Unlock your full potential by mastering the most common Operate Pallet Jacks and Stackers interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Operate Pallet Jacks and Stackers Interview

Q 1. Describe your experience operating pallet jacks.

My experience with pallet jacks spans over eight years, encompassing various warehouse environments and product types. I’ve operated both manual and electric pallet jacks, handling loads ranging from light consumer goods to heavy industrial machinery. This extensive experience has given me a deep understanding of their operational capabilities, limitations, and safety protocols. I’m proficient in maneuvering them in tight spaces, navigating uneven surfaces, and loading/unloading trucks efficiently. For example, I once managed to optimize the loading process in our warehouse by implementing a more strategic pallet placement plan, resulting in a 15% increase in efficiency.

Q 2. What are the different types of pallet jacks you are familiar with?

I’m familiar with several types of pallet jacks, each suited for different needs. These include:

- Manual Pallet Jacks: These are the most basic type, requiring physical effort to lift and move pallets. They are cost-effective and simple to maintain but are less efficient for heavy loads or long distances.

- Electric Pallet Jacks: Powered by batteries, these are much easier to operate, especially with heavier loads. They offer increased speed and efficiency compared to manual jacks. Different models offer varying lift heights and load capacities.

- High-Lift Pallet Jacks: These electric jacks can lift pallets to significantly greater heights than standard pallet jacks, allowing for easier loading onto higher shelves or truck beds. They’re invaluable for multi-tiered storage systems.

- Walkie Stackers: While technically a stacker, these combine the functionality of a pallet jack with the ability to lift pallets vertically to several different heights. They’re ideal for stacking and retrieving pallets in a warehouse.

Q 3. Explain the proper lifting techniques for using a pallet jack.

Proper lifting techniques are crucial to prevent injuries and ensure efficient operation. Before lifting, always check the weight of the pallet to ensure it’s within the jack’s capacity. Then:

- Assess the load: Ensure the pallet is stable and the load is evenly distributed.

- Position the jack: Center the forks under the pallet and engage the lifting mechanism smoothly. Avoid jerky movements.

- Lift slowly and steadily: Don’t rush the process. Keep your back straight and use your legs to lift.

- Maintain control: Keep a firm grip on the handle throughout the operation.

- Lower slowly: Lower the pallet gently, avoiding sudden drops, which can damage goods or the pallet jack itself.

Remember, taking your time and using proper form is essential to prevent injuries like back strains.

Q 4. How do you ensure the safety of yourself and others while operating a pallet jack?

Safety is paramount. My safety procedures include:

- Pre-operation inspection: Always inspect the jack for any damage before each use. Check the forks, wheels, hydraulic system, and battery (if applicable).

- Clear the path: Ensure the area is clear of obstacles before operating the jack. This includes people, other equipment, and debris.

- Proper lifting techniques: Use the correct lifting techniques, as previously described, to avoid strain and injury.

- Awareness of surroundings: Maintain awareness of your surroundings and other workers at all times. Use caution when maneuvering around corners or in narrow spaces.

- Load limits: Never exceed the rated load capacity of the pallet jack.

- Protective gear: Consider wearing safety shoes and gloves when necessary.

Furthermore, I always communicate with co-workers to avoid collisions and ensure a safe working environment. A near-miss incident last year, where I almost collided with another forklift, reinforced the importance of constant vigilance and communication.

Q 5. What are the common causes of pallet jack malfunctions?

Common pallet jack malfunctions are often related to wear and tear or improper use. Some of the most frequent issues include:

- Hydraulic leaks: Leaks can reduce lifting capacity and require immediate attention.

- Wheel damage: Worn or damaged wheels can affect maneuverability and stability.

- Fork damage: Bent or broken forks compromise the jack’s ability to handle loads safely.

- Battery issues (electric jacks): Low battery charge or faulty battery components can prevent operation.

- Pump malfunction (manual jacks): A faulty pump makes lifting and lowering difficult.

Q 6. How do you troubleshoot common pallet jack problems?

Troubleshooting depends on the specific problem. For instance:

- Hydraulic leaks: Check all hydraulic connections for damage or looseness. If a leak is detected, it’s crucial to stop using the jack immediately and seek professional repair.

- Wheel damage: Replace damaged wheels.

- Fork damage: Bent forks should be repaired or replaced. Avoid using the jack if forks are severely damaged.

- Battery issues: Check the battery charge and replace if needed. A professional may need to address more complex electrical problems.

- Pump malfunction: If the pump is faulty in a manual jack, seek professional repair.

In many cases, simple visual inspections can identify the problem. For more complex issues, contacting a qualified technician is essential to ensure safe and proper repair.

Q 7. What safety precautions do you take before operating a pallet jack?

Before operating a pallet jack, my safety precautions include:

- Visual inspection: Thoroughly inspect the jack for any damage or leaks.

- Check hydraulic fluid level (if applicable): Ensure the fluid level is adequate.

- Test the lifting and lowering mechanisms: Confirm smooth operation before loading.

- Assess the load: Verify the weight and stability of the pallet to ensure it’s within the jack’s capacity.

- Clear the surrounding area: Remove any obstacles that could impede movement.

- Battery check (electric jacks): Ensure the battery has sufficient charge.

These steps are not optional; they’re integral to safe operation and prevent accidents. A few extra minutes spent on these checks can save time and prevent potential injuries or damage.

Q 8. Describe your experience operating stackers.

