Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Offset Bindery interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Offset Bindery Interview

Q 1. Explain the difference between perfect binding and saddle stitching.

Perfect binding and saddle stitching are two common bookbinding methods, but they differ significantly in their approach and the resulting product. Think of it like this: perfect binding is like gluing a stack of papers together to form a book’s spine, while saddle stitching is like stapling the pages together through the center fold.

Perfect Binding: This method involves gluing the edges of a block of printed sheets together to create a smooth spine. The pages are then glued to a cover. This is ideal for books with a significant page count (more than 48 pages typically), like novels or textbooks, where a thicker spine is needed for durability. The spine is often squared off, and the cover wraps around the glued block of pages.

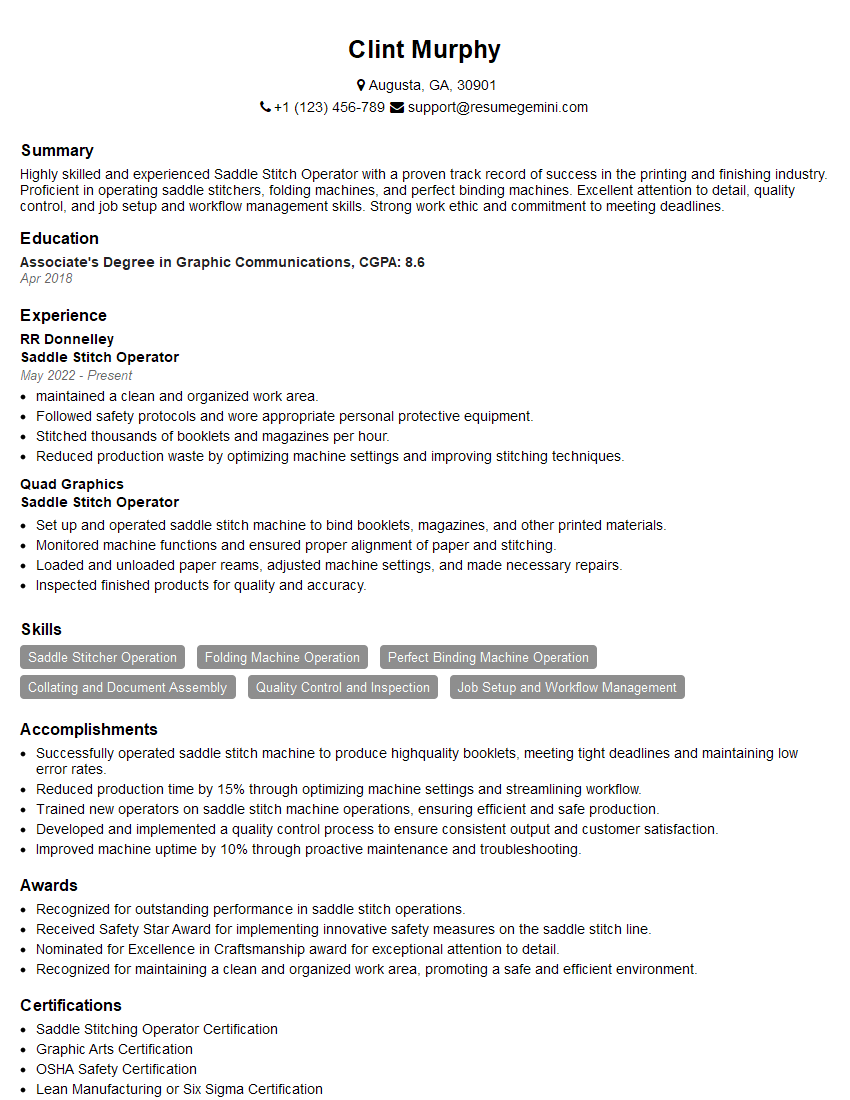

Saddle Stitching: This is a simpler, less expensive method where pages are folded in half and then stapled through the center fold. It’s best suited for magazines, brochures, or booklets with a lower page count (generally under 48 pages) and requires a page count that’s a multiple of four. This creates a noticeable spine with visible staples.

The choice between the two depends entirely on the project’s page count, budget, and desired aesthetic.

Q 2. Describe the process of three-knife trimming.

Three-knife trimming is a precise cutting process used to create perfectly square and even edges on a block of printed sheets before binding. Imagine a guillotine, but with three blades instead of one. This increases the efficiency and precision of the cut.

