Preparation is the key to success in any interview. In this post, we’ll explore crucial Mycelium Cultivation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Mycelium Cultivation Interview

Q 1. Explain the life cycle of a common mycelium species.

The life cycle of a common mycelium species, like that of Pleurotus ostreatus (oyster mushroom), begins with the spore. These microscopic reproductive units, analogous to seeds in plants, germinate under suitable conditions, sprouting into a hypha – a single, thread-like filament. Multiple hyphae intertwine to form the mycelium, the vegetative part of the fungus, which is essentially a network of these filaments. This mycelium grows and spreads, absorbing nutrients from its substrate. Once the mycelium reaches a certain maturity and environmental cues are met (like sufficient nutrients and moisture), it initiates fruiting. This stage involves the formation of primordia, small knots of mycelium that develop into mushrooms (the fruiting bodies). The mushrooms then release spores, completing the cycle and beginning anew. Think of it like a plant – the mycelium is the root system, unseen but vital, and the mushroom is the flower, its visible reproductive structure.

Q 2. Describe different methods for mycelium cultivation (e.g., solid substrate, liquid culture).

Mycelium cultivation employs several methods, each with advantages and disadvantages. Solid substrate cultivation is the most traditional, using materials like straw, sawdust, or grain as a growing medium. The mycelium colonizes this substrate, eventually leading to fruiting. This method is relatively simple and inexpensive, suitable for home cultivation and small-scale production. Liquid culture, on the other hand, involves growing mycelium in a liquid nutrient solution (broth), often under sterile conditions. This allows for rapid growth and a more controlled environment, making it ideal for large-scale production and creating inoculum for solid substrate cultivation. Another method is Agar plate cultivation, which utilizes a petri dish with agar gel as the growth medium. This is primarily used for isolating pure mycelium cultures and studying their morphology.

Q 3. What are the optimal environmental conditions (temperature, humidity, light) for mycelium growth?

Optimal environmental conditions are crucial for successful mycelium growth. The ideal temperature range generally falls between 20-25°C (68-77°F), though this varies depending on the species. Maintaining high humidity (around 90-95%) is vital to prevent the mycelium from drying out. Light is generally not a significant factor for mycelium growth; in fact, many species thrive in the dark. However, excessive light can lead to heat buildup and inhibit growth. Think of it like a plant’s roots – they don’t require sunlight but do need appropriate temperature and moisture to flourish.

Q 4. How do you maintain sterility during mycelium cultivation?

Maintaining sterility is paramount to prevent contamination by unwanted bacteria, fungi, or other microorganisms. This is achieved through several techniques: Sterilization of all equipment and substrates using autoclaves (high-pressure steam sterilization) or other methods like pressure cookers. Aseptic techniques – these are practices like working in a clean environment (e.g., a laminar flow hood), using sterile gloves and tools, and carefully transferring mycelium to avoid contamination. Antimicrobial agents, like specific fungicides or antibiotics, can be used in certain situations but must be used carefully to avoid harming the desired mycelium. Imagine it like performing surgery – strict cleanliness and precision are essential for success.

Q 5. Explain the process of substrate preparation for mycelium growth.

Substrate preparation is a critical step, as the substrate provides the nutrients for mycelium growth. The process generally involves: Selection of a suitable substrate (e.g., straw, sawdust, grain). Preparation – this might involve chopping, soaking, or pasteurization to ensure the substrate is suitable for colonization. Sterilization – the substrate must be sterilized to eliminate existing microorganisms. For instance, straw might be soaked, then pasteurized using steam to kill competing organisms before inoculation with mycelium. This process must be done meticulously, as a contaminated substrate will likely lead to failure. Proper substrate preparation is like providing a fertile ground for a plant to grow strong.

Q 6. What are common contaminants encountered in mycelium cultivation and how are they controlled?

Common contaminants include bacteria (Bacillus spp., Pseudomonas spp.), other fungi (Trichoderma spp., Penicillium spp.), and molds. These compete with the desired mycelium for resources and can produce substances that inhibit its growth or even kill it. Control strategies include thorough sterilization of equipment and substrates, aseptic techniques during inoculation and handling, and the use of selective media in some cases. Early detection is key – regular monitoring of the cultures for signs of contamination is crucial, and contaminated cultures should be discarded immediately to prevent spreading. For example, if you see unusual colors or textures developing, take action immediately.

Q 7. Describe different techniques for inoculating a substrate with mycelium.

