Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Operation and Maintenance of Naval Gun Weapons Systems interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Operation and Maintenance of Naval Gun Weapons Systems Interview

Q 1. Describe the process of conducting a preventative maintenance check on a naval gun system.

Preventative maintenance (PM) on a naval gun system is crucial for ensuring its readiness and preventing costly breakdowns. It’s a systematic process involving visual inspections, functional tests, and lubrication, all documented meticulously. Think of it like a regular health check-up for the gun.

- Visual Inspection: This involves checking for corrosion, wear and tear on components, loose bolts, hydraulic leaks, and any signs of damage to the barrel, breech mechanism, or other parts. We’re looking for anything out of the ordinary.

- Functional Tests: This stage involves actually operating parts of the system to verify their proper function. This might include cycling the breech mechanism, testing the elevation and traversing systems, and checking the operation of safety mechanisms. We’re making sure everything moves as it should.

- Lubrication: Proper lubrication is essential for reducing friction and wear. Specific lubricants are used depending on the component and environmental conditions. We use specialized greases and oils designed for marine environments to combat corrosion.

- Documentation: Every step of the PM process is meticulously documented, including readings from any measuring instruments used, observations made during the inspections, and the type and quantity of lubricants used. This ensures traceability and accountability.

For instance, during a PM check on a Mark 45 gun, we would pay close attention to the condition of the barrel rifling, ensuring it’s free from obstructions or damage. We would also test the hydraulic system to make sure that the gun elevates and traverses smoothly and accurately.

Q 2. Explain the function of the fire control system in a naval gun.

The fire control system (FCS) is the brain of the naval gun, responsible for accurately aiming and firing the weapon. It’s a complex system that integrates data from various sensors to calculate the precise aiming solution, considering factors like target range, speed, bearing, wind, and even the motion of the ship itself. Imagine it as a highly sophisticated targeting system that makes sure every shot counts.

The FCS typically includes:

- Radar: Provides target range and bearing information.

- Optical Sights: Offer visual confirmation of the target.

- Fire Control Computer: Processes all the data to calculate the firing solution.

- Actuators: Move the gun to the calculated aiming position.

The computer continuously updates the aiming solution, compensating for the movement of the target and the ship. This ensures that even while the ship is rolling and pitching in rough seas, the gun remains accurately aimed at the target.

Q 3. What are the common malfunctions encountered in naval gun systems, and how are they diagnosed?

Naval gun systems, being complex electromechanical systems, can experience a variety of malfunctions. These can range from relatively minor issues to critical failures. Diagnosis involves a systematic approach, starting with a thorough inspection and moving towards more in-depth troubleshooting. Think of it as a medical diagnosis for a patient—we need to find the root cause.

- Malfunctions: Common malfunctions include hydraulic leaks, malfunctions in the breech mechanism (failure to open or close properly), problems with the aiming system (inaccurate pointing), ammunition feeding issues (jams or misfires), and electrical faults in the control systems.

- Diagnosis: Diagnosis begins with a visual inspection, followed by functional checks. Built-in diagnostics and error codes often provide clues. Specialized tools and instruments such as pressure gauges, multimeters, and borescopes are used to pinpoint the problem. Technical manuals and troubleshooting guides are vital resources.

For example, if the gun fails to fire, the diagnosis might involve checking the ammunition, the firing circuit, the electrical connections, and the condition of the firing pin. A hydraulic leak would require a visual inspection to locate the leak point, followed by pressure testing to determine the extent of the damage.

Q 4. How do you troubleshoot a malfunctioning aiming system?

Troubleshooting a malfunctioning aiming system requires a methodical approach. It’s like detective work, systematically eliminating possible causes. We start with the simplest checks and proceed to more complex ones.

- Check for Obstructions: Ensure there are no obstructions hindering the movement of the gun or the operation of the sensors.

- Verify Power and Connections: Check power supplies, fuses, and electrical connections to the aiming system’s components.

- Inspect Sensors: Carefully examine the radar, optical sights, and other sensors for any damage or misalignment.

- Test Actuators: Verify that the actuators responsible for moving the gun are functioning correctly and not binding or malfunctioning.

- Check Fire Control Computer: Test the computer’s internal diagnostics. Error codes can provide valuable clues to the problem.

- Calibration: If the problem persists, recalibration of the aiming system might be necessary. This process is typically done using specialized equipment and procedures.

If the problem isn’t resolved after these steps, more advanced diagnostics and potentially specialized personnel might be required.

Q 5. Describe the safety procedures for handling ammunition in a naval environment.

Ammunition handling in a naval environment demands strict adherence to safety procedures to prevent accidents. It’s critical to follow established protocols rigorously. Think of it as handling highly sensitive material. Any lapse in procedure could have disastrous consequences.

- Designated Personnel: Only authorized and trained personnel are permitted to handle ammunition.

- Proper Storage: Ammunition is stored in designated magazines under strictly controlled environmental conditions to prevent corrosion and degradation.

- Personal Protective Equipment (PPE): Appropriate PPE, including gloves, eye protection, and hearing protection, must be worn when handling ammunition.

- Fire Prevention: Smoking and open flames are strictly prohibited in ammunition handling areas.

- Grounding: Static electricity can be a hazard. Ammunition handling areas may require grounding procedures.

