Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Operating Loaders interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Operating Loaders Interview

Q 1. Describe your experience operating different types of loaders (e.g., wheel loaders, skid steer loaders).

My experience encompasses a wide range of loaders, primarily wheel loaders and skid steer loaders. I’ve operated various models, from small, compact skid steers used for landscaping and tight-space operations to large, high-capacity wheel loaders employed in construction and material handling on large-scale projects. With wheel loaders, I’m proficient in tasks like loading trucks, stockpiling materials, and excavating. Skid steers, with their maneuverability, have been invaluable for tasks requiring precision and agility in confined areas, such as trenching, backfilling, and snow removal. I’m also familiar with the operation and maintenance of telehandlers, which offer a unique combination of lifting and extending capabilities, further expanding the range of tasks I can undertake. Each loader type demands a unique operating technique and understanding of its capabilities and limitations; I adapt my approach accordingly to maximize efficiency and safety.

For instance, on a recent road construction project, I utilized a large wheel loader to efficiently load and transport tons of gravel, while on a smaller residential project, a compact skid steer was instrumental in creating precise landscaping features. This versatility demonstrates my adaptability and proficiency across diverse loader applications.

Q 2. Explain the pre-operational checks you perform on a loader before commencing work.

Pre-operational checks are crucial for ensuring both safety and equipment longevity. My routine includes a thorough visual inspection of the entire loader, covering several key areas. First, I check all fluid levels – engine oil, hydraulic fluid, coolant, and transmission fluid – ensuring they’re within the manufacturer’s recommended ranges. I then inspect the tires for proper inflation and any signs of damage, like punctures or cuts. Next, I examine the linkage and hydraulic systems for leaks or damage. I also test the functionality of all controls, including steering, brakes, lift arms, and bucket operation. I pay close attention to the condition of the bucket itself, checking for any damage that could compromise its structural integrity or ability to effectively hold and move materials. Finally, I activate the safety mechanisms, like the horn and warning lights, to ensure they’re working correctly. This methodical approach significantly reduces the risk of accidents and breakdowns.

Think of it like a pilot’s pre-flight check; every component is critical to safe and efficient operation. Ignoring even a minor issue can lead to major problems down the line.

Q 3. How do you ensure the stability of a loader during operation, particularly on uneven terrain?

Maintaining stability on uneven terrain is paramount for safe loader operation. The key is understanding the loader’s weight distribution and center of gravity. I always avoid abrupt movements, especially when maneuvering on slopes or inclines. Smooth and gradual transitions minimize the risk of tipping. I also adjust my speed according to the terrain’s roughness and slope. On steep inclines, I always approach them slowly and strategically, keeping the loader’s weight balanced. If the ground is soft or unstable, I may need to adjust my loading strategy to distribute the weight more evenly or use wider tracks/tires to improve stability. Never exceeding the loader’s rated capacity is essential. Overloading dramatically increases the risk of tipping, even on relatively flat ground. Furthermore, I carefully observe the surrounding environment, always aware of potential obstacles and uneven surfaces. I avoid overloading and maintain a low center of gravity by keeping the load centered and minimizing bucket tilt when possible. This approach ensures a safer working environment and reduces the risk of equipment damage and injuries.

Q 4. What are the common safety procedures you follow when operating a loader?

Safety is my top priority. I always follow these procedures: First, ensure that the work area is clear of obstructions and personnel before starting any operation. I use audible warning signals before moving the loader to alert bystanders. I maintain a safe distance from other equipment and personnel at all times. I always wear the appropriate personal protective equipment (PPE), including a hard hat, safety glasses, and high-visibility clothing. Before starting the engine or engaging in any operation, I carefully inspect the area. Before dismounting the loader, I ensure it is parked on level ground, the engine is switched off and the parking brake is engaged. I strictly adhere to the manufacturer’s operating instructions and all company safety protocols. Regularly servicing the loader and promptly reporting any defects or maintenance requirements ensures peak performance and reduces the risk of accidents. Proactive risk assessment is crucial to anticipate potential hazards and take preventive measures.

Q 5. Describe your experience with different loader attachments (e.g., buckets, forks, grapple).

My experience with loader attachments extends to buckets of various sizes and types (general-purpose, light-material, heavy-duty), forks (for pallet handling), and grapples (for handling logs, scrap metal, or other irregularly shaped materials). Each attachment requires a different operating technique, understanding its specific capabilities and limitations. For example, using forks demands precision and awareness of the load’s center of gravity to prevent tipping. With grapples, I need to adjust the closing force depending on the material’s density and shape to ensure a secure grip without damaging the material. I understand the importance of matching the attachment to the job, selecting the right bucket for the material type and quantity, and so on. The improper use of attachments can lead to accidents or inefficient operations, which is something I always avoid.

For example, on one project, I used a grapple attachment to efficiently sort and load scrap metal, while on another, I used pallet forks to quickly and safely move construction materials.