Several inoculation techniques exist: Grain spawn – This involves growing mycelium on sterilized grain (like wheat or rye) and then using this ‘spawn’ to inoculate the main substrate. Liquid culture inoculation – a liquid culture of mycelium is injected or sprayed onto the substrate. Agar plug inoculation – small plugs of agar containing mycelium are placed directly into the substrate. The choice of method depends on the scale of cultivation and the type of substrate. Successful inoculation requires careful aseptic technique to prevent contamination. Each method offers a degree of control over the process. For example, grain spawn is good for large-scale solid substrate cultivation, while liquid culture offers a highly controlled and efficient way to produce inoculum.

Q 8. How do you assess the health and growth rate of mycelium?

Assessing the health and growth rate of mycelium involves a multi-faceted approach combining visual inspection with quantitative measurements. Healthy mycelium typically exhibits a robust, vigorous growth, with a dense, white (or species-specific color) network of hyphae – the thread-like filaments that make up the mycelium. A slow growth rate, discoloration (e.g., yellowing, browning), or the presence of contaminants like bacteria or other fungi are major warning signs.

- Visual Inspection: Look for the density, color, and texture of the mycelium. A healthy colony will show a uniform, dense growth, while unhealthy colonies might display sparse growth, discoloration, or unusual textures. For example, a healthy oyster mushroom mycelium will be fluffy and white, while a contaminated one might show dark spots or slimy areas.

- Growth Rate Measurement: Regularly measure the radial expansion of the mycelium on a suitable substrate. Consistent, rapid growth indicates a thriving colony. You can do this by marking the initial extent of the mycelium and then measuring its increase over time, say daily or weekly.

- Microscopic Examination (optional): For more detailed analysis, microscopic examination can reveal the presence of contaminants or abnormal hyphae structures. This allows for early detection of problems and enables timely intervention.

Think of it like growing a plant. A healthy plant grows vigorously, has vibrant leaves, and is free from pests or diseases. Similarly, healthy mycelium shows rapid, uniform growth and a healthy appearance, free from contamination.

Q 9. What are the key indicators of a successful mycelium cultivation process?

A successful mycelium cultivation process hinges on several key indicators. These aren’t just about the final yield but encompass the entire process from spawn production to fruiting.

- Rapid and Uniform Mycelial Growth: The mycelium should colonize the substrate quickly and evenly, demonstrating its vigor and health. This is an indication of the suitable environment (temperature, moisture, and nutrition).

- Absence of Contamination: Contamination by bacteria, molds, or other fungi is a major concern. A clean, pure mycelium culture is essential for a successful harvest. Regular monitoring for any discoloration or unusual odor is crucial.

- High Yield: The final yield of mushrooms or other products should be high, reflecting the efficiency of the cultivation process. Factors affecting yield include the substrate used, environmental controls, and strain selection.

- Healthy Fruiting Bodies (for mushrooms): If cultivating mushrooms, the fruiting bodies (mushrooms) should be healthy, well-formed, and free from defects. This indicates a successful completion of the lifecycle.

- Consistent Product Quality: Repeated successful runs, yielding similar results in terms of quantity and quality of the final product, is a key sign that the whole process is robust and repeatable.

Imagine baking a cake – you wouldn’t expect a consistently good cake if your ingredients are spoiled, or your oven temperature is uncontrolled. Similarly, consistent monitoring of the environment, substrates and mycelium health is crucial for successful and consistent yield.

Q 10. Explain the concept of spawn production in mushroom cultivation.

Spawn production is a crucial step in mushroom cultivation. It involves creating a pure culture of the desired mushroom species, which is then used to inoculate the substrate (the growing medium). This pure culture, which can take the form of grain spawn, liquid spawn, or plug spawn, acts as the starting point for the growth of the mycelium that will eventually produce mushrooms.

- Grain Spawn: This involves growing the mycelium on a sterile grain, such as wheat or rye. The grain provides nutrients, and the sterile environment prevents contamination. This method is common due to its relatively simple process and easy storage.

- Liquid Spawn: This involves growing the mycelium in a liquid nutrient solution. This method provides rapid growth and allows for large-scale production, commonly used in industrial settings. This spawn is then used to inoculate the substrate.

- Plug Spawn: Wooden dowels are inoculated with mycelium and used to directly inoculate the substrate, often logs or woodchips.

Think of spawn as the ‘seed’ for your mushroom crop. Just as you wouldn’t plant a spoiled seed, you need a healthy, pure spawn to achieve a successful harvest. A contaminated spawn can lead to ruined batches and wasted resources.

Q 11. Discuss different types of substrates used in mycelium cultivation (e.g., agricultural waste, wood chips).

Mycelium cultivation utilizes a diverse range of substrates, each with its own advantages and disadvantages. The choice depends on factors like the target species, cost-effectiveness, and availability.