The process involves feeding a stack of sheets into a three-knife trimmer. The three blades simultaneously cut the top, bottom, and head edges of the stack with utmost accuracy. This ensures perfectly aligned pages and a professional finish. It’s especially important for perfect binding, where even edges are crucial for a smooth spine. The machine’s precise settings are crucial for consistent and accurate cuts to avoid misalignment and wasted material.

Improper three-knife trimming can lead to uneven pages, making binding difficult and impacting the final product’s quality. Regular maintenance and operator skill are key to successful three-knife trimming.

Q 3. What are common issues encountered during the folding process and how are they resolved?

Folding is a critical step, and several issues can arise. One common problem is ‘folding breaks’, where the paper tears along the fold line. This often happens with heavier paper stock or when the folding machine’s rollers are not properly adjusted or maintained. Another issue is ‘poor registration’, where the pages don’t align correctly, leading to misaligned text or images. This usually indicates a problem with the feeding mechanism or the folding knives’ alignment.

Solutions: Folding breaks are often resolved by using a heavier-weight paper, adjusting the machine’s rollers for more gentle pressure, or using a higher quality paper stock that’s less prone to tearing. Poor registration requires careful calibration of the folding machine and may involve adjusting the knife position, feeder settings, and potentially replacing worn parts.

Preventive maintenance, including regular cleaning and lubrication, is essential for minimizing these issues. Operators should also be trained to identify and correct minor misalignments before they become major problems.

Q 4. How do you ensure accurate gathering of sheets?

Accurate gathering of sheets is essential for creating a correctly sequenced book. Inconsistent gathering leads to frustrating errors and ultimately affects the final quality. Think of it like building a house – you need each brick in the right place! Several methods help ensure accuracy:

- Gathering machines: These automated systems use sophisticated sensors and mechanisms to accurately pick up and sequence sheets at high speeds. They are the most efficient solution for large-volume projects.

- Manual gathering: For smaller runs, manual gathering is often used. This requires careful attention to detail and following a precise sequence. Using a well-lit workspace and employing a second person for quality control helps.

- Collation checks: Regardless of the gathering method, regular collation checks are crucial. This involves visually inspecting gathered sections for missing or out-of-sequence pages.

Implementing robust quality control procedures and using the appropriate technology for the project’s size are crucial for accurate gathering.

Q 5. What are the safety precautions you take while operating bindery equipment?

Safety is paramount in the bindery. Bindery equipment involves heavy machinery with sharp blades and moving parts. Operating this equipment without proper safety measures can lead to serious injuries.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, and closed-toe shoes. Depending on the task, hearing protection may also be required.

- Machine Guards: Ensure all safety guards are in place and functioning correctly before operating any equipment. Never attempt to bypass safety features.

- Lockout/Tagout Procedures: Follow proper lockout/tagout procedures when performing maintenance or repairs on equipment to prevent accidental start-ups.

- Training: All operators must receive thorough training on the safe operation and maintenance of all bindery equipment.

- Cleanliness: Maintaining a clean and organized workspace reduces the risk of tripping hazards and accidents.

Regular safety inspections and training sessions are essential for maintaining a safe working environment.

Q 6. Explain the importance of quality control in the bindery process.

Quality control is the backbone of a successful bindery operation. It ensures that the final product meets the client’s specifications and expectations. Without robust quality control, even small errors can significantly impact the overall quality and perception of the printed materials.

- In-process checks: Regular checks at each stage of the binding process – from folding and gathering to trimming and binding – help identify and correct problems early on. This is much more efficient and cost-effective than fixing errors at the very end.

- Final inspection: A thorough final inspection of the bound materials ensures that the final product meets the required standards and specifications.

- Documentation: Maintaining detailed records of each job and quality control checks provides valuable data for continuous improvement and troubleshooting.

A commitment to quality control not only improves the final product but also reduces waste, improves efficiency, and enhances the reputation of the bindery.

Q 7. How do you troubleshoot common malfunctions in a perfect binding machine?

Troubleshooting perfect binding machines requires a systematic approach. Let’s say the machine isn’t applying glue properly. This could stem from several sources:

- Check the glue tank: Is the glue tank empty or low? Is the glue the correct viscosity and temperature?

- Examine the glue rollers: Are the glue rollers clean and properly positioned? Are they worn or damaged, requiring replacement?

- Inspect the glue application system: Is there a blockage in the glue lines or pumps? Are the settings correctly adjusted for the paper stock being used?

