Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Offset Printing Principles interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Offset Printing Principles Interview

Q 1. Explain the difference between offset lithography and other printing methods.

Offset lithography distinguishes itself from other printing methods primarily through its indirect printing process. Unlike direct printing techniques where ink is applied directly from the printing plate to the substrate (like in letterpress or screen printing), offset lithography uses an intermediate surface – a rubber blanket cylinder. This cylinder transfers the image from the printing plate to the final substrate (paper, cardboard etc.), enabling high-quality, high-volume printing with remarkable precision and detail.

Consider this analogy: imagine trying to paint a detailed picture directly onto a canvas. It’s challenging to maintain consistent pressure and detail across the surface. Offset lithography is like using a stencil on a separate surface (the blanket cylinder) to create the image before transferring it to the canvas (the substrate), resulting in a much more even and consistent final product.

Other methods, like flexography (using flexible relief plates), gravure (using etched cylinders), and screen printing (using a mesh stencil) each have their unique advantages depending on the application, substrate, and desired effect, but offset lithography stands out for its versatility and image fidelity in mass production scenarios.

Q 2. Describe the four main printing plates used in offset printing.

Offset printing uses four primary types of printing plates, each serving a unique purpose in the CMYK (Cyan, Magenta, Yellow, Key/Black) color model. These are:

- Cyan (C): Reproduces the blue hues in the image.

- Magenta (M): Reproduces the red hues in the image.

- Yellow (Y): Reproduces the yellow hues in the image.

- Key/Black (K): Provides sharpness, detail and saturation to the overall image. It’s often referred to as the ‘key’ plate as it registers all the other plates.

Each plate is carefully created to ensure precise alignment during the printing process, guaranteeing accurate color reproduction and image sharpness.

Q 3. What are the key components of an offset printing press?

A modern offset printing press consists of several crucial components working in a synchronized manner:

- Printing Plates Cylinders: Hold the printing plates (C, M, Y, K), transferring the image to the blanket cylinder.

- Blanket Cylinder: A rubber cylinder that receives the image from the printing plates and transfers it to the substrate.

- Impression Cylinder: Presses the substrate against the blanket cylinder, transferring the inked image to the final material.

- Ink Fountains and Ductor Rolls: Deliver and control the amount of ink to the printing plates.

- Dampening System: Applies a water-based solution to the plates to control the ink-water balance and prevent the non-image areas from being inked (lithographic principle).

- Feeding System: Accurately feeds paper sheets into the press.

- Delivery System: Collects and stacks the printed sheets.

Beyond these core components, modern presses often include sophisticated automated systems for color registration, quality control, and waste management.

Q 4. Explain the process of platemaking in offset printing.

Platemaking in offset printing involves creating the printing plates from digital files. The process generally follows these steps:

- Image Preparation: The digital image is prepared using specialized software, ensuring proper color separation, resolution, and trapping. This step is critical for color accuracy and print quality.

- Plate Exposure: The prepared image is then exposed onto a photosensitive plate using a plate imager. This can be a computer-to-plate (CTP) system, which offers superior quality, speed, and automation compared to traditional film-based methods.

- Plate Processing: The exposed plate is processed in a developing solution to remove the unexposed areas, revealing the image. Different types of plates (e.g., thermal, violet, UV) require specific processing chemicals and procedures.

- Plate Mounting: Finally, the processed plate is mounted onto the printing cylinder of the press, ensuring accurate alignment and preventing damage during operation.

Maintaining strict quality control at each stage of platemaking is essential for achieving consistent high-quality prints.

Q 5. How do you ensure proper ink-water balance on an offset press?

Proper ink-water balance is crucial in offset printing. It’s the delicate balance between the ink and the dampening solution (water) on the printing plate. Too much water leads to blurry images and poor ink transfer. Too much ink results in smudging and offsetting. The goal is to have just the right amount of each, creating a balance where the ink adheres only to the image areas and the non-image areas remain clean.

Maintaining this balance involves adjusting the ink and dampening solution levels, along with factors like ink viscosity, fountain roller settings and the type of paper being used. Experienced press operators carefully monitor the printed sheets for even ink coverage and color fidelity, making minute adjustments until the ideal balance is achieved. Specialized instruments like densitometers can measure the ink density and aid in this process.

Think of it like baking a cake: you need the right balance of wet and dry ingredients to get the perfect result. Too much water makes it soggy, too much dry ingredients make it dry and crumbly. The same principle applies to ink-water balance in offset printing.

Q 6. What are the common causes of dot gain in offset printing?

Dot gain, the enlargement of dots during printing, is a common challenge in offset printing, leading to a loss of detail and an overall darker appearance. Several factors contribute to this:

- Paper Absorption: Highly absorbent paper absorbs ink, causing the dots to spread and grow larger.

- Ink Properties: The viscosity and tackiness of the ink affect how it spreads on the paper.

- Pressure: Excessive pressure during printing forces the ink into the paper fibers, contributing to dot gain.

- Plate Characteristics: The quality and condition of the printing plate affect ink transfer, potentially causing uneven dot expansion.

