Are you ready to stand out in your next interview? Understanding and preparing for Network Cable Installation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Network Cable Installation Interview

Q 1. Explain the difference between twisted-pair, coaxial, and fiber optic cables.

Network cables come in various types, each with unique characteristics. Twisted-pair, coaxial, and fiber optic cables differ primarily in their construction, transmission medium, and performance capabilities.

- Twisted-Pair Cable: This is the most common type used in local area networks (LANs). It consists of pairs of copper wires twisted together to reduce electromagnetic interference (EMI). Categories like Cat5e, Cat6, and Cat6a specify bandwidth and performance characteristics. Think of it like a phone cord – multiple wires twisted together to prevent signal noise.

- Coaxial Cable: This cable features a central conductor surrounded by an insulating layer, a conductive shield, and an outer jacket. It’s used for applications like cable television and older Ethernet networks. Its shielding offers better EMI protection than twisted-pair, making it suitable for carrying higher bandwidth signals over longer distances, although less so than fiber.

- Fiber Optic Cable: This uses strands of glass or plastic to transmit data as pulses of light. Fiber offers significantly higher bandwidth, longer transmission distances, and better immunity to EMI than both twisted-pair and coaxial cables. Think of it as a superhighway for data, capable of carrying far more traffic with much less interference.

In short: Twisted-pair is cost-effective for shorter distances and lower bandwidth needs. Coaxial provides better shielding. Fiber offers the best performance and distance capabilities, but is more expensive.

Q 2. Describe the process of terminating a Cat5e cable.

Terminating a Cat5e cable involves preparing the cable ends and connecting them to an RJ45 connector. Precision is key to ensure a reliable connection. Here’s a step-by-step process:

- Cut the Cable: Cut the cable to the desired length, ensuring a clean cut.

- Strip the Outer Jacket: Carefully remove the outer jacket, exposing the twisted pairs. Avoid damaging the individual wires.

- Untwist and Straighten: Untwist the pairs slightly and straighten the individual wires.

- Arrange the Wires: Arrange the wires according to the T568A or T568B wiring standard (choose one consistently). Common standards have a specific color order (e.g., orange/white, orange, green/white, blue, blue/white, green, brown/white, brown). Using a punch down tool helps here.

- Crimp the Connector: Insert the wires into the RJ45 connector, ensuring they are fully seated. Crimp the connector firmly using a crimping tool. Improper crimping is a frequent cause of connection problems.

- Test the Connection: Use a cable tester to verify the connectivity.

Using the incorrect wiring standard (T568A vs. T568B) can lead to connectivity issues, so consistency across all cables in a network is crucial. Remember, neatness and precision are vital for successful termination.

Q 3. What are the common cable testing tools and how do you use them?

Several tools are crucial for testing network cables. These allow us to identify faulty cabling before it impacts network performance.

- Cable Tester: This device checks for continuity, shorts, and open circuits in the cable, verifying proper wire pairing. Many testers also display wiring diagrams for easy troubleshooting.

- Tone Generator and Probe: This pair helps trace cable paths within a wall or ceiling. The generator sends a tone through the cable, which is then located with the probe.

- Multimeter: This is a versatile tool used to test voltage, continuity, and resistance. Helpful for confirming proper connections at both ends of the cable.

For example, if a cable tester reveals an open circuit, we know a wire is broken, and we can trace the fault using the tone generator and probe. A multimeter can help test the integrity of connectors for continuity issues.

Q 4. Explain the TIA/EIA standards for structured cabling.

TIA/EIA standards, particularly TIA-568, define guidelines for structured cabling systems. These standards ensure interoperability and reliability across different network devices and manufacturers. They cover various aspects, including:

- Cabling Topology: They specify the physical layout of the cabling infrastructure, typically using a star topology for easier management and troubleshooting.

- Cable Types: Define the acceptable cable types and categories (e.g., Cat5e, Cat6) based on bandwidth and performance requirements.

- Connector Standards: Specify the use of RJ45 connectors for twisted-pair cabling.

- Testing Procedures: Outline the procedures and tests to ensure the cable infrastructure meets performance requirements.

Adherence to TIA/EIA standards is essential for creating a robust and scalable network that can support current and future needs. Following these standards ensures compatibility between various equipment, preventing interoperability issues and maximizing network performance.

Q 5. How do you troubleshoot common network connectivity issues?

Troubleshooting network connectivity problems involves a systematic approach. Here’s a typical process:

- Identify the Problem: Pinpoint the affected devices and the nature of the problem (e.g., no connectivity, slow speeds, intermittent connection).

- Check the Physical Layer: Inspect the cables and connectors for damage, loose connections, or incorrect terminations. Use a cable tester to verify cable integrity.

- Check the Device Configuration: Verify that network settings (IP address, subnet mask, gateway) are correctly configured on all affected devices.

- Test Network Connectivity: Use tools like ping, tracert (traceroute), or network monitoring software to isolate the problem. Ping helps confirm reachability. Tracert shows the path and potential bottlenecks.

- Check Network Devices: Examine switches, routers, and other network hardware for any errors or malfunctions.

- Consult Network Documentation: Review network diagrams and documentation to understand the network topology and device configurations.

