments due to its cost-effectiveness.

- Shellac: A natural resin finish known for its warm, mellow tone and its ability to enhance the resonance of the wood. It’s highly responsive to environmental changes (humidity) making it vulnerable to cracking or checking. It’s a traditional finish found on high-quality instruments but requires more careful maintenance.

- Oil and wax finishes: These offer minimal protection but are very environmentally friendly, allowing the wood to ‘breathe’. They often enhance the wood’s natural beauty and feel, but require regular application and maintenance. They’re prone to scratches and water damage. Commonly used on instruments like ukuleles and some acoustic guitars.

The choice of finish depends on the instrument, the desired aesthetic, and the level of protection needed. For instance, a delicate violin might benefit from a high-quality lacquer, while a more robust bass guitar might be better suited for polyurethane.

Q 9. How do you maintain the intonation of a string instrument?

Maintaining the intonation of a string instrument involves several key steps. Intonation refers to how accurately the notes played match the intended pitch. It’s crucial for playing in tune.

- Adjusting the bridge: The bridge’s position significantly impacts intonation. Slight adjustments to its forward/backward tilt and left/right placement can be made by a qualified luthier, and only by someone experienced enough to know what they are doing.

- String height (action): Too high an action makes the instrument harder to play and can affect intonation, while too low an action causes buzzing. This is adjusted by adjusting the bridge or the nut.

- Nut adjustments: The nut’s slots, where the strings rest, must be properly sized and shaped. Incorrect nut slots can significantly affect the intonation, particularly at the upper fretboard regions. Again, this requires the skills of a luthier.

- Neck relief/bow: The neck’s curvature (relief) must be properly adjusted. Too much relief makes the strings too high, affecting intonation and playability; too little relief can lead to buzzing. A truss rod adjustment can typically solve this (although, again, often best left to a professional).

- Temperature and humidity: Changes in environment can affect the wood, impacting intonation. Storing the instrument in a stable environment is essential.

- Regular restringing: Old strings lose tension and their properties resulting in intonation issues. Regular restringing with high-quality strings is vital.

Maintaining intonation is an ongoing process. Regular check-ups by a qualified luthier are highly recommended.

Q 10. Describe your experience with repairing electronic musical instruments.

My experience with repairing electronic musical instruments spans several years and includes keyboards, synthesizers, guitars with electronics, and effects pedals. I’ve encountered a wide range of issues, from simple component replacements (like potentiometers, capacitors, and jacks) to more complex circuit board repairs. I’m proficient in using multimeters, oscilloscopes, and soldering equipment for diagnostics and repairs. One memorable instance involved diagnosing a faulty oscillator in a vintage synthesizer – that required tracing the signal path through a complex circuit board using an oscilloscope. In another case, I repaired a guitar’s faulty pickup system, replacing damaged wiring and ensuring proper grounding to eliminate hum and noise. I prioritize a methodical approach: visual inspection, systematic testing, and component-level troubleshooting. Safety precautions are always paramount when working with electronics, including proper grounding and isolation.

Q 11. Explain the process of replacing a bridge on a violin.

Replacing a violin bridge is a delicate procedure best left to experienced luthiers. It requires precision and an understanding of how the bridge affects the instrument’s sound and playability.

- Removing the old bridge: Gently pry the old bridge off the top plate, taking care not to damage the finish or the soundpost (a small dowel inside the instrument).

- Preparing the new bridge: The new bridge needs to be the correct size and shape for the violin. Often, a luthier carefully fits it to the instrument.

- Positioning the new bridge: The bridge must be precisely positioned. Its feet should sit firmly on the top plate and it should be centered and correctly aligned. The f-holes and the bridge should be symmetrical.

- Setting the string height (action): The height of the bridge needs to be adjusted to set the string action. Too high makes it difficult to play, and too low causes buzzing.

- Soundpost adjustment (if necessary): Sometimes, the soundpost needs to be checked and potentially readjusted to optimize the instrument’s resonance after the bridge is replaced. This is highly delicate and requires special tools.

- Final adjustments and tuning: Fine-tuning and adjustments to the bridge are often necessary to achieve optimal intonation and playability.

Incorrect bridge placement can significantly affect the violin’s intonation and tone. Improper fitting can result in damage to the instrument. Therefore, this task is best left to a professional.

Q 12. How do you diagnose and repair problems with instrument electronics?

