The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Operating and maintaining hydraulic cranes and equipment interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Operating and maintaining hydraulic cranes and equipment Interview

Q 1. Describe your experience with different types of hydraulic cranes (e.g., mobile, tower, overhead).

My experience encompasses a wide range of hydraulic crane types, including mobile, tower, and overhead cranes. I’ve worked extensively with various models from leading manufacturers, gaining hands-on experience with their unique operating characteristics and maintenance requirements. For instance, with mobile cranes, I’ve focused on the intricacies of their outrigger systems, ensuring stability during lifts. My experience with tower cranes includes the complexities of their hoisting mechanisms and counterweight balancing, while with overhead cranes I’ve mastered the nuances of their trolley and bridge movements. Each type demands a distinct skill set – from understanding load charts and safe working limits to mastering the intricacies of their control systems. For example, I once had to troubleshoot a malfunctioning slew motor on a large mobile crane at a construction site, requiring a deep understanding of hydraulics and electrical systems, something I’ve encountered in many situations.

Q 2. Explain the process of pre-operational crane inspections.

Pre-operational crane inspections are critical for safety. My process involves a thorough visual check of all components, followed by functional testing. The visual inspection covers everything from checking for leaks in hydraulic lines and cylinders to ensuring the structural integrity of the boom, jib, and supporting structures. I specifically look for signs of wear and tear, corrosion, and damage. After the visual inspection, I conduct functional tests which involve slowly moving each part of the crane through its full range of motion, carefully listening for unusual noises, vibrations or binding. I pay close attention to the hydraulic system, checking for leaks and verifying that the pressure is within the safe operating range. Documentation is crucial, using a standardized checklist to ensure nothing is overlooked. This methodical approach helps prevent accidents caused by mechanical failures.

Q 3. What are the critical safety procedures you follow before operating a hydraulic crane?

Safety is paramount. Before operating any hydraulic crane, I always follow these procedures: First, I thoroughly inspect the crane as described earlier. Next, I verify that all safety devices, such as the overload protection system, emergency stops, and load-limiting devices, are functioning correctly. I always check the load charts and ensure the load weight and configuration are within the crane’s capacity. I confirm that the area around the crane is clear of obstructions and personnel, establishing a safe working radius. I also obtain the necessary permits and authorizations before starting any lifting operation. Finally, I always wear appropriate personal protective equipment (PPE), such as safety helmets, gloves, and high-visibility clothing. For instance, once, while working at a refinery, I had to stop a lift because an unapproved person entered the crane’s swing radius. Strict adherence to these procedures is my top priority.

Q 4. How do you identify and address hydraulic leaks in a crane system?

Identifying hydraulic leaks requires a systematic approach. I start with a visual inspection, looking for wet spots, dripping fluid, or discolored areas on hydraulic lines, fittings, and cylinders. If a leak is detected, I’ll carefully trace the source by using cleaning solvent to remove any existing fluid and then operating the crane to identify the exact point of leakage. The next step is to determine the severity of the leak. A slow leak might only require tightening a fitting, while a major leak would necessitate replacing a hose or cylinder seal. For example, on a recent project, I discovered a small leak in a high-pressure hose. Rather than shut the crane down completely, I carefully isolated the section and proceeded with the replacement to avoid unnecessary delays and cost. I always document the leak and repair thoroughly.

Q 5. Describe your experience troubleshooting hydraulic system malfunctions.

Troubleshooting hydraulic system malfunctions requires a systematic and logical approach. I start by gathering information, identifying the symptoms, such as unusual noises, slow response times, or complete system failure. Next, I systematically check each component of the system. This may involve checking pressure gauges, inspecting hydraulic lines for blockages or kinks, and testing the functionality of valves and actuators. My experience allows me to quickly isolate the issue and then take the necessary corrective action, sometimes requiring specialized tools and diagnostics. For instance, on one occasion, I found a damaged hydraulic pump relief valve that caused the entire crane to have high pressure. This requires a keen understanding of the hydraulic circuitry and the use of pressure gauges for diagnosis.

Q 6. What are the common causes of hydraulic pump failure and how do you diagnose them?

Common causes of hydraulic pump failure include wear and tear, contamination of hydraulic fluid, overheating, and insufficient lubrication. To diagnose these issues, I begin with a visual inspection, checking for any obvious signs of damage or leaks. I then assess the fluid condition, checking for discoloration, contamination, or low fluid levels. I carefully analyze pressure readings to see if they are within normal operating ranges. If abnormalities are detected, I may use specialized diagnostic equipment to pinpoint the problem further, such as a pressure transducer or a vibration analyzer. For example, a sudden drop in pressure may indicate a pump failure, while excessive vibration could indicate bearing wear. Each scenario requires different troubleshooting methodologies.

Q 7. Explain the principles of hydraulic pressure and flow in crane systems.