- Agricultural Waste: This includes materials like straw, corn stalks, rice hulls, coffee grounds, and sawdust. These are readily available, often inexpensive, and environmentally friendly options. Straw, for instance, is commonly used for cultivating oyster mushrooms.

- Wood Chips: Hardwood chips are commonly used, especially for shiitake and other wood-loving mushrooms. The size and type of wood influence the rate of decomposition and nutrient availability for mycelium.

- Compost: A specifically formulated mix of agricultural wastes, often including horse manure, straw, and other materials. Compost is widely used for cultivating many popular mushroom species. Its complexity allows for fine-tuning of the nutrient content.

- Other Substrates: Other materials such as coconut coir, spent grain from breweries, and even paper waste are being explored as sustainable alternatives for growing mycelium.

Choosing the right substrate is akin to selecting the right soil for a particular plant. A nutrient-rich substrate ensures the vigorous growth of the mycelium, while an unsuitable substrate may result in stunted growth or even failure.

Q 12. Describe the challenges of scaling up mycelium cultivation.

Scaling up mycelium cultivation presents numerous challenges, many stemming from the delicate nature of the process. Maintaining sterility, consistency, and efficient resource management become significantly more complex as the scale increases.

- Maintaining Sterility: Preventing contamination becomes exponentially harder as the volume of substrate increases. Large-scale facilities need robust sterile environments and efficient procedures.

- Consistent Environmental Control: Maintaining uniform temperature, humidity, and airflow across a large cultivation area requires sophisticated environmental control systems.

- Substrate Management: Handling and processing large quantities of substrate efficiently and consistently requires specialized equipment and optimized logistics.

- Automation and Technology: Automated systems for processes such as substrate mixing, inoculation, and harvesting are crucial for efficient large-scale operation.

- Cost Optimization: Finding cost-effective ways to manage energy consumption, labor, and waste disposal becomes critical in large-scale cultivation.

Think of it as moving from baking a single cake to running a bakery. Maintaining the same quality and consistency in production requires specialized equipment, careful planning, and efficient processes.

Q 13. How do you ensure the quality and consistency of mycelium products?

Ensuring the quality and consistency of mycelium products involves meticulous attention to detail throughout the entire cultivation process. This includes stringent quality control measures at each stage.

- Spawn Quality: Starting with high-quality, pure spawn is critical. This necessitates careful handling of cultures, stringent sterilization procedures, and regular testing for contamination.

- Substrate Consistency: Using consistent substrate composition and employing standardized procedures for substrate preparation is vital. The substrate’s moisture content, pH, and nutrient levels must be tightly controlled.

- Environmental Control: Precisely regulating temperature, humidity, and air exchange throughout the cultivation period guarantees consistent growth conditions.

- Harvesting and Post-Harvest Handling: Employing standardized procedures for harvesting, cleaning, and packaging prevents contamination and maintains product quality. This ensures uniform product appearance and quality, improving the consumer experience.

- Regular Testing: Throughout the process, regular testing, such as microscopic examination for contamination and quality analysis of the final product, should be conducted.

Similar to a pharmaceutical company, meticulous processes and quality checks ensure a consistent and high-quality final product.

Q 14. Explain the role of quality control in mycelium cultivation.

Quality control (QC) in mycelium cultivation is a proactive and continuous process, not just a final step. It ensures that all steps adhere to standards, minimizing contamination and maximizing product consistency. QC involves various measures implemented at each stage of the process.

- Incoming Material Inspection: Examining substrates and other inputs for quality, purity, and freedom from contamination.

- Environmental Monitoring: Regularly checking temperature, humidity, and airflow to ensure optimal growth conditions.

- Microscopic Examination: Regularly observing the mycelium under a microscope to detect any contamination or abnormal growth patterns.

- Sampling and Testing: Taking samples at various stages of growth to assess growth rate, purity, and overall quality.

- Documentation and Record-Keeping: Maintaining detailed records of all parameters including environmental conditions, substrate composition, and growth stages. This allows for traceability and identification of any potential issues.

- Staff Training and Hygiene: Regular training of personnel in proper hygiene and aseptic techniques.

A robust QC program helps identify and correct problems early, preventing large-scale losses and ensuring a consistent supply of high-quality products.

Q 15. What are the potential applications of mycelium in bioremediation?

Mycelium, the vegetative part of a fungus, demonstrates remarkable potential in bioremediation due to its ability to break down complex organic compounds. This process leverages the enzyme production of fungi to degrade pollutants, rendering them less harmful or even harmless. Think of mycelium as nature’s tiny cleanup crew.