Managing dot gain involves careful selection of paper, inks, and printing settings. Accurate color calibration and professional color management are vital in mitigating this issue.

Q 7. How do you troubleshoot common press problems, such as slurring or ghosting?

Troubleshooting press problems requires systematic investigation and practical experience. For instance:

Slurring: This results in blurred images and is often caused by incorrect ink-water balance, excessive pressure, worn printing plates, or improper paper feeding. Troubleshooting involves checking for consistent dampening, adjusting the ink-water balance, inspecting the plates for damage, and verifying correct paper feeding settings.

Ghosting: This refers to a faint, duplicate image appearing alongside the main print. It is usually due to ink transfer to the non-image areas of the plate, caused by factors like inadequate ink-water balance, worn rollers, or ink contamination. Addressing this involves cleaning the press rollers, adjusting the dampening system, and possibly replacing worn-out components.

A methodical approach, including thorough inspection, adjustments and sometimes replacement of worn parts, are needed to resolve such problems. Maintaining accurate press records can help track down recurring issues and prevent them in the future.

Q 8. Explain the significance of color management in offset printing.

Color management in offset printing is crucial for achieving consistent and accurate color reproduction across different stages of the printing process, from design to final output. Think of it as a recipe – you need precise measurements to ensure the final dish tastes as expected. Inconsistent color can lead to significant issues, including wasted materials, client dissatisfaction, and brand damage.

It involves a series of processes and technologies aimed at standardizing color across various devices and workflows. This includes using color profiles (like ICC profiles) to describe how a specific device (monitor, printer, scanner) interprets and renders colors. These profiles act as translators, ensuring the color you see on your screen closely matches the printed output. Color management software helps in converting colors between different color spaces (like RGB for screens and CMYK for print) while minimizing color shifts.

For example, a vibrant Pantone-specified red in the design file needs to be accurately translated to the CMYK values used by the printing press. Without proper color management, that red might end up looking dull or completely different on the printed piece.

Q 9. What is the role of a prepress technician in the offset printing process?

A prepress technician acts as the crucial bridge between the digital design and the physical printing process in offset printing. They are essentially the quality control gatekeepers, ensuring the print job is ready for the press. Their responsibilities are multifaceted and demanding, requiring a high level of technical proficiency and attention to detail.

- File Preparation: They receive design files and prepare them for printing. This includes checking for resolution, color spaces, fonts, and bleeds (the extra area extending beyond the trim size).

- Imposition: They arrange pages correctly for efficient printing on sheets, considering factors like margins, folds, and the number of colors. This is like solving a complex puzzle to optimize paper usage.

- Proofing: They create color proofs (soft and hard copy) to check color accuracy and ensure the final print matches the design intent. This is crucial to avoid costly reprint errors.

- Plate Making: They work closely with the plate-making department to ensure the plates are properly created, exposed, and ready for the press.

- Quality Control: Throughout the process, they perform thorough quality checks to identify and correct potential issues before the job goes to press.

Imagine a prepress technician as the conductor of an orchestra, ensuring every instrument (software, hardware, and personnel) plays in perfect harmony to achieve a flawless final product.

Q 10. Describe the different types of paper used in offset printing and their suitability for various applications.

Offset printing employs a variety of papers, each with specific properties making them suitable for different applications. The choice depends heavily on the desired outcome, budget, and the print job’s technical requirements.

- Coated Paper: Offers a smooth, glossy surface, ideal for high-quality images and vibrant colors. Commonly used in magazines, brochures, and catalogs.

- Uncoated Paper: Provides a matte or slightly textured surface, better suited for text-heavy documents and applications where a more natural feel is desired. Often used for books, stationery, and business cards.

- Recycled Paper: Environmentally friendly option, available in both coated and uncoated versions. The quality can vary, so selection is important.

- Specialty Papers: This includes a broad range like textured papers, metallic papers, and synthetic papers (e.g., plastics), offering unique visual and tactile qualities suitable for demanding applications like luxury packaging and fine art prints.

For instance, a glossy coated paper would be inappropriate for a novel, as it can feel uncomfortable to hold and turn pages. Conversely, uncoated paper wouldn’t be suitable for a high-gloss fashion magazine; the images would lack vibrancy.

Q 11. How do you ensure accurate color reproduction in offset printing?

Accurate color reproduction in offset printing requires a meticulous approach that integrates multiple steps and considerations.

- Color Management System (CMS): Implementing a robust CMS is vital, ensuring consistency across all stages, from design to press. This involves employing color profiles and using color management software to ensure accurate color conversions.

- Color Proofing: Creating accurate soft and hard proofs (like a contract proof) allows for client review and verification before production. This is a critical step to catch and correct discrepancies early on.

- Calibration and Profiling: Regularly calibrating and profiling all devices involved (monitors, printers, scanners, and the printing press itself) ensures that color interpretation remains consistent across the workflow.

- Press Calibration: The printing press itself needs to be meticulously calibrated and standardized. This involves adjusting ink densities, water balance, and other press settings to achieve accurate color reproduction.