My experience with operating stackers spans over five years, encompassing various warehouse environments and product types. I’ve consistently demonstrated proficiency in safe operation, efficient pallet handling, and adherence to all relevant safety regulations. I’m comfortable operating both electric and manual stackers, and my skills include maneuvering in tight spaces, precise load placement, and efficient stacking procedures. For instance, in my previous role at Acme Distribution, I consistently exceeded daily targets for pallet movement while maintaining a perfect safety record.

Q 9. What are the different types of stackers you are familiar with?

I’m familiar with a range of stacker types, including:

- Electric Rider Stackers: These offer superior maneuverability and lifting capacity, ideal for large warehouses and heavy loads. They provide excellent control and comfort during extended use.

- Electric Pedestrian Stackers: These are more compact and suitable for narrower aisles and smaller warehouses. They are very efficient for lighter-duty applications.

- Manual Stackers: These are hydraulically operated by the operator’s physical effort. They are best suited for smaller businesses or applications with occasional lifting tasks. The manual effort requires good physical fitness.

- High-Lift Stackers: These can lift pallets to significant heights, crucial for multi-tiered storage systems. The use requires strict adherence to safety protocols.

My experience covers various mast configurations and load capacities within these types, giving me a broad understanding of their operational characteristics.

Q 10. How do you safely load and unload pallets using a stacker?

Safe loading and unloading involves a methodical approach. Firstly, I always ensure the area is clear of obstructions and personnel. I then engage the parking brake and carefully position the stacker forks under the pallet, ensuring even weight distribution. Slow and controlled lifting is essential, always checking the load’s stability. During unloading, I similarly use slow, controlled lowering and precise placement to prevent damage or accidents. For instance, if dealing with unstable pallets, I use additional support or strapping to enhance stability throughout the operation. Visual checks before, during and after every operation are standard procedure for me.

Q 11. What are the weight limitations of the stackers you’ve operated?

The stackers I’ve operated have weight limitations ranging from 2,000 lbs (907 kg) for pedestrian stackers to 6,000 lbs (2722 kg) for larger rider stackers. I always check the load capacity rating displayed on the machine before handling any load. Exceeding these limits is a serious safety hazard and I would never compromise on safety in this regard. Knowing the limitations of each stacker is crucial for safe operation.

Q 12. Explain the proper procedures for stacking pallets to ensure stability.

Stable pallet stacking is paramount. I follow a tiered approach: 1. Ensure a solid base: the floor must be level and strong enough to support the load. 2. Distribute weight evenly: pallets should be evenly positioned and interlocked to prevent toppling. 3. Don’t exceed height limits: The height of a stack is restricted by the racking system and the stacker’s capability. 4. Avoid overhang: Pallets should be positioned so that the weight is centrally distributed. 5. Regular inspection: I always inspect the stack for signs of instability during the process. Think of it like building a tower of blocks – each layer must support the next.

Q 13. How do you handle uneven surfaces while operating a stacker?

Uneven surfaces present a challenge, requiring extra caution. I operate slowly and carefully, adjusting my speed and steering to maintain stability. Avoid sudden movements or sharp turns. If the surface is significantly uneven, I might need to use additional support or find a more stable area to operate. In some cases, I may need to use smaller, more maneuverable stackers. Safety is always my priority when operating on less-than-ideal surfaces.

Q 14. Describe your experience with different types of pallet configurations.

My experience includes handling various pallet configurations, including standard pallets, double-stacked pallets, and those with unusual dimensions or weight distributions. I’ve worked with pallets containing both uniform and non-uniform loads. Understanding these variations is vital for safe and efficient handling. For example, I use different techniques for securing double-stacked pallets compared to single ones. My adaptability to different configurations ensures smooth workflow in diverse operational scenarios.

Q 15. How do you maintain and inspect pallet jacks and stackers?

Maintaining and inspecting pallet jacks and stackers is crucial for safety and operational efficiency. It involves a regular routine of checks and preventative maintenance.

- Daily Inspection: Before each use, I visually inspect the jack or stacker for any obvious damage, such as cracks in the frame, leaks in hydraulic fluid, or worn tires. I also check the lift mechanism for smooth operation and the wheels for free rotation.

- Weekly Inspection: A more thorough inspection is conducted weekly. This includes checking hydraulic fluid levels and ensuring there are no leaks. I also lubricate moving parts as needed, paying close attention to the pump and lift cylinder. I examine the load wheels and forks for any wear and tear.

- Monthly Inspection: This involves a more comprehensive check, potentially including checking the condition of the hydraulic seals and hoses for any signs of damage or deterioration. I also examine safety features like the emergency stop mechanism to ensure it functions correctly.

- Preventative Maintenance: This includes regular fluid changes, replacing worn parts before they become a safety hazard, and adhering to the manufacturer’s recommended maintenance schedule. This helps extend the equipment lifespan and prevents unexpected breakdowns.

Think of it like a car – a little regular maintenance prevents major problems down the line. Ignoring minor issues can lead to costly repairs or, worse, accidents.

