Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Oil and Gas Production Support interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Oil and Gas Production Support Interview

Q 1. Explain the concept of artificial lift in oil and gas production.

Artificial lift in oil and gas production refers to methods used to enhance the flow of hydrocarbons from a reservoir to the surface when natural reservoir pressure is insufficient. Think of it like giving a tired pump an extra boost. As a reservoir depletes, the pressure driving the oil and gas upwards diminishes, leading to reduced production rates. Artificial lift systems provide the necessary additional energy to overcome this pressure deficit and maintain or increase production.

Q 2. Describe different types of artificial lift systems and their applications.

Several artificial lift methods exist, each with its own strengths and weaknesses:

- Rod Pumps: These are the most common type, using a subsurface pump driven by a surface-mounted rod string. They’re reliable and suitable for a wide range of well conditions but can be expensive to install and maintain, and have limitations on depth and production rate.

- Submersible Pumps (ESP): Electrically powered pumps submerged in the wellbore. ESPs are highly efficient and can handle high production rates, but they are sensitive to sand production and require specialized expertise for installation and maintenance. I’ve seen several successful implementations of ESPs in high-volume wells where rod pumps proved insufficient.

- Gas Lift: High-pressure gas is injected into the wellbore to reduce the hydrostatic pressure and improve flow. It’s relatively simple to implement and is effective in gas-condensate wells or those with higher gas-oil ratios. However, it requires a reliable gas supply and careful pressure management.

- Progressive Cavity Pumps (PCP): These pumps use a rotating helical rotor within a stator to move fluid. They’re highly efficient with viscous fluids and handle solids well, making them suitable for heavy oil applications. However, they have a lower maximum flow rate compared to some other methods.

- Hydraulic Jet Pumps: These use high-velocity jets of fluid to lift the produced fluids. They’re suitable for wells with low flow rates and can be relatively inexpensive to install, but efficiency can be lower compared to other methods.

The choice of system depends on factors such as well depth, fluid properties, production rate, cost, and available infrastructure.

Q 3. How do you troubleshoot a decrease in production from a well?

Troubleshooting a production decrease requires a systematic approach. I’d typically follow these steps:

- Review historical production data: Analyze trends to determine if the decline is gradual or sudden, and if there are any correlating factors (e.g., changes in reservoir pressure, fluid properties).

- Inspect surface equipment: Check for leaks, blockages, or malfunctions in the flow lines, separators, and other surface facilities. A seemingly small leak can significantly impact overall production.

- Analyze well test data: Perform pressure buildup or drawdown tests to assess reservoir performance and identify potential problems such as formation damage or water coning.

- Run production logging tools (PLT): These tools provide detailed information about the flow profile in the wellbore, helping identify zones with flow restrictions or fluid entry points. This is crucial for pinpointing the source of the problem.

- Consider artificial lift system issues: If an artificial lift system is in place, assess its performance. For example, a malfunctioning ESP could lead to a dramatic drop in production. This might involve reviewing pump performance curves, checking for gas lock or other operational issues.

- Investigate reservoir issues: Factors like water or gas coning, reservoir depletion, or formation damage can reduce production. Analyzing reservoir simulation models and geological data can help in identifying these issues.

The exact troubleshooting steps will vary based on the specific well and its characteristics. However, a methodical approach combining data analysis, equipment inspection, and well testing is crucial for effective diagnosis and remediation.

Q 4. What are the key performance indicators (KPIs) you monitor in oil and gas production?

Key Performance Indicators (KPIs) monitored in oil and gas production include:

- Oil Production Rate (OPR): The volume of oil produced per unit of time (e.g., barrels per day).

- Gas Production Rate (GPR): The volume of gas produced per unit of time (e.g., cubic feet per day).

- Water Production Rate (WPR): The volume of water produced per unit of time. High water production can indicate reservoir issues or changes in the fluid contact.

- Liquid Production Rate (LPR): The total volume of liquids (oil and water) produced.

- Wellhead Pressure (WHP): The pressure at the wellhead, which reflects the reservoir pressure and the flow conditions in the wellbore.

- Artificial Lift Efficiency (ALE): The ratio of produced fluid to the energy consumed by the artificial lift system. This is critical for optimizing energy usage.