Q 6. How do you calculate the load capacity of a loader safely and efficiently?

Calculating a loader’s load capacity safely and efficiently involves several factors. First, always refer to the manufacturer’s specifications for the particular loader model and attachment being used. The manufacturer’s stated capacity is usually provided as a maximum weight, but it often needs to be adjusted for factors like terrain conditions (slope, soil type), the attachment type, and the position of the load. Overloading is a major safety hazard and can damage the machine. Operating within the recommended load limits ensures both safety and productivity. The load charts provided by manufacturers provide crucial data and should always be used as the guide. These charts help estimate capacities based on factors like the material’s density, bucket type, and working conditions. Experienced operators learn to estimate loads through familiarity with materials and visual cues, but the manufacturer’s data is the ultimate authority. Never try to guesstimate; erring on the side of caution is always the better choice.

Q 7. Explain the process of loading and unloading materials using a loader.

Loading and unloading materials involves a systematic approach. First, I position the loader strategically for optimal access to the material pile or delivery point, ensuring clear access and a stable working platform. I then adjust the bucket or attachment to a suitable position. When loading, I engage the bucket smoothly, avoiding jerky movements. Care is taken to ensure that the bucket is properly filled but not overloaded. Then, I lift the loaded bucket and carefully maneuver it to the desired location, being mindful of overhead obstructions. For unloading, I position the bucket above the designated area and gradually lower the load while maintaining control of the bucket to prevent any spills or damage. Throughout the entire process, maintaining awareness of the surrounding environment and keeping a safe distance from obstacles and people are crucial aspects of safe operation. Each material type requires an adapted technique – loose materials like sand and gravel require careful control during lifting and dumping, whereas palletized goods must be lifted and handled with precision to avoid damage.

Q 8. How do you handle unexpected mechanical issues while operating a loader?

Handling unexpected mechanical issues in a loader requires a calm and systematic approach. My first step is always safety – securing the machine and assessing the situation to prevent further damage or injury. This includes turning off the engine and engaging the parking brake. Then, I’ll perform a preliminary diagnosis, trying to pinpoint the problem. For example, if the engine stalls, I’d check fuel levels, look for obvious leaks, and inspect the battery connections. For hydraulic issues, I’d check fluid levels and listen for unusual noises.

If I can’t identify the problem or if it’s something beyond my expertise (like a major hydraulic failure), I immediately report it to my supervisor and follow the established reporting procedure. I have experience troubleshooting minor issues like replacing a blown fuse or tightening loose bolts, but I’m always mindful of my limitations. Safety is paramount – I’d rather wait for a qualified mechanic than risk further damage or injury by attempting a complex repair myself.

For instance, once I experienced a sudden loss of steering power. After safely stopping the loader, I initially suspected a hydraulic leak. A quick check revealed a loose hose clamp. After tightening it, the steering resumed normal operation. However, I still reported the incident, as it indicated a potential maintenance need. This proactive approach ensures the continued safe operation of the equipment.

Q 9. What is your experience with maintaining loader logs and reporting maintenance needs?

Maintaining accurate loader logs and reporting maintenance needs is crucial for both safety and equipment longevity. I’m proficient in using both digital and paper-based logging systems. My logs always include details like the date, operating hours, type of work performed, fuel consumption, and any issues encountered.

When reporting maintenance needs, I’m meticulous in my descriptions. I avoid vague terms and provide specific details – for example, instead of saying ‘engine problem,’ I’d write ‘engine sputtering at high RPMs, accompanied by unusual smoke from exhaust.’ This clear and concise reporting ensures the mechanic has the necessary information to address the issue efficiently. I prioritize preventative maintenance by noting any minor issues, such as abnormal noises or fluid leaks, that may indicate a larger problem down the line. This approach significantly reduces downtime and expensive repairs. I’ve always strived to maintain a consistent and accurate record, enabling my supervisors to effectively track operational costs and schedule routine servicing.

Q 10. Describe your understanding of different types of loader controls and operating systems.

Loader controls and operating systems vary considerably, depending on the age and manufacturer. I’m experienced with both mechanical and electro-hydraulic control systems. Mechanical systems rely on levers and linkages to control hydraulic functions, requiring more physical effort and precision. Electro-hydraulic systems use joysticks and electronic controls, providing more responsive and precise control, and often offer features like automatic shifting and enhanced safety features.

I’m also familiar with different operating systems, including those with varying levels of sophistication. Some have basic functionality, while others feature advanced features such as load sensing, automatic bucket leveling, and integrated diagnostics. I adapt my operating style to suit each specific system. For example, with mechanical systems, I pay close attention to precise lever movements, while with electro-hydraulic systems, I appreciate the added control and precision offered by the joysticks. Regardless of the system, safety is my top priority and I always conduct thorough pre-operational checks. I’ve worked with loaders from various manufacturers, like Caterpillar, John Deere, and Komatsu, gaining extensive experience across different control systems.

