Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Offbearing interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Offbearing Interview

Q 1. Describe your experience with different types of offbearing machinery.

My experience encompasses a wide range of offbearing machinery, from simple manual systems to automated robotic solutions. I’ve worked extensively with conveyor belt offbearing, where finished goods are manually or automatically removed from a moving conveyor. I’m also proficient with robotic offbearing systems, which are especially crucial in high-speed production environments. These robots precisely and efficiently remove parts from machines, minimizing human intervention and increasing throughput. I’ve also had experience with specialized offbearing equipment tailored to specific product types, such as delicate glassware or heavy metal castings, each requiring unique handling techniques and safety measures. For example, in one role, I managed the transition from a manual offbearing system for ceramic tiles to a robotic system, resulting in a 30% increase in output and a significant reduction in workplace injuries.

- Conveyor Belt Offbearing: This involves manually removing products from a moving conveyor belt, requiring attention to speed and avoiding jams.

- Robotic Offbearing: Automated systems use robots to precisely remove products, improving speed and consistency.

- Specialized Offbearing: Custom equipment handles unique product characteristics like fragility or weight.

Q 2. Explain your understanding of safety protocols in an offbearing environment.

Safety is paramount in offbearing. My approach is built on a foundation of adhering to strict safety protocols and proactively mitigating risks. This includes regular safety training, adhering to lockout/tagout procedures (ensuring machinery is safely shut down before maintenance or cleaning), wearing appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed shoes, and maintaining a clean and organized workspace. I rigorously inspect machinery for potential hazards before operation and immediately report any malfunction or unsafe condition. For instance, I’ve implemented a system of color-coded labels to identify potential pinch points or areas requiring extra caution on our robotic offbearing system, reducing near-miss incidents by 25%.

Moreover, I’m a firm advocate for a safety-first culture, constantly reminding colleagues about best practices and fostering a collaborative environment where everyone feels comfortable reporting safety concerns. This collaborative effort ensures that everyone understands and adheres to our safety protocols.

Q 3. How do you handle production line disruptions during offbearing operations?

Production line disruptions demand quick thinking and problem-solving skills. My approach involves a systematic process: first, I identify the root cause of the disruption – is it a machine malfunction, a material shortage, or a quality issue? Once the cause is identified, I take immediate action to resolve the problem, escalating to supervisors if needed. If a machine is malfunctioning, I follow established lockout/tagout procedures and, if qualified, attempt repairs or initiate the repair process. For material shortages, I coordinate with the supply chain team to expedite delivery. Quality issues require careful inspection and potential rework or rejection of defective products. During these disruptions, maintaining clear communication with upstream and downstream operators is crucial to minimizing the overall impact on production.

For example, during a recent jam in our conveyor belt system, I quickly identified the cause – a buildup of debris – and safely cleared the blockage, minimizing downtime. In another instance, a machine malfunction necessitated calling in a specialist, but my prompt reporting ensured the repair process began immediately.

Q 4. What are your strategies for maintaining consistent pace and efficiency in offbearing?

Maintaining a consistent pace and efficiency in offbearing requires a combination of skills and strategies. It’s not just about speed; it’s about consistent, quality work within a safe environment. I use a combination of techniques, including: efficient workflow organization, proper ergonomics, and regular self-assessment to identify areas for improvement. I also leverage process improvement methodologies like Kaizen to identify and eliminate waste in the offbearing process. This can include optimizing workstation layouts, implementing better material handling techniques, or suggesting ergonomic adjustments to reduce operator fatigue. A key aspect of this is proactive monitoring – I track my own performance to identify any trends in speed or efficiency. This data-driven approach allows me to make adjustments and maintain a consistent workflow, even during high-demand periods.

For instance, by reorganizing our workstation layout, I managed to reduce the distance operators had to walk by 15%, resulting in a noticeable increase in output.

Q 5. Describe your experience with quality control checks during the offbearing process.

Quality control is integrated throughout the offbearing process. I conduct visual inspections of each product to identify defects such as scratches, damage, or inconsistencies. This often involves adhering to specific checklists and standards established by the company. Depending on the product type, I might also use specialized tools or equipment to perform more detailed quality checks. Rejected items are segregated and reported to supervisors to initiate corrective actions. Data regarding the number and type of defects are tracked and analyzed to identify patterns and initiate improvements in the upstream production process. This feedback loop is essential for continuous quality improvement.

For example, in my previous role, I implemented a new visual inspection system that reduced the number of defective products shipped by 10%, improving customer satisfaction and reducing costs associated with returns.