Hydraulic crane systems utilize the principle of Pascal’s Law: pressure applied to a confined fluid is transmitted equally in all directions. In a crane, a hydraulic pump generates high-pressure fluid, which is then directed to hydraulic actuators (cylinders). The pressure in the cylinders creates force, which moves the boom, jib, and hook. Flow rate determines the speed of movement. A higher flow rate means faster movement, while a lower flow rate means slower movement. The system includes valves that control the direction and amount of fluid flow, allowing for precise control of the crane’s movements. Pressure and flow are intricately linked; insufficient pressure will result in sluggish movement, while excessive pressure can damage components. Maintaining the correct pressure and flow is crucial for efficient and safe crane operation.

Q 8. How do you interpret hydraulic schematics and diagrams?

Hydraulic schematics are the roadmaps for understanding a crane’s hydraulic system. They use standardized symbols to represent components like pumps, valves, cylinders, and hoses, showing how hydraulic fluid flows through the system. Interpreting them involves understanding these symbols and tracing the fluid path to understand how each component interacts.

For example, a rectangle might represent a hydraulic pump, a circle with lines might represent a directional control valve, and a cylinder could be depicted by a rectangle with a rod extending from it. By carefully following the lines and noting the direction of flow indicated by arrows, you can determine how the movement of a control lever affects the operation of the crane’s boom, hoist, or other components. I always start by identifying the power source (pump), then trace the flow to the actuators (cylinders) to understand how pressure is used to generate movement. Understanding pressure relief valves is critical, as these safeguard the system from overpressure.

Think of it like reading a plumbing diagram for your house. You need to understand how the water flows from the source (main water line) to each fixture (sink, toilet, etc.). Similarly, a hydraulic schematic guides you through the flow of hydraulic fluid within the crane’s system.

Q 9. What are the different types of hydraulic fluids used in cranes and their applications?

Several types of hydraulic fluids are used in cranes, each suited to different operating conditions. The choice depends on factors like temperature range, load requirements, and the presence of potential contaminants.

- Mineral Oils: These are the most common and are suitable for a wide range of applications. They offer a good balance of performance and cost-effectiveness.

- Synthetic Fluids: These offer superior performance in extreme temperatures, resisting both very high and very low temperatures better than mineral oils. They are also often more resistant to degradation. They’re more expensive, but their extended lifespan can justify the added cost for demanding applications.

- Fire-Resistant Fluids: These are crucial for applications where fire hazards are significant. Water-glycol and phosphate ester fluids are common examples, offering protection against fire but might compromise performance compared to traditional mineral or synthetic oils. They require careful handling due to their specific properties.

In my experience, selecting the correct fluid is critical for system longevity and efficiency. Improper fluid selection can lead to premature component wear, leaks, and even catastrophic failure.

Q 10. How do you maintain hydraulic hoses and fittings to prevent failures?

Maintaining hydraulic hoses and fittings is crucial for preventing leaks and potential system failures. Regular inspections are key. I’d look for:

- Visual Inspection: Regularly check for abrasions, cuts, bulges, kinks, or cracks in the hoses. Look for any signs of fluid leakage at the fittings.

- Pressure Testing: Periodically pressure-test hoses to verify their integrity. This is usually done by a qualified technician using specialized equipment.

- Proper Routing: Ensure hoses are properly routed to avoid sharp bends, contact with hot surfaces, or excessive friction. Chafing can weaken hoses dramatically.

- Tight Fittings: Make sure all fittings are securely tightened to the manufacturer’s specifications. Over-tightening can damage fittings, while under-tightening can lead to leaks.

- Proper Support: Provide adequate support for hoses to prevent sagging or unnecessary stress on connections.

For example, I once discovered a small abrasion on a hose near a sharp edge of a crane’s component. This seemingly minor issue could have easily led to a major leak and a costly downtime. Replacing the hose proactively prevented a potential accident.

Q 11. Describe your experience with hydraulic cylinder maintenance and repair.

Hydraulic cylinder maintenance and repair involves a systematic approach. I’ve handled numerous repairs, from simple seal replacements to more complex overhauls. It often begins with assessing the issue. Is there a leak? Is the cylinder extending or retracting properly? Is there unusual noise?

My process includes:

- Inspection: A thorough visual inspection to identify leaks, damage to the rod, or any external issues.

- Disassembly: Careful disassembly of the cylinder, taking note of the order of components for reassembly.

- Cleaning: Thorough cleaning of all parts using appropriate solvents to remove any dirt or debris.

- Inspection and Replacement of Seals: Examination of seals for wear and tear. Replacing any damaged seals is a common and crucial step. Seals are often the source of leaks.

- Reassembly: Careful reassembly of the cylinder, ensuring proper lubrication and alignment.

- Testing: Testing the repaired cylinder for leaks and proper operation before reinstallation.