- Operating Costs: Includes the costs associated with production, maintenance, and other related activities.

- Production Downtime: The percentage of time the well is not producing. Minimizing downtime is crucial for maximizing profitability.

These KPIs, along with others specific to the operation, are regularly monitored and analyzed to evaluate well performance, identify areas for improvement, and make data-driven decisions for optimization.

Q 5. Explain the importance of production optimization.

Production optimization is crucial for maximizing the economic recovery of hydrocarbons from a reservoir. It involves systematically improving the efficiency of the production process, maximizing production rates, minimizing operating costs, and extending the life of the well. Imagine it as fine-tuning a complex machine to get the best possible performance. For instance, optimizing artificial lift settings can significantly increase production without incurring additional costs.

Improved optimization can lead to:

- Increased hydrocarbon recovery

- Reduced operating costs

- Extended well life

- Improved profitability

Q 6. How do you manage production data and identify trends?

Production data management involves collecting, storing, processing, and analyzing data from various sources. This often involves using specialized software and databases. In my experience, we leverage SCADA (Supervisory Control and Data Acquisition) systems to monitor real-time production data, while historical data is stored in relational databases. We use data analytics tools to identify trends, such as production decline rates or water cut increases. Data visualization techniques, like charts and graphs, help to easily spot anomalies and trends that might indicate a problem. For example, a sudden increase in water cut may indicate a change in the reservoir’s fluid contacts.

Identifying trends can be done using various statistical methods, from simple moving averages to more advanced techniques like regression analysis. These allow us to make predictions about future production and proactively address potential issues.

Q 7. Describe your experience with production logging tools and their interpretation.

Production logging tools (PLT) are essential for diagnosing wellbore problems and optimizing production. These tools are deployed downhole to measure various parameters, including flow rates, pressure, and fluid properties. I have extensive experience interpreting data from a range of PLT tools, including:

- Flow meters: Measure the flow rates of oil, gas, and water at different depths in the wellbore, enabling identification of flow restrictions or fluid entry points.

- Pressure gauges: Measure pressure along the wellbore, providing insights into pressure drops and flow resistances.

- Temperature sensors: Measure temperature profiles, which can indicate flow patterns, fluid mixing, or the presence of gas.

- Fluid samplers: Collect samples of fluids at different depths for analysis of fluid properties.

Interpreting PLT data involves correlating the measured parameters with the well’s geology and production history. For example, a significant pressure drop across a particular zone could indicate a restriction in the formation or a problem with the well completion. We utilize specialized software to analyze the data, creating visual representations of flow profiles and pressure distributions. This information helps in identifying the root cause of production problems and optimizing well operations.

Q 8. What are the common challenges faced in oil and gas production?

Oil and gas production faces numerous challenges, broadly categorized into geological, operational, and economic factors. Geologically, we might encounter low reservoir permeability, which restricts fluid flow, or complex reservoir heterogeneity, making prediction and management difficult. Think of trying to drain water from a sponge with unevenly sized pores – some areas drain easily, others are stubbornly resistant. Operationally, challenges include equipment failures (like pump malfunctions or pipeline corrosion), wellbore instability (leading to collapse or damage), and the need for efficient water management (producing water alongside oil and gas adds costs and complexity). Economically, fluctuating oil and gas prices, regulatory hurdles, and the high capital investment required for exploration and production create significant uncertainty and risk. For example, a sudden price drop can make a previously profitable project suddenly uneconomical. Successfully navigating these challenges requires a multidisciplinary approach, employing advanced technologies and robust risk management strategies.

Q 9. How do you ensure safety compliance in oil and gas production operations?

Safety compliance is paramount in oil and gas production. We adhere to a comprehensive safety management system (SMS), encompassing risk assessment, hazard identification, and the implementation of control measures. This includes regular safety audits and training programs, strict adherence to industry standards (like those set by OSHA and API), and the use of advanced safety technologies such as gas detection systems and emergency shutdown procedures. For example, before any work is undertaken near a wellhead, a thorough risk assessment is conducted, identifying potential hazards (like gas leaks or equipment malfunctions) and specifying the necessary safety precautions, including permit-to-work systems and emergency response plans. A culture of safety is crucial; every employee is empowered to halt operations if they perceive an unsafe condition. This proactive approach, coupled with robust regulatory compliance, is vital for minimizing accidents and protecting both personnel and the environment.