- Emergency Procedures: Everyone involved must be thoroughly trained in emergency procedures in case of an accident or fire.

The specific safety procedures will vary depending on the type of ammunition and the naval vessel, but the overall principles of careful handling, proper storage, and strict adherence to regulations are always paramount.

Q 6. What are the different types of naval gun ammunition, and their respective applications?

Naval gun ammunition varies widely depending on the target and the desired effect. Each type has specific properties and applications. Think of them like specialized tools for different jobs.

- High-Explosive (HE): Designed to produce a large explosion upon impact, effective against surface targets and some lightly armored structures.

- High-Explosive Incendiary (HEI): Combines the explosive power of HE with an incendiary component to start fires.

- Armor-Piercing (AP): Features a hard, dense core designed to penetrate armor plating.

- Armor-Piercing Incendiary (API): Combines the armor-piercing capabilities of AP with an incendiary element.

- Illuminating (ILLUM): Contains a flare that illuminates the target area at night or in low-visibility conditions.

- Practice Rounds: These rounds are used for training purposes and are designed to be less destructive than live ammunition.

The selection of ammunition depends on the mission, target type, and desired outcome. For example, AP rounds might be used against heavily armored targets, while HE rounds are more appropriate for lightly armored targets or structures.

Q 7. Explain the process of loading and unloading ammunition for a specific naval gun system (e.g., Mark 45).

The loading and unloading process for a specific naval gun system like the Mark 45 is a highly standardized and safety-critical procedure. It’s a delicate balance of precision and safety. Every step is meticulously planned to prevent accidents.

The process typically involves:

- Preparation: The gun is prepared for loading by ensuring it is properly aimed and secured.

- Ammunition Handling: Trained personnel use specialized equipment to carefully handle and transfer ammunition rounds from the magazine to the loading mechanism of the gun.

- Loading: The loading mechanism automatically (or semi-automatically, depending on the specific configuration) inserts the round into the breech.

- Breech Closure: The breech mechanism securely closes and locks, ensuring the round is correctly positioned for firing.

- Unloading: The process is reversed for unloading. The breech mechanism is opened, and the round is carefully removed and returned to the magazine or a designated storage area. All procedures are strictly followed to ensure safe handling.

Throughout the entire process, safety precautions are strictly followed. This includes using designated pathways and equipment, following strict communication protocols, and ensuring proper safety checks at each stage. Improper handling can lead to serious accidents.

Q 8. How do you ensure the accuracy and precision of a naval gun system?

Ensuring the accuracy and precision of a naval gun system is a multifaceted process involving meticulous attention to detail at every stage, from initial design to ongoing maintenance. It’s like aiming a high-powered rifle – even a slight misalignment can drastically affect the outcome.

Regular Calibration and Testing: We conduct frequent tests using laser rangefinders and sophisticated targeting systems to verify the accuracy of the gun’s aiming mechanisms. This involves firing test rounds at various ranges and analyzing the impact points to detect any deviations. Any adjustments needed are made to the sighting mechanisms or the fire control system.

Barrel Condition: The barrel’s condition directly impacts accuracy. Erosion, pitting, and even minor imperfections can affect projectile trajectory. Regular inspection, cleaning, and, when necessary, re-lining are crucial. Think of it like keeping a finely tuned instrument – any damage impacts performance.

Fire Control System Maintenance: The fire control system, the ‘brain’ of the weapon, must be perfectly functioning. This includes radars, computers, and other sensors. Regular checks, updates, and calibrations of the software and hardware are non-negotiable to ensure accurate targeting solutions. A malfunction here could mean a miss by miles.

Environmental Factors Compensation: Environmental conditions like wind speed, temperature, and humidity can influence projectile trajectory. Modern fire control systems incorporate algorithms to compensate for these variables, ensuring accuracy even in challenging conditions. It’s like adjusting your aim based on the wind blowing your arrow off-course.

Ammunition Quality Control: Consistent ammunition quality is critical. Defects in the ammunition can lead to erratic flight paths and reduced accuracy. Strict quality control measures are in place to ensure that only suitable ammunition is used.

Q 9. Describe the various types of fire control radars used in naval gun systems.

Naval gun systems employ a variety of fire control radars, each with specific roles and capabilities. These radars are the eyes of the system, providing the targeting information needed for accurate fire.

Target Acquisition Radars: These radars search for and locate targets, providing initial range and bearing data. They’re like the initial scout, providing the general location of the enemy.

Tracking Radars: Once a target is acquired, tracking radars continuously monitor its position, velocity, and course, providing updated data to the fire control computer. This is the steady hand, keeping the target in sight.

Gun-laying Radars: These radars provide precise aiming data to the gun, ensuring the projectile reaches the target. They’re the ultimate precision instrument, ensuring the shot is on target.

Illumination Radars: Some systems employ illumination radars to guide semi-active radar homing projectiles. These illuminate the target, allowing the projectile to lock onto it. Think of it as providing a spotlight for the projectile to follow.

The specific types and configurations of these radars vary based on the naval gun system and its intended purpose. For example, a close-in weapon system might prioritize rapid target acquisition and tracking, while a long-range naval gun would require more sophisticated and powerful radars with extended range capabilities.