- Ink Selection: Utilizing high-quality inks with accurate color properties is fundamental for achieving the intended results.

For example, a brand might specify exact Pantone colors for its logo. Accurate color reproduction is vital for maintaining brand identity consistency across all marketing materials.

Q 12. What are the different types of inks used in offset printing?

Offset printing uses a variety of inks, each catering to different needs and applications.

- Conventional Inks: These are oil-based inks that provide rich colors and excellent gloss. They are widely used due to their versatility and cost-effectiveness.

- UV (Ultraviolet) Inks: Cured instantly by UV light, they offer fast drying times, enhanced durability, and scratch resistance. Ideal for applications requiring immediate handling, such as packaging.

- Vegetable-Based Inks: Environmentally friendly option, often using soy-based oils. They can provide vibrant color but might not always achieve the same level of gloss and richness as conventional inks.

- Metallic Inks: Special inks that give a metallic finish, like gold or silver, adding a premium touch to packaging and high-end printing projects.

- Specialty Inks: Includes fluorescent inks, pearlescent inks, and other specialized inks offering unique visual effects.

The choice of ink often depends on the substrate (paper type), desired finish, drying speed, and environmental concerns. For instance, a fast-paced packaging job might require UV inks for quick turnaround, whereas a high-end art print might use conventional inks for their richer color depth.

Q 13. Explain the importance of maintaining proper press registration.

Maintaining proper press registration in offset printing is paramount for ensuring that all colors and elements align perfectly on the final printed piece. Misregistration, where colors or images are slightly misaligned, can significantly impact the quality and appearance of the print.

Press registration is achieved by aligning the printing plates and ensuring they accurately transfer their ink to the paper in the correct position. This involves a precise alignment of the different printing units (typically four for CMYK printing) to ensure that each color prints in its designated area. Imperfect registration can lead to blurred images, mismatched colors, and overall unappealing results.

Imagine printing a simple red circle on a blue square. If the press is misregistered, the red circle may be slightly offset from the blue square, resulting in a messy, unprofessional look. Proper registration ensures the red circle is perfectly centered within the blue square.

Techniques to ensure accurate registration include meticulous plate mounting, regular press checks during the run, and adjustments to the press settings as needed. Consistent monitoring and timely adjustments are crucial in preventing registration errors and maximizing the output quality.

Q 14. How do you calculate the number of sheets needed for a specific print job?

Calculating the number of sheets needed for a specific print job involves several steps and requires careful consideration of different factors.

First, determine the following:

- Number of pages: How many pages are in the final printed piece?

- Sheets per signature: How many pages are printed on a single sheet (e.g., 16 pages for a common signature)?

- Number of colors: How many colors are used in the print job (e.g., 4 for CMYK)? This is particularly relevant if you’re not printing all colors on one pass, which might be the case for high-end work.

- Waste: Account for potential waste during the printing process. This includes spoilage, misprints, and sheets set aside for quality control.

- Sheet size: What is the size of the paper being used?

Calculation Example: Let’s say we need to print 1000 brochures, each with 16 pages, using 4-color printing. A signature consists of 8 pages printed per sheet. We would calculate as follows:

- Total number of pages: 1000 brochures * 16 pages/brochure = 16000 pages

- Total signatures: 16000 pages / 8 pages/signature = 2000 signatures

- Number of sheets: 2000 signatures * 1 sheet/signature = 2000 sheets

- Accounting for waste: Add a percentage for waste (e.g., 5%). 2000 sheets * 0.05 = 100 sheets. Total: 2100 sheets

It’s always wise to slightly overestimate the number of sheets to allow for unexpected issues during the production process. This prevents job delays and ensures a sufficient supply of materials.

Q 15. Describe the process of quality control in offset printing.

Quality control in offset printing is a multifaceted process ensuring consistent, high-quality output. It starts long before the press even runs, encompassing every stage from pre-press to post-press.

- Pre-press: This includes meticulous file preparation, checking for color accuracy, image resolution, and proper imposition. We use color profiles and proofing systems (like soft proofing and contract proofing) to match the desired output. Any discrepancies are caught and corrected at this crucial stage to prevent costly errors later.

- Press Checks: Once the press is running, we conduct regular checks throughout the print run. This involves examining the first few sheets for color accuracy, registration (alignment of colors), and dot gain (spread of ink). We use densitometers and spectrophotometers to precisely measure these parameters, comparing them to the pre-press proof.

- In-process monitoring: During long runs, we maintain consistent ink densities, moisture levels, and paper feed. Regular adjustments are made based on the monitoring data.

- Post-press inspection: Finally, the finished printed materials undergo a thorough inspection for defects like scratches, smudges, mis-cuts, or incorrect folding. This often involves a final visual check followed by a sampling process for quality verification.

For example, during a large print job for a client’s brochure, we discovered a slight misregistration in the initial sheets. Immediate adjustment of the press settings corrected the issue, preventing a large number of faulty copies.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are some common safety precautions in the offset printing environment?