Q 10. Explain the principles of reservoir simulation and its role in production planning.

Reservoir simulation utilizes mathematical models to predict the behavior of fluids (oil, gas, and water) within a reservoir under various operating conditions. It’s like creating a digital twin of the reservoir. The principles involve solving complex equations governing fluid flow, heat transfer, and rock properties. This simulation helps us understand reservoir pressure, fluid saturation, and production rates over time. It’s crucial for production planning because it allows us to optimize well placement, predict production decline curves, and evaluate the effectiveness of different recovery techniques such as waterflooding or enhanced oil recovery (EOR). For example, before drilling a new well, reservoir simulation can help determine the optimal location to maximize production while minimizing water production. By running simulations with different scenarios (e.g., varying injection rates or production strategies), we can choose the approach that yields the best economic outcome, minimizing costs and maximizing returns.

Q 11. Describe your experience with well testing and interpretation.

My experience with well testing and interpretation encompasses a wide range of techniques, from pressure buildup and drawdown tests to multi-rate testing and interference testing. Well testing provides critical data to characterize reservoir properties like permeability, porosity, and skin factor (which reflects near-wellbore damage or improvement). For instance, a pressure buildup test involves shutting in a producing well and measuring the pressure recovery over time. This data is then analyzed using specialized software and analytical models (like the Horner method or the superposition principle) to estimate reservoir parameters. The interpretation phase involves carefully evaluating the test data, considering potential uncertainties and biases, and integrating the results with other geological and geophysical data. A crucial aspect of interpretation is accounting for factors that can affect the test results such as non-Darcy flow effects at high flow rates. This integrated approach ensures the accurate characterization of the reservoir, forming a solid foundation for production optimization and forecasting.

Q 12. How do you optimize well performance to maximize production?

Optimizing well performance involves a combination of strategies aimed at maximizing hydrocarbon production while minimizing operating costs. This encompasses several key aspects: First, proper well completion design – selecting the right type of completion (e.g., gravel pack, hydraulic fracturing) based on reservoir characteristics to enhance permeability and improve fluid flow. Second, artificial lift optimization – using techniques such as gas lift or ESPs (Electrical Submersible Pumps) to enhance production from wells with low reservoir pressure. Third, reservoir management strategies – such as waterflooding or polymer injection, to improve sweep efficiency and displacement of hydrocarbons. Lastly, regular monitoring and maintenance – tracking production data, conducting well integrity checks, and addressing any issues promptly, prevents production decline. For example, by implementing a smart well completion with downhole sensors, real-time data on pressure, temperature, and flow rates can be obtained which then enables proactive interventions, preventing potential problems and maintaining optimal production levels.

Q 13. What are the different types of flow regimes in oil and gas wells?

Oil and gas wells can exhibit various flow regimes, depending on the properties of the fluids and the wellbore geometry. These regimes include single-phase flow (either oil, gas, or water flowing alone), two-phase flow (e.g., oil and gas, or oil and water), and three-phase flow (oil, gas, and water). Within these categories, there are further distinctions. For instance, two-phase flow can be bubbly flow (gas bubbles dispersed in liquid), annular flow (liquid flowing as a film along the pipe wall, with gas in the center), or stratified flow (liquid and gas flowing in separate layers). Identifying the flow regime is crucial for well design, artificial lift selection, and pipeline design because different flow regimes have different pressure drop characteristics and transportation efficiencies. Incorrectly predicting flow regime can lead to inefficiencies or even equipment failure. For example, the presence of high gas production may lead to a high-velocity annular flow regime causing erosion or corrosion problems in the wellbore or pipeline if not properly accounted for.

Q 14. Explain your understanding of multiphase flow in pipelines.

Multiphase flow in pipelines involves the simultaneous transport of oil, gas, and water. Understanding this complex phenomenon is vital for pipeline design, operation, and safety. The flow behavior is governed by the interactions between the phases (oil, gas, water), the pipeline geometry, and the flow rate. Factors like fluid properties (viscosity, density), pressure, and temperature significantly influence the flow pattern. Modeling multiphase flow is crucial for accurate prediction of pressure drop, liquid holdup (the fraction of the pipeline occupied by liquid), and flow assurance issues (like hydrate formation or slug flow, which can damage pipelines). This is often done using specialized software that solves the governing equations, taking into account the complex interactions between phases. For example, a pipeline transporting high-pressure gas along with liquid hydrocarbons would necessitate careful design to prevent the gas from separating and creating pockets that can cause instability, leading to pipeline blockages and potentially catastrophic failure. Accurate modeling ensures the pipeline operates safely and efficiently.

