The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Operation Supervision interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Operation Supervision Interview

Q 1. Describe your experience in optimizing operational processes.

Optimizing operational processes is about streamlining workflows to achieve maximum efficiency and effectiveness. It involves identifying bottlenecks, eliminating waste, and leveraging technology to improve outcomes. My approach is multi-faceted, beginning with a thorough assessment of the current state. This involves analyzing data, observing workflows, and interviewing stakeholders to understand pain points and areas for improvement.

For example, in a previous role managing a customer service team, we identified a significant delay in ticket resolution due to inefficient routing and a lack of standardized procedures. By implementing a new ticketing system with automated routing rules and creating comprehensive knowledge base articles, we reduced average resolution time by 40% and improved customer satisfaction scores by 15%. This involved not just technological upgrades, but also comprehensive training and process redesign.

Another key component is continuous improvement. I utilize methodologies like Lean and Six Sigma to systematically identify and eliminate waste. This includes regularly reviewing key performance indicators (KPIs) and making data-driven adjustments to optimize processes over time.

Q 2. How do you manage a team during a crisis or unexpected downtime?

Managing a team during a crisis, such as unexpected downtime, requires swift action, clear communication, and decisive leadership. My approach follows a structured framework. First, I assess the situation, identifying the root cause of the downtime and its impact on operations. Then, I assemble the relevant team members, establishing clear roles and responsibilities. Effective communication is crucial, ensuring everyone understands the situation, their role, and the overall plan.

For instance, during a major server outage at my previous company, I immediately activated our emergency response plan. This involved establishing a central communication hub using a dedicated Slack channel to ensure seamless information flow. We quickly identified the problem, isolated the affected systems, and implemented a temporary workaround while the engineers worked on a permanent fix. We also proactively communicated with our clients to keep them informed of the situation and estimated restoration time. Open, honest communication minimized panic and maintained trust. Transparency is key in maintaining team morale during stressful times.

Finally, a post-incident review is essential. We analyze the event to identify areas for improvement in our emergency response plan and prevent similar incidents in the future. This is a critical step in continuous improvement and ensuring preparedness for future challenges.

Q 3. Explain your approach to performance management and employee development.

My approach to performance management and employee development is based on a collaborative and supportive model. I believe in setting clear expectations, providing regular feedback, and fostering a culture of continuous learning. Performance reviews are not just annual events; they are ongoing conversations. I use a combination of methods, including regular one-on-one meetings, 360-degree feedback, and performance monitoring using relevant KPIs.

For employee development, I focus on identifying individual strengths and areas for growth. I tailor development plans to each employee’s aspirations and needs, providing opportunities for training, mentoring, and skill development. This might involve assigning challenging projects, sponsoring attendance at conferences, or providing access to online learning resources. I actively encourage employees to pursue professional certifications or further education relevant to their roles and career goals.

For example, I mentored a junior team member who expressed an interest in project management. I assigned her increasing responsibility in project planning and execution, provided her with relevant training materials, and regularly reviewed her progress. She eventually earned her PMP certification and is now a highly effective project manager within the team. This investment in employee development benefits both the individual and the organization.

Q 4. How do you prioritize tasks and allocate resources effectively?

Prioritizing tasks and allocating resources effectively is fundamental to operational success. I utilize several techniques, including the Eisenhower Matrix (urgent/important), which helps categorize tasks based on their urgency and importance. This allows me to focus on high-impact activities and delegate or defer less critical tasks. I also employ project management methodologies like Agile, adapting them to the specific context to ensure flexibility and responsiveness.

Resource allocation involves considering both human and material resources. I analyze the skills and availability of team members, matching individuals to tasks based on their expertise. For material resources, I consider factors such as budget constraints, availability, and potential bottlenecks. This often involves working closely with procurement and other support departments to ensure timely resource acquisition.

Transparency and communication are vital in resource allocation. I make sure that team members understand the rationale behind task assignments and resource priorities, fostering buy-in and collaboration. Regular progress tracking and adjustments ensure that resources are utilized efficiently and that project goals are met.

Q 5. What metrics do you use to measure operational efficiency?

Measuring operational efficiency involves tracking several key performance indicators (KPIs). The specific metrics vary depending on the context, but common examples include:

- Throughput: The amount of work completed per unit of time.

- Cycle time: The time it takes to complete a process from start to finish.

- Defect rate: The percentage of flawed outputs.

- On-time delivery rate: The percentage of projects or tasks completed on schedule.

- Customer satisfaction: Measured through surveys and feedback.

- Cost per unit: The cost of producing one unit of output.

- Resource utilization: The efficiency of resource usage (e.g., equipment, personnel).

Analyzing these metrics provides valuable insights into operational performance, highlighting areas for improvement and enabling data-driven decision-making. Regular reporting and dashboards are essential for monitoring progress and identifying trends.

Q 6. Describe a time you had to resolve a conflict within your team.

In a previous role, a conflict arose between two team members regarding project priorities. One team member, let’s call him Mark, felt his project was being unfairly deprioritized in favor of another team member’s, Sarah’s. The tension was impacting team morale and productivity.

My approach involved fostering open communication. I scheduled a meeting with both Mark and Sarah, encouraging them to express their concerns and perspectives in a respectful manner. I actively listened to each of their points of view, acknowledging their valid concerns. The core issue was a lack of clear communication regarding project deadlines and overall project objectives. We jointly reviewed the project timelines and adjusted priorities based on a clear understanding of overall goals and dependencies.

I helped them to reframe the conflict as a problem to be solved collaboratively, rather than a personal dispute. The key was to focus on finding a solution that balanced both their project needs within the overall organizational goals. By establishing clear expectations, fostering teamwork, and resolving the communication breakdown, we were able to restore positive working relationships and improve team productivity.

Q 7. How do you ensure adherence to safety regulations and protocols?

Ensuring adherence to safety regulations and protocols is paramount. My approach is multifaceted and starts with a strong safety culture. This means prioritizing safety above all else and creating an environment where employees feel empowered to report hazards and raise safety concerns without fear of reprisal. Regular safety training is crucial, covering relevant regulations, safe work practices, and emergency procedures. This training is tailored to specific roles and updated regularly to reflect changes in regulations or best practices.

I implement a robust system for tracking safety incidents, conducting thorough investigations, and taking corrective actions to prevent recurrence. This involves documenting near misses and implementing preventative measures. Regular safety audits are conducted to identify potential hazards and ensure compliance with regulations. We use checklists and standardized procedures to minimize the risk of human error.

Furthermore, I actively engage with regulatory bodies to ensure our practices are up-to-date and compliant. The use of appropriate safety equipment is mandated and its proper use is rigorously monitored. Ultimately, the success of a safe work environment depends on a collective commitment from every member of the team, starting with leadership demonstrating a visible and unwavering dedication to safety.

Q 8. How do you handle employee absenteeism and maintain productivity?

Addressing employee absenteeism requires a multi-pronged approach focusing on both prevention and mitigation. It begins with understanding the root causes. Is it due to illness, family emergencies, burnout, or dissatisfaction? I start by analyzing absenteeism data to identify trends – are certain days, departments, or shifts more affected? This helps pinpoint potential issues.

Prevention involves fostering a positive and supportive work environment. This includes promoting work-life balance, offering flexible work arrangements where possible, and providing opportunities for professional development to boost morale and engagement. Regular check-ins with employees are crucial, allowing for early identification of potential problems before they escalate into prolonged absences.

When absences do occur, clear communication channels are vital. I implement a robust system for reporting and tracking absences, ensuring prompt notification of supervisors. Depending on the reason, we explore options such as temporary replacements, redistribution of workload among colleagues, or leveraging remote work capabilities to minimize disruption. For recurring absences, I engage in confidential discussions with the employee to address underlying concerns and explore solutions collaboratively, possibly involving HR or employee assistance programs. Ultimately, the goal is to minimize the impact on productivity while supporting the well-being of our employees.

Q 9. Explain your experience with inventory management and control.

My experience with inventory management involves implementing and optimizing systems to ensure efficient tracking, control, and utilization of resources. I’ve worked with both manual and automated inventory management systems, employing techniques like FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) to manage stock rotation effectively, minimizing waste due to spoilage or obsolescence. In one previous role, we transitioned from a spreadsheet-based system to a cloud-based inventory management software. This drastically improved accuracy and reduced manual errors. The software automated reporting, generating real-time data on stock levels, allowing us to proactively identify low stock items and optimize our ordering processes.

Critical to effective inventory management is regular stocktaking and reconciliation. This ensures the physical inventory matches the recorded inventory, identifying discrepancies and allowing for timely corrective actions. Implementing robust quality control measures at every stage – from receiving to storage to dispatch – is also essential. This minimizes losses due to damage or defects. Finally, regular analysis of inventory data – identifying slow-moving items, predicting future demand, and optimizing storage space – allows for continuous improvement and cost reduction.