For example, if a computer can’t connect, I would first check the cable connection, then the computer’s network settings, followed by pinging the gateway and then the DNS server to find the point of failure.

Q 6. What are the different types of connectors used in network cabling?

Various connectors are used in network cabling, each suited to specific cable types and applications.

- RJ45: This is the most common connector for twisted-pair cabling, used with Cat5e, Cat6, and other categories.

- BNC: Used with coaxial cables, often found in older Ethernet networks and video systems. Requires special tools and care.

- SC, LC, ST: These are fiber optic connectors, each with its own unique design and mechanism. Proper handling is important to prevent fiber damage.

- F-Type: Used with coaxial cables in applications such as cable television.

Choosing the right connector is vital. Using an RJ45 on fiber optic cabling or vice-versa is impossible and will cause connectivity problems. Understanding the differences helps in selecting and installing the appropriate hardware.

Q 7. Describe your experience with different cable pulling techniques.

Cable pulling involves carefully routing cables through conduits, walls, or ceilings. Several techniques exist, each suited to different environments and circumstances.

- Hand Pulling: For shorter runs and easily accessible paths, manual pulling is sufficient. Lubricant is often applied to the cable to reduce friction.

- Cable Pulling Grip: A mechanical grip secures the cable, allowing for controlled pulling without causing damage. This is crucial when working with longer runs or multiple cables.

- Cable Pulling Equipment: For longer distances or challenging environments, motorized cable pullers are used. These provide controlled tension and reduce the risk of cable damage.

- Fish Tape: This flexible tape can navigate tight spaces and is used to pull a rope or string through the conduit first, which is then used to pull the cable. Often used in confined areas or retrofitting cables into existing infrastructure.

Safety is paramount. Always understand the conditions and limitations of the chosen technique and environment. Using the correct technique helps reduce damage, ensure correct installation, and minimize potential workplace hazards.

Q 8. How do you identify and avoid common cable installation errors?

Identifying and avoiding cable installation errors is crucial for a robust network. Many errors stem from poor planning, improper termination, or insufficient testing. My approach is threefold: meticulous planning, careful execution, and thorough testing.

Planning: Before I even touch a cable, I meticulously review blueprints, network diagrams, and specifications. This ensures I understand the exact cable routing, termination points, and any special requirements (e.g., fire-rated cabling in certain areas).

Execution: During installation, I pay close attention to detail. This includes using the correct tools, properly stripping and terminating cables, and ensuring secure connections. I avoid sharp bends and kinks that can damage cables. For example, I always use cable ties to secure cables neatly and prevent them from being pulled or snagged. Over-bending a fiber optic cable, even slightly, can cause micro-fractures that severely impair performance.

Testing: After installation, I perform thorough testing using cable certifiers to verify signal integrity, attenuation, and return loss. This ensures that the network performs optimally. A common error is not testing every segment of cabling. I test each cable segment individually, ensuring no weak points exist.

By combining careful planning, precise execution, and rigorous testing, I significantly reduce the likelihood of errors and ensure a reliable network infrastructure.

Q 9. Explain the importance of grounding and bonding in network cabling.

Grounding and bonding are essential for network cable safety and performance, especially with copper cabling. They protect equipment from voltage surges, prevent electromagnetic interference (EMI), and ensure the safety of personnel.

Grounding: This connects the metallic parts of the cabling infrastructure (like cable trays and racks) to the earth. This provides a path for stray electrical currents to safely flow into the ground, preventing damaging voltage spikes. Think of it like a lightning rod – it provides a safe path for a powerful surge.

Bonding: This connects the metal components within the cabling system to each other. This ensures that all metallic parts are at the same electrical potential, preventing voltage differences that could lead to EMI or ground loops. Imagine a metal pipe running along the same path as your cable. If the pipe has a differing voltage from the cable ground, you’ll have a ground loop which induces noise onto your network.

Both grounding and bonding are critical for reducing noise, protecting sensitive electronics, and meeting safety standards. Failure to do this properly can lead to data corruption, equipment damage, and even electrical shock.

Q 10. What safety precautions do you take when working with network cables?

Safety is paramount during network cable installation. My safety procedures include:

Proper Personal Protective Equipment (PPE): This includes safety glasses, gloves, and appropriate footwear. Working with sharp tools and potential electrical hazards necessitates protection.

Lockout/Tagout Procedures: Before working near energized equipment, I always follow lockout/tagout procedures to prevent accidental power-ups. This is non-negotiable, especially when working with higher voltage systems in telecommunications rooms.

Awareness of Surroundings: I am constantly aware of my surroundings, paying attention to overhead obstacles, potential fall hazards, and other workers. I carefully navigate confined spaces and use proper lifting techniques when necessary.

Working at Heights Safety: When working at heights, I always use appropriate fall protection equipment and follow all relevant safety regulations. A proper harness and safety line are always used if working from ladders or elevated platforms.

Following these safety precautions isn’t just about following rules; it’s about ensuring my safety and the safety of those around me. A minor mistake can have significant consequences.

Q 11. Describe your experience with fiber optic cable splicing.