Q 15. How do you handle equipment failures and downtime in a production facility?

Handling equipment failures and downtime requires a proactive and reactive approach. Proactive measures include rigorous preventative maintenance schedules, thorough equipment inspections, and utilizing predictive analytics to identify potential issues before they escalate. This might involve using vibration sensors on critical machinery to detect early signs of wear and tear.

Reactively, a well-defined emergency response plan is crucial. This plan should outline clear procedures for isolating the failed equipment, ensuring safety of personnel, and initiating repairs. This often involves a tiered approach: first, isolating the problem to prevent further damage or safety risks; second, conducting a thorough root cause analysis to understand why the failure occurred to prevent recurrence; and third, implementing the necessary repairs using pre-qualified contractors or in-house expertise, while simultaneously prioritizing repairs based on impact on overall production.

For example, during my time at [Previous Company Name], a critical compressor failed unexpectedly. Our response plan swung into action. The failed compressor was isolated, emergency shutdowns were initiated following safety protocols, and the root cause analysis quickly determined a bearing failure due to insufficient lubrication. Within 24 hours, a replacement compressor was installed, and production resumed. We then implemented changes to the lubrication schedule and upgraded our monitoring systems to prevent similar occurrences.

Career Expert Tips:

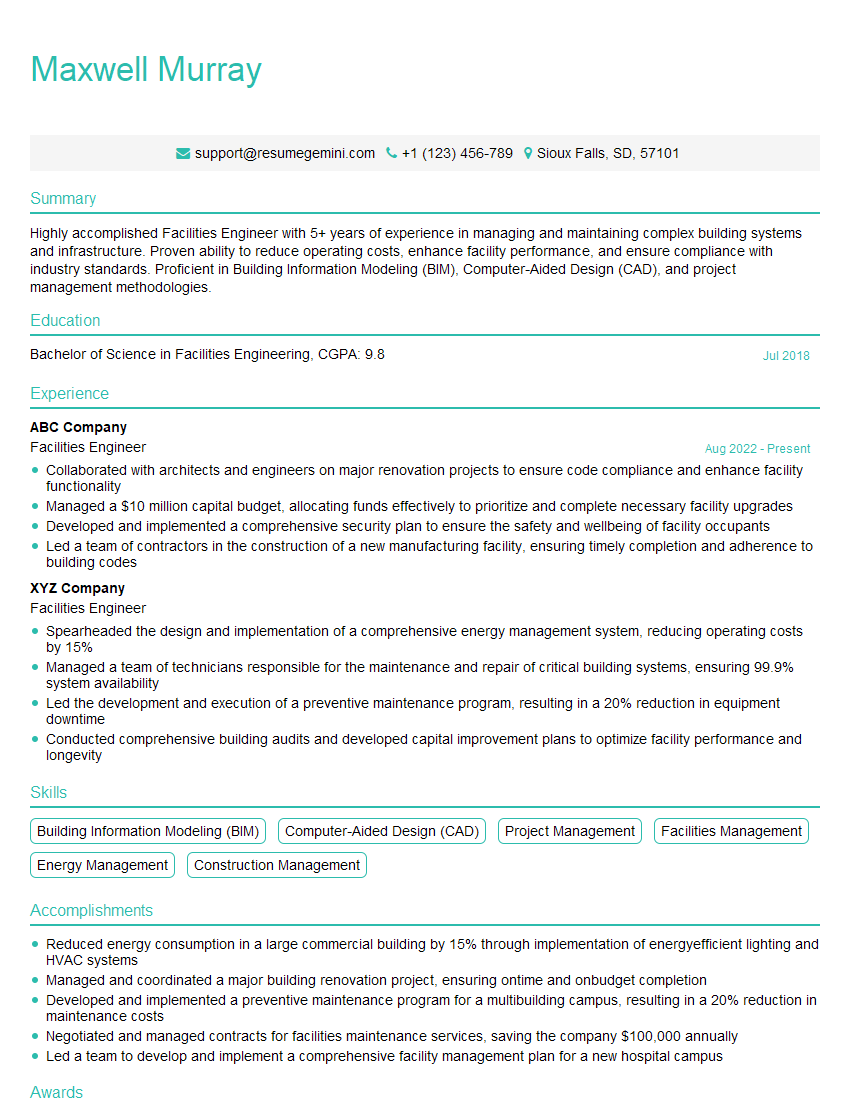

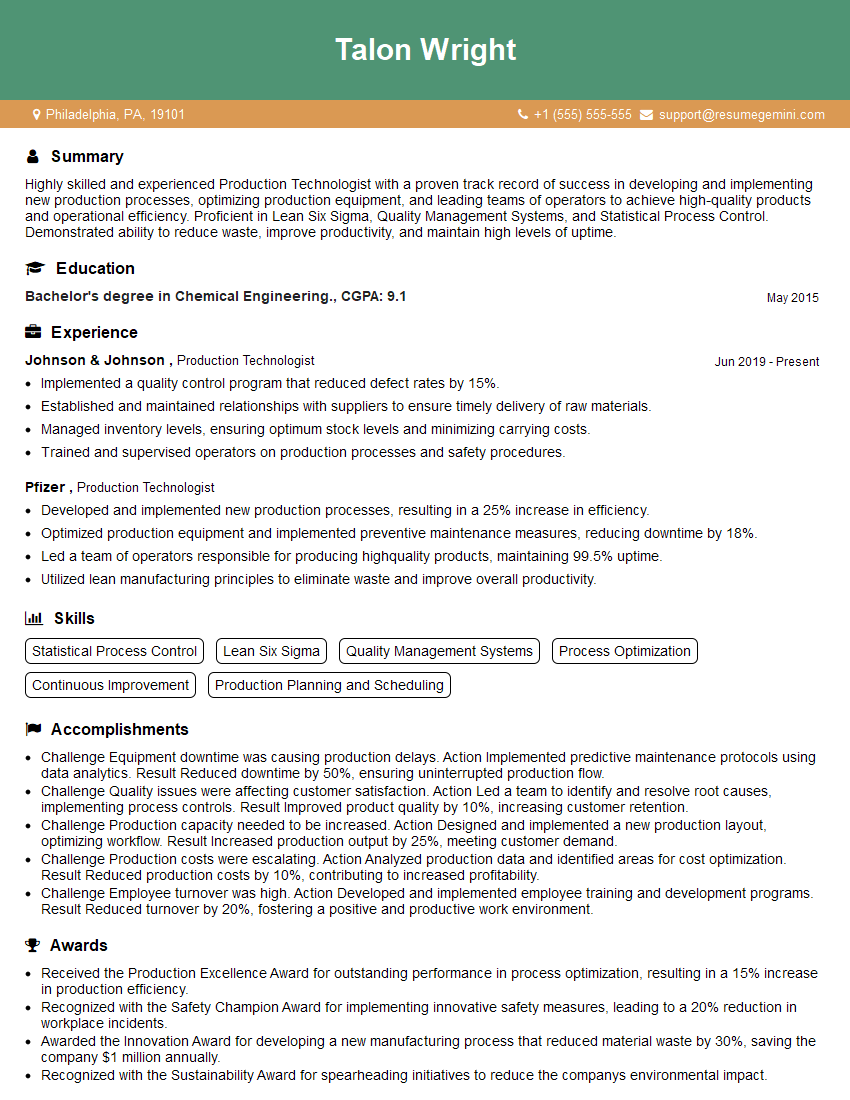

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with production scheduling and planning.

Production scheduling and planning is the backbone of efficient oil and gas operations. It involves forecasting production volumes based on reservoir performance, equipment capacity, and market demand. This forecasting informs the creation of detailed production schedules which optimize resource allocation (personnel, materials, and equipment). I’ve used various software packages for this, including [Mention specific software e.g., Aspen HYSYS, etc.], to model reservoir behavior and optimize production scenarios.