Q 10. How do you identify and address bottlenecks in operational workflows?

Identifying bottlenecks requires a systematic approach. I begin by carefully mapping the entire workflow, using tools like process flow diagrams or swim lane diagrams to visualize each step. This provides a clear picture of the entire process and helps to pinpoint areas of congestion. This could involve analyzing data on cycle times, identifying repetitive tasks, and observing the physical flow of materials or information. For example, if I see a high number of tasks piling up at a specific stage in the process, it suggests a bottleneck.

Once the bottleneck is identified, I use a combination of quantitative and qualitative methods to analyze the root cause. Is it a lack of resources, inefficient processes, poorly designed equipment, or inadequate training? After determining the root cause, I develop solutions, prioritizing interventions with the highest impact. This might involve investing in new equipment, re-engineering processes, providing additional training, or reorganizing personnel. After implementing solutions, I monitor the results closely, using key performance indicators (KPIs) to measure the effectiveness of the changes and make further adjustments as needed.

Q 11. Describe your approach to implementing new technologies or processes.

Implementing new technologies or processes requires a structured and phased approach. I start with a thorough needs assessment, clearly defining the problem and the expected outcomes of the new technology or process. This helps determine the feasibility of the implementation and secure buy-in from stakeholders. Then, I select the appropriate technology or process, taking into consideration cost, compatibility with existing systems, and training requirements.

A key aspect is change management. I engage employees early in the process, involving them in the selection and implementation stages. This helps mitigate resistance and fosters ownership. The implementation itself is typically phased, starting with a pilot program to test the new system or process in a limited environment. This allows for early identification and resolution of potential issues before full-scale deployment. Ongoing training and support are crucial to ensure successful adoption. Post-implementation, continuous monitoring and evaluation of the new technology or process, along with regular feedback sessions, ensure optimal performance and ongoing improvement.

Q 12. How do you track and analyze key performance indicators (KPIs)?

Tracking and analyzing KPIs is essential for monitoring operational performance and identifying areas for improvement. The specific KPIs used depend on the nature of the operation, but common examples include production output, cycle time, defect rate, customer satisfaction, and employee turnover. I use a combination of manual and automated methods to collect KPI data. Automated systems, like dashboards and reporting tools, provide real-time data, allowing for proactive interventions. Manual data collection might be needed for some qualitative metrics.

Data analysis involves using statistical methods and data visualization techniques to identify trends, patterns, and anomalies. This might involve calculating averages, variances, and correlations to understand the relationship between different KPIs. I use tools like spreadsheets and specialized business intelligence software to analyze data and create reports. Regular review of KPI data, along with comparisons to benchmarks and past performance, allows us to identify areas of strength and weakness, informing strategic decision-making and continuous improvement efforts.

Q 13. How do you ensure consistent quality in your operations?

Ensuring consistent quality requires a holistic approach that integrates quality control measures throughout the entire operational process. This starts with clear definition of quality standards and expectations, documented in quality manuals and procedures. These standards should align with industry best practices and customer requirements. I implement regular quality checks at various stages of the process, using methods like statistical process control (SPC) and quality audits to identify deviations from established standards.

Employee training and empowerment are crucial. Employees need proper training to understand quality standards and procedures and should be empowered to identify and report quality issues. A culture of continuous improvement, where employees are encouraged to suggest improvements and participate in problem-solving, is also vital. Corrective and preventive actions (CAPA) are implemented to address quality issues and prevent recurrence. Regular review of quality data, including defect rates and customer feedback, allows for continuous improvement and ensures sustained quality in operations.

Q 14. Describe your experience with budget management and cost control.

Effective budget management involves planning, monitoring, and controlling expenses to achieve operational goals within allocated resources. I start with a thorough budget planning process, forecasting revenues and expenses based on historical data, market trends, and operational plans. The budget is broken down into smaller, manageable units, assigning responsibilities to specific individuals or teams. Regular monitoring of actual expenses against the budget is crucial, using reporting tools and dashboards to track progress.

Cost control measures are implemented to prevent overspending. This might involve identifying areas for cost reduction, negotiating better prices with suppliers, improving operational efficiency, and optimizing resource utilization. Regular variance analysis helps identify deviations from the budget and pinpoint the reasons for overspending. Corrective actions are promptly implemented to address variances and keep operations within budget. Collaboration with finance and other departments ensures transparency and effective communication throughout the budget management process.

Q 15. How do you delegate tasks and responsibilities effectively?

Effective delegation isn’t just about assigning tasks; it’s about empowering individuals to succeed. I start by clearly defining the task, its objectives, and expected outcomes. This includes specifying deadlines, resources available, and potential challenges. Then, I carefully assess each team member’s skills, experience, and workload before assigning the task to the most suitable person. I believe in providing the right level of autonomy – enough to foster ownership and initiative, but also with readily available support and guidance if needed. For instance, in a past project involving a website redesign, instead of micromanaging the design team, I provided them with clear design specifications, user stories, and access to all necessary assets. I then scheduled regular check-ins to address any roadblocks and ensure alignment with project goals, fostering a collaborative environment where everyone felt empowered.

- Clearly define tasks and expectations

- Assess team member capabilities

- Provide appropriate autonomy and support

- Establish clear communication channels

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you stay current with industry best practices and trends?

Staying current in operations supervision requires a multifaceted approach. I actively participate in professional organizations like APICS (The Association for Operations Management) and attend industry conferences and webinars. This provides access to the latest research, innovations, and best practices. Furthermore, I subscribe to relevant industry publications and journals, and regularly review online resources and case studies. Networking with peers and colleagues through online forums and industry events also keeps me informed about emerging trends and challenges. A recent example is my adoption of lean principles after attending a workshop on optimizing operational efficiency. I immediately implemented some of these techniques, such as value stream mapping, within our team, which resulted in a noticeable improvement in our workflow.

Q 17. What is your experience with root cause analysis and problem-solving?

Root cause analysis is crucial for effective problem-solving. I’m proficient in various techniques, including the 5 Whys, Fishbone diagrams (Ishikawa diagrams), and Pareto analysis. My approach involves gathering data, interviewing stakeholders, and systematically eliminating possibilities until the underlying cause is identified. For example, when our production line experienced a significant drop in output, I employed the 5 Whys technique. By repeatedly asking ‘Why?’ we discovered the root cause was a malfunctioning component within a critical machine, not simply operator error as initially suspected. This allowed us to address the problem effectively and prevent future occurrences. This methodical approach helps avoid simply treating symptoms and instead targets the core issue.

Q 18. Describe a time you had to make a difficult decision with limited information.

During a major equipment failure at a critical juncture of a project, I had to make a decision with limited information. We had two options: attempt a costly, time-consuming on-site repair, or use a less efficient alternative that would delay the project but prevent complete shutdown. With incomplete data on the repair’s feasibility and potential downtime, I convened a quick meeting with key personnel, weighing the risks and benefits of each option. We considered the impact on deadlines, budget, and overall project success. Ultimately, we opted for the less efficient alternative to maintain some level of operational continuity, minimizing long-term damage to the project. Although this decision resulted in a minor delay, it prevented a potentially catastrophic failure. This experience taught me the importance of swift decision-making, even with imperfect information, and the value of collaborative risk assessment.

Q 19. How do you motivate and engage your team members?

Motivating and engaging my team is paramount. I focus on creating a positive and supportive work environment, fostering open communication, and recognizing individual contributions. I believe in leading by example, demonstrating a strong work ethic and commitment to the team’s goals. Regular feedback, both positive and constructive, is key, along with providing opportunities for professional development. I also strive to empower team members by giving them a voice in decision-making processes and allowing them to take ownership of their work. For example, I instituted weekly team meetings where everyone shares updates, challenges, and ideas, promoting a collaborative spirit. This not only improves morale but also fosters innovation and better problem-solving. Celebrating achievements, both big and small, is also crucial in boosting team morale and reinforcing positive behavior.

Q 20. What is your experience with data analysis and reporting?

Data analysis and reporting are essential for informed decision-making in operations supervision. I’m proficient in using various tools, such as Excel, SQL, and business intelligence software, to collect, analyze, and visualize operational data. This includes creating reports on key performance indicators (KPIs), identifying trends, and pinpointing areas for improvement. For example, I routinely analyze production data to identify bottlenecks and inefficiencies in our workflow. This analysis informs our efforts to optimize processes, reduce waste, and improve overall productivity. The ability to effectively communicate these findings through clear and concise reports is just as important, ensuring that all stakeholders have access to the information necessary for effective decision-making.