I have extensive experience with fiber optic cable splicing, having worked on numerous projects involving both single-mode and multi-mode fibers. The process requires precision and specialized equipment. A typical splice involves the following steps:

Fiber Preparation: Carefully cleaning and stripping the fiber coating to expose the optical fiber core. This is critical to ensure a clean and accurate splice.

Cleaving: Precisely cleaving the fiber using a fiber cleaver to create a perfectly flat end face. A poor cleave will severely degrade the connection. This requires a steady hand and a good quality cleaver.

Fusion Splicing (most common): Using a fusion splicer, which aligns the two fiber ends and melts them together using an electric arc. This creates a strong and reliable connection. This machine automatically measures the splice loss. The machine’s precise alignment guarantees a low loss splice.

Mechanical Splicing (alternative): An alternative method using a mechanical connector that aligns and physically joins the fibers. This is generally faster but can have higher insertion losses than fusion splicing.

Testing: Testing the splice using an optical power meter or OTDR (Optical Time-Domain Reflectometer) to verify that the signal attenuation is within acceptable limits. Testing ensures the splice is performed successfully and meets required specifications.

My experience spans various fiber types and splice methods, ensuring I can adapt to different project requirements and maintain high quality standards.

Q 12. How do you manage cable slack and prevent cable damage?

Managing cable slack and preventing cable damage is crucial for a long-lasting and high-performing network. My approach involves a combination of techniques:

Proper Cable Routing: I plan cable routes carefully to minimize bends and kinks, using cable trays, conduits, and other support systems to keep cables organized and protected. Sharp bends can significantly increase signal attenuation and eventually damage the cable.

Slack Management: I leave sufficient slack at termination points and within cable pathways. This allows for future adjustments or re-routing without straining the cables. Too little slack can cause damage, whereas too much slack can create tripping hazards.

Cable Ties and Supports: I use cable ties and other support systems to secure cables neatly and prevent them from sagging or becoming tangled. This ensures they are protected from damage and reduces the chance of tripping hazards.

Strain Relief: I use strain relief devices at termination points to prevent excessive strain on the cables. These prevent pulling or bending that can compromise the connection and damage the cable over time. I pay special attention to this at wall plates, patch panels, and equipment.

By implementing these techniques, I ensure that the cables are not only protected but also organized for ease of maintenance and troubleshooting.

Q 13. What is the difference between single-mode and multi-mode fiber optic cables?

Single-mode and multi-mode fiber optic cables differ in their core size and light propagation characteristics. This affects their bandwidth, distance capabilities, and cost.

Single-Mode Fiber: Has a smaller core diameter (around 9 microns), allowing only one mode of light propagation. This results in lower signal attenuation over long distances, making it ideal for long-haul applications and high-bandwidth networks. Think of it as a single lane highway – the light signal travels efficiently in a straight line.

Multi-Mode Fiber: Has a larger core diameter (around 50 or 62.5 microns), allowing multiple modes of light propagation. This results in higher signal attenuation over long distances and limited bandwidth, making it suitable for shorter distances and lower-bandwidth applications. This is like a multi-lane highway – signals travel on multiple paths, leading to signal dispersion and attenuation.

The choice between single-mode and multi-mode fiber depends on the specific application’s requirements for bandwidth, distance, and cost. Single-mode is more expensive but offers higher bandwidth and longer reach.

Q 14. How do you document cable runs and label cables properly?

Proper documentation and labeling are crucial for maintaining and troubleshooting a network. My documentation process involves:

As-Built Drawings: I create detailed as-built drawings showing the exact cable runs, termination points, and equipment connections. These are essential for future maintenance and modifications.

Cable Labels: I clearly label each cable using standardized labeling systems, including information such as cable type, termination points, and network segment. I use heat-shrink labels for durability and clarity. For example, a label might read:

'10GBASE-SR-100-Patch-Panel-A-to-Switch-B'Database Management: In larger projects, I utilize a cable management database to store detailed information about each cable, including its location, length, type, and connections. This allows for easy searching and retrieval of information. These databases often integrate with network monitoring tools.

Documentation Updates: If there are any changes during or after installation, such as rerouting cables or adding new ones, I ensure the documentation is updated accordingly to maintain accuracy.

Accurate documentation saves time, reduces errors, and ensures the long-term integrity of the network infrastructure. This is particularly helpful for troubleshooting complex networks.

Q 15. What experience do you have with different cable management systems?

My experience with cable management systems is extensive, encompassing various approaches from simple cable ties and Velcro straps to sophisticated structured cabling systems. I’ve worked with patch panels, cable trays, raceways, and fiber optic cable management solutions in a variety of settings. For example, in a recent project for a large office building, we implemented a structured cabling system utilizing a 66-block patch panel, meticulously labeled and organized, in a dedicated server room. This ensured easy access for maintenance and future upgrades, minimizing downtime. In contrast, for smaller projects in tight spaces, using adhesive cable clips and strategic Velcro straps proved to be efficient and neat. The key is choosing the appropriate system based on the scale, environment, and future scalability needs of the network.

- Patch Panels: Centralized connection points for easy cable organization and management.

- Cable Trays: Support and organize cables, improving airflow and reducing clutter.

