Preparation is the key to success in any interview. In this post, we’ll explore crucial Nail Mill Automation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Nail Mill Automation Interview

Q 1. Explain your experience with PLC programming in a nail mill environment.

My experience with PLC programming in nail mill environments spans over eight years, encompassing various projects from initial design to commissioning and ongoing maintenance. I’m proficient in multiple PLC platforms, including Allen-Bradley and Siemens, and have extensive experience writing ladder logic programs to control critical processes such as wire feeding, nail heading, cutting, and sorting. For instance, I developed a program to optimize the wire feed rate based on real-time sensor data, resulting in a 15% increase in production efficiency. This involved using PID control loops to maintain consistent wire tension and compensate for variations in wire diameter. Another significant project involved integrating a new high-speed nail cutting system, requiring careful synchronization of multiple PLC inputs and outputs to ensure accurate cutting and minimize waste.

I’m also experienced in using function blocks for modularity and reusability, making code maintenance and troubleshooting significantly easier. I regularly work with various communication protocols, such as Ethernet/IP and Profinet, for seamless integration of different automation components within the nail mill.

Q 2. Describe your troubleshooting process for a malfunctioning automated nail sorting system.

My troubleshooting process for a malfunctioning automated nail sorting system follows a structured approach. Think of it like diagnosing a medical condition – you need a systematic approach. First, I’d visually inspect the system for any obvious mechanical issues, like jams or broken components. Then, I’d review the system’s alarm logs and PLC data to identify any error codes or unusual readings from sensors. This often reveals clues about the source of the problem.

Next, I’d use a combination of techniques. For example, I’d use the PLC’s online monitoring tools to observe the real-time behavior of variables and outputs. If a specific sensor is showing faulty readings, I would test the sensor itself and the associated wiring to determine if the fault is with the sensor or the connection. If the problem is in the PLC programming, I would analyze the ladder logic, step by step, using breakpoints to identify the source of the malfunction and implement the necessary corrections.

Finally, after resolving the issue, I’d thoroughly document the problem, its root cause, and the solution implemented for future reference and preventative maintenance. This helps to build a knowledge base and minimize the recurrence of similar problems.

Q 3. What are the common types of sensors used in nail mill automation and their applications?

Several types of sensors are crucial in nail mill automation. They’re the system’s ‘eyes and ears,’ providing feedback on the production process. Let’s explore some key examples:

- Photoelectric Sensors: Used for detecting the presence or absence of nails, ensuring proper spacing and counting. These are often used in the sorting and packaging stages.

- Proximity Sensors (Inductive/Capacitive): Detect the presence of metal objects (nails) without physical contact. They are vital for monitoring the flow of nails through various stages of the process, triggering actions like initiating the cutting mechanism or activating sorting chutes.

- Ultrasonic Sensors: Measure distances and levels, useful in monitoring material levels in hoppers and ensuring consistent wire feed.

- Load Cells: Measure the weight of materials, particularly important for ensuring consistent nail weight and preventing overfilling.

- Temperature Sensors: Monitor the temperature of machinery components to prevent overheating and ensure optimal operating conditions. These are vital for predictive maintenance, preventing catastrophic failures.

The choice of sensor depends on the specific application and its requirements. For example, photoelectric sensors are ideal for high-speed counting and detection, while proximity sensors are preferred where non-contact sensing is essential.

Q 4. How familiar are you with SCADA systems and their role in nail mill monitoring and control?

I’m very familiar with SCADA (Supervisory Control and Data Acquisition) systems. In a nail mill, a SCADA system acts as a central control room, providing a comprehensive overview of the entire manufacturing process. Think of it as a dashboard for the entire nail mill. It integrates data from various PLCs, sensors, and other automation components, displaying real-time data on production parameters such as production rate, machine status, and energy consumption.

This allows operators to monitor the entire mill from a central location, facilitating quick identification of issues and enabling timely intervention. Furthermore, SCADA systems are instrumental in data logging and analysis, which is critical for optimizing production efficiency and scheduling maintenance. They enable historical trend analysis to predict potential problems and optimize the entire production process.

My experience includes working with various SCADA platforms, including Ignition and Wonderware. I’ve configured SCADA systems to display key performance indicators (KPIs) using custom dashboards and reports, allowing for better decision-making and enhanced operational efficiency. For example, I’ve set up alarm systems within the SCADA system to alert operators of critical events, such as low material levels or equipment malfunctions, minimizing downtime.