Q 10. Explain the concept of ballistic trajectory and its relevance to naval gunnery.

Ballistic trajectory describes the path a projectile follows under the influence of gravity and other forces. Understanding this is fundamental to naval gunnery, as it allows us to accurately predict where a projectile will land. Imagine throwing a baseball – its path isn’t a straight line, but a curve influenced by gravity and air resistance.

In naval gunnery, we must consider several factors affecting the ballistic trajectory:

Gravity: The primary force causing the projectile to fall back to earth. We must calculate the time of flight and adjust for this accordingly.

Air Resistance: Air friction slows the projectile down, affecting its range and accuracy. This is more significant at longer ranges.

Wind: Wind can significantly deflect the projectile’s path. Our fire control systems compensate for this by measuring wind speed and direction.

Coriolis Effect: The Earth’s rotation affects long-range trajectories, requiring corrections to ensure accuracy. This is particularly important for longer ranges and larger caliber guns.

Muzzle Velocity: The speed at which the projectile leaves the barrel greatly influences its trajectory and range.

Fire control computers use sophisticated algorithms and ballistics tables to calculate the necessary firing angles and adjustments to compensate for these factors. Accurate trajectory prediction is essential for successful naval gunnery.

Q 11. How do you maintain the structural integrity of a naval gun system?

Maintaining the structural integrity of a naval gun system is critical for safety and operational effectiveness. It’s like maintaining the structural integrity of a bridge—it’s about preventing failure and ensuring the longevity of the weapon.

Regular Inspections: We conduct meticulous visual inspections to detect any signs of wear, corrosion, or damage. This involves examining every component of the gun, from the barrel to the mounting structure.

Non-Destructive Testing (NDT): Advanced techniques like ultrasonic testing and radiography are used to identify internal flaws or defects that might not be visible to the naked eye. This is like an X-ray for the gun, revealing hidden issues.

Stress Analysis: Regular stress analysis helps us assess the gun’s ability to withstand the forces generated during firing. It’s akin to assessing the load-bearing capacity of a structure.

Preventive Maintenance: A rigorous preventive maintenance schedule ensures that all components are properly lubricated and function correctly. This minimizes wear and tear and extends the service life of the weapon. This is like regularly servicing a car to prevent breakdowns.

Corrosion Control: Naval environments are extremely corrosive. We employ protective coatings, regular cleaning, and cathodic protection to minimize corrosion and maintain structural integrity.

Q 12. Describe your experience with hydraulic and pneumatic systems in naval guns.

Hydraulic and pneumatic systems are integral to the operation of many naval gun systems, providing the power for critical functions like elevating, traversing, and loading. Think of them as the muscles of the weapon system.

Hydraulic Systems: These systems use pressurized hydraulic fluid to generate the force needed for moving heavy components. Regular maintenance involves checking fluid levels, inspecting hoses and seals for leaks, and ensuring proper operation of hydraulic pumps and valves. A leak in the hydraulic system could render the gun immobile.

Pneumatic Systems: Pneumatic systems use compressed air to power various functions, often for smaller movements or for operating auxiliary systems. Maintenance includes checking air pressure, inspecting air lines for leaks, and ensuring the proper function of air compressors and valves. Air leaks can reduce the efficiency or even damage the system.

My experience involves troubleshooting malfunctions, conducting preventative maintenance, and performing repairs on both hydraulic and pneumatic systems. I’m proficient in diagnosing problems, identifying faulty components, and making the necessary repairs to restore full functionality. Understanding the intricacies of these systems is crucial for keeping naval guns operating smoothly and safely.

Q 13. What are the environmental factors that affect the performance of naval gun systems?

The marine environment presents numerous challenges to the performance of naval gun systems. These environmental factors can significantly impact accuracy, reliability, and longevity.

Saltwater Corrosion: The constant exposure to saltwater leads to rapid corrosion of metallic components. This necessitates regular cleaning, protective coatings, and cathodic protection to mitigate this.

Extreme Temperatures: Naval guns may operate in extremely high or low temperatures, affecting the performance of lubricants and other materials. We use specialized lubricants and materials designed to withstand these temperature extremes.

High Humidity: High humidity contributes to corrosion and can impact the performance of electronic components. We use sealed enclosures and desiccant packs to protect sensitive electronics.

Wind and Sea State: Wind and wave action can affect aiming accuracy and the stability of the gun platform. Modern fire control systems incorporate algorithms to compensate for these environmental factors.

Salt Spray and Airborne Debris: These can contaminate and damage moving parts, reducing performance. Regular cleaning and preventative maintenance are crucial.

Understanding and mitigating the effects of these environmental factors are crucial for ensuring the operational readiness and longevity of naval gun systems. We use a combination of preventative maintenance, protective measures, and sophisticated compensation algorithms to ensure that the guns perform reliably, even under the most challenging conditions.

Q 14. Explain the process of cleaning and lubricating a naval gun barrel.

Cleaning and lubricating a naval gun barrel is a crucial maintenance procedure that directly impacts accuracy, lifespan, and safety. It’s like regularly cleaning and oiling a high-precision rifle barrel to maintain its accuracy and prevent wear. Improper cleaning can lead to malfunctions and damage.

Safety First: Always ensure the weapon is completely unloaded and rendered safe before commencing cleaning.