- Check the pressure rollers: Are the pressure rollers applying the correct amount of pressure to ensure even glue distribution?

A methodical approach, coupled with knowledge of the machine’s workings and components, is key to resolving malfunctions quickly and efficiently. Consulting the machine’s manual and seeking assistance from experienced technicians are always recommended when faced with complex problems.

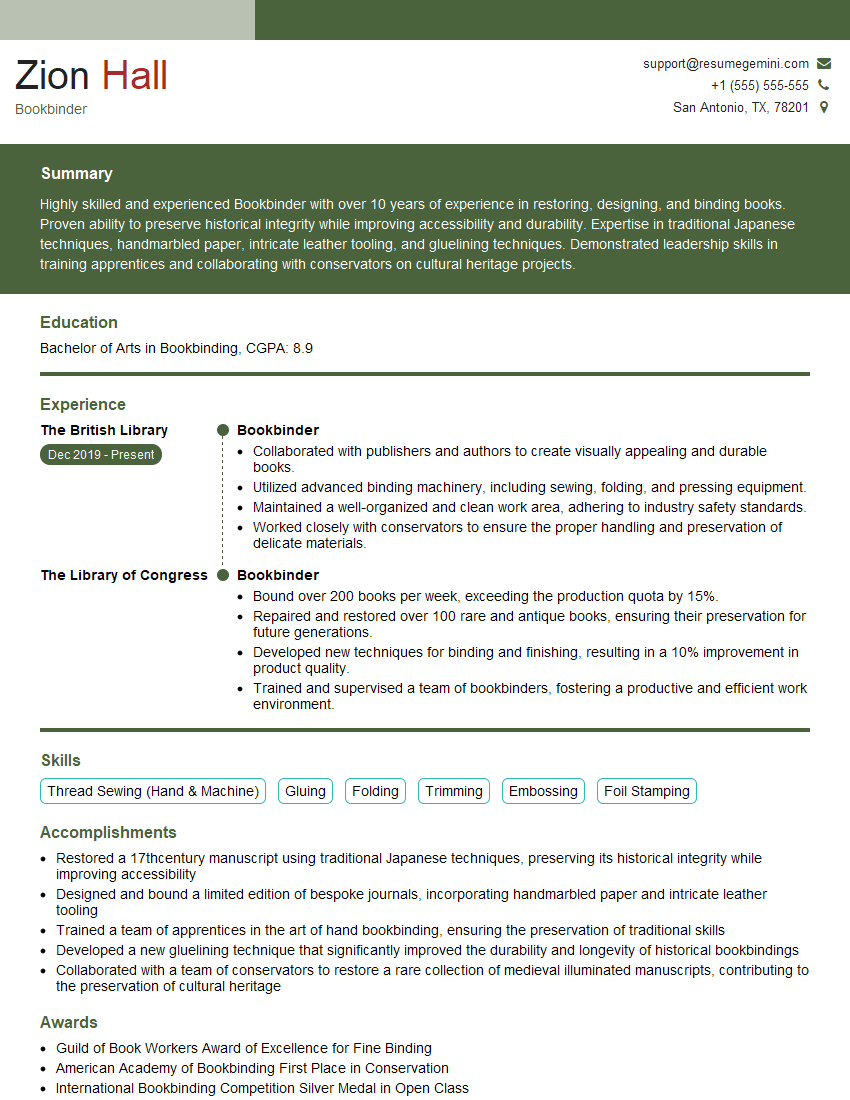

Q 8. What are the different types of covers used in case binding?

Case binding offers a range of cover options, each contributing to the final product’s look and feel. The choice depends on factors like budget, desired durability, and aesthetic appeal.

- Hard Cover: The most durable and prestigious option. These covers are typically made from boards (like chipboard or binder board), covered with cloth, paper, or even leather. Think of a high-quality textbook or a beautifully bound novel.

- Soft Cover: More economical, soft covers use flexible materials like paperboard or cardstock. They are ideal for brochures, booklets, or lower-budget books. You often find soft covers on magazines and paperback books.

- Self Cover: This option uses the printed pages themselves as the cover. It’s a cost-effective choice, but it’s less durable and generally only suitable for thinner publications.

- Wraparound Cover: This method extends the cover around the spine and often uses heavier stock for additional strength and durability.

Selecting the appropriate cover type is crucial for achieving the desired quality and longevity of the final product. The right cover can enhance the perceived value of your printed materials, regardless of whether it’s a marketing brochure or an academic text.