Q 5. Explain your experience with HMI programming and its importance in nail mill operation.

HMI (Human-Machine Interface) programming is essential for effective nail mill operation. The HMI is the operator’s interface to the automation system, providing a user-friendly way to monitor and control the process. Think of it as the control panel of a car – it allows the driver to operate the vehicle. A well-designed HMI simplifies complex operations and makes the system more intuitive for operators.

My experience includes developing HMIs using various software packages, including FactoryTalk View and WinCC. I focus on creating clear, concise, and easy-to-navigate interfaces that provide operators with real-time information about the nail-making process. This includes visual representations of machine status, sensor readings, and production statistics. I also design the HMIs with intuitive controls for adjusting parameters, initiating automated sequences, and handling alarms.

An effective HMI reduces errors, improves operator efficiency, and ensures consistent product quality. For example, I’ve designed HMIs with custom screens displaying production data, allowing operators to quickly identify and address any deviations from setpoints. This improves overall product quality and reduces waste.

Q 6. Describe your experience with robotic systems used in nail manufacturing (e.g., palletizing, handling).

I have significant experience integrating robotic systems into nail manufacturing processes, primarily for palletizing and handling. Robotic systems offer several advantages over manual operations, such as increased speed, accuracy, and consistency. These systems increase efficiency and reduce the risk of workplace injuries.

Specifically, I’ve worked on projects involving the implementation of robotic palletizing systems. These robots are programmed to pick up boxes of nails from a conveyor system, precisely position them on pallets, and wrap them securely, thereby significantly increasing the speed and efficiency of the packaging process. I’ve also integrated robots for handling tasks such as loading and unloading raw materials and transferring finished goods, minimizing manual handling and improving safety.

Programming these robots involves using specialized robot programming languages and interfaces, requiring understanding of robot kinematics and motion control. I’m proficient in integrating robot systems with PLCs and SCADA systems to ensure seamless operation and data monitoring within the overall automation framework.

Q 7. What are the key performance indicators (KPIs) you would monitor in a nail mill automation system?

In a nail mill automation system, several Key Performance Indicators (KPIs) are crucial for monitoring and optimizing performance. These can be grouped into categories:

- Production KPIs: These measure the efficiency of the production process. Examples include:

- Production rate (nails per minute/hour)

- Overall Equipment Effectiveness (OEE)

- Yield (percentage of acceptable nails produced)

- Downtime (percentage of time the system is not producing)

- Quality KPIs: These focus on the quality of the nails produced. Examples include:

- Defect rate (percentage of defective nails)

- Nail length and diameter consistency

- Nail strength

- Maintenance KPIs: These track the maintenance needs of the system. Examples include:

- Mean Time Between Failures (MTBF)

- Mean Time To Repair (MTTR)

- Maintenance costs

- Energy KPIs: These assess the energy efficiency of the system. Examples include:

- Energy consumption per unit of production

By continuously monitoring these KPIs, we can identify areas for improvement, optimize the system’s performance, and reduce operational costs.

Q 8. How do you ensure the safety of personnel working around automated nail mill machinery?

Ensuring personnel safety around automated nail mill machinery is paramount. It’s not just about compliance; it’s about creating a culture of safety. We achieve this through a multi-layered approach.

- Machine Guarding: Every machine has robust guarding, often incorporating light curtains and pressure mats to create safety zones. If a worker enters a restricted area, the machine automatically shuts down. Think of it like a car’s airbag system – multiple layers of protection.

- Lockout/Tagout Procedures (LOTO): Strict LOTO procedures are implemented before any maintenance or repair work is performed. This ensures that all power sources are isolated and the machine cannot be accidentally started. This is crucial, as even a seemingly harmless part of the machinery could cause serious injury if accidentally activated.

- Personal Protective Equipment (PPE): Workers are required to wear appropriate PPE such as safety glasses, hearing protection, and steel-toed boots at all times. This is as fundamental as wearing a seatbelt in a car – it’s a basic preventative measure.

- Regular Training and Safety Audits: We conduct regular safety training programs, covering both theoretical knowledge and hands-on practice. We also conduct frequent safety audits to identify potential hazards and implement corrective actions before incidents occur. A proactive approach is far more effective than a reactive one.