Q 11. How do you ensure the safe transport and storage of the loader?

Safe transport and storage of a loader are critical for preventing damage and ensuring operational readiness. For transport, I adhere to all relevant regulations, which include using appropriate trailers and securing the loader correctly to prevent movement during transit. This includes using chains, straps, or other securing devices according to the manufacturer’s specifications and local regulations. I always ensure the machine is properly cleaned before transport to prevent spreading debris.

During storage, I ensure the loader is parked on a level surface away from hazards and protected from the elements. I disconnect the battery, lower the bucket to the ground, and engage the parking brake. For long-term storage, I would also consider adding wheel chocks and covering the machine to protect it from moisture and damage. I strictly follow all safety procedures, ensuring that the loader is adequately protected from potential damage or theft while in transit or storage. This preventative care minimizes maintenance costs and extends the operational lifespan of the loader.

Q 12. Explain the procedures for fueling and lubricating a loader.

Fueling and lubricating a loader are routine but essential maintenance procedures. Before fueling, I always ensure the engine is turned off and the area is well-ventilated to prevent fire hazards. I use the correct type of fuel, as specified in the operator’s manual, and avoid overfilling the tank. I carefully wipe up any spills immediately. The fueling process should always be conducted with caution and in compliance with all safety regulations.

Lubrication is equally important. I regularly check fluid levels (engine oil, hydraulic oil, transmission oil, coolant), using the dipsticks and gauges provided. I use only the recommended lubricants, as specified in the operator’s manual, and refill as needed. I meticulously check for leaks and address any issues promptly. Neglecting lubrication can lead to premature wear and tear, costly repairs, and even catastrophic failure. A well-lubricated loader not only operates more smoothly but also contributes significantly to its operational lifespan. Proper fueling and lubrication are therefore integral parts of my routine maintenance checks.

Q 13. What are the legal and regulatory requirements for operating a loader in your region?

Legal and regulatory requirements for operating a loader vary depending on location. However, some common regulations include possessing a valid operator’s license or certification, adhering to all traffic laws when operating on public roads, and complying with workplace safety regulations. In my region, operators must undergo regular safety training to maintain their certifications. This training covers safe operating procedures, emergency response techniques, and understanding relevant legislation.

Moreover, the loader itself must be regularly inspected and maintained to comply with safety standards. These inspections cover various aspects of the machine, including brakes, lights, tires, and safety features. Regular documentation of these inspections and maintenance activities is mandatory to comply with the regulations. I always stay informed about any changes or updates to the regulations to maintain full compliance and ensure safe and legal operation of the loader. Ignoring these regulations can lead to serious penalties, including fines and suspension of operating privileges.

Q 14. How do you adapt your operating techniques to different types of materials (e.g., sand, gravel, rocks)?

Adapting operating techniques to different materials is essential for efficient and safe operation. For example, when handling sand, I might use a faster bucket swing speed and a shallower digging depth to maximize the volume moved. With gravel, I’d adjust the bucket angle and digging depth to prevent material spillage. Rocks require a much different approach. I’d use a slower, more deliberate technique, focusing on applying sufficient force to break up larger pieces and minimizing the risk of damage to the bucket or loader.

The bucket’s position, the angle of the swing, the amount of pressure applied, and the travel speed all need to be adjusted based on the material’s characteristics. For instance, when moving heavy rocks, I would use lower travel speeds and carefully control the bucket’s angle to prevent tipping or overloading the loader. My experience has taught me to anticipate the behavior of different materials and adjust my operating style accordingly. I’ve learned how to gauge the proper amount of force needed to avoid damaging the bucket or causing spills, ensuring both efficiency and safety in every operation. This knowledge allows me to optimize the loader’s performance across a variety of tasks.

Q 15. Describe your experience with working in confined spaces using a loader.

Operating a loader in confined spaces demands heightened awareness and precision. It’s crucial to understand the loader’s dimensions – including turning radius, lift height, and overall footprint – relative to the space’s constraints. Before starting any work, a thorough site assessment is paramount. This includes identifying potential obstacles like pipes, walls, or other equipment. I always create a mental map of the space, visualizing the loader’s path and ensuring there’s ample clearance for every maneuver.

For example, during a recent project involving trench backfilling in a narrow alleyway, I meticulously planned each bucket movement, opting for smaller, more controlled actions rather than large, sweeping ones. I also utilized the loader’s mirrors extensively and engaged spotters to ensure visibility of blind spots. Safety is never compromised; if a space is too confined for safe operation, I won’t hesitate to suggest alternative methods or equipment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you effectively communicate with other workers on the site when operating a loader?

Effective communication is paramount on any construction site, especially when operating heavy machinery. I utilize a combination of visual and verbal cues. Before initiating any movement, I use hand signals to confirm my intentions with ground personnel – this is especially crucial in noisy environments where verbal communication might be challenging. A simple thumbs-up to confirm their readiness, or a hand signal to stop, prevents accidents. For verbal communication, I rely on clear, concise instructions, using standardized terminology to avoid confusion. When working with diverse teams, I ensure everyone understands the instructions, and adjust my communication style accordingly.