I once had to completely overhaul a hydraulic cylinder on a large tower crane. It was a complex process, but through careful attention to detail and proper procedures, we got the crane back in operation quickly and safely.

Q 12. Explain the process of bleeding air from a hydraulic system.

Bleeding air from a hydraulic system is essential for ensuring proper operation. Air in the system reduces efficiency and can lead to component damage. The process involves several steps:

- Locate Bleeder Valves: Identify all the bleeder valves in the system. These are typically small valves located at high points in the system.

- Loosen Bleeder Valves: Carefully loosen each bleeder valve, using the appropriate wrench. Don’t remove the valve completely initially.

- Operate the System: Operate the hydraulic system to move the fluid and force air out through the bleeder valves. This often involves cycling the crane’s functions.

- Tighten Valves: Tighten the bleeder valves once a steady stream of fluid (free of air bubbles) emerges.

- Check for Leaks: Check for leaks around the bleeder valves and other connections after tightening.

The process can sometimes be tricky depending on the complexity of the system. It is crucial to follow the manufacturer’s instructions and use appropriate safety precautions. A poorly bled system will cause erratic operation and potentially damage components.

Q 13. How do you handle emergency situations during crane operation?

Emergency situations during crane operation require quick thinking and decisive action. Safety is paramount. My response depends on the specific nature of the emergency, but a common framework includes:

- Assess the Situation: Quickly assess the nature of the emergency. Is it a hydraulic failure? An electrical fault? A structural problem?

- Secure the Load: If possible and safe to do so, secure the load to prevent it from falling.

- Shut Down the Crane: Immediately shut down the crane’s power source, engaging any emergency stops.

- Evacuate the Area: Ensure all personnel are clear of the danger zone.

- Call for Help: Notify appropriate personnel (supervisors, emergency services) of the situation.

- Prevent Further Damage: Take steps to prevent any further damage to the crane or surrounding property.

Once the immediate danger is addressed, a thorough investigation should be conducted to determine the root cause of the emergency and prevent similar incidents in the future.

Q 14. What are the limitations and capacity ratings you need to consider when operating a crane?

Operating a crane safely involves understanding and adhering to its limitations and capacity ratings. Ignoring these can lead to catastrophic accidents.

- Load Capacity: Never exceed the crane’s maximum load capacity. This information is clearly stated on the crane’s data plate. The capacity varies depending on the boom length and angle.

- Boom Angle and Radius: The crane’s lifting capacity changes with boom angle and radius. These factors are often shown in a crane’s load chart. Operators must consult this chart for each lift.

- Wind Speed: High winds significantly impact a crane’s stability. Operating beyond the recommended wind speed limits is extremely dangerous. Wind speed limitations are often printed on the crane or specified in operating manuals.

- Ground Conditions: The ground beneath the crane must be level and stable enough to support the weight of the crane and its load. Uneven terrain or soft ground compromises stability.

- Swing Radius: Operators must maintain awareness of the crane’s swing radius, ensuring there is sufficient clearance to prevent collisions with other objects or personnel.

Thinking about these factors beforehand and using the load charts are crucial to avoiding hazardous conditions. Crane operation should always prioritize safe lifting practices above all else.

Q 15. Describe your experience with load charts and calculations.

Load charts are crucial for safe crane operation. They provide a visual representation of the crane’s lifting capacity at various boom lengths and angles. Understanding and correctly interpreting these charts is paramount to prevent overloading and potential accidents. My experience encompasses not just reading load charts but also performing load calculations, taking into account factors like the weight of the load, the boom angle, the radius of the lift, and wind conditions. For instance, I once had to lift a particularly heavy piece of equipment – a large transformer – and had to meticulously calculate the weight distribution and ensure the crane’s capacity was sufficient considering the radius and the slight wind we experienced that day. Using a combination of the crane’s load chart and my calculations, I determined the safest and most efficient lifting technique. This involved using appropriate rigging and multiple lifts if necessary, ensuring the crane remained well within its safe operating limits.

In addition, I’m proficient in using software that assists in these calculations. This helps streamline the process and reduces the chance of human error. We can input parameters like weight, dimensions, and wind speed, and the software calculates the safe operating load, ensuring compliance with regulations.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What safety measures do you employ when working at heights with a crane?

Safety when working at heights with a crane is paramount and involves a multi-layered approach. It starts with a thorough pre-lift planning session where the entire operation is analyzed, accounting for all potential hazards. This includes identifying the safe working load, determining the correct rigging and lifting techniques, and assessing environmental factors such as wind speed and the proximity of power lines or other obstructions. Before commencing any lift, a pre-lift inspection of the crane, its rigging, and the load is mandatory.

- Personal Protective Equipment (PPE): This is crucial and includes hard hats, safety harnesses with fall arrest systems, safety shoes, and high-visibility clothing. We never compromise on PPE; its use is non-negotiable.