- Emergency Shutdown Systems: Easily accessible emergency stop buttons are strategically positioned throughout the facility. These buttons are designed to instantly shut down the entire system in case of an emergency. It’s like having a panic button – quick and accessible in critical situations.

By combining these measures, we create a safe working environment that minimizes the risk of accidents and protects our workforce.

Q 9. Explain your experience with different types of industrial networks (e.g., Ethernet/IP, Profibus).

My experience spans several industrial network protocols, each offering unique advantages in different contexts. Choosing the right one depends on factors such as speed, distance, cost, and the overall architecture of the system.

- Ethernet/IP: I’ve extensively used Ethernet/IP in large-scale nail mill automation projects. Its open standard nature and high bandwidth make it ideal for handling high volumes of data from various sensors, PLCs, and robotic arms. For example, in one project, we used Ethernet/IP to integrate a high-speed vision system that monitored the quality of nails in real-time, feeding that data to the PLC for immediate adjustments.

- Profibus: Profibus has proven reliable in situations requiring deterministic communication. This is particularly important in applications where precise timing is critical, such as coordinating the movements of multiple robots or controlling high-speed production lines. I’ve successfully utilized Profibus for interfacing with legacy equipment on several occasions, smoothly integrating older machines with newer automated systems.

- Other Protocols: My experience also extends to other protocols like Profinet and Modbus, allowing me to tailor the network design to the specific needs of the project. The key is to carefully analyze the application’s requirements and select the most appropriate protocol for optimal performance and cost-effectiveness.

My expertise allows me to design, implement, and troubleshoot these networks efficiently, ensuring seamless communication between various components of the nail mill automation system.

Q 10. How do you approach the integration of new automation equipment into an existing nail mill system?

Integrating new automation equipment into an existing nail mill system requires a meticulous approach. It’s akin to renovating a house – you need to plan carefully to avoid disrupting the existing structure while adding new features.

- Assessment of Existing System: The first step involves a thorough assessment of the current system, including its hardware, software, network infrastructure, and production processes. This provides a baseline understanding of the existing capabilities and limitations.

- Needs Analysis and Equipment Selection: The next step is to define the specific requirements of the new equipment and select the most suitable solution based on performance, compatibility, and cost. This includes compatibility checks with existing PLC programs and network protocols.

- Design and Simulation: A detailed design is then created, incorporating the new equipment into the existing system. Simulation software is used to test the integration and identify potential issues before implementation. This prevents costly rework during the actual installation.

- Implementation and Testing: The new equipment is installed and thoroughly tested to ensure it functions as intended and integrates seamlessly with the existing system. This includes testing both individual components and the entire system as a whole.

- Documentation and Training: Complete documentation of the modified system is essential for future maintenance and troubleshooting. Training for personnel on the operation and maintenance of the new equipment is also crucial for a successful integration.

This systematic approach ensures a smooth and efficient integration of new automation equipment, minimizing downtime and maximizing productivity.

Q 11. Describe your experience with preventative maintenance of automation equipment in a nail mill.

Preventative maintenance is the cornerstone of reliable automation. It’s far cheaper to prevent problems than to fix them, like regular car servicing.

- Scheduled Maintenance: We adhere to a strict preventative maintenance schedule for all automation equipment, including regular inspections, lubrication, and cleaning. This includes a log detailing each task to help optimize preventative actions. The schedule is tailored to the specific needs of each component, considering factors like operating hours and environmental conditions.

- Predictive Maintenance: In addition to scheduled maintenance, we utilize predictive maintenance techniques, such as vibration analysis and thermal imaging, to detect potential problems before they occur. These methods provide an early warning system, like a check engine light in a car, alerting us to potential issues before they escalate into major failures.

- Spare Parts Management: We maintain an inventory of critical spare parts to minimize downtime in case of unexpected failures. Having the necessary parts readily available is crucial; delays in obtaining parts can result in significant production losses. A proactive spare parts inventory can significantly decrease downtime.

- Data Analysis: We collect and analyze data from the automation system to identify trends and potential issues. This data-driven approach helps us refine our preventative maintenance strategies and optimize equipment performance. Think of it as a dashboard for your machinery, providing insights into their health and performance.

Our preventative maintenance program ensures high availability of the automation equipment, reducing downtime and maximizing production efficiency.