Q 21. How do you improve communication and collaboration within your team?

Improving communication and collaboration is an ongoing process that requires consistent effort. I facilitate open and honest communication by establishing clear communication channels and fostering a culture of trust and mutual respect. Regular team meetings, both formal and informal, are vital. Using collaborative tools like project management software can also enhance communication and transparency. For instance, using a shared project management platform allows the team to track progress, share updates, and address issues proactively, enhancing collaboration and reducing the risk of misunderstandings. I also actively encourage feedback and suggestions from team members, creating a safe space for open dialogue and fostering a sense of shared ownership and responsibility.

Q 22. Describe your approach to continuous improvement within your operations.

My approach to continuous improvement is rooted in the PDCA cycle – Plan, Do, Check, Act. It’s not just about identifying problems; it’s about proactively seeking ways to enhance efficiency, quality, and safety. I believe in fostering a culture where improvement suggestions are welcomed and acted upon.

- Plan: This involves analyzing current operational data, identifying areas for improvement, and developing specific, measurable, achievable, relevant, and time-bound (SMART) goals. For example, in a previous role, we identified a bottleneck in our order processing. Our plan was to implement a new software system to streamline the process and reduce processing time by 20%.

- Do: This stage is about implementing the planned changes, testing new processes, and gathering data on their effectiveness. We implemented the new software, trained the team, and monitored the performance closely.

- Check: Here, we analyze the results obtained during the ‘Do’ phase. Did the changes achieve the desired outcome? In our example, we meticulously tracked order processing times and compared them to pre-implementation data.

- Act: This final stage involves standardizing successful changes, documenting lessons learned, and iterating on the process for continuous improvement. We celebrated our success, documented the implementation process for future reference, and identified further optimization opportunities for subsequent improvements.

Beyond PDCA, I also champion data-driven decision-making, regular performance reviews, and employee engagement initiatives to ensure continuous improvement is a shared responsibility.

Q 23. How do you handle pressure and tight deadlines?

Handling pressure and tight deadlines requires a structured and proactive approach. I prioritize tasks using methods like Eisenhower Matrix (urgent/important), ensuring the most critical activities are tackled first. I also break down large projects into smaller, manageable tasks, making them less daunting.

Effective communication is key. I keep stakeholders informed of progress, potential roadblocks, and any necessary adjustments to the timeline. This transparency prevents misunderstandings and allows for collaborative problem-solving. Finally, I believe in the power of delegation and teamwork. I empower my team members, providing them with the necessary resources and support to deliver their assigned tasks effectively.

For instance, during a critical product launch, we faced a significant software bug just days before the deadline. Instead of panicking, I immediately assembled a cross-functional team, prioritized the bug fix, and implemented a robust testing protocol to prevent further issues. Open communication kept everyone informed and motivated throughout this challenging situation.

Q 24. How do you build and maintain positive relationships with stakeholders?

Building and maintaining positive relationships with stakeholders is paramount in operations supervision. It’s about understanding their needs, concerns, and expectations. I achieve this through active listening, clear communication, and consistent follow-through.

- Regular Communication: I schedule regular meetings, utilizing various communication channels (email, phone, in-person) to keep stakeholders updated on project progress, challenges, and achievements.

- Transparency and Honesty: I believe in being open and honest, even when delivering difficult news. This builds trust and credibility.

- Empathy and Understanding: I strive to understand the perspectives of different stakeholders, acknowledging their concerns and finding common ground.

- Collaboration and Teamwork: I foster a collaborative environment where stakeholders feel valued and involved in decision-making processes.

For example, when dealing with a frustrated client due to a production delay, I actively listened to their concerns, explained the reasons for the delay, and proactively offered a solution to mitigate the impact. This approach resulted in maintaining a positive working relationship.

Q 25. Describe your experience with training and mentoring new employees.

Training and mentoring new employees is a rewarding aspect of my role. I believe in a hands-on, personalized approach. My training programs are designed to be practical and relevant, focusing on both theoretical knowledge and practical application.

- On-the-Job Training: I incorporate shadowing opportunities, allowing new employees to observe experienced team members in action.

- Mentorship and Guidance: I act as a mentor, providing ongoing support and guidance, addressing their questions and concerns.

- Feedback and Evaluation: I provide regular feedback, both positive and constructive, to help them improve their performance.

- Continuous Learning: I encourage continuous learning by providing access to resources such as online courses, workshops, and industry conferences.

In one instance, I mentored a new graduate who lacked practical experience. Through a structured training program combining shadowing, practical projects, and regular feedback sessions, he quickly developed his skills and became a valuable team member.

Q 26. What is your approach to risk management within your operations?

My approach to risk management is proactive and systematic. It involves identifying potential risks, assessing their likelihood and impact, developing mitigation strategies, and regularly monitoring the effectiveness of those strategies.

- Risk Identification: I utilize various methods such as brainstorming sessions, checklists, and hazard analyses to identify potential risks.

- Risk Assessment: I assess the likelihood and potential impact of each identified risk using a qualitative or quantitative approach.

- Risk Mitigation: I develop strategies to mitigate identified risks, focusing on eliminating or reducing their likelihood and impact. These strategies might involve implementing new safety protocols, improving training programs, or investing in new technologies.

- Risk Monitoring: I regularly monitor the effectiveness of implemented mitigation strategies, adapting them as needed.

For example, in a previous role, we identified the risk of equipment malfunction during a critical production phase. To mitigate this, we implemented a preventive maintenance program and invested in redundant equipment. This proactive approach ensured minimal disruption to operations.

Q 27. How do you ensure compliance with relevant regulations and standards?

Ensuring compliance with relevant regulations and standards is a non-negotiable aspect of operational supervision. My approach involves a multi-faceted strategy that combines proactive measures, regular audits, and employee training.

- Stay Updated: I actively monitor changes in regulations and industry best practices to ensure our operations remain compliant.

- Develop Compliance Policies: We develop and implement comprehensive policies and procedures that outline our compliance standards.

- Regular Audits: I conduct regular internal audits to identify any compliance gaps.

- Employee Training: I ensure that all employees receive adequate training on relevant regulations and standards.

- Documentation: Maintaining accurate and comprehensive documentation is vital for demonstrating compliance.

For instance, to ensure compliance with data privacy regulations, we implemented robust data security protocols, conducted regular data security audits, and trained all employees on data privacy policies. This ensured our operations aligned with relevant regulations.

Q 28. Describe your experience with project management and execution.

My experience in project management and execution is extensive. I utilize a structured approach, employing project management methodologies like Agile or Waterfall, depending on the project’s requirements.

- Project Planning: I meticulously plan projects, defining scope, objectives, timelines, and resources.

- Task Assignment and Delegation: I effectively delegate tasks to team members based on their skills and experience.

- Progress Monitoring: I regularly monitor progress against the project plan, identifying and addressing any deviations promptly.

- Risk Management: I proactively manage risks, identifying and mitigating potential issues that could impact project success.

- Communication: I ensure clear and effective communication throughout the project lifecycle, keeping stakeholders informed.

- Completion and Review: Upon project completion, I conduct a thorough review, evaluating successes, challenges, and lessons learned for future projects.

In one instance, I successfully managed the implementation of a new manufacturing process, adhering to a strict timeline and budget. I utilized Agile methodologies to adapt to evolving needs, leading to the project’s on-time and under-budget completion.

Key Topics to Learn for Operation Supervision Interview

- Operational Efficiency & Optimization: Understanding key performance indicators (KPIs), process improvement methodologies (Lean, Six Sigma), and strategies for maximizing resource utilization.

- Team Management & Leadership: Effective communication, delegation, motivation techniques, conflict resolution, and performance management strategies within a team environment. Consider practical applications like addressing team conflict or motivating underperforming staff.

- Risk Management & Mitigation: Identifying potential operational risks, developing mitigation strategies, and implementing contingency plans. Think about real-world scenarios and how you would approach them.

- Resource Allocation & Budgeting: Understanding budgetary constraints, optimizing resource allocation across various projects, and justifying resource requests effectively.

- Quality Control & Assurance: Implementing quality control measures, monitoring performance against standards, and identifying areas for improvement in operational processes.

- Technology & Systems: Familiarity with relevant operational technologies and software, and the ability to troubleshoot technical issues impacting operations. Consider how technology impacts efficiency and problem-solving.

- Reporting & Analysis: Developing clear and concise reports, analyzing operational data to identify trends and insights, and communicating findings effectively to stakeholders.

- Problem-Solving & Decision-Making: Demonstrating the ability to analyze complex operational problems, identify root causes, and develop effective solutions under pressure. Practice using structured problem-solving frameworks.