- Crane Inspection: Rigorous pre-operational checks of all crane components, including the hydraulic systems, brakes, and load indicators are a daily requirement. Any defects detected are immediately addressed before operation begins.

- Communication: Clear and concise communication between the crane operator, the rigger, and the ground crew is crucial. We use hand signals and radios to ensure everyone is aware of the lift plan and any unexpected events.

- Exclusion Zones: Establishing clear exclusion zones around the lifting area keeps unauthorized personnel away from the danger zone, minimizing the risk of injury.

- Emergency Procedures: We’re always prepared for unexpected situations. Emergency procedures, including the use of emergency stops and evacuation plans, are known to every member of the crew.

I have a strong record of safety and have successfully managed numerous high-risk lifts involving significant heights without any incidents.

Q 17. How do you perform regular maintenance on hydraulic crane components (e.g., valves, pumps, cylinders)?

Regular maintenance is the cornerstone of safe and efficient crane operation. My maintenance procedures follow manufacturer guidelines and industry best practices. I meticulously check and service hydraulic components regularly. This typically involves:

- Visual Inspections: Checking for leaks, damage, or corrosion on all components such as valves, pumps, cylinders, and hoses.

- Fluid Level Checks: Ensuring the hydraulic fluid is at the correct level and is clean and free of contamination.

- Filter Changes: Replacing hydraulic fluid filters regularly to remove contaminants and prolong the life of the system.

- Pressure Testing: Performing pressure tests on hydraulic components to verify their functionality and identify any leaks or blockages.

- Valve Adjustments: Checking and adjusting hydraulic valves to ensure proper operation and smooth control of the crane movements.

- Cylinder Maintenance: Inspecting the cylinders for scoring, leaks, or damage to the seals. This often involves cleaning and lubrication.

- Pump Maintenance: Regular lubrication and checking for wear on pump components. Pump pressure and flow rate checks are part of routine maintenance.

Detailed records are kept of all maintenance activities, allowing us to easily track the history and condition of the crane and its components. Predictive maintenance techniques, like oil analysis, are also implemented to identify potential problems before they occur.

Q 18. Explain your understanding of hydraulic control systems (e.g., proportional valves, servo valves).

Hydraulic control systems are the brains behind the smooth and precise operation of hydraulic cranes. I’m familiar with both proportional and servo valves, crucial components in these systems. Proportional valves control the flow of hydraulic fluid based on the input signal, offering smooth, proportional control of the crane’s movements. Servo valves, on the other hand, are even more precise, offering faster response times and higher accuracy. These are often found in more sophisticated cranes requiring very precise positioning.

For example, a proportional valve might control the speed of the hoist, allowing for gradual lifting and lowering of the load, while a servo valve might be used for precise positioning in applications like placing steel beams on a high-rise building. Understanding how these valves interact within the overall hydraulic system is crucial for troubleshooting any issues. For example, if the crane’s hoist speed is erratic, I know how to diagnose whether the issue stems from the proportional valve, the pump, or the hydraulic fluid itself.

Q 19. What is your experience with different types of crane control systems (e.g., joystick, lever)?

My experience includes operating cranes with various control systems. The most common are joystick and lever controls. Joystick controls offer more intuitive control, particularly for intricate movements. They are becoming increasingly popular due to their ergonomic design and precise control. Lever controls, on the other hand, offer a more traditional approach to crane operation, and are still commonly found in many older cranes. Understanding the nuances of each control system is important; the sensitivity and response time can differ significantly between different makes and models. For instance, the feel and responsiveness of a joystick controlling a modern, high-capacity crane differ vastly from the lever controls of an older, simpler crane. This requires adaptation and experience to ensure safe and efficient operation. I’m adept at adapting to different control systems quickly and safely.

Q 20. How do you ensure compliance with relevant safety regulations and standards?

Compliance with safety regulations and standards is not just a matter of following rules; it’s a commitment to safety. I ensure compliance by rigorously adhering to all relevant local, national, and international standards (e.g., OSHA, ASME). This starts with understanding the specific regulations for each crane and its application. Regular inspections, maintenance, and operator training are crucial components. Thorough documentation, including maintenance logs, inspection reports, and training records, is maintained. I stay up-to-date on any changes or updates to these regulations through professional development and industry publications. Staying compliant involves proactive measures like participating in safety audits and training programs to identify and address potential hazards before they lead to accidents. We don’t view compliance as a box to tick; it’s an ongoing process integral to safe operation.

Q 21. Describe your experience with using diagnostic tools for hydraulic systems.

Diagnostic tools play a crucial role in efficient hydraulic system troubleshooting and maintenance. My experience includes the use of various diagnostic tools, including pressure gauges, flow meters, and digital analyzers. These allow me to accurately measure key parameters such as hydraulic pressure, flow rate, and temperature. For instance, if a cylinder is not functioning correctly, I can use a pressure gauge to check the pressure in the hydraulic line leading to the cylinder. A low pressure might indicate a leak or blockage. I also utilize advanced diagnostic equipment that helps isolate problems within the hydraulic system, often identifying issues that aren’t immediately apparent through visual inspection. This allows for targeted repairs instead of unnecessarily replacing parts. Data loggers can be used to monitor the system’s performance over time and anticipate potential failures, paving the way for predictive maintenance and avoiding costly breakdowns.