- Raceways: Enclose cables for protection and aesthetics, often used in visible areas.

- Fiber Optic Cable Management: Specialized systems for handling delicate and high-bandwidth fiber optic cables.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with installing network cables in various environments (e.g., office buildings, data centers).

My experience installing network cables spans diverse environments, from the clean, controlled setting of a data center to the often-challenging conditions of an older office building. In data centers, I’ve worked extensively with high-density fiber optic cabling, adhering to strict standards for redundancy and performance. This involved meticulous planning, precision termination, and rigorous testing. In office settings, I’ve encountered obstacles such as cramped spaces, existing infrastructure limitations, and the need to minimize disruption to ongoing operations. For instance, in one office renovation, we had to creatively route cables through existing walls and ceilings, carefully documenting each run to ensure future maintainability. The key is adapting installation methods to the specific environment while maintaining quality and adherence to best practices.

Q 17. How do you handle difficult cable installations (e.g., tight spaces, long distances)?

Difficult cable installations require creativity, planning, and the right tools. When faced with tight spaces, I utilize techniques such as micro-bend cables or smaller diameter cabling to navigate confined areas. For long distances, we might use fiber optics, which offer higher bandwidth and longer reach compared to copper cables. Another solution is employing cable extenders or media converters. For example, when installing cables in a historic building with limited access points, we carefully mapped the route using infrared cameras, minimizing damage to existing structures. A thorough pre-installation survey and planning are essential to avoid unforeseen challenges and delays.

- Micro-bend Cables: Smaller diameter cables for easier installation in tight spaces.

- Fiber Optics: Ideal for long distances and high bandwidth requirements.

- Cable Extenders/Media Converters: Overcome distance limitations for copper cabling.

Q 18. What are your troubleshooting skills related to network connectivity issues?

My troubleshooting approach is systematic and methodical. I begin by identifying the symptoms, then systematically isolate the problem using a combination of tools and techniques. This might involve using cable testers to check for continuity, signal strength, and shorts. I also leverage network monitoring tools such as ping, traceroute, and packet analyzers to pinpoint network bottlenecks or connectivity issues. For example, when a user reported intermittent network connectivity, I used a cable tester to discover a faulty cable. In another case, a network-wide slow down was traced to a faulty switch using a packet analyzer and analyzing network performance data. Clear communication with the end user is key to understanding the problem fully and providing effective solutions.

Q 19. Explain your understanding of network topologies (e.g., star, ring, mesh).

Network topologies define how devices are connected within a network. The three main types are:

Star Topology: All devices connect to a central hub or switch. This is the most common topology in modern networks due to its scalability, ease of management, and fault isolation. If one device fails, the rest of the network remains unaffected.

Ring Topology: Devices are connected in a closed loop, with data traveling in one direction. Less common now, as a single cable failure can take down the entire network.

Mesh Topology: Devices connect to multiple other devices, creating redundant paths. This topology is highly reliable and fault-tolerant, often used in critical infrastructure networks.

Understanding these topologies is crucial for designing and troubleshooting networks. For instance, a star topology is ideal for a small office network, while a mesh topology might be necessary for a large enterprise network that needs high availability.

Q 20. What is your experience with various network standards (e.g., IEEE 802.3, 802.11)?

My experience includes working with various network standards. IEEE 802.3 defines Ethernet standards, specifying physical and data link layers. I’m proficient in various Ethernet standards, including 10BASE-T, 100BASE-TX, and 10GBASE-T, understanding their capabilities and limitations. IEEE 802.11 covers Wi-Fi standards, from 802.11a/b/g/n/ac/ax. I’m aware of the differences in speed, range, and security protocols of each standard. A clear understanding of these standards is crucial for selecting the right equipment and designing networks to meet specific performance and security requirements. For instance, when choosing cabling for a high-speed network, 10GBASE-T cabling would be selected to support 10 Gigabit Ethernet speeds, while 802.11ax Wi-Fi would be considered for high-density wireless environments requiring high throughput and low latency.

Q 21. Describe your familiarity with cable testing equipment.

I’m familiar with a variety of cable testing equipment, including:

- Cable Certifiers: These test cables for compliance with standards, ensuring proper signal transmission and identifying faults like shorts, opens, and miswiring. They provide detailed reports on cable performance.

- Tone Generators and Probes: Used to trace cables within bundles or walls, facilitating identification and routing.

- Optical Time-Domain Reflectometers (OTDRs): Used for testing fiber optic cables, identifying breaks, bends, and other impairments that might affect signal transmission.

- Multimeters: Used for basic electrical testing to confirm power and connectivity.

Proficiency with these tools is essential for ensuring the quality and reliability of network installations, allowing for quick identification and resolution of any potential issues during installation and troubleshooting.

Q 22. What are the common causes of signal attenuation in network cables?

Signal attenuation, or signal loss, in network cables is the weakening of a signal as it travels along the cable. Think of it like water flowing through a pipe – the further it goes, the weaker the flow. Several factors contribute to this:

- Cable Length: The longer the cable, the greater the attenuation. This is simply due to the increased distance the signal must travel.

- Cable Quality: Lower-quality cables, using inferior materials or poor manufacturing techniques, will exhibit higher attenuation than high-quality cables. A poorly shielded cable, for example, is susceptible to interference.