Career Expert Tips:

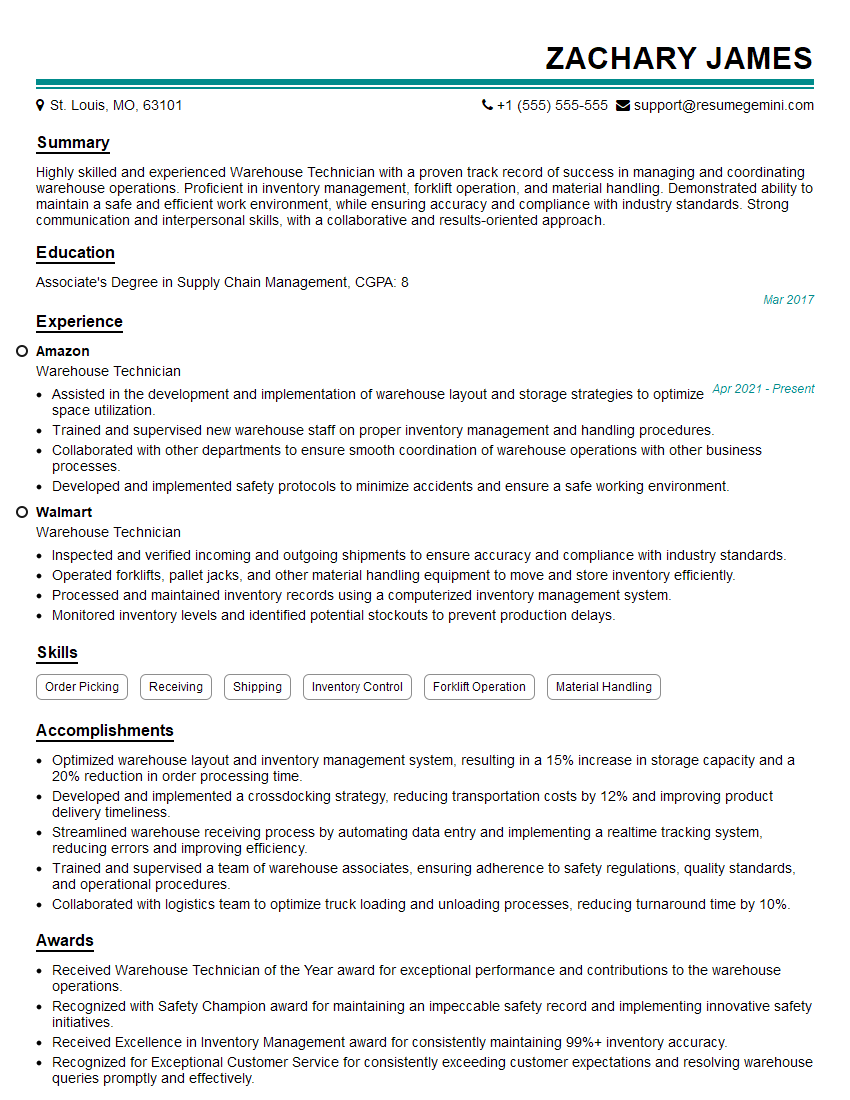

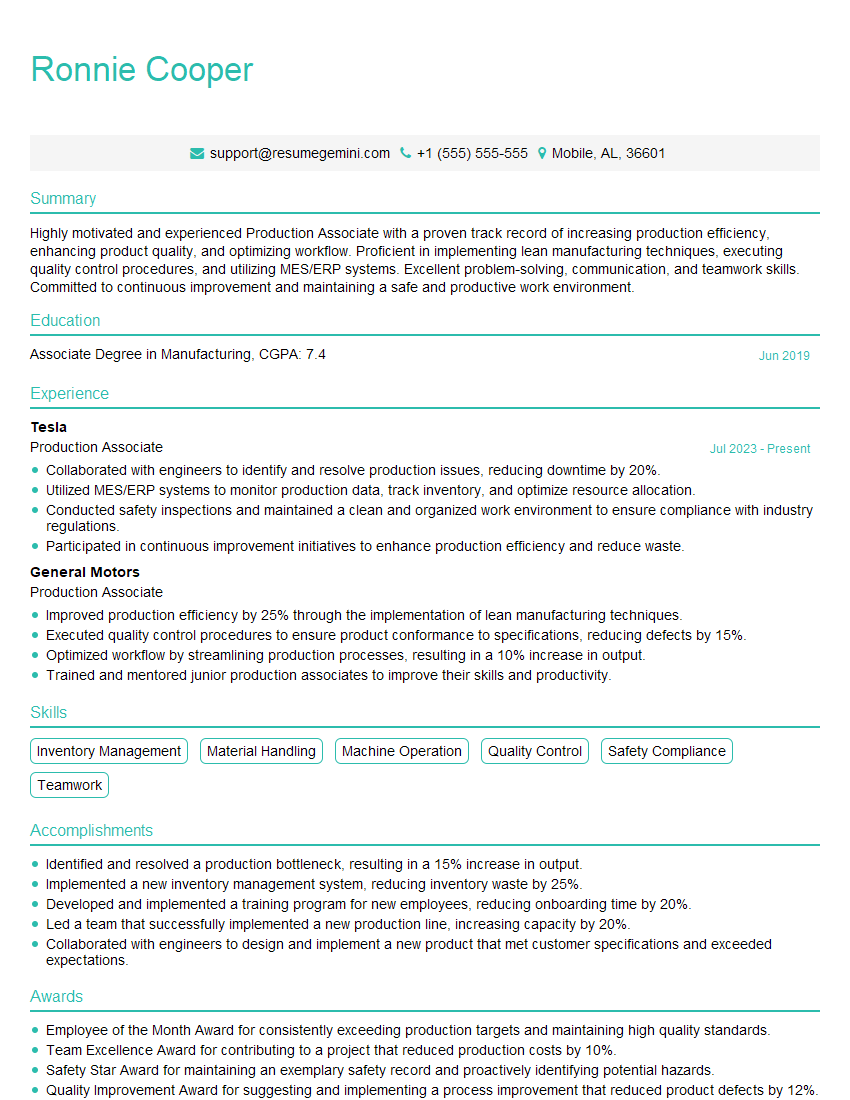

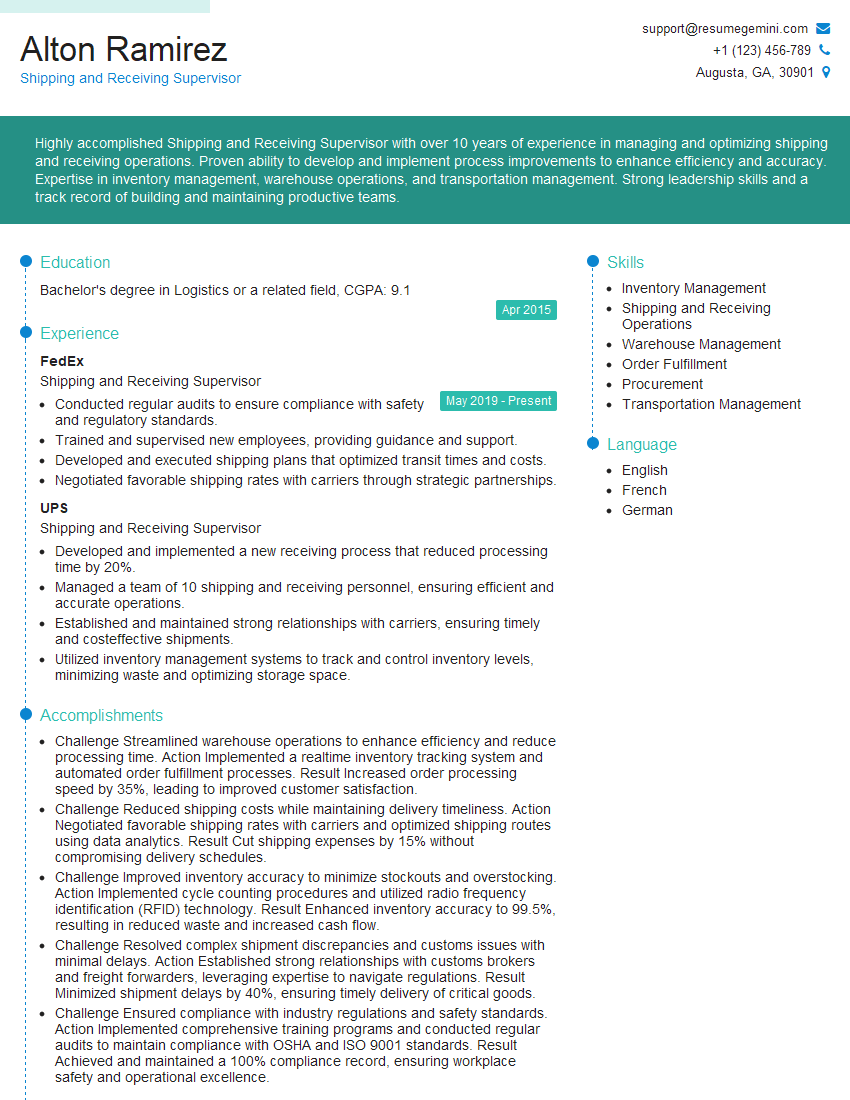

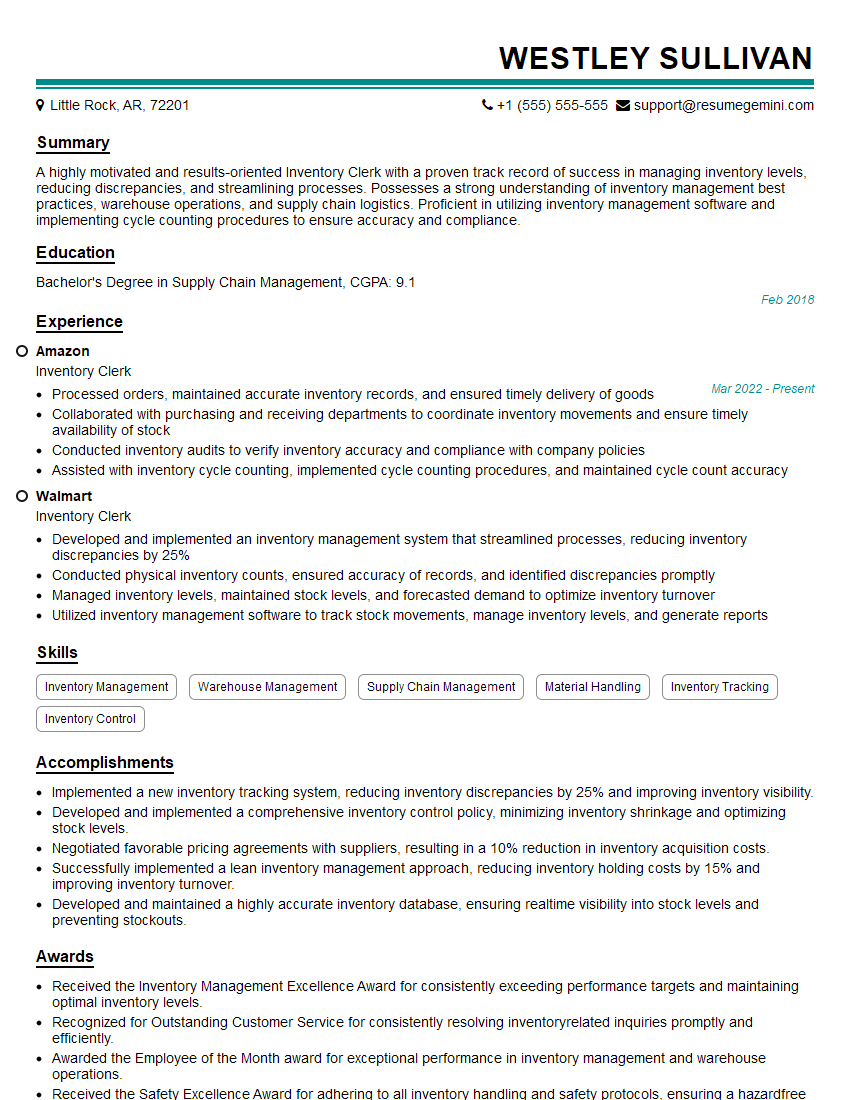

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the load capacity limits for the pallet jacks you’ve used?

The load capacity limits of pallet jacks and stackers vary considerably depending on the model and manufacturer. I’ve worked with pallet jacks ranging from 3,000 to 5,500 lbs capacity, and stackers with capacities ranging from 2,500 to 8,000 lbs. It’s crucial to always check the manufacturer’s rated load capacity plate on the equipment before operation, and never exceed this limit. Overloading can lead to catastrophic equipment failure, causing injury and significant damage.

For example, I recall one instance where a coworker attempted to lift a load exceeding the capacity of the pallet jack. Fortunately, we noticed before the machine buckled, avoiding a potential accident. That reinforced the importance of always confirming the load capacity before commencing any lifting operation.

Q 17. How do you identify and report damaged equipment?

Identifying and reporting damaged equipment is a vital safety procedure. The process typically involves the following steps:

- Identification: I visually inspect the equipment for any signs of damage, noting the specific type and location of the damage (e.g., cracked frame, bent forks, hydraulic leak). I take photos or videos to document the damage.

- Reporting: I immediately report the damage to my supervisor or the designated maintenance personnel. This is usually done using a formal damage report form specifying the equipment details, type of damage, and location.