Safety in an offset printing environment is paramount. The machinery and materials involved require strict adherence to safety protocols. Some key precautions include:

- Personal Protective Equipment (PPE): This is non-negotiable. We always use safety glasses, gloves, and hearing protection. Depending on the task, additional PPE like respirators might be needed to avoid exposure to inks and chemicals.

- Machine Safety: Before operating any machinery, we conduct thorough checks and lockout/tagout procedures to prevent accidental starting. We are trained on emergency stops and safe operating procedures for each machine.

- Chemical Handling: Offset printing involves solvents and chemicals. We follow strict guidelines for their storage, handling, and disposal, ensuring proper ventilation and avoiding skin contact.

- Fire Safety: Flammable materials are present in the printing process, so fire safety is critical. We maintain fire extinguishers and have well-defined evacuation procedures in place.

- Ergonomics: We use lifting aids for heavy materials and practice good posture to minimize risk of injuries.

For instance, a spill of cleaning solution necessitates immediate cleanup, the use of absorbent materials, and proper disposal according to the safety data sheets.

Q 17. Explain the differences between CMYK and Pantone color systems.

CMYK and Pantone are two distinct color systems used in offset printing, each with its own advantages and disadvantages.

- CMYK (Cyan, Magenta, Yellow, Key/Black): This is a subtractive color model. It relies on the mixture of four process colors to create a broad range of hues. Think of it as starting with white and subtracting color. It’s cost-effective for mass production since it only utilizes four inks.

- Pantone (PMS): This is a spot color system that uses pre-mixed inks, each with its unique formulation and color code. Pantone offers exceptional color consistency and accuracy, especially for specific brand colors or intricate designs requiring precise shades. It’s ideal for projects needing vibrant, accurate colors and smaller print runs.

The key difference is that CMYK is a process that mixes inks to create colors, while Pantone utilizes pre-mixed, specific inks. A company logo, for example, might use Pantone colors to ensure precise branding, whereas the rest of a brochure might use the CMYK system for cost-efficiency.

Q 18. How do you deal with a paper jam on an offset press?

Dealing with a paper jam on an offset press requires a systematic approach to avoid further damage to the machine or the printed materials.

- Safety First: Turn off the press and ensure it’s completely stopped before attempting to clear the jam. Never reach into moving machinery.

- Locate the Jam: Carefully examine the paper path to identify the location of the jam. Most jams occur near the feed tray, rollers, or delivery system.

- Gentle Removal: Gently remove the jammed paper. Avoid tearing the sheets, as this can cause further jams or damage the rollers. Use appropriate tools like tweezers or a small wooden spatula if needed.

- Check for Obstructions: After removing the jammed paper, check for any debris or foreign objects that may have caused the jam.

- Restart the Press: Once the jam is cleared and any obstructions removed, carefully restart the press, monitoring it closely for any further issues.

Remember, always consult the press’s manual for specific instructions on jam clearing. Improper handling can damage the press and could result in injury.

Q 19. What are the various finishing techniques used after offset printing?

Offset printing is often followed by various finishing techniques to enhance the final product’s appearance, durability, and functionality. These include:

- Cutting: Trimming the printed sheets to the desired size and shape using guillotine cutters or die cutters.

- Folding: Folding the sheets into brochures, leaflets, or other formats using folding machines.

- Binding: Combining multiple pages using techniques such as saddle stitching, perfect binding, wire-o binding, or case binding.

- Laminating: Applying a protective film to enhance durability and water resistance.

- Die-cutting: Creating custom shapes and designs using dies.

- Embossing/Debossing: Adding raised or indented designs to the surface.

- UV Coating: Applying a protective UV coating for added durability and shine.

The choice of finishing techniques depends on the project’s requirements. For instance, a high-end brochure might benefit from lamination, embossing, and UV coating, while a simple leaflet might just need cutting and folding.

Q 20. Describe your experience with different types of offset printing presses.

My experience encompasses a wide range of offset printing presses, from smaller format machines ideal for short-run jobs to large-format presses for high-volume production. I’ve worked extensively with both single-color and multi-color presses, including:

- Heidelberg Speedmaster: Known for their reliability, speed, and precision, these presses are industry workhorses. I’ve operated several models within the Speedmaster range, gaining experience with their sophisticated control systems and automated features.

- Komori Lithrone: These presses are renowned for their innovative technology and high-quality output. I’ve worked on models focusing on automation and reduced makeready times.

- Roland: I have experience with Roland presses, particularly their focus on eco-friendly ink technologies and advanced color management.

My expertise extends beyond just operation; it includes understanding the intricacies of each press’s capabilities, maintenance, and troubleshooting. The experience with different models has provided a thorough understanding of various printing technologies and their applications.

Q 21. How do you maintain the quality of printed materials throughout the entire production process?

Maintaining print quality throughout the entire production process involves a holistic approach, encompassing all stages.

- Consistent Material Sourcing: Using high-quality paper and inks from reliable suppliers ensures consistent results. Variations in paper stock can significantly affect the final print quality.