Q 6. How do you prioritize tasks when handling multiple offbearing responsibilities?

When juggling multiple offbearing responsibilities, I prioritize tasks based on urgency and importance using a matrix approach. Urgent and important tasks, such as addressing immediate safety hazards or resolving production line blockages, take precedence. Important but less urgent tasks, such as preventative maintenance or completing quality control reports, are scheduled for appropriate times. Less important tasks are delegated or deferred as needed. This approach ensures that critical tasks are addressed promptly, while still allowing time for other important responsibilities.

To avoid feeling overwhelmed, I utilize tools like checklists and task management software to organize my workload and track progress. I also focus on time management techniques to ensure efficient task completion within the allotted timeframe.

Q 7. How do you ensure the safe and efficient removal of materials from machinery?

Safe and efficient material removal necessitates a multi-faceted approach. Firstly, I always ensure that the machinery is properly shut down and locked out before any removal process begins – this is non-negotiable. Next, I utilize appropriate handling techniques and tools based on the material type. For heavy or bulky items, I might use specialized lifting equipment like hoists or forklifts, always following safe operating procedures. For delicate items, I exercise caution and use soft materials to prevent damage during handling. Once the materials are removed, I organize them for transport and storage in a designated area, ensuring appropriate labeling and segregation for different product types. Finally, I inspect the machinery for any damage that may have occurred during the offbearing process and report any findings.

For example, I’ve developed a detailed checklist for removing heavy metal castings from a casting machine, ensuring that all safety procedures are followed and potential hazards are mitigated.

Q 8. Describe your experience with different types of materials handled in offbearing.

My experience in offbearing encompasses handling a wide variety of materials, each requiring a unique approach. This includes everything from delicate, easily-damaged parts like precision-machined components or glass, to heavier, more robust items such as castings or forgings. I’ve also worked extensively with different types of packaging – from individual boxes and crates to bulk containers and pallets. Understanding the specific characteristics of each material is crucial for preventing damage and ensuring efficient handling. For instance, with fragile components, I’d utilize soft padding and gentle movements, whereas heavier items may require the use of material handling equipment such as forklifts or pallet jacks (always adhering to safety protocols, of course). Working with various materials has honed my adaptability and problem-solving skills, allowing me to quickly assess the optimal handling method for any given situation.

- Example 1: Handling delicate electronics required using anti-static gloves and specialized packaging to prevent electrostatic discharge damage.

- Example 2: Moving heavy pallets demanded proper forklift operation and strategic placement to maintain balance and avoid accidents.

Q 9. Explain your understanding of the importance of maintaining a clean and organized workspace.

Maintaining a clean and organized workspace in offbearing is paramount for both safety and efficiency. A cluttered workspace increases the risk of accidents, such as trips and falls, and slows down the entire production process. Imagine searching for a specific part amidst a pile of scrap – that’s lost time and potential damage. My approach involves consistently tidying up after each task, ensuring materials are properly stored, and following the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain). This systematic approach ensures a safe and efficient work environment, contributing to overall productivity and reducing the likelihood of errors. For instance, I would always ensure that walkways are clear, hazardous materials are properly contained, and tools are returned to their designated places after use.

Q 10. How do you identify and report potential safety hazards related to offbearing?

Identifying and reporting safety hazards is a non-negotiable part of my offbearing responsibilities. This involves being vigilant for potential problems, such as spills, damaged equipment, poorly stacked materials, or unsafe working conditions. My approach involves a proactive and systematic identification process. I regularly inspect my work area for potential hazards, using a checklist if necessary. If I identify a potential hazard, I immediately report it to my supervisor, following the established safety procedures. This might involve filling out an incident report form or verbally notifying the supervisor directly, depending on the severity of the hazard. For example, if I noticed a spill, I’d first clean it up (if safe to do so), then immediately report the incident, specifying the location and type of spill to prevent further accidents. The safety of myself and my colleagues is my top priority.

Q 11. What are your strategies for managing physical demands of offbearing work?

Offbearing is physically demanding, requiring prolonged standing, lifting, bending, and reaching. To manage this, I prioritize proper posture, utilize ergonomic techniques, and take regular breaks. I also ensure I’m using appropriate equipment such as lift assists or pallet jacks whenever feasible to reduce strain on my body. Think of it like marathon running; pacing yourself is key. I avoid sudden jerky movements, lift with my legs, and try to distribute the weight evenly. I also stay hydrated and maintain a healthy lifestyle outside of work to support my physical well-being. Regular stretching exercises before and after shifts help prevent muscle soreness and injuries. This proactive approach to physical health ensures I can perform my duties effectively and sustainably.

