Unlock your full potential by mastering the most common Operating Farm Equipment interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Operating Farm Equipment Interview

Q 1. Describe your experience operating a tractor.

My experience operating tractors spans over 15 years, encompassing a wide range of tasks from plowing and tilling to hauling and spraying. I’ve operated tractors in diverse environments, from flat, open fields to hilly, challenging terrain. I’m proficient in various tractor operations, including using implements such as plows, harrows, cultivators, and sprayers, and I’m comfortable working long hours to ensure timely completion of field operations. For example, during one particularly busy harvest season, I worked consistently for 12 hours a day for three weeks straight, ensuring all the crops were harvested efficiently and effectively.

Q 2. What types of tractors have you operated?

Throughout my career, I’ve operated various types of tractors, including:

- Wheel Tractors: These are the most common type, offering versatility for various tasks. I’ve extensively used both 2WD and 4WD wheel tractors, adapting my techniques based on terrain and implement requirements. For instance, I used a 4WD tractor with a heavy disc harrow on our hilly land to ensure even soil preparation.

- Crawler Tractors (or Track Tractors): These are ideal for wet or muddy conditions due to their low ground pressure. I’ve utilized crawler tractors for tasks like land clearing and heavy tillage where traction is paramount. The reduced soil compaction was crucial in preventing damage to sensitive crops during a particularly wet spring.

- Specialty Tractors: I have experience with orchard tractors (narrower for row crops) and vineyard tractors (even more specialized for grape vines). These require precision and careful maneuvering to avoid damaging the delicate plants.

Q 3. Explain the pre-operational checks you perform on farm equipment.

Pre-operational checks are crucial for safety and efficiency. My routine involves:

- Visual Inspection: Checking for any leaks (oil, fuel, hydraulic fluid), loose bolts, damaged belts, or worn parts. I always pay close attention to the tires for any cuts or excessive wear. One time, a small crack I caught early prevented a major tire blowout during operation.

- Fluid Levels: Checking and topping off engine oil, coolant, fuel, and hydraulic fluid as needed. Maintaining proper fluid levels is key to preventing engine damage and ensuring smooth operation.

- Safety Systems: Testing the brakes, lights, PTO (Power Take-Off) engagement, and other safety features. Ensuring these are functioning correctly is a top priority. I always test the emergency stops before starting any operation.

- Implement Check: If using an implement, I thoroughly inspect it for damage, proper attachment, and functionality. A quick check can prevent costly delays or damage to equipment.

- Documentation: I always document my pre-operational checks. This ensures accountability and helps track maintenance needs.

Q 4. How do you maintain the proper tire pressure for different field conditions?

Maintaining proper tire pressure is vital for optimal traction, fuel efficiency, and reducing soil compaction. I adjust tire pressure based on the field conditions:

- Hard, dry soil: Higher tire pressure for better fuel economy and reduced slippage. I usually inflate to the maximum pressure recommended by the manufacturer, but I always take into account the weight of the tractor and implements.

- Soft, wet soil: Lower tire pressure for increased footprint and better traction. Lower pressure distributes the weight more evenly, preventing sinking and reducing soil compaction. I always monitor the ground conditions and adjust the tire pressure accordingly.

- Row Crops: I might use lower tire pressure on some rows to minimize soil compaction, while higher pressure is used on other rows to prevent the tires from getting stuck in soft spots.

I always consult the manufacturer’s recommendations and use a reliable tire pressure gauge to ensure accurate readings.

Q 5. Describe your experience with different types of planters.

My experience with planters includes various types, each suited for different needs:

- Conventional Planters: These are the most common type, using individual seed units to place seeds in the ground. I’m proficient in adjusting planting depth, spacing, and seed rate to achieve optimal germination.

- No-Till Planters: Designed for planting directly into undisturbed soil, minimizing soil erosion and improving soil health. I’ve used these extensively on our no-till farm, learning to manage the unique challenges of planting directly into residue.

- Precision Planters: These utilize technology like GPS and variable rate technology to optimize seed placement and fertilizer application. I’ve worked with precision planters, learning to calibrate and manage the technology to enhance planting accuracy and efficiency.

I’m adept at calibrating and maintaining all types of planters to ensure accurate seed placement and spacing, contributing to higher yields.