Initial Inspection: Visually inspect the bore for any damage, obstructions, or excessive fouling.

Cleaning Solvents: Use appropriate solvents, specifically designed for the type of propellant used. Follow the manufacturer’s recommendations carefully.

Cleaning Rods and Patches: Utilize specialized cleaning rods and patches to remove residue and fouling from the bore. Avoid excessive force to prevent damage to the barrel.

Thorough Cleaning: Continue the cleaning process until patches emerge clean. This might require several passes.

Drying: Thoroughly dry the bore using dry patches to prevent corrosion.

Lubrication: Apply a suitable gun barrel lubricant to the bore, ensuring an even coating. This protects the barrel from corrosion and ensures smooth projectile movement.

Final Inspection: Perform a final inspection to ensure the barrel is clean, dry, and properly lubricated.

The frequency of cleaning depends on the gun’s use and the type of propellant, but regular cleaning is essential for maintaining optimal performance and extending the barrel’s lifespan. Ignoring this crucial step can lead to decreased accuracy, premature wear, and potential malfunctions.

Q 15. How do you conduct a post-firing inspection of a naval gun system?

A post-firing inspection of a naval gun system is critical for ensuring its continued safe and effective operation. It’s essentially a thorough check-up after the weapon has been fired, identifying any potential issues before they escalate into major problems. Think of it like a post-workout check-up for a high-performance athlete.

The inspection typically involves several key steps:

- Visual Inspection: A careful examination of the gun barrel for any signs of damage, erosion, or deformation. We look for cracks, pitting, or bulging. We also check the breech mechanism for any signs of wear or damage, paying close attention to the breech block and locking mechanism.

- Bore Inspection: Using a bore scope, we thoroughly inspect the inside of the barrel for any obstructions, damage, or signs of excessive wear. This helps identify potential problems early on, such as rifling damage or residue buildup.

- Mechanism Check: We check the functionality of all moving parts, including the elevation and traverse mechanisms, recoil system, and loading mechanism. This often involves operational tests under controlled conditions.

- Ammunition Check: If any ammunition remains, we inspect it for damage and ensure it’s properly stored. Any spent casings are collected and accounted for.

- Documentation: All findings are meticulously documented, including any identified issues or necessary maintenance actions. This detailed record is essential for tracking the gun’s condition and predicting future maintenance needs.

During one inspection, we discovered a minor crack in the breech block of a 5-inch gun after a series of rapid firing exercises. Early detection allowed for a timely repair, preventing a potentially serious malfunction during a critical operation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different types of gun mounts and their maintenance?

My experience encompasses various gun mounts, from the older, hydraulically powered systems to the more modern, digitally controlled ones. Each type presents unique maintenance challenges.

- Hydraulic Mounts: These require regular checks of hydraulic fluid levels, pressure, and leaks. Maintenance involves understanding hydraulic schematics and performing fluid changes, filter replacements, and leak detection and repair. For example, I’ve worked extensively with the hydraulic systems in Mk 45 caliber guns, focusing on preventative maintenance to avoid catastrophic fluid loss.

- Electric/Electro-Hydraulic Mounts: These systems combine hydraulic power with electronic controls, adding a layer of complexity. Maintenance includes troubleshooting electrical and electronic components, calibrating sensors, and ensuring proper software operation. I’ve been involved in the maintenance of the Phalanx CIWS system, where understanding both the hydraulic and electronic components was essential for effective troubleshooting.

- Digital Control Systems: These systems utilize advanced digital controls, requiring specialized software and diagnostic tools. Maintenance involves software updates, network diagnostics, and sensor calibration. I’ve worked with modern systems that use advanced predictive maintenance tools, which help forecast potential issues based on data analysis.

Understanding the specific design and operational characteristics of each type of mount is crucial for effective maintenance. Failure to do so can lead to system malfunctions and potential safety hazards.

Q 17. Describe the procedures for handling and disposing of damaged or spent ammunition.

Handling and disposing of damaged or spent ammunition is a critical safety procedure. It requires strict adherence to established safety protocols and regulations.

- Damaged Ammunition: Damaged ammunition should never be handled directly. We use specialized tools and protective gear. The ammunition is carefully contained and reported to the proper ordnance disposal unit for safe destruction. Improper handling could lead to an explosion.

- Spent Ammunition: Spent casings and other spent ammunition components are collected, accounted for, and disposed of according to established procedures. This often involves segregation based on ammunition type and environmental regulations.

- Safety Procedures: All personnel involved are trained in the safe handling of ammunition, and strict safety protocols are followed during collection, transportation, and disposal. This includes personal protective equipment, such as gloves and eye protection, as well as safety barriers.

- Documentation: Detailed records are maintained for all ammunition handling and disposal activities. This documentation is crucial for accountability and traceability.

During one instance, a faulty round jammed in the breech mechanism. Following established procedures, we carefully extracted the round using dedicated tools and deactivated it before disposal. Proper training and adherence to safety protocols prevented a serious incident.

Q 18. How do you ensure the proper functioning of the gun’s elevation and traverse mechanisms?

Ensuring proper functioning of elevation and traverse mechanisms is crucial for accurate fire control. These mechanisms allow the gun to be aimed accurately at the target.