My experience includes developing and implementing production schedules for both onshore and offshore facilities. This includes integrating operational constraints (like maintenance windows or pipeline capacity limitations) into the schedules to maintain optimal production while minimizing downtime. For instance, at [Previous Company Name], I was instrumental in creating a dynamic scheduling system that adjusted production plans in real-time, based on actual well performance data. This resulted in a 10% increase in annual production.

Q 17. How do you manage production costs effectively?

Managing production costs effectively requires a multi-faceted approach. This includes optimizing operational efficiency through improved equipment utilization, minimizing energy consumption, and implementing cost-effective maintenance strategies. A strong focus on preventative maintenance, as opposed to solely reactive repairs, is key here. This reduces unexpected downtime and associated costs.

Further, cost optimization involves careful procurement of materials and services, negotiating favorable contracts with suppliers, and utilizing advanced analytics to identify areas for cost reduction. For example, at [Previous Company Name], we implemented a data-driven approach to optimize chemical usage in water treatment, leading to significant savings. We also leveraged data analytics to predict equipment failures, allowing us to schedule maintenance proactively and reduce the cost of unplanned downtime.

Q 18. What is your experience with pipeline integrity management?

Pipeline integrity management is crucial for ensuring safe and reliable operations. It involves a comprehensive program of inspection, maintenance, and repair to prevent pipeline failures and environmental incidents. This involves regularly inspecting pipelines using various methods, including in-line inspection (ILI) tools which identify internal corrosion and defects, and external inspections for signs of physical damage.

My experience encompasses all aspects of pipeline integrity management, from developing and implementing inspection plans to managing repair activities. I’m familiar with industry standards and regulations related to pipeline safety, such as [Mention specific standards/regulations e.g., API 1160]. A key part of my work has been risk assessment – identifying and prioritizing areas requiring immediate attention based on the severity and likelihood of failure. At [Previous Company Name], I led a project that improved our pipeline integrity program, reducing the number of incidents by 15% in two years.

Q 19. Explain your experience with different types of gas processing equipment.

Gas processing equipment varies widely depending on the composition of the raw gas and the desired product specifications. I’m experienced with a range of equipment, including:

- Dehydration units: These remove water vapor from natural gas to prevent corrosion and hydrate formation in pipelines. I’ve worked with both glycol dehydration and membrane dehydration systems.

- Sweetening units: These remove acid gases like hydrogen sulfide (H2S) and carbon dioxide (CO2). Common technologies include amine treating and Claus plants.

- Fractionation units: These separate the gas into its components (methane, ethane, propane, etc.). This requires sophisticated cryogenic equipment for efficient separation.

- Compression units: These increase the pressure of the gas to facilitate transportation through pipelines.

My experience includes troubleshooting and optimizing the performance of these units, ensuring efficient and safe gas processing. For example, I was involved in upgrading an amine treating unit at [Previous Company Name] that improved its efficiency and reduced operating costs.

Q 20. Describe the importance of water management in oil and gas production.

Water management is critical in oil and gas production due to the large volumes of water produced alongside hydrocarbons. Effective water management involves several key aspects:

- Produced water treatment: This involves treating produced water to remove contaminants such as oil, salts, and chemicals before disposal or reuse.

- Wastewater disposal: This requires adherence to strict environmental regulations, often involving injection into deep wells or treatment for discharge into surface waters.

- Water recycling: Recycling treated produced water for operational purposes, like hydraulic fracturing or steam generation, reduces fresh water consumption and minimizes environmental impact.

Ignoring effective water management can lead to environmental contamination and regulatory penalties. In my experience, I’ve been involved in designing and implementing water treatment facilities and managing produced water disposal. For example, I led a project at [Previous Company Name] that implemented a water recycling program which reduced our reliance on freshwater sources by 20%.

Q 21. How do you handle environmental concerns related to oil and gas production?

Environmental concerns are paramount in oil and gas production. Responsible operations require a commitment to minimizing emissions of greenhouse gases (GHGs), preventing air and water pollution, and protecting biodiversity. This involves implementing robust environmental management systems, complying with all applicable environmental regulations, and continuously striving to reduce our environmental footprint.

My experience includes developing and implementing environmental management plans, conducting environmental impact assessments, and managing environmental compliance programs. I am familiar with various emissions reduction technologies, such as carbon capture and storage (CCS) and methane detection and repair programs. At [Previous Company Name], I led a team that implemented a comprehensive GHG emission reduction program, resulting in a significant decrease in our carbon footprint. We also implemented stringent monitoring and reporting procedures to ensure regulatory compliance and to track environmental performance.