Diagnosing and repairing problems with instrument electronics requires a systematic approach. I typically start with a visual inspection, checking for any obvious signs of damage like broken wires, loose connections, or damaged components. Then, I use a multimeter to test voltages, currents, and resistances in the circuit. An oscilloscope can be used for analyzing signal waveforms and identifying frequency-related issues.

- Systematic testing: I isolate sections of the circuit to identify the faulty component or area.

- Schematic diagrams: If available, schematic diagrams greatly aid in understanding the circuit’s functionality and tracing the signal path.

- Component-level troubleshooting: Once the faulty component is identified, I replace it with a suitable part ensuring the correct values and specifications.

- Soldering skills: Proper soldering technique is crucial for reliable connections. I use a temperature-controlled soldering iron to avoid damage.

- Grounding and shielding: Often, noise issues in electronic instruments arise due to poor grounding or shielding. Addressing these is crucial for restoring clarity and minimizing hum.

Repairing instrument electronics requires a combination of technical expertise, precision, and patience. A thorough understanding of electronics and experience working with delicate instruments are essential.

Q 13. What are the common problems associated with wind instrument pads, and how do you address them?

Wind instrument pads are crucial for airtight seals, enabling proper note production. Problems with pads can severely impact playability and tone.

- Leaks: This is the most common problem, caused by worn-out pads, debris under the pads, or poor pad seating. Leaks result in weak or unresponsive notes.

- Sticking pads: Pads can become sticky due to moisture or age. This makes it difficult to press the keys or valves smoothly, hindering playability.

- Pad cracks or tears: Physical damage to the pads will cause leaks and require replacement.

- Misaligned pads: If pads are not properly aligned, they may not seal properly leading to leaks.

Addressing these issues involves:

- Cleaning: Carefully removing any debris under the pads.

- Pad adjustment: Adjusting the pad height and alignment with specialized tools, if necessary.

- Pad replacement: If pads are worn, torn, or beyond repair, replacing them is crucial. This is best done by a professional repair technician.

- Pad lubrication (if applicable): Some pads benefit from light lubrication to improve sealing and prevent sticking.

Regular maintenance, such as cleaning the instrument and protecting it from extreme temperatures and humidity, helps extend the life of the pads and minimize problems.

Q 14. Describe your experience with instrument restoration techniques.

My experience in instrument restoration encompasses a wide range of techniques and challenges. It involves a deep understanding of the instrument’s history, construction, and materials. Restoration projects can range from minor repairs to extensive overhauls. I’ve worked on antique instruments, restoring their original finish and addressing structural damage. I’ve also worked with modern instruments, requiring repair or cosmetic restoration. Techniques I employ include:

- Wood repair: Using specialized glues and clamps to repair cracks and structural damage. Often, I will carefully select the right wood for repairs to match the instrument’s age and type.

- Finish restoration: This can involve cleaning, repairing cracks, and applying new finish (carefully matching existing finish if possible). The goal is to maintain the instrument’s historical integrity.

- Hardware restoration: Cleaning, polishing, or replacing damaged hardware, such as tuners, bridges, or plating.

- Historical research: Knowing the instrument’s maker, age, and model can significantly impact the restoration process and ensures that appropriate materials and techniques are used. Historical photos are incredibly useful for guiding the work.

A recent project involved restoring a vintage clarinet with cracked wood. I painstakingly repaired the cracks using a specialized glue and wood filler before carefully reapplying a historically accurate finish.

Q 15. How do you evaluate the condition of a musical instrument?

Evaluating a musical instrument’s condition involves a systematic approach combining visual inspection, auditory assessment, and often, hands-on testing. It’s like giving the instrument a thorough medical checkup!

Visual Inspection: This covers checking for cracks, dents, scratches, wear and tear on the finish, loose parts, and signs of previous repairs. I’d look carefully at the wood for warping, swelling, or insect damage. For stringed instruments, I’d examine the bridge, neck alignment, and fretboard condition. For wind instruments, I’d check for dents, leaks, and the condition of pads and keys.

Auditory Assessment: I’d play the instrument to listen for buzzing, rattles, uneven tone, or other undesirable sounds. This helps pinpoint issues with resonance, intonation, or individual parts. For example, a buzzing sound in a violin could indicate a loose string or a problem with the bridge.

Hands-on Testing: This might involve checking the action (string height) on a guitar, testing the key response on a piano, or checking the airflow in a woodwind instrument. It’s about understanding how the instrument feels and responds mechanically.

The specific techniques vary depending on the instrument type and its construction, but the core principle is always thoroughness and attention to detail. A detailed report is then compiled, highlighting any issues and their severity.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What types of tools and equipment are essential for your work?