Q 6. What are the safety procedures for operating a combine harvester?

Safety is paramount when operating a combine harvester. My procedures include:

- Pre-operational Checks: Thorough inspection of all components, including the engine, cutterbar, header, auger, and unloading system. Checking for any obstructions, loose parts, or damaged components before starting operation is a must.

- Personal Protective Equipment (PPE): Always wearing appropriate PPE, including hearing protection, safety glasses, gloves, and a seatbelt. A strong work ethic includes protecting yourself and others.

- Awareness of Surroundings: Maintaining constant awareness of the surroundings, including other equipment and personnel, and avoiding hazards like power lines or ditches. A 360-degree situational awareness is critical.

- Safe Operation: Following all manufacturer’s safety guidelines and operating the machine within its limitations. Knowing the limits of the machine and your capabilities is important.

- Regular Maintenance: Adhering to a regular maintenance schedule to prevent mechanical failures and ensure the machine operates safely and efficiently.

Q 7. How do you adjust combine settings for different crops and conditions?

Combine settings depend heavily on crop type and conditions. Adjustments usually involve:

- Concave Clearance: Adjusting the distance between the concave and rotor to match the crop type and moisture content. Too tight, and you risk excessive grain damage; too loose, and you lose efficiency.

- Rotor Speed: Adjusting the speed of the rotor to optimize threshing and separation based on the crop. For dry crops, higher speeds are often appropriate; wet crops might require slower speeds to avoid excessive grain damage.

- Fan Speed: This controls the air flow used to separate grain from chaff. It needs adjustment based on the moisture content of the crop. Too low, and chaff may be missed; too high, and grain might be lost.

- Sieve Settings: These control the size of the openings that allow grain to pass through. This needs adjusting depending on the grain size.

- Chaffer Settings: These control the openings that allow chaff to pass through while keeping the grain. Similar adjustments are made for various crops.

I regularly monitor the combine’s performance, making adjustments as needed to optimize grain quality and minimize losses. Regular monitoring during operation is key to a successful harvest.

Q 8. Explain your experience with baling equipment.

My experience with baling equipment encompasses a wide range of operations, from small square balers to large round balers. I’m proficient in operating, maintaining, and troubleshooting various makes and models. This includes everything from pre-baling preparations like proper windrowing and conditioning to the baling process itself, ensuring optimal bale density and shape. I understand the importance of timely adjustments to bale size and density based on crop type and moisture content. For example, I’ve successfully operated a John Deere round baler for hay production, adjusting the tension and density settings to achieve consistent, high-quality bales, minimizing waste and maximizing storage efficiency. I’m also familiar with the safety procedures associated with baler operation, including proper twine management and recognizing potential hazards like wrapping or entanglement.

Beyond operation, I’m skilled in preventative maintenance, including regular lubrication, blade sharpening, and component inspections to prevent costly breakdowns during peak seasons. My experience also extends to bale handling and storage, ensuring they are correctly stacked and protected from the elements.

Q 9. Describe your experience with sprayers and application techniques.

My experience with sprayers covers various types, including boom sprayers, airblast sprayers, and hand-held sprayers. I’m comfortable calibrating sprayers for accurate application rates, understanding the impact of factors like nozzle type, pressure, and speed on application uniformity. Application techniques vary greatly depending on the target pest or nutrient and the crop being treated. For instance, I’ve used boom sprayers for herbicide application in large soybean fields, adjusting the spray height and pressure to ensure even coverage and minimize drift. I’ve also used airblast sprayers for orchard applications, targeting specific areas and adjusting air flow to ensure penetration into the canopy.

I understand the importance of safe handling procedures, including proper personal protective equipment (PPE) usage and environmentally conscious application to minimize off-target drift. This includes understanding local regulations and best practices for chemical application. I’m familiar with various types of nozzles and their spray patterns, allowing me to select the most effective nozzle for the specific application.

Q 10. How do you calibrate a sprayer for accurate application?