Q 12. What are your preferred methods for documenting automation system designs and processes?

Thorough documentation is essential for maintaining and upgrading automation systems. Without proper documentation, even simple changes can become nightmares.

- Engineering Drawings: Detailed engineering drawings are created for all aspects of the automation system, showing the layout, wiring diagrams, and component specifications. These drawings act as blueprints, providing a complete overview of the system architecture.

- PLC Programs and Ladder Logic: All PLC programs are thoroughly documented, including comments and descriptions of each function. This allows engineers to easily understand and modify the code in the future. Well-commented code is like a well-written instruction manual – clear, concise, and easy to follow.

- Network Diagrams: Network diagrams illustrate the communication pathways between various components of the automation system. This helps in troubleshooting network problems and understanding data flow. This is crucial to quickly resolve network issues.

- Database Systems: We also use database systems to manage and track information relating to maintenance logs, spare parts inventory, and performance data. This centralized approach ensures easy accessibility and consistency of information.

- Version Control: Using version control software allows us to track changes made to the system over time. This enables us to easily revert to previous versions if necessary. It’s like having a backup of your system’s history.

By combining these methods, we ensure clear and comprehensive documentation, which is crucial for efficient maintenance, troubleshooting, and future upgrades.

Q 13. Explain your understanding of different types of robotic end-effectors used in nail handling.

Robotic end-effectors in nail handling are crucial for efficient and precise manipulation. The choice depends on factors such as nail size, shape, and production rate.

- Vacuum Grippers: These are commonly used for handling multiple nails simultaneously. They use suction to pick up and release nails, making them suitable for high-speed applications. Vacuum grippers are often favored for their simplicity and adaptability.

- Mechanical Grippers: These grippers use jaws or fingers to grasp nails individually. They offer more control and precision than vacuum grippers but are typically slower. Mechanical grippers are particularly effective with delicate or oddly shaped nails.

- Magnetic Grippers: If the nails are ferromagnetic, magnetic grippers can be used. These offer a fast and efficient way to handle large quantities of nails. However, they’re unsuitable for non-magnetic materials.

- Custom Grippers: Sometimes, custom-designed grippers are necessary to handle specialized nail types or geometries. For instance, a unique design might be required to grip nails with unusual coatings or shapes.

Selecting the appropriate end-effector is crucial for optimizing the efficiency and reliability of the robotic nail handling system. The choice depends on careful analysis of the nail characteristics and production requirements.

Q 14. How do you address downtime in a nail mill automation system?

Downtime in a nail mill automation system is costly, so addressing it swiftly and effectively is vital. Our approach follows a structured methodology.

- Immediate Actions: The first step is to quickly assess the situation and take immediate action to minimize further disruptions. This could involve shutting down affected parts of the system or implementing temporary workarounds.

- Diagnosis and Root Cause Analysis: Once the immediate crisis is addressed, a thorough diagnosis is conducted to identify the root cause of the downtime. We use diagnostic tools, PLC logs, and operator reports to pinpoint the problem systematically.

- Problem Resolution: Based on the root cause analysis, we implement the necessary repairs or replacements. This may involve replacing faulty components, upgrading software, or adjusting process parameters.

- Preventative Measures: Following successful resolution, we implement preventative measures to avoid similar issues in the future. This may involve upgrading equipment, modifying processes, or enhancing training programs.

- Post-Incident Review: Finally, a post-incident review is conducted to assess the effectiveness of the response and identify areas for improvement in future downtime situations. This forms a vital part of continuous improvement.

By following this systematic approach, we aim to minimize the impact of downtime, restore production quickly, and prevent future occurrences.

Q 15. What programming languages are you proficient in for automation applications?

For nail mill automation, proficiency in several programming languages is crucial. My expertise lies primarily in PLC programming languages like Ladder Logic (used extensively in industrial control systems), and Structured Text (for more complex logic and algorithms). I’m also proficient in Python, which I utilize for data analysis, creating supervisory control and data acquisition (SCADA) systems interfaces, and implementing machine learning algorithms for predictive maintenance. Finally, I have experience with C# and C++ for developing custom applications and integrating with various hardware components. For instance, I used Python to develop a script that automatically analyzed sensor data from a nail-forming machine, identifying patterns that predicted potential malfunctions before they occurred.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with vision systems in a nail mill environment.