Next Steps

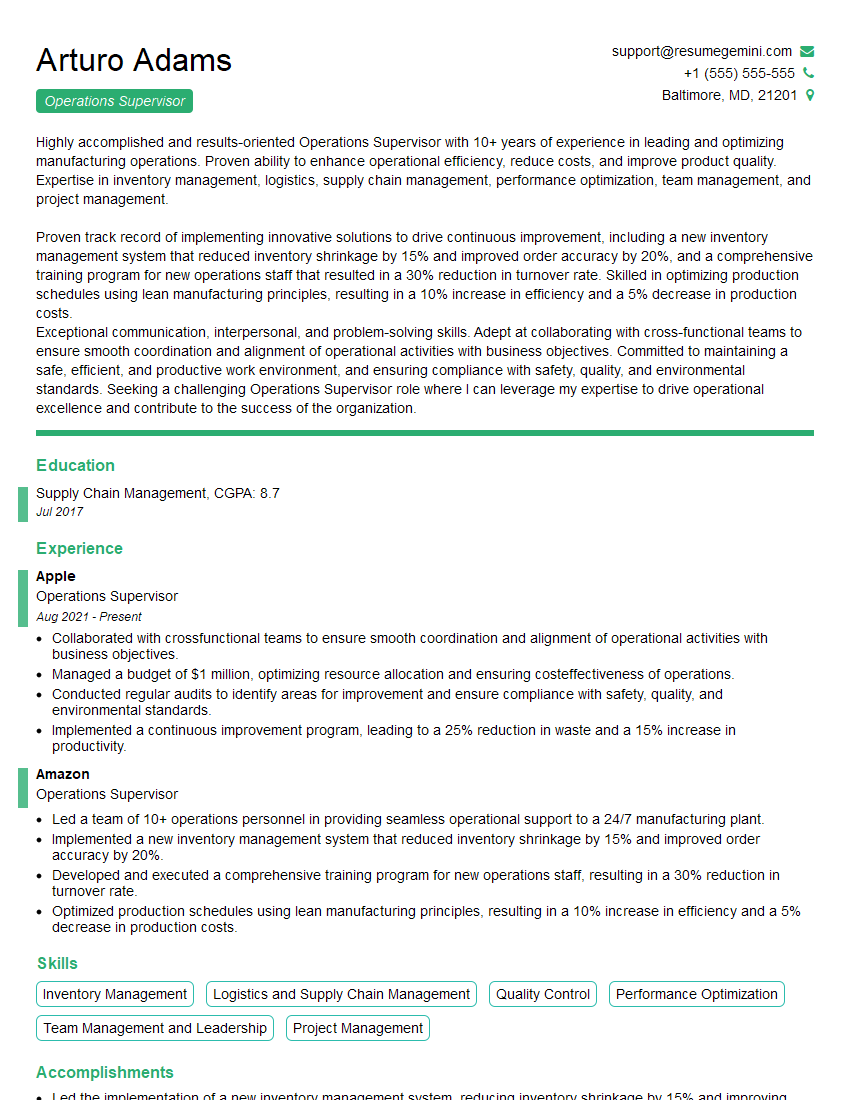

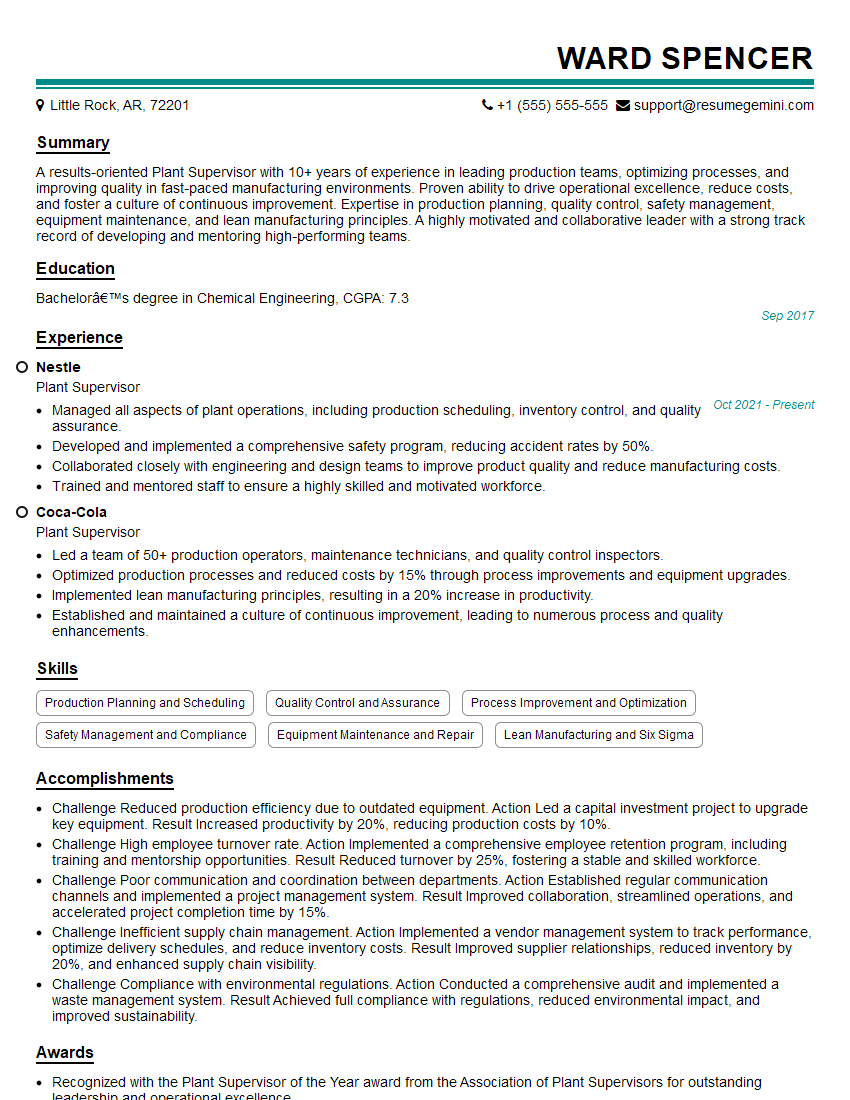

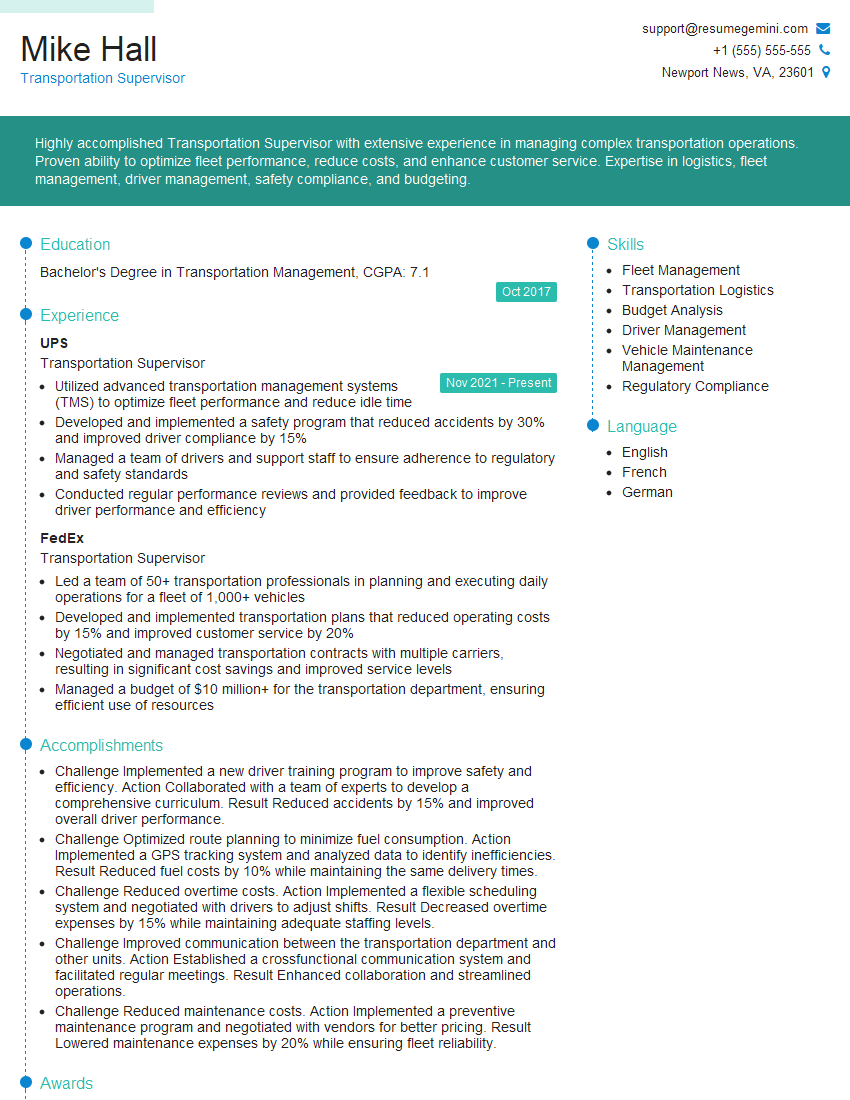

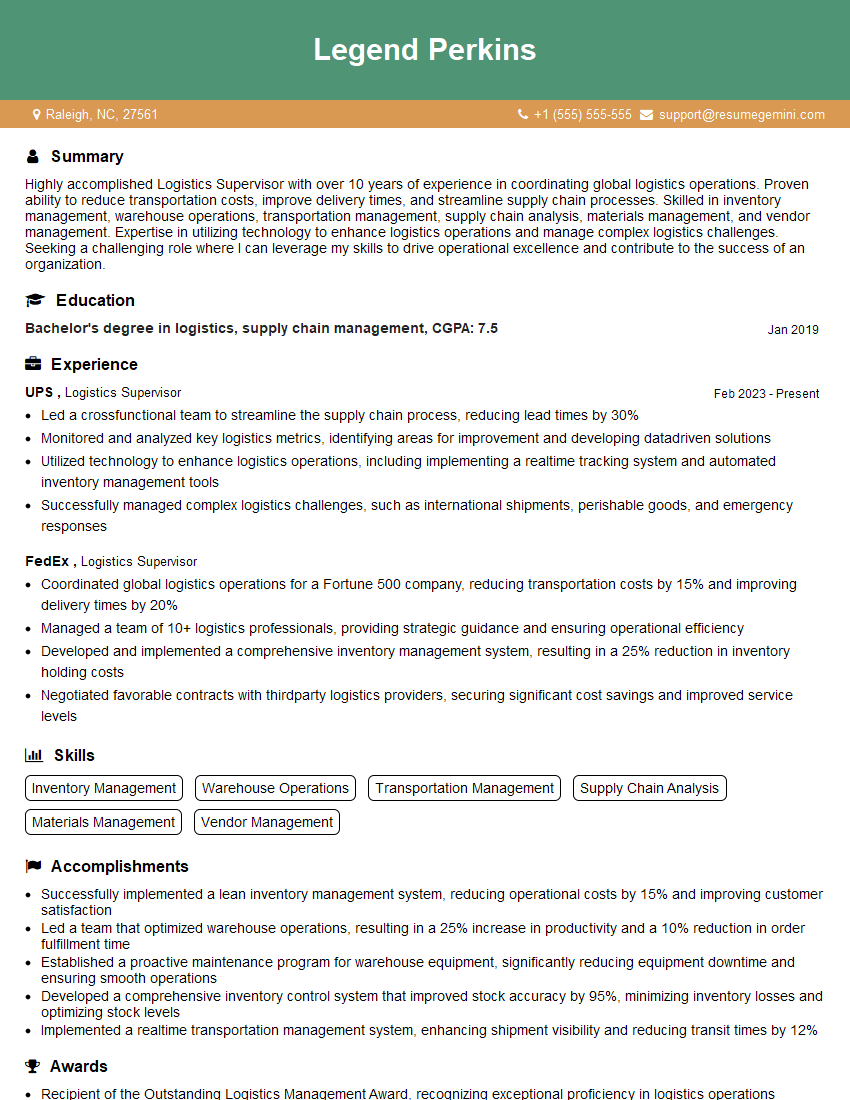

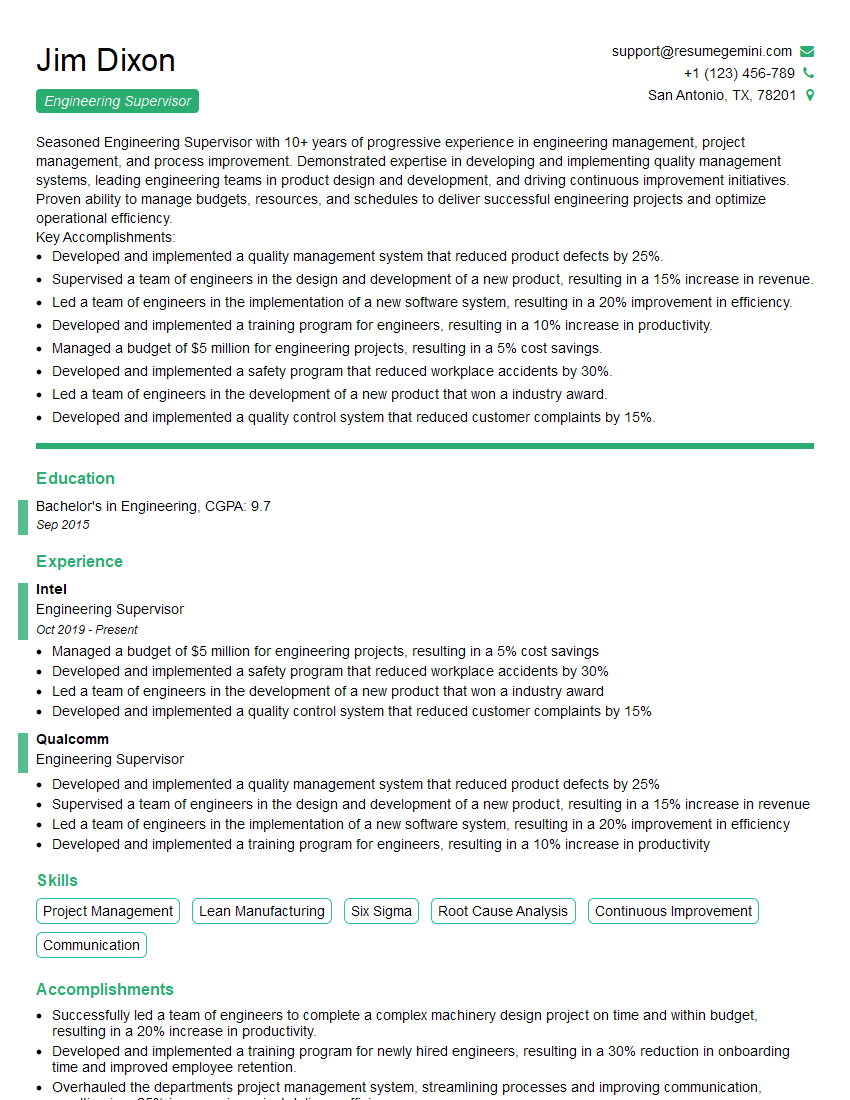