- Rigorous Pre-press Preparation: Accurate color profiles, high-resolution images, and proper imposition are crucial for consistent color and registration across the entire run.

- Precise Press Operation: Careful monitoring of ink density, moisture, and paper feed, coupled with regular maintenance, ensures consistent output. Regular calibration of color measurement instruments is essential.

- Effective Quality Control: Regular press checks throughout the print run, along with a thorough post-press inspection, identifies and addresses any discrepancies promptly.

- Proper Finishing: Ensuring that the finishing process complements the quality of the printing itself is vital. This requires choosing the appropriate finishing methods for the specific material and desired outcome.

For instance, a consistent review of color proofs at each stage, from design to printing to final product, guarantees that the final product matches the client’s expectations. This dedication to quality control assures the client of consistent quality.

Q 22. What are your skills in troubleshooting and problem-solving in an offset printing setting?

Troubleshooting in offset printing requires a systematic approach. I start by identifying the problem – is it a color issue, registration problem, paper jam, or something else? Then, I methodically eliminate possibilities. For instance, if we have inconsistent color, I’d check the ink density, the rollers, the plates, and the dampening system, one by one. I’ve had instances where a seemingly minor issue like a slightly worn blanket cylinder caused significant dot gain, leading to muddy colors. Solving this required replacing the cylinder. Another time, a recurring paper jam was traced back to a misaligned feeder tray – a simple adjustment solved a significant production bottleneck. I document all troubleshooting steps, including the solution, to prevent similar issues in the future. My experience allows me to quickly diagnose and resolve issues, minimizing downtime and maximizing efficiency.

Q 23. Describe your experience with color correction and proofing methods.

Color correction is crucial in offset printing to ensure the final product matches the client’s expectations. I’m proficient in using color management systems like G7 and various colorimetric software. My experience includes working with color profiles (ICC profiles), soft proofing using digital proofs, and hard proofing with physical samples. For example, I’ve tackled projects where the initial digital proof showed a significant color shift compared to the intended color. To correct this, I adjusted the CMYK values, paying close attention to color separation and ensuring that the adjustments didn’t negatively impact other color areas. I also understand the nuances of different printing presses and substrates and how they can influence color. I always conduct thorough color checks throughout the printing process, from platemaking to the final printed sheet, to ensure accuracy.

Q 24. Explain your experience with different types of printing substrates.

My experience spans a wide range of printing substrates, including various types of paper (coated, uncoated, matte, gloss), card stock, and specialty materials like synthetics. I’m familiar with the properties of each, understanding how things like paper weight, grain direction, and absorbency impact the printing process. For instance, printing on uncoated paper requires different ink settings compared to coated paper due to its higher ink absorption. Using the wrong ink or settings can lead to feathering or blotchy printing. I’ve also worked with textured papers, where maintaining consistent ink lay is more challenging. This requires adjusting the pressure settings and dampening solutions on the press carefully. Understanding these nuances allows me to make informed decisions regarding substrate selection and press settings to achieve optimal print quality.

Q 25. How familiar are you with preflighting files and identifying potential printing issues?

Preflighting is a critical step to prevent costly printing errors. I’m highly proficient in using preflighting software, meticulously checking files for color spaces, resolution, fonts, bleeds, and other potential issues before they reach the press. For example, I’ve identified numerous instances of missing fonts, low-resolution images, and incorrect color profiles that would have resulted in significant delays and reprints had they not been caught during preflighting. I’m adept at detecting potential trapping problems, which can lead to unsightly gaps between colors. I’ve also helped clients modify their files to meet printing specifications, ensuring a smooth and efficient printing process. My goal is to catch every potential problem before it becomes a significant issue.

Q 26. Describe your knowledge of different types of paper coatings and their impact on printing.

Different paper coatings significantly affect how ink interacts with the substrate. For instance, a glossy coating provides a smooth, high-gloss finish, enhancing vibrancy and color saturation. However, it can also lead to increased dot gain if not properly managed. Matte coatings, on the other hand, reduce glare and provide a softer, more subtle finish. They often require different ink formulations to achieve the desired color density. UV coatings offer protection and additional gloss or matte finishes. I’ve found that understanding these characteristics is vital for optimizing press settings and ink formulations. Choosing the right coating and managing its impact on ink behavior is crucial for delivering high-quality prints that meet client expectations.

Q 27. What is your experience with managing print projects and meeting deadlines?

I have extensive experience in managing print projects from start to finish. This includes handling client briefs, scheduling print runs, managing resources, and ensuring timely delivery. I use project management tools to track progress, identify potential delays, and proactively address issues. For example, in one project with a tight deadline, I implemented a streamlined workflow that improved efficiency by 15%, ensuring we delivered on time and within budget. I believe in clear communication with clients throughout the process, keeping them informed of the project’s status and addressing any concerns. Meeting deadlines while maintaining the highest quality is a top priority.

Q 28. How familiar are you with industry-standard software used in offset printing?