My toolkit is as diverse as the instruments I work on! Essential tools range from basic hand tools to specialized equipment. Think of it as a surgeon’s precision kit, but for musical instruments.

Basic Hand Tools: Screwdrivers (various sizes and types), pliers (needle-nose, slip-joint), wrenches, files, sandpaper, knives, and measuring tools (calipers, rulers).

Specialized Tools: This includes things like fretting tools for guitar repair, specialized wood clamps, bending irons for wood repair, specialized glues, and tools for working with specific materials (e.g., ivory, ebony).

Equipment: Depending on the repair, I might use a soldering iron for electronics work, a power sander for refinishing, and various cleaning agents for different materials. A good workbench with sufficient lighting is crucial, as is a microscope for intricate work.

Safety Equipment: Eye protection (safety glasses), hearing protection (earplugs), and a dust mask are essential to protect me from potential hazards during repair.

The exact tools needed change depending on the job, but having a well-organized and comprehensive collection is crucial for efficient and accurate repairs.

Q 17. Describe a time you had to troubleshoot a complex instrument repair issue.

I once faced a challenging repair on a vintage oboe. The instrument had a persistent leak despite repeated attempts to replace the pads. After careful examination, I discovered that the problem wasn’t the pads themselves but a previously unnoticed crack within the wood body, hidden under the pad. It was like finding a hidden fault in an old building.

Troubleshooting Steps:

Thorough Inspection: I re-examined the oboe with a magnifying glass and a bright light, carefully checking every seam and joint. This was key to finding the hidden crack.

Crack Identification: Once located, I determined the crack’s size and depth. It required delicate handling.

Repair Method Selection: Given the instrument’s age and value, I opted for a minimally invasive repair using a specialized wood adhesive and a clamping technique. I aimed for a repair method that wouldn’t alter the oboe’s appearance significantly.

Repair Execution: I carefully cleaned the crack, applied the adhesive, and clamped it securely until the glue had fully cured. Patience was essential to ensure the repair was strong and durable.

Testing and Refinement: After the glue cured, I tested the oboe thoroughly, checking for any remaining leaks. Minor adjustments were necessary to ensure a perfect seal.

The oboe was restored to its original state. The case highlights the need for careful observation and the ability to adapt to unexpected challenges in instrument repair.

Q 18. How do you stay updated on the latest techniques and technologies in musical instrument repair?

Staying updated in this field requires a multi-pronged approach. It’s an ongoing learning process.

Professional Associations: I actively participate in professional organizations focused on musical instrument repair. These provide access to publications, workshops, and conferences with the latest developments.

Trade Publications and Journals: I regularly read specialized magazines and journals that feature articles on new techniques, tools, and materials in instrument repair. This is like keeping up-to-date with medical journals for a surgeon.

Online Resources: Online forums, communities, and educational websites are invaluable for sharing knowledge and getting insights from other professionals. I also keep track of important blogs and podcasts.

Continuing Education: I regularly take workshops and advanced training courses to refine my skills and learn new techniques. This allows me to stay at the forefront of the field.

Continuous learning is vital; the world of musical instrument repair is always evolving.

Q 19. What safety precautions do you take while working with musical instruments?

Safety is paramount in my work. Musical instruments involve various materials, sharp tools, and potentially hazardous substances. My safety practices include:

Personal Protective Equipment (PPE): Always using safety glasses, hearing protection, and a dust mask when appropriate.

Proper Tool Handling: Always using tools correctly and carefully. Keeping my workspace organized and clean minimizes the risk of accidents. It’s all about preventing slips and falls.

Chemical Safety: When working with solvents, glues, and finishes, I ensure proper ventilation and use appropriate gloves and respiratory protection.

Ergonomics: I maintain good posture and use appropriate tools to minimize strain and potential injuries.

Electrical Safety: If working with any electronic components, I always ensure that the power is off before making any repairs or modifications.

A safe workspace is an efficient workspace. Prevention of accidents is always my top priority.

Q 20. Describe your understanding of acoustics and its role in instrument design.

Acoustics is fundamental to instrument design. It’s the science of sound, and understanding it is critical to building instruments that produce desirable sounds.

Understanding the Role of Acoustics: The shape, size, and material properties of an instrument directly impact how it resonates and produces sound. For example, the soundboard of a guitar affects the volume and tone of the instrument, a poorly designed one will make the guitar sound flat and lifeless.