- Tagging: Damaged equipment is immediately removed from service and clearly labeled as “Out of Service” or “Do Not Use” to prevent accidental use.

- Follow-up: I follow up with the maintenance team to ensure the equipment is repaired or replaced promptly.

Safety is paramount; using damaged equipment poses significant risks. A seemingly minor crack can lead to catastrophic failure, resulting in injuries or property damage.

Q 18. What is your experience with different types of pallet materials (wood, plastic)?

My experience includes working with both wood and plastic pallets. Wood pallets are more common and are generally more robust, but they can be prone to splintering and damage from moisture. Plastic pallets are more durable and resistant to moisture and pests, making them more hygienic for food and pharmaceutical applications. However, they can be more expensive and are less easily repaired.

The choice of pallet material influences the handling techniques. For instance, damaged wood pallets require extra caution to avoid splinters and uneven lifting. With plastic pallets, the focus is on ensuring proper alignment to avoid bending or cracking the plastic.

Q 19. How do you handle situations where pallets are damaged or unstable?

When encountering damaged or unstable pallets, safety is my top priority. I would follow these steps:

- Assessment: I would first assess the extent of the damage. If the damage is significant, such as broken boards or severely warped structure, I would not attempt to move the pallet.

- Reporting: I would immediately report the issue to my supervisor.