My experience with vision systems in nail mills centers around quality control and defect detection. I’ve worked with systems that use high-resolution cameras to inspect nails for imperfections like bends, cracks, or inconsistencies in size and shape. This typically involves integrating cameras with a robust image processing system. The software analyzes the images, compares them to pre-defined quality standards, and triggers automated rejection mechanisms for faulty nails. I have hands-on experience with several vision system manufacturers, including Cognex and Keyence, and I’m familiar with configuring and calibrating the systems for optimal performance in the demanding environment of a nail mill. For example, I implemented a system that used machine learning to improve the accuracy of defect detection by continuously learning from the images it processed, significantly reducing false positives and negatives.

Q 17. How familiar are you with different types of industrial motors used in nail mill automation?

Nail mill automation relies heavily on several types of industrial motors. I’m familiar with AC induction motors, which are robust and widely used for driving conveyors, feeders, and other material handling systems. Servo motors provide precise control and are essential for applications requiring accurate positioning and speed, such as in nail-heading and cutting mechanisms. Stepper motors are also used, especially for smaller, precise movements. I understand the selection criteria for each type, considering factors like torque requirements, speed, precision, and environmental conditions. For example, in one project, I optimized the selection of servo motors for a nail-pointing machine to improve its speed and accuracy, leading to a significant increase in production output.

Q 18. Explain your experience with pneumatic and hydraulic systems used in nail manufacturing.

Pneumatic and hydraulic systems play significant roles in nail manufacturing. Pneumatic systems are commonly used for actuating grippers, clamps, and ejection mechanisms due to their simplicity, speed, and relatively low cost. Hydraulic systems, on the other hand, are often preferred for applications requiring higher force, such as powering the presses used for forming the nail heads. My experience includes troubleshooting malfunctions in both types of systems, designing new pneumatic and hydraulic circuits, and selecting appropriate components to meet specific performance needs. I’m well-versed in safety protocols and preventative maintenance for these systems to ensure safe and efficient operation. For instance, I redesigned a pneumatic clamping system to eliminate a recurring leak, reducing downtime and improving overall efficiency.

Q 19. How do you ensure the accuracy and precision of automated nail manufacturing processes?

Ensuring accuracy and precision in automated nail manufacturing requires a multi-faceted approach. This begins with selecting high-quality components and precision tooling. Regular calibration and maintenance of machines are crucial, as are robust quality control systems incorporating vision systems and in-line gauging. Real-time data monitoring and analysis allow for quick identification and correction of deviations from established parameters. Feedback control loops are essential in many processes; for instance, controlling the speed of a conveyor based on the rate of nail production. Finally, implementing statistical process control (SPC) techniques helps to identify trends and prevents potential issues before they impact quality. One example of how I improved precision was by integrating a closed-loop control system for the wire feeding mechanism, significantly reducing variations in nail length.

Q 20. Describe your approach to managing a project involving the implementation of new automation technology in a nail mill.

My approach to managing a project involving new automation technology begins with a thorough needs assessment, focusing on the specific goals and challenges of the nail mill. This includes detailed discussions with mill management and operators to understand their workflows and limitations. A detailed project plan is then developed with clearly defined milestones, timelines, and responsibilities. Regular progress meetings ensure alignment and address any emerging issues promptly. The process includes rigorous testing and commissioning to ensure seamless integration of the new technology and operator training. Effective communication is key; regular updates keep all stakeholders informed. A successful automation project in a nail mill demands a methodical and collaborative approach, balancing technical expertise with practical considerations.

Q 21. What are the potential challenges associated with implementing automation in an older nail mill?

Implementing automation in older nail mills presents several unique challenges. Older mills often lack the infrastructure needed for modern automation, such as robust power supplies, network connectivity, and sufficient space for new equipment. Retrofitting new equipment into an existing layout can be complex and costly. Legacy equipment might not be compatible with modern automation systems, requiring extensive modifications or replacements. Furthermore, older mills might have outdated safety systems that need upgrading to meet current standards. Finally, integrating new systems with existing control systems can be tricky, requiring careful planning and specialized expertise. Overcoming these challenges involves careful planning, risk assessment, and a phased approach that minimizes disruption to production.

Q 22. How do you ensure compliance with safety regulations when working with automated nail mill equipment?