I’m proficient in industry-standard software used in offset printing, including Adobe Creative Suite (Photoshop, Illustrator, InDesign), preflighting software like PitStop, and color management software such as G7. I understand the importance of using these tools effectively to ensure accurate color reproduction, proper file preparation, and efficient workflow management. I also have experience with RIP software and different press control systems used in various printing presses. This broad range of software expertise allows me to contribute to every stage of the offset printing process, from design to production.

Key Topics to Learn for Offset Printing Principles Interview

- Color Management: Understanding color spaces (CMYK, RGB), color separation techniques, and the impact of dot gain on final print output. Practical application: Troubleshooting color inconsistencies between proof and final print.

- Platemaking & Imposition: Familiarize yourself with different plate types (CTP, conventional), the imposition process, and considerations for sheet size and orientation. Practical application: Optimizing plate layout for efficient printing and minimizing waste.

- Press Operation & Maintenance: Knowledge of different press types (sheetfed, web), understanding the printing process (inking, dampening, impression), and basic press maintenance procedures. Practical application: Identifying and troubleshooting common press problems like slurring or ghosting.

- Paper & Ink Selection: Understanding the properties of different paper types (weight, finish, absorbency) and their impact on print quality. Knowledge of various ink types and their compatibility with different substrates. Practical application: Selecting appropriate paper and ink for specific print jobs to achieve desired results.

- Quality Control & Print Finishing: Implementing quality control measures throughout the printing process, including pre-press checks, press checks, and post-press inspections. Familiarity with common finishing techniques (cutting, folding, binding). Practical application: Ensuring consistent print quality and meeting client specifications.

- Pre-press workflow: Understanding the steps involved in preparing files for offset printing, including trapping, image resolution, and color profiles. Practical application: Preparing files correctly to avoid common pre-press errors.