- Alternative Solutions: If the damage is minor, I might attempt to stabilize the pallet using additional bracing or supports. However, this should only be done if it can be accomplished safely and doesn’t compromise the load’s stability.

- Rejection: In most cases of significant damage, I would reject the pallet and notify the appropriate personnel to handle its removal and disposal.

It’s better to be cautious and avoid risks than to attempt to handle an unstable load, which can lead to injury or damage to goods and equipment.

Q 20. Explain your understanding of warehouse safety regulations.

My understanding of warehouse safety regulations encompasses a wide range of aspects, including:

- Load Capacity: Never exceeding the rated load capacity of any equipment.

- Personal Protective Equipment (PPE): Always wearing appropriate PPE, including safety shoes, gloves, and high-visibility vests.

- Safe Operating Procedures: Adhering to all safe operating procedures for pallet jacks, stackers, and other warehouse equipment.

- Proper Training: Ensuring adequate training on the operation and maintenance of equipment before using it.

- Housekeeping: Maintaining a clean and organized warehouse to minimize tripping hazards.

- Emergency Procedures: Knowing and following established emergency procedures in case of accidents or equipment malfunctions.

- Load Stability: Ensuring that loads are properly secured and stable before moving them.

Compliance with these regulations ensures a safe and productive work environment and minimizes the risk of accidents and injuries.

Q 21. Describe your experience working in a fast-paced warehouse environment.