Q 9. Describe the process of setting up a saddle stitching machine for a specific job.

Setting up a saddle stitching machine is a precise process requiring careful attention to detail. Incorrect setup can lead to misaligned stitching, poor quality, and even machine damage.

- Paper Size and Type: First, you need to adjust the machine’s guides to match the exact dimensions of your folded sheets. The paper type also influences the settings; heavier stock requires adjustments to the stitching pressure.

- Stitch Length and Position: The stitch length is determined by the thickness of the publication. Thicker documents need longer stitches for secure binding. The stitch position needs to be accurately centered to maintain aesthetic balance.

- Clamp Pressure and Speed: These settings affect the quality of the stitching. The clamps need enough pressure to hold the paper securely without damaging it. The machine’s speed needs adjustment based on the paper type and thickness – slower speeds are preferred for heavier stock to prevent jams.

- Needle Selection: Different needle sizes are necessary for different paper thicknesses. Using an incorrect needle size can lead to broken needles or poor stitching.

- Testing: Before starting the full job, always run a test to ensure everything is correctly aligned and functioning correctly. Make adjustments as needed to ensure consistent stitching quality.

Proper setup is vital for maintaining efficient production and high-quality results. A well-maintained and properly calibrated machine ensures a smooth workflow, reducing downtime and waste.

Q 10. How do you calculate the required number of sheets for a particular print job?

Calculating the required number of sheets involves understanding the page count, sheet size, and printing method (e.g., signatures).

Example: Let’s say you need to print a 64-page booklet using standard letter-size sheets (8.5″ x 11″). Assuming you’re printing in a standard 4-color process and using signatures (groups of pages printed on a single sheet and folded), you’d work as follows:

- Pages per sheet: With a standard 8.5×11 sheet, you can print 4 pages per sheet (double-sided).

- Number of sheets per signature: To get 64 pages, you’d need 16 sheets per signature (64 pages / 4 pages/sheet = 16 sheets). If you’re printing in signatures, each sheet will have multiple pages from the booklet.

- Number of signatures: Depending on the machine and workflow, your print job could be several signatures bound together.

- Total sheets required: You will then take the number of signatures required multiplied by the number of sheets per signature.

Always add extra sheets to account for potential spoilage or errors during the printing process. Accurate sheet calculation is crucial for cost control and efficient production planning.

Q 11. What are the different types of folding patterns?

Folding patterns are essential for creating different booklet formats and layouts. The choice depends on the final product’s desired size and aesthetics.

- Half Fold: The simplest fold, where a sheet is folded in half. Think of a standard flyer or brochure.

- Letter Fold: Involves multiple folds, creating panels suitable for newsletters or multi-page documents. The number of folds will depend on the final product size.

- Roll Fold: This creates a leaflet-like structure where pages are folded into thirds or more. Common in brochures and maps.

- Gate Fold: A more complex fold that creates a series of panels unfolding like a gate. Good for creating visual impact.

- Parallel Fold: Sheets are folded in parallel, creating multiple panels of equal size. Often used for creating larger, multi-panel leaflets.

Understanding folding patterns is critical for optimizing printing and binding efficiency. Incorrect folding can lead to misaligned pages and compromised readability, thus mastering different folding patterns ensures a professional and user-friendly final product.

Q 12. Explain the role of scoring in the bindery process.

Scoring is the process of creating a shallow crease in the paper or cardstock before folding. This helps to prevent cracking or tearing, especially on heavier stocks. It’s an important step in ensuring clean, sharp folds and a professional finish.

Practical Application: Imagine trying to fold a thick piece of cardboard without scoring it. It would likely crack or tear along the fold line. Scoring creates a weakened area, allowing the paper to fold neatly along the crease without damage. This is particularly important for hard covers and other thicker materials used in case binding.

Scoring is frequently used in conjunction with other bindery processes like folding, perfect binding, and case making. It contributes significantly to the overall quality and aesthetics of the final product.

Q 13. How do you identify and address inconsistencies in the finished product?

Identifying inconsistencies in the finished product requires a systematic approach. Start by visually inspecting a sample from the batch, checking for:

- Misaligned images or text: This indicates problems with the printing or imposition process.

- Uneven folds or creases: This suggests issues with the folding machine setup or paper quality.

- Loose or incomplete binding: Points to problems with the binding process, the adhesive used, or the paper’s integrity.

- Inconsistent color or ink density: This usually indicates problems with the printing press itself.