Specific applications include:

- Oil spill cleanup: Certain mycelium species can effectively absorb and metabolize hydrocarbons present in oil spills, reducing environmental damage.

- Heavy metal removal: Mycelium can bind to and immobilize heavy metals like lead and cadmium in contaminated soil, preventing their further spread into the environment. This is often referred to as biosorption.

- Pesticide degradation: Mycelium can break down persistent organic pollutants (POPs), like some pesticides, into less toxic compounds.

- Wastewater treatment: Mycelium can be used in constructed wetlands or bioreactors to remove organic matter and nutrients from wastewater.

The effectiveness of these applications depends on selecting the appropriate fungal species and optimizing growth conditions to maximize enzymatic activity.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the use of mycelium in the creation of biomaterials.

Mycelium’s unique properties – its rapid growth, self-assembly capabilities, and ability to bind various materials – make it a valuable resource for creating sustainable biomaterials. Essentially, we’re using a living organism as a natural manufacturing process.

Examples include:

- Packaging materials: Mycelium can be grown in molds to create packaging alternatives to polystyrene and plastic, offering a biodegradable and compostable solution. Think of mushroom packaging – sturdy yet environmentally friendly.

- Construction materials: Mycelium-based bricks and insulation panels are being developed as eco-friendly alternatives to traditional materials. They offer good insulation properties and are potentially carbon-negative.

- Textiles: Research is underway to create leather-like materials from mycelium, potentially reducing reliance on animal agriculture.

- Biocomposites: Mycelium can be combined with agricultural waste (like hemp hurds or wood chips) to create strong and lightweight composite materials suitable for various applications.

The design and manufacturing process involve growing mycelium on a substrate and then shaping and curing the resulting material. Further research into optimizing growth conditions and material properties is ongoing.

Q 17. Explain the concept of mycoremediation and provide specific examples.

Mycoremediation is the use of fungi, specifically their mycelial networks, to remove or degrade pollutants from the environment. This is a biological approach to environmental cleanup, offering a sustainable alternative to traditional methods.

Specific examples include:

- Petroleum hydrocarbon remediation: Species like Pleurotus ostreatus (oyster mushroom) have been successfully used to degrade oil and diesel fuel components in contaminated soil.

- Polychlorinated biphenyl (PCB) remediation: Certain fungal species can break down PCBs, persistent toxic chemicals, rendering them less harmful.

- Explosives remediation: Some fungi can degrade TNT and other explosives, addressing soil contamination at former military sites or munitions factories.

- Heavy metal remediation: Mycelium can bind to heavy metals (e.g., lead, cadmium) in contaminated soil, preventing their further leaching and uptake by plants.

The success of mycoremediation hinges on carefully selecting the appropriate fungal species, understanding the specific pollutants, and optimizing environmental conditions for optimal fungal growth and pollutant degradation.

Q 18. Discuss the economic viability of mycelium-based products.

The economic viability of mycelium-based products is a growing area, with significant potential for profitability. The cost-effectiveness depends heavily on factors such as:

- Production scale: Larger-scale production can lead to economies of scale, lowering the cost per unit.

- Substrate cost: The cost of the agricultural waste used as a substrate can significantly impact the overall cost of production.

- Energy consumption: Optimizing energy use during cultivation and processing is crucial for maintaining profitability.

- Market demand: The growing consumer demand for sustainable and eco-friendly products drives market growth and improves economic viability.

- Automation: Implementing automation in the cultivation and processing steps will reduce labor costs and improve efficiency.

While initial investment costs might be high, the long-term potential for profit, coupled with increasing market demand and the environmental benefits, presents a compelling economic case for mycelium-based industries.

Q 19. What are the environmental benefits of using mycelium-based products?

Mycelium-based products offer several significant environmental benefits:

- Reduced carbon footprint: Mycelium cultivation often uses agricultural waste as a substrate, reducing landfill waste and potentially sequestering carbon dioxide.

- Biodegradability: Mycelium-based products are biodegradable and compostable, reducing pollution from persistent plastics.

- Renewable resource: Mycelium is a rapidly renewable resource, unlike many traditional materials.

- Reduced reliance on fossil fuels: Mycelium-based materials can replace products that rely on petroleum-based plastics or energy-intensive manufacturing processes.

- Soil improvement: Used mycelium substrates, once composted, can enrich the soil with beneficial nutrients.

Overall, using mycelium-based products helps reduce our dependence on unsustainable materials and manufacturing processes, contributing to a more circular and environmentally friendly economy.

Q 20. Describe the safety considerations associated with mycelium cultivation.