- Regular Lubrication: Proper lubrication is essential to reduce friction and wear on moving parts. We follow manufacturer’s recommendations on lubrication frequency and type of lubricant.

- Functional Checks: Regular functional checks are performed to verify smooth and accurate operation. This typically involves manual and automated tests of the mechanisms’ range of motion and response times.

- Calibration: Periodic calibration ensures the accuracy of the elevation and traverse systems. This usually involves using specialized equipment to align the gun’s pointing system to a reference point.

- Troubleshooting: Troubleshooting involves diagnosing the root cause of malfunctions and implementing the necessary repairs or replacements. This might include checking electrical connections, hydraulic pressure, or mechanical linkages.

For instance, during a routine inspection, we detected a slight binding in the traverse mechanism. After lubrication and adjustment, the issue was resolved, ensuring the gun’s continued accuracy.

Q 19. What is your experience with troubleshooting electrical issues in naval gun systems?

Troubleshooting electrical issues requires a systematic approach, combining theoretical knowledge with practical experience. We use a combination of diagnostic tools and techniques to isolate and resolve problems.

- Diagnostic Tools: We utilize multimeters, oscilloscopes, and specialized diagnostic software to identify electrical faults. This helps pinpoint the source of the problem, whether it’s a faulty sensor, a broken wire, or a malfunctioning circuit board.

- Schematic Diagrams: Detailed schematic diagrams are invaluable tools for tracing circuits and identifying components. They are essential for understanding the electrical system’s architecture and for pinpointing potential failure points.

- Systematic Approach: We employ a systematic approach to troubleshooting, starting with visual inspections and moving on to more advanced diagnostic techniques. This prevents random guesswork and ensures efficient problem-solving.

- Safety Procedures: Safety is paramount. We always follow appropriate safety protocols when working with high-voltage systems, ensuring the safety of personnel and the equipment.

In one case, we encountered intermittent failures in the gun’s elevation control system. Using a combination of diagnostic tools and schematic diagrams, we traced the fault to a corroded connection in the wiring harness. Replacing the harness resolved the issue.

Q 20. Describe your experience with the use of technical manuals and schematics.

Technical manuals and schematics are the bible of naval gun system maintenance. They are indispensable tools for understanding system design, performing maintenance tasks, and troubleshooting malfunctions.

- System Understanding: Technical manuals provide a comprehensive overview of the system’s design, operation, and maintenance procedures. This knowledge is essential for effective maintenance and troubleshooting.

- Maintenance Procedures: They contain detailed instructions for performing various maintenance tasks, from routine inspections to major overhauls. Following these procedures ensures proper maintenance and prolongs the system’s lifespan.

- Troubleshooting: Schematics are crucial for troubleshooting electrical and mechanical problems. They help identify components, trace circuits, and diagnose malfunctions. They’re like a map for navigating the complex inner workings of the system.

- Parts Identification: Manuals and schematics assist in identifying and ordering spare parts, ensuring the right parts are used for repairs.

I’ve relied extensively on both technical manuals and schematics throughout my career. They are invaluable resources for completing my tasks efficiently and safely, ensuring the systems remain operational and effective.

Q 21. How do you manage inventory of spare parts for naval gun systems?

Managing inventory of spare parts for naval gun systems is critical for maintaining operational readiness. It’s a complex task that requires careful planning and execution.

- Inventory Control System: We utilize a computerized inventory control system to track all spare parts. This system provides real-time visibility into stock levels, allowing us to anticipate and manage potential shortages.

- Demand Forecasting: We use historical data and predictive models to forecast future demand for spare parts, allowing us to order parts proactively and avoid disruptions to maintenance operations.

- Parts Ordering: We follow established procedures for ordering spare parts, ensuring that parts are procured from reliable sources and meet quality standards.

- Storage and Handling: We maintain a secure and organized storage facility for spare parts, ensuring they are protected from damage and deterioration.

- Regular Audits: Regular audits are conducted to verify the accuracy of inventory records and identify any discrepancies.

Effective inventory management prevents costly downtime due to lack of parts. For instance, by implementing a robust forecasting model, we significantly reduced the frequency of emergency part orders, enhancing operational readiness.

Q 22. Explain the process of conducting a system functional test.

A system functional test for a naval gun weapon system is a comprehensive evaluation ensuring all components operate as designed and integrated correctly. It’s like giving the entire system a thorough health check before deployment.

The process typically involves several stages:

- Pre-test checks: This includes verifying power supply, ammunition readiness (dummy rounds are usually used during testing), and communication systems are functional. We’ll also inspect for any physical damage or anomalies.

- Sequential testing: Each subsystem—from the aiming systems and fire control computer to the loading mechanism and the gun barrel itself—is tested individually, following a predetermined sequence. This allows us to pinpoint problems quickly. We might test the elevation and traverse motors, the breech mechanism, and the firing circuit separately.

- Integrated testing: Once individual subsystems pass, we conduct integrated tests, simulating real-world scenarios. This might include tracking a target (simulated or real), executing a firing sequence, and verifying the accuracy of the projectile’s trajectory.

- Data analysis: All test data—sensor readings, firing data, and system logs—are meticulously analyzed to ensure performance meets specifications. This might reveal subtle inconsistencies that weren’t apparent during individual subsystem tests.