- Damaged or soiled covers: This suggests issues in the handling or finishing stages.

Addressing inconsistencies: Once the problem area is identified, investigate the root cause. This might involve checking machine settings, evaluating paper quality, adjusting the binding process, or reviewing the printing setup. Sometimes, the entire batch may need re-processing to ensure quality control.

Maintaining detailed records of the production process helps in quickly pinpointing and resolving inconsistencies. A proactive approach to quality control ensures a consistently high-quality final product.

Q 14. What are the different types of adhesives used in binding?

A variety of adhesives are used in the bindery process, each suited for specific applications and materials.

- PUR (Polyurethane Reactive): A strong, durable adhesive, ideal for perfect binding and case binding. It creates a flexible, long-lasting bond, even with heavier stock.

- Hot Melt: A fast-setting, thermoplastic adhesive often used in saddle stitching and some types of case binding. It’s cost-effective but less flexible than PUR.

- Casein: A water-based adhesive, historically common in bookbinding, though less frequently used now. It’s considered a more traditional option, known for its durability.

- EVA (Ethylene Vinyl Acetate): This hot melt adhesive is durable and provides a good bond. Often used for smaller books or booklets.

The choice of adhesive impacts the final product’s durability, flexibility, and overall quality. The wrong adhesive can lead to binding failure or aesthetic issues. Choosing the right adhesive is a critical decision in the binding process.

Q 15. Describe your experience with different types of binding equipment.

My experience with bindery equipment spans a wide range of technologies, from traditional to highly automated systems. I’m proficient in operating and maintaining various types of binding machines, including:

- Perfect Binding Machines: I’ve worked extensively with these machines, handling everything from setup and adjustments to troubleshooting common issues like improper gluing or inaccurate three-knife trimming. I’m familiar with both inline and offline systems.

- Saddle Stitch Binding Machines: I have experience with high-speed saddle stitchers, capable of handling large print runs efficiently. This includes understanding the impact of different paper weights and thicknesses on stitching quality and the importance of proper feeder adjustments to avoid jams.

- Wire-O Binding Machines: I’m skilled in operating wire-O binding machines, from setting the correct wire size and pitch to ensuring consistent punching and wire insertion. I understand the importance of proper paper alignment for a clean, professional finish.

- Spiral Binding Machines: My experience includes using both manual and electric spiral binding machines, understanding the nuances of selecting the appropriate coil size and ensuring consistent punching for a secure and aesthetically pleasing bind.

- Case Binding Machines (partial experience): While my primary focus has been on other binding methods, I have some experience assisting with and observing case binding processes, understanding the importance of accurate cover placement and adhesive application.

This diverse experience allows me to adapt quickly to different equipment and optimize workflows for maximum efficiency and quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle a jammed machine?

Handling a jammed machine requires a systematic approach, prioritizing safety and minimizing damage. My first step is always to turn off the machine and ensure power is completely disconnected. Then, I carefully assess the situation:

- Identify the Jam Location: Pinpoint where the jam is occurring—paper feeder, stitching mechanism, or other areas.

- Safe Removal: Carefully remove the jammed material, ensuring I don’t force anything that could cause further damage. I use appropriate tools to avoid injuries, like soft gloves or specialized paper removal tools.

- Clean Up: Once the jam is cleared, I thoroughly clean the affected area to remove any stray paper or debris that could cause future jams.

- Inspect for Damage: After clearing the jam, I inspect the machine for any signs of damage to the rollers, sensors, or other components. If any damage is evident, I report it immediately and follow the proper procedures for repair or maintenance.

- Restart & Test: After addressing the jam and potential damage, I carefully restart the machine and run a small test batch to ensure it’s functioning correctly before resuming full production.

For instance, I once had a major jam on a high-speed saddle stitcher due to a misfeed. By following this process, I quickly resolved the issue, preventing costly downtime and potential damage. Each machine has its nuances; my experience gives me the ability to quickly diagnose and address various jam scenarios.

Q 17. What is the importance of maintaining bindery equipment?

Maintaining bindery equipment is crucial for ensuring consistent output quality, minimizing downtime, and extending the lifespan of the machines. Regular maintenance prevents costly repairs and production delays. My approach to maintenance includes:

- Preventative Maintenance: Following manufacturer’s recommended schedules for lubrication, cleaning, and part replacement. This includes daily, weekly and monthly checks depending on the machine’s use.