I have extensive experience working in fast-paced warehouse environments, where efficiency and accuracy are crucial. I’m adept at managing multiple tasks simultaneously, prioritizing deadlines, and working effectively under pressure. This often involves coordinating with other team members to ensure smooth workflow and efficient order fulfillment. I’m comfortable with high-volume operations and adapt quickly to changing demands. For example, during peak seasons, we frequently face increased order volumes and tighter deadlines. In these situations, I focus on maintaining a consistent work pace while prioritizing safety and accuracy to avoid errors.

My ability to work efficiently under pressure, coupled with my strong attention to detail, has allowed me to consistently meet and exceed expectations in demanding warehouse settings.

Q 22. How do you prioritize tasks and manage your time effectively in a warehouse setting?

Prioritizing tasks and managing time effectively in a warehouse is crucial for efficiency. I use a combination of methods to achieve this. First, I understand the daily workflow and prioritize tasks based on urgency and importance. This often involves checking the daily schedule and identifying deadlines for orders or shipments. Tasks are prioritized according to the ‘urgency-importance’ matrix. High-urgency, high-importance tasks (e.g., preparing urgent shipments) take precedence over low-urgency, low-importance tasks (e.g., cleaning a less used area). I also leverage techniques like time blocking, allocating specific time slots for specific types of tasks (e.g., 9:00 AM – 11:00 AM: pallet jack operation for loading, 11:00 AM – 12:00 PM: order picking). Visual aids, such as checklists or kanban boards, can further help visualize the task flow and ensure timely completion. Finally, I remain flexible, adjusting my schedule as needed to accommodate unexpected requests or emergencies, prioritizing them appropriately.

For example, if a rush order arrives, I’d immediately adjust my planned tasks to ensure this high-priority order is completed on time, even if it means temporarily postponing some less urgent tasks. Proactive communication with supervisors regarding any potential delays is also key to effective time management.

Q 23. How do you adapt to changes in warehouse procedures or workflows?

Adaptability is essential in a warehouse environment. Changes in procedures or workflows are common, and I approach them proactively. First, I listen attentively to instructions regarding new procedures, asking clarifying questions to fully understand the changes and their implications. I focus on understanding the ‘why’ behind the changes – this improves acceptance and ensures smoother implementation. I then actively practice the new procedures, seeking feedback and making adjustments as needed. I find that actively participating in training sessions and workshops enhances my ability to rapidly adapt. Also, I regularly review updated documentation, making sure I’m always up-to-date with the latest changes. If I encounter difficulties, I don’t hesitate to ask for help from colleagues or supervisors; collaborative problem-solving is crucial for successful adaptation.

For instance, when our warehouse implemented a new inventory management system, I participated in the training sessions, studied the new software, and practiced using it until I was proficient. I also took notes and highlighted key areas where I needed further clarification. This proactive approach ensured a smooth transition and minimized any disruption to my workflow.

Q 24. Describe a time you had to solve a problem while operating a pallet jack or stacker.

In one instance, while operating a pallet jack, I encountered a situation where a pallet was unevenly loaded, causing it to tilt precariously during transport. This presented a safety hazard and potential damage to the goods. Instead of proceeding, I stopped immediately, assessed the situation, and took corrective action. I carefully re-balanced the pallet by slightly shifting the items. I also checked the pallet’s overall condition to ensure its structural integrity. Then, using extra caution and a slower pace, I successfully moved the pallet to its destination. I also reported the incident to my supervisor, highlighting the importance of proper pallet loading procedures to prevent similar incidents. This experience reinforced the importance of prioritizing safety and using sound judgment while operating warehouse equipment.

Q 25. How do you communicate effectively with your team members and supervisors in a warehouse setting?

Effective communication is the cornerstone of teamwork in a warehouse. I prioritize clear, concise, and respectful communication with colleagues and supervisors. I actively listen to instructions, ask clarifying questions if needed, and provide updates on my progress regularly, especially for time-sensitive tasks. I use appropriate channels for communication – face-to-face communication for immediate feedback, radio communication for quick updates during operation, and email for formal reports or detailed information. I also strive to be proactive and inform my team members and supervisors of any potential problems or delays I foresee. In situations where conflicts arise, I address them constructively and collaboratively, finding mutually beneficial solutions. I believe in building positive relationships with team members; mutual respect and open dialogue are critical for team success.

Q 26. What are your strengths and weaknesses as a warehouse worker?

My strengths include my proficiency in operating pallet jacks and stackers, my dedication to safety, and my ability to work independently and as part of a team. I’m a quick learner and adapt easily to new procedures. My attention to detail ensures accuracy in tasks, and I’m always willing to go the extra mile to contribute to team goals. A weakness I’m working on is delegating tasks effectively. While I’m capable of handling a high workload, I sometimes tend to take on too much myself. I’m actively improving this by better prioritizing tasks and clearly communicating my capacity limitations.

Q 27. Why are you interested in this position?

I’m interested in this position because it offers an opportunity to utilize and further develop my skills in warehouse operations, particularly in handling pallet jacks and stackers. I’m drawn to the company’s reputation for efficiency and safety, which aligns perfectly with my work ethic. The opportunity to contribute to a well-organized and collaborative team environment is particularly appealing. I’m eager to learn from experienced professionals and contribute to the overall success of the warehouse.

Q 28. What are your salary expectations?

My salary expectations are in line with the industry standard for a warehouse worker with my experience and skill set. I’m open to discussing a competitive compensation package that reflects my value and contribution to the company.