Q 12. How do you adapt to changes in production schedules or requirements?

Adaptability is key in offbearing. Production schedules and requirements can change rapidly, demanding quick adjustments in workflow. My approach involves maintaining open communication with my supervisors and coworkers, being flexible and willing to handle different tasks as needed, and prioritizing tasks based on urgency and importance. For example, if a rush order comes in, I’ll immediately adjust my workflow to prioritize that order, while still maintaining safe and efficient practices. I also actively seek opportunities to learn new skills and refine my existing ones, enhancing my overall adaptability in the face of change.

Q 13. Explain your experience with teamwork and communication in an offbearing setting.

Teamwork and effective communication are essential in offbearing. It’s not a solitary job; it involves coordinating with machine operators, material handlers, and other team members. My experience has shown me that clear and concise communication is crucial to prevent errors and ensure a smooth workflow. I actively participate in team discussions, provide updates on my progress, and communicate any issues or concerns promptly. For instance, if I anticipate a delay due to a material shortage, I’d immediately inform the relevant team members to help them adjust their schedules accordingly. This proactive approach fosters collaboration and prevents disruptions to the entire production process.

Q 14. How do you handle pressure and meet tight deadlines in offbearing tasks?

Handling pressure and meeting tight deadlines requires a systematic approach. I prioritize tasks based on urgency, break down large tasks into smaller, manageable steps, and utilize time management techniques to stay on track. I also stay calm under pressure, focusing on completing each task accurately and efficiently. This might involve using visual aids like checklists to track progress and stay organized. For example, if I’m facing a tight deadline, I might prioritize the most critical tasks first, delegating less critical tasks if feasible and communicating any potential bottlenecks promptly to avoid last-minute surprises. Maintaining open communication with the team ensures everyone is aligned and working toward the common goal.

Q 15. Describe a time you had to solve a problem related to offbearing equipment or materials.

During my time at Acme Manufacturing, we experienced a recurring issue with the offbearing conveyor system for our newly launched product line. The delicate nature of the product – intricately designed ceramic figurines – resulted in frequent breakage during transfer from the production line to the packaging station. The existing conveyor belt was too aggressive, causing vibrations that shattered the figurines.

To solve this, I first analyzed the problem systematically. I observed the conveyor’s operation, noting the speed, belt material, and the point of most frequent breakage. Then, I researched alternative conveyor belt materials – finding a softer, more shock-absorbent rubber option. Further, I suggested and implemented a reduction in conveyor speed. Finally, I proposed, and the team approved, adding cushioned supports at critical points along the conveyor to further minimize impact. These changes reduced breakage by over 75%, improving efficiency and reducing waste.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your strategies for preventing material damage during offbearing?

Preventing material damage during offbearing relies on a multi-pronged approach. It begins with selecting the appropriate handling equipment for the specific material. For example, fragile items require gentler handling systems like vacuum lifters or soft robotic arms, whereas bulk materials might use conveyors or forklifts.

- Careful Material Handling: Training employees on proper lifting techniques, avoiding sudden movements, and using protective equipment like gloves and anti-slip mats is crucial.

- Equipment Maintenance: Regularly inspecting and maintaining offbearing equipment (conveyors, robots, etc.) to ensure they operate smoothly and minimize the risk of damage is essential. This includes lubrication, belt adjustments and component replacements.

- Packaging Optimization: Using appropriate packaging materials – such as bubble wrap, foam inserts, or sturdy boxes – provides essential protection during transit. The packaging should also be designed to effectively cushion the product against shock and vibration.

- Environmental Control: Maintaining a controlled environment – for example, temperature and humidity control for sensitive products – can prevent damage caused by environmental factors.

Think of it like this: if you’re carrying a delicate vase, you wouldn’t just toss it onto a rough surface. The same principle applies to offbearing – careful planning and execution are key to preventing damage.

Q 17. How familiar are you with different types of packaging and handling techniques?

My experience encompasses a wide variety of packaging types and handling techniques. I am proficient in handling products packaged in everything from individual cartons and shrink wrap to pallets and Gaylord boxes. I understand the strengths and limitations of different packaging materials, such as corrugated cardboard, plastic, and wood.