- Regular Inspections: Conducting thorough visual inspections for signs of wear, tear, or potential problems—loose screws, worn rollers, or damaged belts. Addressing any minor issues before they escalate.

- Calibration and Adjustment: Regularly calibrating the machine to ensure accurate settings for optimal performance. This might involve adjusting the paper guides, glue settings, or stitching pressure.

- Record Keeping: Maintaining detailed records of all maintenance activities, including dates, tasks performed, and parts replaced. This helps in tracking maintenance history and identifying potential patterns or recurring issues.

- Operator Training: Ensuring that all operators are properly trained on safe and effective machine operation and basic preventative maintenance to minimize misuse and potential damage.

Imagine a car; regular oil changes, tire rotations, and inspections prevent major breakdowns. Bindery equipment is similar—proactive maintenance is far more cost-effective than reactive repairs.

Q 18. Describe your experience with pre-press and post-press processes.

My understanding of pre-press and post-press processes is vital for successful bindery operations. In pre-press, I’m involved in understanding:

- File Preparation: Working with design and pre-press teams to ensure that files are properly formatted and ready for printing. This includes checking for bleed, margins, and color profiles to prevent issues during printing and binding.

- Paper Selection and Specifications: Consulting on appropriate paper stocks based on binding method and project requirements. Different paper weights, thicknesses, and finishes can impact the effectiveness of various binding techniques.

- Imposition: Understanding the imposition process to optimize printing and ensure efficient binding. This involves arranging pages for efficient sheet folding and gathering.

In post-press, after the printing process, my role extends to:

- Finishing Operations: Ensuring the printed sheets are properly folded, gathered, and collated before binding. This includes attention to detail to maintain page order and prevent misalignment.

- Quality Control: Performing thorough quality checks before, during, and after the binding process to identify and correct any errors or defects.

- Packaging and Delivery: Overseeing final packaging and preparation for delivery, ensuring the finished products meet client expectations.

A seamless flow between pre-press and post-press is essential. I proactively work across departments to anticipate and avoid potential problems that might impact the final product’s quality and timeline.

Q 19. What are your troubleshooting skills in bindery operations?

My troubleshooting skills are honed through years of experience and a systematic approach. I use a combination of practical knowledge and problem-solving techniques. When faced with a bindery challenge, I follow these steps:

- Identify the Problem: Clearly define the nature of the problem – a misalignment, incorrect binding, or a machine malfunction.

- Gather Information: Collect data on the materials used, machine settings, and the sequence of events leading up to the problem.

- Check Common Causes: Examine the most likely causes, such as improper machine setup, incorrect material specifications, or operator error.

- Systematic Testing: Perform tests to eliminate potential causes and isolate the problem. This might involve running test batches with different settings or materials.

- Consult Resources: Refer to manuals, online resources, or experienced colleagues for guidance.

- Document Solutions: Record the problem, the troubleshooting steps taken, and the solution implemented to avoid similar issues in the future.

For example, recently I encountered a problem with inconsistent glue application on a perfect binding machine. Through systematic testing, I identified a clogged glue nozzle as the culprit. By cleaning the nozzle and recalibrating the glue settings, the issue was quickly resolved.

Q 20. How do you manage multiple projects simultaneously in a bindery environment?

Managing multiple projects simultaneously in a bindery environment requires excellent organizational skills and efficient prioritization. My approach involves:

- Project Scheduling: Using project management tools or techniques to create a clear schedule, outlining deadlines and task dependencies for each project. This often involves collaborating with production managers.

- Resource Allocation: Effectively allocating personnel and equipment to different projects based on their priorities and resource requirements.

- Communication and Collaboration: Maintaining open communication with the printing team, pre-press, and clients to keep everyone informed of project progress and potential challenges.

- Prioritization: Focusing on high-priority projects with tight deadlines and allocating resources accordingly. This includes adjusting schedules as needed to accommodate unforeseen issues.

- Flexibility and Adaptability: Being able to adapt to unexpected changes or delays and adjust the schedule to meet shifting priorities. This is key in a fast-paced environment.

I often use Kanban boards or similar visual tools to track progress and identify potential bottlenecks. This allows me to proactively address any challenges that might impact project completion.

Q 21. What is your experience with different paper stocks and their impact on binding?

Different paper stocks significantly impact the binding process. Understanding these impacts is essential for selecting the right paper and achieving a high-quality result. Factors to consider include:

- Paper Weight: Heavier papers require adjustments to machine settings, especially for stitching and folding. Too heavy a paper can lead to machine jams or damage.