Calibrating a sprayer is crucial for accurate and efficient application. The process involves several steps: First, measure the width of the spray boom. Second, measure the ground speed using a GPS or by timing the distance traveled. Third, collect a sample of the spray solution to determine the volume being dispensed over a measured distance, often using a graduated container and a stopwatch. These measurements will help determine the number of gallons per acre the sprayer delivers. Then, using that figure and the desired application rate for the specific chemical or nutrient, you can calculate the needed adjustments to the sprayer’s settings, such as flow rate or speed.

For example, if your sprayer delivers 10 gallons per acre and you need to apply 2 gallons per acre of herbicide, you either need to reduce the speed of the tractor by half, or make adjustments to the flow rate to apply half the solution. This requires careful attention to detail and proper calculations to avoid over-application or under-application, which can result in reduced crop yield and environmental damage. In practice, I regularly calibrate my sprayers before each application to compensate for variations in nozzle wear, ground speed, and pressure. This ensures consistent and efficient chemical application.

Q 11. What is your experience with GPS guidance systems in farm equipment?

My experience with GPS guidance systems is extensive. I’m proficient in operating various systems, including those that provide auto-steering, variable rate application (VRA), and section control. Auto-steering significantly increases efficiency and reduces overlaps, saving fuel, seed, and chemicals. VRA allows for targeted application of inputs based on soil variability or other factors. This can lead to significant cost savings and improved environmental stewardship. Section control automatically shuts off individual sprayer nozzles when passing over already treated areas, further reducing overlap and waste. For example, I regularly use GPS guidance systems on our combine and planter. This enables me to cover the ground more quickly and precisely, minimizing overlap and maximizing efficiency.

Beyond operation, I understand the importance of system calibration and maintenance to ensure accuracy and reliability. This includes regular updates of the GPS maps and ensuring optimal signal reception.

Q 12. How do you troubleshoot common mechanical issues in farm equipment?

Troubleshooting mechanical issues involves a systematic approach. I typically start by identifying the symptom, like unusual noises or performance issues. Then, I visually inspect the equipment, looking for obvious problems such as leaks, broken parts, or loose connections. For example, if a tractor is losing power, I might check the fuel system, engine oil levels, and air filters.

If the problem isn’t immediately apparent, I consult manuals, diagrams, and online resources to help diagnose the issue and locate potential causes. I use my experience and knowledge to systematically isolate the problem through testing various components. I understand the importance of safe practices when troubleshooting, including disconnecting power sources before working on electrical components and using appropriate safety equipment. If I’m unable to resolve the issue, I’ll reach out to experienced mechanics or equipment dealers for further assistance.

Q 13. What is your experience with preventative maintenance?

Preventative maintenance is crucial for maximizing equipment lifespan and minimizing downtime. My approach involves a regular schedule of inspections and servicing. This includes checking fluids (engine oil, hydraulic fluid, coolant, transmission fluid), inspecting belts and hoses for wear, lubricating moving parts, and changing filters. I also perform seasonal checks tailored to the specific demands of each season. For example, before planting season, I’ll thoroughly inspect the planter and ensure all components are in optimal working condition.

I maintain detailed records of all maintenance activities, including dates, parts replaced, and any noted issues. This enables me to track maintenance trends and identify potential problems early, which will prevent more significant issues from arising, ultimately saving time and money. A proactive approach minimizes costly breakdowns during peak operational times.

Q 14. Describe your experience with irrigation systems.

My experience with irrigation systems includes both center pivot and drip irrigation. I understand the principles of water management, including pump operation, pressure regulation, and flow control. I’m familiar with various irrigation scheduling techniques to optimize water use and minimize water waste. For example, I’ve installed and maintained a center pivot irrigation system for a large corn field, regularly checking for leaks and blockages in the pipes. I’ve also used soil moisture sensors to monitor soil conditions and make necessary adjustments to the irrigation schedule based on current weather conditions and crop needs.

I’m also familiar with the importance of proper water quality management to prevent the accumulation of salts and other potential problems in the soil. Regular maintenance of the irrigation system, including cleaning and flushing of the lines, is critical for efficient and long-lasting operation.

Q 15. How familiar are you with different types of irrigation equipment?