Safety considerations in mycelium cultivation are crucial to avoid contamination and ensure product safety. Key aspects to consider include:

- Contamination control: Strict sterile techniques are essential to prevent bacterial or fungal contamination, which can ruin a batch. This involves using sterile equipment, clean rooms, and appropriate sterilization methods.

- Substrate selection: Using clean and uncontaminated substrates is vital. Agricultural waste needs proper sourcing and handling to minimize contamination risk.

- Allergenicity: Some individuals may exhibit allergic reactions to certain fungal species. Proper handling and protective equipment are required in such cases.

- Mycotoxin production: Certain fungal species can produce mycotoxins (toxic metabolites), posing a potential health risk. Selecting appropriate, non-toxigenic fungal strains is critical. Proper handling and control of the environment are key to avoiding mycotoxin production.

- Waste disposal: Proper disposal of used substrates and waste materials is crucial to avoid environmental contamination.

Understanding and managing these safety aspects ensures the responsible and safe production of mycelium-based products.

Q 21. How do you troubleshoot common problems in mycelium cultivation (e.g., contamination, slow growth)?

Troubleshooting problems in mycelium cultivation requires careful observation and a systematic approach.

Contamination:

- Cause: Introduction of unwanted bacteria or fungi.

- Troubleshooting: Improve sterilization techniques, use clean equipment and substrates, maintain a clean workspace.

Slow growth:

- Cause: Improper environmental conditions (temperature, humidity, aeration), nutrient deficiency, or incorrect substrate pH.

- Troubleshooting: Optimize environmental conditions, check substrate composition and pH, ensure adequate aeration.

Other issues:

- Mycelium not spreading: Check for proper substrate moisture and nutrient levels.

- Discolored mycelium: Could indicate contamination or an adverse reaction to the substrate.

- Unusual texture/odor: May also signal contamination.

Regular monitoring, detailed record-keeping, and adjusting growth conditions based on observations are key to successful troubleshooting.

Q 22. What are the different types of fruiting bodies produced by different mycelium species?

Mycelium, the vegetative part of a fungus, produces a remarkable diversity of fruiting bodies, depending on the species. These fruiting bodies, often what we think of as mushrooms, vary dramatically in shape, size, color, and texture. Think of it like comparing apples and oranges – both fruits, but vastly different!

- Mushrooms (Agaricus bisporus): The classic button mushroom, with its familiar white cap and gills.

- Oyster Mushrooms (Pleurotus ostreatus): These have a fan-shaped, oyster-like cap and are known for their delicate flavor.

- Shiitake Mushrooms (Lentinula edodes): These have a brown, umbrella-shaped cap with a characteristic umami taste.

- Lion’s Mane Mushrooms (Hericium erinaceus): These are unique, with long, cascading spines resembling a lion’s mane and are prized for their medicinal properties.

- Morels (Morchella spp.): These have a honeycomb-like cap and are highly sought-after culinary delicacies.

The diversity extends beyond shape and size. Some fruiting bodies are edible, while others are toxic or inedible. Understanding the specific species and its fruiting body characteristics is crucial for safe and effective cultivation and harvesting.

Q 23. Explain the process of harvesting and post-harvest handling of mycelium products.

Harvesting and post-harvest handling are critical steps in ensuring the quality and safety of mycelium products. The process varies depending on the species and the intended use of the product (e.g., food, packaging, pharmaceuticals).

Harvesting: This generally involves carefully removing the mature fruiting bodies from the substrate. For mushrooms, this often means using a sharp knife to cut the stems close to the substrate, avoiding damage to the remaining mycelium. For other mycelium products, such as those used in packaging, the harvest process might involve removing the entire mycelium-grown structure.

Post-Harvest Handling: Immediately after harvest, the products need careful handling to maintain their quality and prevent spoilage. This includes:

- Cleaning: Removing any debris or substrate from the fruiting bodies.

- Cooling: Rapidly cooling the harvested products to slow down enzymatic activity and microbial growth. This often involves refrigeration or cold storage.

- Sorting and Grading: Sorting the products by size, quality, and appearance. This ensures consistency and helps in pricing and marketing.

- Packaging: Using appropriate packaging to maintain freshness and prevent damage during transportation and storage.

- Storage: Storing the products under optimal conditions (temperature, humidity, and ventilation) to extend their shelf life.

Proper post-harvest handling is crucial for minimizing waste and maximizing the value of the mycelium products. Think of it as the final mile in a marathon – you’ve worked hard, and careful handling ensures your success.

Q 24. What are some emerging technologies used in mycelium cultivation?