- Paper Finish: Coated papers might require different glue types or adjustments to the gluing process compared to uncoated papers. A glossy finish, for example, can affect adhesion.

- Paper Texture: Textured papers can create challenges for consistent feeding and punching. This might require adjustments to machine rollers or feeders.

- Paper Type: Certain paper types, like recycled papers, might require specific handling during the binding process to prevent issues with machine jams or uneven finishing.

For instance, using a very heavy cover stock with a perfect binding job might require using stronger adhesives and adjusting the three-knife trimmer settings to ensure a clean cut and prevent tearing. My experience allows me to quickly assess the impact of different paper stocks and make necessary adjustments to ensure a successful outcome.

Q 22. How do you ensure the efficiency of the bindery operations?

Ensuring efficient bindery operations requires a multifaceted approach focusing on workflow optimization, preventative maintenance, and skilled personnel. Think of it like a well-oiled machine – each part needs to function smoothly and in coordination.

Streamlined Workflow: We implement lean manufacturing principles. This involves analyzing the entire process, from pre-press to post-bindery, identifying bottlenecks (e.g., slow drying times, inefficient stacking), and implementing solutions such as improved material flow, better scheduling, and cross-training employees to handle multiple tasks.

Preventative Maintenance: Regularly scheduled maintenance on all bindery equipment is crucial. This includes cleaning, lubrication, and parts replacement as needed. Imagine a car – regular servicing prevents major breakdowns. This minimizes downtime and keeps the machines running at peak efficiency. We meticulously track maintenance schedules using a computerized system.

Employee Training and Skill Development: A skilled workforce is essential. We invest in comprehensive training programs for our bindery staff, covering safe operating procedures, quality control, and troubleshooting techniques. This ensures consistent output and minimizes errors.

For instance, in a recent project with a tight deadline, we identified a bottleneck in the perfect binding machine. By implementing a more efficient stacking method and cross-training operators, we reduced processing time by 15%, successfully meeting the delivery date.

Q 23. What are your skills in using different types of software related to bindery?

My software skills encompass a range of applications crucial for efficient bindery operations. I’m proficient in MIS (Management Information Systems) software for job tracking and scheduling, ensuring seamless project flow and accurate costing. I also utilize prepress software like Adobe Acrobat Pro to verify the accuracy of page counts, imposition, and other pre-bindery requirements. Furthermore, I’m familiar with specific machine control software used for various bindery equipment, allowing me to optimize settings for different projects. This includes software for controlling saddle stitchers, perfect binders, and three-knife trimmers.

For example, I use Prinergy software to manage workflow and ensure all files are correctly processed before reaching the bindery floor. This minimizes errors and avoids costly re-work.

Q 24. Describe your experience in a fast-paced bindery setting.

My experience in fast-paced bindery environments has honed my ability to prioritize tasks, multitask effectively, and maintain accuracy under pressure. It’s like a well-orchestrated dance – each step must be precise and coordinated.

In my previous role, we consistently handled high-volume projects with short turnaround times. We frequently worked on multiple projects concurrently, requiring excellent organizational skills and the ability to adapt to changing priorities. I developed efficient methods for managing multiple jobs and ensuring timely completion, even under tight deadlines. For instance, I implemented a color-coded system for prioritizing tasks and organizing materials, significantly improving our overall efficiency.

Q 25. How do you ensure consistent quality across large print runs?

Maintaining consistent quality across large print runs involves a combination of meticulous quality control checks at every stage of the process, from the initial setup to the final inspection. It’s about building quality into the process, not just inspecting for it at the end.

Regular Calibration: We regularly calibrate all machines to ensure accuracy in cutting, folding, and binding. Think of it as fine-tuning a musical instrument – maintaining precision is key.

In-process Inspection: We conduct regular inspections at each stage of the process – folding, stitching, gluing – to identify and correct any deviations early on.

Statistical Process Control (SPC): We utilize statistical methods to monitor key process parameters and identify trends, which helps us proactively address potential quality issues before they become widespread.

Final Inspection: A thorough final inspection of the finished product ensures that the quality standards are met before shipment.

For instance, using SPC charts helped us identify a slight variation in the glue application on a recent large-scale book binding project. We were able to adjust the machine settings promptly, preventing significant defects and maintaining the high quality of the entire print run.

Q 26. Explain your experience with different types of finishing techniques.