Q 22. What is your understanding of pressure transient analysis?

Pressure transient analysis (PTA) is a powerful technique used to understand the properties of a reservoir by analyzing the pressure response of a well to production or injection changes. Think of it like taking the well’s ‘pulse’ to learn about the reservoir’s ‘heart’. We do this by observing how pressure changes over time at the wellbore after a production or injection event. The pressure changes are governed by the reservoir’s permeability, porosity, and fluid properties, along with the geometry of the reservoir and the wellbore itself.

We use specialized software to analyze pressure drawdown and buildup tests. Drawdown tests measure pressure decline during production, while buildup tests monitor pressure recovery after shutting in the well. The resulting data is interpreted using established models, such as the radial diffusivity equation, to estimate reservoir parameters like permeability, skin factor (which represents the near-wellbore damage or stimulation), and reservoir pressure. For example, a sharp pressure decline indicates a high permeability reservoir, while a slow decline suggests low permeability. A positive skin factor implies near-wellbore damage, while a negative skin factor indicates stimulation effects. This information is crucial for optimizing production strategies and reservoir management.

Q 23. How do you use production data to optimize reservoir management?

Production data is the lifeblood of reservoir management. We use data like flow rates (oil, gas, water), pressures, temperatures, and compositions to monitor reservoir performance and make informed decisions. It’s like having a detailed patient chart in medicine – it helps us diagnose problems and prescribe solutions.

We utilize this data in several ways: Firstly, for reservoir performance monitoring; tracking production decline curves helps us predict future production and identify potential problems early on. Secondly, for reservoir simulation modeling; we use historical production data to calibrate our reservoir models, ensuring they accurately reflect reservoir behavior. This helps us predict the response to different development strategies. Thirdly, for optimization of production strategies; analyzing water cut (the proportion of water in the produced fluid) allows us to understand reservoir depletion and water influx. This helps in adjusting production rates or implementing water management strategies. Finally, for identifying potential problems like water coning or gas channeling; early detection allows for timely intervention, preventing significant production loss.

Q 24. Explain the concept of well control and safety procedures.

Well control refers to the procedures and equipment used to prevent uncontrolled flow of fluids (oil, gas, or water) from a wellbore. Safety procedures are the protocols followed to ensure the well is operated safely and prevent accidents. This is paramount in the oil and gas industry, as uncontrolled well flow can lead to significant environmental damage, equipment damage, and severe injuries or fatalities. Think of it like a carefully controlled pressure cooker – a sudden release can be catastrophic.

Well control procedures involve using specialized equipment like blowout preventers (BOPs), which are essentially valves that can rapidly shut off the flow from the well. We follow strict procedures during drilling, completion, and production operations to ensure the well remains under control. These procedures cover all aspects of well operation from drilling fluids management to emergency shutdown procedures. Regular training and drills are crucial to ensure personnel are prepared to handle any well control emergencies. Safety procedures are equally important, encompassing risk assessments, emergency response plans, and strict adherence to safety regulations. We perform regular inspections and maintenance of equipment to prevent failures. A robust safety culture emphasizing proactive risk management is essential to a safe work environment.

Q 25. Describe your experience with automation and remote monitoring in oil and gas production.

I have extensive experience with automation and remote monitoring systems in oil and gas production. These technologies have revolutionized the industry, improving efficiency, safety, and production optimization. Think of it as having a remote doctor constantly monitoring a patient’s vital signs.

Specifically, I’ve worked with SCADA (Supervisory Control and Data Acquisition) systems, which provide real-time monitoring and control of wellhead parameters (pressure, temperature, flow rate) from a central location. This allows for remote adjustments to production rates and early detection of any anomalies. Furthermore, I have experience with advanced analytics applied to production data gathered from these systems. This allows for predictive maintenance of equipment and proactive identification of potential issues. Remote monitoring also reduces the need for constant on-site personnel, improving safety by minimizing exposure to hazardous environments. For example, using remote sensors to monitor tank levels reduces the need for manual checks, decreasing the risk of human error.

Q 26. How do you contribute to a collaborative and safe work environment?