Q 22. What is your experience with different types of hydraulic filters and their importance?

Hydraulic filters are crucial for maintaining the longevity and efficiency of a hydraulic crane system. They prevent contaminants – like dirt, metal shavings, and water – from damaging sensitive components like valves, pumps, and actuators. I have extensive experience working with various filter types, including:

- Suction filters: These are typically located at the pump inlet and protect the pump from larger particles.

- Return line filters: Situated on the return line from the actuators, these filters capture smaller particles that bypass the suction filter.

- Pressure filters: These filters are placed in the pressure line, filtering the hydraulic fluid before it reaches the actuators, ensuring the cleanest possible fluid for precise operation.

- Full-flow filters: These filter 100% of the hydraulic fluid flow, offering the highest level of protection.

- Bypass filters: These filters allow a portion of the fluid to bypass the filter when pressure drop becomes excessive, protecting the system from complete shutdown during heavy contamination. However, regular maintenance of these filters is critical to ensure that they do not become clogged.

The importance of regular filter replacement cannot be overstated. A clogged filter restricts fluid flow, causing reduced performance, overheating, and ultimately, catastrophic equipment failure. We follow strict schedules based on operating hours and fluid analysis, which helps prevent these issues. For example, on one project involving a large port crane, regular filter changes prevented a costly shutdown during peak operations, saving significant time and money.

Q 23. How do you manage and dispose of used hydraulic fluids responsibly?

Responsible management and disposal of used hydraulic fluids is paramount for environmental protection and worker safety. We adhere to all local, regional and national regulations. Our process involves several steps:

- Collection: Used hydraulic fluid is carefully collected in designated, leak-proof containers to prevent spills and contamination.

- Filtration (Optional): In some cases, depending on the fluid and regulations, we may filter the used fluid to remove larger contaminants before disposal, reducing the environmental impact.

- Recycling/Disposal: The used hydraulic fluid is then handed over to a licensed hazardous waste disposal company certified to handle and recycle or safely dispose of used hydraulic fluids. We maintain detailed records of all transactions, ensuring full traceability and compliance.

- Container Cleaning: Empty containers are thoroughly cleaned and prepared for reuse or proper disposal according to regulations.

Ignoring proper disposal methods can lead to significant fines and environmental damage. Our commitment to responsible disposal reflects our dedication to environmental sustainability.

Q 24. Describe a time you had to troubleshoot a complex hydraulic crane issue. What was your approach?

During a large construction project, the main boom of a 250-ton hydraulic crane experienced sudden, intermittent loss of lift capacity. My approach involved a systematic troubleshooting methodology:

- Gather Information: I started by interviewing the crane operator to get a clear understanding of the circumstances leading to the failure, including the load at the time, the sequence of events, and any unusual sounds or vibrations.

- Visual Inspection: I conducted a thorough visual inspection of the hydraulic system, hoses, cylinders, and the boom itself, checking for leaks, damage, or loose connections.

- Pressure Testing: Using pressure gauges, I systematically checked the pressure at various points in the hydraulic circuit to identify any pressure drops or blockages, isolating the problem to a section of the hydraulic lines within the boom itself.

- Component Testing: The section of the hydraulic lines was then carefully removed, inspected, and pressure tested further to identify the exact point of failure. In this case, a small crack in a hydraulic line inside the boom was discovered.

- Repair/Replacement: The damaged section of the hydraulic line was replaced, and a thorough leak test was conducted to ensure the repair was successful.

- Verification: Following the repair, a complete functional test was performed to confirm the restoration of full lift capacity and safe operation.

This systematic approach ensured a quick and efficient resolution, minimizing downtime and avoiding potential safety hazards. This case highlighted the importance of methodical troubleshooting and the value of understanding the entire hydraulic system’s functionality.

Q 25. Explain your understanding of different types of crane hooks and their proper usage.

Crane hooks are critical safety components, and selecting the right type is essential. The most common types are:

- Straight Hooks: These are simple, versatile hooks suitable for general lifting applications. They are generally less expensive but may not be as efficient in certain situations.

- Clevis Hooks: These hooks incorporate a clevis pin that provides a more secure connection. They’re typically safer for applications involving heavy lifting or demanding environments.

- Grab Hooks: These are specifically designed to grab and lift cylindrical objects such as pipes or drums.

- Self-Closing Hooks: Automatic closing hooks, usually found in specialized lifting applications, are self-locking and offer extra security.