Resonance: Instruments are designed to resonate at specific frequencies to amplify the sound produced by the strings (guitar), air column (wind instruments), or striking mechanism (piano). The resonance determines the instrument’s overall tonal character.

Material Properties: The type of wood, metal, or other materials used affects the instrument’s resonance, tone quality, and durability. For instance, the density and stiffness of spruce wood are highly relevant to a violin’s tone.

Shape and Size: The physical dimensions of an instrument are crucial in determining its acoustic properties. A longer string on a guitar, for example, will produce a lower note. Similarly, the length of a flute’s air column impacts its pitch.

Designing an instrument involves a careful interplay between these factors, and modern acoustic analysis software assists in optimizing instrument designs for optimal performance.

Q 21. How do you handle customer interactions and manage expectations regarding repairs?

Handling customer interactions involves clear communication, empathy, and setting realistic expectations. It is critical for building trust and ensuring customer satisfaction.

Clear Communication: I begin by thoroughly explaining the instrument’s condition, the nature of the repair needed, the estimated time for completion, and the associated costs. I use clear, simple language, avoiding jargon whenever possible.

Realistic Expectations: I make sure customers understand what is realistically achievable and when. I manage expectations by clearly stating any limitations or potential challenges in the repair process.

Regular Updates: I provide regular updates throughout the repair process, keeping customers informed of any progress or unexpected issues. This transparency builds trust and reduces anxiety.

Empathy and Patience: I address customer concerns with patience and empathy, recognizing that a damaged instrument can be emotionally significant. I strive to build a professional yet personalized relationship with each customer.

Post-Repair Follow-up: After the repair is completed, I follow up with customers to ensure they are satisfied and to address any further concerns. This shows a commitment to customer satisfaction.

Building strong customer relationships is vital to establishing a successful career as a musical instrument repair professional.

Q 22. Explain your experience with different types of adhesives and their applications in instrument repair.

Choosing the right adhesive is crucial in instrument repair, as it directly impacts the structural integrity and sound quality of the instrument. My experience encompasses a wide range of adhesives, each suited to specific materials and repair types.

- Hide glue: A traditional, animal-based glue ideal for wood repairs, particularly on antique instruments. It’s reversible with heat and water, a significant advantage when dealing with valuable pieces. I often use it for repairing cracks in soundboards and gluing in loose braces on acoustic guitars. Its flexibility allows for some movement in the wood without compromising the joint.

- Titebond wood glue: A modern, versatile, and readily available PVA (polyvinyl acetate) glue. It offers excellent strength and water resistance, making it suitable for various wood joints and repairs. I use this frequently for repairs that need strong bonds but don’t require reversibility.

- Epoxy resins: These two-part adhesives are exceptionally strong and provide excellent adhesion to a variety of materials, including wood, metal, and plastics. They are invaluable for filling cracks, repairing broken parts, and bonding dissimilar materials. However, they are not reversible, so careful application is vital.

- Cyanoacrylate (super glue): This fast-setting adhesive is useful for small repairs and bonding delicate parts. However, its rigidity can be detrimental in some applications, making it less ideal for repairs where wood movement is expected. I use it sparingly, primarily for minor cracks or attaching small decorative elements.

Selecting the right adhesive involves considering factors such as the material being repaired, the type of joint, the required strength, and the need for reversibility. For example, I wouldn’t use epoxy to glue a loose bridge on a violin, as the rigidity could negatively impact the instrument’s tone, whereas hide glue would be more appropriate.

Q 23. How do you maintain accurate records and documentation of your repair work?

Maintaining meticulous records is essential for accountability, repeatability, and client communication. My documentation process involves a combination of digital and physical records.

- Detailed repair notes: I create a comprehensive written report for each repair job, detailing the instrument’s condition before and after the repair. This includes descriptions of damages, materials used, the repair process itself, and any challenges encountered. Photographs are a crucial part of this process, providing visual documentation of the before, during, and after stages.

- Client communication log: I maintain a log of all communications with the client, including initial consultation notes, updates on progress, and final discussions about the completed work. This ensures transparency and fosters strong client relationships.

- Digital inventory: I use a database to track all repairs, including client information, instrument details, repair dates, materials used, and cost. This system allows me to easily search for past repairs and generate reports, aiding in future inventory management and trend analysis.

This multi-faceted approach ensures that all aspects of each repair are properly documented, creating a comprehensive record for future reference and promoting professional integrity. For instance, detailed photos of a crack repair help with future evaluations and allow the client to see exactly what work was performed. This meticulous approach minimizes misunderstandings and maintains a high standard of professionalism.