My familiarity with irrigation equipment is extensive, encompassing various types suited for different terrains and crops. I’ve worked extensively with center pivot systems, which are highly efficient for large, flat fields. These systems utilize a central pivot point and long arms with sprinklers, rotating across the field. I’m also proficient with drip irrigation, a water-saving method where water is delivered directly to plant roots via tubes or emitters. This is particularly useful for orchards and vineyards. Furthermore, I’m experienced with flood irrigation, suitable for flat lands, and subsurface drip irrigation, which minimizes water loss due to evaporation and improves water penetration.

- Center Pivot: Ideal for large, level fields; high efficiency.

- Drip Irrigation: Water conservation; suited for orchards, vineyards.

- Flood Irrigation: Simplest; suitable for flat land, but can lead to waterlogging.

- Subsurface Drip Irrigation: Reduces evaporation; improves water penetration.

I understand the principles of water management, including scheduling, pressure regulation, and filter maintenance crucial for optimal irrigation efficiency and crop health. For example, I’ve successfully implemented a water-monitoring system on a large-scale farm, significantly reducing water waste and improving crop yields.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with livestock handling equipment?

My experience with livestock handling equipment includes working with a variety of systems designed to ensure animal welfare and efficiency. I’m comfortable operating and maintaining everything from simple corral systems and loading ramps to more advanced automated systems such as self-locking gates and hydraulic chute systems. I’ve worked with cattle, sheep, and pigs, each requiring slightly different approaches to safe and humane handling.

Safety is paramount. I’m trained in safe livestock handling procedures, understanding the importance of minimizing stress on the animals and preventing injury to both the animals and the handlers. For instance, I’ve designed and implemented a new chute system on a farm that significantly reduced animal stress during loading, improving overall animal welfare and productivity.

I’m also familiar with equipment for feeding and watering livestock, ensuring proper distribution and preventing waste.

Q 17. Describe your experience with different types of harvesting equipment.

My experience with harvesting equipment is comprehensive, covering a range of machinery depending on the crop. For grain harvesting, I’m highly skilled in operating combines, adjusting settings for optimal grain quality and minimizing losses. This includes understanding the interaction of different components, like the header, thresher, and cleaning system, to achieve optimal performance. For example, I once solved a major combine blockage by identifying a faulty cleaning shoe and promptly replacing it, preventing significant yield loss.

I’m also proficient with forage harvesting equipment, including balers (round and square), mowers, and tedders. I understand the importance of timely harvesting to maximize yield and quality. In addition, I have experience with specialized harvesting equipment such as potato harvesters and cotton pickers.

Regular maintenance and pre-harvest checks are essential to ensure trouble-free operation. I always perform thorough inspections before each harvest, paying close attention to critical components.

Q 18. Explain your experience with soil conservation techniques.

My understanding of soil conservation techniques is rooted in a practical, hands-on approach. I’m well-versed in various methods aimed at preserving soil health and preventing erosion. This includes no-till farming, where soil is not plowed, reducing erosion and improving soil structure. I’ve also worked with cover cropping, planting crops like rye or clover to protect soil during fallow periods and improve soil fertility. Contour farming, where crops are planted along the contours of slopes, is another technique I utilize to slow water runoff and prevent erosion.

Furthermore, I’m familiar with crop rotation strategies to improve soil health and prevent nutrient depletion. For example, I’ve implemented a successful crop rotation program on a farm, leading to a significant improvement in soil fertility and a reduction in pesticide usage.

Water management is crucial. Implementing efficient irrigation techniques, as previously discussed, is a key part of soil conservation, minimizing water waste and preventing soil compaction.

Q 19. How do you handle equipment malfunctions in the field?

Handling equipment malfunctions in the field requires a systematic approach. My first step is always safety; ensuring the machine is turned off and secured before any troubleshooting begins. I then conduct a thorough visual inspection to identify the problem. If the issue is minor and I’m equipped to fix it, I’ll proceed with the repair using appropriate tools and safety precautions. For instance, I’ve quickly resolved multiple hydraulic hose leaks using repair kits in the field.

If the problem is more complex or beyond my immediate expertise, I’ll follow the manufacturer’s troubleshooting guide or contact a qualified mechanic. I always document the malfunction, repairs, and downtime, to track equipment performance and inform future maintenance decisions. Proactive maintenance is key; regular servicing greatly reduces the frequency of unexpected breakdowns.