Mycelium cultivation is benefiting from several emerging technologies that are improving efficiency, yield, and sustainability. These include:

- Automation and Robotics: Automated systems for substrate preparation, inoculation, environmental control, and harvesting are reducing labor costs and improving consistency.

- Precision Fermentation: This allows for precise control of environmental factors like temperature, pH, and nutrient levels, resulting in higher yields and improved quality. Imagine fine-tuning a recipe to perfection!

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are being used to optimize cultivation processes, predict yields, and detect potential problems early. It’s like having an expert constantly monitoring your cultivation system.

- 3D Bioprinting: This technique is enabling the creation of complex mycelium structures for various applications, including tissue engineering, packaging materials, and architectural components. This is opening up entirely new possibilities!

- Genomic Sequencing and Genetic Engineering: Improved understanding of mycelium genetics is paving the way for the development of superior strains with desirable traits, such as faster growth rates, higher yields, and improved nutritional profiles.

These technologies are transforming the industry, making it more efficient, sustainable, and innovative.

Q 25. How do you design and implement a quality management system for a mycelium cultivation facility?

A robust quality management system (QMS) is essential for a successful mycelium cultivation facility. It should cover all aspects of the process, from substrate preparation to product packaging. The principles of Good Manufacturing Practices (GMP) should be followed rigorously.

Designing the QMS: This involves:

- Defining Quality Standards: Establishing clear quality standards for all aspects of the process, including raw materials, substrate, environmental conditions, and final products.

- Implementing Standard Operating Procedures (SOPs): Developing detailed SOPs for all steps in the cultivation process, ensuring consistency and reproducibility.

- Monitoring and Measurement: Implementing a comprehensive monitoring system to track key parameters like temperature, humidity, pH, and microbial contamination. Regular measurements are crucial for detecting and addressing problems early.

- Documentation: Maintaining accurate records of all aspects of the cultivation process. This includes batch records, environmental monitoring data, and quality control test results.

- Corrective Actions: Having systems in place to address deviations from quality standards and prevent recurrence of problems.

Implementing the QMS: This requires training personnel, regular audits, and continuous improvement. Regular internal and external audits ensure the QMS remains effective and up-to-date. The objective is to create a culture of quality throughout the facility.

Q 26. Describe your experience with different types of laboratory equipment used in mycelium cultivation.

My experience encompasses a wide range of laboratory equipment crucial for successful mycelium cultivation. This includes:

- Autoclaves: Essential for sterilizing substrates and equipment to prevent contamination.

- Incubators: To provide controlled temperature and humidity conditions for mycelium growth.

- Microscopes: For examining mycelium morphology, identifying contaminants, and assessing the quality of the substrate.

- pH meters and conductivity meters: To monitor the chemical properties of the substrate and ensure optimal conditions for growth.

- Spectrophotometers: To measure the growth and metabolic activity of mycelium.

- Clean benches/laminar flow hoods: To provide a sterile environment for inoculation and other aseptic manipulations.

- Bioreactors: For large-scale cultivation of mycelium in a controlled environment.

Proficiency in using and maintaining this equipment is paramount for efficient and reliable mycelium cultivation. It’s like having the right tools for a skilled craftsman – precision and accuracy are key.

Q 27. Discuss your experience with data analysis and interpretation in the context of mycelium cultivation.

Data analysis and interpretation are crucial for optimizing mycelium cultivation processes and improving yields. We collect a large amount of data, such as environmental parameters (temperature, humidity, CO2 levels), substrate characteristics (pH, nutrient content), and growth kinetics (mycelium biomass, fruiting body yield).

Data Analysis Techniques: I utilize various techniques, including:

- Descriptive Statistics: To summarize and visualize data, highlighting trends and patterns.

- Regression Analysis: To identify the relationship between different variables and predict outcomes.

- Statistical Process Control (SPC): To monitor and control the cultivation process and identify potential problems.

- Machine Learning (ML) algorithms: To predict optimal growing conditions and improve yields. This is a developing area, with immense potential.

Interpretation: The interpretation of this data is crucial for making informed decisions regarding process optimization, troubleshooting, and improving overall efficiency. For example, identifying correlations between temperature fluctuations and contamination rates can inform strategies for improving environmental control.

My experience shows that data-driven decision making is critical for success in this field. It’s about using the information to tell a story – a story of how to grow the best mycelium possible.

Q 28. What are your career aspirations within the field of Mycelium Cultivation?

My career aspirations involve leveraging my expertise in mycelium cultivation to contribute to the development of sustainable and innovative solutions. I’m particularly interested in:

- Developing new applications for mycelium-based products: This could range from sustainable packaging materials to novel biomaterials for construction and medicine. The potential applications seem limitless!