Q 24. Describe your knowledge of different musical instrument families and their unique characteristics.

My knowledge of musical instrument families is extensive, encompassing their construction, materials, and unique sonic characteristics.

- String Instruments: I have expertise in repairing violins, violas, cellos, double basses, guitars (acoustic and electric), and other stringed instruments. I understand the intricacies of their construction, from the delicate soundboards of violins to the bracing systems of guitars, and know how to address issues like bridge adjustments, soundpost placement, and fretwork.

- Woodwind Instruments: My experience includes repairing clarinets, flutes, saxophones, oboes, and bassoons. I’m familiar with the intricacies of their key mechanisms, pads, and tone holes and can diagnose and repair leaks, cracks, and other common problems.

- Brass Instruments: I understand the construction and function of trumpets, trombones, French horns, and tubas. I can address issues relating to valves, slides, and dents. Understanding the acoustics of these instruments is key for effective repair.

- Percussion Instruments: While less frequently repaired, I also possess knowledge of the maintenance and repair of percussion instruments, addressing issues such as head replacement and tuning.

Understanding the unique characteristics of each instrument family is crucial. A repair technique effective on a guitar might be inappropriate for a clarinet, highlighting the importance of specialized knowledge within each category. For example, the delicate nature of a violin’s varnish requires a different approach to repairs than the more robust finish of a trumpet.

Q 25. What are your strengths and weaknesses as a musical instrument technician?

My strengths lie in my meticulous attention to detail, my problem-solving abilities, and my commitment to delivering high-quality repairs. I am adept at diagnosing complex issues, finding creative solutions, and working effectively both independently and as part of a team. I thrive in environments requiring precision and patience.

A weakness I’m actively working to improve is time management when faced with multiple urgent repair requests. While I strive for excellence in every repair, occasionally I need to refine my prioritization skills to ensure timely completion of all tasks. I’ve implemented a task management system to address this, breaking down larger projects into smaller, more manageable steps.

Q 26. How do you handle pressure and tight deadlines in your work?

Pressure and tight deadlines are inherent aspects of this profession. I handle them effectively by prioritizing tasks, utilizing efficient workflows, and communicating proactively with clients.

- Prioritization: I assess the urgency of each repair based on factors like the instrument’s importance, the client’s needs, and the complexity of the repair. This allows me to focus on the most time-sensitive tasks first.

- Efficient workflow: I maintain a well-organized workspace and utilize time-saving techniques to streamline the repair process. This includes optimizing my tool selection and pre-planning repair steps.

- Proactive communication: I keep clients informed about the progress of their repairs, managing expectations and proactively addressing any potential delays. Transparency builds trust and reduces stress for both the client and myself.

For example, if I have multiple urgent repairs, I’ll create a detailed schedule, allocating specific time slots for each instrument, and consistently update the client on the anticipated completion time. This proactive approach minimizes stress and helps me deliver exceptional results, even under pressure.

Q 27. What are your salary expectations?

My salary expectations are commensurate with my experience and skills, and are competitive within the industry. I am open to discussing a specific salary range based on the details of the position and benefits package.

Q 28. Why are you interested in this position?

I am deeply interested in this position because it offers the opportunity to utilize my skills and experience in a challenging and rewarding environment. I’m particularly drawn to [Company Name]’s reputation for excellence and commitment to preserving musical heritage. I’m confident that my skills and dedication would make me a valuable asset to your team. I am eager to contribute to a collaborative and supportive work environment where I can continuously learn and grow in my profession.

Key Topics to Learn for Your Musical Instrumentation Skills Interview

Ace your upcoming interview by mastering these key areas. Remember, demonstrating a deep understanding of both theory and practical application will set you apart.

- Instrument-Specific Techniques: Deep dive into the nuances of your instrument. This includes advanced techniques, maintenance, and troubleshooting common issues. Consider showcasing your understanding of historical playing styles and their impact on your chosen instrument.

- Music Theory Fundamentals: Demonstrate a solid grasp of music theory relevant to your instrument. This includes scales, chords, harmony, rhythm, and sight-reading. Be ready to discuss how theoretical knowledge informs your practical playing.

- Ensemble Playing and Collaboration: Discuss your experience in ensemble settings. Highlight your ability to listen actively, adapt to different musical styles, and contribute effectively to a group performance. Explain how you handle constructive criticism and contribute to a positive team dynamic.