Q 20. What is your understanding of fuel efficiency in farm equipment?

Fuel efficiency is a critical factor in farm profitability. I understand that minimizing fuel consumption involves several key strategies. Proper machine maintenance is essential – well-maintained equipment operates more efficiently. This includes regular oil changes, filter replacements, and timely attention to any mechanical issues.

Operator skill is another crucial element. Efficient driving techniques, such as avoiding harsh acceleration and braking, and maintaining appropriate speeds, can significantly impact fuel consumption. For instance, I’ve trained other operators on fuel-efficient driving techniques, resulting in a noticeable reduction in fuel costs. Choosing the right equipment for the job is also essential, avoiding the use of oversized machines for smaller tasks.

Modern technology plays a role too. Many new machines come equipped with fuel-monitoring systems which provide valuable data for analysis and optimization.

Q 21. How do you maintain accurate records of equipment usage and maintenance?

Accurate record-keeping is paramount for efficient farm management. I utilize both paper-based and digital methods to track equipment usage and maintenance. Paper logs are used to record daily operational data such as hours of use, fuel consumption, and any repairs performed. This information is then transferred to a digital database, usually a spreadsheet or farm management software, allowing for easier analysis and reporting. This helps in tracking equipment costs, scheduling maintenance, and assessing the overall efficiency of each piece of equipment.

The digital records provide valuable data for future planning. For example, tracking fuel consumption over time helps identify inefficiencies and inform decisions about equipment upgrades or operator training. Regularly reviewing this data allows me to anticipate potential maintenance needs and schedule downtime accordingly, minimizing disruption to farm operations.

Q 22. Describe your experience with various tillage implements.

My experience with tillage implements spans a wide range, from traditional methods to more modern, conservation-focused approaches. I’m proficient in operating and maintaining various tools, including moldboard plows, chisel plows, disk harrows, and cultivators. Moldboard plows, for instance, are excellent for deep tillage and complete soil inversion, ideal for preparing land for planting crops like corn or soybeans that benefit from a deep seedbed. However, they can be quite demanding on fuel and contribute significantly to soil erosion if not managed carefully. In contrast, chisel plows perform less intensive tillage, leaving crop residue on the surface – a key aspect of no-till or conservation tillage farming. This helps improve soil health, reduce erosion, and conserve moisture. I’ve also had extensive experience with disk harrows for seedbed preparation and weed control, and cultivators for managing weeds in established crops. The choice of implement heavily depends on the soil type, crop, and the desired level of soil disturbance.

For example, on a clay soil with a high residue cover, I might opt for a chisel plow followed by a lighter pass with a cultivator. Conversely, on lighter, sandier soil, a disk harrow might suffice. This kind of decision-making requires a thorough understanding of soil mechanics and the specific needs of the crop being grown.

Q 23. How do you ensure the safety of yourself and others while operating equipment?

Safety is paramount in all my operations. Before starting any task, I always conduct a thorough pre-operational check of the equipment, ensuring all safety features – lights, brakes, PTO shields – are in proper working order. I meticulously inspect for any leaks, loose parts, or damage that could compromise safety. I also check the field for obstacles like rocks, ditches, or uneven terrain that could pose a risk. While operating, I maintain a safe distance from other equipment and personnel, and I always wear appropriate personal protective equipment (PPE), including hearing protection, safety glasses, and sturdy work boots.

Furthermore, I adhere strictly to all posted speed limits and avoid operating equipment when visibility is poor due to darkness or inclement weather. I’m trained in first aid and emergency procedures, and I understand how to effectively use fire extinguishers on the equipment and in the immediate vicinity. Communication is key. I maintain clear communication with my co-workers and supervisors through radio or other means to prevent collisions and coordinate movements within the field.

Q 24. What are the environmental considerations when operating farm equipment?

Environmental considerations are integrated into every aspect of my work. I’m mindful of soil erosion and take precautions such as contour farming and using conservation tillage techniques. Using no-till practices, for example, significantly reduces soil erosion compared to conventional tillage. I avoid over-application of fertilizers and pesticides and strive to use environmentally friendly products whenever possible. I’m also careful to prevent fuel and oil spills and follow proper procedures for disposing of used oil and other hazardous waste.