- Documentation: A detailed report is created, documenting the test procedure, results, and any corrective actions.

For example, during a functional test of a Mark 45 Mod 4 gun system, we would verify the accuracy of the laser rangefinder, the functionality of the automated loading system, and the effectiveness of the recoil system.

Q 23. What are the key performance indicators (KPIs) for a naval gun system?

Key Performance Indicators (KPIs) for a naval gun system are crucial for evaluating its effectiveness and readiness. They fall into several categories:

- Accuracy: Measured by the circular error probable (CEP), which indicates how closely shots cluster around the target point. A smaller CEP signifies higher accuracy.

- Rate of Fire: The number of rounds the system can fire per minute, crucial for suppressing enemy fire or engaging multiple targets quickly. This depends on the gun’s design and automation.

- Reliability: The probability that the system will function correctly when needed. This involves tracking mean time between failures (MTBF) and mean time to repair (MTTR).

- Availability: The percentage of time the system is operational and ready for use. This considers maintenance schedules and downtime.

- Survivability: The system’s ability to withstand damage and continue functioning. This might involve assessing the gun’s resistance to shock, impact, and enemy fire.

- Maintainability: How easily the system can be maintained, repaired, and upgraded, often reflected in maintenance time and resource requirements.

Imagine comparing two gun systems: System A boasts a higher rate of fire but lower accuracy, while System B prioritizes accuracy but has a lower rate of fire. The choice depends on the operational needs. For coastal defense, accuracy might be more critical than a rapid rate of fire.

Q 24. How do you ensure compliance with safety regulations during gunnery operations?

Ensuring compliance with safety regulations during gunnery operations is paramount. It’s not just about following procedures; it’s about protecting personnel and equipment.

Our safety protocols include:

- Strict adherence to safety manuals and procedures: These manuals outline safety precautions for each stage of operation, from ammunition handling to live-fire exercises.

- Thorough safety briefings: Before any operation, all personnel receive detailed briefings that cover potential hazards and emergency procedures. We use clear, concise language and visual aids to ensure everyone understands their roles.

- Regular safety inspections: We conduct regular inspections of the gun system, ammunition storage areas, and the surrounding environment to identify and rectify any potential hazards.

- Use of safety equipment: All personnel wear appropriate Personal Protective Equipment (PPE), including hearing protection, eye protection, and potentially specialized gear depending on the nature of the task.

- Emergency response plans: Comprehensive emergency response plans are in place to address scenarios such as accidental discharges, malfunctions, or fires. These plans detail communication protocols, evacuation procedures, and medical assistance.

- Range safety officers: Live-fire exercises are always overseen by trained range safety officers who monitor operations and ensure compliance with safety regulations.

For instance, before loading ammunition, we’ll always perform a thorough visual inspection, ensuring the rounds are of the correct type and are not damaged. We’ll also ensure that the gun is properly secured and personnel are positioned safely.

Q 25. Describe your experience in working with a team to maintain a naval gun system.

Teamwork is essential in maintaining a naval gun system. I’ve been part of several teams, each possessing unique strengths. Effective teamwork involves clear communication, defined roles, and mutual respect.

In one instance, our team faced a critical malfunction in the automated loading system of a 5-inch gun. Instead of assigning blame, we followed a structured troubleshooting approach. The electricians focused on the electrical circuitry, while the ordnance specialists examined the mechanical components. The engineers used diagnostic software to identify the root cause, which turned out to be a faulty sensor. Through collaboration and open communication, we resolved the issue within a few hours, minimizing operational downtime.

I’ve also been involved in preventative maintenance projects, where our team works collaboratively to schedule and execute maintenance tasks according to the manufacturer’s recommendations and our own best practices. This proactive approach prevents small issues from escalating into major problems, enhancing the system’s reliability and operational readiness. We utilize a computerized maintenance management system (CMMS) to track all maintenance activities and parts inventory.

Q 26. How do you handle emergency situations during gunnery operations?

Handling emergency situations during gunnery operations requires quick thinking, decisive action, and adherence to established protocols. This is where training and experience truly shine.

My approach involves:

- Immediate assessment of the situation: Determine the nature and severity of the emergency—is it a malfunction, an accidental discharge, a fire, or something else?

- Initiating emergency procedures: Follow established emergency procedures relevant to the situation. This might involve activating safety mechanisms, securing the weapon, or initiating emergency response protocols.

- Effective communication: Communicate clearly and concisely with the team, ensuring everyone understands their role in the emergency response. This involves using established communication channels and clear verbal instructions.

- Prioritization of safety: Prioritize the safety of personnel and the prevention of further damage. Evacuation may be necessary, depending on the situation.

- Post-incident analysis: Once the emergency is under control, a thorough post-incident analysis is conducted to determine the root cause, identify areas for improvement, and prevent future occurrences. This often involves writing detailed reports and participating in review boards.

For example, during a live-fire exercise, a malfunction in the firing mechanism occurred. We immediately ceased fire, secured the weapon, and evacuated the immediate area. Following established protocols, we then conducted a thorough investigation to identify the cause of the malfunction and implemented corrective actions.

Q 27. What is your understanding of the principles of gunnery and ballistics?