For instance, during a large-scale demolition project, I used a combination of hand signals and short, clear radio communications to coordinate the precise movement of materials with the crane operator and other workers. Clear, concise communication prevents errors and ensures everyone is aware of the loader’s position and intended actions.

Q 17. Explain your understanding of different ground conditions and their effect on loader operation.

Different ground conditions significantly impact loader operation and efficiency. Soft ground, like mud or clay, can cause the loader to bog down, reducing traction and potentially damaging the machine. Conversely, rocky or uneven terrain can lead to instability and impact the loader’s maneuverability and lifting capacity. Understanding these conditions allows me to adjust my operation accordingly. On soft ground, I may need to reduce speed and load capacity, possibly using wider tires or tracks to distribute weight. On rocky surfaces, I adjust my speed and trajectory to avoid sudden jolts that could damage the loader or cause instability.

For example, when working on a site with particularly soft, marshy ground, I switched from using a standard wheeled loader to a tracked loader, which provided much better traction and minimized the risk of getting stuck. Regular checks of tire pressure are also vital, adjusting them as per the ground condition to maintain optimal grip and performance.

Q 18. How do you deal with challenging weather conditions during loader operation?

Challenging weather conditions, such as heavy rain, snow, or high winds, pose significant hazards during loader operation. Reduced visibility, slippery surfaces, and strong winds all affect machine control and safety. In such cases, my primary focus is on safety. I may reduce my operating speed significantly, increase following distances, and use extra caution when making turns or maneuvering in confined spaces. If visibility is severely compromised, I might pause operation altogether until conditions improve. In snowy conditions, I’ll ensure all working surfaces and access routes are clear. I always check weather forecasts before starting work to plan accordingly and adjust my strategy throughout the day as needed.

During a winter project where heavy snowfall reduced visibility, I prioritized slow and steady operation, using extra caution on inclines and declines. I also wore extra layers of protective clothing and had adequate lighting to enhance visibility.

Q 19. How do you identify and respond to potential hazards during loader operation?

Hazard identification is a constant process during loader operation. I regularly check for potential hazards such as unstable ground, overhead power lines, nearby personnel, and obstacles in the loader’s path. Before starting any work, I conduct a thorough site assessment and adhere to all relevant safety procedures. I maintain a safe operating distance from other workers and equipment, and always ensure there’s a clear escape route in case of emergencies. I’m also vigilant about potential equipment malfunctions, regularly inspecting the loader for any signs of damage or wear and tear.

Once, I noticed a cracked hydraulic hose during a pre-operational check, promptly reporting it and preventing a potential hazardous situation. Regular inspections and careful monitoring of equipment health are crucial to preventing accidents.

Q 20. What is your experience working with different types of loaders in various job sites?

My experience encompasses working with various types of loaders – wheeled loaders, tracked loaders, and compact loaders – in diverse job sites, including construction, demolition, and agricultural settings. Wheeled loaders excel in smooth, level terrains, while tracked loaders are ideal for challenging terrain, offering superior traction. Compact loaders are perfect for confined spaces. The choice of loader depends entirely on the job requirements. For example, in a recent project involving moving large amounts of earth on a flat construction site, a wheeled loader was the most efficient and cost-effective option. However, in another job involving clearing debris from a rocky and uneven demolition site, a tracked loader proved essential.

I am proficient in operating different models and sizes, adapting my techniques based on the specific machine’s capabilities and limitations. This adaptability is a key element of my job, ensuring the right machine is utilized effectively for every scenario.

Q 21. Describe a time you had to solve a problem or overcome a challenge while using a loader.

During a road construction project, we encountered an unexpected challenge: a large, unexpectedly buried utility pipe that wasn’t marked on the site plans. This pipe was directly in the path of our excavation work. Initially, the immediate reaction was to halt the operation and contact the utility company. However, this would have significantly delayed the project timeline and impacted our budget. Therefore, I devised a solution that involved carefully maneuvering the loader around the pipe using small, precise bucket movements, coupled with meticulous ground observation to avoid any damage.

The solution demanded patience and precision but ultimately allowed us to continue the excavation safely and efficiently, completing the project on time and without any damage to the utility infrastructure. This experience emphasized the importance of adaptability, problem-solving, and the utilization of all available tools and skills to overcome unexpected obstacles in a safe and productive manner.

Q 22. Explain your knowledge of loader maintenance schedules and preventative measures.

Loader maintenance is crucial for ensuring operational efficiency, safety, and longevity. A comprehensive maintenance schedule typically involves both preventative and corrective measures. Preventative maintenance focuses on proactively identifying and addressing potential issues before they escalate into major breakdowns. This is akin to regular check-ups at the doctor – better to catch things early!