Minimizing fuel consumption is another important environmental goal, so I ensure proper equipment maintenance and use fuel-efficient operating practices. I also keep up-to-date with best management practices related to water quality and soil health, avoiding activities that could lead to water pollution. Understanding the local environment and its sensitivities is important; for example, working around waterways requires extra vigilance to avoid runoff contamination.

Q 25. What is your experience with different types of fertilizer application equipment?

My experience includes operating various fertilizer application equipment, including spreaders for dry granular fertilizers and sprayers for liquid fertilizers. I’m familiar with calibrating these machines to ensure accurate application rates. Spreaders require careful adjustment based on the fertilizer type and desired application rate, and factors like wind speed and ground conditions must be taken into account. With liquid application systems, things like nozzle size and pressure need to be carefully considered to achieve even and effective fertilizer distribution. I’m comfortable working with different fertilizer types, from nitrogen and phosphorus to potash, and understand the specific application requirements for each.

For example, broadcasting granular fertilizers requires a different approach compared to banding or applying fertilizer through a side-dressing system. I regularly maintain these systems, checking for clogs, leaks, and proper operation of metering systems to ensure precision and efficiency.

Q 26. Describe your experience with precision agriculture techniques.

I have significant experience with precision agriculture techniques, including GPS-guided machinery, variable-rate technology (VRT), and yield monitoring. I’m proficient in using GPS guidance systems to operate equipment accurately and efficiently, minimizing overlaps and maximizing coverage. VRT allows for applying inputs, such as fertilizer and pesticides, at varying rates based on soil conditions or yield data. This targeted application ensures optimal nutrient use, reduces waste, and minimizes environmental impact.

Yield monitors provide real-time data on crop yields, which is invaluable for identifying areas of high and low productivity. This data is used to refine future farming practices and optimize yields. I can integrate data from different sources, like soil maps and yield maps, to create more detailed and precise plans for the next growing season. I also use software to analyze this data, to identify areas needing attention, and ultimately to improve crop yields and manage resources more sustainably.

Q 27. How do you adapt to changing weather conditions during fieldwork?

Adapting to changing weather conditions is a crucial skill. I constantly monitor weather forecasts and adjust my fieldwork schedule accordingly to avoid working during periods of heavy rain, strong winds, or extreme temperatures. If conditions change unexpectedly while I’m working, I take appropriate safety precautions, such as reducing speed, increasing spacing, or halting operations altogether if necessary. For example, during a sudden downpour, I’d immediately stop work to prevent soil compaction and reduce the risk of accidents.

Depending on the specific situation, I might alter the implement or technique. For instance, I might change the tillage depth to accommodate soft, wet soils or switch to a different fertilizer application method if the weather isn’t ideal for spraying or spreading. I’m well versed in recognizing the potential impact of weather on various operations and have strategies to mitigate risks associated with moisture content, soil conditions, and equipment capabilities.

Q 28. What is your experience working in a team environment during fieldwork?

Teamwork is essential in agriculture. I’ve worked extensively in team environments, coordinating tasks with other operators, mechanics, and field supervisors. Effective communication is key. I use radios to maintain constant contact with others in the field, ensuring smooth operations and preventing accidents. I’m adept at delegating tasks, providing support to my team members, and working collaboratively to achieve shared goals.

For example, during harvest, coordinating the operation of multiple combines, grain carts, and trucks requires meticulous planning and excellent communication to ensure efficient grain handling and minimize delays. I am comfortable both leading and assisting within a team context, always prioritizing safety and productivity.

Key Topics to Learn for Operating Farm Equipment Interview

- Equipment Operation & Maintenance: Understanding the functionality of various farm machinery (tractors, harvesters, planters, etc.), including preventative maintenance procedures and troubleshooting common mechanical issues.

- Safety Procedures & Regulations: Demonstrating knowledge of safe operating practices, adhering to all relevant safety regulations, and understanding emergency response protocols.

- Precision Farming Techniques: Familiarity with GPS-guided systems, yield monitoring, and other technologies used to optimize farming efficiency and resource management. This includes understanding data analysis related to farm operations.

- Crop Handling & Storage: Knowledge of proper harvesting, handling, and storage techniques for various crops, minimizing losses and maintaining quality.