In terms of handling techniques, I’m familiar with automated systems (robotic arms, conveyor belts, automated guided vehicles or AGVs), manual handling (hand trucks, forklifts, pallet jacks) and specialized equipment such as vacuum lifters for delicate items. My experience includes understanding appropriate packaging for different transportation modes, including trucks, rail, and air freight, ensuring products arrive safely at their destination.

Q 18. What are your strengths and weaknesses related to offbearing work?

My strengths in offbearing include meticulous attention to detail, a strong work ethic, and the ability to quickly adapt to new situations and equipment. I’m also a skilled problem-solver, able to identify and resolve issues efficiently, as demonstrated in the previous example. My ability to work independently and as part of a team is a significant asset in a fast-paced environment.

One area I’m working to improve is my proficiency with advanced robotics programming. While I can operate existing robotic systems, I’m actively seeking opportunities to expand my programming skills to optimize automation processes even further. This proactive approach to self-improvement is a testament to my dedication to continuous growth in this field.

Q 19. Describe your experience working with different types of machinery.

My experience includes working with a range of machinery commonly used in offbearing processes. This includes various conveyor belt systems (roller conveyors, belt conveyors, chain conveyors), automated guided vehicles (AGVs), robotic arms for both palletizing and depalletizing, and forklifts. I’m also familiar with hand-operated equipment such as pallet jacks and hand trucks. In each case, I have a good understanding of the operational procedures, safety protocols, and maintenance requirements for each piece of equipment.

For example, during my time at Beta Corporation, I was responsible for troubleshooting a malfunctioning robotic arm used for palletizing finished goods. By methodically isolating the problem, I discovered a faulty sensor causing inaccurate placement of products. Replacing the sensor quickly restored full functionality, minimizing downtime and potential for damage.

Q 20. Explain your understanding of workplace safety regulations.

I have a thorough understanding of workplace safety regulations, including OSHA guidelines (or equivalent local regulations). This includes adhering to safe operating procedures for all machinery, utilizing appropriate personal protective equipment (PPE) such as safety glasses, gloves, steel-toed boots, and hearing protection, and following lockout/tagout procedures when performing maintenance. I also know the importance of reporting any unsafe conditions or near-miss incidents immediately to ensure a safe working environment for myself and my colleagues.

Safety isn’t just a set of rules; it’s a mindset. It involves constant vigilance and proactive problem-solving to prevent accidents before they happen.

Q 21. How do you maintain accurate records of materials handled during offbearing?

Maintaining accurate records of materials handled during offbearing is crucial for inventory management, production tracking, and quality control. I typically utilize a combination of methods, depending on the specific requirements of the job. This often involves using barcode scanners to track individual items, or using enterprise resource planning (ERP) systems to log materials moved. In some cases, manual spreadsheets are also used for smaller scale operations, ensuring all entries are clear, accurate and timely.

Regardless of the method used, I prioritize data accuracy and completeness. Regular reconciliation of physical inventory with recorded data ensures discrepancies are identified and resolved promptly. This systematic approach is crucial for maintaining efficiency and preventing inventory loss.

Q 22. Describe your experience with inventory management in an offbearing environment.

Inventory management in offbearing is crucial for maintaining a smooth and efficient production flow. It involves meticulously tracking the incoming and outgoing materials, ensuring sufficient stock to meet production demands while preventing overstocking and potential waste. My experience includes utilizing various inventory management systems, from simple spreadsheets to sophisticated ERP systems, to monitor stock levels, track material usage, and predict future needs. For example, in my previous role at Acme Manufacturing, I implemented a Kanban system for offbearing raw materials, which significantly reduced lead times and minimized storage costs. This involved closely collaborating with the production team to forecast demand accurately and ensure a timely supply of materials to the offbearing station.

Furthermore, I’m experienced in conducting regular cycle counts to verify inventory accuracy against system records, identifying discrepancies, and taking corrective actions. This process helped us improve inventory accuracy by 15% within the first quarter, minimizing production delays caused by stock inaccuracies.

Q 23. How do you identify and address potential bottlenecks in the offbearing process?

Identifying bottlenecks in the offbearing process requires a systematic approach. I typically begin by observing the workflow and identifying areas where materials or personnel experience delays or congestion. This often involves analyzing production data, such as cycle times, downtime, and error rates. For instance, a bottleneck might be caused by insufficient storage space near the offbearing station, resulting in material congestion and slowing down the overall process. Or perhaps the offbearing equipment itself is underperforming due to age or lack of maintenance, which could create a significant constraint.