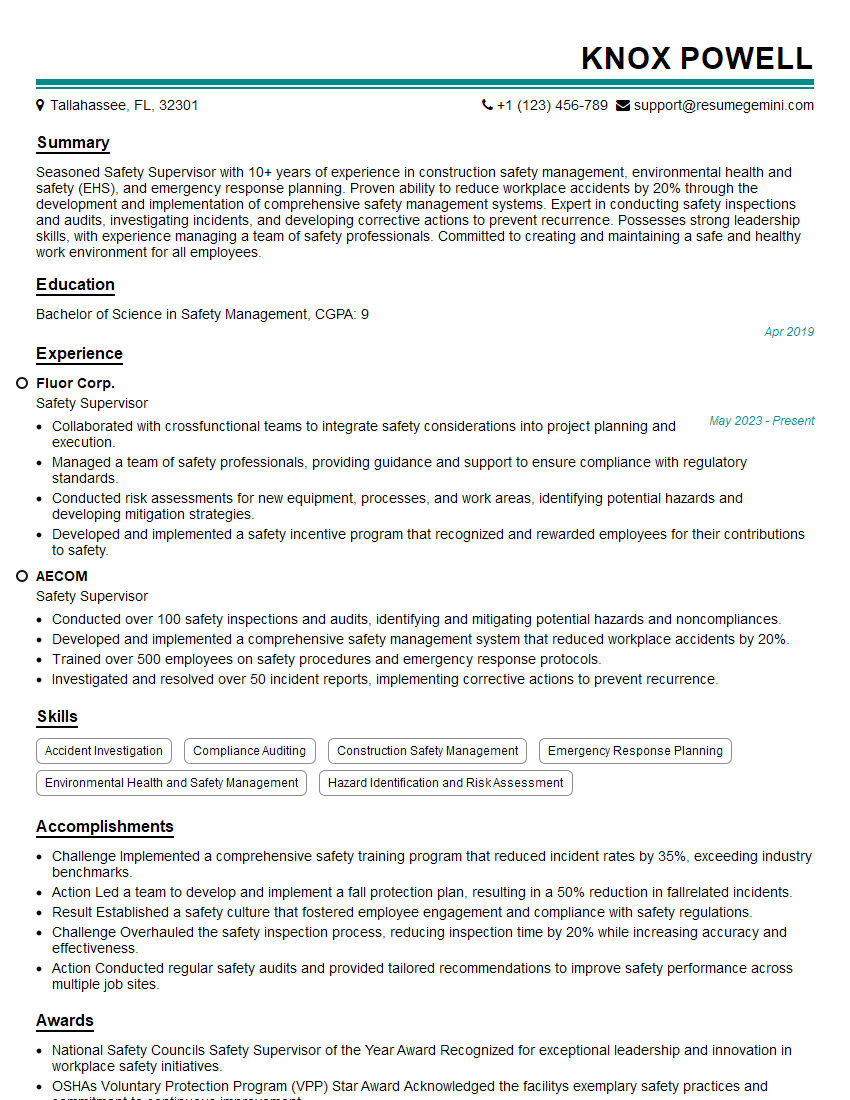

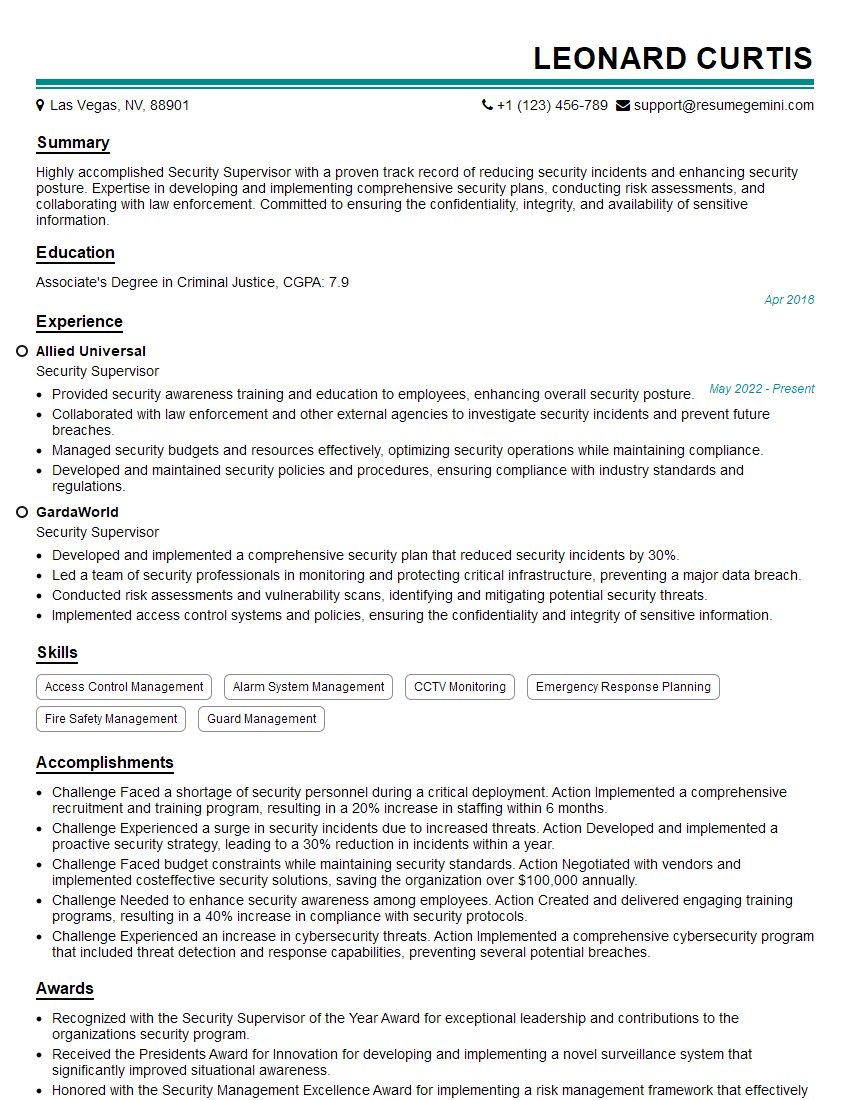

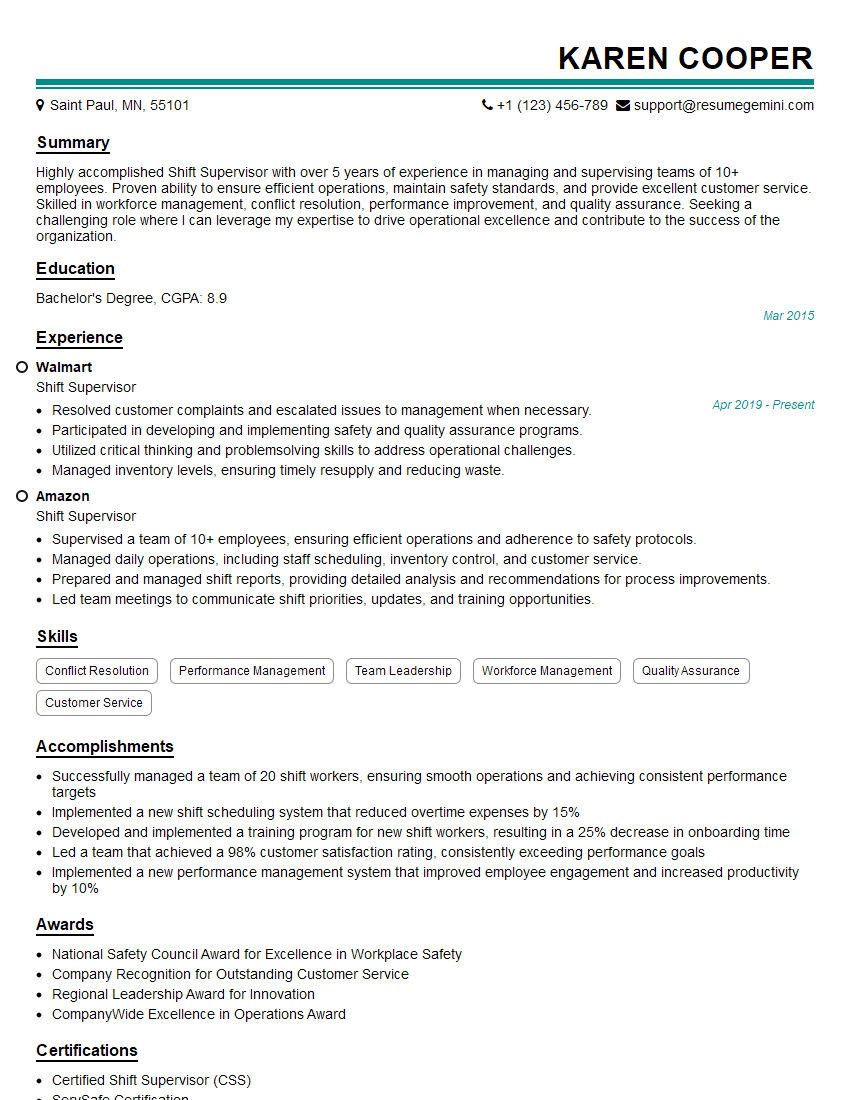

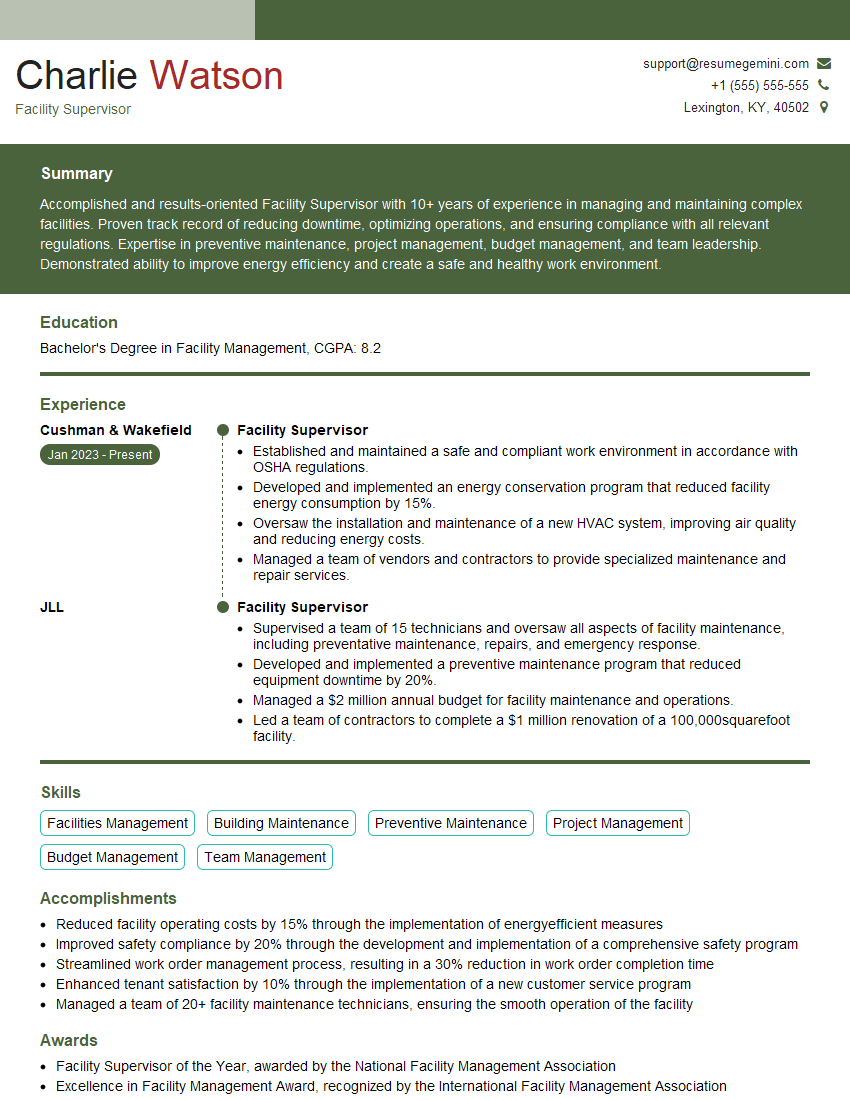

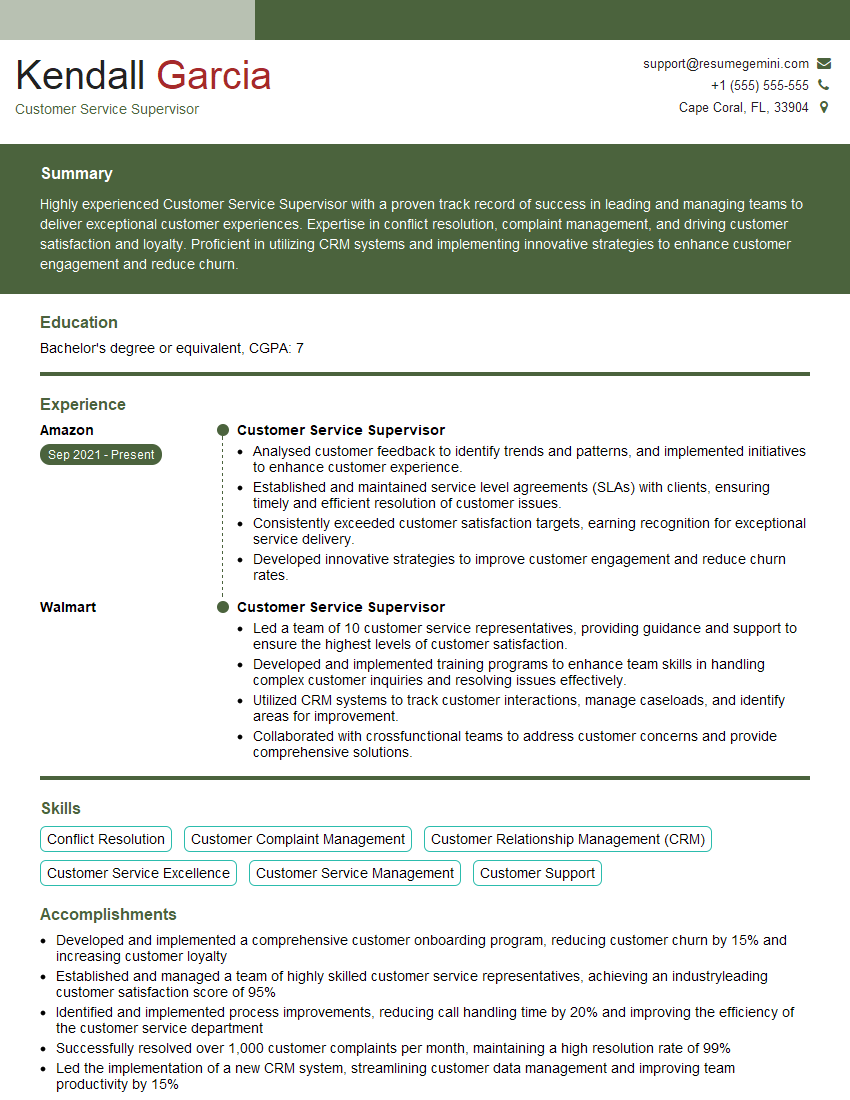