- Soil Management & Conservation: Understanding the principles of soil health, erosion control, and sustainable farming practices. This includes the practical application of these principles in relation to equipment use.

- Environmental Awareness: Demonstrating awareness of environmental impact and responsible use of resources, including fuel efficiency and minimizing pollution.

- Problem-Solving & Troubleshooting: Ability to diagnose and resolve equipment malfunctions efficiently and effectively, minimizing downtime and maximizing productivity. This includes describing your approach to problem-solving in a farm setting.

- Record Keeping & Reporting: Understanding the importance of accurate record-keeping related to equipment usage, maintenance, and yields. This includes familiarity with relevant reporting methods.

Next Steps

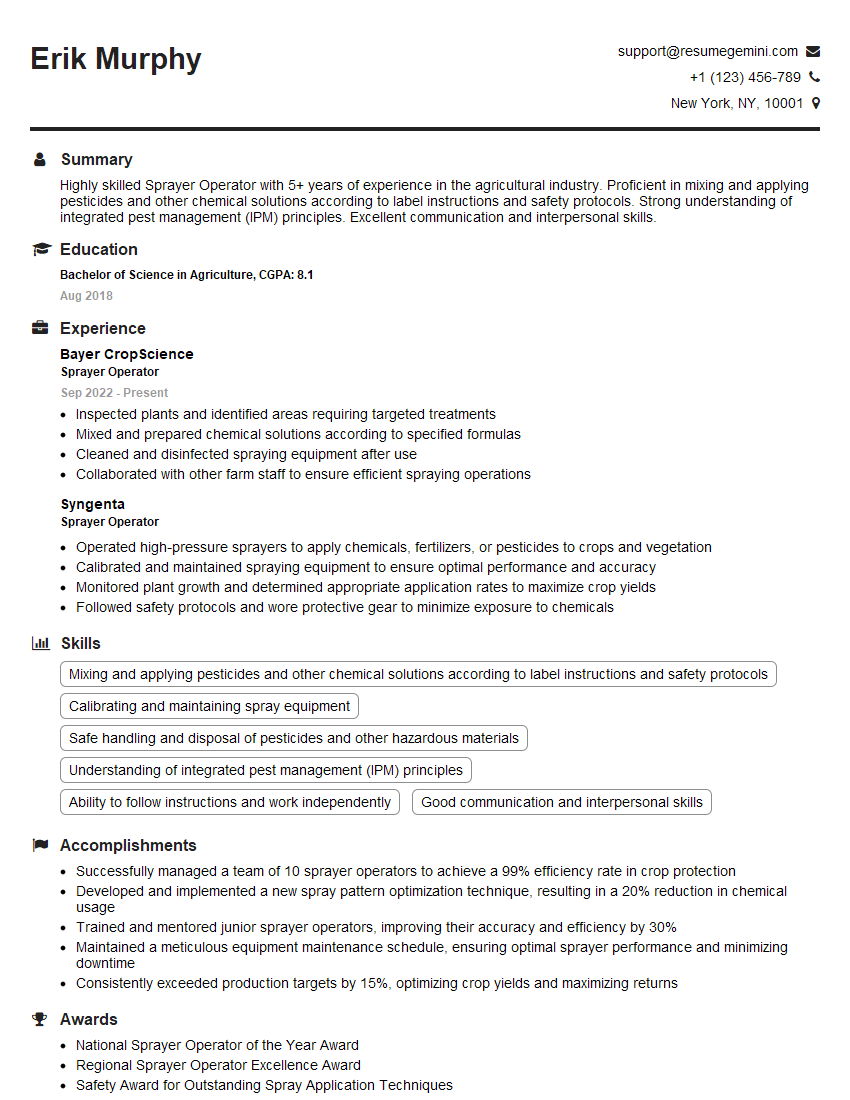

Mastering the operation of farm equipment is crucial for a successful and rewarding career in agriculture. The demand for skilled operators is high, and proficiency in this area significantly enhances your job prospects and earning potential. To stand out from the competition, create a compelling and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional resume that showcases your qualifications effectively. They provide examples of resumes tailored to Operating Farm Equipment roles, helping you present your experience in the best possible light. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good