Safety is paramount in nail mill automation. My approach is multifaceted, starting with rigorous adherence to OSHA (or equivalent regional) standards. This involves implementing and enforcing strict lockout/tagout procedures for all maintenance and repair activities, ensuring all machinery is equipped with emergency stop buttons readily accessible, and implementing comprehensive safety training programs for all personnel involved. We use light curtains and proximity sensors to prevent accidental contact with moving parts, and regular machine inspections are conducted to identify and rectify potential hazards before they escalate. Beyond this, I advocate for a culture of safety, promoting employee reporting of near-misses and actively participating in safety audits to identify areas for improvement. This isn’t just about checking boxes; it’s about creating a safe and productive work environment. For example, on a recent project, we discovered a blind spot in a safety system which we rectified by adding additional sensors and modifying the control logic, preventing a potential injury.

Q 23. What is your experience with data analytics in relation to improving nail mill automation efficiency?

Data analytics plays a critical role in optimizing nail mill automation. I’ve extensively used data from various sources – PLC data logs, sensor readings, production output records – to identify bottlenecks and inefficiencies. For example, we used statistical process control (SPC) charts to track the variation in nail dimensions and identify the root causes of defects, leading to adjustments in machine parameters. Machine learning algorithms were also used to predict potential equipment failures based on historical data, allowing for proactive maintenance and preventing costly downtime. We visually represent this data through dashboards to quickly identify key performance indicators (KPIs) like production rate, defect rate, and energy consumption, allowing for targeted improvements. A real-world example involved analyzing sensor data to identify a slight vibration pattern in a key component just before failure, allowing us to schedule maintenance before a complete shutdown occurred. This saved the company significant production loss and repair costs.

Q 24. Describe your experience with different types of control strategies (e.g., PID control, motion control).

My experience encompasses a range of control strategies, primarily PID control and motion control. PID control is essential for regulating parameters like temperature and pressure within the nail manufacturing process. I’ve implemented PID controllers to maintain the precise temperature of the heating elements, crucial for achieving the desired nail hardness and preventing defects. Motion control, on the other hand, is fundamental to precisely controlling the movement of robotic arms used for material handling and nail placement. I’ve worked with various motion control systems, integrating them with PLCs and utilizing advanced algorithms like trapezoidal profiling to optimize speed and accuracy. For instance, in one project, we used a combination of PID and motion control to synchronize the movement of multiple robotic arms involved in picking and placing nails, significantly increasing throughput. Understanding the nuances of each control system and their application within the nail mill environment is key to achieving optimal performance and precision.

Q 25. How do you stay updated on the latest advancements in nail mill automation technology?

Staying current in this rapidly evolving field requires a multi-pronged approach. I regularly attend industry conferences and trade shows, such as the Automation Fair or similar events, to network with peers and learn about new technologies. I actively participate in professional organizations like the ISA (Instrumentation, Systems, and Automation Society), accessing their publications and resources. I also subscribe to industry journals and online publications that cover automation advancements and regularly research emerging technologies. Furthermore, I actively participate in online communities and forums dedicated to automation, which keeps me abreast of the latest challenges and solutions. Continuous learning is essential to maintain a competitive edge in this dynamic industry.

Q 26. Describe a situation where you had to troubleshoot a complex automation problem in a nail mill.

One particularly challenging situation involved a recurring jam in the nail feeding mechanism. Initial troubleshooting pointed to potential issues with the vibratory feeder, but after thorough inspection and data analysis, it was discovered that the issue stemmed from inconsistent nail alignment upstream. The solution involved a systematic approach. First, we meticulously analyzed the PLC data logs to pinpoint the exact timing of the jams. Next, we examined the video footage from high-speed cameras to visually identify the point of failure. It turned out a minor misalignment in a conveyor belt earlier in the process was causing slight variations in nail orientation, leading to the jams. Correcting this misalignment and implementing a more robust alignment system solved the problem, illustrating the importance of comprehensive data analysis and a systematic approach to troubleshooting.

Q 27. How do you handle conflicts or disagreements within a team working on a nail mill automation project?