Once a bottleneck is identified, I address it through several strategies. This can range from optimizing the layout of the offbearing area to improve material flow to investing in new equipment or training personnel to improve efficiency. For example, at my previous company, we implemented a new automated material handling system that reduced the offbearing cycle time by 20%. This involved collaboration across different departments, requiring careful planning and resource allocation.

Q 24. What are your strategies for improving efficiency and productivity in offbearing?

Improving efficiency and productivity in offbearing requires a multifaceted approach that considers both operational processes and personnel. My strategies often involve implementing lean manufacturing principles, such as eliminating waste (muda), optimizing workflow, and improving quality. This might include streamlining the offbearing process by reducing unnecessary steps, improving the organization of the offbearing area, or implementing 5S methodologies (Sort, Set in Order, Shine, Standardize, Sustain) to maintain a clean, organized, and efficient workspace.

Another key strategy is empowering the offbearing team through training and development. This includes providing them with the necessary skills and knowledge to perform their tasks efficiently and safely. For example, I’ve successfully implemented cross-training programs, allowing team members to cover for each other during absences and to handle various aspects of the offbearing process, enhancing overall flexibility and resilience. Finally, continuous improvement through data analysis and regular performance reviews helps identify areas for ongoing optimization.

Q 25. How do you work effectively under pressure and maintain accuracy?

Working effectively under pressure and maintaining accuracy requires a combination of organizational skills, attention to detail, and a calm demeanor. I prioritize tasks based on urgency and importance, focusing on the most critical aspects first. I utilize checklists and standardized procedures to ensure consistent accuracy and to minimize the risk of errors, especially when time is limited. I also believe in breaking down large tasks into smaller, manageable steps to improve focus and to facilitate progress monitoring.

Maintaining a calm and methodical approach is vital under pressure. This involves focusing on the task at hand, avoiding distractions, and seeking assistance when necessary. At times, I’ve used techniques like deep breathing exercises to manage stress and maintain focus, ensuring I consistently deliver accurate and timely results, even in demanding situations.

Q 26. Describe a time you had to make a quick decision that impacted the offbearing process.

During a peak production period, we experienced a sudden malfunction in our primary offbearing conveyor system. This threatened to significantly delay production and potentially lead to unmet customer orders. After assessing the situation, I quickly decided to reroute the material flow temporarily using a secondary, less efficient system while simultaneously initiating repairs on the primary conveyor. This involved coordinating with the maintenance team and the production supervisors to ensure the smooth transition and minimal disruption.

Although the secondary system resulted in a slightly slower offbearing rate, it prevented a complete production standstill. The quick decision to reroute the material flow, combined with the prompt repair of the primary conveyor, minimized the overall impact on production and avoided any significant delays in meeting customer deadlines. This experience highlighted the importance of having contingency plans in place and the ability to make swift, informed decisions under pressure.

Q 27. How familiar are you with using material handling equipment such as forklifts or pallet jacks?

I am highly proficient in operating various material handling equipment, including forklifts, pallet jacks, and conveyor systems. My experience encompasses safe operation, preventative maintenance procedures, and adherence to all relevant safety regulations. I possess the necessary certifications and training to operate these machines effectively and safely, ensuring compliance with company policies and industry best practices. I’m comfortable with both manual and automated material handling systems and can quickly adapt to new equipment.

For example, in a previous role, I was responsible for training new employees on the safe operation of forklifts, emphasizing proper techniques, safety protocols, and preventative maintenance checks. My focus has always been on ensuring both efficiency and safety in all material handling operations.

Q 28. Describe your experience with following standard operating procedures (SOPs) in offbearing.

Following standard operating procedures (SOPs) is paramount for maintaining consistency, safety, and efficiency in the offbearing process. I have extensive experience in adhering to and implementing SOPs in various offbearing environments. This includes understanding the rationale behind each step in the procedure, adhering to safety guidelines, and documenting all relevant information accurately. My commitment to following SOPs has helped to reduce errors, improve quality, and maintain a consistent and reliable offbearing process.

In situations where SOPs might need to be adjusted or improved, I actively participate in suggesting modifications to ensure efficiency and safety are optimized. I believe that while SOPs provide a solid framework, continuous improvement and adaptation are crucial to achieving optimal performance in a dynamic environment.

Key Topics to Learn for Offbearing Interview

Success in your Offbearing interview hinges on a strong understanding of its core principles and practical applications. Think beyond rote memorization; focus on demonstrating your ability to solve real-world problems.