- Frequency: Higher frequency signals (like those used in Gigabit Ethernet) attenuate more rapidly than lower frequency signals. This is a fundamental characteristic of signal propagation.

- Bends and Kinks: Sharp bends or kinks in the cable can introduce significant attenuation. These disrupt the signal’s path and cause reflections.

- Environmental Factors: External factors such as temperature extremes, humidity, and electromagnetic interference (EMI) can all impact signal quality and lead to increased attenuation.

- Connector Issues: Poorly crimped connectors or damaged connectors introduce significant signal loss at the termination points. A loose connection can act as a bottleneck for the signal.

Understanding these causes allows for proactive mitigation strategies such as selecting appropriate cable types and lengths, implementing proper cable management techniques, and using high-quality connectors and terminations.

Q 23. How do you ensure network cable installations meet industry standards and regulations?

Ensuring compliance with industry standards and regulations is paramount for reliable and safe network installations. We adhere to standards like TIA-568 (Commercial Building Telecommunications Cabling Standards) and ISO/IEC 11801 (Information technology – Generic cabling for customer premises).

This involves:

- Proper Cable Selection: Choosing cables that meet the required bandwidth and performance specifications for the application (e.g., Cat5e, Cat6a, fiber optic).

- Correct Termination: Utilizing proper crimping tools and techniques to ensure reliable and consistent connections, minimizing signal loss and errors.

- Testing and Verification: Employing cable testers to certify that the installed cables meet the specified standards, ensuring the network performs as expected. This typically includes testing for signal attenuation, return loss, and near-end crosstalk.

- Documentation: Maintaining comprehensive documentation, including cable diagrams, termination points, and test results. This is crucial for future troubleshooting and maintenance.

- Safety Compliance: Adhering to all relevant safety regulations regarding cable routing, grounding, and working at heights, if necessary.

By consistently following these steps, we ensure the network’s longevity, reliability, and safety, minimizing the risk of future problems and downtime.

Q 24. What is your experience working with various types of cable trays and pathways?

My experience encompasses a wide range of cable trays and pathways, including:

- Ladder Trays: Ideal for high-density cabling, offering easy access and scalability. I’ve worked with various materials like steel and aluminum.

- Cable Trays: These provide a flat surface for cable routing and are suitable for smaller installations. Different types are available depending on capacity and environmental conditions.

- Conduit: Used for protecting cables from physical damage and environmental factors. I am experienced with various conduit materials, including PVC and metallic conduits. Pulling cables through conduit requires appropriate techniques to prevent damage.

- Overhead Cable Pathways: I’m proficient in installing and securing cables in overhead pathways, ensuring proper support and stress relief.

- Underfloor Pathways: Installing cables in underfloor pathways, considering factors like accessibility and potential hazards associated with the space.

I’m adept at selecting the most appropriate cable pathway based on the specific project requirements, considering factors like cable density, environmental conditions, and budget constraints. For example, in a high-security environment, I’d likely choose metallic conduits for better protection against tampering.

Q 25. How do you handle unexpected challenges during a cable installation?

Unexpected challenges are a common occurrence in cable installations. My approach involves:

- Assessment: Carefully evaluate the nature of the challenge. Is it a structural issue, a cabling problem, or something else?

- Problem Definition: Clearly define the problem and its potential impact on the project timeline and budget.

- Solution Brainstorming: Explore various solutions, considering the available resources and constraints.

- Risk Assessment: Evaluate the potential risks and consequences of each solution.

- Solution Implementation: Implement the chosen solution, documenting every step of the process.

- Verification: Verify the solution’s effectiveness and document the final outcome.

- Communication: Maintain clear and consistent communication with the project stakeholders throughout the entire process.

For instance, I once encountered unexpected conduit routing issues during an installation. By collaborating with the structural engineers and exploring alternative pathways, we successfully resolved the issue with minimal project delay.

Q 26. How do you prioritize tasks and manage your time effectively during a cable installation project?

Effective task prioritization and time management are essential for successful cable installation projects. I employ a structured approach:

- Project Planning: Develop a detailed project plan that outlines all tasks, dependencies, and timelines.

- Task Prioritization: Prioritize tasks based on criticality and dependencies, using methods like MoSCoW (Must have, Should have, Could have, Won’t have).

- Resource Allocation: Allocate resources (materials, personnel, tools) effectively.

- Regular Monitoring: Monitor progress against the project plan and make necessary adjustments.

- Risk Management: Identify and mitigate potential risks that could impact the project timeline.

- Communication: Maintain consistent communication with the project team and stakeholders.

I utilize project management software to track progress, manage tasks, and facilitate communication, ensuring tasks are completed efficiently and on schedule.

Q 27. What is your experience with cable labeling and documentation software?

I have extensive experience with various cable labeling and documentation software, including:

- Visio: For creating detailed cable diagrams and network maps.

- AutoCAD: For designing complex cabling systems and integrating them into building plans.

- Specialized Cable Management Software: I’m proficient with several dedicated software solutions that streamline the labeling and documentation process, offering features like automated report generation and barcode integration.