My experience encompasses a wide array of finishing techniques, including:

Binding: Perfect binding, saddle stitching, wire-o binding, case binding – each requiring a distinct set of skills and knowledge to ensure a high-quality finish.

Cutting and Trimming: Using various guillotine cutters and three-knife trimmers to achieve precise cuts and create clean, finished edges.

Folding: Folding sheets accurately to create different formats, ensuring consistent alignment and neatness.

Embossing and Debossing: Adding texture and visual interest to the final product.

Die-cutting: Creating custom shapes and designs using die-cutting machines.

For instance, I recently managed a project requiring both perfect binding for a softcover book and case binding for a more robust hardcover edition. This demanded a deep understanding of the unique requirements of each process to ensure a high-quality, professional outcome for both.

Q 27. Describe your experience with different types of binding glues.

My experience extends to a variety of binding glues, each suited for different applications and materials. Choosing the right glue is crucial for ensuring a strong, lasting bind.

PUR (Polyurethane Reactive): Excellent for high-quality, durable bindings, especially for books with thick pages or heavy stock. It offers strong adhesion and flexibility.

EVA (Ethylene Vinyl Acetate): A more economical choice, suitable for less demanding applications, offering a good balance of adhesion and flexibility.

Hot Melt Adhesives: Used for various binding applications, offering quick setting times, although less flexible than PUR or EVA.

The choice of glue depends heavily on the project specifications, budget, and required durability. For example, I’d choose PUR glue for a high-end coffee table book requiring long-lasting durability, while EVA might suffice for a less demanding paperback.

Q 28. How do you maintain a clean and organized work environment in the bindery?

Maintaining a clean and organized bindery is paramount for safety, efficiency, and quality. It’s not just about tidiness; it’s about preventing accidents, minimizing downtime, and ensuring a professional work environment.

5S Methodology: We implement the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to organize our workspace. This systematic approach minimizes clutter, improves workflow, and prevents accidents.

Regular Cleaning: We have a dedicated cleaning schedule for all machines and work areas, removing debris and ensuring proper machine maintenance. This prevents jams, reduces wear and tear, and enhances safety.

Material Storage: We use a designated storage system for materials, keeping them organized and easily accessible. This prevents waste, minimizes material handling time, and keeps the floor free from clutter.

A well-organized workspace promotes efficiency and reduces errors, improving productivity and enhancing overall quality. I actively encourage and participate in maintaining a clean and organized environment.

Key Topics to Learn for Offset Bindery Interview

- Offset Printing Fundamentals: Understanding the principles of offset lithography, including the image transfer process from plate to blanket to paper. Consider the different types of printing plates and their properties.

- Bindery Processes: Familiarize yourself with various binding methods like perfect binding, saddle stitch, wire-O, and case binding. Understand the advantages and limitations of each method and when they are most appropriate.

- Pre-Press Preparation: Learn about the role of pre-press in ensuring accurate and efficient printing and binding. This includes understanding imposition, color management, and file preparation.

- Post-Press Finishing: Explore different finishing techniques like cutting, folding, scoring, perforating, and die-cutting. Understand how these processes contribute to the final product’s quality and appeal.

- Paper Stock & Handling: Gain knowledge of different paper types, weights, and finishes. Learn about proper paper handling techniques to minimize waste and maximize efficiency.

- Troubleshooting & Problem-Solving: Develop your ability to identify and solve common issues that arise during the printing and binding process. This includes understanding potential causes of misalignment, color inconsistencies, and binding failures.

- Quality Control & Inspection: Familiarize yourself with quality control procedures and best practices for inspecting finished products to ensure they meet customer specifications.

- Safety Procedures & Equipment Operation: Understand the safety protocols and operating procedures for relevant machinery and equipment within an offset bindery environment.

- Production Workflow & Scheduling: Gain an understanding of how different stages of production are coordinated to ensure timely completion of projects.

Next Steps

Mastering the intricacies of offset bindery opens doors to exciting career opportunities within the printing and publishing industries. A strong understanding of these processes demonstrates valuable technical skills and problem-solving abilities, making you a highly sought-after candidate. To maximize your job prospects, creating a compelling and ATS-friendly resume is crucial. We highly recommend using ResumeGemini to build a professional resume that showcases your skills and experience effectively. ResumeGemini provides helpful tools and resources, and we even offer examples of resumes tailored specifically to the Offset Bindery industry. Take the next step towards your dream career – build your best resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good