- Aural Skills and Ear Training: Showcase your ability to recognize intervals, chords, and melodies by ear. Explain how this skill enhances your musical understanding and improvisation capabilities. Practice transcribing short musical passages.

- Improvisation and Creativity: Prepare examples demonstrating your improvisational skills and creative approach to music. Be ready to discuss your approach to musical problem-solving and your ability to adapt to different musical contexts.

- Technology and Musical Instrumentation: Discuss your familiarity with music technology relevant to your instrument. This might include digital audio workstations (DAWs), notation software, or electronic instruments. Explain how technology enhances your musical workflow and creative process.

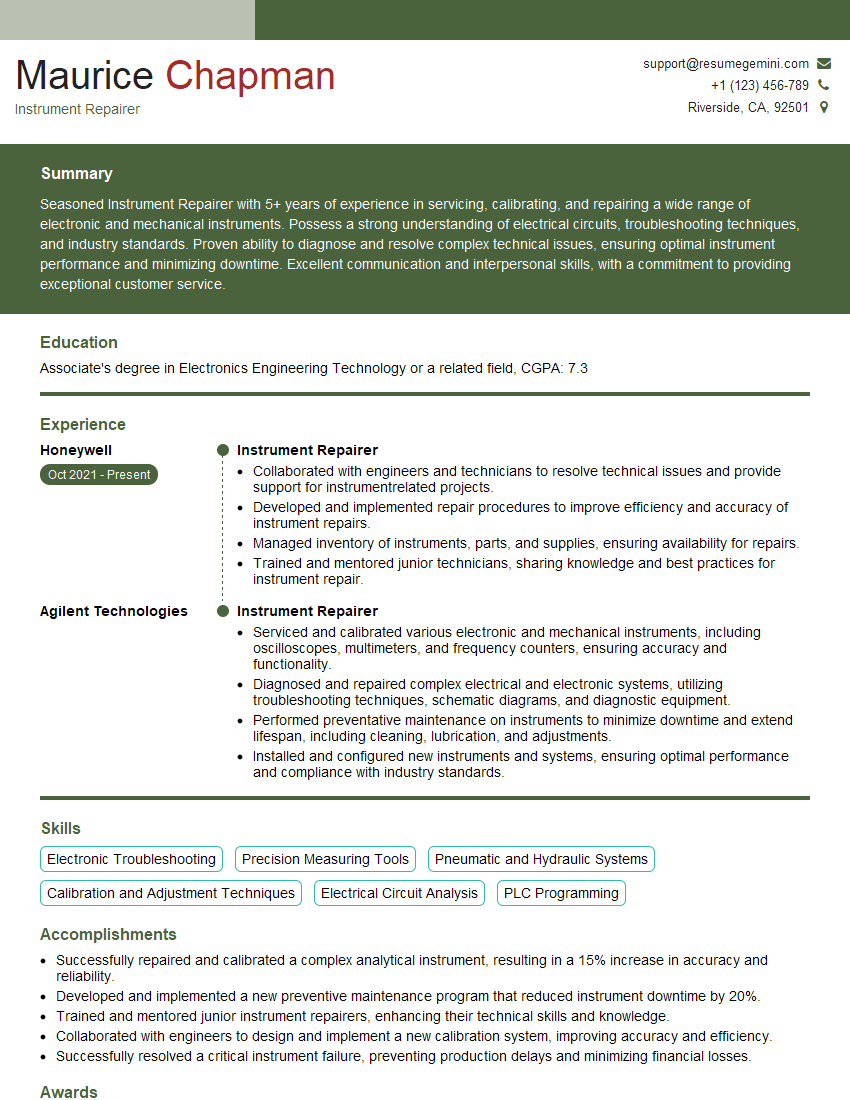

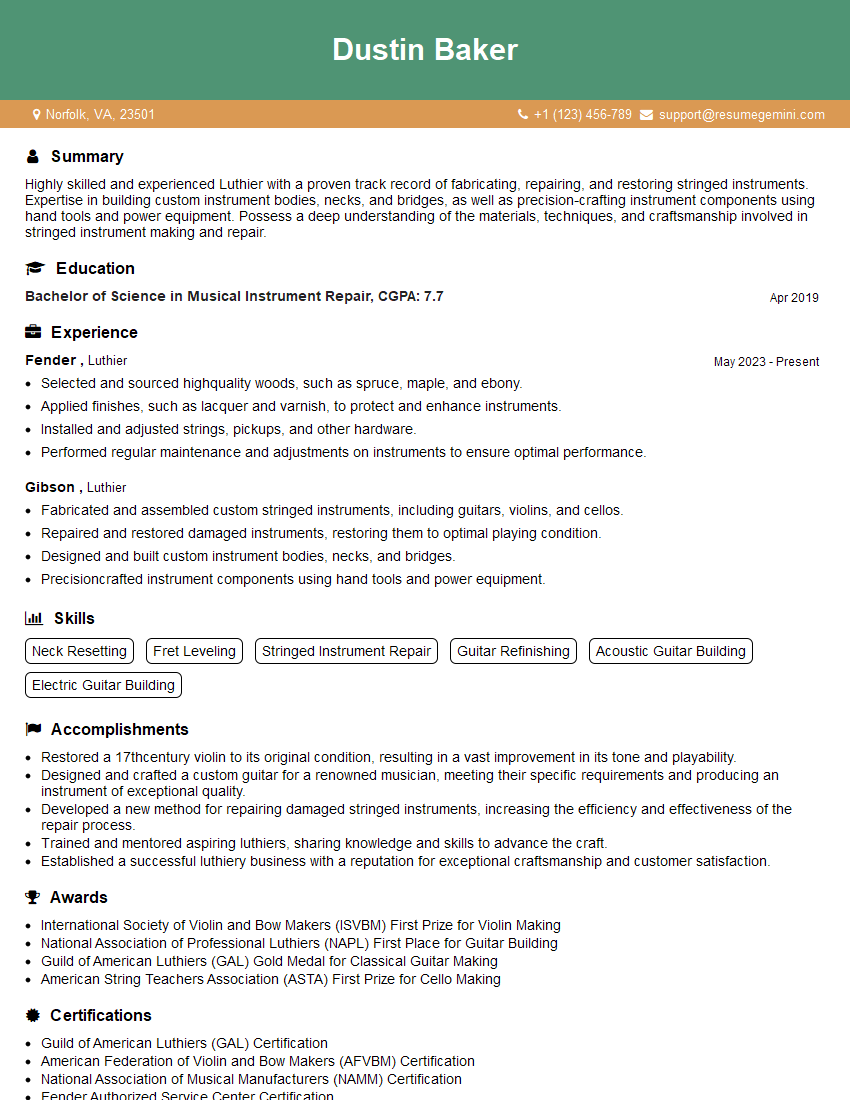

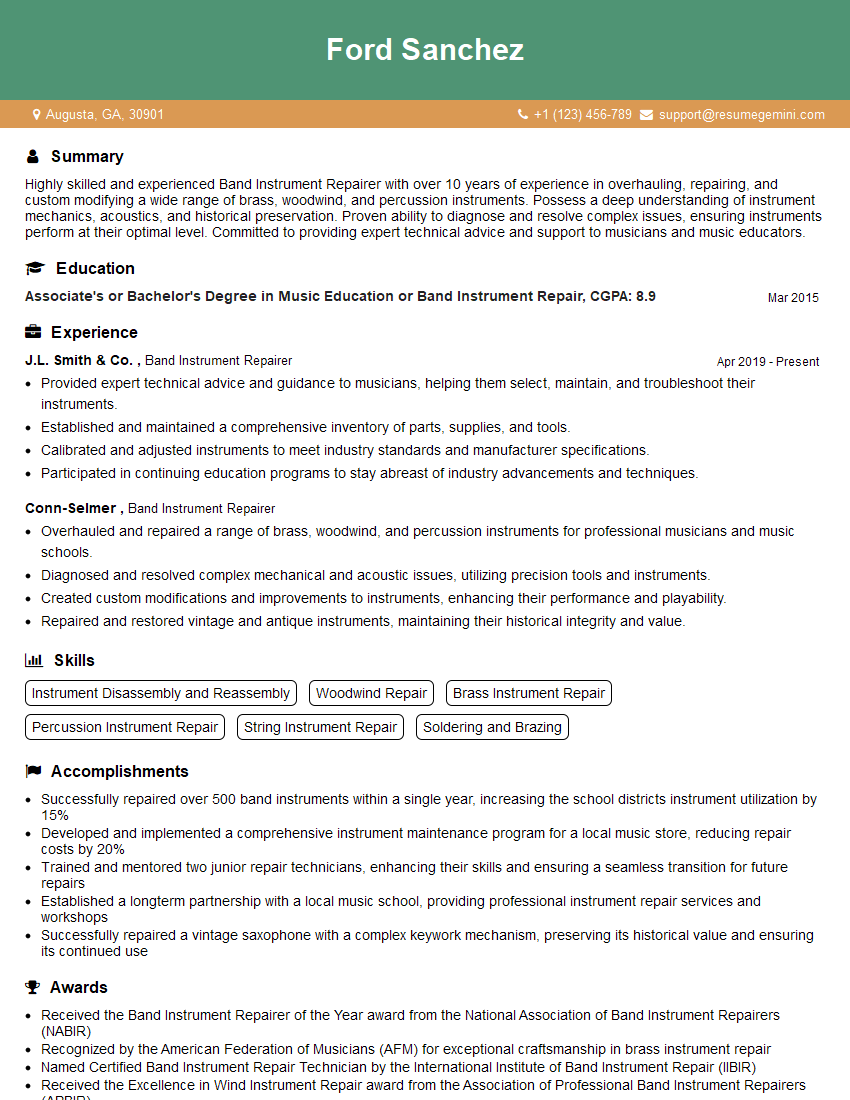

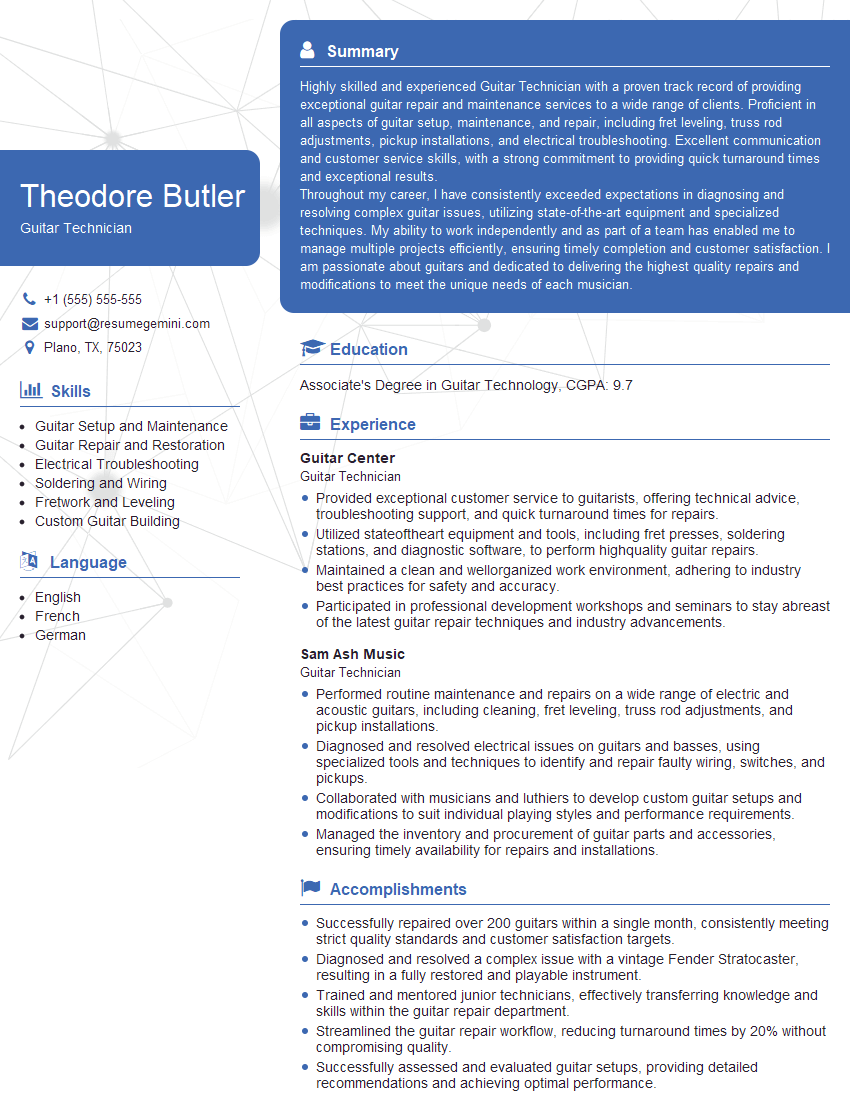

Next Steps: Level Up Your Career

Mastering musical instrumentation skills opens doors to exciting career opportunities. To maximize your job prospects, a well-crafted resume is crucial. An ATS-friendly resume ensures your application gets noticed. ResumeGemini is a trusted resource to help you build a professional, impactful resume that highlights your unique skills and experience. We provide examples of resumes tailored to Musical Instrumentation Skills to guide you. Invest the time to create a strong resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good