Conflict resolution is crucial for successful project completion. My approach emphasizes open communication and collaborative problem-solving. I encourage team members to express their perspectives openly and respectfully. When disagreements arise, I facilitate structured discussions, ensuring all viewpoints are considered. I encourage active listening and compromise, focusing on identifying common goals. If the conflict persists, I mediate using a structured process, clarifying the root cause and defining a mutually agreeable solution. In one instance, a disagreement arose over the selection of a specific automation component. By fostering open discussion, we explored the advantages and disadvantages of each option and ultimately selected the most cost-effective and efficient solution for the project, which improved team cohesion.

Q 28. What are your salary expectations for this role?

My salary expectations for this role are commensurate with my experience and the industry standard for a senior automation engineer with my expertise in nail mill automation. I am open to discussing a specific compensation package based on a detailed review of the role’s responsibilities and the company’s compensation structure.

Key Topics to Learn for Nail Mill Automation Interview

- Mechanical Systems: Understanding the mechanics of nail manufacturing, including feeding mechanisms, hammering systems, and cutting processes. Consider the role of different materials and their impact on automation.

- Automation Technologies: Familiarize yourself with Programmable Logic Controllers (PLCs), SCADA systems, robotics, and sensor technologies used in nail mill automation. Explore their integration and control strategies.

- Process Optimization: Learn about techniques for improving efficiency, reducing waste, and enhancing the overall quality of nail production through automation. This includes understanding key performance indicators (KPIs).

- Safety and Maintenance: Study safety protocols and preventative maintenance strategies specific to automated nail mill environments. Understanding the importance of regular inspections and troubleshooting is crucial.

- Data Analysis and Reporting: Explore how data from automated systems is collected, analyzed, and used to improve processes. Familiarize yourself with data visualization techniques relevant to this industry.

- Troubleshooting and Problem-Solving: Practice identifying and resolving common issues in automated nail mill systems. Develop your analytical skills to diagnose problems efficiently and effectively.

- Industry Standards and Regulations: Understand relevant safety and quality standards within the nail manufacturing industry and how automation contributes to compliance.