Proper usage involves inspecting the hook regularly for cracks, deformation, and wear. The rated capacity of the hook must never be exceeded, and proper load distribution is essential. For example, using a straight hook on a heavy load may be sufficient when properly secured, while a clevis hook with a safety latch should be preferred for enhanced security and safety, especially when working at heights.

Q 26. What is your experience with load testing and certification of hydraulic cranes?

Load testing and certification of hydraulic cranes are crucial for ensuring safety and compliance with regulations. My experience includes:

- Planning and Preparation: This involves carefully reviewing the crane’s specifications, developing a detailed test plan, and ensuring that all necessary equipment and personnel are available.

- Test Execution: Load testing is typically performed by applying a calibrated test load to the crane’s hook and observing its behavior under load. We use certified load cells and other precision equipment to ensure accurate measurement.

- Documentation: Detailed records of the testing process, including the test load used, the crane’s response, and any observations, must be meticulously documented. This documentation forms the basis of the certification.

- Certification: Following successful load testing, a certification report is issued, confirming that the crane meets safety standards and is fit for service. This certification must be renewed at specified intervals to ensure that the crane remains in safe operating condition.

During my career, I have overseen numerous load tests on various hydraulic cranes, ranging from small mobile cranes to massive tower cranes. Accurate and thorough load testing and documentation are vital for maintaining operational safety and compliance.

Q 27. Describe your experience with preventative maintenance schedules for hydraulic cranes.

Preventative maintenance is the cornerstone of ensuring the longevity and safe operation of hydraulic cranes. We use a structured schedule that includes:

- Daily Inspections: These include visual checks of hydraulic fluid levels, hose and fitting integrity, and general condition of the crane.

- Regular Fluid Analysis: Periodic testing of the hydraulic fluid samples helps detect early signs of contamination or degradation and allows us to adjust the filter change schedules to ensure optimal system health.

- Scheduled Maintenance: We follow manufacturer-recommended schedules for servicing components such as hydraulic pumps, valves, and cylinders. This can range from minor adjustments and lubrications to component overhauls.

- Specialized Inspections: More comprehensive inspections and maintenance tasks will be performed at longer intervals based on usage and environmental conditions. These might include a more detailed examination of structural elements, wire ropes, and safety systems.

A well-maintained crane is less prone to unexpected breakdowns, which minimizes downtime and enhances safety. We meticulously document all maintenance activities, creating a clear history of the crane’s condition, making future maintenance and repairs more efficient.

Q 28. How do you ensure the accurate and safe operation of crane load indicators and sensors?

Accurate and safe operation of crane load indicators and sensors is crucial for preventing accidents. We ensure accuracy and safety through:

- Regular Calibration: Load indicators and sensors require regular calibration to ensure accurate readings. We use certified calibration equipment and follow established procedures.

- Functional Testing: Before each use, we perform functional tests to verify the accuracy and responsiveness of the load indicators and sensors. This ensures that the system is working correctly and providing reliable data.

- Visual Inspection: We regularly inspect the load indicators and sensors for any signs of damage, wear, or malfunction. Any damage is immediately reported and addressed.

- Operator Training: Crane operators are thoroughly trained on the proper use and interpretation of load indicators and sensors and receive regular refresher courses.

A malfunctioning load indicator or sensor could lead to overloading, which can result in catastrophic crane failure. Our rigorous approach to maintenance and training greatly minimizes this risk.

Key Topics to Learn for Operating and Maintaining Hydraulic Cranes and Equipment Interview

- Hydraulic System Fundamentals: Understanding pressure, flow, and the role of hydraulic fluid; diagnosing leaks and pressure drops.

- Crane Mechanics and Components: Familiarization with boom, hoist, swing mechanisms, and their interrelation; knowledge of different crane types (e.g., tower, mobile).

- Safe Operating Procedures: Detailed knowledge of pre-operational checks, load capacity calculations, and emergency procedures; adherence to safety regulations and best practices.

- Preventative Maintenance: Regular inspection schedules, lubrication routines, and component replacement; understanding of wear and tear patterns and their implications.

- Troubleshooting and Repair: Identifying common malfunctions, using diagnostic tools, and performing basic repairs; understanding the importance of accurate record-keeping.

- Electrical Systems: Basic understanding of crane electrical components, wiring diagrams, and troubleshooting electrical faults.

- Load Handling and Rigging: Proper techniques for lifting and moving loads, understanding of different rigging equipment, and load stability calculations.

- Regulations and Compliance: Awareness of relevant safety standards, certifications, and legal requirements for crane operation and maintenance.

- Communication and Teamwork: Effective communication with colleagues, supervisors, and clients; importance of teamwork and collaboration in a construction environment.