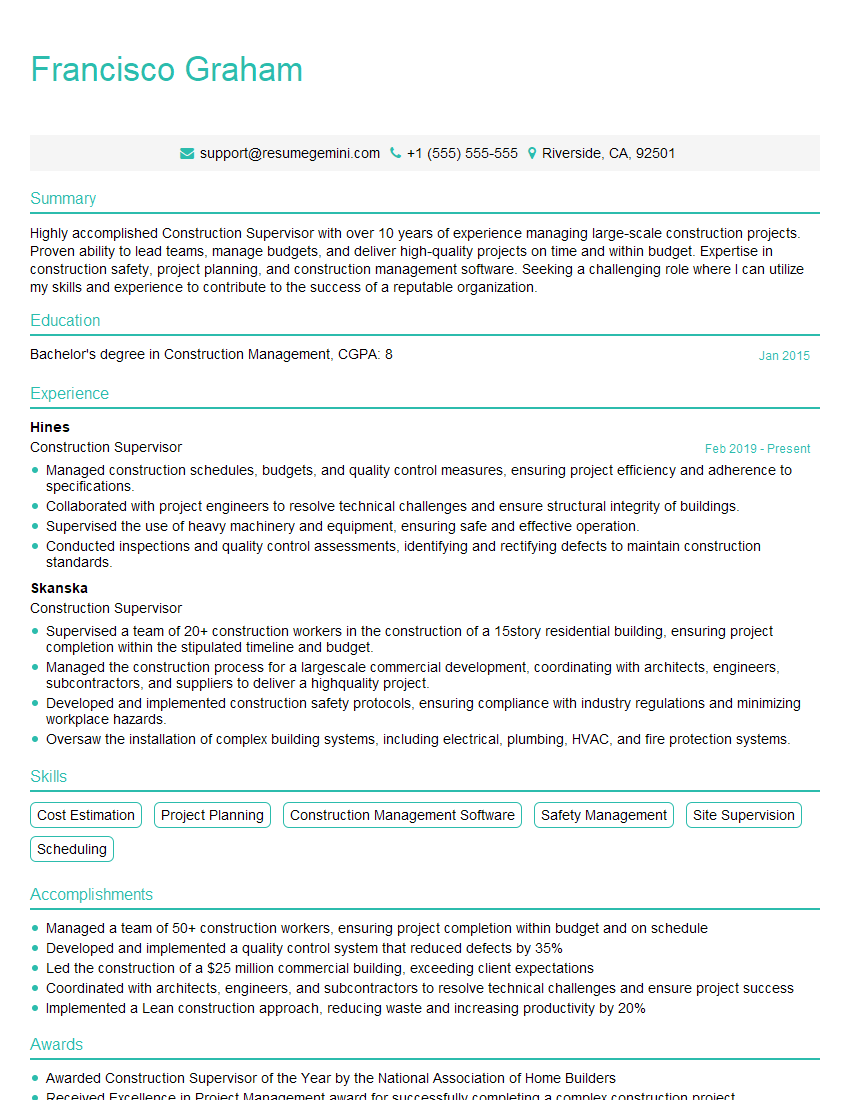

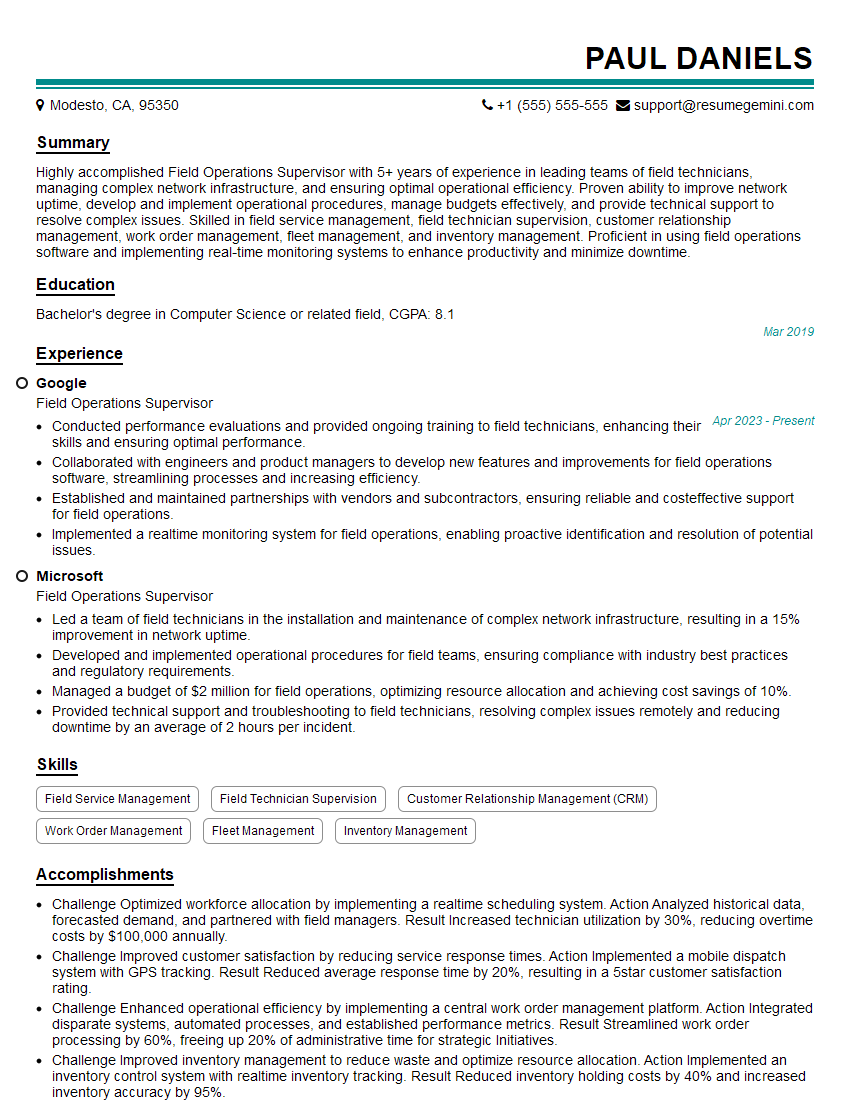

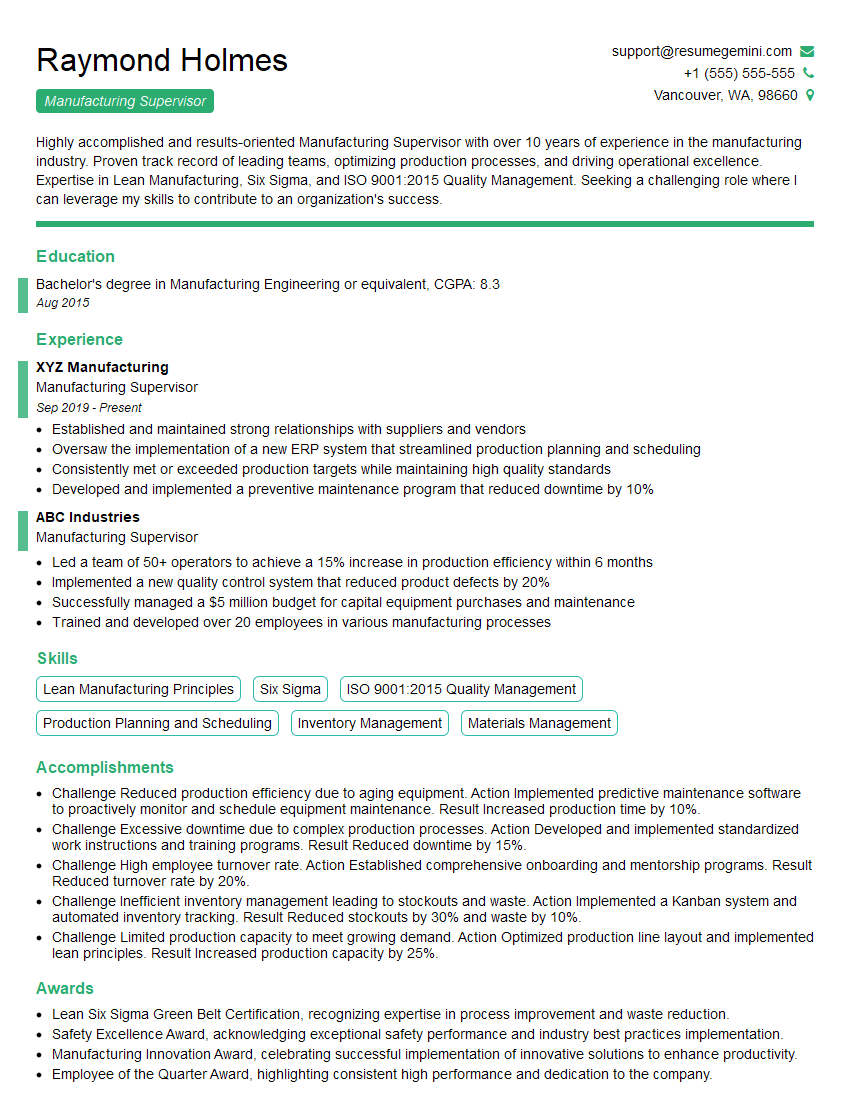

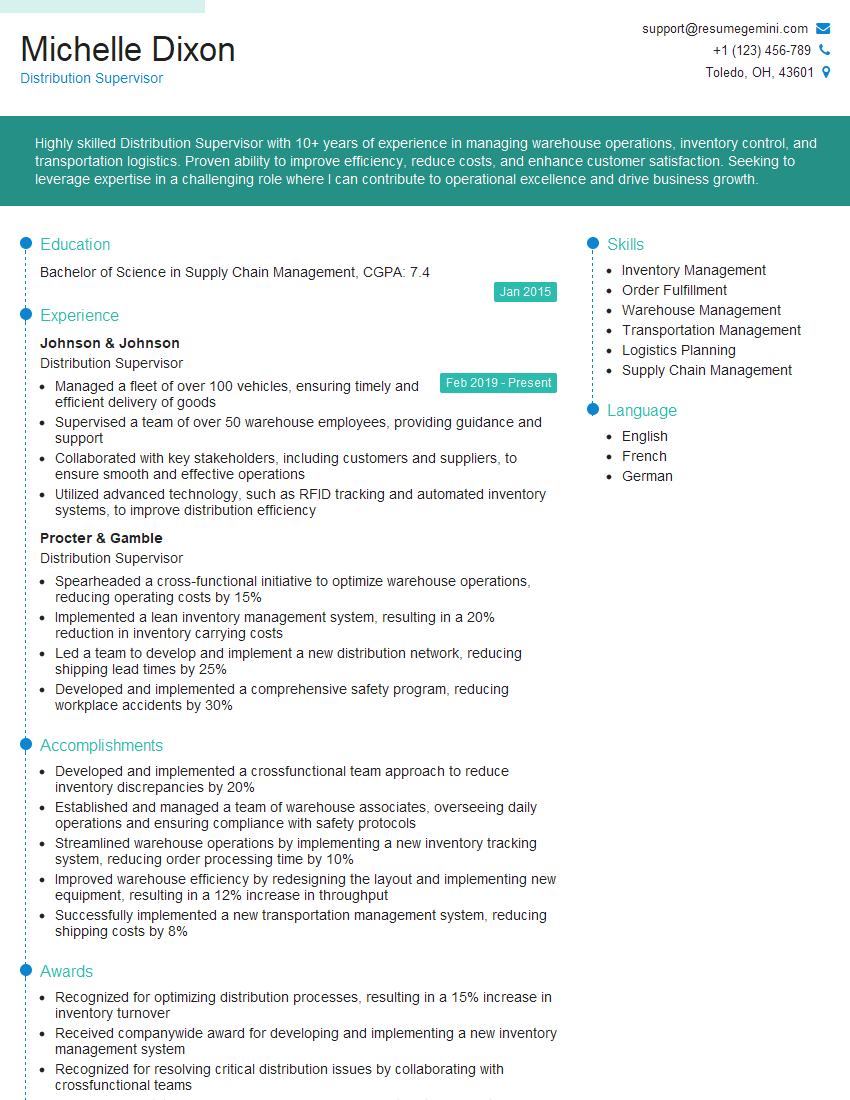

Mastering Operation Supervision opens doors to leadership roles with increased responsibility and earning potential. To accelerate your career growth, a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you craft a professional and impactful resume that highlights your skills and experience effectively. We provide examples of resumes tailored to Operation Supervision to give you a head start. Invest time in crafting a compelling resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good