Next Steps

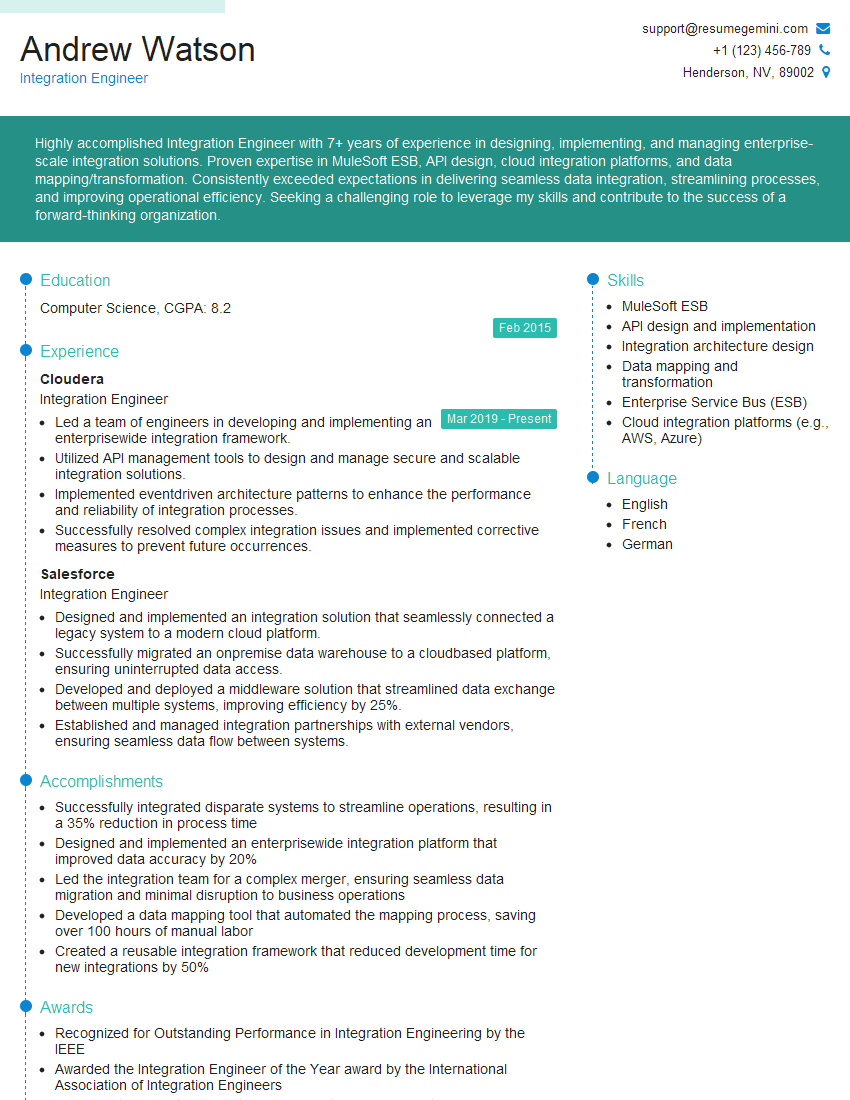

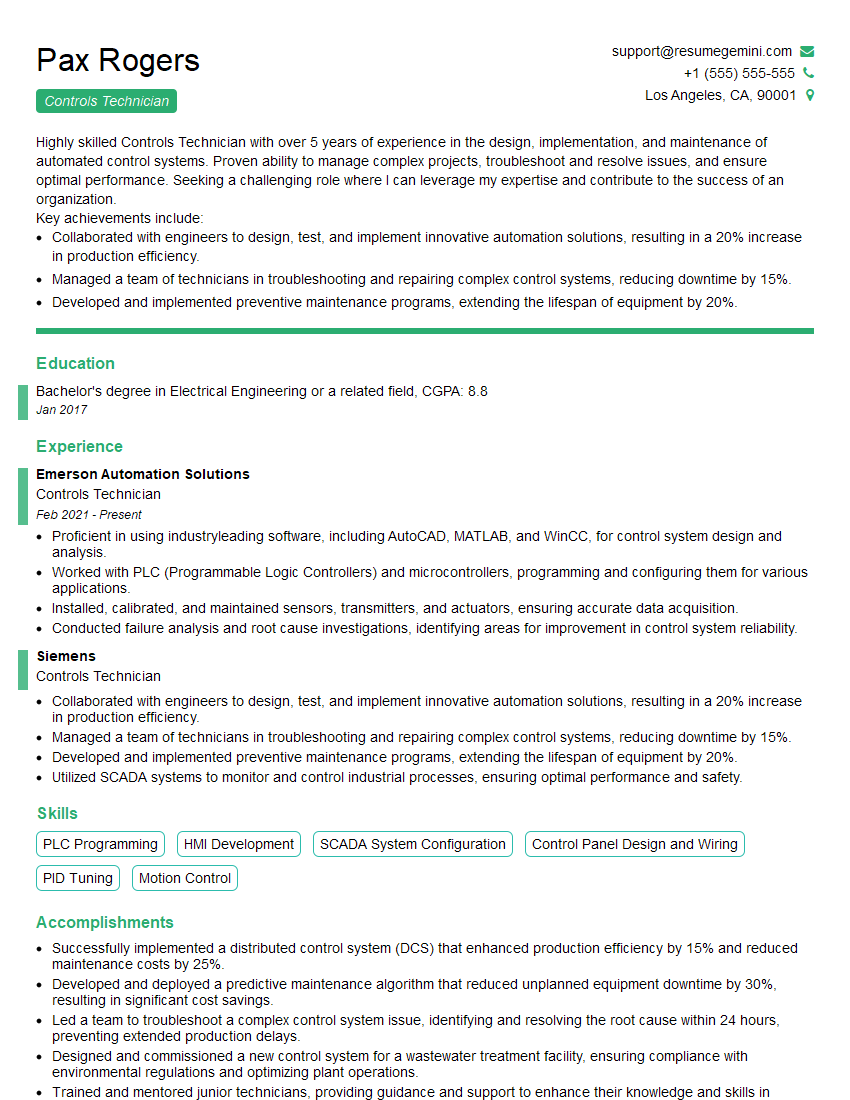

Mastering Nail Mill Automation opens doors to exciting career opportunities in a growing industry, offering competitive salaries and the chance to work with cutting-edge technologies. To maximize your chances of landing your dream job, it’s crucial to present yourself effectively. Creating an ATS-friendly resume is essential for getting past Applicant Tracking Systems and reaching the hiring manager. We strongly recommend using ResumeGemini to build a professional and impactful resume that highlights your skills and experience in Nail Mill Automation. ResumeGemini offers examples of resumes tailored to this specific field to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good