Key Topics to Learn for Operate Pallet Jacks and Stackers Interview

- Safe Operation Procedures: Understanding pre-operation checks, proper lifting techniques, load stability assessment, and emergency shutdown procedures.

- Equipment Familiarization: Knowing the different types of pallet jacks and stackers, their functionalities, and limitations. This includes understanding battery operation (if applicable) and maintenance indicators.

- Load Handling and Transportation: Practical application of safe load placement, maneuvering in confined spaces, and efficient transportation of goods to designated areas. This also involves understanding weight limits and load distribution.

- Maintenance and Troubleshooting: Basic knowledge of routine maintenance checks, identifying common malfunctions (e.g., hydraulic leaks, battery issues), and reporting them appropriately.

- Workplace Safety Regulations: Familiarity with relevant safety regulations, including personal protective equipment (PPE) requirements and adherence to warehouse safety protocols.

- Efficiency and Productivity: Understanding strategies for optimizing workflow, minimizing downtime, and maximizing efficiency in pallet jack and stacker operation.

- Communication and Teamwork: The importance of clear communication with colleagues, supervisors, and other warehouse personnel to ensure safety and coordination.

Next Steps

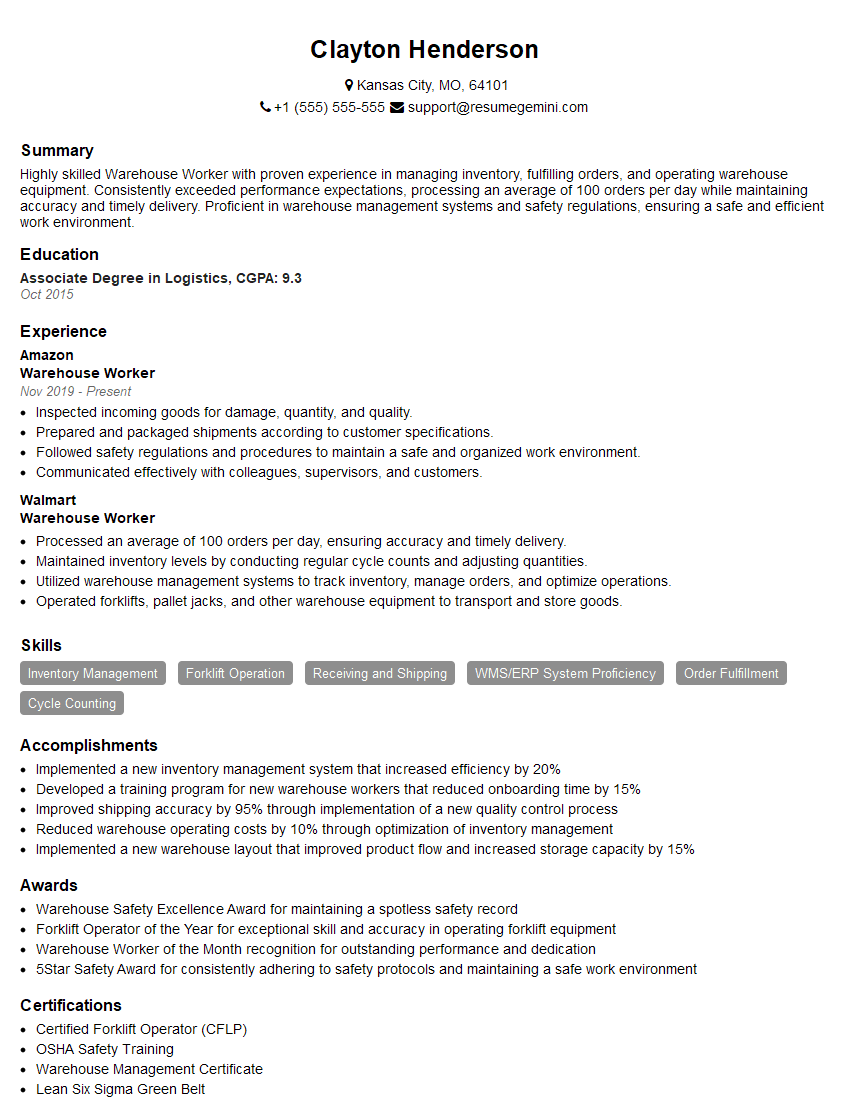

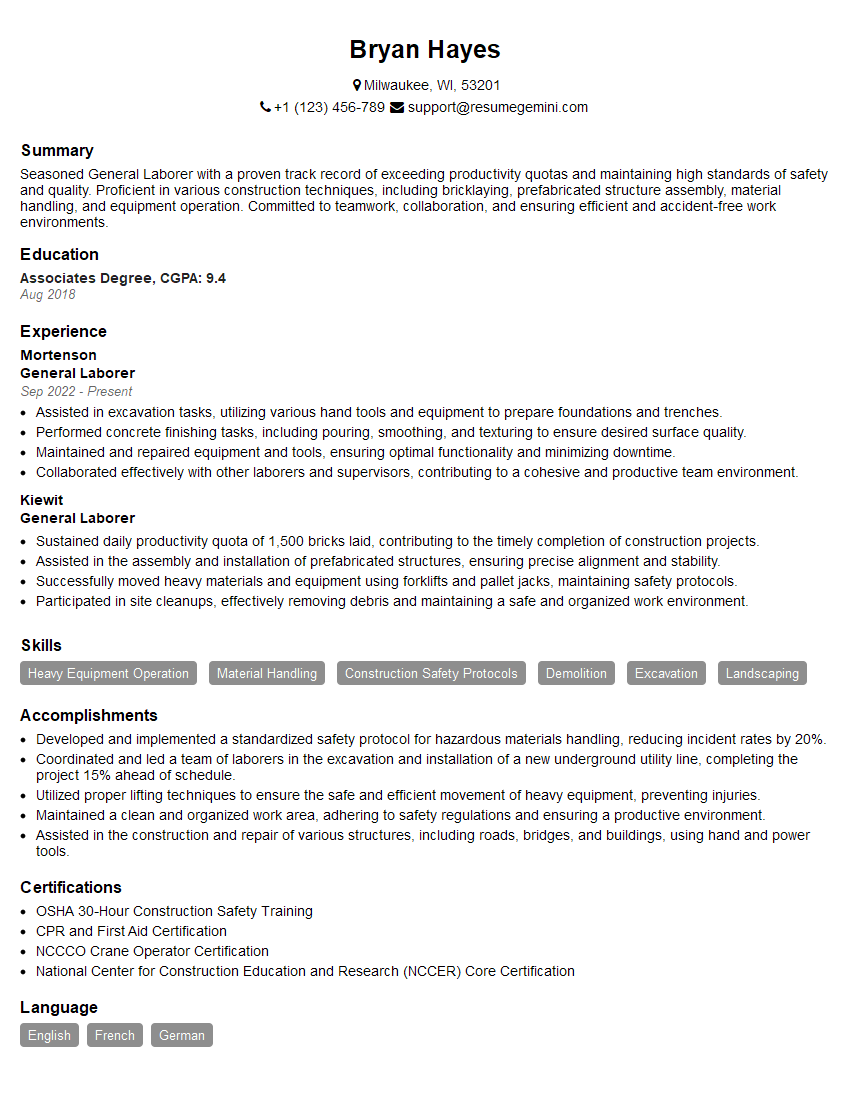

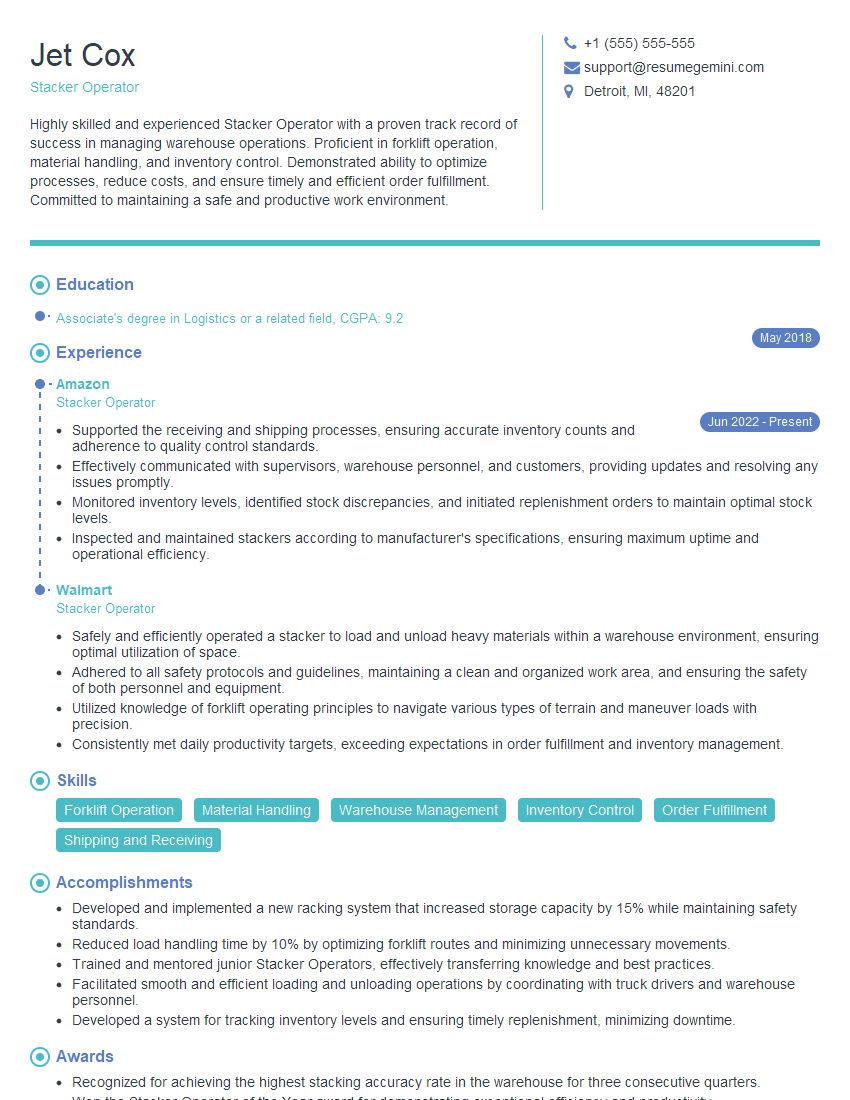

Mastering the operation of pallet jacks and stackers is crucial for advancement in many warehouse and logistics roles, opening doors to increased responsibility and higher earning potential. A strong resume is your key to unlocking these opportunities. To significantly improve your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored specifically to Operate Pallet Jacks and Stackers to guide you through the process. Take the next step towards your career success – build your resume with ResumeGemini today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good