- Improving the efficiency and sustainability of mycelium cultivation: This includes exploring new cultivation techniques and optimizing existing processes to reduce environmental impact.

- Mentoring and training the next generation of mycelium cultivators: Sharing my knowledge and experience to help others enter and thrive in this exciting field.

- Contributing to research on the medicinal and nutritional properties of mycelium: Uncovering the full potential of this remarkable organism for human health.

Ultimately, I aspire to be a leader in the field, driving innovation and contributing to the widespread adoption of mycelium-based solutions for a more sustainable future. It’s a journey of discovery and innovation, and I’m excited to see what the future holds.

Key Topics to Learn for Mycelium Cultivation Interview

- Substrate Preparation: Understanding different substrate types (e.g., grain, straw, wood), sterilization techniques, and their impact on mycelium growth and yield.

- Mycelium Inoculation and Growth: Mastering various inoculation methods (e.g., liquid culture, grain spawn), understanding environmental factors (temperature, humidity, airflow) affecting mycelial colonization, and recognizing signs of healthy and contaminated growth.

- Fruiting Body Development: Knowledge of environmental controls necessary for fruiting (light, temperature, humidity, CO2), understanding the different stages of fruiting, and troubleshooting common issues.

- Harvesting and Post-Harvest Handling: Proper techniques for harvesting different types of fungi, handling to prevent bruising and contamination, and storage methods to maintain quality and extend shelf life.

- Sterile Technique and Contamination Control: Proficiency in maintaining sterile conditions throughout the cultivation process, identifying common contaminants, and implementing effective prevention and remediation strategies.

- Strain Selection and Genetics: Understanding the importance of selecting high-yielding and disease-resistant strains, basic principles of fungal genetics and breeding, and the implications for commercial cultivation.

- Scaling and Automation: Knowledge of techniques for scaling up cultivation from small-scale to large-scale operations, including automation and efficient process design.

- Quality Control and Assurance: Implementing procedures for monitoring and ensuring the quality and safety of the final product, including testing for contaminants and heavy metals.

- Troubleshooting and Problem-Solving: Ability to diagnose and solve common problems encountered during mycelium cultivation, such as slow growth, contamination, and poor yields. This includes understanding root cause analysis techniques.

- Safety Procedures and Regulations: Understanding relevant safety protocols for handling fungal cultures and working in a cultivation facility, and awareness of any regulatory requirements related to the cultivation and sale of fungi.