Next Steps

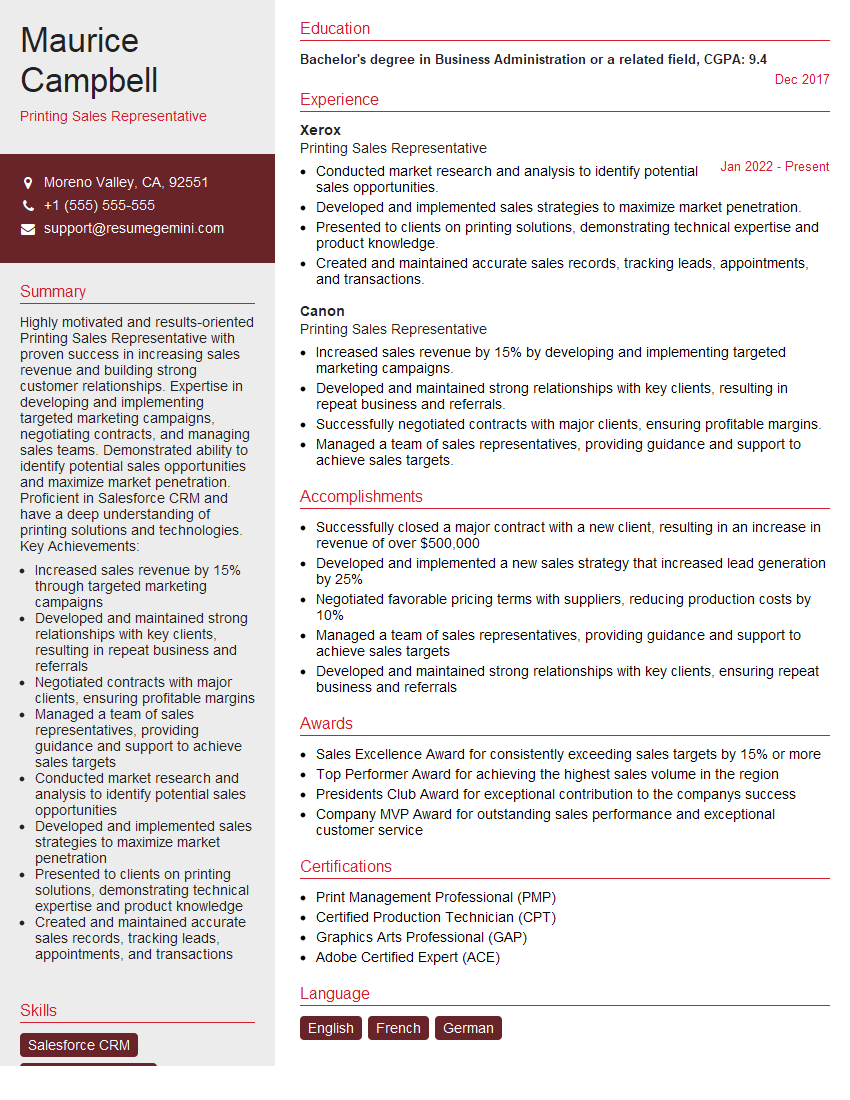

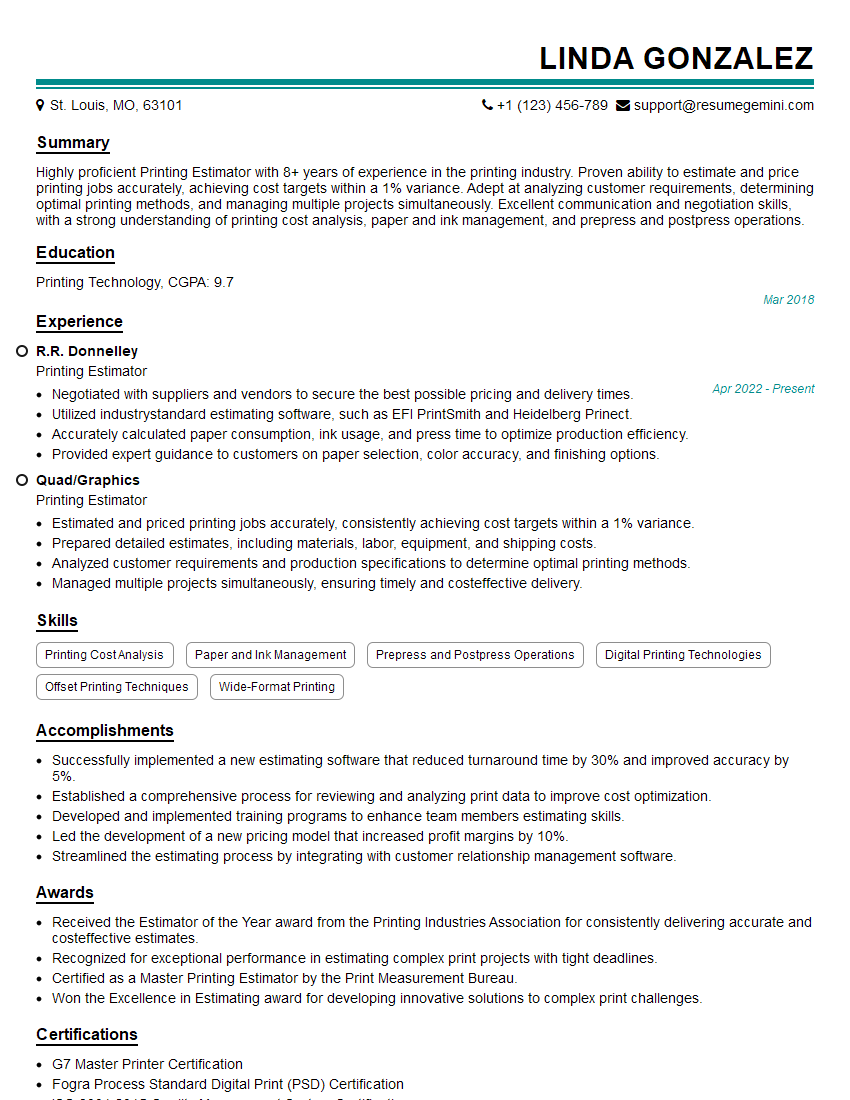

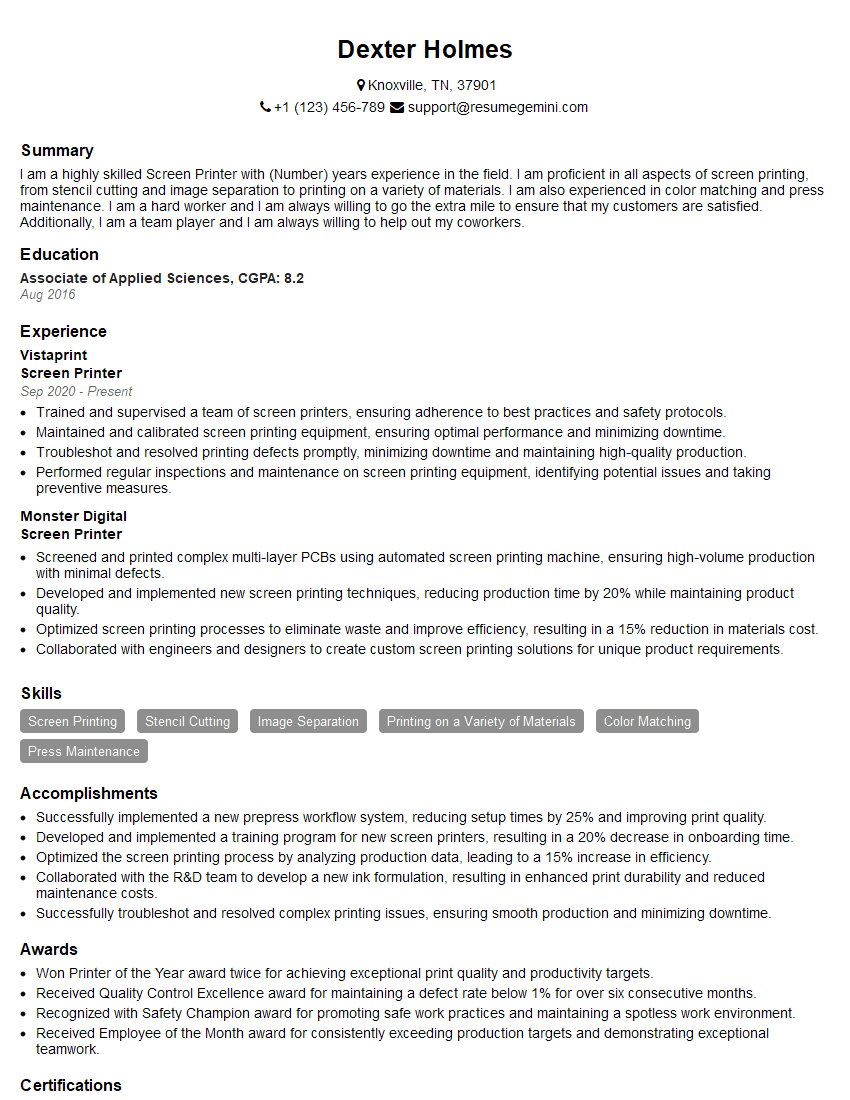

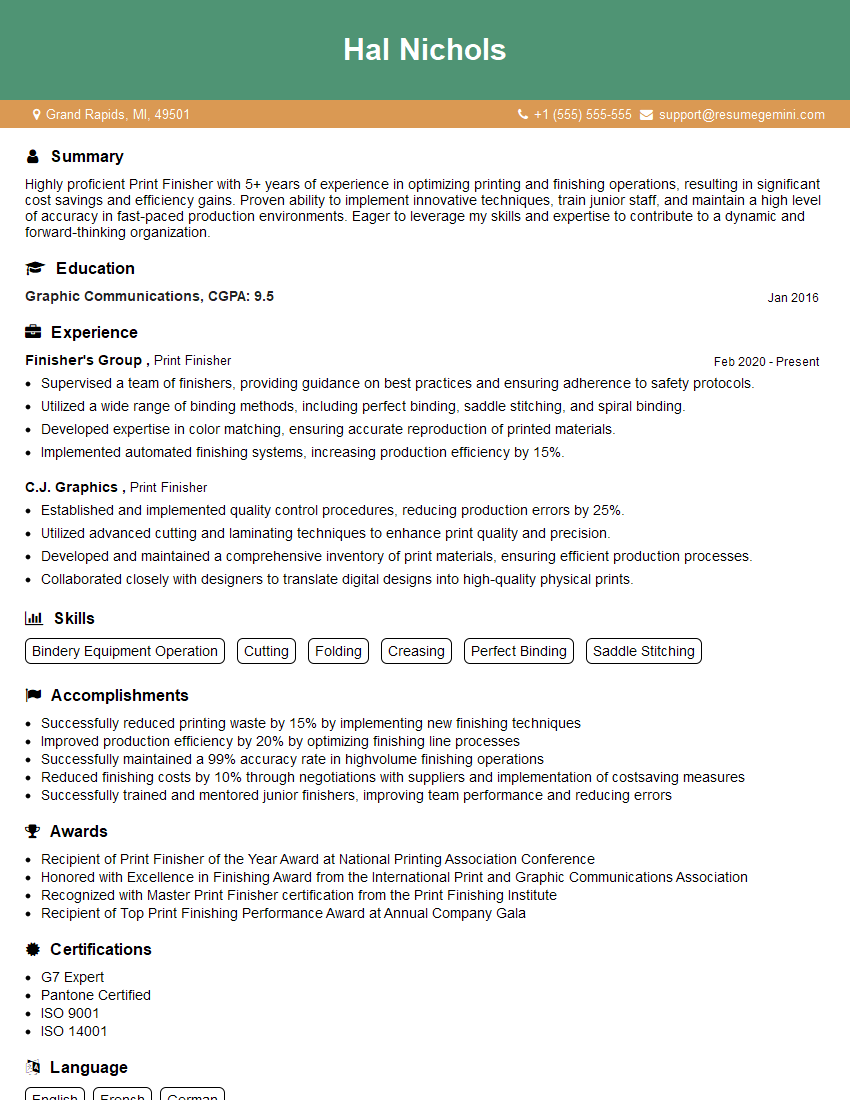

Mastering Offset Printing Principles is crucial for career advancement in the graphic arts industry. A strong understanding of these concepts demonstrates technical proficiency and problem-solving skills, making you a highly valuable asset to any printing company. To significantly increase your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. We recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides a streamlined process and offers examples of resumes tailored to Offset Printing Principles, helping you present your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi I am a troller at The aquatic interview center and I suddenly went so fast in Roblox and it was gone when I reset.

Hi,

Business owners spend hours every week worrying about their website—or avoiding it because it feels overwhelming.

We’d like to take that off your plate:

$69/month. Everything handled.

Our team will:

Design a custom website—or completely overhaul your current one

Take care of hosting as an option

Handle edits and improvements—up to 60 minutes of work included every month

No setup fees, no annual commitments. Just a site that makes a strong first impression.

Find out if it’s right for you:

https://websolutionsgenius.com/awardwinningwebsites

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good