- Daily Inspections: These are essential and should include checking fluid levels (engine oil, hydraulic fluid, coolant), tire pressure, inspecting for leaks, and visually examining the bucket, arms, and other components for damage.

- Weekly Inspections: More thorough checks, including lubrication of moving parts, tightening bolts, and inspecting hoses and belts for wear and tear. Think of this as a more detailed health check.

- Monthly Inspections: This level often includes more specialized checks, possibly involving the use of diagnostic tools to identify potential issues within the engine or hydraulic system. Consider this like a more advanced medical screening.

- Scheduled Maintenance: This typically involves major servicing intervals, such as replacing filters, servicing the hydraulic system, or changing engine fluids, all based on the manufacturer’s recommendations and the machine’s operating hours. This is analogous to a major annual physical.

Corrective maintenance addresses issues as they arise. For instance, if a hydraulic hose bursts, this requires immediate repair or replacement. This is like treating an injury or illness as it develops.

Detailed records of all maintenance activities are extremely important for tracking machine health and complying with safety regulations. These records can help identify patterns and prevent future problems.

Q 23. How do you ensure the safe operation of a loader around other equipment and personnel?

Safe operation of a loader around other equipment and personnel is paramount. My approach involves a multi-layered strategy encompassing pre-operation planning, situational awareness, and adherence to strict safety protocols.

- Pre-Operation Planning: Before starting work, I meticulously plan the task, identifying potential hazards, and establishing safe working zones. This involves considering the movement of other equipment and personnel and establishing clear communication channels.

- Situational Awareness: Maintaining constant situational awareness is crucial. This includes continuously scanning my surroundings, using mirrors and cameras where available, and being aware of blind spots. It’s like being a pilot – always aware of your environment.

- Communication: Clear and consistent communication is key. This means using hand signals, radios, or other communication devices to coordinate movements with other operators and ground personnel. Misunderstandings can lead to accidents.

- Safety Protocols: I strictly adhere to all safety regulations, including wearing appropriate PPE (Personal Protective Equipment), such as high-visibility clothing, safety glasses, and hearing protection. I also ensure the loader is in good working order and all safety features are functioning correctly. This ensures the safety of not just myself, but others too.

- Speed and Maneuvering: I operate the loader at a safe speed, appropriate to the conditions, avoiding abrupt movements that could cause instability or endanger others. I always use caution during turning maneuvers and close-quarters operations.

Regular safety meetings and training refreshers are critical to maintain a high level of safety awareness.

Q 24. Describe your experience with using GPS or other technology integrated with loaders.

I have extensive experience using GPS and other technology integrated with loaders. This technology significantly enhances efficiency and precision in various applications.

- GPS Guidance Systems: These systems guide the loader’s movements with high accuracy, enabling precise placement of materials and minimizing spillage. This is particularly useful in applications such as grading, trenching, or stockpile management. For example, I used a GPS-guided loader to precisely level a large area for a construction project, significantly reducing the time and labor required.

- Machine Monitoring Systems: Telematics and machine monitoring systems provide real-time data on the loader’s performance, including fuel consumption, operating hours, and potential maintenance issues. This allows for proactive maintenance planning and optimization of fuel efficiency. Think of it like having your vehicle’s engine information dashboard right there in real-time.

- Payload Management Systems: Some loaders are equipped with systems that accurately measure the weight of each load, preventing overloading and improving operational efficiency. This is incredibly important for avoiding damage to the machine and ensures the load is always within weight limits.

These technologies not only improve efficiency but also contribute to safer operation by reducing operator workload and providing valuable data for improved safety procedures. The data generated helps identify areas for improvement in our processes, which leads to safer and more efficient operations overall.

Q 25. How do you stay updated with the latest safety regulations and best practices in loader operation?

Staying updated on safety regulations and best practices is an ongoing commitment. I utilize several methods to ensure my knowledge is current.

- Regular Training Courses: I actively participate in training courses and workshops offered by equipment manufacturers, industry associations, and regulatory bodies. This includes both classroom-based and online learning modules. Keeping my skills up-to-date is crucial for operational efficiency and safety.

- Industry Publications and Websites: I regularly read industry publications, journals, and websites to stay informed about new regulations, technologies, and best practices. This ensures I’m aware of the latest advancements and emerging trends.

- Networking with Other Professionals: Networking with other operators and professionals at industry events and conferences provides opportunities to share experiences and learn from best practices.

- Compliance Audits: Participating in regular compliance audits and safety inspections ensures I’m adhering to the latest standards and identifying any potential areas for improvement.

Proactive approach to safety is essential and requires continuous learning and adaptation. Staying current with regulations and best practices ensures compliance and minimizes risks.

Q 26. What are your salary expectations for this loader operator position?

My salary expectations are in line with the industry standard for experienced loader operators with my skill set and experience in this region. I’m open to discussing a competitive compensation package that reflects my value and contributions to the company.

Q 27. What are your career goals related to operating loaders and heavy equipment?