Next Steps

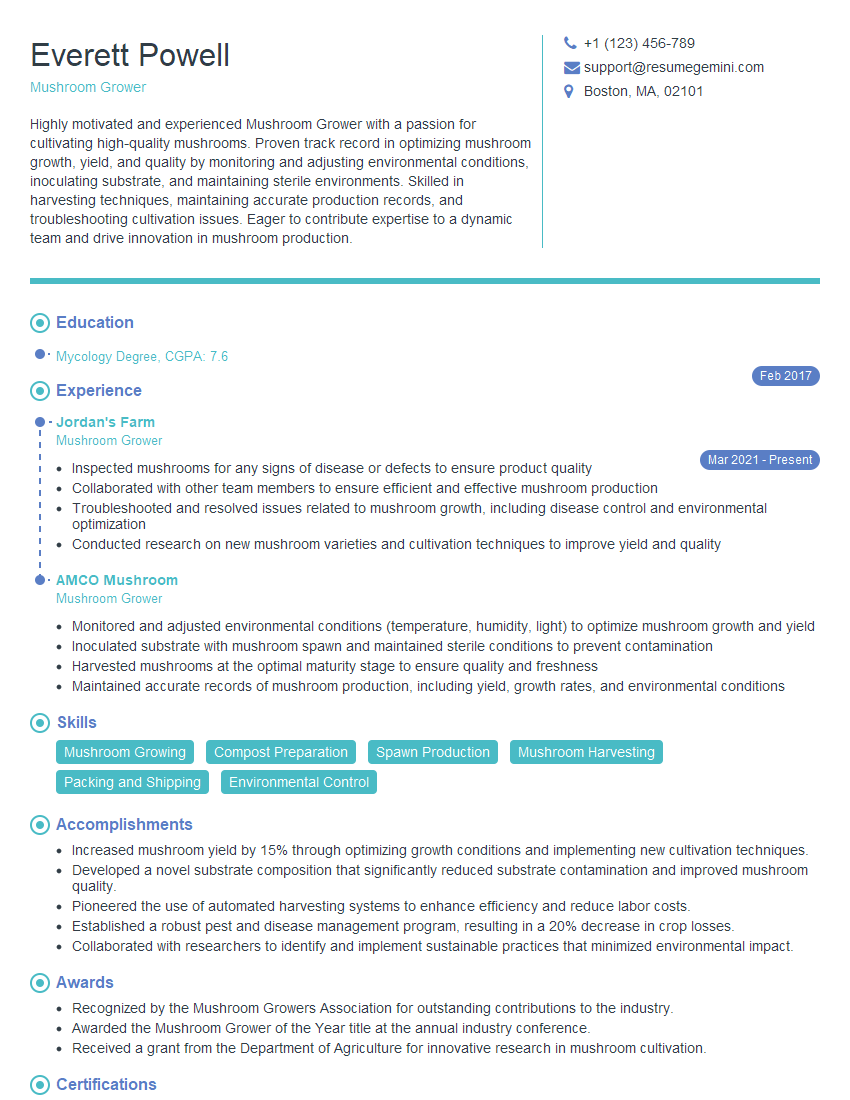

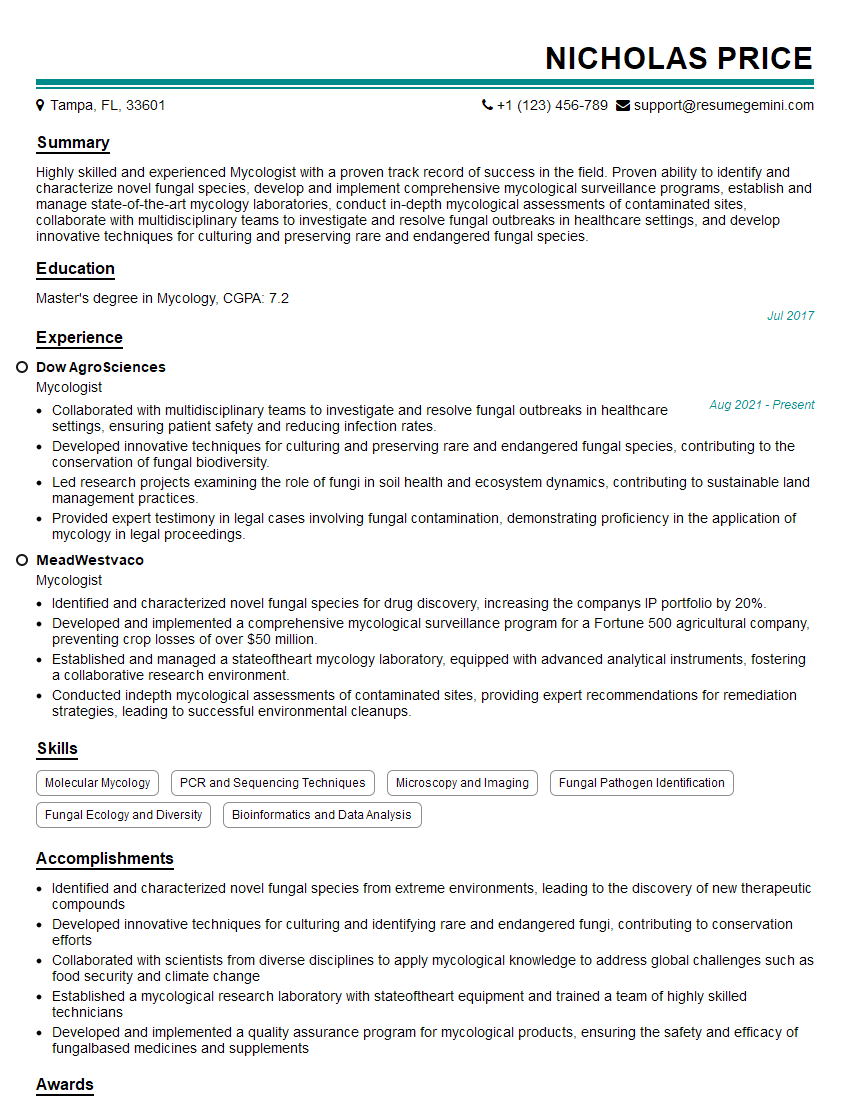

Mastering Mycelium Cultivation opens doors to exciting career opportunities in a rapidly growing industry. To stand out, a well-crafted resume is crucial. An ATS-friendly resume significantly increases your chances of getting your application noticed. ResumeGemini is a trusted resource that can help you build a professional, impactful resume optimized for applicant tracking systems. Examples of resumes tailored to Mycelium Cultivation are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good