Contributing to a collaborative and safe work environment is a top priority for me. I believe in fostering open communication, mutual respect, and teamwork. I actively participate in safety meetings and contribute to hazard identification and risk mitigation strategies. Think of it like building a strong team in sports – everyone has a role and works together to achieve the common goal.

Specifically, I encourage open communication by actively listening to colleagues, sharing my expertise, and soliciting feedback. I always follow safety protocols and encourage others to do the same. I also contribute to training programs to improve safety awareness and competency. Moreover, I proactively identify and address safety hazards, promoting a culture of continuous improvement. Finally, I believe in leading by example, demonstrating a commitment to safety and collaboration in all my actions.

Q 27. What is your experience with different types of oil and gas reservoirs?

I’ve worked with various types of oil and gas reservoirs, including conventional reservoirs (sandstone, carbonate), unconventional reservoirs (shale gas, tight gas), and enhanced oil recovery (EOR) projects. Each reservoir type presents unique challenges and opportunities in terms of production and reservoir management.

Conventional reservoirs are typically characterized by higher permeability and porosity, making them easier to produce from. Unconventional reservoirs, on the other hand, are characterized by low permeability and require specialized techniques like hydraulic fracturing (fracking) to enhance production. EOR projects involve techniques like waterflooding, polymer flooding, or chemical injection to increase oil recovery from mature fields. Understanding the specific characteristics of each reservoir type is crucial for designing effective production strategies. For instance, the optimal well spacing and completion techniques differ significantly between conventional and unconventional reservoirs. My experience spans diverse reservoir types, enabling me to adapt my approach to specific challenges.

Q 28. Describe your understanding of different completion techniques.

Completion techniques are crucial for maximizing hydrocarbon production from a well. These techniques refer to the processes and equipment used after drilling to prepare the well for production. Think of it like preparing a field for a harvest – the better the preparation, the better the yield.

I am familiar with various completion techniques, including:

- Openhole completion: The simplest type, where the wellbore is left open after drilling.

- Cased-hole completion: Involves running casing and cementing it to stabilize the wellbore and isolate different zones.

- Perforated completion: Creates holes in the casing to allow fluid flow into the wellbore.

- Fracturing (hydraulic fracturing): Creates artificial fractures in the reservoir rock to enhance permeability and increase production, particularly important for unconventional reservoirs.

- Gravel packing: Protects the wellbore from sand production.

Key Topics to Learn for Oil and Gas Production Support Interview

- Production Optimization: Understanding techniques for maximizing hydrocarbon recovery, including reservoir management strategies and artificial lift methods. Practical application: Analyzing production data to identify bottlenecks and propose solutions for increased efficiency.

- Well Testing and Analysis: Interpreting pressure and flow data to assess well performance and diagnose production issues. Practical application: Using well test data to determine the need for interventions such as stimulation or workovers.

- Facility Operations and Maintenance: Knowledge of processing equipment (separators, compressors, etc.) and their maintenance schedules. Practical application: Troubleshooting equipment malfunctions and ensuring safe and efficient facility operation.

- Health, Safety, and Environment (HSE): Understanding and adhering to HSE regulations and best practices within the oil and gas industry. Practical application: Identifying and mitigating potential HSE risks in production operations.

- Data Acquisition and Analysis: Proficiency in using SCADA systems and other data analysis tools to monitor and interpret production data. Practical application: Creating reports and presentations based on production data to communicate performance and identify areas for improvement.

- Troubleshooting and Problem-Solving: Developing a systematic approach to diagnose and resolve production issues, applying critical thinking skills to complex scenarios. Practical application: Utilizing root cause analysis techniques to pinpoint the origin of production problems.

- Regulatory Compliance: Familiarity with relevant industry regulations and reporting requirements. Practical application: Ensuring compliance with governmental and company standards.

Next Steps

Mastering Oil and Gas Production Support opens doors to a rewarding and challenging career with significant growth potential. To maximize your job prospects, a strong, ATS-friendly resume is crucial. ResumeGemini can help you craft a compelling resume that showcases your skills and experience effectively. ResumeGemini offers a user-friendly platform and provides examples of resumes tailored specifically to Oil and Gas Production Support roles, ensuring your application stands out from the competition. Invest the time to build a professional and impactful resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good