My career goals involve continued growth and advancement in the heavy equipment operating field. I aim to enhance my skills and expertise, potentially obtaining specialized certifications. I aspire to take on more leadership roles, possibly supervising a team of operators or mentoring new hires. Long-term, I envision myself as a highly skilled and respected operator contributing to large-scale construction and infrastructure projects.

Q 28. Are there any questions you have for me about this loader operator position?

Yes, I have a few questions. First, could you elaborate on the specific types of loaders used in this role? Secondly, what are the company’s safety protocols and training programs for loader operators? Finally, what are the typical project durations and the potential for overtime?

Key Topics to Learn for Operating Loaders Interview

- Machine Operation & Safety: Understanding the controls, pre-operational checks (including safety inspections), and safe operating procedures for various loader types (e.g., wheel loaders, backhoe loaders).

- Load Handling & Stability: Practical application of techniques for efficient loading and unloading, maintaining stability during operation, and understanding load capacity limitations to prevent tipping or accidents.

- Maintenance & Troubleshooting: Basic preventative maintenance procedures, recognizing common mechanical issues, and understanding the importance of reporting malfunctions promptly.

- Attachment Usage & Application: Familiarity with different attachments (buckets, forks, grapple, etc.) and their appropriate use in various applications (e.g., construction, demolition, material handling).

- Site Awareness & Communication: Understanding site safety regulations, effective communication with colleagues and supervisors, and awareness of surroundings to avoid collisions or accidents.

- Regulations & Compliance: Knowledge of relevant health and safety regulations, operating permits, and environmental considerations specific to operating loaders.

- Fuel Efficiency & Optimization: Techniques to maximize fuel efficiency through appropriate operation and maintenance practices.

- Problem-Solving & Decision-Making: Approaches to problem-solving during operation, including identifying and addressing potential hazards and making informed decisions in dynamic situations.