These tools enable me to create accurate, up-to-date documentation, ensuring easy identification and maintenance of the cabling infrastructure. This also simplifies troubleshooting and future modifications. For instance, using barcode labeling allows for swift identification of specific cables during maintenance or repairs.

Q 28. Describe a time you had to troubleshoot a complex network cabling problem.

During a large-scale data center upgrade, we experienced intermittent network connectivity issues on a specific segment. Standard testing tools indicated no obvious faults. The problem was intermittent and difficult to reproduce.

My troubleshooting process involved:

- Systematic Investigation: We systematically checked each component of the affected segment, starting from the patch panel and working towards the end devices.

- Signal Tracing: Using a signal tracer, we pinpointed areas of significant signal attenuation.

- Visual Inspection: A thorough visual inspection revealed a loose connection within a poorly crimped connector deep within a cable bundle.

- Corrective Action: The faulty connector was identified, removed, and replaced with a properly crimped one.

- Testing and Verification: After replacing the connector, comprehensive testing was performed to verify that the connectivity issues were resolved.

This experience highlighted the importance of thorough testing, detailed documentation, and a methodical troubleshooting approach. The seemingly minor issue of a poorly crimped connector, easily missed without meticulous inspection, could have resulted in significant downtime and financial loss.

Key Topics to Learn for Network Cable Installation Interview

- Network Cabling Standards: Understanding TIA/EIA standards (e.g., T568A/B), fiber optic cabling types (single-mode, multi-mode), and their practical implications in different network environments.

- Cable Termination Techniques: Mastering the art of crimping RJ45 connectors, fiber optic termination (fusion splicing, mechanical splicing), and troubleshooting common termination issues like shorts and opens.

- Testing and Troubleshooting: Familiarizing yourself with cable testing equipment (e.g., cable testers, OTDRs), understanding test results, and efficiently troubleshooting connectivity problems in various network setups.

- Network Topologies: Grasping the fundamentals of different network topologies (star, bus, ring, mesh) and their impact on cable installation and network performance. Understanding how to select the appropriate topology for a given scenario.

- Safety Procedures and Best Practices: Knowing and adhering to safety regulations concerning working at heights, handling tools and equipment, and proper cable management techniques.

- Practical Application: Be prepared to discuss your experience with different cabling projects, including the challenges faced and solutions implemented. Highlight your problem-solving skills and ability to work independently and as part of a team.

- Advanced Concepts (Optional): Explore topics like structured cabling systems, fiber optic splicing techniques, network infrastructure design, and data center cabling for more senior roles.