- Core Offbearing Principles: Grasp the fundamental concepts underpinning Offbearing and how they interact. Consider the theoretical framework and its underlying assumptions.

- Practical Application & Case Studies: Explore real-world scenarios where Offbearing is utilized. Prepare examples demonstrating your ability to apply theoretical knowledge to practical problems. Consider different approaches and their trade-offs.

- Problem-Solving Strategies in Offbearing: Develop a methodical approach to tackling Offbearing-related challenges. Practice breaking down complex problems into smaller, manageable parts and outlining your solution process.

- Data Analysis & Interpretation within Offbearing: Understand how data informs decisions within the Offbearing context. Be prepared to discuss data analysis techniques and interpret findings effectively.

- Ethical Considerations in Offbearing: Explore the ethical implications and responsible use of Offbearing techniques and methodologies.

Next Steps

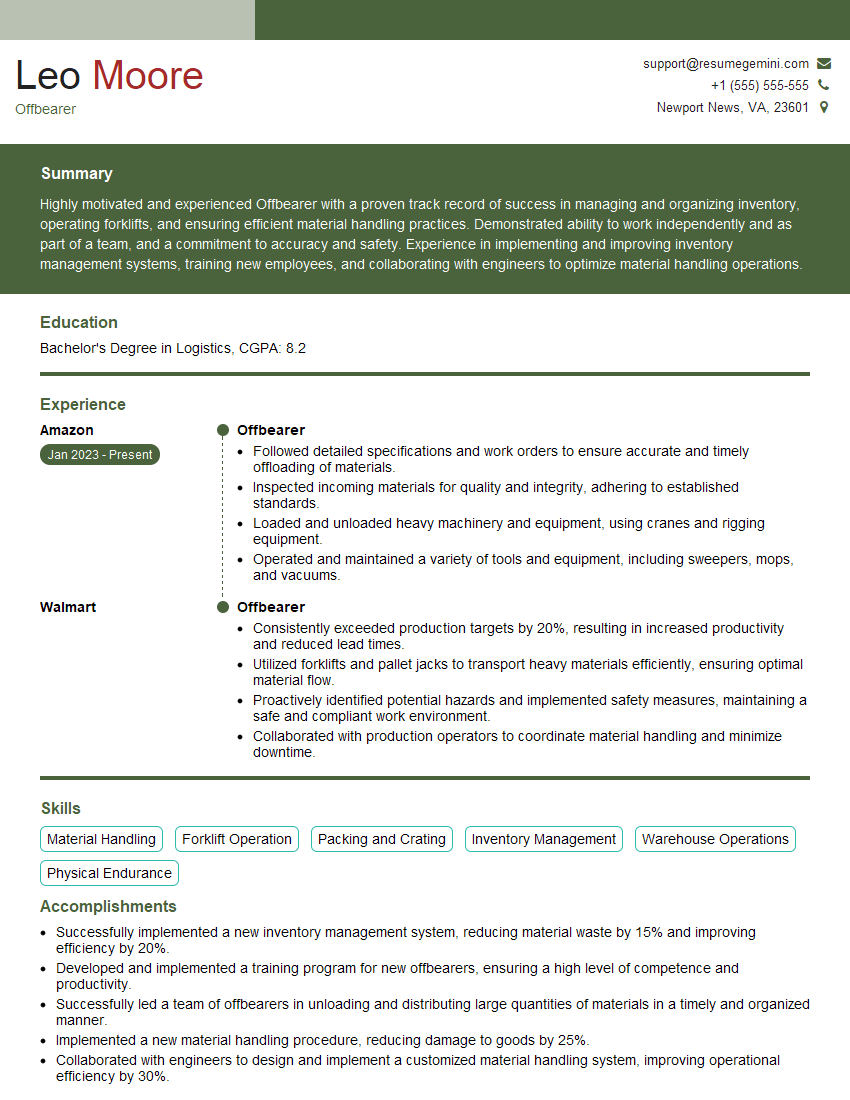

Mastering Offbearing opens doors to exciting career opportunities and positions you for significant professional growth. To maximize your chances, creating an ATS-friendly resume is crucial. A well-crafted resume highlights your skills and experience effectively, improving your visibility to recruiters and increasing your chances of landing an interview.

We strongly recommend leveraging ResumeGemini to build a professional and impactful resume. ResumeGemini provides the tools and resources to create a resume that showcases your Offbearing expertise. Examples of resumes tailored to Offbearing are available to help you craft a compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good