Next Steps

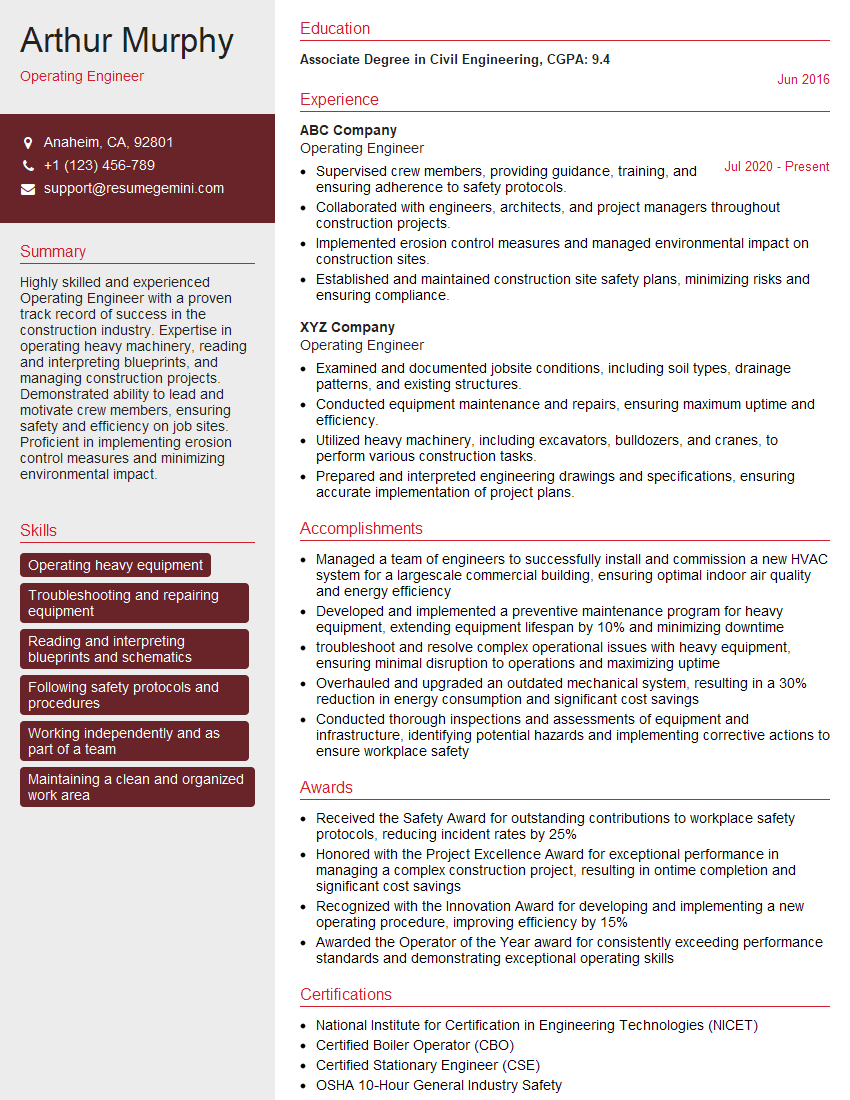

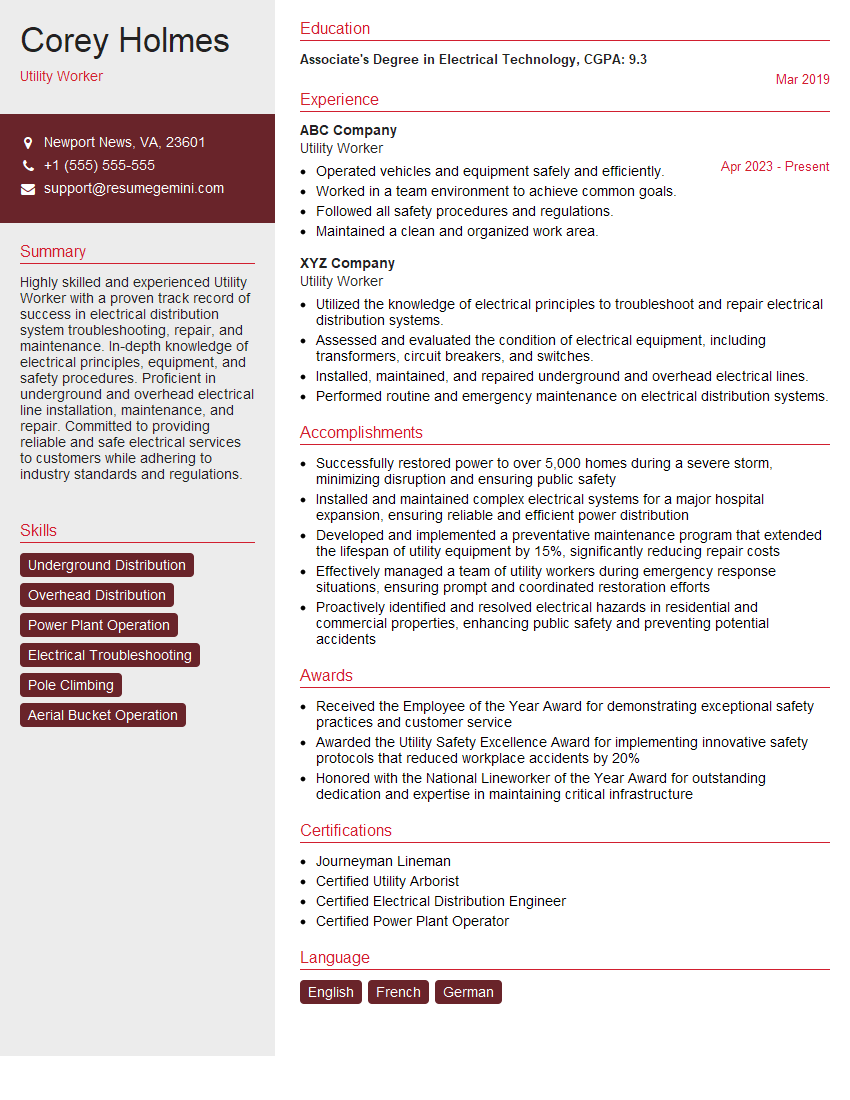

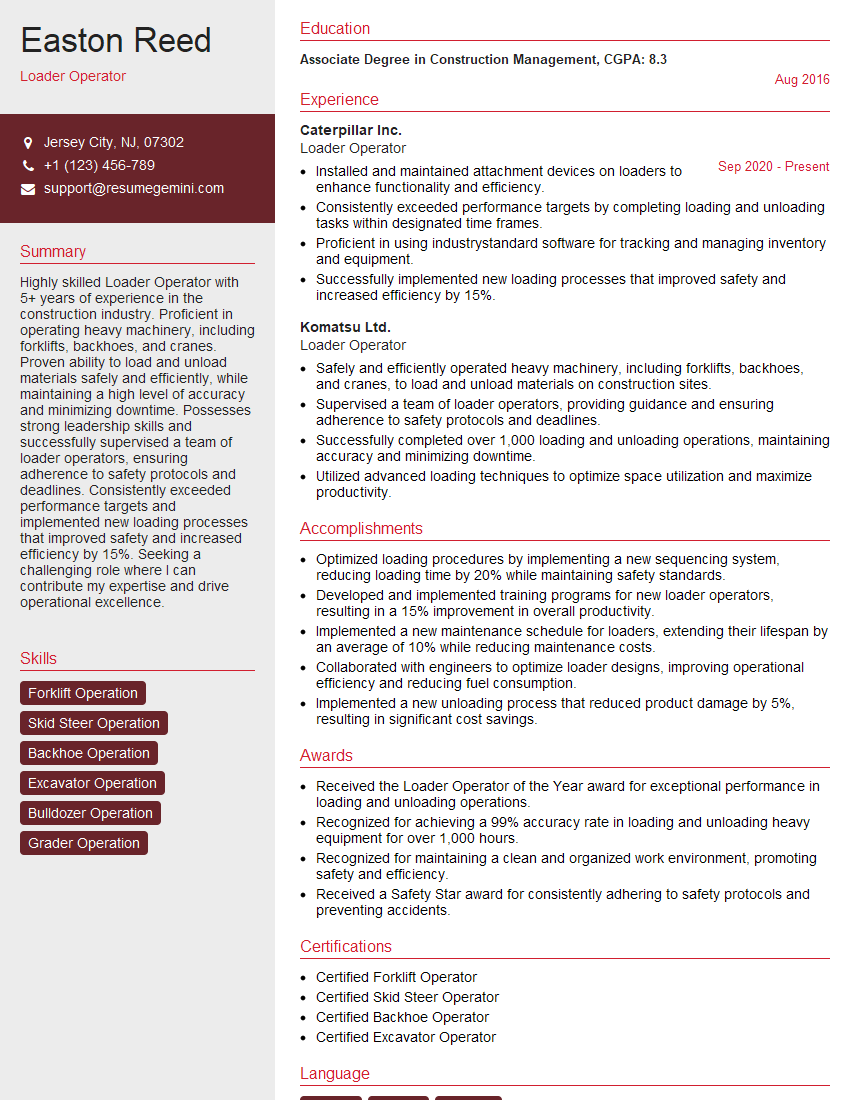

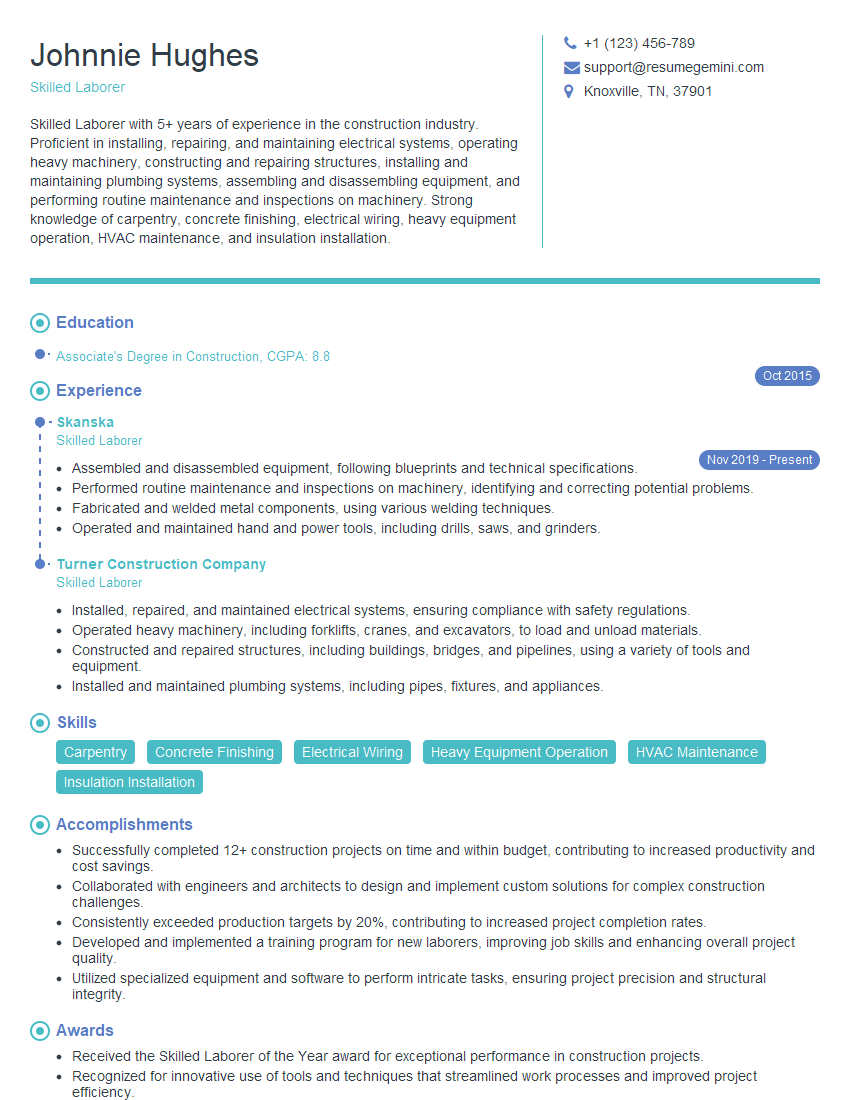

Mastering the operation of loaders opens doors to diverse and rewarding career opportunities within construction, logistics, and material handling industries. To significantly boost your job prospects, it’s crucial to create a resume that stands out and is easily parsed by Applicant Tracking Systems (ATS). ResumeGemini can help you craft a professional and ATS-friendly resume tailored to highlight your skills and experience in Operating Loaders. We provide examples of resumes specifically designed for this field to help you present yourself effectively to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good