Next Steps

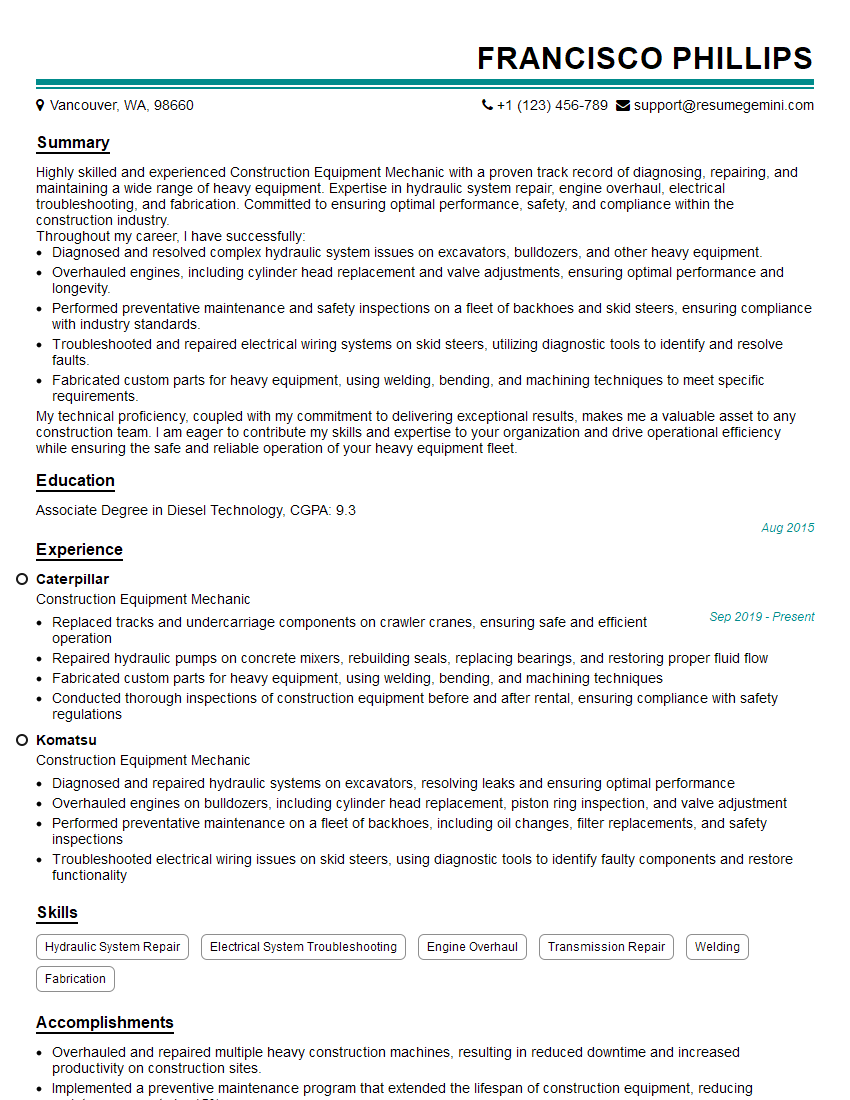

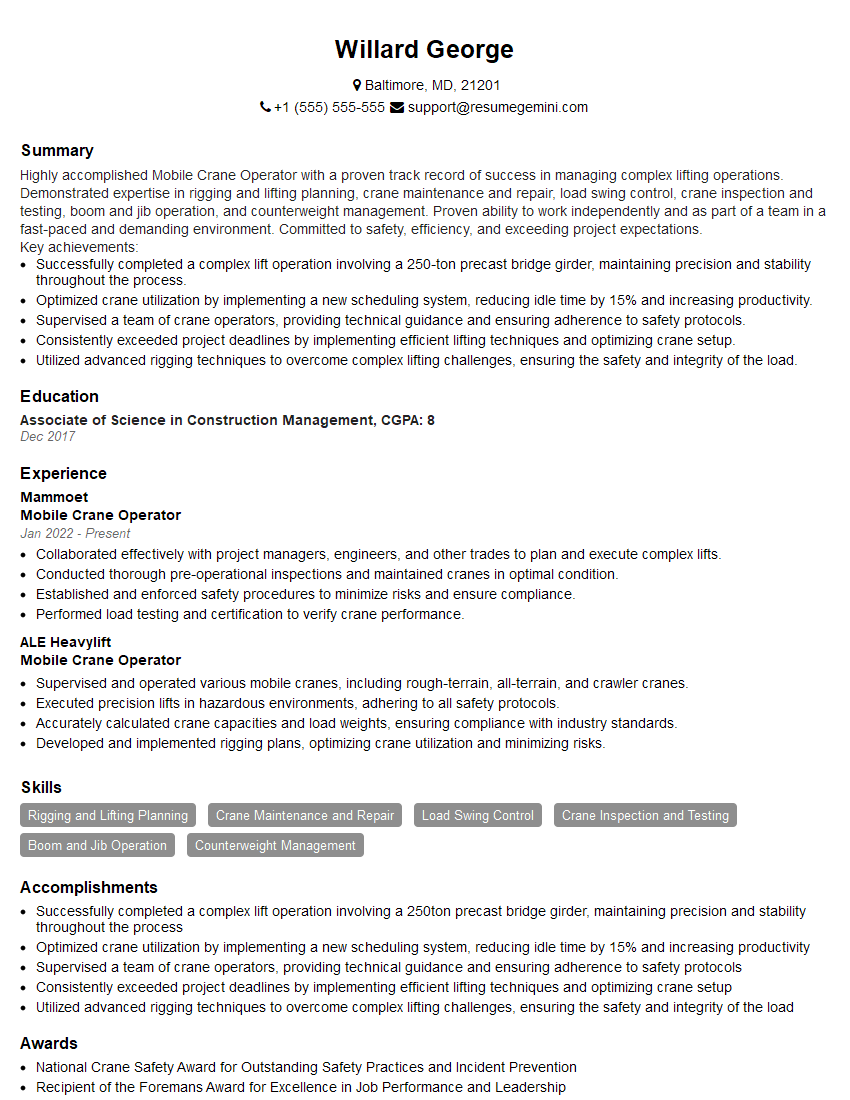

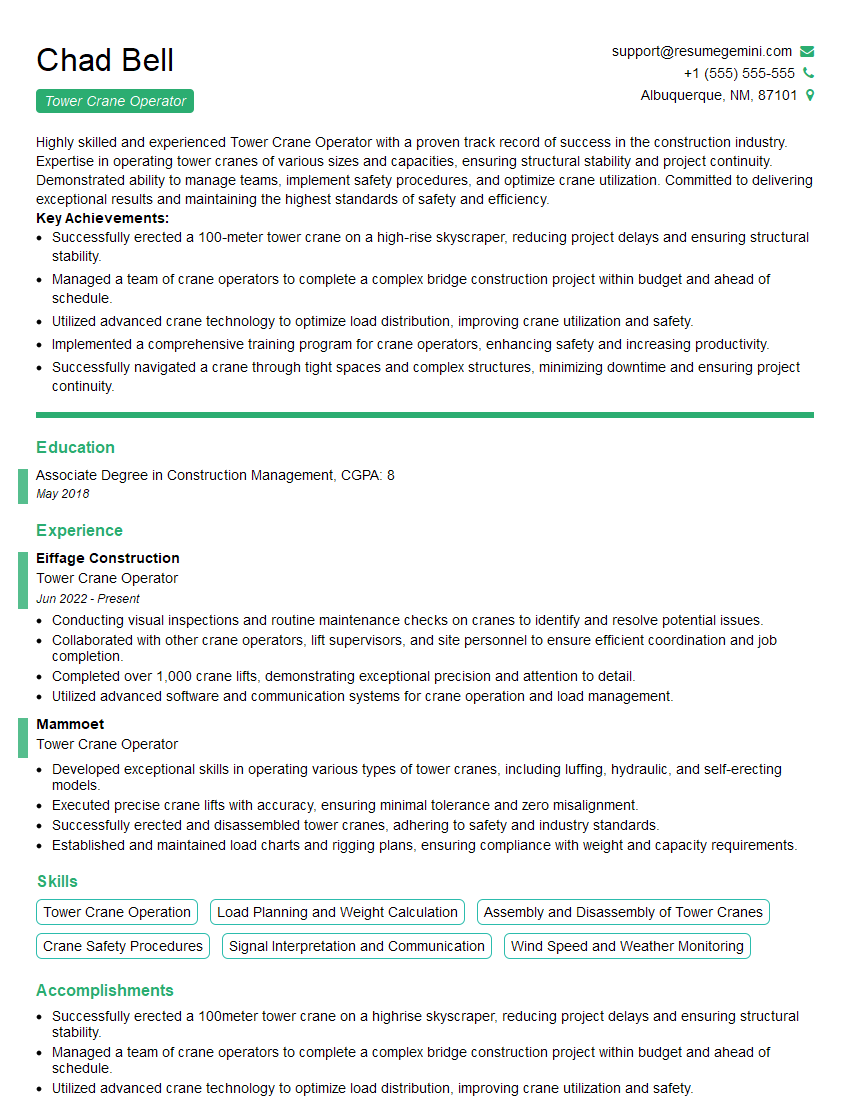

Mastering the operation and maintenance of hydraulic cranes and equipment opens doors to rewarding careers in construction, logistics, and heavy industries. It demonstrates a high level of technical skill and commitment to safety, qualities highly sought after by employers. To significantly boost your job prospects, focus on crafting a compelling and ATS-friendly resume that highlights your expertise. ResumeGemini is a valuable resource to help you build a professional resume that effectively showcases your skills and experience. Examples of resumes tailored to Operating and Maintaining Hydraulic Cranes and Equipment are available to help guide your creation. Invest the time to build a strong resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good