Next Steps

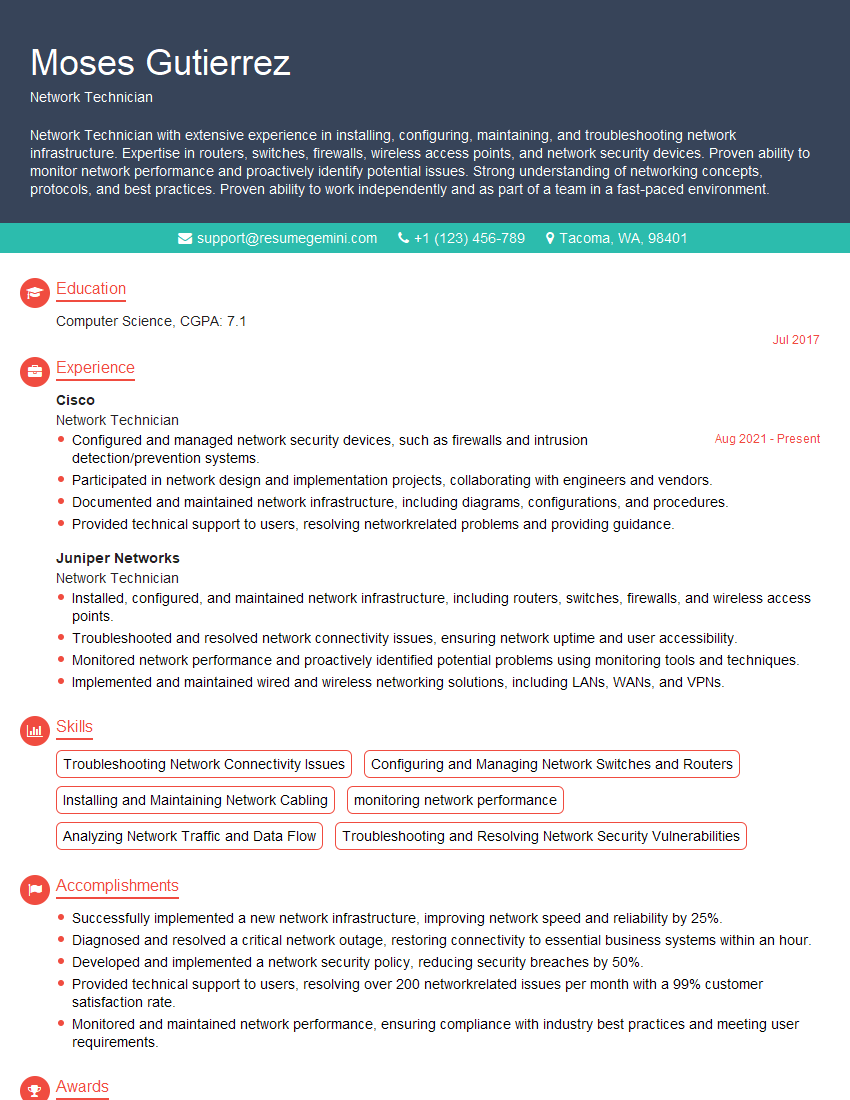

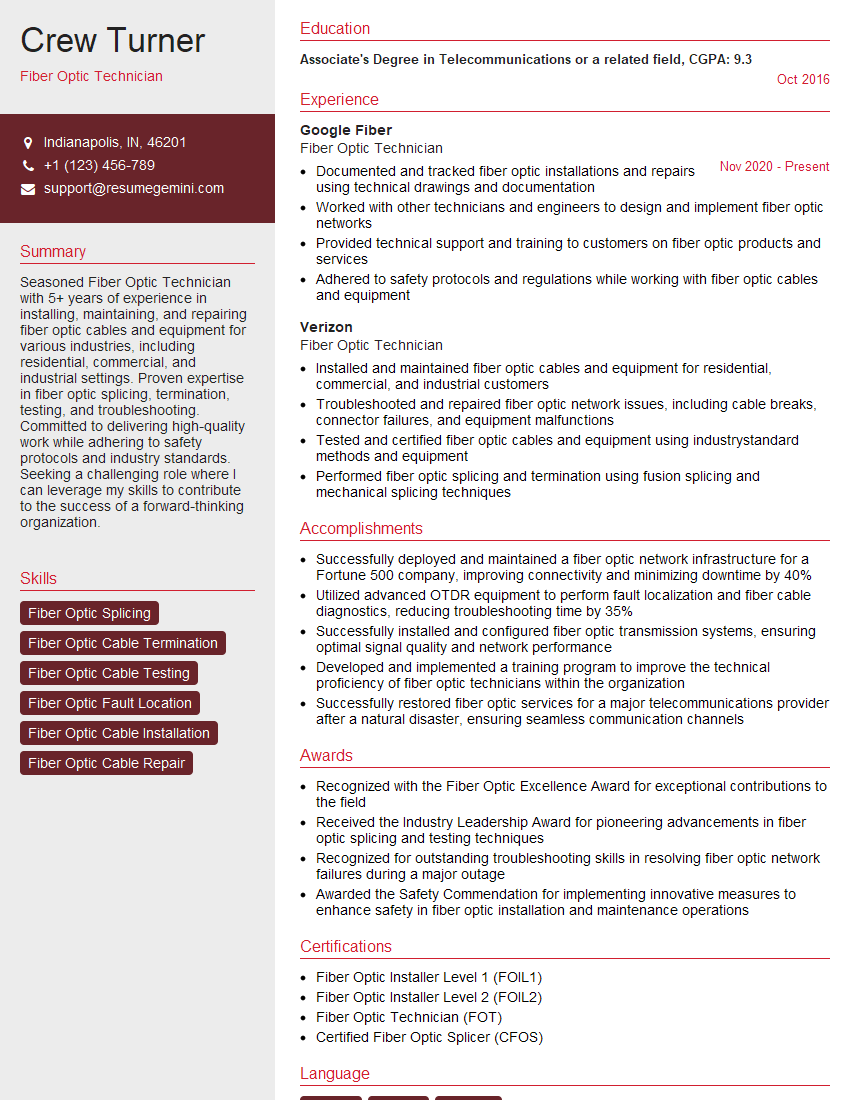

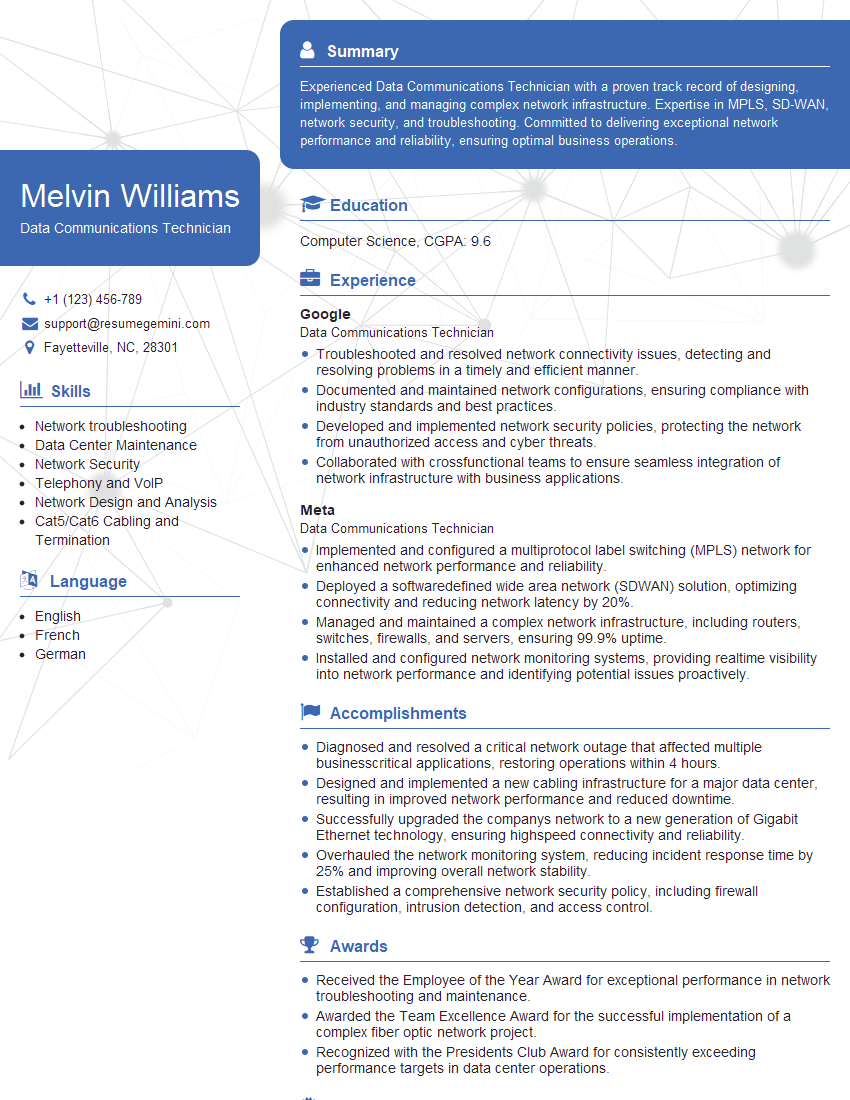

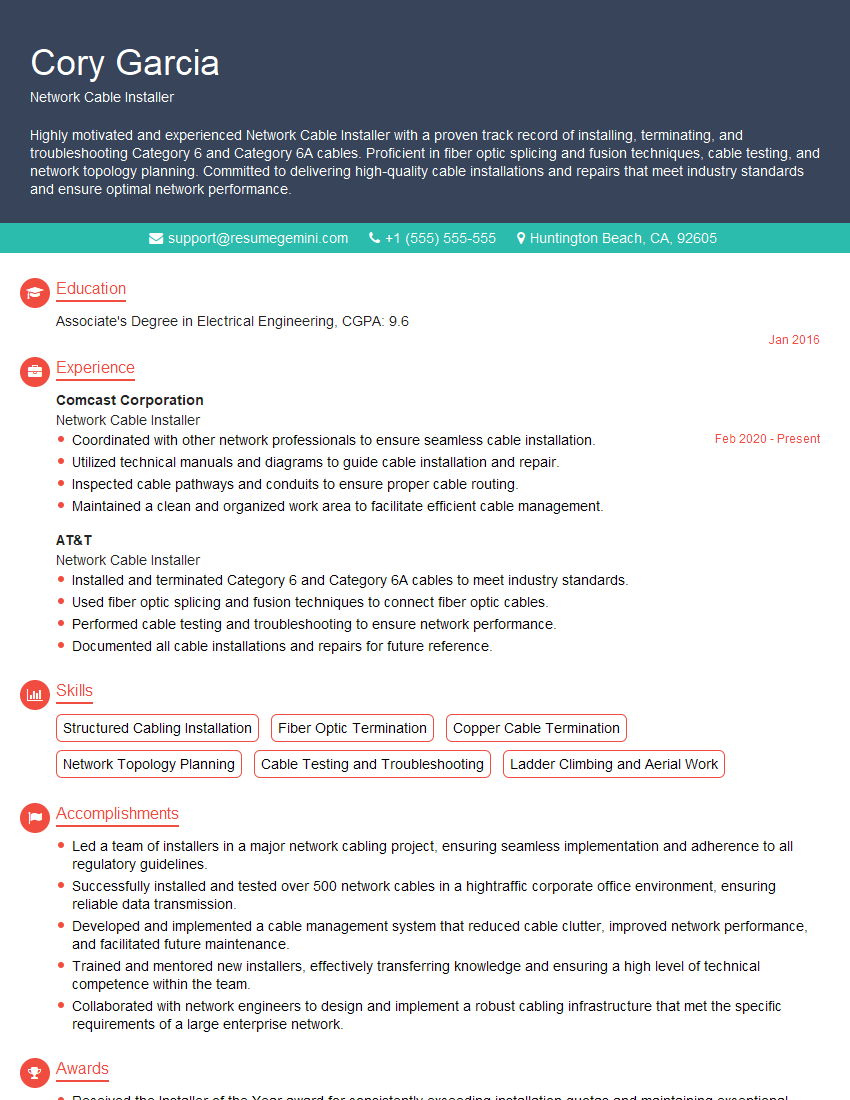

Mastering network cable installation opens doors to exciting career opportunities in IT infrastructure, telecommunications, and various other tech-related fields. Your expertise in this area is highly valuable, offering a strong foundation for career growth and advancement. To maximize your job prospects, it’s crucial to present your skills effectively. Create an ATS-friendly resume that highlights your accomplishments and technical abilities. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. They provide examples of resumes tailored to Network Cable Installation to guide you through the process. Invest time in crafting a compelling resume—it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good