Gunnery and ballistics are fundamental to naval gun weapon systems. Gunnery involves the science and art of aiming and firing weapons accurately, while ballistics focuses on the projectile’s flight path and behavior.

My understanding encompasses:

- Interior ballistics: This deals with the forces and pressures within the gun barrel during firing. Understanding interior ballistics is crucial for optimizing projectile velocity and minimizing barrel wear.

- Exterior ballistics: This covers the projectile’s flight after leaving the barrel, considering factors like gravity, air resistance, wind, and the Earth’s rotation. Accurate prediction of projectile trajectory is essential for effective targeting.

- Terminal ballistics: This studies the projectile’s behavior upon impact with the target, encompassing penetration, fragmentation, and blast effects.

- Fire control systems: These integrate sensors, computers, and actuators to control the gun’s aiming and firing, compensating for environmental factors and target movement. A deep understanding of fire control systems is vital for accurate and efficient firing.

- Ammunition types and characteristics: Different ammunition types—high-explosive, armor-piercing, etc.—have different ballistic properties and are selected based on the target and mission requirements. I have a thorough understanding of the characteristics of various ammunition types and their impact on targeting calculations.

For example, understanding the effects of wind drift on projectile trajectory is crucial for adjusting aim in a live-fire exercise. A strong headwind will deflect the projectile, necessitating a corresponding change in aiming parameters.

Q 28. Explain your experience with different types of naval gun systems.

My experience encompasses various naval gun systems, including:

- Mark 45 Mod 4 5-inch gun: This highly automated system is known for its accuracy and rate of fire. I’ve been involved in its maintenance, troubleshooting, and functional testing, understanding its complex integrated systems.

- Mk 38 Mod 2 25mm chain gun: A smaller, rapid-fire system ideal for close-in defense against smaller threats. I’ve worked with this system, focusing on its maintenance and its role in integrated defense systems.

- Older legacy systems: I’ve also worked on older naval gun systems, providing insights into their operation, maintenance, and the challenges of maintaining obsolescent technology.

This experience allows me to compare and contrast the design features, operational capabilities, and maintenance requirements of different systems. I can analyze the advantages and disadvantages of each system based on its intended role and operational context. For example, while the Mk 45 offers superior range and accuracy, the Mk 38 is better suited for close-range defense due to its high rate of fire.

Key Topics to Learn for Operation and Maintenance of Naval Gun Weapons Systems Interview

- Weapon System Fundamentals: Understanding the operational principles of various naval gun systems, including their components, functionalities, and limitations. This includes theoretical knowledge of projectile ballistics and weapon system dynamics.

- Maintenance Procedures: Detailed knowledge of preventative maintenance schedules, troubleshooting common malfunctions, and performing repairs according to established protocols. Practical experience with diagnostic tools and equipment is crucial.

- Safety Procedures and Regulations: A thorough understanding of all safety regulations and protocols associated with handling, operating, and maintaining naval gun weapons systems. This includes familiarity with risk assessment and mitigation strategies.

- Fire Control Systems: Knowledge of the operation and maintenance of fire control systems, including radar, targeting, and tracking systems. Understanding the integration of these systems with the weapon system is essential.

- Ammunition Handling and Storage: Safe and efficient procedures for handling, storing, and managing ammunition, adhering to strict safety guidelines and regulations. This includes understanding the different types of ammunition and their properties.

- Troubleshooting and Problem-Solving: Demonstrating the ability to diagnose and resolve complex technical issues efficiently and effectively using systematic problem-solving approaches. This might include experience with fault isolation and repair techniques.

- Technical Documentation and Reporting: Experience in accurately documenting maintenance procedures, repairs, and any identified issues. This includes familiarity with technical manuals and reporting systems.

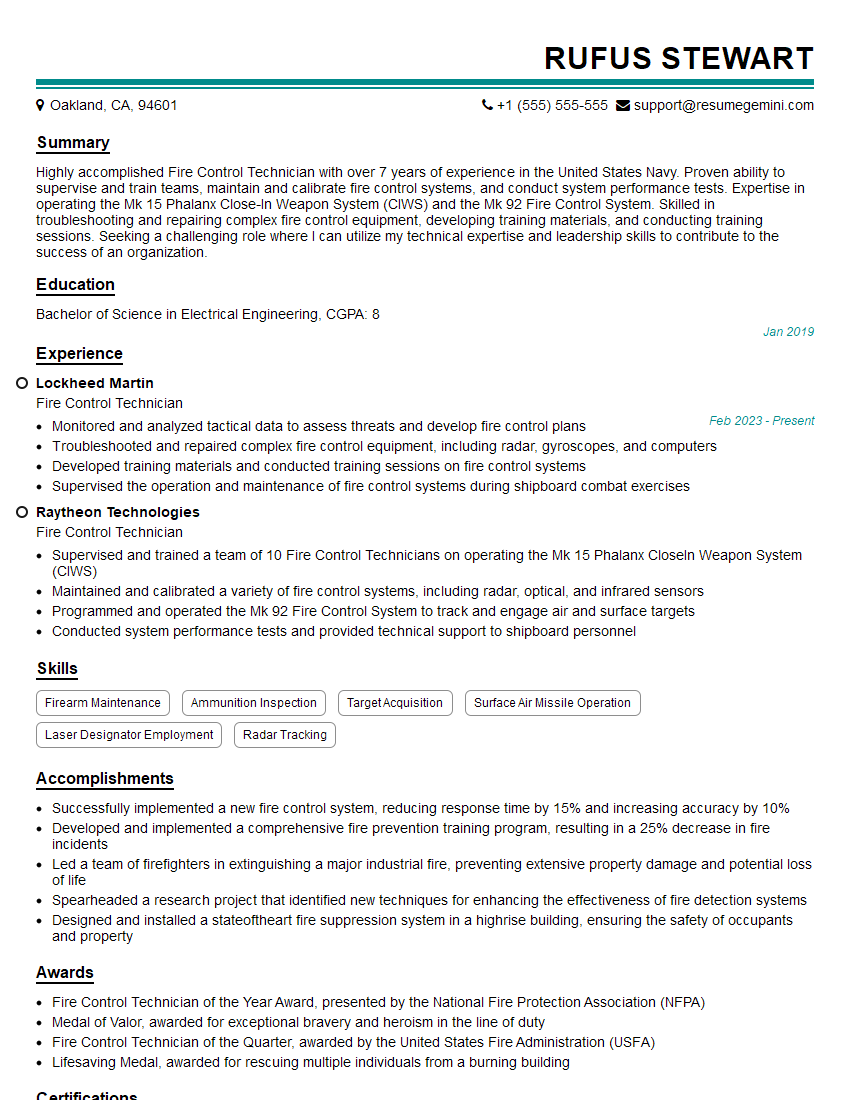

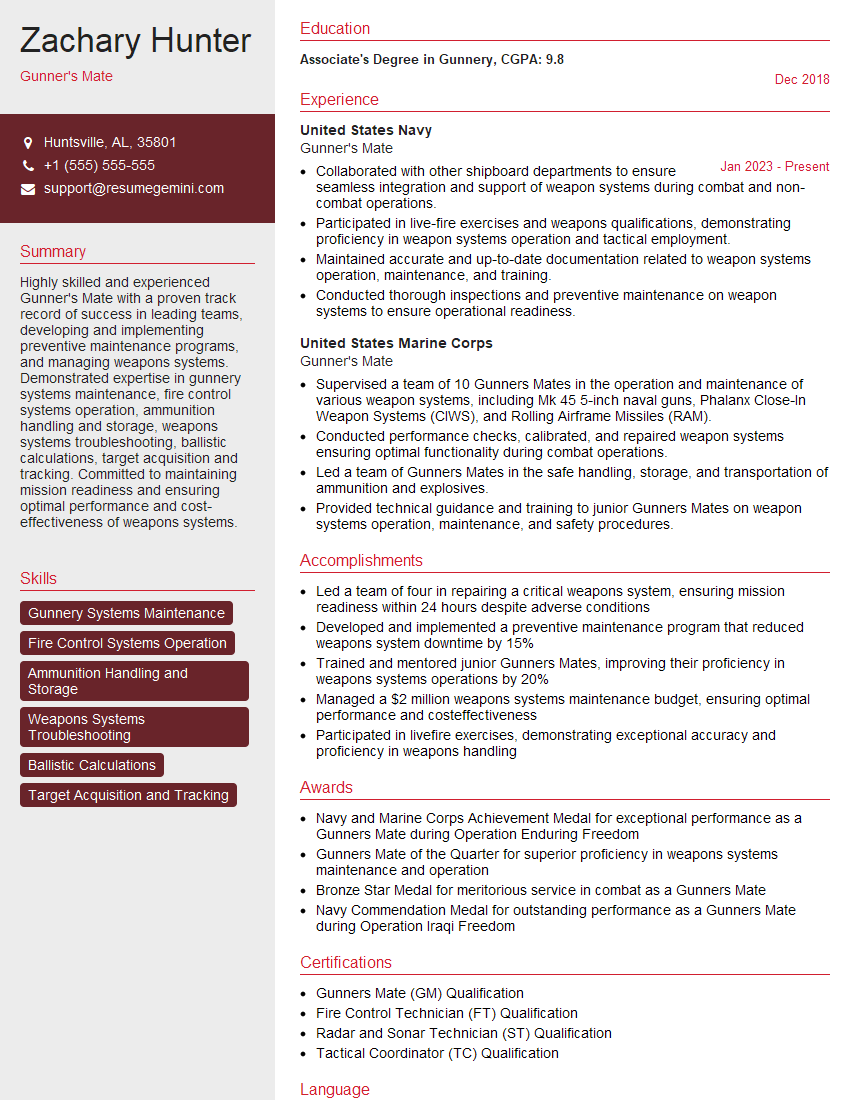

Next Steps

Mastering the operation and maintenance of naval gun weapons systems opens doors to exciting and challenging careers within the naval field, offering opportunities for specialization and advancement. To maximize your job prospects, crafting a compelling and ATS-friendly resume is vital. ResumeGemini can significantly enhance your resume-building experience, helping you create a document that showcases your skills and experience effectively. ResumeGemini offers examples of resumes tailored specifically to Operation and Maintenance of Naval Gun Weapons Systems, providing you with valuable templates and guidance. Invest time in crafting a strong resume – it’s your first impression to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good